Abstract

Molten salt is an indispensable electrolyte for electrochemically extracting reactive metals that cannot be obtained by a carbothermic reduction or a low-cost metallothermic reduction route. The choice of the molten salt is highly related to its thermodynamic properties, electrode materials, and the interactions of oxides/sulfides with the molten salts. Herein, thermodynamic properties of molten chlorides fitted with a solid oxide/sulfide cathode are systematically studied in terms of the electrochemical window, the exchange reactions between the oxides/sulfides and the electrolytes, and the role of cations/anions governing the deposition potential of various species in a unary molten salt or a molten-salt mixture. Thermodynamically, the choice of a molten salt for electrolysis should combine the electrochemical window of a molten salt and the in situ formed most stable oxides/sulfides possessing cations from the molten salt itself. This paper sets a guideline for screening molten salts for electrochemical reduction of solid oxides/sulfides and sheds light on the design of an appropriate salt melt for material synthesis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Molten salt is an excellent oxygen-free liquid medium used for coolants in nuclear reactors [1], solar heat harvester [2], and enabling chemical/electrochemical reactions owing to its high heat capacity, wide electrochemical window, low vapor pressure, and good ionic conductivity, etc. [3]. In the electro-metallurgical field, the molten salt is a common electrolyte for extracting reactive metals that cannot be prepared by carbothermic or low-cost metallothermic reduction routes. The electrochemical extraction of metals in molten salts highly depends on the physicochemical properties of the molten salts, feedstock (e.g., oxides, sulfides), and the interactions of the feedstock with the molten salts. For example, the Hall-Héroult process uses cryolite as an electrolyte to dissolve Al2O3 which is then electrochemically split to liquid Al at the cathode while the O2− is discharged at the carbon anode generating CO2 [4]. However, a similar manner cannot be applied to extract refractory metals like Ti, Zr, and Ta, which is due to the low solubilities of their oxides in a suitable molten-salt electrolyte even though the molten salt possesses a wider electrochemical window than that of oxides.

Direct electrochemical reduction solid oxides/sulfides, also known as the FFC Cambridge process [5], opens a way to extract most reactive refractory metals (Ti [6], Zr [7], Ta [8], Nb [9, 10]), and Tb [11], Si [12, 13], Ge [14], etc. [15, 16]). Calcium chloride (CaCl2) and CaCl2-based molten salts (e.g., CaCl2-NaCl [14, 17, 18], CaCl2-KCl [19], CaCl2-LiCl [20], CaCl2-MgCl2-NaCl [21]) are the most commonly used electrolytes for the electrochemical reduction of solid oxides to prepare metals and alloys because the molten CaCl2 has a wide electrochemical window and a high solubility for CaO [22]. In addition to considering the solubility of oxide ion in molten salts, the first criterion of selecting a molten salt is that the molten salt should be thermodynamically more stable than the oxides to be reduced. For example, the Ellingham diagrams of oxides, halides, and sulfides are commonly used for comparing the stability of different species in order to select appropriate reductants or electrolytes for chemical/electrochemical reductions [23]. Unlike the metallothermic and carbothermic reductions, electrochemical reduction employs electrons as reductants and the reaction interfaces are surrounded by the electrolytes which not only provide an oxygen-free medium but also take part in the reaction. Since the electrochemical reduction of solid oxide is a heterogeneous reaction, the oxide ions should be transferred from solid oxide precursors into liquid electrolyte. The oxide ions from the solid oxide precursors could be in the form of either solid or liquid forms depending on the solubility of the oxides in the molten salts. For example, the reduction of solid TiO2 in molten CaCl2 will give soluble CaO into CaCl2 while the insoluble solid MgO will be produced in molten NaCl-KCl-MgCl2 [24,25,26]. If the melt consists of cations of Mg, Na and Ca, and anions of Cl, it is clear that Mg2+ is the first to be reduced because NaCl and CaCl2 are more stable than MgCl2. But when the molten salt contains both O2− and Cl−, MgCl2, NaCl, CaCl2, MgO, Na2O, and CaO could exist in the melt. As a result, the melt could contain complex anions, i.e., oxychlorides, which may possess different solubilities from the oxides. In addition, the exchange of oxide ions between the oxide precursors and molten salts happens at the current collector/oxide/molten-salt three-phase interlines where oxide receives electrons from the current collector and simultaneously releases oxide ions into the electrolyte [27, 28], and the released oxide ions will be attracted by the cations of the molten salt forming another oxide species. Note that the in situ formed oxides possessing cations from molten salts should be thermodynamically more stable than that of the solid oxide at the cathode. Otherwise, the less thermodynamically stable oxides will be reduced rather than the oxide feedstock. That is the reason why TiO2 cannot be fully reduced to Ti in molten NaCl and KCl, albeit the electrochemical windows of molten NaCl and KCl are much higher than the decomposition potential of TiO2. In those cases, the in situ formed Na2O and K2O are less stable than TiO2. Thus, the reduction of solid oxides in molten halide salts is controlled by both electrochemical windows of molten salt itself and the oxides with cations from molten salt itself. Moreover, it is found that TiO2 could be reduced to Ti in molten CaCl2-NaCl eutectic, meaning that the interaction between CaCl2 and NaCl plays a decisive role in controlling the thermodynamic properties of the electrolyte. Therefore, it is worthwhile to study the general rule of designing molten salts for the electrochemical reduction of solid oxides/sulfides in molten salts.

In addition to the solid oxides, the same principle is applicable for electrochemical reduction of solid/liquid sulfides in the molten salts [29, 30]. In this paper, the thermodynamic considerations of screening molten salts for electrochemical reduction of solid oxides/sulfides were systematically analyzed, and the role of inclusion of various cations and anions in the molten salt was investigated as well.

Thermodynamic calculation and experimental method

Thermodynamic data were obtained by HSC Chemistry 5, and activities of all species involved in the calculation are at the unit activity (a = 1) or stand pressure (p = patm). For example, the electrochemical windows of CaCl2 and CaO were obtained by Eq. (1)

where ∆G is the Gibbs free energy change of the dissociation reaction (e.g., CaCl2 ⇄ Ca + Cl2(g), 2CaO ⇄ 2Ca + O2(g), n is the number of moles of exchange electrons, and F is the Faraday constant). The potential difference of CaO/O2 and CaCl2/Cl2 was calculated by subtracting ECaO from ECaCl2 (assuming the deposition potential of CaO/Ca and CaCl2/Ca is the same). The similar comparison was conducted with the same method. In this paper, molten chloride was taken as an example; other molten halide systems could be analyzed with the same approach as the chlorides. Deposition potentials of various metals are referred to that of chlorine evolution.

Cyclic voltammetry was conducted in 500 g molten CaCl2 and CaCl2-1 wt% CaO which contained in an Al2O3 crucible (ID 85 mm, height 100 mm), respectively. The salt was vacuumed dried at 250 °C for 12 h in a stainless steel (SS) reactor heated by a vertical tube furnace. Then Ar gas flowed into the reactor while ramping the temperature to 850 °C. A three-electrode system consists of a molybdenum wire (ID 1 mm) working electrode, a graphite rod (ID 15 mm) counter electrode, and a Ag/AgCl reference electrode assembled in a one-end-closed mullite tube containing NaCl-KCl eutectic with 10 wt% AgCl. The Ar flow was maintained in the whole process of electrochemical measurements.

Results and discussion

The electrochemical window of pure molten chlorides

In a molten chloride system without any other anions, the deposition potentials of some selective cations are shown in Fig. 1. These deposition potentials equal to the electrochemical window of the unary molten salts whose cathodic limit reactions are the deposition of metal and the anodic limit reaction is generating chlorine at an inert anode. This diagram could be used for predicting the sequences of deposition potential of various metals in a chloride melt. It is found that Na is much more reactive than Al, Si, and Ti because the thermodynamic deposition potential is more negative. Thus, the Al, Si, and Ti could be deposited without co-deposition of Na under controlled potential range. It should point out that the materials of the electrode significantly affect the practical electrochemical window. For example, most alkaline and alkaline earth ions can be alloyed with metalloids and noble metals at a potential of 0.2 to1.0 V more positive than that of the deposition of pure alkaline and alkaline earth metals [31]. For the anode, most metals could be oxidized to metal ions at a potential of more than 1.0 V negative than that of chlorine gas evolution [32]. Therefore, the exact electrochemical window should combine the theoretical data and the use of electrode materials.

The passage of oxide ions during the reduction of oxides in molten salts

Unlike the electrochemical reduction of metal ions in the chloride melts free of other anions, the oxide ions will take part in the electrochemical reduction of solid oxides/sulfides in molten chlorides. Taking oxide as an example, four typical reactions could happen for the oxides in molten salts. The first kind of reaction is the compounding reaction taking place between the oxides or partially reduced oxides and chlorides (Eq. (2)), generating oxychlorides that are either soluble or insoluble in the molten salts [6, 33, 34]. Note that most solid metal oxides are quite stable in molten chlorides free of other anions [35, 36]. However, the compounding reaction is common between the electro-generated oxide ions with the oxide feedstock, which has been observed for many oxides [37,38,39].

The other three kinds of electrochemical reactions are shown in Fig. 2 (Eqs. (2)–(5)). Previously, the cathodic reduction reaction of oxide was usually expressed in the form of dissociation of oxides to metal and oxygen ions (e.g., MOx + 2xe− ⇄ M + xO2−), giving an impression that the molten salt is inert and does not take part in the reduction process. It is true that the molten salt is only shuttling O2− between cathode and anode and is not consumed in the whole electrochemical reactions. If the molten salt was not involved in the electrochemical reduction, TiO2 and SiO2 can be reduced to Ti and Si in molten NaCl since the electrochemical window of NaCl is much higher than the decomposition potential of TiO2 and SiO2. This question is very common for the new comer of the molten-salt electrochemistry field. To answer this question, the passage of O2− during electrochemical reduction should be reconsidered. Since all reactions take place inside the molten salt full of mobile anions and cations, the electro-generated O2− would combine with the cations coming from molten salt itself to keep the charge neutral at the reaction interface. To enable the reaction to happen continuously, the electro-generated oxide should be thermodynamically more stable than the oxide to be reduced. For example, the electro-generated Na2O is less stable than TiO2 and SiO2; thus, TiO2 and SiO2 cannot be fully reduced to Ti and Si in molten NaCl. This is different from the reduction of TiCl4 and SiCl4 in NaCl because the NaCl is thermodynamically stable than TiCl4 and SiCl4.

Therefore, the selection of molten-salt electrolytes should not only consider the electrochemical window of the molten salt itself, but also the dissociation potential of the oxide/sulfides with the same cations of the electrolyte. As shown in Fig. 3a, the decomposition potentials of most metal oxides/metals are more negative than that of Na2O/Na (assuming the inclusion of Na2O does not affect the sodium decomposition potential but does shift the oxygen potential more negatively). The difference between Figs. 1 and 3 is the inclusion of oxide anions. In CaCl2 melt, the deposition potentials of most oxides lie on the top of CaO/Ca (Fig. 3b), meaning that these metals can be extracted from their oxides in molten CaCl2. Note that all the potentials presented in Fig. 3 are obtained by the comparison of the Gibbs free energy change.

To test the effect of adding CaO in CaCl2 on the deposition potential of Ca, the cyclic voltammograms recorded in both CaCl2 and CaCl2-1 wt% CaO are shown in Fig. 4. The deposition potentials of Ca are the same in both molten CaCl2 and CaCl2-1 wt% CaO, indicating that inclusion of oxygen ions does not change the deposition potential of Ca, and the difference of dissociation potential of CaCl2 and CaO is ascribed to the different potential of anodic reactions. Similarly, the dissociation potential of Na2O is much smaller than that of NaCl, which is due to a relatively negative oxygen evolution potential from Na2O to O2.

In multi-cation chloride melts

The electrochemical reduction of solid oxides in molten CaCl2 and NaCl is quite different, i.e., the TiO2 can be reduced to Ti in molten CaCl2 but cannot be reduced to Ti in molten NaCl. However, the TiO2 can be reduced to Ti in molten NaCl-CaCl2 mixture [40]. To understand this phenomenon, thermodynamic data of the reaction between chlorides and oxides could be used to predict the capability of a molten-salt mixture for electrochemically extracting specific metals from their oxide precursors. Taking the CaCl2-NaCl eutectic as an example, the oxide ions in the molten CaCl2-NaCl prefer to exist in the form of CaO; i.e., Na2O can spontaneously react with CaCl2 to generate CaO and NaCl. Thus, Na2O is not a thermodynamically stable oxide species in molten CaCl2-NaCl. In other words, Ca2+ is an active cation regulating the reduction of solid oxides in the CaCl2-NaCl eutectic. To establish a general guideline for assessing the active cations in a molten-salt mixture, for example, CaCl2 is taken as a standard reference, and the reaction of MxOy with CaCl2 could be written as

The Gibbs free energy of reaction (6) is

A negative ∆G means that the reaction (6) is spontaneous and vice versa. The spontaneous reactions indicate that the MxOy will be converted to CaO, meaning that the CaO is more stable than MxOy. As shown in Fig. 5, the oxides corresponding to the top line is more stable in the chloride than those located on the lower lines and vice versa. For example, CaO is stable in molten LiCl but Li2O will be spontaneously converted to CaO in molten CaCl2. Thus, Figs. 3 and 5 can be used to determine if a molten-salt mixture could be used for electrochemical reduction of a specific oxide, as well as predicting the most stable oxide existed in the molten-salt mixtures. Likewise, this principle is suitable for the reciprocal molten salts containing multiple cations such as Li+, Na+, K+, Ca2+, Mg2+, and Al3+. The deposition potentials of these cations follow their basic thermodynamic data, and the most stable oxide can be predicted by Eq. (7). Note that the formation of oxychlorides or oxyfluorides could change solubilities of the oxides as well as the electrochemical behaviors of the cations.

In multi-anion chloride melts

Apart from a chloride melt with multiple cations, a melt of a specific cation and multiple anions was also analyzed in terms of the electrochemical window and deposition potentials of various reactions. In a molten NaCl containing O2−, OH−, and CO32−, the sequence of deposition potential from positive to negative is Fe2O3/Fe, Na2O/Na, OH−/H2, SiO2/Si, CO32−/C, and TiO2/Ti (Fig. 6a). Only Fe2O3 can be reduced to Fe while TiO2 and SiO2 cannot be reduced to Ti and Si. For the molten CaCl2 containing O2−, OH−, and CO32−, the sequence of deposition potential from positive to negative is Fe2O3/Fe, CO32−/C, OH−/H2, SiO2/Si, TiO2/Ti, and CaO/Ca (Fig. 6b). Unlike in the CaCl2-based melt, all reduction potentials are more positive than that of CaO/Ca. Moreover, the reduction of CO32− to C is much more positive than that of SiO2/Si and TiO2/Ti, meaning that CaCl2-based melts do not allow a high concentration of CO32− which could result in generating carbon at the cathode contaminating the electrolytic Ti and Si as well as decreasing the current efficiency. The Li-, Mg-, Ba-, and Sr-based melts have similar properties of CaCl2, and K-, Rb-, and Cs-based melts have similar properties of the Na-based melts. Although CO32− could be easily reduced in Ca-, Li-, Ba-, and Mg-based melts, these melts could be used for electrochemical reduction of CO2 to C [18].

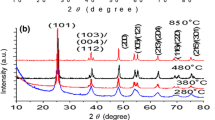

Electrolytes for the electrolysis of solid sulfides

The thermodynamic properties of molten chloride-sulfide systems were analyzed by the same method that applied for the chloride-oxide systems. For the NaCl-sulfide system (Fig. 7), different from the NaCl-oxide system, all typical sulfides could be deposited prior to the deposition of Na2S/Na. For the CaCl2-sulfide system, the electrochemical window is higher than that of NaCl-sulfide system, and all typical sulfides could be reduced to their corresponding metals prior to the deposition of Ca. It is noted that the decomposition potentials of sulfides are much lower than that of oxides which could be achieved in all molten alkaline or alkaline earth chlorides supposing all these melts are capable of conducting S2− between anode and cathode. The electrochemical reduction of solid sulfides could be interpreted by Fig. 2 if the MOx was replaced by MSx.

Figure 8 depicts the sequence of the stability of sulfides in molten chlorides, and the sulfides of the top line are more stable than those of the lower lines. This diagram could be used to predict the most stable sulfide in the molten chloride-sulfide mixtures. To be able to conduct S2−, the stable sulfide should have a high enough solubility in molten chlorides. For example, the Na2S has a high solubility in NaCl, KCl, and NaCl-KCl [29, 30, 41, 42], while the Li2S has a low solubility in molten LiCl that has poor S2− conductivity [43].

Conclusions

The thermodynamic properties of molten chlorides were systematically analyzed with the aim of selecting an appropriate electrolyte for electrochemical reduction of solid oxides/sulfides. A thermodynamically favorable molten-salt electrolyte should have a wider electrochemical window of both molten salt itself and an oxide/sulfide possessing cation of the molten salt than that of the oxides/sulfides to be reduced. For example, a metal oxide could be fully reduced metal in molten NaCl if the dissociation potential of the metal oxide is smaller than that of both NaCl and Na2O. For a molten-salt mixture, the most stable oxides/sulfides could be predicted by a thermodynamic assessment, which is key to governing the possibility of fully reducing an oxide to metal. Unlike chloride-oxide system, most typical sulfides can be thermodynamically reduced to metals/alloys in molten alkaline and alkaline earth melts. In addition to the thermodynamic viewpoint, the molten-salt electrolyte of the high conductivity of O2−/S2− is requisite for rapidly removing the released O2−/S2− from the cathode into molten salts and thereby maintaining a continuous reduction process. In CaCl2-based melts, to minimize or avoid carbonate ions could reduce the carbon contamination at the cathode as well as improve the current efficiency of the electrolysis cell. Moreover, the thermodynamic analysis for the chloride melt could be also applied to other halide systems, and it could be a powerful tool for designing molten salts for both electrometallurgy and material synthesis.

References

Sawan ME, Youssef MZ (2006) Fusion Eng Des 81(1-7):505–511

Weinstein LA, Loomis J, Bhatia B, Bierman DM, Wang EN, Chen G (2015) Chem Rev 115(23):12797–12838

Lantelme F, Groult H (2013) Molten salts chemistry-from lab to applications. Elsevier, USA

Galasiu I, Galasiu R, Thonstad J (2007) Inert anode for aluminum electrolysis. Aluminum-Verlag Marketing and koummunikation GmbH, Düsseldorf

Chen GZ, Fray DJ, Farthing TW (2000) Nature 407(6802):361–364

Jiang K, Hu XH, Ma M, Wang DH, Qiu GH, Jin XB, Chen GZ (2006) Angew Chem Int Edit 45(3):428–432

Peng JJ, Jiang K, Xiao W, Wang DH, Jin XB, Chen GZ (2008) Chem Mater 20(23):7274–7280

Wu T, Jin XB, Xiao W, Hu XH, Wang DH, Chen GZ (2007) Chem Mater 19(2):153–160

Wu T, Xiao W, Jin X, Liu C, Wang D, Chen GZ (2008) PCCP 10(13):1809–1818

Yan XY, Fray DJ (2005) Adv Funct Mater 15(11):1757–1761

Wang DH, Qiu GH, Jin XB, Hu XH, Chen GZ (2006) Angew Chem Int Edit 45(15):2384–2388

Jin XB, Gao P, Wang DH, Hu XH, Chen GZ (2004) Angew Chem Int Edit 43(6):733–736

Nohira T, Yasuda K, Ito Y (2003) Nat Mater 2(6):397–401

Yin H, Xiao W, Mao X, Wei W, Zhu H, Wang D (2013) Electrochim Acta 102:369–374

Abdelkader AM, Kilby KT, Cox A, Fray DJ (2013) Chem Rev 113(5):2863–2886

Xiao W, Wang D (2014) Chem Soc Rev 43(10):3215–3228

Yan XY, Fray DJ (2005) J Electrochem Soc 152(1):D12–D21

Hu L, Song Y, Ge J, Zhu J, Han Z, Jiao S (2017) J Mater Chem A 5(13):6219–6225

Weng W, Wang M, Gong X, Wang Z, Wang D, Guo Z (2016) Electrochim Acta 212:162–170

Ge J, Han Z, Zhu J, Jiao S (2017) J Electrochem Soc 164(4):D248–D252

Dong Y, Slade T, Stolt MJ, Li L, Girard SN, Mai L, Jin S (2017) Angew Chem Int Edit 56(46):14453–14457

Wang SL, Zhang FS, Liu X, Zhang LJ (2008) Thermochim Acta 470(1-2):105–107

Vignes A (2011) Extractive metallurgy 1. John Wiley & Sons, Inc., London

Yuan Y, Li W, Chen H, Wang Z, Jin X, Chen GZ (2016) Faraday Discuss 190:85–96

Ito M, Morita K (2004) Mater Trans 45(8):2712–2718

Lebedev VA, Sal’nikov VI, Tarabaev MV, Sizikov IA, Rymkevich DA (2007) Russ J Appl Chem 80(9):1491–1497

Xiao W, Jin X, Deng Y, Wang D, Chen GZ (2007) Chem-Eur J 13(2):604–612

Xiao W, Jin X, Deng Y, Wang D, Hu X, Chen GZ (2006) Chemphyschem 7(8):1750–1758

Wang T, Gao H, Jin X, Chen H, Peng J, Chen GZ (2011) Electrochem Commun 13(12):1492–1495

Yin H, Chung B, Sadoway DR (2016) Nat Commun 7:1–5

Kim H, Boysen DA, Newhouse JM, Spatocco BL, Chung B, Burke PJ, Bradwell DJ, Jiang K, Tomaszowska AA, Wang K, Wei W, Ortiz LA, Barriga SA, Poizeau SM, Sadoway DR (2013) Chem Rev 113(3):2075–2099

Yin H, Chung B, Chen F, Ouchi T, Zhao J, Tanaka N, Sadoway DR (2018) Nat Energy 3(2):127–131

Zhu Y, Wang DH, Ma M, Hu XH, Jin XB, Chen GZ (2007) Chem Commun 24:2515–2517

Peng JJ, Zhu Y, Wang DH, Jin XB, Chen GZ (2009) J Mater Chem 19(18):2803–2809

Yin HY, Gao LL, Zhu H, Mao XH, Gan FX, Wang DH (2011) Electrochim Acta 56(9):3296–3302

Ishitsuka T, Nose K (2002) Corros Sci 44(2):247–263

Lebedev VA, Sal’nikov VI, Sizikov IA, Rymkevich DA (2007) Russ J Appl Chem 80(9):1503–1508

Suzuki RO, Aizawa M, Ono K (1999) J Alloys Compd 288(1–2):173–182

Wang DH, Jin XB, Chen GZ (2008) Annu Rep Prog Chem Sect C 104:189–234

Peng Y, Wang D, Wang Z, Gong X, Wang M, Qi T, Meng F (2018) J Alloys Compd 738:345–353

Matsuzaki T, Natsui S, Kikuchi T, Suzuki RO (2017) Mater Trans 58(3):371–376

Jiang R, Fan J, Hu L, Dou Y, Mao X, Wang D (2017) Electrochim Acta 261:578–587

Masset P, Guidotti RA (2007) J Power Sources 164(1):397–414

Funding

We greatly thank the financial support from NSFC (51704060, 51334004), the National Thousand Youth Talent Program of China, the Fundamental Research Funds for the Central Universities (N172505002), and the 111 Project (B16009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, H., Zhao, H., Qu, J. et al. Thermodynamic considerations of screening halide molten-salt electrolytes for electrochemical reduction of solid oxides/sulfides. J Solid State Electrochem 23, 903–909 (2019). https://doi.org/10.1007/s10008-019-04193-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-019-04193-w