Abstract

In this paper, poly[poly(N-vinyl-carbazole)] (PPVK) films electrodeposited in tetrahydrofuran (THF) containing 12 % boron trifluoride diethyl etherate (BFEE) were studied as electrode active material for supercapacitors. The morphology and thermal property were characterized by SEM, atomic force microscopy (AFM), and thermogravimetry (TG), respectively. The electrochemical capacitive behaviors of the PPVK films were also investigated by cyclic voltammetry, galvanostatic charge/discharge, and electrochemical impedance spectroscopy. The electrochemical results showed that the specific capacitance of PPVK films in CH3CN solution was about 126 mF cm−2 at 1.5 mA cm−2 and the capacitance retention was only 14.4 % after 1000 cycles. It was exciting to improve the specific capacitance up to 169.3 mF cm−2 at 1.5 mA cm−2 and to make the cyclic stability increase to 81.8 % capacitance retention after 5000 cycles when the equivalent BFEE was added into the CH3CN solution containing 0.05 M Bu4NBF4 electrolyte. These results clearly demonstrated that BFEE was an efficient promoter for the enhancement of the capacitance performance of PPVK films. Therefore, with the help of BFEE electrolyte, the PPVK films have potential application as capacitive materials in high-performance energy storage devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the miraculous development brought about by electrical vehicles and energy product [1–3], research on supercapacitors which are also known as electrochemical capacitors or ultracapacitors is flourishing at an unprecedented rate. Owing to the characteristics of fast charging ability, high power capability, long cyclic life, environmental friendly, and safe energy storage, supercapacitors are considered as one of the most significant technologies tailoring for promising energy storage [4–8]. As a kind of potential capacitive materials for supercapacitors, conducting polymers (CPs) which entailed excellent electrochemical reversibilities, fast switching between redox states, high conductivity in a doped state, mechanical flexibility, and unlimited structural modification possibility have been intensively investigated [9–13]. Among a diversity of CPs, polypyrrole (PPy) [14], polyaniline (PANI) [15, 16], and polythiophene (PTh) [17] have been widely used to research their capacitance properties. Presently, many researchers are attracted to develop new structural CPs, such as polyindoles [18–23], poly(3,4-ethylenedioxythiophene) (PEDOT) derivatives [24], copolymers [25–27], and its analogs [28–30].

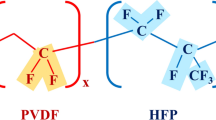

Polycarbazole-based materials have widely been applied in sensors, anticorrosion, solar cells, and light-emitting devices [31–34]. Through the smart design, lots of polycarbazole-based materials possessing new features such as hydrogen storage and electrochemical properties have come out [35–37]. For example, Han’ group reported that microporous polycarbazoles derived from 1,3,5-tri(9-carbazolyl)benzene and its similar monomers showed high hydrogen storage ability [35]; Gu et al. prepared high selective adsorption carbazole–spacer–carbazole polymers PCz–C n–Cz (n = 3–6) by FeCl3 oxidative coupling polymerization [36]. Additionally, Ates et al. fabricated a new polymer based on 9H-carbazole-9-carbothioic methacrylic thioanhydride on glassy carbon electrode by an electropolymerization method. The prepared polymer had specific capacitance of 2.46 F g−1 [38]. The microcapacitor application of poly(carbazole-co-terthiophene) was also reported by Ates et al. [39]. The obtained highest specific capacitance was 2.01 mF cm−2 for the copolymer, which was higher than those of polycarbazole (1.10 mF cm−2) and polyterthiophene (0.75 mF cm−2). The N-vinyl-carbazole was an electrochemically prepared corresponding polymer with 1.6 × 10−7 S cm−1 [40]. It was reported that the protons released during the electropolymerization of N-vinyl-carbazole induced the chemical polymerization of vinyl group. The competitive reaction possibly hindered the further electrochemical polymerization of N-vinyl-carbazole [37]. Therefore, the extremely low conductivity possibly came from the short conjugated chain length of polymer. Ates et al. reported that the polymer prepared by the electropolymerization of N-vinyl-carbazole only showed a very low specific capacitance of about 0.29 F g−1 [41]. However, the N-vinyl-carbazole can form into poly(N-vinyl-carbazole) (PVK) by the firstly chemical polymerization of vinyl group. The obtained PVK is nonconjugated vinyl polymer with pendant carbazole units. Polyethylene as main chain plays a helpful role in high-quality film formation [42, 43]. Through the electrochemical polymerization occurred on the carbazole units of PVK, free-standing poly[poly(N-vinyl-carbazole)] (PPVK) film has been prepared in tetrahydrofuran (THF) containing boron trifluoride diethyl etherate (BFEE) electrolytes by our group [44]. The conductivity of the PPVK films reached 10−2 S cm−1, which was much higher than that of PVK [38]. From the enhanced conductivity, it infers that the PPVK will have a higher capacitive behaviors compared to PVK. To the best of our knowledge, the PPVK as electrode materials for supercapacitors has not been reported yet.

Herein, the capacitive behaviors of the PPVK films synthesized from THF containing BFEE (12 %, by volume) and Bu4NBF4 (0.05 M) were investigated in CH3CN solution containing different electrolytes by cyclic voltammetry, galvanostatic charge/discharge, and electrochemical impedance spectroscopy. It was found that the addition of BFEE into CH3CN could significantly enhance the specific capacitance and cyclic life of PPVK films.

Experimental

Materials

PVK (M w = 90,000) was purchased from J&K Chemical Ltd., China. BFEE came from Beijing Changyang Chemical Plant, China. Tetrabutylammonium tetrafluoroborate (Bu4NBF4, Acros Organics, 95 %) was dried in vacuum at 60 °C for 24 h before use. THF (99.9 %, analytical grade) came from Shanghai Titan Scientific Co. Ltd.). Acetonitrile (CH3CN, >99 %, Beijing East Longshun Chemical Plant) was purified by distillation with calcium hydride under a nitrogen atmosphere before use.

Preparation of PPVK films

Electrochemical syntheses and tests were carried out on a CHI 660B potentiostat/galvanostat (Shanghai Chenhua Instrumental Co., Ltd., China). The polished glass carbon (GC, diameter 3 mm) electrode was used as the working electrode, which was purchased from Tianjin Aida Hengsheng Technology Development Co. Ltd. China. The reference electrode was Ag/AgCl; the counter electrode was platinum wire (1 mm diameter). In order to get a lot of polymers for characterization, large stainless steel sheets were employed as the working and counter electrodes, respectively. The PPVK films were grown potentiostatically in THF solution containing BFEE (12 %, by volume) and Bu4NBF4 (0.05 M). All electrolytic solutions were deaerated for about 10 min by a continuous stream of pure argon and maintained under an argon atmosphere during experiments.

Characterizations

The surface morphologies of PPVK films were investigated by means of a JEOL JSM6700F scanning electron microscope and atomic force microscopy (AFM, Bruker Dimension Icon ScanAsyst). The thermogravimetric analysis (TGA) was performed with a thermal analyzer of NETZSCH TG209 under a nitrogen stream in the temperature range of 0–1000 K with a heating rate of 10 K/min.

Results and discussion

Electrochemical polymerization of PVK

PVK was difficult to dissolve in conventional solvents apart from THF. However, the electrochemical polymerization of PVK does not occur in THF containing Bu4NBF4 due to the strong nucleophilicity of THF. The introduction of BFEE into THF solution can decrease the nucleophilicity, successfully ensuring the polymerization occurrence of PVK [44]. Our previous study demonstrated that when the volume amount of BFEE reached 12 %, the oxidation onset potential of the PVK precursor was lowest. However, when BFEE exceeded 12 %, nonconjugated polymer was precipitated immediately [44]. Figure 1 showed the linear sweep voltammetry (LSV) of PVK in THF solution containing 12 % BFEE and 0.05 M Bu4NBF4. The knee point of LSV curve at about 0.64 V shows the oxidation onset potential of PVK; between 0.64 and 1.5 V, no knee point appears, meaning the polymerization is realized through two symmetric positions on PVK units and the structure of the obtained PPVK films is stable in the potential range. When the potential is higher than the oxidation onset potential value, a dark film is rapidly yielded on the surface of working electrode. FT-IR spectrum of polymer (Fig. S1) indicated that the polymer, namely PPVK, was obtained through the electrochemical polymerization of the carbazole units on PVK precursor (Scheme 1).

Thermal property and surface morphology of PPVK

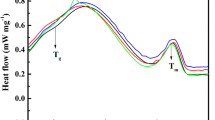

The thermal stability is a vital parameter for the application of conducting polymers. The TG and TGA of PPVK were investigated from 300 to 1300 K at N2 atmosphere. As seen from TG curve in Fig. 2, there was 15 % weight loss before 512 K; this was mainly due to the degradation of doping anion BF4 −1 and other moisture which trapped in the polymer. From 512 to 696 K, the weight loss was up to 26.3 %, possibly owing to the overflow of some oligomers decomposed from the PPVK films. The decomposition of the polymer took place between 708 and 786 K. Moreover, no evident thermal degradation occurred in the measured temperature from 786 to 1280 K. From TGA curve, it was seen that the fastest loss rates of PPVK films occurred at 404, 500, 653, and 762 K in the different decomposition stages.

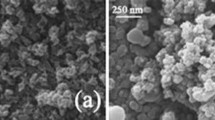

The microstructures/nanostructures of polymer films greatly improve their electrochemical behaviors due to the large specific surface area and the nanometer size effect. Therefore, the surface morphology of PPVK films was investigated by SEM and AFM, respectively. As shown in Fig. 3, the rough PPVK films were consisting of some granules with the average diameter of about 250 nm.

Capacitance performances of the PPVK films

Generally, the specific capacitances of electrode materials for supercapacitors are evaluated by their mass specific capacitance (C M, F g−1). However, the electrode specific capacitance (C E, mF cm−2) is also an important parameter to evaluate the practically accessible capacitance over a unit g`eometric area of the electrode substrate [45]. In order to accurately reflect the specific capacitance of PPVK films, an optimizing strategy has been conducted. The specific capacitance of PPVK films was obtained in the CH3CN solution containing 0.05 M Bu4NBF4 by galvanostatic charge/discharge method. Figure 4a shows the effect of polymerization potential on the specific capacitance of PPVK films. It was observed that at a fixed mass of PPVK films, the specific capacitance increased with potentials and reached a maximum value at 0.9 V. When the potential exceeded 1.0 V, the specific capacitance decreased rapidly. Since the monomer concentration can affect the quality of conducting polymers, the effect of PVK concentration on the specific capacitance of PPVK has been recorded in Fig. 4b. When the PVK concentration was 0.09 M, the specific capacitance of as-obtained PPVK films reached a maximum value. Additionally, the different deposited charges also produced diverse specific capacitances, namely, the best capacitive behaviors of as-obtained PPVK films were found when the deposited charge density was 0.4 C cm−2 (Fig. 4c). When polymerization time was prolonged, white polymers were formed on the electrode surface, whereafter filled the whole solution. This is due to the immense accumulation of protons during the electrochemical reaction induced by the chemical reactions, i.e., chemical polymerization of vinyl group on the PVK precursor in solution [37]. This phenomenon went against the further formation of PPVK films. In addition, when the deposited charge density further increased, the thickness of PPVK films was also thickened, which resulted in the higher resistance between active materials and ions. Therefore, the capacitive contribution of the inner PPVK decreased, which resulted in relatively lower specific capacitance. Therefore, the preparation condition of PPVK films in below text was the applied potential of 0.9 V, the PVK precursor concentration of 0.09 M, and deposited charge density of 0.4 C cm−2.

Figure 5a shows the capacitance–voltage (CVs) of PPVK films in CH3CN solution containing 0.05 M Bu4NBF4 at the scan rate of 10, 25, 50, 75, and 100 mV s−1. At 10 mV s−1, the oxidation peak appeared at 1.1 V and a reduction peak located at 0.9 V, which was attributed to the doping and dedoping process of BF4 −1 ions in PPVK films. The redox peaks in CV curves showed a distinct shift with increasing scan rate from 10 to 100 mV s−1: The oxidation peak appeared a positive shift, and the reduction peak shifted negatively. This was attributed to the increase in the electrical resistance of the thick film. The results of CV curves were quantified by calculating the specific capacitance (C E, F cm−2):

a Cyclic voltammograms of PPVK in CH3CN solution containing 0.05 M Bu4NBF4 at different potential scan rates, b specific capacitance as a function of its scan rate, c galvanostatic charge/discharge curves of PPVK electrode at different current densities, and d specific capacitance of PPVK electrode as a function of current density

where E 1 and E 2 are the cutoff potentials in cyclic voltammetry, i(E) is the instantaneous current, i(E)d(E) is the total voltammetric charge obtained by integration of the positive and negative sweeps in the cyclic voltammograms, v is the scan rate, and S is the area of the electrode. Calculated by this equation, the specific capacitances were 121.3, 88.7, 47.8, 28.9, and 19.3 mF cm−2, respectively. Obviously, with increasing scan rate, the specific capacitance decayed severely (Fig. 5b). This can be attributed to the ion exchange mechanism. At low scan rate, the BF4 −1 ions had adequate time to diffuse into the electrode, while at high scan rate, the diffusion of ions was limited by the insufficient time, and the limitation was more prominent for a thick film. So, the less accessibility for ions into the active materials results in the decrease of the specific capacitance.

Furthermore, the charge–discharge measurements were conducted at a diversity of current density. As shown in Fig. 5c, all charge–discharge curves are similar in shape, indicating that the PPVK films can be stably performed in the range of current densities. However, there was a visible ohmic loss (IR drop) at all current densities, indicating that the PPVK films had a big resistance. The specific capacitance was calculated according to the following equation.

where ΔV (V) is the discharge potential range, I (A) represents the discharge current density, S is the area of the electrode, and Δt (s) is the discharge time. In Fig. 5d, the specific capacitances of PPVK films calculated by this equation (ΔV = 0.7) were 126, 117.1, 109.6, 102.8, and 96 mF cm−2 at the discharge current densities of 1.5, 2, 2.5, 3, and 3.5 mA cm−2, respectively. When the IR drop was excluded, the corresponding specific capacitances of PPVK films calculated by this equation (ΔV = 0.7 − ΔV IR drop) (Fig. S2) were 143.5, 142.8, 142.4, 139.4, and 137.9 mF cm−2.

The excellent long-term cycle stability is essential for supercapacitor operation. Figure 6 shows the cyclic life of PPVK films in CH3CN containing 0.05 M Bu4NBF4. Before 150 cycles, the specific capacitance gradually increased possibly due to the permeation of more and more ions into the film with increasing cycles. Unfortunately, when the permeation of ions reached saturation, the specific capacitance did not increase but decrease after about 150 cycles. And after 1000 cycles, the specific capacitance of PPVK films was only 14.4 % of the initial value, which indicated the significant instability of PPVK films in CH3CN solution. The instability of PPVK films in CH3CN solution mainly came from the two aspects as follows: (1) In neutral solution, the redox potentials of PPVK are relatively higher, which goes against the electrochemical stability of PPVK during the long cyclic process possibly due to the overoxidation occurrence of PPVK; (2) in the electrolyte, the appearance of trace water possibly damages the electrochemical activity of PPVK, which results in the instability of PPVK films in ACN.

Generally, the electrolyte has great effect on the capacitance performance of supercapacitors [46, 47]. Among different solvents such as organic solvent, water, and ionic liquid, the BFEE is one of the most important solvents because it can lower the oxidation potential of the aromatic monomers and also reduce the potential of the redox of conducting polymers [48]. To improve the capacitance performance of PPVK films, especially cycling stability, the mixed electrolyte of CH3CN and 50 % BFEE (by volume) containing 0.05 M Bu4NBF4 was attempted; the results were shown in Fig. 7. It was seen from Fig. 7a that at 10 mV s−1, the CVs showed a couple of broader anodic and cathodic peaks and a broader electrochemical active window when the introduction of BFEE to CH3CN solution and the specific capacitance reached 141.6 mF cm−2, which was higher than that in CH3CN solution (121.3 mF cm−2). With the scan rate increasing, the shape of CV curve gradually turned into fusiformis and the specific capacitance decreased from 141.6 to 14.3 mF cm−2 (Fig. 7b). This indicated that high scan rate is adverse to the fast doping and dedoping of large (EtO)2BF3 − anions, which induces IR drop. It was also seen from Fig. 7c that the IR drop became more serious when the current density increased, which led to the reduction of specific capacitance. For example, the specific capacitance decreased to 126 from 169.3 mF cm−2 with increasing from 1.5 to 3.5 mA cm−2 (Fig. 7d). When the IR drop was excluded, the specific capacitances (Fig. S3) were 207, 205.2, 205, 204.1, and 202.7 mF cm−2. These results implied that the addition of BFEE into CH3CN solution could improve the specific capacitance of PPVK films mainly because BFEE with good ionic conductivity accelerates the ionic transfer.

a Cyclic voltammograms of PPVK in CH3CN and 50 % BFEE (by volume) containing 0.05 M Bu4NBF4 at different potential scan rates, b specific capacitance as a function of its scan rate, c galvanostatic charge/discharge curves of PPVK electrode at different current densities, and d specific capacitance of PPVK electrode as a function of current density

The electrochemical impedance spectroscopy (EIS) of PPVK films was also carried out in CH3CN and 50 % BFEE containing 0.05 M Bu4NBF4 at 0.9 V. In Fig. 8a, the impedance curve shows a nearly vertical straight line in the low-frequency region and a flattened semicircle in the high-frequency region. The intercept of the plot with the real axis in the high-frequency region represents solution resistance (R s), viz., R s = 314 Ω. Additionally, the diameter of the semicircle was determined by the charge transfer resistance, and the value was about 65 Ω, indicating that the efficient electron transport occurred in PPVK films. In Fig. 8b, the |Z| value of PPVK films was almost independent of frequency at the high-frequency region. In the phase angle plot (Fig. 8c), the maximum phase angle of PPVK films reached −68.4° at 0.01 Hz. Additionally, according to C E = 1/(2Sπf|Z im|), the calculated specific capacitance reached 184 mF cm−2 (Fig. 8d). The highest low-frequency capacitance comparison with other types of polycarbazole-based materials which were studied in supercapacitors was shown in Table 1. As seen from Table 1, PPVK has a promising result for higher specific capacitance.

The cyclic life of PPVK films was also studied in CH3CN and 50 % BFEE containing 0.05 M Bu4NBF4 and compared with that in CH3CN containing 0.05 M Bu4NBF4; the results were shown in Fig. 9. Surprisingly, PPVK films showed excellent cyclic stability in the mixed solution of CH3CN and BFEE, still maintained a specific capacitance of 81.8 % after 5000 cycles, which was higher than that of PPVK in CH3CN containing 0.05 M Bu4NBF4 (capacitance retention of 14.4 % after 1000 cycles). The stability enhancement of PPVK films was mainly attributed to the reasons as follows: (1) The presence of BFEE lowers the redox potential of PPVK, which prevents the overoxidation of PPVK at high potential and (2) the additional BFEE can react with the trace water in the electrolyte to form protonic acid, H+[BF3OH]−, which results in the stability improvement of PPVK films.

For further investigation of the energy storage ability of PPVK films as electrode in two-electrode cell, an asymmetric supercapacitor based on PPVK and PEDOT electrodes (PPVK//PEDOT) was built. Notice that p-doped PPVK is not suitable to build symmetrical supercapacitor (see Fig. S4). Figure 10a showed galvanostatic charge–discharge curves of PPVK//PEDOT device in CH3CN and 50 % BFEE containing 0.05 M Bu4NBF4 at different current densities. As a function of current density, the specific capacitances (Fig. 10b) were 38.5, 35.6, 31.9, 29, and 27.2 mF cm−2. The specific power (P) and specific energy (E) values can be calculated by the following relationships:

where C is the specific capacitance of the device (F m−2), V is the potential window (V), E is the specific energy (Wh m−2) of the electrode, and Δt is the discharge time (h) for the potential. In Fig. 10c, the energy density of the device was in 63.9∼90.3 mWh m−2 and the power density was in 1.625∼13 W m−2. These results demonstrated that PPVK can be used as a potential electrode material for supercapacitors.

Conclusions

The capacitive performance of electrodeposited PPVK films has been investigated in CH3CN and CH3CN/BFEE, respectively, in which PPVK films were prepared from THF containing BFEE (12 %, by volume) and Bu4NBF4 (0.05 M). The PPVK films coating the smooth GC electrode showed a desirable thermal stability as electrode materials for supercapacitors. Electrochemical results indicated that PPVK films in CH3CN solution showed a lower specific capacitance of about 126 mF cm−2 at 1.5 mA cm−2 and only exhibited a 14.4 % capacitance retention after 1000 cycles. However, when the BFEE was added into the CH3CN solution, the specific capacitance of PPVK films could increase to 169.3 mF cm−2 at 1.5 mA cm−2, and especially, its cyclic stability reached 81.8 % after 5000 cycles. Undoubtedly, the enhanced capacitive performance comes from the effect of BFEE, indicating that BFEE can efficiently enhance the capacitance performance of PPVK films.

References

Thackeray MM, Wolverton C, Isaacs ED (2012) Electrical energy storage for transportation-approaching the limits of, and going beyond, lithium-ion batteries. Energy Environ Sci 5:7854–7863

Dunn B, Kamath H, Tarascon JM (2011) Electrical energy storage for the grid: a battery of choices. Science 334:928–935

Hawkins TR, Gausen OM, Strømman AH (2012) Environmental impacts of hybrid and electric vehicles-a review. Int J Life Cycle Ass 17:997–1014

Chen S, Zhu J, Wu X, Han Q, Wang X (2010) Graphene oxide-MnO2 nanocomposites for supercapacitors. ACS Nano 4:2822–2830

Pech D, Brunet M, Durou H, Huang P, Mochalin V, Gogotsi Y, Taberna PL, Simon P (2010) Ultrahigh-power micrometre-sized supercapacitors based on onion-like carbon. Nat Nanotech 5:651–654

Conway BE (1999) Electrochemical supercapacitors: scientific fundamentals and technological applications. Kluwer Academic lenum Publishers, New York

Wang G, Zhang L, Zhang J (2012) A review of electrode materials for electrochemical supercapacitors. Chem Soc Rev 41:797–828

Lang X, Hirata A, Fujita T, Chen M (2011) Nanoporous metal/oxide hybrid electrodes for electrochemical supercapacitors. Nat Nanotech 6:232–236

Chandrasekhar P (1999) Conducting polymers, fundamentals and applications: a practical approach. Kluwer Acdemic Publishers, The Netherlands

Inzelt G (2012) Conducting polymers: a new era in electrochemistry. In: Scholz F (ed) Monographs in electrochemistry, 2nd edn. Springer, Heidelberg Berlin

Malinauskas A, Malinauskiene J, Ramanavičius A (2005) Conducting polymer-based nanostructurized materials: electrochemical aspects. Nanotechnology 16:R51

Dai TY, Tang R, Yue XX, Xu L (2015) Capacitance performances of supramolecular hydrogels based on conducting polymers. Chin J Polym Sci 33:1018–1027

Tang G, Jiang ZG, Li X (2014) Simultaneous functionalization and reduction of graphene oxide with polyetheramine and its electrically conductive epoxy nanocomposites. Chin J Polym Sci 32:975–985

Moniruzzaman M, Sahoo S, Ghosh D, Das CK, Singh R (2013) Preparation and characterization of polypyrrole/modified multiwalled carbon nanotube nanocomposites polymerized in situ in the presence of barium titanate. J Appl Polym Sci 128:698–705

Xiao L, Cao Y, Xiao J, Schwenzer B, Engelhard MH, Saraf LV, Nie Z, Exarhos GJ, Liu J (2012) A soft approach to encapsulate sulfur: polyaniline nanotubes for lithium-sulfur batteries with long cycle life. Adv Mater 24:1176–1181

Liew SY, Thielemans W, Walsh DA (2014) Polyaniline-and poly (ethylenedioxythiophene)-cellulose nanocomposite electrodes for supercapacitors. J Solid State Electrochem 18:3307–3315

Wu F, Chen J, Chen R, Wu S, Li L, Chen S, Zhao T (2011) Sulfur/polythiophene with a core/shell structure: synthesis and electrochemical properties of the cathode for rechargeable lithium batteries. J Phys Chem C 115:6057–6063

Ma X, Zhou W, Mo D, Hou J, Xu J (2015) Effect of substituent position on electrodeposition, morphology, and capacitance performance of polyindole bearing a carboxylic group. Electrochim Acta 176:1302–1312

Zhou Q, Zhu D, Ma X, Xu J, Zhou W, Zhao F (2016) High-performance capacitive behavior of layered reduced graphene oxide and polyindole nanocomposite materials. RSC Adv 6:29840–29847

Zhou X, Chen Q, Wang A, Xu J, Wu S, Shen J (2016) Bamboo-like composites of V2O5/polyindole and activated carbon cloth as electrodes for all-solid-state flexible asymmetric supercapacitors. ACS Appl Mater Interfaces 8:3776–3783

Raj RP, Ragupathy P, Mohan S (2015) Remarkable capacitive behavior of a Co3O4-polyindole composite as electrode material for supercapacitor applications. J Mater Chem A 3:24338–24348

Zhou X, Wang A, Pan Y, Yu C, Zou Y, Zhou Y, Chen Q, Wu S (2015) Facile synthesis of a Co3O4@carbon nanotubes/polyindole composite and its application in allsolid-state flexible supercapacitors. J Mater Chem A 3:13011–13015

Zhou W, Ma X, Jiang F, Zhu D, Xu J, Lu B, Liu C (2014) Electrochemical fabrication of a porous network MnO2/poly(5-cyanoindole) composite and its capacitance performance. Electrochim Acta 138:270–277

Ma X, Zhou W, Mo D, Zhang K, Wang Z, Jiang F, Hu D, Dong L, Xu J (2015) Electrochemical preparation of poly(2, 3-dihydrothieno[3, 4-b][1, 4]dioxin-2-yl) methanol)/carbon fiber core/shell structure composite and its high capacitance performance. J Electroanal Chem 743:53–59

Cebeci FC, Sezer E, Sarac AS (2009) A novel EDOT-nonylbithiazole-EDOT based comonomer as an active electrode material for supercapacitor applications. Electrochim Acta 54:6354–6360

Estrada LA, Liu DY, Salazar DH, Dyer AL, Reynolds JR (2012) Poly[bis-EDOT-Isoindigo]: an electroactive polymer applied to electrochemical supercapacitors. Macromolecules 45:8200–8211

Mo D, Zhou W, Ma X, Xu J, Zhu D, Lu B (2014) Electrochemical synthesis and capacitance properties of a novel poly(3, 4-ethylenedioxythiophene bis-substituted bithiophene) electrode material. Electrochim Acta 132:67–74

Wijsboom YH, Sheynin Y, Patra A, Zamoshchik N, Vardimon R, Leitus G, Bendikov M (2011) Tuning of electronic properties and rigidity in PEDOT analogs. J Mater Chem 21:1368–1372

Wang Z, Xu J, Lu B, Zhang S, Qin L, Mo D, Zhen S (2014) Poly(thieno[3,4-b]-1,4-oxathiane): medium effect on electropolymerization and electrochromic performance. Langmuir 30:15581–15589

Feng Z, Mo D, Zhou W, Zhou Q, Xu J, Lu B, Zhen S, Wang Z, Ma X (2016) Electrosynthesis and electrochemical capacitive behavior of a new nitrogen PEDOT analogue-based polymer electrode. New J Chem 40:2304–2314

Shakir M, Khan MS, Al-Resayes SI, Khan AA, Baig U (2014) Electrical conductivity, isothermal stability, and ammonia-sensing performance of newly synthesized and characterized organic-inorganic polycarbazole-titanium dioxide nanocomposite. Ind Eng Chem Res 53:8035–8044

Mangadlao JD, De Leon AC, Felipe MJ, Cao P, Advincula PA, Advincula RC (2015) Grafted carbazole-assisted electrodeposition of graphene oxide. ACS Appl Mater Interfaces 7:10266–10274

Cowan SR, Schulz P, Giordano AJ, Garcia A, MacLeod BA, Marder SR, Kahn A, Ginley DS, Ratcliff EL, Olson DC (2014) Chemically controlled reversible and irreversible extraction barriers via stable interface modification of zinc oxide electron collection layer in polycarbazole-based organic solar cells. Adv Func Mater 24:4671–4680

He R, Xu J, Xue Y, Chen D, Ying L, Yang W, Cao Y (2014) Improving the efficiency and spectral stability of white-emitting polycarbazoles by introducing a dibenzothiophene-S,S-dioxide unit into the backbone. J Mater Chem C 2:7881–7890

Chen Q, Luo M, Hammershøj P, Zhou D, Han Y, Laursen BW, Yan CG, Han BH (2012) Microporous polycarbazole with high specific surface area for gas storage and separation. J Am Chem Soc 134:6084–6087

Gu C, Bao Y, Huang W, Liu D, Yang R (2016) Four simple structure carbazole-based conjugated microporous polymers with different soft connected chains. Macromol Chem Phys 217:748–756

Karon K, Lapkowski M (2015) Carbazole electrochemistry: a short review. J Solid State Electrochem 19:2601–2610

Ates M, Uludag N, Arican F (2014) Synthesis of 9H-carbazole-9-carbothioic methacrylic thioanhydride, electropolymerization, characterization and supercapacitor applications. Polym Bull 71:1557–1573

Ates M, Eren N (2014) Electrochemical copolymerization of carbazole and 2, 2′: 5′-2′′terthiophene: characterization and micro-capacitor application. Iran Polym J 23:581–589

Reyna-González JM, Roquero P, Rivera E (2009) A comparative investigation between poly(N-vinyl-carbazole) and poly(3, 6-N-vinyl-carbazole): spectroscopy, conductivity, thermal and optical properties. Des Monom Polym 12:233–245

Ates M, Sarac AS (2009) Capacitive behavior of polycarbazole-and poly(N-vinyl-carbazole)-coated carbon fiber microelectrodes in various solutions. J Appl Electrochem 39:2043–2048

Park YH, Shin HC, Lee Y, Son Y, Baik DH (1999) Electrochemical preparation of polypyrrole copolymer films from PSPMS precursor. Macromolecules 32:4615–4618

Deng S, Advincula RC (2002) Polymethacrylate functionalized polypyrrole network films on indium tin oxide: electropolymerization of a precursor polymer and comonomer. Chem Mater 14:4073–4080

Xu J, Zhou W, Peng H, Pu S, Wang J, Yan L (2006) Electrosyntheses of freestanding and conducting poly[poly(N-vinyl-carbazole)] films in tetrahydrofuran containing additional boron trifluoride diethyl etherate. Polym J 38:369–375

Wu M, Snook GA, Gupta V, Shaffer M, Fray DJ, Chen GZ (2005) Electrochemical fabrication and capacitance of composite films of carbon nanotubes and polyaniline. J Mater Chem 15:2297–2303

Yang M, Cheng B, Song H, Chen X (2010) Preparation and electrochemical performance of polyaniline-based carbon nanotubes as electrode material for supercapacitor. Electrochim Acta 55:7021–7027

Wang K, Huang J, Wei Z (2010) Conducting polyaniline nanowire arrays for high performance supercapacitors. J Phys Chem C 114:8062–8067

Jin S, Xue G (1997) Interaction between thiophene and solvated Lewis acids and the low-potential electrochemical deposition of a highly anisotropic conducting polythiophene film. Macromolecules 30:5753–5757

Ates M, Uludag N (2015) Poly(9H-carbazole-9-carbothioic Dithioperoxyanhydride) formation and capacitor study. International Journal of Polymeric Materials and Polymeric Biomaterials 64:755–761

Ates M (2014) A novel synthesis of 4-toluene 9H-carbazole-9-carbodithioate, electropolymerization and impedance study. Express Polym Lett 8:480–490

Ates M, Uludag N, Karazehir T, Arican F (2013) A novel synthesis of (3, 6-bis(2, 3-dihydrothieno[3, 4-b][1, 4]dioxin-5-yl)-9-(4-vinylbenzyl)-9H-carbazole), alternating polymer formation, characterization, and capacitance measurements. J Solid State Electrochem 17:2417–2242

Ates M, Uludag N (2013) Synthesis of 6-(3, 6-di(thiophene-2-yl)-9H-carbazole-9-yl)-hexanoic acid, alternating copolymer formation, characterization and impedance evaluations. Designed Monomers and Polymers 16(4):398–406

Ates M, Uludag N, Karazehir T, Arican F (2012) Synthesis of 2-(3, 6-bis(2, 3-dihydrothieno[3, 4-b][1, 4]dioxin-5-yl)-9H-carbazole-9-yl)ethyl methacrylate, electropolymerization, characterization and impedimetric study. J Electrochem Soc 160:G46–G54

Ates M, Uludag N (2012) Circuit model evaluation of poly(methyl pyrrole-co-2-(9H-carbazole-9-yl)ethyl methacrylate) on carbon fiber. Polym-Plast Technol Eng 51:493–499

Ates M, Karazehir T, Uludag N (2012) Electrolyte effects of poly(3-methylthiophene) via PET/ITO and synthesis of 5-(3,6-di(thiophene-2-yl)-9H-carbazole-9-yl) pentanitrile on electrochemical impedance spectroscopy. J Appl Polym Sci 125:3302–3312

Ates M, Uludag N, Sarac AS (2011) Electrochemical impedance of poly(9-tosyl-9H-carbazole-co-pyrrole) electrocoated carbon fiber. Mater Chem Phys 127:120–127

Ates M, Uludag N, Arican F, Karazehir T (2015) Synthesis of methyl 4-(9H-carbazole-9-carbanothioylthio) benzoate: electropolymerization and impedimetric study. Turk J Chem 39:194–205

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51263010, 51463008, 51572117), Ganpo Outstanding Talents 555 projects, the Science and Technology Landing Plan of Universities in Jiangxi province (KJLD14069), the Natural Science Foundation of Jiangxi Province (20161BAB206147), and the Doctoral Starting up Foundation of Jiangxi Science and Technology Normal University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Guo Ye and Jingkun Xu contributed equally to this work.

Electronic supplementary material

ESM 1

(DOCX 443 kb)

Rights and permissions

About this article

Cite this article

Ye, G., Xu, J., Ma, X. et al. Enhancing effect of boron trifluoride diethyl etherate electrolytes on capacitance performance of electropolymerized poly[poly(N-vinyl-carbazole)] films. J Solid State Electrochem 21, 81–90 (2017). https://doi.org/10.1007/s10008-016-3335-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3335-z