Abstract

With rapidly growing commercial markets of portable electronics, supercapacitors (SCs) have become one of the most promising energy storage devices due to their unique characteristics. However, the low energy densities severely restrict their practical application. Furthermore, the liquid-electrolyte has leak issues under deformation, resulting in device failure or performance degradation. Herein, a novel material which has a porous carbon (PC) nanostructure skeleton connected by tannic acid (TA) with Co metal compounds which can provide pseudocapacitance is designed. PC is derived by activation C60 which is sp2 carbon that ensures the efficient transmission of electrons and Co metal compounds increase the active site of the Faraday redox reaction and improve the specific capacitance. TA makes porous carbon skeleton and Co metal compounds more closely linked, effectively improving ion transport efficiency and optimizing cycle performance. The composite showed a reversible specific capacity of 1475 mF cm−2 at a charge/discharge current density of 2 mA cm−2 and a specific capacity of 1174 mF cm−2 at 30 mA cm−2 when measured by a three-electrode system conducted in 2.0 M KOH electrolyte. In addition, the assembled solid-state symmetric SCs with the electrode materials have excellent cycling stability that cycled for 5000 cycles at 5 mA cm−2 and the capacitance retention rate reached 95.76%. The device can also provide continuous and stable energy that lights up the red light-emitting diode (LED) with excellent bendability. This strategy provides a novel device design method and can be effectively applied to future flexible electronic products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Based on the deteriorating global environment and the urgent need for advanced energy storage equipment, supercapacitors have attracted wide attention because of their advantages such as high power density, fast charge and discharge rate, good cycle stability, and environmental friendliness [1,2,3]. In the beginning, according to the energy storage mechanism, supercapacitors can be divided into double electric layer capacitors and pseudocapacitor capacitors [3,4,5,6]. Recently, hybrid capacitors which combine a faradic battery electrode with a capacitive or pseudocapacitive electrode have been developed to share and develop between the battery and the capacitive storage communities [7]. The electrode material of the double electric layer capacitor is mainly carbon-based active material, which can physically adsorb ions on the surface of the active material to achieve the purpose of energy storage [8]. This reversible ion adsorption and desorption method on the surface is simple, but the capacity is not high enough. However, pseudocapacitors can undergo a rapid reversible Faraday redox reaction on the surface of the electrode material, so theoretically, they have a higher capacity [9, 10]. However, due to the accumulation of charge on the electrode surface, the fast and stable redox reaction depends on the dynamic characteristics of the electrode, so suitable materials and reasonable design are key factors in high-performance capacitors [11].

In recent years, textile carbon cloth (cc) has been successfully used as an electrode for supercapacitors because of its good electrical conductivity, network interconnection, and excellent mechanical flexibility [12]. However, its limited specific surface area and double-layer charge storage mechanism limit its application in high-performance supercapacitors. This problem can be mitigated by loading a variety of other active materials onto the carbon cloth substrate [13]. For example, polymer conductive polymers with controllable structures (polyaniline [14, 15], polypyrrole [16]), cobalt–nickel binary oxides [17], Sb2O3 [18], Fe2O3 [19], and Co3O4 [20] have been successfully integrated with carbon cloth, thus achieving enhanced performance. Although much progress has been made, the performance of electrodes based on textile carbon cloth still fails to meet the requirements of high performance compared with secondary batteries and special cycle stability which is greatly affected by the strong interfaces between carbon skeletons and active materials [21, 22].

Transition metal compounds (TMCs), as a promising electrode material, can provide high reversible capacitance for the Faraday redox reaction compared with carbon-based materials and have better electrochemical stability compared with polymer materials [22]. However, the mechanism was not well understood until Trasatti and Buzzanca discovered the pseudocapacitance properties of RuO2, which has theoretical specific capacitance values as high as 1300 ~ 2200 F g−1 [23, 24]. Because of the variety of oxidation states of a fast Faraday redox reaction which can transfer multiple electrons that extend the discharge time, the energy density of TMCs increases [25]. In recent years, the research of transition metal hydroxide and derivatives such as sulfide and selenide has received extensive attention. Among them, some transition metal hydroxides and their derivatives such as Ni-, Co-, Cu-, and Cd-based materials belong to battery materials based on charge storage mechanism [26]. They are usually assembled with capacitive electrode materials to make up hybrid SCs, which can obtain a high operating potential and provide a large and fast charge storage capacity.

Tannic acid (TA), as the 2nd most abundant phenolic compound in nature, shows strong surface adhesion to versatile substrates due to plentiful hydrophilic hydroxyl groups and the hydrophobic aromatic ring which can react with various substances via covalent and non-covalent interactions [27,28,29].

We report that we have prepared a novel material which has high-energy carbon nanostructure skeleton that is connected by TA with Co metal compounds which can provide pseudocapacitance. The carbon nanostructure skeleton made of sp2 bonded carbon guarantees a very good electric conductivity and the large specific surface area provides increased capacity for many physical adsorption sites. Besides, Co-metal compounds further increase the active site of the Faraday redox reaction and improve the specific capacitance. TA makes carbon skeleton and Co metal compounds more effectively linked which improved ion transport efficiency that the composite showed a reversible specific capacity of 1475 mF cm−2 at a charge/discharge current density of 2 mA cm−2 and maintained a high specific capacity of 1174 mF cm−2 at 30 mA cm−2, and simultaneously optimized cycle performance. Moreover, the assembled solid-state symmetric SCs are flexible and durable with almost 100% capacitance retention after bending 500 times and can provide continuous power to LED, indicating their applications in flexible electronics.

Experimental section

Materials

All the chemical reagents were of analytical grade and directly used in the chemical reactions. Tin dichloride (SnCl2) and Palladium dichloride (PdCl2) were purchased from Aladdin Industrial Co., Ltd. Hydrochloric acid (HCl), nickel (II) sulfate hexahydrate (NiSO4·6H2O), citric acid monohydrate (C6H8O7·H2O), ammonia water (NH3·H2O, 25 wt%), sodium hypophosphite monohydrate (NaH2PO2·H2O), ethanol, toluene, potassium hydroxide (KOH), formaldehyde (37 ~ 40 wt %), cobalt (II) nitrate hexahydrate (Co(NO3)2 6H2O), and polyvinyl alcohol (PVA) were purchased from Sinopharm Chemical Reagent Co., Ltd. Fullerene (C60, AR, Suzhou Dade Carbon Nano Technology Co., Ltd), tannic acid (TA, AR, Macklin Biochemical Co., Ltd), deionized water (DIW) was used for the whole experiment process.

Ni@cc substrate synthesis

The electroless Ni plating technology [30, 31] was used to prepare the Ni@cc substrate. (1) Sensitizing treatment, a mixed solution of 0.05 M SnCl2 and 0.12 M HCl was prepared as a sensitizing solution and heated to 30 °C, and the cleaned cotton cloth was soaked in the solution for 15 min. Then the cotton cloth was removed and washed with DIW 3 times. (2) Activating treatment, a mixture of 100 μg ml−1 PdCl2 and 0.03 M HCl was prepared and heated to 30 °C as an activating solution. The cotton cloth after sensitized treatment was soaked in the solution for 15 min. Then, the cotton cloth was taken out and washed with DIW 3 times which was named as activated cotton cloth. (3) Electroless Ni plating reaction, the mixed solution of 0.05 M NiSO4·6H2O and 0.10 M C6H8O7·H2O was prepared and then heated to 70 °C. The ammonia water was dropped into the solution until the pH was 10.0. Then, the solution of 0.10 M NaH2PO2·H2O was added to the above solution. The temperature and pH values of the reaction system were maintained at about 70 °C and 10, respectively. The activated cotton cloth was soaked in the solution for 20 min, taken out and washed with DIW and ethanol 3 times, and then dried in the oven at 60 °C to obtain nickel-coated cotton cloth (Ni@cc).

Porous carbon (PC)-coated Ni@cc substrate synthesis

One hundred milligrams of C60 dissolved in 100 ml toluene, and 1000 mg KOH dissolved in 100 ml ethanol, and the two were mutually soluble to obtain a mixed solution. The mixed solution was then sprayed on Ni@cc with a spray gun and dried in an oven for 12 h. The treated cotton cloth substrate was then put in a corundum boat and annealed in a tube furnace at 800 °C for 60 min in a 100 sccm argon (Ar) gas flow to obtain activated C60 which is referred to as porous carbon (PC)-coated Ni@cc substrate.

Synthesis of Co compounds-TA-PC-coated Ni@cc composite materials

0.1 ml ammonia was added in 13 ml water and 3 ml ethanol to obtain a mixed solution. Subsequently, 2 ml 0.015 M TA was added in the mixed solution and 1 ml formaldehyde solution (3.7 wt %) was then added and followed by stirring for 24 h. Then PC-coated Ni@cc substrate was dipped in the above solution and shaken in a shaker for 4 h. Next, 200 μL 0.17 M Co(NO3)2 solution was added in the solution and stirred for 12 h. Then the solution with PC-coated Ni@cc substrate was transferred into a Teflon-lined stainless-steel autoclave (50-mL volume) for hydrothermal treatment at 100 ℃ for 18 h. The Co compounds-TA-PC-coated Ni@cc composite materials were obtained after washing with DIW and ethanol and finally baked in a 60 °C vacuum drying oven for 24 h.

Fabrication of solid-state symmetric SCs

Polymeric gel electrolytes were prepared as follows: DI water (30 mL), PVA (3.0 g), and 2 M KOH (30 mL) were mixed by magnetic stirring at 85 °C for 1 h. Subsequently, the same size of Co compounds-TA-PC-coated Ni@cc composite electrodes were immersed into the gel-electrolyte for 5 min and then allowed to solidify at 40 °C for 2 h. The process was repeated 2–3 times to ensure the uniform coating of PVA/KOH gel electrolyte. The device was prepared by assembling the two gel-coated electrodes in parallel by applying extra gel to bridge the two electrodes and leaving it overnight at room temperature. No separator was applied to the device.

Physical and chemical characterization

The samples were characterized by scanning electron microscopy (SEM, JSM-6510LV), X-ray diffraction (XRD, Rigaku Ultimate IV) with Cu radiation (V = 40 kV, I = 40 mA) at a scan rate of 5° min−1 from 10 to 80° (2θ). Their chemical composition was characterized by Fourier transform infrared spectroscopy (FTIR, Bruker Tensor 27, Germany), Thermal gravity analysis (TG209F3 Tarsus, Germany), and X-ray photoelectron spectroscopy (XPS, Thermo Scientific K-Alpha). The specific surface areas (SSA) and pore size distributions of the samples were determined by N2 adsorption/desorption (Micromeritics, ASAP 2460) using the Brunauer–Emmett–Teller (BET) method (calculated based on the linear relative pressure range from 0.005 to 0.05) and Barrett–Joyner–Halenda (BJH) model, respectively.

Electrochemical characterization

To evaluate the performance of the materials as an electrode for supercapacitor. Cyclic voltammetry (CV), galvanostatic charge-discharge (GCD), and electrochemical impedance spectroscopy (EIS) in the frequency range 100 kHz to 0.01 Hz were performed to evaluate the electrochemical performance of the electrodes in 2.0 M KOH aqueous solution on an electrochemical workstation (CHI 660E). A standard three-electrode test system consisting of a working electrode, an opposing electrode (platinum foil), and a reference electrode (Ag/AgCl) is adopted. The working electrode is prepared by sandwiching an aC60-TA-Co electrode between two pieces of nickel foam.

The capacity of the electrode is the surface capacitance calculated from the constant discharge curve, the formula is as follows (1) [32]:

I is the discharge current (A), Δt is the discharge time (s), ΔV is the voltage change excluding the voltage drop (IR drop) during the discharge process, and S is the area of electrode contacts with the electrolyte.

In order to study the practical application of electrode material, a symmetrical supercapacitor was fabricated and its electrochemistry was studied. The energy density and power density of the device can be calculated by Eqs. (2) and (3) [33]:

E represents the energy density of the device, C represents the specific capacitance value of the device, V represents the operating voltage of the device during the discharge process, P represents the power density of the device, and Δt represents the discharge time during the constant current charge and discharge process of the device.

Results and discussion

Characterization of Co compounds-TA-PC-coated Ni@cc composite material

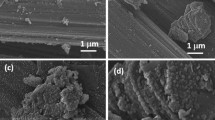

The schematic diagram of Co compounds-TA-PC-coated Ni@cc composite material is illustrated in Fig. 1(a). In this work, nickel is plated on cotton cloth which was a key step in making electrode materials and made it transformed into a nickel-coated cotton cloth (Ni@cc) with high electrical conductivity and good toughness. The changes in morphology and appearance of the process of Co compounds-TA-PC-coated Ni@cc composite material have been shown from SEM images (Fig. 1). The metal nickel is uniformly attached to the surface of cotton cloth and tightly covered on the exposed surface of cotton cloth which showed in Fig. 1(b1–b3 and c1–c3). Also, the addition of nickel enhanced the toughness and integrity of the Ni@cc substrate in the subsequent high-temperature annealing process. After spraying C60 and KOH mixed solution on the Ni@cc substrate and calcined at high temperature, the substrate with porous carbon (PC) surface was obtained. The PC-coated Ni@cc substrate was characterized by SEM which showed in Fig. 1(d2 and d3); it can be seen that the crystal structure of C60 was broken after activation and the porous carbon has a multistage pore structure similar to that of sponge which showed in the inset of Fig. 1(d3). As PC can be polymerized with polyphenol when formaldehyde is used as a crosslinking agent, initially formed TA-formaldehyde oligomer can be adsorbed on the Ni@cc substrate surface which would further be grown into a polymer framework after the solution is mixed, showed in Fig. 1(e2 and e3). Formaldehyde has an important role because it can form a methylene bridge which would randomly connect TA units and generate isotropic growth of the cross-linked TA frame between two TA molecules, which is critical for achieving a uniform coating onto the surface of Ni@cc substrate. Moreover, Co compounds-TA-PC-coated Ni@cc showed good flexibility in the inset of Fig. 1(e1).

a Schematic diagram of the preparation of Co compounds-TA-PC-coated Ni@cc electrode. Optical photos, SEM images of surface morphology, and cross-section of cotton cloth (b1–b3), Ni@cc substrate (c1–c3), PC-coated Ni@cc substrate (d1–d3), and Co compounds-TA-PC-coated Ni@cc (e1–e3). The inset image of (e1) shows the bent state of the Co compounds-TA-PC-coated Ni@cc electrode. The inset image of (d3) is the amplification of the surface morphology of the PC-coated Ni@cc substrate

After hydrothermal reaction, TA coating which contained a large number of phenol groups was successfully deposited on the PC-coated Ni@CC substrate material, which allowed it to chelate with the Co compounds, showed in Fig. 2. The Co compounds-TA-PC on the surface of Ni@CC substrate electrode was characterized by SEM (Fig. 2c–f) and the corresponding energy dispersion spectrum (EDS) showed that the Co element is evenly distributed.

Figure 3 shows the microscopic fine structure of the Co compounds-TA-PC-coated Ni@cc sample through transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HRTEM). Co compounds-TA-PC-coated Ni@cc has a sponge-like structure with hierarchical pores as seen from the TEM image in Fig. 3a. It can be seen that the Co compound particles coated on the substrate in Fig. 3b. There are no lattice fringes observed in the HRTEM image of Co compounds particles as shown in Fig. 3c demonstrated the amorphous nature of the Co compounds particles.

The FTIR diagram showed in Fig. 4a confirms that TA has been successfully polymerized and attached on the substrate surface. The FTIR spectra of Co compounds-TA-PC-coated Ni/cc showed new absorption bands at 2837 and 2937 cm−1, which are related to the formation of methylene bridges [27]. Also, the intensity of multiple absorption peaks decreased significantly in the wave number range of 600 ~ 1600 cm−1 [34]. These peaks come from the vibration of C-H bonds in the benzene ring (628, 738 cm−1), ester group (860, 1007 cm−1), aromatic ring (1443, 1528, 1607 cm−1), which is basically consistent with the literature, and this reduction indicates the polymerization of TA [35,36,37].

The thermogravimetric analyzer was used to analyze the relationship between material mass and temperature to further explore the composition of the material. In Fig. 4b, it can be seen from the TG and DTG curves that the mass decreases fast from 100 to 150°, which is the loss of water remaining in the material itself, and the mass decreases slower after that, which is the reduction of carbon in the material.

The XRD data showed in Fig. 4c reveal typical peaks corresponding to (111), (200), and (220) planes in Ni [38] which exhibits that Ni had been successfully plated on the base in Co compounds-TA-PC-coated Ni/cc, TA-PC-coated Ni/cc, and PC-coated Ni/cc and Ni@cc. An interlayer spacing of 0.34 nm has been calculated from the (002) peak using the Bragg formula, close to that in graphite [39] as well as in PC-coated Ni/cc and the interlayer spacing increased to 0.39 nm in Co compounds-TA-PC-coated Ni/cc.

Nitrogen adsorption–desorption isotherms of PC-coated Ni@cc and Co compounds-TA-PC-coated Ni@cc samples were performed to demonstrate the porous structure of prepared samples. Figure 5a, c show the PC-coated Ni@cc and Co compounds-TA-PC-coated Ni@cc samples N2 adsorption–desorption type IV isotherms curves, which signifies the mesoporous structure of the materials. The specific surface area (SSA) of PC-coated Ni@cc and Co compounds-TA-PC-coated Ni@cc were estimated from the Brunauer–Emmett–Teller (BET) model and the results exhibited 304.93 and 253.95 m2 g−1, respectively. Figure 5b and d illustrates the pore distribution curves of as-prepared PC-coated Ni@cc and Co compounds-TA-PC-coated Ni@cc samples, which were estimated from the BJH model. The average pore diameter size (4 V/A) of PC-coated Ni@cc and Co compounds-TA-PC-coated Ni@cc were observed at 7.69 and 8.66 nm, respectively. Besides, the cumulative pore volumes were 0.1737 and 0.1689 cm3 g−1 for PC-coated Ni@cc and Co compounds-TA-PC-coated Ni@cc samples, respectively. It can be seen that a significant surface area and porous structure have been created due to activated C60. As a result, a lot of active sites and the construction of multi-scale conductive channels shortened the diffusion path of ions/electrons during the charging and discharging process. After the Co compounds coated on the substrate with porous surface, the surface area and pore channels remained largely unchanged with redox reactive sites increased substantially. This all improves the overall electrochemical performance of the electrode material.

Figure 6a shows the XPS full spectrum analysis diagram of Co compounds-TA-PC-coated Ni/cc, in which Co 2p, O 1s, C 1s, and N 1s signals can be clearly seen. In the Co 2p spectrum (Fig. 6b), it is shown that the Co 2p spectrum of the mixed valence state has 6 peaks. The peaks with binding energies of 781.3 eV and 795.61 eV were attributed to Co2+, and the fitting peaks at 781.8 eV and 801.8 eV were related to Co3+ [40]. These results confirmed the presence of different valance states of Co elements on the surface of Co compounds-TA-PC-coated Ni/cc electrode. Figure 6c shows the C 1s spectrum and it can be seen that the carbon bond in PC derived from activated carbon is an sp2 carbon bond that ensures the effective transmission of electrons in the electrode material. Figure 6d and e reveals O and N existed in Co compounds-TA-PC-coated Ni/cc that would further increase pseudocapacitance of the material. The detailed XPS N 1s spectrum of Co compounds-TA-PC-coated Ni/cc is shown in Fig. 6e, in which the prominent band can be deconvoluted into two peaks, namely, pyrrolic N (399.8 ± 0.2 eV) and pyridinic N (398.4 ± 0.2 eV). As a result, the existence of oxygen and nitrogen atoms located at the edges of carbon layers could improve the wettability of carbon in the electrolyte and the pseudocapacitance due to faradaic redox reactions might contribute to the capacitance as well [41, 42].

Electrochemical performance of Co compounds-TA-PC-coated Ni@cc

The electrochemical performances of Co compounds-TA-PC-coated Ni@cc electrode are tested by using a three-electrode configuration with 2 M KOH as electrolyte with Pt foil and Ag/AgCl as the counter and reference electrodes, respectively (Fig. 7). The pseudocapacitance behavior can be clarified by a pair of redox peaks in the cyclic voltammetry (CV) curves which corresponds to galvanostatic charge–discharge (GCD) curves. It can be seen from the CV curves showed in Fig. 7a that with the increase of scanning rate, the peak current density of the CV curve increases and the integral area of the CV curve also expands. However, the shape of the CV curve does not change significantly with the increase of scanning rate. This indicates that the prepared Co compounds-TA-PC-coated Ni@cc electrode has excellent rate performance and good electrochemical reversible reaction which is attributed to the good connection between the porous carbon layer on the Ni@cc substrate surface and Co compounds formed by the complexation of TA that ensures the rapid transport of electrons and diffusion of ions. Moreover, the broad redox peaks shown in the CV curves for the Co compounds-TA-PC-coated Ni@cc electrode indicated that the pseudocapacitance is mainly attributed to the reversible Faradic redox reactions of Co in different oxidation states which are generally involved in this system and presented as follows (Eqs. (4) and (5)) [43,44,45]:

a CV curves of Co compounds-TA-PC-coated Ni@cc at different scan rates. b Charge-discharge curves of Co compounds-TA-PC-coated Ni@cc at different current densities. c Area-specific capacitance as a function of current density. d Nyquist plot of Co compounds-TA-PC-coated Ni@cc. Inset magnifies the data in the high-frequency range

Such broadening of some redox peaks in the CV curves may be mainly attributed to the effect of amorphous morphology and/or microstructural properties of the electrode materials [43].

Figure 7b shows GCD curves of Co compounds-TA-PC-coated Ni@cc electrode at different current densities which showed typical pseudocapacitance characteristics. The area-specific capacitance calculated from the discharge at a current density of 2 mA cm−2 is 1475 mF cm−2, which remains 1114 mF cm−2 at a current density of 2 mA cm−2. From the discharge curves, the specific capacitance was calculated as 1475, 1300, 1220, 1200, 1150, and 1114 mF cm−2 at current densities of 2, 5, 8, 10, 20, and 30 mA cm−2, respectively, as summarized in Fig. 7c. It can be seen that the introduction of Co compounds improved the specific pseudocapacitance of Co compounds-TA-PC-coated Ni@cc electrode. Moreover, the introduction of nitrogen and oxygen atoms which are located at the edges of carbon could improve the wettability of material in electrolyte and the pseudocapacitance due to faradaic redox reactions of oxidation/reduction of pyridinic ring which is related to pyridinic N and pyrrolic N and reversible surface reaction of oxygen functionality might contribute to the capacitance as well [42, 46]. Figure 7d shows the Nyquist plot obtained from electrochemical impedance spectroscopy (EIS) in the frequency range of 0.01 Hz to 100 kHz and a magnified view of the curve in the high-frequency region in the inset. From the plots, we can see that the Co compounds-TA-PC-coated Ni@cc electrode demonstrates a nearly ideal capacitive behavior with a vertical slope at the low-frequency region and an ionic resistance of as small as 2.83 Ω.

The performance of Co compounds-TA-PC-coated Ni@cc, Co compounds-PC-coated Ni@cc, TA-PC-coated Ni@cc, and PC-coated Ni@cc and Ni@cc as an electrode material for SCs was investigated using GCD that the current density is 2 mA cm−2 which is showed in Fig. 8. From Fig. 8a, b, it can be seen that the introduction of oxygen and nitrogen atoms provided pseudocapacitance as well, and with the addition of Co compounds, the curve changes from the original isosceles triangle to curved curves, as showed in Fig. 8c. The charge and discharge curves of TA-PC-coated Ni@cc and PC-coated Ni@cc and Ni@cc electrodes show good symmetry and nearly linear discharge slopes which showed the behavior of an electrical double-layer capacitor, and Co compounds of Co compounds-TA-PC-coated Ni@cc and Co compounds-PC-coated Ni@cc improved pseudocapacitance as a highly reversible redox reaction occurs between the electrolyte and electrode materials. The improvement in conductivity of the nanocomposite material, which is a critical parameter for supercapacitors, was confirmed by the EIS study (Fig. 8d). It can be seen that with the addition of TA, Co compounds-TA-PC-coated Ni@cc has faster ion diffusion rate at the interface between electrode and electrolyte compared with Co compounds-PC-coated Ni@cc. Figure 8e shows the area-specific capacitance calculated from the discharge at a current density from 2 to 30 mA cm−2. It is obvious that the complexation between TA and metal atoms greatly improves the specific capacitance and capacitance multiplier properties of the material. The effect of Co content on the pseudocapacitance has been explored as well which showed in Fig. 8f. Co compounds-TA-PC-coated Ni/cc-0.17 is the material we discussed in the manuscript that the 0.17 means 0.17 M Co(NO3)2 solution in the experimental section. It can be seen that as the Co content decreased, the capacitance decreased as well and the Co content increased causing a decline of rate performance.

a CV curves of PC-coated Ni@cc at different scan rates. b CV curves of Co compounds-TA-PC-coated Ni/cc, Co compounds-PC-coated Ni/cc, TA-PC-coated Ni/cc, and PC-coated Ni/cc at 20 mV s−1. GCD curves (c) and Nyquist plots (d) of Co compounds-TA-PC-coated Ni/cc, Co compounds-PC-coated Ni/cc, TA-PC-coated Ni/cc, and PC-coated Ni/cc and Ni@cc. e Area-specific capacitance of Co compounds-TA-PC-coated Ni/cc and Co compounds-PC-coated Ni/cc as a function of current density. f Area specific capacitance of different Co content of Co compounds-TA-PC-coated Ni/cc

We have made two Co compounds-TA-PC-coated Ni@cc electrodes with PVA/KOH gel electrolyte to assemble solid-state symmetric SCs which showed in Fig. 9a. The cycling test showed in Fig. 9a that the assembled SCs have a retention of 95.76% in capacitance at 5 mA cm−2 after 5000 times of charging/discharging. The assembled SCs can also provide continuous and stable energy that lights up the red LED (inset in Fig. 9a). GCD curves are recorded to investigate the influence of bending. As shown in Fig. 9b, no significant change in device performance can be observed under the bending state even after bending 500 times. These results will demonstrate the excellent capacitive and flexible properties of the assembled flexible SCs in this work.

a Cycling stability of solid-state symmetric SCs with Co compounds-TA-PC-coated Ni@cc as electrodes at 5 mA cm−2 with the inset showing the lighting up of the red LED. b GCD curves of solid-state symmetric SCs with Co compounds-TA-PC-coated Ni@cc in normal state, bending state, and after bending 500 times at 2 mA cm−2. The inset shows the photographs of the normal and bending states of the solid-state symmetric SCs

Conclusions

In summary, we have successfully prepared Co compounds-TA-PC-coated Ni@cc electrode which PC made of activated C60 and complexed with Co compounds with TA. The Co compounds-TA-PC-coated Ni@cc binder-free electrode exhibited a maximum surface capacitance of 1475 mF cm−2 at a current density of 2 mA cm−2 and maintained an initial capacitance of 75.5% at a current density of up to 30 mA cm−2 in a three-electrode configuration with 2 M KOH as electrolyte. Further, solid-state symmetric SCs with Co compounds-TA-PC-coated Ni@cc electrodes and PVA/KOH gel electrolyte achieved extraordinary cycle stability that 95.76% capacitance retained after 5000 continuous charge and discharge cycles at 5 mA cm−2 current density and excellent flexibility. This excellent performance can be attributed to the complexation of TA with Co compounds so that Co ions can be uniformly dispersed on the surface of porous carbon-coated Ni@CC substrate and provided a considerable pseudocapacitance. In addition, N and O atoms provided pseudocapacitance as well and the PC provided good electrical conductivity of the electrode material. The Co compounds-TA-porous carbon binder-free electrode reported in this paper has great prospects for portable energy storage devices.

Data availability

No data was used for the research described in the article.

References

Garland TN, Kaveti R, Bandodkar AJ (2023) Biofluid-activated biofuel cells, batteries, and supercapacitors–a comprehensive review. Adv Mater 35(52):2303197. https://doi.org/10.1002/adma.202303197

Mathis TS, Kurra N, Wang X, Pinto D, Simon P, Gogotsi Y (2019) Energy storage data reporting in perspective—guidelines for interpreting the performance of electrochemical energy storage systems. Adv Eng Mater 9:1902007. https://doi.org/10.1002/aenm.201902007

Pankratov D, Falkman P, Blum Z, Shleev S (2014) A hybrid electric power device for simultaneous generation and storage of electric energy. Energy Environ Sci 7:989–993. https://doi.org/10.1039/C3EE43822H

Zhu S, Ni J, Li Y (2020) Carbon nanotube-based electrodes for flexible supercapacitors. Nano Res 13:1825–1841. https://doi.org/10.1007/s12274-020-2729-5

He J, Sun K, Wu M (2022) All-pseudocapacitive coordination towards flexible asymmetric fiber-shaped supercapacitors with ultrahigh energy and power density. J Mater Chem A 10(41):21838–21847. https://doi.org/10.1039/D2TA06456A

Wu M, Sun K, He J (2023) Hierarchically 3D fibrous electrode for high-performance flexible AC-line filtering in fluctuating energy harvesters. Adv Func Mater 33(45):2305039. https://doi.org/10.1002/adfm.202305039

Simon P, Gogotsi Y (2020) Perspectives for electrochemical capacitors and related devices. Nat Mater 19:1151–1163. https://doi.org/10.1038/s41563-020-0747-z

Libich J, Máca J, Vondrák J, Čech O, Sedlaříková M (2018) Supercapacitors: properties and applications. Energy Storage 17:224–227. https://doi.org/10.1016/j.est.2018.03.012

Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7:845–854. https://doi.org/10.1038/nmat2297

Zhu S, Wang L, Gu CY, Liu HC, Mu YW, Ni JF, Han GY (2022) Boosting capacitive performance of nitrogen-doped carbon by atomically dispersed iron. J Power Sources 532:231335. https://doi.org/10.1016/j.jpowsour.2022.231335

Simon P, Gogotsi Y, Dunn B (2014) Where do batteries end and supercapacitors begin? Science 343:1210–1211. https://doi.org/10.1126/science.1249625

Wang Y, Wu X, Han Y, Li T (2021) Flexible supercapacitor: overview and outlooks. Energy Storage 42:103053. https://doi.org/10.1016/j.est.2021.103053

Soni S, Pareek K, Jangid DK, Rohan R (2020) Carbon cloth-MnO2 nanotube composite for flexible supercapacitor. Energy Storage 2:e189. https://doi.org/10.1002/est2.189

Dong L, Liang G, Xu C, Liu W, Pan Z-Z, Zhou E, Kang F, Yang Q-H (2017) Multi hierarchical construction-induced superior capacitive performances of flexible electrodes for wearable energy storage. Nano Energy 34:242–248. https://doi.org/10.1016/j.nanoen.2017.02.031

Gao S, He S, Zang P, Dang L, Shi F, Xu H, Liu Z, Lei Z (2016) Polyaniline nanorods grown on hollow carbon fibers as high-performance supercapacitor electrodes. ChemElectroChem 3:1142–1149. https://doi.org/10.1002/celc.201600153

Wei C, Xu Q, Chen Z, Rao W, Fan L, Yuan Y, Bai Z, Xu J (2017) An all-solid-state yarn supercapacitor using cotton yarn electrodes coated with polypyrrole nanotubes. Carbohyd polym 169:50–57. https://doi.org/10.1016/j.carbpol.2017.04.002

Guo R, Li J, Jia Y, Xin F, Sun J, Dang L, Liu Z, Lei Z (2019) Nitrogen-doped carbon sheets coated on CoNiO2@textile carbon as bifunctional electrodes for asymmetric supercapacitors. J Mater Chem A 7:4165–4174. https://doi.org/10.1039/C9TA00014C

Fei J, Cui Y, Li J, Xu Z, Yang J, Wang R, Cheng Y, Hang J (2017) A flexible Sb2O3/carbon cloth composite as a free-standing high performance anode for sodium ion batteries. Chem Commun 53:13165–13167. https://doi.org/10.1039/C7CC06945F

Li T, Yu H, Zhi L, Zhang W, Dang L, Liu Z, Lei Z (2017) Facile electrochemical fabrication of porous Fe2O3 nanosheets for flexible asymmetric supercapacitors. J Phys Chem C 121:18982–21899. https://doi.org/10.1021/acs.jpcc.7b04330

Liao Q, Li N, Jin S, Yang G, Wang C (2015) All-solid-state symmetric supercapacitor based on Co3O4 nanoparticles on vertically aligned graphene. ACS Nano 9:5310–5317. https://doi.org/10.1021/acsnano.5b00821

Wang TS, Liu X, Wang Y, Fan LZ (2020) High areal capacity dendrite-free Li anode enabled by metal–organic framework-derived nanorod array modified carbon cloth for solid state Li metal batteries. Adv Funct Mater 31:2001973. https://doi.org/10.1002/adfm.202001973

Ren K, Liu Z, Wei T, Fan Z (2021) Recent developments of transition metal compounds-carbon hybrid electrodes for high energy/power supercapacitors. Nano-Micro Lett 13:129. https://doi.org/10.1007/s40820-021-00642-2

Trasatti S, Buzzanca G (1971) Ruthenium dioxide: a new interesting electrode material. Solid state structure and electrochemical behaviour. J Electroanal Chem 29:A1–A5. https://doi.org/10.1016/S0022-0728(71)80111-0

Hu CC, Chang KH, Lin MC, Wu YT (2006) Design and tailoring of the nanotubular arrayed architecture of hydrous RuO2 for next generation supercapacitors. Nano Lett 6(12):2690–2695. https://doi.org/10.1021/nl061576a

Zhu Y, Ji X, Pan C, Sun Q, Song W, Fang L, Chen Q, Banks CE (2013) A carbon quantum dot decorated RuO2 network: outstanding supercapacitances under ultrafast charge and discharge. Energy Environ Sci 6:3665–3675. https://doi.org/10.1039/C3EE41776J

Zhang A, Liang Y, Zhang H, Geng Z, Zeng J (2021) Doping regulation in transition metal compounds for electrocatalysis. Chem Soc Rev 50:9817–9844. https://doi.org/10.1039/D1CS00330E

Wang H, Li X, Jiang Y, Li M, Xiao Q, Zhao T, Yang S, Qi C, Qiu P, Yang J, Jiang Z, Luo W (2022) A universal single-atom coating strategy based on tannic acid chemistry for multifunctional heterogeneous catalysis. Angew Chem Int Ed 61:e202200465. https://doi.org/10.1002/ange.202200465

Ejima H, Richardson JJ, Liang K, Best JP, Van Koeverden MP, Such GK, Cui J, Caruso F (2013) One-step assembly of coordination complexes for versatile film and particle engineering. Science 341:154–157. https://doi.org/10.1126/science.1237265

Wei J, Liang Y, Hu Y, Kong B, Zhang J, Gu Q, Tong Y, Wang X, Jiang SP, Wang H (2016) Hydrothermal synthesis of metal-polyphenol coordination crystals and their derived metal/N-doped carbon composites for oxygen electrocatalysis. Angew Chem 55:12470–12474. https://doi.org/10.1002/ange.201606327

Zhang L, Zhu P, Zhou F, Zeng W, Su H, Li G, Gao J, Sun R, Wong CP (2016) Flexible asymmetrical solid-state supercapacitors based on laboratory filter paper. Acs Nano 10(1):1273–1282. https://doi.org/10.1021/acsnano.5b06648

Zhang L, Yu X, Zhu P, Zhou F, Li G, Sun R, Wong CP (2018) Laboratory filter paper as a substrate material for flexible supercapacitors. Sustainable Energy & Fuels 2(1):147–154. https://doi.org/10.1039/C7SE00411G

Amirtha RM, Hsu H-H, Abdelaal MM, Anbunathan A, Mohamed SG, Yang C-C, Hung T-F (2022) Constructing a carbon-encapsulated carbon composite material with hierarchically porous architectures for efficient capacitive storage in organic supercapacitors. Int J Mol Sci 23(12):6774. https://doi.org/10.3390/ijms23126774

Abdelaal MM, Hung TC, Mohamed SG, Yang CC, Hung TF (2022) Two birds with one stone: hydrogel-derived hierarchical porous activated carbon toward the capacitive performance for symmetric supercapacitors and lithium-ion capacitors. ACS Sustain Chem Eng 10(14):4717–4727. https://doi.org/10.1021/acssuschemeng.2c00266

Rahmanifar MS, Hesari H, Noori A, Masoomi MY, Morsali A, Mousavi MF (2018) A dual Ni/Co-MOF-reduced graphene oxide nanocomposite as a high performance supercapacitor electrode material. Electrochim Acta 275:76–86. https://doi.org/10.1016/j.electacta.2018.04.130

Wang J, Yao Y, Zhang C, Sun Q, Cheng D, Huang X, Feng J, Wan J, Zou J, Liu C, Yu C (2021) Superstructured macroporous carbon rods composed of defective graphitic nanosheets for efficient oxygen reduction reaction. Adv Sci 8:2100120. https://doi.org/10.1002/advs.202100120

Liu MM, Cai C, Li J, Zhao J, Teng W, Liu R (2018) Stober synthesis of tannic acid-formaldehyde resin polymer spheres and their derived carbon nanospheres and nanocomposites for oxygen reduction reaction. J Colloid Interface Sci 528:1–9. https://doi.org/10.1016/j.jcis.2018.05.070

Erdem P, Bursali EA, Yurdakoc M (2013) Preparation and characterization of tannic acid resin: study of boron adsorption. Environ Prog Sustain Energy 32:1036–1044. https://doi.org/10.1002/ep.11703

Richardson J, Scates R, Twigg M (2003) X-ray diffraction study of nickel oxide reduction by hydrogen. Appl Catal A 246:137–150. https://doi.org/10.1016/S0926-860X(02)00669-5

Lin M-C, Gong M, Lu B, Wu Y, Wang D-Y, Guan M, Angell M, Chen C, Yang J, Hwang B-J, Dai H (2015) An ultrafast rechargeable aluminium-ion battery. Nature 520:324–328. https://doi.org/10.1038/nature14340

Kalasina S, Kongsawatvoragul K, Phattharasupakun N, Phattharaphuti P, Sawangphruk M (2020) Cobalt oxysulphide/hydroxide nanosheets with dual properties based on electrochromism and a charge storage mechanism. RSC Adv 10(24):14154–14160. https://doi.org/10.1039/D0RA01714K

Ren W, Li D, Liu H, Mi R, Zhang Y, Dong L (2013) Lithium storage performance of carbon nanotubes with different nitrogen contents as anodes in lithium ions batteries. Electrochimica Acta 105:75–82. https://doi.org/10.1016/j.electacta.2013.04.145

Lota G, Grzyb B, Machnikowska H, Machnikowski J, Frackowiak E (2005) Effect of nitrogen in carbon electrode on the supercapacitor performance. Chem Phys Lett 404(1–3):53–58. https://doi.org/10.1016/j.cplett.2005.01.074

Shim HW, Lim AH, Kim JC, Jang E, Seo SD, Lee GH, Kim KD, Kim DW (2013) Scalable one-pot bacteria-templating synthesis route toward hierarchical, porous-Co3O4 superstructures for supercapacitor electrodes. Sci Rep 3(1):2325. https://doi.org/10.1038/srep02325

Yang S, Liu Y, Hao Y, Yang X, Goddard WA III, Zhang XL, Cao B (2018) Oxygen-vacancy abundant ultrafine Co3O4/graphene composites for high-rate supercapacitor electrodes. Adv Sci 5(4):1700659. https://doi.org/10.1002/advs.201700659

Edison TNJI, Atchudan R, Sethuraman MG, Lee YR (2016) Supercapacitor performance of carbon supported Co3O4 nanoparticles synthesized using Terminalia chebula fruit. J Taiwan Inst Chem Eng 68:489–495. https://doi.org/10.1016/j.jtice.2016.09.021

Yang W, Li Y, Feng Y (2018) High electrochemical performance from oxygen functional groups containing porous activated carbon electrode of supercapacitors. Materials 11(12):2455. https://doi.org/10.3390/ma11122455

Acknowledgements

The authors thank “Wuhan Engineering Technology Research Center for Advanced Fibers” for providing partial support for materials processing.

Funding

This work was supported by the National Natural Science Foundation of China (51873166, 51873165).

Author information

Authors and Affiliations

Contributions

Ziqi Tan: conceptualization, validation, writing—original draft, supervision. Min Yu: methodology, resources, data curation, investigation. Yali Cao: investigation, resources. Qi Sun: data curation. Xue Liu: discussion, writing—review and editing. Qiongzhen Liu: discussion, writing—review and editing. Yuedan Wang: discussion, writing—review and editing. Mufang Li: discussion, writing—review and editing. Dong Wang: supervision, discussion, project administration, funding acquisition.

Corresponding authors

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tan, Z., Yu, M., Cao, Y. et al. Optimizing the fabrication of Co compounds coating on modified carbon cloth with enhanced pseudocapacitive performance and cyclic stability. J Solid State Electrochem 28, 2787–2799 (2024). https://doi.org/10.1007/s10008-024-05818-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-024-05818-5