Abstract

The photosensitivity of the titanium dioxide films on titanium substrate formed by the electrochemical, thermal, or sol-gel method was compared under the same conditions. The surface topologies of the samples were characterized by the atomic-force microscopy. It was found that the comparable increases of the sample photopotentials were observed either after the introducing of F¯-containing component into the anodizing solution or after the annealing of pure titanium at 500 °C. The cumulative effect of the anodic oxidation and further heat treatment of titanium on IPCE of Ti|TiO2 system was established.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Semiconducting metal oxides are being actively investigated as catalysts for various photoelectrochemical processes [1]. From this standpoint, the titanium dioxide, being a large-gap semiconductor with the band gap of 3.2 eV, is one of the most promising materials; for example, its application in dye-sensitized solar cells makes it possible to converse the solar energy with high efficiency [2]. Moreover, the TiO2-photoanodes of various types (monocrystalline, polycrystalline, or thin films) are highly resistant to photocorrosion in electrolyte solutions [1]. It was noted [3] that the application of thin-film oxide electrodes is quite reasonable because only the near-surface area (~10−2 μm) of the bulk semiconductor photoelectrodes worked actively. The thin-film photosensitive TiO2 electrodes on metallic substrate can be formed by various methods such as anodic oxidation or heat treatment of titanium, chemical vapor deposition, sputtering, hydrothermal, and sol-gel techniques [1–6]. Nowadays, the method of anodic formation of photosensible titanium dioxide porous films composed by the nanotubes is of particular interest [7–10]. At the same time, the literature review shows that the design of photoelectrochemical cells, sources of radiation, and electrolyte solutions may differ significantly, which makes it difficult to compare the photoactivity of TiO2 films formed by different methods, and, consequently, to estimate the preference of one or another method.

Within the work presented, the thin films of TiO2 on titanium substrate were formed using the thermal, electrochemical, or sol-gel method. The film parameters, such as photopotential (E ph) and photocurrent density (j ph), were measured. Moreover, the ratio of incident monochromatic photon to current conversion efficiency (IPCE, %) was calculated by the following equation [11]:

where j ph was the photocurrent density, mA/cm2; λ was the wavelength of the monochromatic light, nm; P was the incident light intensity, mW/cm2. In addition the energy storing efficiency (K st) of the photogalvanic cell was calculated with Eq. (2) [12]:

where e was the absolute value of the electron charge, C; E ph was the photopotential of the electrode (the difference of the electrode potentials under lighting and in the dark) under condition of the open-circuit, V; E g was the band gap of the semiconductor, J.

Experimental section

Preparation of thin-film TiO2 electrodes

Photoelectrochemical measurements were carried out for electrodes obtained by the oxidation of commercial titanium VT1–0 (99%) plates. Before every oxidation, the surface of titanium electrode was treated sequentially with sandpaper (the abrasive grain size of 29–32 μm), diamond paste (the grit of 20–28 μm), and GOI polishing paste №3 (abrasiveness of 8–17 μm), and then the surface was degreased and washed with ethyl alcohol.

An atomic-force microscope Nova SPM Solver P47H-PRO was used to estimate the surface topology and roughness (R a ) of the oxidized samples.

Anodic oxidation of titanium (anodic oxide films)

Nonporous (barrier) thin oxide films of TiO2 were formed by anodic oxidation of the commercial titanium plates in aqueous solutions of phosphoric (H3PO4) [13] or boric (H3BO3) acids with concentration of 0.01 mol/l for both solutions [14] (all reagents were of “chemically pure” grade). However, porous TiO2 oxide layers formed when fluorine ions (as NH4F (0.135 mol/l)) were added to the same acid solutions [15]. Anodization of titanium was carried out at 23 ± 1 °C in two stages. The first stage was conducted under galvanostatic conditions (the density current j = 10 mA/cm2) and the voltage was increased up to the value required. The second stage was voltastatic one (direct voltage, DV) and the sample was hold under required voltage (10–100 V) for 10–30 min. Anodic oxide films (AOFs) obtained at different forming voltages turned interference colors: goldish (at 10 V), sky blue (at 20 V), blue (at 30–40 V), and blue-violet (at 50 V). The color of AOF became more intense with the exposition time increasing at constant forming voltage U f. The thicknesses of AOFs were proportional to the anodizing coefficient (2.4–2.8 nm/V [16, 17]), e.g., they were equal to 24–28, 48–56, and 72–84 nm at U f equal to 10, 20, and 30 V, respectively.

Thermal oxidation of titanium (thermal oxide films)

The thermal oxide films were obtained by the heat treatment (HT) of the titanium plates in a muffle furnace. The thermal oxidizing was carried out for 1 h at 500 °C in air. The soaking at the temperature required was preceded by the heating of the sample simultaneously with the furnace for 1 h. After the thermal processing, the titanium electrode was cooled down to the ambient temperature directly in the furnace. In this case, TiO2 films had saturated blue color. According to the data from ref. [17], thermal oxide films (TOFs) obtained under the above conditions (thermal oxidizing for 1 h at 500 °C in air) had the thickness on the order of 20–23 nm. Moreover, the titanium electrodes with AOFs underwent the same heat treatment, as described above, to establish the contribution of the annealing process into the values of photoelectrochemical properties of TiO2. Here, we should mention that, according to ref. [17], the thickness of AOFs did not increase after the annealing under the conditions stated above.

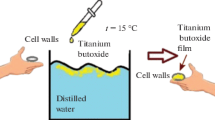

Thin oxide films of TiO2 formed by sol-gel method (sol-gel oxide films)

This type of TiO2 films was obtained according to the procedure described in ref. [18–20]. At first the solution of titanium (IV) isopropoxide (Aldrich, 98%) in isopropyl alcohol (“chemical pure” grade) was obtained by the components mixing and further stirring during 5 h at 70 °C. Titanium (IV) isopropoxide was then hydrolyzed with ethanol (96% “chemical pure” grade) (about 15 ml) added drop-by-drop till the sol formed. That sol was further used to obtain the thin coatings of TiO2 on the titanium substrate.

In order to obtain porous films of titanium dioxide, the polyethylenimine (PEI, Aldrich 99.8%, Mn ~10,000) was applied. PEI (0.5 g) was dissolved in isopropyl alcohol (80 g) and this solution was stirred at 70 °C during 4 h. The titanium (IV) isopropoxide (10 g) was added dropwise to the above solution and then the resulting mixture was stirred at 70 °C for 5 h. After that, the hydrolysis was carried out as it was specified above. Some properties of such films were described earlier [18–20].

The films on the surface of Ti electrodes were obtained by the dipping method and fixed by keeping in the furnace in air at 500 °C for 1 h. The resulting films were colored saturated blue. The estimated value of the thickness of the films obtained was about 30–35 nm.

Photoelectrochemical measurements

Photoelectrochemical properties of the oxidized titanium electrodes were studied in a quartz cell (92–95% of light transmission) at 18 ± 1 °C. The samples were illuminated by monochromatic ultraviolet light (254 or 366 nm) with a Benda UV-Handlampe NU-6 W or by mixed light with a gas discharge lamp of high pressure HWL (MBFT) 160 W. The radiation spectra of the light sources applied are shown in Fig. 1. The incident light intensity, P, of the lamps was registered by the monochromator of an AvaSpec-3648 spectrometer. The real resolution of the instrument was about 0.17 nm within the wavelength range of 250–350 nm. Values of P were equal to 6.5 and 0.387 mW/cm2 for λ = 254 and 366 nm, respectively.

Spectrum of the light sources applied. a Benda UV-Handlampe. b HWL (MBFT) 160 W (http://www.osram.com)

The photopotential of the titanium electrode, E ph (the potential difference under lighting and in the dark [12]), was determined with respect to the shaded platinum electrode using a measuring potentiostat PI50–1 within ±5 mV. The photocurrent was measured in a short-circuited electrochemical cell Ti|TiO2|0.5 M Na2SO4|Pt equipped with a self-recording ampere-voltmeter within the current range of 10 μA with accuracy of 1.5%. The distance between the electrodes was 2 mm.

Results and discussion

The surface topology of Ti|TiO2 electrodes

Thermal oxide

The AFM image of titanium surface after annealing is shown in Fig. 2a. These data indicate that the oxide layer formed is dense, nonporous and its relief is the same as the initial surface topology. After the annealing of titanium covered with the native oxide film its surface roughness (R a ) decreased slightly from 0.026 to 0.022 μm.

Oxide obtained by sol-gel method

In Fig. 2b, the surface of titanium substrate with TiO2 deposited by the sol-gel method and then heat-fixed is shown. It is seen that the film is a continuous coating with the submicron relief formed by individual TiO2 particles or their agglomerates. However, the surface roughness (R a = 0.024 μm) is the same as for the initial surface. The same results were obtained in the work [17].

Anodic oxide films

AOFs of 25–250-nm thickness were obtained by electrochemical oxidation of titanium (Fig. 3a) in 0.01 M aqueous solutions of H3PO4 or H3BO3 under the formation voltage U f = 10–100 V. The color of the samples changed depending on U f value and, accordingly, on the thickness of the oxide film formed. According to the data of AFM, the topology of the oxidized electrode depends on the formation voltage U f and the corresponding exposition time. At the initial stage of the oxidation process, being carried out in H3PO4 aqueous solution, the regularly arranged pyramidal species formed and grew at titanium active centers (Fig. 3b). Those species were being gradually covered with the oxide film under further potentiostatic polarization. As a result of the above process, the surface relief became smooth (Fig. 3c, d); the surface roughness was rather low, for example, R a = 0.018 μm for AOF formed in H3PO4 solution at 30 V during 10 min. Thus, the increase of U f promoted the formation of more dense and smooth surface layer, and any pores formation was not observed at that. The initial stages of the oxide formation described above are less pronounced in the case of H3BO3 aqueous solution.

Figure 4 demonstrates the influence of the forming electrolyte composition and subsequent heat treatment on topology of the anodic oxide films. In the presence of F− ions in the forming electrolyte (0.01 M H3PO4) more loose and bulky oxide layer formed (compare Fig. 4a, b) and its roughness increased sharply (up to R a = 0.073–0.075 μm). It should be noted that the heat treatment of all AOFs obtained smoothes slightly their surfaces relief, e.g., it can be seen in Fig. 4c.

The potentials of Ti|TiO2 electrodes

The dark potential E st of titanium electrode covered with native oxide film (NOF) steadies within 5 min in 0.5 M aqueous solution of Na2SO4 and reaches the value of −0.60 ± 0.05 V. After AOF formation, the E st value of Ti|TiO2 electrode becomes much more positive and varies from −0.04 to −0.30 V. However, there is no any dependence of E st potential of the oxidized titanium on U f, like it was established for tantalum [21]. The shift of E st potential into the positive direction is probably caused by both the significant increase of the thickness of the oxide layer and the decrease of its imperfection. So NOF thickness was about 2–10 nm [17] whereas the thickness of AOFs obtained by us was larger than 20 nm. The electrolyte used (aqueous solutions of H3BO3 or H3PO4) promoted formation of dense nonporous layers at least up to the forming voltage of 50 V [22]. E st values of Ti|TiO2 electrodes obtained in H3PO4 aqueous solutions in the presence of F− ions are more negative (E st = −(0.30÷0.50) V), probably because fluoride-ion can partially destroy the oxide film, which results in huge amount of defects and lower thickness of AOF. The same trend in variation of E st values results from the heat treatment of the electrodes covered with AOFs and is probably caused by the heat stress microcracking. The stationary dark potentials of the electrodes with TOF measured in 0.5 M aqueous solution of Na2SO4 are more positive than the potentials of the samples with NOFs: −(0.30 ÷ 0.38) and −0.60 ± 0.05 V, respectively. The dark potential of sol-gel oxide film (S-GOF) samples is equal to –(0.30 ÷ 0.33) V and coincides with the value of E st for the heat treated titanium electrodes. Thus, after the heat treatment of TiO2 films obtained by sol-gel or electrochemical methods, their dark potentials become closer. Such behavior is probably the result of the structural changes of the anodic oxide, i.e., of its amorphous-crystalline (“anatase–rutile”) transition.

Photoelectrochemical properties of Ti|TiO2 electrodes obtained by different methods

The photoelectrochemical parameters of Ti|TiO2 electrodes produced by different methods and measured under the same conditions are shown in the Table 1. For AOFs, the data obtained at U f = 30 V only, as the best ones in this series, are presented. It was established that the native oxide film on titanium was photosensitive at λ = 254 nm only.

The registered photopotential values of the samples studied decreased, as expected, with increasing the light wavelength. Thus, the energy storing efficiency of the photovoltaic cell decreases according to Eq. (2). For some TiO2 thin-film electrodes, the range of ultraviolet radiation, which allows obtaining the sufficiently high IPCE values, is relatively narrow (from 250 to 380 nm) [5, 23]. In this case, the efficiency of the energy conversion of the incident photon to current can reach 25% at λ = 300–330 nm. Indeed for the samples with TOFs, S-GOFs, and AOFs, the values of IPCE increase in 3–8 times upon transition from λ = 254 nm to λ = 366 nm. It should be noted that IPCE values (at λ = 254 nm) for the samples with S-GOFs are higher significantly as compared with the other Ti|TiO2 electrodes studied.

The photocurrent density of the oxidized titanium surface, when illuminating by the mixed light, \( {j}_{\mathrm{ph}}^{\mathrm{mixed}} \), usually does not exceed 17–22% of the value registered under UV irradiation (λ = 254 nm), \( {j}_{\mathrm{ph}}^{\mathrm{UV}} \), whereas \( {j}_{\mathrm{ph}}^{\mathrm{mixed}} \) is within 36–45% of \( {j}_{\mathrm{ph}}^{\mathrm{UV}} \) value for the oxide films formed in the presence of F¯ anions. The F¯ ions, as it was shown above, promoted the formation of very highly developed surface of TiO2 anodic films. That probably occurs due to the competition between the electrochemical formation of TiO2:

and F¯ -induced chemical destruction of AOF:

It is known [24] that the fluoride-containing solutions promote, under certain conditions, the formation of well-ordered TiO2 nanotubes. It stretches significantly the titanium dioxide photoactivity into the region of visible spectrum, which is one of the reasons for attention to F¯-containing solutions [15, 25–27].

The best IPCE values obtained under UV irradiation for the films under investigation are shown in italic in the Table 1. From these results, it can be concluded that the most effective methods of titanium surface processing are sol-gel method followed by the TiO2-film heat fixing, as well as the anodization in F¯-containing solutions with after heat treatment. The data in the table illuminate both individual effects of the samples processing and the cumulative effect from variation of the anodizing electrolyte composition and heat treatment of the samples. The anodic oxide films are amorphous as a rule [28]. The photoelectrochemical characteristics of AOFs increased significantly after annealing at 500 °C. The oxide is crystallizing during the heat treatment and the phase transition of “anatase–rutile” type takes place at temperatures above 400 °C [6, 29]. In ref. [30], it was shown that the mixture of anatase with rutile exhibited the better photocatalytic activity versus the most of organic compounds due to its more pronounced photoeffect.

The adding of NH4F to the acid solutions results in the increase of the interfacial area, due to almost triple enhancement of the surface roughness, (Fig. 4b) and, therefore, in the growth of photocurrent density more than in three times also. Heat treatment of such samples gives additional sesquialteral increase of j ph value.

Conclusions

The photosensitivities of titanium dioxide films, formed on titanium substrate by various methods, were measured under equal conditions and compared. The films had different surface topology depending on the method of their formation. It was found that the comparable contributions into the increase of E ph value came from the addition of F¯-containing component to the anodizing solution and from the annealing of the initial titanium at 500 °C. Moreover, the cumulative effect of the anodic oxidation and heat treatment of titanium, when both stages were carried out sequentially, on E ph values was established. The addition of F¯ ions in electrolytes for the electrochemical formation of the oxide film on titanium resulted in smaller relative reduction of the photocurrent value when transiting from ultraviolet to the mixed light.

References

Grimes CA, Varghese OK, Ranjan S (2008) Light, water, hydrogen: the solar generation of hydrogen by water photoelectrolysis. Springer, New York

Gratzel M (2001) Sol-gel processed TiO2 films for photovoltaic applications. J Sol-Gel Sci and Technol 22:7–13

Arakelyan VM, Shakhnazaryan GE, Khachaturyan EA (2005) Photo-electrochemical transformation of solar energy TiO2 thin films. International Scientific J For Alternative Energy and Ecology 11:38–41

Bak T, Nowotny J, Nowotny MK, Sheppard LR (2009) Dynamics of TiO2-based photoelectrochemical cell. Ionics 15:671–679

Wang Y, Hao Y, Cheng H, Ma J, Xu B (1999) The photoelectrochemistry of transition metal-ion-doped TiO2 nanocrystalline electrodes and higher solar cell conversion efficiency based on Zn2+- doped TiO2 electrode. J Mater Sci 34:2773–2779

Sankapal BR, Sartale SD, Lux-Steiner MC (2006) Chemical and electrochemical synthesis of nanosized TiO2 anatase for large-area photon conversion. C R Chimie 9:702–707

Hu MZ, Lai P, Bhuiyan MS, Tsouris C, Gu B, Paranthaman MP, Gabitto J, Harrison L (2009) Synthesis and characterization of anodized titanium-oxide nanotube arrays. J Mater Sci 44:2820–2827

Sreekantan S, Hazan R, Lockman Z (2009) Photoactivity of anatase-rutile TiO2 nanotubes formed by anodization method. Thin Solid Films 518:16–21

Srimuangmaka K, Niyomwasb S (2011) Effects of voltage and addition of water on photocatalytic activity of TiO2 nanotubes prepared by anodization method. Energy Procedia 9:435–439

Butail G, Ganesan PG, Teki R, Mahima R, Ravishankar N, Duquette DJ, Ramanath G (2011) Branched titania nanotubes through anodization voltage control. Thin Solid Films 520:235–238

Mintsouli I, Philippidis N, Poulios I, Sotiropoulos S (2006) Photoelectrochemical characterisation of thermal and particulate titanium dioxide electrodes. J Appl Electrochem 36:463–474

Pleskov YV (1990) Fotoelektrochimicheskoe preobrazovanie solnechnoj energii. Chimiya, Moscow

Davydov AD (2001) Breakdown of valve metal passivity induced by aggressive anions. Electrochim Acta 46:3777–3781

Bajrachnyj BI, Andryushchenko FK (1985) Elektrohimiya ventil'nyh metallov. Vishcha shkola, Har'kov

Roy P, Berger S, Schmuki P (2011) TiO2 nanotubes: synthesis and applications. Angew Chem Int Ed 50:2904–2939

Glukhov LM, Bukhan’ko NG, Davydov AD (2008) Growth of anodic oxide films on titanium-nickel alloys and breakdown of alloy passivity with halide ions. Russ J of Electrochem 44:332–337

Vera ML, Alterach MA, Rosenberger MR, Lamas DG, Schvezov CE, Ares AE (2014) Characterization of TiO2 nanofilms obtained by sol-gel and anodic oxidation. Nanomater Nanotechnol 4:4–10

Vinogradov AV, Agafonov AV, Vinogradov VV (2011) Studies on the effect of the stabilizer activity on the structure and properties of titania-based hybrid films. RussChemBull 60:1862–1870

Vinogradov AV, Agafonov AV, Vinogradov VV (2009) Sol-gel synthesis of titanium dioxide based films possessing highly ordered channel structure. J Mendeleev Comm 19:340–341

Vinogradov AV, Agafonov AV, Vinogradov VV (2010) Study of surfaces of TiO2 based nanostructured films obtained under action of various templates. Protection of Metals and Physical Chemistry of Surfaces 46:555–558

Grishina EP, Eremenko DV, Tsyplakova LN, Kyrov VN, Nevsky OI (1990) Electrochemical behavior of systems Ag-H2SO4-Ta2O5 and Cu-H2SO4-Ta2O5 at different conditions of the polarization. Izv Vyssh Uchebn Zaved Khim Khim Tekhnol 33:65–71

Kuromoto NK, Simão RA, Soares GA (2008) Titanium oxide films produced on commercially pure titanium by anodic oxidation with different voltages. Mater Charact 58:114–121

Van de Krol R, Schoonman J (2008) Photo-electrochemical production of hydrogen. In: Hanjali K, van de Krol R (eds) Sustainable energy technologies. Springer, Dordrecht

Macak JM, Tsuchiya H, Ghicov A, Schmuki P (2005) Dye-sensitized anodic TiO2 nanotubes. Electrochem Commun 7:1133–1137

YanBiao L, BaoXue Z, BiTao X, Jing B, LongHai L (2007) TiO2 nanotube arrays and TiO2-nanotube-array based dye-sensitized solar cell. Chin Sci Bull 52:1585–1589

Bauer S, Kleber S, Schmuki P (2006) TiO2 nanotubes: tailoring the geometry in H3PO4/HF electrolytes. Electrochem Commun 8:1321–1325

Macak JM, Tsuchiya H, Taveira L, Aldabergerova S, Schmuki P (2005) Smooth anodic TiO2 nanotubes. Angew Chem Int Ed 44:7463–7465

Yung L (1967) Anode Oxide Films. Energia, Leningrad

Sosnov EA, Malkov AA, Malygin AA (2011) Temperature effect on polymorphic transformations in silica matrix-titania coating systems. Inorg Mater 47:563–569

Khoroshikh VM, Belous VA (2009) Titanium dioxide films for photocatalysis and medicine. Fizicheskaja ingeneria poverchnosti 7:223–238

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grishina, E., Kudryakova, N. & Agafonov, A. Photoelectrochemical properties of thin films on titanium obtained by thermal, electrochemical, or sol-gel method. J Solid State Electrochem 21, 1777–1784 (2017). https://doi.org/10.1007/s10008-017-3542-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3542-2