Abstract

Ultraviolet (UV)-induced graft copolymerization of glycidyl methacrylate GMA onto poly(ethylene terephthalate) (PET) films and the subsequent sulfonation on the monomer units in the grafting chain using sulfuric acid were carried out to prepare proton exchange membranes (PEMs) for fuel cells. A maximum grafting value of 23.5% was found for 15 vol% GMA after 4-h radiation time. Optimum concentration of sulfuric acid was selected for the sulfonation reaction to be 1 mol/L based on the degree of sulfonation and the tensile strength studies of the membrane. The radiation grafting and the sulfonation have been confirmed by titrimetric and gravimetric analysis as well as FTIR spectroscopy. The maximum ion exchange capacity (IEC) of 2.085 meq g−1 was found at 46.99% degree of sulfonation and the maximum proton conductivity was found to be 60.35 mS cm−1 at 30 °C and relative humidity of 100%. The various physical and chemical properties of the PEMs such as water uptake, mechanical strength, thermal durability, free-volume content, and methanol permeability were also studied as function of sulfuric acid concentration. To investigate the suitability of the prepared membrane for fuel cell applications, its properties were compared with those of Nafion 112 as standard membrane.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to the increasing demand for energy because of the huge world economic growth, there have been extensive efforts to find new energy resources. Nowadays, the fossil fuel is one of the most abundant energy sources. Although it is cheap and having high energy density, its supply is limited and will be depleted. Moreover, combustion of fossil fuel emits carbon dioxide (CO2) which has severe impacts on the environment [1], leading to a temperature increase of the earth’s near surface of 0.8 °C over the past century [2]. The way to mitigate climate change and satisfy growing energy demand is to deploy renewable energy technology on a large scale [3].

Recently, the polymer exchange membrane fuel cell (PEMFC) has been the most promising and important candidate for power applications ranging from micro-power and transportation to large-scale stationary power systems for buildings and distributed generation. PEMFCs have many advantages such as low operating temperature, sustained operation at a high current density, light weight, compactness, the potential for low cost and volume, long stack life, fast start-ups, and suitability for discontinuous operation [4,5,6,7,8,9,10,11,12]. In a PEMFC, the electrolyte is a polymeric membrane having some special properties such as high proton conduction at the fuel cell operating temperature, low permeability to the fuel (hydrogen) and the oxidant (oxygen), enough hydration to allow good operations, and good chemical and mechanical stability for long-term operations. From the different proton exchange membranes (PEMs), perfluorosulfonated membranes like Nafion are the most used and extensively studied. But they have some drawbacks such as low stability at higher temperature (> 80 °C) and high cost. They are not environmental friendly (because of their high fluorine content) and high permeable to methanol. Hence, various approaches have been tried to develop new alternative membranes with better characteristics for PEMFC to overcome these drawbacks of Nafion [13].

Extensive research has been conducted with the goal of developing alternative membranes to Nafion, working on the reduction of the methanol permeability. Moreover, a lot of researchers have worked on developing new synthetic polymeric membranes containing ionic clusters [14,15,16,17] or by the surface treatment of the Nafion membranes or by blending Nafion membranes with other polymer/inorganic materials [18,19,20,21,22].

Radiation graft polymerization is one of the most used methods enabling introduction of an active monomer functional group at the inner or surface polymer chains in a film for the modification of the chemical and physical properties of a wide range of polymer materials. In the last few decades, different kinds of grafting polymerization techniques including ion radiation-induced, photo-induced (UV and chemical initiator), and plasma-induced grafting polymerizations have been reported [23,24,25]. The UV radiation technique is more available and less expensive than the other techniques [26].

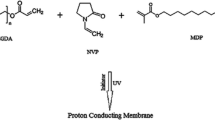

Radiation-grafted sulfuric acid membranes have been considered to be the most important alternative proton conducting materials for PEM fuel cells and direct methanol fuel cells DMFC [27], due to their wider pH range working characteristics [28]. The radiation-induced graft copolymerization of various monomers such as acrylic acid, methacrylic acid, 4-vinylpyridine, acrylonitrile, vinyl acetate, N-vinyl-3-morpholinone, and 2-methyl-5-vinylpyridine onto polyethylene terephthalate (PET) films has been reported previously in literature [29,30,31]. It is known that styrene is a widely used monomer for grafting due to its easy polymerization and easy sulfonation. It provides thermal stability due to the presence of the aromatic ring system [32]. But membranes grafted by sulfonated polystyrene are unstable in an oxidative environment on fuel cells, leading to radical induced degradation of the membrane material [29, 30]. Accordingly, this will lead to a loss of grafted component and consequent loss of proton exchange sites and consequently loss of proton conductivity. To avoid this loss, glycidyl methacrylate (GMA) is used instead of styrene in the investigation reported here. A PET-based PEM was successfully prepared by UV radiation grafting of GMA monomer onto PET films, and selective sulfonation by sulfuric acid was carried out. The effects of different monomer concentrations and sulfonation on grafted membranes of PET have been also studied. The membrane has been investigated by determination of several chemical and physical parameters, including water uptake, tensile strength, ion exchange capacity, proton conductivity, thermal durability, FTIR spectroscopy, and positron annihilation lifetime spectroscopy. These results are presented in the context of other perfluorinated membranes (e.g., Nafion) to evaluate its potential use as a proton exchange membrane (PEM) in fuel cells.

It is known that many important properties of the membrane such as gas permeability are related to the nanosized free volume inside the membrane. Specially the free-volume holes inside the polymer control the diffusion rate of gases or molecules inside the polymer [33]. The size and distribution of these free volumes is calculated using the positron annihilation lifetime spectroscopy, which is a nondestructive technique.

The positron annihilation lifetime (PAL) spectroscopy is capable of directly probing the nanometer-sized free-volume holes. PALS was developed based on the formation of positronium (Ps), the bound state between a positron and an electron. When positrons are injected into materials, there exist three states of positrons with different lifetimes. The shortest-lifetime (~ 0.125 ns) state is para-positronium (p-Ps), in which the spins are anti-parallel. The middle-lifetime (~ 0.45 ns) state is a free positron without forming a bound state. The longest-lifetime (1–10 ns) state is orthopositronium (o-Ps) with parallel electron and positron spins. The o-Ps lifetime has a strong correlation with the size of the free-volume holes; that is, as the holes become smaller, the o-Ps lifetime decreases. Therefore, the information about the free-volume structures in materials can be obtained by PAL spectra.

The relation between o-Ps lifetime and a spherical hole of Radius R can be calculated using the Tao Eldrup model: [34, 35].

where τ3 and R (the average of o-Ps hole volume radius) are expressed in the units of ns and Å, respectively, and Ro = R + ΔR and ΔR are the thickness of the homogenous electron layer in which the positron annihilated. ΔR was calibrated to be 1.656 Å [36]. The free volume, FV, could be estimated using the following equation:

In the present study, the free-volume hole size was estimated for sulfonated PET-g-GMA with different degree of sulfonation and the effect of free volume on conductivity, methanol permeability, and mechanical properties was investigated.

Experimental

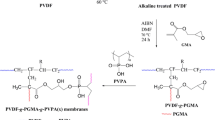

Grafting procedure

The PET films of thickness 51 μm (purchased from Alfa Aesar) were cut into square pieces of known weight, washed with acetone, and then dried in a vacuum oven at 60 °C for 1 h. The dried films were placed into quartz tube containing monomer solution of glycidyl methacrylate (purchased from Alfa Aesar) of known concentration. The photografting mixture consists of methanol which used as a solvent, benzophenone (ph2CO) (Purchased from Aldrich with different concentrations) which works as photoinitiator, glycidyl methacrylate (monomer) and purged with nitrogen. The quartz tube was finally exposed to low-pressure mercury lamp (low-pressure mercury lamp with main wavelength of 254 nm purchased from General Electric) for UV irradiation for different time intervals. The obtained grafted PET films were washed with deionized water several times to remove unreacted monomer and the homopolymer then it was dried in an evacuated oven at 60 °C, until a constant weight was obtained.

The degree of grafting (D.G.%) was calculated using the following equation:

where Wg and Wo are the film weights of grafted and original PET films, respectively.

The introduced epoxy groups of GMA were converted into amine groups by the amination process to facilitate the process of sulfonation of GMA where the epoxy group of poly GMA were reacted with ethylene diamine (EDA) (purchased from Aldrich with purity 99%) at concentration of 5% for 3 h at temperature 50 °C in oil bath.

Finally, the grafted films were sulfonated by immersion in different concentration of sulfuric acid (0.5%, 1%, 1.5%, and 2% M) in dichloromethane as a solvent at room temperature for 3 h. The sulfonated grafted PET film was then washed with distilled water to remove the unreacted sulfuric acid adhering on the surface. The degree of sulfonation of dried sulfonated films was calculated according to the following equation:

where Ws and Wg are the weights sulfonated films and grafted and films, respectively.

Polymer structure, characterization, evaluation, and instrumentation

Fourier transform infrared spectra (FTIR) were recorded using RUKER ALFA FTIR USA spectrometer with resolution 0.9 cm−1 which provides the composition information on the sulfonated PET-grafted PGMA membrane. The tensile strength of the membrane under investigation was measured at room temperature by UNIVERSAL MATERIALS TESTING MACHINE LLOYD (model LR 5K plus). The measurements were performed at a cross-head speed set at a constant speed of 10 mm/min. Ion exchange capacity (IEC) of the sulfonated samples was measured using a typical titration method. The dried membrane in the protonic form was equilibrated with 25 ml of 3 M NaCl solution for 24 h. A large excess of Na+ ions in the solution ensured nearly complete ion exchange. Then, 10 ml of the solution was titrated against 0.05 M NaOH solution using phenolphthalein as indicator. Finally, drops of 0.05 M NaOH solution were added, until the color of solution changes from colorless to pink. The IEC was calculated using the following equation:

where VNaOH (ml) is the volume of the 0.05 M NaOH solution used for titration, n is the factor corresponding to the ratio of the amount of NaCl taken to immerse the polymer to the amount used for titration that is 2.5, and Wdry (g) is the dry weight of the polymer electrolyte membrane in the protonic form. The membrane water uptake was determined by the weight difference between dry and wet membranes. The vacuum dried membranes were weighed (W0) and then immersed in deionized water at room temperature for 24 h. The wet membrane was blotted dry and immediately weighed again (W1). The water uptake of the membranes was calculated according to the following equation:

where W1 is the weight of the wet membrane and Wo is the weight of the dry membrane.

Measurements of contact angle were performed at 24 °C and ambient relative humidity (60% RH) in a Video-Based Contact Angle Meter model OCA 20 (Data Physics Instruments GmbH, Filderstadt, Germany). Contact angle measurements were obtained by analyzing the shape of a distilled water drop after it had been placed over the aminated PET-G-GMA film with different degree of grafting for 30 s. Image analyses were carried out by SCA20 software.

The degradation process and thermal stability of the membrane under investigation were determined using a thermogravimetric analyzer (TGA) Instrument model Q50, USA, which was used to characterize the thermal stability of the membranes with heating rate 10 °C/minute under nitrogen atmosphere. About 15 mg of sample was used for each run.

A methanol permeability measurement was also carried out using a liquid diffusion cell shown in Fig. 1, composed of two compartments containing solution A and B. One compartment A (VA = 150 mol) was filled with 10 mol L−1 methanol solution, and the other compartment (VB = 150 mol) was filled with deionized water only. The tested sulfonated membrane PET-g-PGMA was immersed in deionized water for hydration before measurements and then vertically placed between the two compartments by a screw clamp. The amount of methanol diffused from compartment A to B across the membrane was measured over time. The methanol permeability P was calculated by the following equation:

where k was the slope of the straight line plot of methanol concentration in solution B versus permeation time and VB, L, and A are the volume of solution B, the thickness, and the effective area of the tested membrane.

To determine the proton conductivity, σ, measurements of the membrane were carried out at a 100% RH as a function of concentration of sulfuric acid (mol/L) content. Proton conductivity (σ) of the membranes was derived from AC impedance spectroscopy. The measurements were done over a frequency range from 50 Hz to 5 MHz with an oscillating voltage of 50–500 mV, using a system based on a HIOKILCR Hi-Tester, Model 3532, Japan. The out of plane of proton conductivity, σ, for the membranes under study can be obtained based on the measured resistance

where R stands for the resistance (Ω) of the membrane, L is the thickness (cm) of the membrane, and S is the contact surface area (cm2) of the electrode.

Positron annihilation lifetime measurements were conducted using 22NaCl radioactive material enveloped between 25 μm Kapton foil. The source is sandwiched between 10 layers of the membrane with a total thickness of 1 mm on each side to ensure that most of the positrons annihilate inside the membrane material. Using a fast-fast coincidence spectrometer, spectra were collected containing more than 2 million counts each. LT.0 9 [37] program was used for analyzing these spectra. The source correction contribution was measured using a well-annealed aluminum specimen with 99.00% purity and it was found to be 15%. The spectra were analyzed into three lifetime (τ1, τ2, τ3) components with their corresponding intensities (I1, I2, I3).

Results and discussion

Preparation of the sulfonated PET-grafted GMA film

Radiation-induced graft copolymerization of glycidyl methacrylate (GMA) onto PET films was performed using simultaneous UV radiation technique, and the grafted films were sulfonated by sulfuric acid to obtain proton exchange membranes for the fuel cell applications. Many factors such as monomer concentration, radiation exposure time, photoinitiator concentration, and temperature affect the grafting yield of GMA into PET film. So, these parameters were optimized to get high-performance proton exchange membrane PEM in this study. Figure 2 shows the degree of grafting, D.G. (%) of GMA monomer onto the PET film as a function of monomer concentration after 4 h of simultaneous UV irradiation. As can be seen from Fig. 2, D.G increased with increasing monomer concentration and reached a maximum value of 23.5% grafting yield at 15 vol% GMA due to the increase of monomer concentration and its diffusion into the PET films which leads to an increment in the grafting yield. After 15 vol% monomer concentration, the grafting yield started to decrease with a further increase in monomer concentration because of increasing homopolymerization rather than grafting which leads to an increase of the viscosity of the grafting solution and thus hinders the movement of the monomer toward the substrate and reduces the grafting yield [31, 32].

Using 15% monomer GMA concentration, the grafting copolymerization was carried out with UV irradiation at different concentrations of photoinitiator (ph2CO). Figure 3 shows the effect of variation of photoinitiator (ph2CO) concentration on degree of grafting. It is clear that increasing photoinitiator concentration from 1 to 2 wt% was accompanied by an increased degree of grafting. This may have been due to an increase in the number of active sites formed on PET film, which may increase diffusion of monomer toward PET. Beyond 2 wt% photoinitiator (ph2CO) concentration, the DG decreases. This may be explained by the formation of homopolymer.

Using the optimum conditions (15% GMA monomer concentration and 2 Wt% of ph2CO) for PET-g- PGMA, grafting copolymerization was conducted with UV irradiation at different radiation periods (Fig. 4). We observe that firstly, D.G increased with increasing radiation time up to 4 h, then it leveled off, reaching a saturation grafting value of 23.5%. With increasing radiation time, the number of monomer molecules that diffuse into the PET surface also increases, and thus resulting in a higher degree of grafting. The leveling off of grafting may be attributed to the saturation of active PET back bone by homopolymers which form a diffusion barrier on the PET surface [38]. Using the optimum conditions for PET-g-GMA (15% GMA monomer concentration, 2 wt% of ph2CO, and 4-h radiation time) and we studied effects of changing the temperature of the experiment. As noticed from Fig. 5, the degree of grafting increases with increasing temperature from 25 to 35 °C. This could be explained by temperature enhancement of the diffusion of monomer toward active site on PET. Beyond 35 °C, the D.G. decrease may be due to homopolymer formation.

Measurements of contact angles of a water drop on surfaces of the plain PET and aminated PET-g-GMA are presented in Fig. 6 versus degree of grafting. It can be seen from Fig. 6, that with increasing percentage of grafted GMA, contact angles increased monotonically. This result suggests that the surface polarity of PET is augmented by an increase of the content of GMA in PET-g-GMA samples. Furthermore, the contact angle results assure of increasing the hydrophilic nature of the prepared membranes.

The incorporation of sulfuric groups in the grafted PET film can improve the solubility of the products, so that they can be cast into the membranes as PEMs. The sulfonation was performed by using sulfuric acid H2SO4 as sulfonating agent. The –SO3H is added to the aromatic ring by electrophilic substitution reaction [39]. Complete sulfonation, i.e., one sulfuric acid group per aromatic group in the PET film, is expected for this type of reaction. But the degree of sulfonation can vary considerably with the conditions of the sulfonation reaction [39]. Figure 7 shows that the degree of sulfonation, D.O.S (%) (calculated using Eq. 4) increases with increasing sulfuric acid concentration up to concentration 1 M/L. After that it starts to decrease. Therefore, the sulfonation conditions was chosen to be 1 M/L% of sulfuric acid at room temperature for 3 h. It is known that, for fuel cell applications, it is important that the graft-type PET have a homogeneous distribution of sulfuric acid in the direction perpendicular to the film surface to exhibit high proton conductivity between two electrodes in a fuel cell device [40]. More homogenous distribution of sulfuric acid to the film surface gives a more rigid structure having higher tensile strength. We examined the tensile strengths of the sulfonated films (Table 1) prepared with different concentrations of sulfuric acid and selected the optimum concentration of sulfuric acid to be 1 M/L. The sulfonation reaction at higher sulfuric acid concentration is accompanied by decreasing tensile strength of the film. This may be due to side reactions, resulting in the degradation of the sulfonated chains that make the film more fragile [40]. The sulfonation level is the percentage of sulfonated PET units to the total PET units. The results of tensile strength and elongation at break of the PET-g sulfonated GMA (PET-g-SGMA) are summarized in Table 1. As seen from Table 1, the optimum concentration for the sulfuric acid was taken to be at 1 M/L where it gives the largest elongation at break of the sulfonated PET-g-S GMA.

FTIR spectroscopy

To investigate the complex formation of the sulfonated PET-g-GMA membranes, FTIR studies were conducted. Figure 8 shows the IR spectra of blank PET, grafted and sulfonated film with D.G 23.5%. The pure PET film is characterized by a strong absorption band around 730 cm−1 [41] representing the bending vibration of the C=O–O of ester group, absorption bands around 2966 and 2906 cm−1 [41] representing asymmetric and symmetric stretching vibration of –CH2– group of ethylene, respectively, and the band around 1724 cm−1 representing the stretching vibration of the O=C–O of ester group and the band at 3058 cm−1 representing the stretching vibration of the C=C–H of the aromatic benzene ring. The grafting of GMA is confirmed by the presence of new absorption bands around 898 cm-1, 873 cm−1, and 1386 cm−1 which are characteristic absorption bands of epoxy group of GMA. The opening of epoxy rings through the amination process indicated by the appearance of bands around 3425 cm−1 which are ascribed to stretching vibration of the O–H groups from the epoxy ring opening reaction. The sulfonation process is indicated by the presence of broad absorption bands around 2500 and 3500 cm−1 representing absorption of O–H of the sulfonic acid and a band at 1144 cm−1 and 1030 cm−1 representing vibration of the O=S=O group.

Thermal stability

The thermal properties of pure PET and PET-g-SGMA membranes were preliminarily evaluated by The thermogravimetric analysis (TGA) in N2 heating at 10 °C min−1 as shown in Fig. 9. TGA of pristine PET and sulfonated PET-g-GMA with different degrees of sulfonation showed a maximum weight loss around 400 °C attributed to the decomposition of sulfonate groups. Hence, PET-g-SGMA membranes are stable to 400 °C, which is well above the operating temperature of up to 200 °C in PEMFCs. The data thus indicate that the PET-g-SGMA membrane is thermally stable within the temperature range for proton exchange membrane fuel cell (PEMFC) applications.

IEC and water uptake

Sulfuric acid is a very common and effective reagent in the sulfonation of the aromatic polymer, where the ─SO3H is added to the aromatic ring by electrophilic substitution as the degree of sulfonation (D.O.S) is defined as the percentage of repeat PET units that have been sulfonated. A higher degree of sulfonation indicates that more repeat units have been sulfonated. In this study, the effects of sulfuric acid concentration on the IEC and water uptake of the membranes under investigation were reported. Figure 10 shows the IEC and water uptake of the membranes, sulfonated in the (0.5–2 Ml/L) sulfuric acid solution with 1,2-dichloroethane as a solvent at 30 °C for 4 h, respectively, as a function of sulfuric acid concentration. It is seen that the sulfonation reaction of the GMA occurred easily: the maximum sulfonation could be achieved in the 1 mol/L sulfuric acid concentration, which was reflected in high values of IEC and water uptake. However, IEC and water uptake decreased with further increase in sulfuric acid concentration. It was found that water uptake increased with increasing the concentration of sulfuric acid. This behavior was caused by the hydrophilicity of the sulfonated GMA as shown by the contact angle measurements. GMA helps in increasing the liquid retention in the PET membrane due to its property of hydrophilicity. Since GMA absorbs water on the surface through a strong interaction with surface ─SO3− groups and the formation of hydrogen bonds. Furthermore, the membrane became more brittle when sulfonated at a higher concentration (> 1 M/L) because of the decreasing in the free-volume size resulting in decrease in water uptake and IEC of the membrane. The variation of membrane’s degree of sulfonation with the concentration can be attributed to side reactions, notably the formation of sulfonyl chlorides and crosslinking by sulfone formation [42]. The treatment in NaOH and HCl solutions after sulfonation has ensured the hydrolysis of the sulfonyl chlorides. Hence, it is the crosslinking by formation of noncharged sulfone that reduces the IEC, water uptake, and proton conductivity. So, the higher concentration of sulfonation will induce more serious side reactions.

Another important parameter used to characterize ionomers is the equivalent weight (EW), where the EW is defined to be the weight of the polymer in acidic form required to neutralize 1 equivalent of NaOH. The EW can be calculated using IEC values using the following equation:

Higher EW means that there are fewer active ionic species (e.g., protons) present. If it takes more of the polymer to neutralize 1 equivalent of hydroxyl ions, there must be fewer active ionic species within the polymer. Because the ionic conductivity is generally proportional to the number of active ionic species in the polymer, one would therefore like to lower the EW to increase conductivity. As noticed from Fig. 11, the smallest value of equivalent weight is given at concentration of 1 M/L of sulfuric acid which represent the maximum number of active sites (maximum number of protons). The EW of PET-g-SGMA was calculated to be 479.61 while the value of Nafion 212 is 1190 indicating high proton conductivity of PET-g-SGMA as compared with Nafion 212.

To enhance the sulfonation results, the number of the SO3 groups Ns (mol) in the PET-g-SGMA was calculated from IEC data using the following equation [43]:

WDry denotes the weight of the dried PET-g-SGMA (g). As noticed from Fig. 12, The maximum number of sulfuric groups occurred at concentration 1 M/L of sulfuric acid concentration which in turn confirmed the results of IEC and water uptake and EW results.

Methanol permeability (methanol crossover)

The methanol permeability measurement is one of the most important key tests of electrolyte membranes for DMFC application to determine methanol crossover through the membrane. To obtain the highest fuel cell performance, PEMS should have low methanol permeability because the methanol crossover from the anode to the cathode causes a lower cell voltage and decreases fuel cell efficiency [44]. Before methanol permeability measurement, all the membrane samples were soaked in water for hydration. The resulting methanol permeability of PET-g-SGMA is shown in Fig. 13 as function of sulfuric acid concentration. As seen from Fig. 13, the methanol permeability at concentration 1 M/L of sulfuric was calculated to be 2.1 × 10−6 cm2/s while for Nafion 212 membrane is found to be 15.5 × 10−6 cm2/s [45] at room temperature. It is noticeable that the methanol permeability of sulfonated PET-g-GMA is lower than Nafion 212 and hence the membrane under investigation could be a good candidate to be used in a fuel cell.

Proton conductivity

Proton conductivity is one of the most important properties of the polymer electrolyte membrane (PEM) for fuel cell application that strongly affects the cell efficiency. The higher the proton conductivity the more efficient the cell is. Study of proton conductivity of the membrane is important for understanding the membrane transport properties. The proton conductivity measurements of the membrane were measured at a 100% RH as a function of concentration of sulfuric acid (mol/L) content by using Ac impedance spectroscopy in a high frequency range and the results are shown in Fig. 14. As noticed from Fig. 14, the conductivities initially increased with the amount of sulfuric acid (M/L), up to the maximum value of 60.35 mS cm−1. After that, the proton conductivity of the sulfonated PET-g-SGMA membranes decreased again as the amount of concentration of sulfuric acid (M/L) increased above 1 (M/L) of sulfuric acid in 1,2-dichloroethane. In addition, the conductivity of Nafion 212 as standard material was measured with the same instrument for comparison, and it was found to be 49 mS cm−1. The initial increase in proton conductivity of the membrane can be assigned to the greater content of sulfuric acid groups in the modified PET molecules, which is responsible for conducting protons. However, the proton conductivity of a membrane is not only dependent on the D.O.S of the polymer; it also changes with water uptake of the membrane. For example, it was reported [42] that the proton conductivity of the Nafion membrane decreased remarkably when the membrane was operated at a temperature above the boiling point of water because water molecules serve as “vehicles” for the transportation of the protons from anode to cathode [42]. In the present study as reported, the water uptake of the sulfonated membranes increases as the concentration of sulfuric acid (M/L) increases up to 1 (M/L) after that it starts to decrease. The same behavior for proton conductivity was observed. Therefore, there should be an optimum value of the amount of sulfuric acid (M/L) used, in which the effect of the D.O.S and the effect of water uptake on proton conductivities of the sulfonated PET membranes are compromised. In this study, the optimum value of the amount of the sulfuric acid (M/L) is found to be 1 (mol/L) in 1,2-dichloroethane. Beyond this value, the water uptake became the predominating factor affecting the proton conductivities of the membrane in a negative manner.

Proton-conductive membranes for the direct methanol fuel cells must have both excellent proton conductivity and low methanol permeation. However, sometimes, it is difficult to satisfy both. To compare the comprehensive character of the membranes, the ratio of proton conductivity and methanol permeability, defined as the selectivity, was calculated. Taking the proton conductivity at concentration 1 M/L of sulfuric acid to be 60.35 mS cm−1 and the average methanol permeability to be 2.1 × 10−6 cm2/s, the selectivity of sulfonated PET-g-GMA was calculated to be 28.73 × 103 S s cm−3, which is almost 3 times more than that of Nafion-212 membrane.

Free-volume holes as function of sulfonic group SO3 content

Free volume is an extremely important intrinsic defect in polymers. Structurally, free volume is due to the randomly distributed holes in the polymer molecular chain segments. In the proton exchange membrane fuel cells, free volume is also the space needed for the directional conduction of protons. The PALS spectra were resolved into three components (τ1, τ2, τ3) with their corresponding intensities (I1, I2, I3) using the LT.09 program [37]. The first components τ1 with intensity I1 is assigned to the p-Ps and free annihilation of positrons in the bulk samples. The intermediate component τ2 with intensity I2 is attributed to the annihilation of positrons that do not form Ps. The third component τ3 with intensity I3 is ascribed as the pick off annihilation of o-Ps atom in the free-volume hole inside the polymer sample. Figure 15 represents the o-Ps lifetime, τ3, and the free-volume hole size, Vh, calculated from Eqs. 1 and 2 of PET-g-SGMA measured at room temperature as function of sulfuric acid concentration. As noticed from Fig. 15, the increase in the sulfuric acid groups up to 1 M/L of sulfuric acid result in enlarged interspaces or free volumes between the polymer backbones which will lead to increase of free volume. After concentration 1 M/L, the free volume begins to decrease as the side reaction is predominating possibly due to crosslinking which induced reduction in the free-volume hole size. As the free volume was reduced, the proton conductivity and methanol permeability was found to decrease. On the other hand, the o-Ps intensity (Fig. 16) which represents the probability of positronium formation was found to increase until 1 M/L concentration of sulfuric acid. After that, it began to decrease. O-Ps intensity is very sensitive to chemical environment and its value represents the yield of positronium formation in the annihilation site and does not reflect the amount of free volume. As it is known, the SO3 groups can work as inhibitor of positronium formation [33]. Therefore, based on the Spur model, SO3 could reduce the positronium formation by its ability of capturing spur electrons thereby I3 could be taken as an indication of the number of SO3 groups inside the sample.

Conclusions

Proton exchange membranes (PEMs) for fuel cells have been successfully prepared by simultaneous UV radiation-induced graft copolymerization of GMA monomer onto PET films and subsequent selective sulfonation by sulfuric acid of the grafted chains in the film state. A maximum grafting value of 23.5% was found for 15 vol% GMA and 4-h radiation time. Optimum concentration of sulfuric acid was found to be 1 mol/L based on tensile strength and degree of sulfonation. The maximum degree of sulfonation was found to be 46.99% at room temperature. The electrolyte properties of the sulfonated membranes were investigated and maximum IEC, water uptake (at 30 °C) and proton conductivity (at 30 °C and 100% RH) were found to be 2.08 meq g−1, 59.09%, and 60.35 mS cm−1, respectively. The prepared membranes were found to have high thermal durability and high mechanical stability. The free-volume results show a higher value at the selected degree of sulfonation. The free volume appears to correlate with the proton conductivity and methanol permeability in a positive manner. The present results suggest that the prepared PEMs are a significant improvement in nonfluorinated membranes as an alternative membrane for Nafion in fuel cells.

References

Dincer I (1998) Energy and environmental impacts: present and future perspectives. Energy Sources 20(4-5):427–453

Hansen J, Ruedy R, Sato M, Lo K (2010) Global surface temperature change. Rev Geophys 48(4):RG4004. https://doi.org/10.1029/2010RG000345

Panwar NL, Kaushik SC, Kothari S (2011) Role of renewable energy sources in environmental protection: a review. Renew Sust Energ Rev 15(3):1513–1524

Nasef MM, Hegazy E-SA (2004) Preparation and applications of ion exchange membranes by radiation-induced graft copolymerization of polar monomers onto non-polar films. Prog Polym Sci 29(6):499–561

Gubler L, Prost N, Gürsel SA, Scherer GG (2005) Proton exchange membranes prepared by radiation grafting of styrene/divinylbenzene onto poly(ethylene-Alt-tetrafluoroethylene) for low temperature fuel cells. Solid State Ionics 176(39-40):2849–2860

Dworjanyn PA, Garnett JL (1988) Synergistic effects of urea with polyfunctional acrylates for enhancing the photografting of styrene to polypropylene. J Polym Sci Part C: Polym Lett 26:135–138

Hollahan JR (1979) Deposition of plasma silicon oxide thin films in a production planar reactor. J Electrochem Soc 126(6):930–934

Deacon C, Wilkie CA (1996) Graft copolymerization of acrylic acid on to acrylonitrile-butadiene-styrene terpolymer and thermal analysis of the copolymers. Eur Polym J 32(4):451–455

Hasegawa S, Suzuki Y, Maekawa Y (2008) Preparation of poly(ether ether ketone)-based polymer electrolytes for fuel cell membranes using grafting technique. Radiat Phys Chem 77(5):617–621

Asano M, Chen J, Maekawa Y, Sakamura T, Kubota H, Yoshida M (2007) Novel Uv-induced photografting process for preparing poly(tetrafluoroethylene)-based proton-conducting membranes. J Polym Sci Part A: Polym Chem 45(13):2624–2637

Ismail AF, Zubir N, Nasef MM, Dahlan KM, Hassan AR (2005) Physico-chemical study of sulfonated polystyrene pore-filled electrolyte membranes by electrons induced grafting. J Membr Sci 254(1-2):189–196

Li J, Sato K, Ichizuri S, Asano S, Ikeda S, Iida M, Oshima A, Tabata Y, Washio M (2005) Pre-irradiation induced grafting of styrene into crosslinked and non-crosslinked polytetrafluoroethylene films for polymer electrolyte fuel cell applications. Ii: characterization of the styrene grafted films. Eur Polym J 41(3):547–555

Nasef MM, Saidi H, Nor HM, Foo OM (2000) Radiation-induced grafting of styrene onto poly (etrafluoroethylene) films. Part Ii. Properties of the grafted and sulfonated membranes. Polym Int 49(12):1572–1579

Gil M, Ji X, Li X, Na H, Eric Hampsey J, Lu Y (2004) Direct synthesis of sulfonated aromatic poly(ether ether ketone) proton exchange membranes for fuel cell applications. J Membr Sci 234(1-2):75–81

Li X, Liu C, Lu H, Zhao C, Wang Z, Xing W, Na H (2005) Preparation and characterization of sulfonated poly(ether ether ketone ketone) proton exchange membranes for fuel cell application. J Membr Sci 255(1-2):149–155

Yamaguchi T, Miyata F, Nakao S-i (2003) Pore-filling type polymer electrolyte membranes for a direct methanol fuel cell. J Membr Sci 214(2):283–292

Yamauchi A, Ito T, Yamaguchi T (2007) Low methanol crossover and high performance of Dmfcs achieved with a pore-filling polymer electrolyte membrane. J Power Sources 174(1):170–175

Jung DH, Cho SY, Peck DH, Shin DR, Kim JS (2002) Performance evaluation of a Nafion/silicon oxide hybrid membrane for direct methanol fuel cell. J Power Sources 106(1-2):173–177

Panero S, Ciuffa F, D'Epifano A, Scrosati B (2003) New concepts for the development of lithium and proton conducting membranes. Electrochim Acta 48(14-16):2009–2014

Hobson LJ, Nakano Y, Ozu H, Hayase S (2002) Targeting improved Dmfc performance. J Power Sources 104(1):79–84

Hobson LJ, Ozu H, Yamaguchi M, Hayase S (2001) Modified Nafion 117 as an improved polymer electrolyte membrane for direct methanol fuel cells. J Electrochem Soc 148(10):A1185–A1190

Walker M, Baumgärtner KM, Feichtinger J, Kaiser M, Räuchle E, Kerres J (1999) Barrier properties of plasma-polymerized thin films. Surf Coat Technol 116-119:996–1000

Holmberg S, Lehtinen T, Näsman J, Ostrovskii D, Paronen M, Serimaa R, Sundholm F, Sundholm G, Torell L, Torkkeli M (1996) Structure and properties of sulfonated poly [(vinylidene fluoride)–G-styrene] norous membranes porous membranes. J Mater Chem 6(8):1309–1317

Flint SD, Slade RCT (1997) Investigation of radiation-grafted Pvdf-G-polystyrene-sulfonic-acid ion exchange membranes for use in hydrogen oxygen fuel cells. Solid State Ionics 97(1-4):299–307

Elomaa M, Hietala S, Paronen M, Walsby N, Jokela K, Serimaa R, Torkkeli M, Lehtinen T, Sundholm G, Sundholm F (2000) The state of water and the nature of ion clusters in crosslinked proton conducting membranes of styrene grafted and sulfonated poly(vinylidene fluoride). J Mater Chem 10(12):2678–2684

Park KR, Kang PH, Nho YC (2005) Preparation of Pfa-G-polystyrene sulfonic acid membranes by the Γ-radiation grafting of styrene onto Pfa films. React Funct Polym 65(1-2):47–56

Brack H-P, Bührer HG, Bonorand L, Scherer GG (2000) Grafting of pre-irradiated poly(ethylene-alt-tetrafluoroethylene) films with styrene: influence of base polymer film properties and processing parameters. J Mater Chem 10(8):1795–1803

Scott K, Taama WM, Argyropoulos P (2000) Performance of the direct methanol fuel cell with radiation-grafted polymer membranes. J Membr Sci 171(1):119–130

Li X, Drache M, Gohs U, Beuermann S (2015) Novel concept of polymer electrolyte membranes for high-temperature fuel cells based on Etfe grafted with neutral acrylic monomers. J Membr Sci 495:20–28

Schmidt C, Schmidt-Naake G (2008) Phosphorsäuredotierte Protonenleiter Auf Basis Von Aminierten Membranen Aus Etfe-Graft-Poly-(Glycidylmethacrylat)-Derivaten. Chem Ing Tech 80(3):317–325

Nasef MM (2000) Gamma radiation-induced graft copolymerization of styrene onto poly(ethyleneterephthalate) films. J Appl Polym Sci 77(5):1003–1012

Gupta B, Grover N, Singh H (2009) Radiation grafting of acrylic acid onto poly(ethylene terephthalate) fabric. J Appl Polym Sci 112(3):1199–1208

Gomaa MM, Hugenschmidt C, Dickmann M, Abdel-Hady EE, Mohamed HFM, Abdel-Hamed MO (2018) Crosslinked Pva/Ssa proton exchange membranes: correlation between physiochemical properties and free volume determined by positron annihilation spectroscopy. PCCP 20(44):28287–28299

Tao SJ (1972) Positronium annihilation in molecular substances. J Chem Phys 56(11):5499–5510

Eldrup M, Lightbody D, Sherwood JN (1981) The temperature dependence of positron lifetimes in solid pivalic acid. Chem Phys 63(1-2):51–58

Nakanishi H, Jean YC, Smith EG, Sandreczki TC (1989) Positronium formation at free-volume sites in the amorphous regions of semicrystalline peek. J Polym Sci B Polym Phys 27(7):1419–1424

Kansy J (1996) Microcomputer program for analysis of positron annihilation lifetime spectra. Nucl Instrum Methods Phys Res Sect A 374(2):235–244

Kang K, Kang PH, Nho YC (2006) Preparation and characterization of a proton-exchange membrane by the radiation grafting of styrene onto polytetrafluoroethylene films. J Appl Polym Sci 99(4):1415–1428

Ahmed M, Khan MB, Khan MA, Alam SS, Halim MA, Khan MAH (2011) Characterization of polyethyleneterephthalate (Pet) based proton exchange membranes prepared by Uv-radiation-induced graft copolymerization of styrene. J Power Sources 196(2):614–619

Takahashi S, Okonogi H, Hagiwara T, Maekawa Y (2008) Preparation of polymer electrolyte membranes consisting of alkyl sulfonic acid for a fuel cell using radiation grafting and subsequent substitution/elimination reactions. J Membr Sci 324(1-2):173–180

Abdel-Hady E, Abdel-Hamed M, Gomaa M (2013) Preparation and characterization of commercial polyethyleneterephthalate membrane for fuel cell applications. J Membra Sci Technol 3:1–8

Abdel-Hady EE, Abdel-Hamed MO, Awad S, Hmamm MFM (2018) Characterization and evaluation of commercial poly (vinylidene fluoride)-G-sulfonatedpolystyrene as proton exchange membrane. Polym Adv Technol 29(1):130–142

Sawada S-i, Maekawa Y (2011) Proton conduction characteristics in radiation-grafted polymer electrolyte membranes based on perfluorinated and aromatic hydrocarbon polymers. ECS Trans 41:2125–2133

Lee C-H, Wang Y-Z (2008) Synthesis and characterization of epoxy-based semi-interpenetrating polymer networks sulfonated polyimides proton-exchange membranes for direct methanol fuel cell applications. J Polym Sci Part A: Polym Chem 46(6):2262–2276

Almeida TP, Miyazaki CM, Paganin VA, Ferreira M, Saeki MJ, Perez J, Riul A (2014) Pedot:Pss self-assembled films to methanol crossover reduction in Nafion® membranes. Appl Surf Sci 323:7–12

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 60 kb)

Rights and permissions

About this article

Cite this article

ElHakim, A.A.A., Awad, S., Radwan, M.F. et al. Preparation and characterization of proton exchange membrane by UV photografting technique. J Solid State Electrochem 23, 2813–2824 (2019). https://doi.org/10.1007/s10008-019-04388-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-019-04388-1