Abstract

A series of poly(selenophene-co-3-methylthiophene) films were synthesized by electrochemical copolymerization of selenophene and 3-methylthiophene under different feed ratios in tetrahydrofuran–boron trifluoride diethyl etherate (THF–BFEE) mixture. Structural interpretation, surface morphology, and electrochemical and electrochromic properties of the resultant copolymer films were determined and comparatively discussed. These copolymer films displayed reversible color changes from sandy-brown in the neutral state to deep blue and black in the oxidized state, clearly different from their parent homopolymers polyselenophene and poly(3-methylthiophene). The copolymers also showed more favorable electrochromic kinetic parameters in comparison with both of their homopolymers, including higher optical contrast, faster switching time, more efficient coloration efficiency, and better optical memory. Under the monomer feed ratio of selenophene/3-methylthiophene in 1:2, the copolymer film exhibited the highest optical contrast of 70% at 1080 nm. Furthermore, excellent redox stability was observed for all the copolymers after secondary electrochemistry doping by cyclic voltammetry in monomer-free BFEE.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrochromism is defined as a reversible change in the color and/or optical properties of a substance induced by the change in electrical conditions [1, 2]. In recent years, because of their high optical contrasts [3], fast switching times [4], and processability [5], together with the ease of fine-tuning their electrochromic performances by structure modification [6], conducting polymers used as active layers in electrochromic devices have received enormous attention.

Since the electrochromic phenomenon of conducting polymers was discovered in 1980s, polythiophene (PT) and its derivatives have played an important role in this field [7, 8]. Polyselenophene (PSe) and its derivatives, as selenium analogues of PT, have also attracted interests because of their newly found exciting optoelectronic properties and relevant promising applications in various fields [9,10,11,12,13,14]. Theoretical prediction and experimental results in the last few years evidenced several advantages of PSe over PT like better interchain charge transfer from intermolecular Se…Se interactions, lower redox potentials, accommodation of more charge upon doping from larger size of selenium atom, and lower band gaps [15]. PSe has also been employed as an effective building block to fine-tune and further enhance the electrochromic performances of conjugated polymers most recently, as summarized in Scheme 1. Our group [16] also synthesized a series of Se-EDOT oligomers previously and obtained the corresponding hybrid polymers with excellent electrochromic performances and outstanding redox stability. Unfortunately, all these improvements in properties need complex synthetic work. As is known, parent PSe polymer suffers from low conductivity, poor stability, and electrochromic performances in terms of electrochromism, mainly resulting from its intrinsic structural instability during the polymerization [16]. Therefore, it is necessary to figure out an easy way to improve the performances and stability of PSe while maintaining its advantages.

As a common method to combine the advantageous properties of different homopolymers, electrochemical copolymerization is one of the simplest and most effective way to obtain conjugated copolymer films. It is feasible for people to realize the electrochemical copolymerization by choosing an appropriate monomer with similar oxidation potential to copolymerize with Se. Poly(3-methylthiophene) (P3MeT), as an important derivative of PT, shows color changes from red to blue in its redox states and has often been used as the primary electrochromic elements in electrochromic devices [17, 18]. Additionally, due to the advantages of P3MeT such as low cost, excellent stability, and high electrical conductivity [19], its monomer 3MeT has always been employed to design novel π-conjugated polymer systems with outstanding electrochromic performances [20, 21]. Most importantly, because of the electron-donating methyl substitution on the thiophene ring, 3MeT has a lowered oxidation potential similar to Se. It is quite expected that the introduction of P3MeT into PSe main chain could probably combine both of the advantages of PSe and P3MeT, and also the copolymers might show some other interesting properties.

In this work, the electrochemical copolymerization between Se and 3MeT was achieved by choosing tetrahydrofuran–boron trifluoride diethyl etherate (THF–BFEE) as the electrolyte [22], and a series of Se-3MeT copolymers with different molecular ratios were obtained in THF–BFEE (1:1, by volume; Scheme 2). Further, the structural properties, surface morphology, electrochemistry, and electrochromic properties of the homopolymers/copolymers were minutely investigated to disclose the effect of different 3MeT feed ratios on the copolymer properties.

Experimental

Materials

Selenophene (Se, 99%; Energy Chemical) and 3-methylthiophene (3MeT, 98%; Energy Chemical) were used as received. BFEE (AR; Beijing Changyang Chemical Plant) was distilled before use. Tetrahydrofuran (THF, AR; Xilong Chemical) was refluxed and distilled over sodium wire. Other chemicals and reagents (AR, > 98%) were purchased commercially and used without any further treatment.

Characterization

Infrared spectra (IR) were recorded using a Bruker Vertex 70 Fourier–transform infrared (FT–IR) spectrometer with samples in KBr pellets. The surface and bulk morphology of polymers deposited on the ITO-coated glasses were carried out employing a VEGA II–LSU scanning electron microscope (Tescan).

Copolymerization

Electrochemical copolymerization and electrochemistry tests were performed with a potentiostat–galvanostat (model 263A, EG&G Princeton Applied Research) under computer control. And the working and counter electrodes were both Pt wire with a diameter of 1.0 mm, respectively. An Ag/AgCl electrode was prepared in 6.0 M HCl (aq) and directly used as the reference electrode during the electrochemical tests. BFEE was refined by a dry nitrogen stream and maintained under a slight overpressure through all the experiments.

Electrochromic experiments

The electrochromic performances studies were recorded on a Model 263 potentiostat–galvanostat (EG&G Princeton Applied Research) and using a SPECORD 200 PLUS UV–Vis spectrophotometer under computer control. During the electrochromic experiments, three-electrode system, including an Ag/AgCl wire, a Pt wire, and an ITO glass as transparent working electrode, was employed.

The optical contrast values (∆T%) between dedoped and doped state at the specific wavelength were used to obtained the optical density (∆OD) (λ max), as illustrated by the following equation [23]:

The ratio between ∆OD and the injected/ejected charge as a function of electrode area (Q d) was defined the coloration efficiency (CE) at the specific dominant wavelength, as illustrated by the following equation [24]:

Result and discussion

Electropolymerization

High-quality homopolymer films can be facilely synthesized by direct electropolymerization in BFEE. In order to decrease the catalytic effect of BFEE on Se (probably leads to the ring-opening reaction and other side reactions), THF was introduced into BFEE to form a binary solvent of 50% (volume fraction, vol) THF and 50% (vol) BFEE. In this system, the onset oxidation potentials (E onset) of Se, as shown in anodic oxidation curves (Fig. 1), was 1.03 V, while that of 3MeT was 0.94 V. The difference in E onset between Se and 3MeT was just 0.09 V, theoretically indicating that the copolymerization could occur easily [25, 26]. By varying the monomer feeding ratios, the E onset values of monomer mixtures were initiated in the range of 0.95~1.05 V. A trend was also observed that the E onset of monomer mixtures gradually shifted to that of 3MeT with increasing the feed ratio of 3MeT. When the feed ratio of Se/3MeT reached 1:5, the E onset of monomer mixtures was reduced to 0.95 V, approximately the same as 3MeT. Namely, we can tune the oxidation potentials of monomer mixtures through controlling monomer feeding ratios.

During the potentiodynamic polymerization, successive cyclic voltammograms (CVs) of monomer mixtures were obtained, as shown in Fig. 2. The cycling behaviors showed characteristic electrosynthesis features of conducting polymers, also in good agreement with 3MeT and Se [26]. From Fig. 2d, e, PSe films were more easily polarized than P3MeT due to easier polarization of Se than S atom. The increase in the reversible redox intensity implied that amount of polymers on the electrode surface was electrodeposited with CV scan proceeding. CV curves of comonomers under different feeding ratios demonstrated difference against Se and 3MeT. The reversible redox couples shifted to lower potentials with the feed ratios of 3MeT increasing, as seen in Fig. 2a–c, which revealed that these copolymers were consisted with different feed ratio comonomers. Compared with Se/3MeT at the feeding ratios of 1:1 and 1:2 (Fig. 2a, b), the 1:5 monomer feeding (Fig. 2c) displayed the broadest redox waves, which could be ascribed to longer chain distribution and higher degree of polarization [27, 28]. Meanwhile, the different broad redox waves in CVs of both homopolymers and copolymers also proved structural changes in the polymer main chain [28,29,30].

We employed the potentiostatic electrosynthesis method to prepare copolymer films for characterization and property investigation. After optimizing the electrical conditions, the polymerization potential for all the homopolymers and copolymers was determined to be 1.20 V vs. Ag/AgCl.

Structural characterization

In order to investigate the homopolymers/copolymers structure and interpret the copolymerization mechanism, infrared spectra of all these homopolymers/copolymers are recorded in Fig. 3. From the spectra, all the polymers exhibited broad absorption bands, mainly due to the wide-chain dispersity of the targeted product (absorption bands overlap one another) and similar to other typical conducting polymers reported previously [30]. As seen in Fig. 3, there are mainly five characteristic peaks for all the polymer films. The peaks at about 705 and 620 cm−1 can be attributed to the stretching vibration of C–Se and C–S bonds, respectively. This confirms that selenophene and 3MeT units were present in the copolymers. A strong peak located at about 1055 cm−1 is originated from the C–H in-plane deformation of selenophene and 3MeT units. The peak at 1298 cm−1 (C–C inter ring stretching vibration) and the 1633 cm−1 peak (C=C stretching vibration) were both observed for all the polymers, revealing that the molecular structures of PSe and P3MeT were not destroyed during the copolymerization.

Morphology

The surface morphology of homopolymers/copolymers is closely related to their photoelectric properties [31]. Figure 4 displays the scanning electron microscopy images (SEM) of dedoped polymer films. Among them, the morphological structure of copolymer (Se/3MeT = 1:2) showed smooth and homogeneous surface. The homopolymer/copolymer films (A, C, E, and F) exhibited compact morphology like a stack of granules. An accumulation state of small globules with interlinked holes among the clusters was observed on the surface of the copolymer (Se/3MeT = 1:2), which may promote the reversible ionic transfer and improve the electrochromic properties [32]. All these homopolymers/copolymers exhibited different morphologies from each other, and this also indicated the different aggregation structures of conducting copolymers.

Spectroelectrochemistry

Spectroelectrochemistry can reveal information about the electronic structure of conducting polymers and examine the spectral changes during the redox switching. All the homopolymers/copolymers coated on ITO glass were switched between the dedoped and doped state in CH3CN–Bu4NPF6 (0.1 mol L−1) electrolyte in order to obtain in situ UV–Vis spectra (Fig. 5).

At the neutral states, all the polymer films exhibited strong absorption in the visible region from 420 to 500 nm due to the valence band–conduction band (π–π*) transition (Fig. 5 and Table 1). With the increase of applied potentials, the intensity of π–π* transition peaks decreased, and the evolution of new absorption bands in the range of 600~900 nm was observed. This represented typical polaron absorption bands (polarons formed in the homopolymer/copolymer backbone). Upon further oxidation, new absorption bands at longer wavelengths (> 900 nm) appeared due to the formation of bipolarons from polarons [33]. Also, the UV–Vis spectra for homopolymers/copolymers displayed well-defined isosbestic points at approximately 600 nm, indicating that the homopolymers/copolymers were interconverted between two distinct forms on both occasions: the neutral form and radical cations [34]. The optical bandgap (E g, opt), defined as the onset of π–π* transition, was calculated for all the homopolymers/copolymers, as shown in Table 1. The E g,opt of PSe was 1.88 eV while 2.10 eV for P3MeT. With increasing the feed ratios of 3MeT, the π–π* transition absorption peaks of copolymers were continuously blue-shifted and the E g,opt of the copolymers increased gradually towards that of P3MeT.

CIE 1976 (L*, a*, b*) color space and photographs were used to determine the color change (− a* and + a* correspond to green and red; − b* and + b* correspond to blue and yellow, respectively). The colorimetric data are given in Table 2. Note that the fully oxidized polymer films coated on ITO glass could be facilely obtained. It is found that by increasing the proportion of 3MeT, more saturated blue colors were achieved and interestingly, the 1:5 copolymer film showed a black color. It was worthy to note that PSe exhibited similar red brown color in both the neutral and oxidized states. Overall, the copolymers and P3MeT showed different colors from sandy-brown to deep blue even black.

Electrochromic switching of homopolymer/copolymer films

The optical contrast (ΔT%) is defined as the transmittance difference between the redox states [35]. Figure 6 illustrates the time–transmittance curves of all the polymer films at indicated wavelengths. Based on these curves, electrochromic parameters including optical contrast, response times, and coloration efficiency for all the homopolymer and copolymer films at different wavelengths are summarized in Table 3. All these copolymer films revealed relatively high optical contrast values, sufficing for various electrochromic applications. Specifically, the copolymer films here showed higher transmittance values in NIR region, indicating promising potential applications in NIR smart windows. It is also found that the optical contrast of the copolymer (Se/3MeT = 1:2) at 1080 nm was remarkably up to 70.2%, higher than all the other polymer films. Overall, a certain proportion of copolymerization between Se and 3MeT could improve the optical contrast of PSe and even exceed P3MeT itself.

Response time is calculated at 95% of the full switching because of the difficulty in perceiving any further color changes with the naked eye beyond this point [36]. These polymers were switched slowly upon redox processes. To be specific, the optical response time of PSe was more than 10 s during the redox states, longer than other copolymers. The fastest optical response time was demonstrated to be 1.0 s at the copolymer under the feeding ratio of 1:5 under 1080 nm from the oxidized to reduced state. Although the response times of the copolymers were comparable, the copolymers (Se/3MeT = 1:2) still had some advantages in response time of the visible region (5.6 s at 750 nm during redox process). In addition, the reduction of the polymer films was inherently faster than oxidation, which can be attributed to the ease of charge transport in the conducting film when it is reduced [35].

The coloration efficiency (CE) of PSe was measured as 14 cm2 C−1 at 510 nm and merely less than 1 cm2 C−1 at 950 nm at the fully doped state. In comparison, the coloration efficiencies of P3MeT were higher than that of PSe at different wavelengths. By introducing 3MeT into the PSe chain, the copolymers displayed improved CE values, typically in the range of 30~60 cm2 C−1. Namely, all the copolymers exhibited intermediate CE values between PSe and P3MeT.

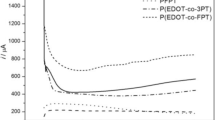

The optical memory is another important parameter since it reveals the energy consumption of electrochromic devices (ECDs) [37]. The optical spectra for all the polymers were monitored at specific wavelength as a function of time under applying potentials for 2 s between 100 s intervals. As seen in Fig. 7, all the films were highly stable in their reduced states and kept their colors without significant loss. However, the oxidized states of polymer films were less stable with the optical contrast loss of 1~7%. Nevertheless, all the copolymers under different feed ratios revealed better optical memory properties than that of homopolymers.

Open circuit stability of PSe (a), P3MeT (f), and P(Se-co-3MeT) films from different monomer feed ratios on the ITO glass in monomer-free CH3CN–Bu4NPF6 (0.10 mol L−1) solution. Monomer feed ratios Se/3MeT = 2:1 (b), 1:1 (c), 1:2 (d), and 1:5 (e). Applied potentials: − 1.0 and 1.4 V. Wavelength: a 950 nm; b–f 1080 nm

Stability

It is known that the good stability of conducting polymers is a key property for applications in advanced technological devices [1, 3, 4, 6, 37]. Therefore, the long-term redox stability of all the films was investigated in both monomer-free CH3CN–Bu4NPF6 (0.10 mol L−1) and BFEE solution at the potential scan rate of 150 mV s−1, as shown in Figs. 8 and 9 and Table 4. Obvious redox peaks of these polymers can be observed from the CVs. It can be seen that PSe and P3MeT films just retained 47.24 and 89.48% of their electroactivity after 100 cycles, respectively. As expected, the copolymers at different feed ratios revealed intermediate stability between PSe and P3MeT films, typically over 70% electroactivity left after 100 cycles. The copolymers under 1:2 and 1:5 feed ratios maintained their activity of 85.43 and 85.96% after 100 cycles, but unfortunately decreased to 52.74 and 62.18% after 1000 cycles, respectively. Although better than PSe, these parameters are inferior to P3MeT and even many typical conducting polymers reported previously, which is not suitable for applications in advanced technological devices. This is mainly due to the exchange of doping ions from BF4 − to PF6 − in different electrolytes, causing irreversible doping–dedoping process.

In contrast, the redox stability of these films was significantly improved when cycling in monomer-free BFEE solution. From Fig. 9, the redox stability of all the homopolymers and copolymers was significantly improved after 100 cycles (Table 4). Interestingly, most of the polymers showed an increased electroactivity, e.g., with more than 100% of their electroactivity after cycling. To be specific, the redox waves of the polymer films were relatively weak at first due to their low doping degree in BFEE. Upon repetitive cycling, the redox current densities of the polymers increased gradually; thus, the polymers demonstrated enhanced electroactivity. This is mainly because the polymers deposited in BFEE was less doped than they could be, and secondary cycling can be employed to further dope them (improve their doping level). This phenomenon was also found by us for P3MeT [38] and even some other electrosynthesized conducting polymers [39]. Even after 1000 cycles, no significant loss in electroactivity was found for all these films, indicating their outstanding redox activity in BFEE.

Conclusion

A series of Se-3MeT copolymers were prepared under different feed ratios of Se and 3MeT by electrochemical copolymerization in THF–BFEE solution. The influence of different feed ratios on the electrochemical, spectroelectrochemical, and kinetic properties of the resultant copolymers were investigated in detail. The copolymer films presented obvious electrochromic characteristics with color changes from sandy-brown to deep blue even black during the doped and dedoped states, higher optical contrast in comparison with parent homopolymers, good electroactive stability, and satisfied electrochromic properties. More specifically, the copolymer prepared at the feed ratio of 1:2 (Se/3MeT) possessed optical contrast of 70.2% (1080 nm), significantly higher than that of parent PSe and P3MeT, even more than other copolymers. The electrochemical and electrochromic properties of all copolymers were significantly better than PSe and even competitive to P3MeT. Also, it is also found that the doping level of the copolymer films can be further enhanced by secondary cyclic voltammetry in BFEE after electropolymerization.

References

Argun AA, Aubert PH, Thompson BC, Schwendeman I, Gaupp CL, Hwang J, Pinto NJ, Tanner DB, MacDiarmid AG, Reynolds JR (2004) Multicolored electrochromism in polymers: structures and devices. Chem Mater 16:4401–4412

Verghese MM, Ram MK, Vardhan H, Malhotra BD, Ashraf SM (1997) Electrochromic properties of polycarbazole films. Polymer 38:1625–1629

Groenendaal L, Zotti G, Aubert PH, Waybright SM, Reynolds JR (2003) Electrochemistry of poly(3,4-alkylenedioxythiophene) derivatives. Adv Mater 15:855–879

Sapp SA, Sotzing GA, Reynolds JR (1998) High contrast ratio and fast-switching dual polymer electrochromic devices. Chem Mater 10:2101–2108

Sonmez G, Sonmez HB, Shen KF, Jost RW, Rubin Y, Wudl F (2005) A processable green polymeric electrochromic. Macromolecules 38:669–675

Schwendeman I, Hickman R, Sonmez G, Schottland P, Zong K, Welsh DM, Reynolds JR (2002) Enhanced contrast dual polymer electrochromic devices. Chem Mater 14:3118–3122

Beaujuge PM, Reynolds JR (2010) Color control in π-conjugated organic polymers for use in electrochromic devices. Chem Rev 110:268–320

Hong SF, Chen LC (2010) A red-to-gray poly(3-methylthiophene) electrochromic device using a zinc hexacyanoferrate/PEDOT:PSS composite counter electrode. Electrochim Acta 55:3966–3973

Aydemir K, Tarkuc S, Durmus A, Gunbas GE, Toppare L (2008) Synthesis, characterization and electrochromic properties of a near infrared active conducting polymer of 1,4-di(selenophen-2-yl)-benzene. Polymer 49:2029–2032

Patra A, Kumar R, Chand S (2014) Selenium-containing π-conjugated polymers for organic solar cells. Isr J Chem 54:621–641

Hollinger J, Gao D, Seferos DS (2014) Selenophene electronics. Isr J Chem 54:440–445

Jiang SL, Zeng YK, Zhou WL, Miao XS, Yu Y (2016) One-minute room-temperature transfer-free production of mono- and few-layer polycrystalline graphene on various substrates. Sci Rep 6:19313

Sun Y, Ma XW, Cheng K, Wu BY, Duan JL, Chen H, Bu LH, Zhang RP, Hu XM, Deng ZX, Xing L, Hong XC, Cheng Z (2015) Strained cyclooctyne as a molecular platform for construction of multimodal imaging probes. Angew Chem Int Ed 54:5981–5984

Zhang K, Duan HL, Karihaloo Zhang K, Duan HL, Karihaloo BL, Wang JX (2010) Hierarchical, multilayered cell walls reinforced by recycled silk cocoons enhance the structural integrity of honeybee combs. Proc Natl Acad Sci U S A 107:9502–9506

Zade SS, Zamoshchik N, Bendikov M (2009) Oligo- and polyselenophenes: a theoretical study. Chem–Eur J 15:8613–8624

Lu BY, Zhen SJ, Zhang SM, Xu JK, Zhao GQ (2014) Highly stable hybrid selenophene-3,4-ethylenedioxythiophene as electrically conducting and electrochromic polymers. Polym Chem 5:4896–4908

Thomas S, Zhang C, Sun SS (2005) Synthesis and characterization of a new acceptor (n-type) fluorinated and terminal-functionalized polythiophene. J Polym Sci A Polym Chem 43:4280–4287

Barbey G, Dian G, Merlet N, Outurquin F, Paulmier C (1989) Direct synthesis of 3-methylselenophene and 3,4-dimethylselenophene. Synthesis 3:181–182

Pang YH, Xu H, Li XY, Ding HL, Cheng YX, Shi GY, Jin LT (2006) Electrochemical synthesis, characterization, and electrochromic properties of poly(3-chlorothiophene) and its copolymer with 3-methylthiophene in a room temperature ionic liquid. Electrochem Commun 8:1757–1763

Leon-Silva U, Nicho ME, Hu H (2008) Comparative study of optical kinetics in single and dual poly3-methylthiophene-based solid electrochromic devices. J Solid State Electrochem 12:71–80

Rios ED, Rosario AV, Nogueira AF, Micaroni L (2010) Electrochromic devices based on poly(3-methylthiophene) and various secondary electrochromic materials. Sol Energy Mater Sol Cells 94:1338–1345

Heinze J, Frontana-Uribe BA, Ludwigs S (2010) Electrochemistry of conducting polymers persistent models and new concepts. Chem Rev 110:4724–4771

Sonmez G (2005) Polymeric electrochromics. Chem Commun 0:5251–5259

Tschuncky P, Heinze J (1993) Voltammetric studies on the electropolymerization mechanism of methoxythiophenes. Synth Met 55:1603–1607

Hu X, Wang GM, Ng H, Wong TKS (1999) Electrochemical copolymerization of bithiophene and aniline in aqueous-organic mixed solution. Chem Lett 12:1323–1324

Lu BY, Chen S, Xu JK, Zhao GQ (2013) Thermoelectric performances of different types of polyselenophene and its copolymers with 3-methylthiophene via electropolymerization. Synth Met 183:8–15

Wang B, Zhao JS, Xiao J, Cui CS, Liu RM (2012) Synthesis and electropolymerization of 9H-carbazol-9-ylpyrene and its electrochromic properties and electrochromic device application. Int J Electrochem Sci 7:2781–2795

Patra A, Wijsboom YH, Zade SS, Li M, Sheynin Y, Leitus G, Bendikov M (2008) Poly (3,4-ethylenedioxyselenophene). J Am Chem Soc 130:6734–6736

Lu BY, Yan J, Xu JK, Zhou SY, Hu XJ (2010) Novel electroactive proton-doped conducting poly (aromatic ethers) with good fluorescence properties via electropolymerization. Macromolecules 43:4599–4608

Lin KW, Zhen SJ, Ming SL, Xu JK, Lu BY (2015) Synthesis and electro-optical properties of new conjugated hybrid polymers from EDOT end-capped dibenzothiophene and dibenzofuran. New J Chem 39:2096–2105

Huang JH, Hsu CH, Hu CW, Chu CW, Ho KC (2010) The influence of charge trapping on the electrochromic performance of poly (3,4-alkylenedioxythiophene) derivatives. ACS Appl Mater Interfaces 2: 351–359

Camurlu P, Cirpan A, Toppare L (2005) Conducting polymers of octanoic acid 2-thiophen-3-yl-ethyl ester and their electrochromic properties. Mater Chem Phys 92:413–418

Lin KW, Chen S, Lu BY, Xu JK (2017) Hybrid π-conjugated polymers from dibenzo pentacyclic centers: precursor design, electrosynthesis and electrochromics. Sci China Chem 60:38–53

Ozkut MI, Algi MP, Oztaş Z, Algi F, Önal AM, Cihaner A (2012) Members of CMY color space: cyan and magenta colored polymers based on oxadiazole acceptor unit. Macromolecules 45:729–734

Cihaner A, Algı F (2008) A new conducting polymer bearing 4,4-difluoro-4-bora-3a, 4a-diaza-s-indacene (BODIPY) subunit: synthesis and characterization. Electrochim Acta 54:786–792

Qin LQ, Xu JK, Lu BY, Lu Y, Duan XM, Nie GM (2012) Synthesis and electrochromic properties of polyacrylate functionalized poly (3,4-ethylenedioxythiophene) network films. J Mater Chem 22:18345–18353

Gazotti WA, Casalbore-Micelli JRG, Geri A, De-Paoli MA (1998) A solid-state electrochromic device based on two optically complementary conducting polymers. Adv Mater 10:60–64

Shi GQ, Xu JK, Fu MX (2002) Raman spectroscopic and electrochemical studies on the doping level changes of polythiophene films during their electrochemical growth processes. J Phys Chem B 106:288–292

Lu BY, Zhang SM, Qin LQ, Chen S, Zhen SJ, Xu JK (2013) Electrosynthesis of poly(3,4-ethylenedithiathiophene) in an ionic liquid and its electrochemistry and electrochromic properties. Electrochim Acta 106:201–208

Funding

This work was supported by the National Natural Science Foundation of China (51463008, 51763010), Innovation Driven “5511” Project of Jiangxi Province (20165BCB18016), Science Foundation for Excellent Youth Talents in Jiangxi Province (20162BCB23053), Key Research and Development Program of Jiangxi Province (20171BBH80007), Natural Science Foundation in Jiangxi Province (20171BAB216018), Science and Technology Foundation of Jiangxi Educational Committee (GJJ150795; GJJ160790), and Scientific Fund of Jiangxi Science & Technology Normal University (2016XJYB002). H. G. and Q. K. thank Jiangxi Educational Committee for a Postgraduate Innovation Program grant (YC2016-S410, YC2017-S409).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gu, H., Lin, K., Liu, X. et al. Enhanced redox stability and optical contrast of electrochromic copolymers from selenophene and 3-methylthiophene. J Solid State Electrochem 22, 599–611 (2018). https://doi.org/10.1007/s10008-017-3803-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3803-0