Abstract

Efficient electrocatalysts for the oxygen evolution reaction (OER) are critical for various energy conversion devices such as metal-air batteries, rechargeable fuel cell, and water splitting for hydrogen production. In this work, a novel non-precious-metal OER catalyst was prepared from the pyrolysis of a Ni-Schiff base complex with thiourea. The derived catalyst is composed of nickel oxide coupled with nickel sulfide loaded on nitrogen-doped carbon matrix (NiO-NiS/N-C), which manifested excellent OER electrocatalytic activity, and an onset potential of 1.54 V vs reversible hydrogen electrode was achieved in alkaline electrolyte. The high performance of as-obtained electrocatalyst was illustrated by fully dispersed active components of NiO coupled with NiS nanoparticles, as well as the strong interaction between NiS, NiO particles, and N-doped carbon substrate. Our findings supply an easier path to fabricate the active catalyst through one-step metal organic framework transformation way and are promising for use in energy conversion systems and also yield new impetus for exploring other non-noble metal catalysts.

ᅟ

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Increasing demand for sustainable energy has stimulated intense research on energy conversion and storage systems that are highly efficient, low cost, and eco-friendly. The oxygen evolution reaction (OER) is a core process in various energy conversion and storage devices, such as metal-air batteries, rechargeable fuel cell, and water splitting for hydrogen production [1–3]. An efficient and robust OER electrocatalysts can reduce the overpotential originated from the sluggish reaction kinetics and achieve a desired current density, thus enhance the energy conversion efficiency [4, 5]. In this regard, the development of electrocatalysts for OER with high activity and strong long-term stability is urgently needed. Although precious metal oxides, such as RuO2 and IrO2, are considered the best catalysts for this oxidation reaction in acidic or alkaline solutions, they are not suitable for large-scale application because of their scarcity and consequently high cost [6, 7]. To realize the low-cost applications, extensive efforts have been devoted to search the efficient and inexpensive non-precious metal electrode materials to replace them.

Up to now, most of the investigated alternative OER electrocatalysts are transition metal based such as Fe, Co, Mn, and Ni [8–10], including simple and mixed-metal oxides, nitride, and sulfide [11–18]. Among them, nickel-based materials are becoming focus of growing research interests because of their earth-abundant nature, rich valence state, and theoretically high catalytic activity [13, 19]. Many scientists committed themselves to studying the OER property of Ni-based structure, spanning from nickel oxides [20], nickel nitride [17], nickel hydroxide [21], nickel oxyhydroxide [22], and double-layer hydroxide [23, 24] to nickel sulfides [25], and they found that the overpotential for OER can be obviously reduced [25]. Meanwhile, non-metal catalysts, such as carbon nanotubes, graphitic carbon nitrides, and graphene, are another kind of active OER catalysts, especially for those doped with nitrogen or sulfur [26–28]. Since the transition metal catalyst and carbon-based materials both have excellent electrocatalytic performance, the unified composite catalysts, coupled transition metal/nanocarbon hybrid materials should also show remarkable activity [28, 29]; thus, the preparation protocol for these kinds of hybrid materials are very significant. Usually, they are synthesized by several techniques, including solvothermal [30], self-assembly [31, 32], and precursor conversion [33].

Pyrolysis of transition metal complex containing heteroatom is a simple and feasible way to produce the transition metal/nanocarbon hybrid; thus, the active metal components supported on carbon substrate for OER formed in situ are obtained practically through one-step approach [33–35]. Meanwhile, the introduction of heteroatoms (e.g., nitrogen, sulfur, phosphorus) into carbon matrix could cause electron modulation to tune their electronic properties and chemical activities, which is useful for catalysis [36–38]. Inspired by the structure of coordination compound and the pyrolysis preparation method, a novel heteroatom-containing compound, Schiff base, is caught by our eyes as precursor for OER. Schiff base is a kind of compounds containing methylene amine (>C = N–) with great coordination chemical performance, commonly formed by condensation of an amine and an active carbonyl group. The compounds of metals coordinated with Schiff base are widely used in many areas, such as pharmaceutically, catalysis and analytical chemistry [39, 40]. Also, the metal-Schiff base complexes are a kind of precursors to make novel catalyst preparation available.

Here, we reported that an original OER catalyst, nickel oxide coupled with nickel sulfide supported on nitrogen-doped carbon composite material (NiO-NiS/N-C), was derived from pyrolysis of Ni-Schiff base complex. The morphology, microstructure, and composition investigations found that the inorganic components of complex were converted into NiO and NiS nanoparticles, and the ligand parts in complex were transformed into nitrogen-doped carbon via carbonization under a nitrogen atmosphere. Electrochemical study showed that NiO-NiS/N-C exhibited highly OER activity with low onset potential 1.54 V vs reversible hydrogen electrode (RHE) and superior stability in 10 h constant potential measurement in alkaline solution.

Experimental section

Materials

Thiosemicarbazide, vanillin, and polytetrafluoroethylene (PTFE, 60 wt.%) solutions were purchased from Aladdin Industrial Co., Ltd. Nickel acetate was from Tianjin Chemical Reagents Institute. Thiourea and potassium hydroxide were bought from Tianjin Sheng Ao Chemical Reagent Co., Ltd. Absolute ethanol was from Tianjin Fuyu Fine Chemical Co., Ltd. Carbon black (Vulcan XC-72R) was provided by Cabot Corporation. All chemicals in this study were of commercially available analytical grade and used without further purification. Carbon fiber paper (marked as CFP; Shanghai Hesen Electric Co., Ltd) was used as the conductive substrate in electrochemistry measurements.

Catalyst preparation

The ligand of vanillin thiosemicarbazone (C9H11N3O2S, HL; shown in Scheme 1) was prepared according to the literature [41]. In general, an ethanol solution of thiosemicarbazide (40 mL, 0.05 M) was added to an ethanol solution of vanillin (40 mL, 0.05 M) in 30 min under magnetic stirring. The mixture was stirred for 2 h under reflux conditions. At the end of the reaction, a large amount of white solid was formed, which was centrifuged out, washed several times with distilled water and ethanol, and dried at 60 °C for 12 h.

For the synthesis of Ni-vanillin thiosemicarbazone complex (Ni(C9H10N3O2S)2, NiL2; Scheme 1), an ethanol solution of nickel acetate (40 mL, 0.002 M) was added to HL ethanol solution (80 mL, 0.002 M) in 30 min under magnetic stirring. Then, the mixture was stirred for 2 h under reflux conditions. The yellow-green products formed at the end of reaction were centrifuged out, washed several times with distilled water and ethanol, and dried at 60 °C for 12 h.

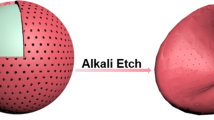

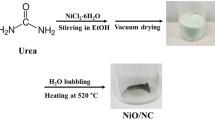

For preparation catalyst NiO-NiS/N-C, the obtained NiL2 (0.2 mmol) and thiourea (4 mmol) were ground and mixed together in an agate mortar. Then, the sample was heated to 750 °C with a rate of 3 °C min−1 in nitrogen atmosphere and kept at 750 °C for 2 h. Then, the resulting black powders were cooled to 200 °C and held at this temperature in air for another 30 min to obtain the nanocomposite. Finally, the product was collected and ground into powder for further characterization.

Scheme 1 depicts the chemical structure of HL, NiL2, and the synthetic process of NiO-NiS/N-C catalyst.

For comparative study, the controlled sample annealing NiL2 at the same condition in air atmosphere was obtained, which generated NiO nanoparticles (NP) confirmed by X-ray diffraction (XRD) and scanning electron microscope (SEM) (see Fig. S1 in the Supporting Information). NiS NP were also prepared by a solvothermal approach reported previously [42], whose characterizations were shown in Fig. S2 in the Supporting Information. Also, NiO and NiS were mixed with XC-72R carbon black to obtain the mixture to compare with the NiO-NiS/N-C catalyst. The detailed preparation method was given in the Supporting Information.

Material characterization

Elemental analyses (C, H, N, and S) for NiL2 were carried out on Vario EL III Element Analyzer. Thermogravimetric (TG) analysis was conducted with a TGA/DTA system (STA449-F3, Netzsch, Germany) using O2 atmosphere with a ramp rate of 10 °C min−1 and temperature range of 100–900 °C. The XRD data was collected on a Bruker advanced D8 X-ray diffractometer using Cu-K α irradiation (λ = 0.154056 nm) as source at 40 kV and 40 mA in the scanning range of 2θ between 10° and 90°. The field emission transmission electron microscopy (TEM; FEI, Tecnai G2F20, USA) and Hitachi (S-4800) scanning electron microscope (SEM) equipped with an energy-dispersive spectroscopy (EDS) analyzer were used for the structure and morphology characterization. X-ray photoelectron spectroscopy (XPS) data were obtained with an AMICUS/ESCA 3400 electron spectrometer from Kratos Analytical using Mg-K α (20 mA, 12 kV) radiation. All binding energies were calibrated using the carbon (C1s = 284.6 eV) as a reference.

Electrochemical measurements

The electrocatalytic performance for OER of as-prepared catalysts were evaluated in 1 M KOH solution by cyclic voltammetry (CV) and linear sweep voltammetry (LSV) techniques on a CHI 760D electrochemical workstation (CH Instruments Inc., Shanghai). A conventional three-electrode system was employed, where a 1-cm2 CFP supported catalysts as a working electrode, saturated calomel electrode (SCE) as the reference electrode, and the graphite rod serves as the counter electrode. The preparation method for the working electrode containing OER catalyst was described as follows. Briefly, 2 mg of as-prepared catalyst was dispersed in 1.0 mL mixture of distilled water and ethanol (v/v = 1:1). Then, 10 μL diluted 1 wt.% PTFE binder (from its 60 wt.% water suspension) was added to the above solution. The mixed solution was sonicated at least 30 min to form a homogenous catalyst ink. Of the well-dispersed solution, 100 μL was then pipetted onto the surface of tailored CFP (ca. 1 cm2) to achieve the electrode loading ∼0.2 mg cm−2 for the electrochemical measurements when dry out at room temperature. Other contrasted samples NiO and NiS were used directly in the same way, and NiO-NiS/XC-72R was applied after the quantitative proportions of varieties were obtained (see Supporting Information for mixture preparation). The working electrodes were scanned for several times by CV (10 mV s−1) until the signals were stabilized, which was done to increase the oxygenated surface functional groups and further improve the hydrophilicity and wettability of the surface, and then, the data for polarization curves were collected by LSV (5 mV s−1). All LSV polarization curves were corrected for the iR compensation in the three-electrode system. The solution resistance was measured to be ∼3 Ω for CFP substrates in 1 M KOH through impedance measurement and iR compensated at 95 % through positive feedback. The long-time stability test for OER was measured with the chronopotentiometric method conducted at 10 mA cm−2 for 10 h without iR compensation.

In analyzing OER performance, the current density was normalized to the geometrical surface area (or normalized per mass of catalysts) and the working potentials E vs SCE were converted to a RHE scale according to Nernst equation E vs RHE = E vs SCE + 0.059 × pH + 0.242 V. The Tafel slope was calculated according to Tafel equation η = blogj + a, where η is the overpotential, b is the Tafel slope, and j is the current density. η was calculated as follows: η = E vs RHE − 1.23 V.

Electrochemical impedance spectroscopy (EIS) measurements were performed by applying AC voltage with 5 mV amplitude in a frequency range from 10,000 to 0.01 Hz and record 1.64 V vs RHE. The electrochemical surface area of the electrodes was related to double-layer charging curves using CV in a potential range of 1.10–1.15 V at scan rates of 2 to 10 mV s−1 in 1 M KOH. The double-layer capacitance (C dl) values of as-synthesized catalysts were determined from the slope of the plot that is current density (at 1.14 V) against scan rate. All experiments were conducted at room temperature.

Results and discussion

To analyze the composition structure of NiL2 (Ni(C9H10N3O2S)2) and prove the successful synthesis, primarily, the elemental analysis was performed. According to the data of Table 1, the measured contents of elements C, H, N, and S are basically consistent with the theoretical value (shown in brackets), which inferred that molecular formula of NiL2 should be correct.

This NiL2 precursor structure was further confirmed by TG (Fig. 1). The weight loss of 84.6 % for NiL2 with increasing temperature is ascribed to the lost of carbon species, heteroatom sulfur and nitrogen. Supposing that NiO is the final component for NiL2 combustion, this loss value (84.6 %) is consistent with the theoretical calculation value of 85.3 % when reaching 800 °C. Also, the calculated theoretical content of NiO (all from NiL2 combustion) was 14.8 %, and the actual residual from TG was 15.4 %, which was accorded well. Unified with elemental analysis, it was certified that the NiL2 (Ni(C9H10N3O2S)2) was successfully synthesized.

In order to know the composition and crystallinity for NiL2 and the final product after calcination, the XRD test was carried out. Figure 2a is the XRD pattern for NiL2 complex, and it shows some crystalline property and several peaks appeared, meaning that HL ligands had coordinated with the Ni2+ ions to form new material NiL2, whose characteristic peaks could not be found in XRD database. The XRD pattern (Fig. 2b) showed that the well-defined diffraction peaks at 2θ values of 37.2°, 43.3°, 62.9°, 75.4°, and 79.4° correspond to (111), (200), (220), (311), and (222) crystal planes, which were characteristics of NiO (Joint Committee on Powder Diffraction Standards (JCPDS) nos. 71–1179). At the same time, some diffraction peaks at ca. 30.0°, 34.5°, 45.7°, 53.2°, and 72.7° that correspond to (100), (101), (102), (110), and (202) were also observed for the NiS (JCPDS nos. 77–1624). These results indicated that two Ni-based compounds (NiO and NiS) formed in the pyrolysis process of Ni-Schiff base complex with thiourea. Also, a broad diffraction peak in the range of 20°–30° is originated from the carbon species, which certified the transformation of carbon substrate from the organic part of complex. No nickel nitride nanoparticles existed, stating that the Ni-S and Ni-O bond was more stable than the Ni-N bond. Even though the N species can escape from the HL organic part and thiourea, the Ni is hard to react with N but easier to be oxidized and combined with the sulfide. So, the final products NiO and NiS were obtained.

SEM and EDS were used to investigate the structure, morphology, and the elemental constitute of synthesized composite catalyst. Typical SEM image (Fig. 3a) revealed that NiO-NiS/N-C catalyst was composed of different size nanoparticles; aggregation occurred due to heating the sample at high temperature. The inset picture in Fig. 3a was the image for NiL2, and it appeared compact and some block pasted together, whose morphology was apparently different from the hybrid product. These results indicated successful transformation of complex to the nickel-based particles, and combined with the elemental test and XRD analysis, it can be inferred that precursor NiL2 was successfully prepared. The compositional analysis of NiL2 after annealing was given in Fig. 3b, which demonstrated the presence of Ni, S, O, C, and a small amount of N element. The inset shown in Fig. 3b showing the carbon content in hybrid reached 33.8 %, which was beneficial to the enhancement of the conductivity of electroactive metal component. Here, N species showed content of 7.8 %, combined with the XRD analysis, and it can be inferred that carbon matrix may be doped by N (simplified by N-C), and the N-doped carbon was about 13.9 % (see calculation in the Supporting Information). The N-doped carbon can be the substrate, and it will effectively enhance OER activity.

The morphology, crystalline state, and dispersion of the obtained nanocomposites were further investigated by TEM. As depicted in Fig. 4a, b, Ni-based compound nanoparticles with a diameter of range from 20 to 50 nm were distributed on carbon substrates, not so evenly perhaps because the NiL2 were annealed at high temperature, but the amorphous carbon substrate was clearly seen by annealing Ni-Schiff base complex with thiourea at 750 °C. Further high-resolution transmission electron microscopy (HRTEM) images (Fig. 4c, d) indicated that the NiO and NiS nanoparticles appeared clear lattice spacing of 0.241 and 0.198 nm, which correspond to the (111) crystal plane of NiO and (102) crystal plane of NiS, respectively. All TEM results were consistent with the XRD analysis and further confirmed that there were two Ni-based compounds formed in the pyrolysis of Ni-Schiff base complex with thiourea. Figure 4d also indicates that the carbon showed mesoporous structure, and the detailed configuration was under further study.

XPS was performed to analyze the chemical compositions and the element bonding configuration for NiO-NiS/N-C nanocomposites. Figure 5a showed the typical survey spectra of NiO-NiS/N-C catalyst, confirming the presence of Ni, C, O, N, and S elements in the sample. The Ni 2p region of the XPS spectra (Fig. 5b) showed a doublet containing a low-energy band (Ni 2p3/2) and a high-energy band (Ni 2p1/2) at 856.0 and 873.6 eV with energy difference of 17.6 eV, which demonstrate the presence of nickel species in the divalent state. The Ni 2p3/2 was also fitted with two spin-orbit doublets, characteristic of NiS and NiO and their shake-up satellites. Compared with pure NiS (852.8 eV) and NiO (854.3 eV) [43, 44], the corresponding peaks for NiO-NiS/N-C nanocomposite catalysts were 854.4 and 856.2 eV, implying the strong interaction between Ni nanocompounds and carbon species, and thus resulted in lower electron density of the Ni atoms in NiO-NiS/N-C nanocomposite catalysts. This shift was considered to be valuable for its enhancement of OER activity [16]. The high-resolution spectrum of N 1 s can be divided into three peaks at 398.8, 399.9, and 400.7 eV (Fig. 5c), which can be assigned to pyridinic N, pyrrolic N, and graphitic N, respectively. The pyridinic N and graphitic N are dominant N types, and the presence of N strongly influences the electronic properties of the carbon species by increasing the density of electron on the electrode surface, which also played significant roles in the OER process [45]. This investigation also confirmed that the carbon species was doped by N, which was accorded well with the EDS and XRD analyses. The C 1 s profile (Fig. 5d) can be divided into several peaks, and the deconvoluted peaks with binding energies at about 284.8, 285.8, and 287.9 eV correspond to C-C, C-O/C-N, and C = O/C = N in the NiO-NiS/N-C nanocomposites, indicating that the carbon framework was not only doped by nitrogen but was oxidized a little, originated from the complex precursor exposed in air, and this result was also verified by our elemental content analysis from EDS (see Supporting Information).

The electrochemical activity of the NiO-NiS/N-C nanocomposite catalyst toward OER was evaluated in 1 M KOH solutions using a standard three-electrode system. The LSV polarization curves are shown in Fig. 6a. As is clearly seen, the bare CFP exhibited negligible catalytic activity for water oxidation, but NiO-NiS/N-C catalyst presented a much greater catalytic current density, rendering a sharp onset potential at ∼1.54 V vs RHE with better OER performance than NiO, NiS, and mixture of NiO-NiS/XC-72R carbon black, indicating that the NiO-NiS/N-C nanocomposite catalyst can perform the OER catalyst very well. The OER activities can also be normalized by per mass of catalyst to facilitate comparisons (see inset in Fig. 6a), and this normalization was used to properly benchmark the activity. Contrasted with Fig. 6a, the value for vertical axis changed much because of the low loading mass for our catalyst, which also indicated the superior performance for OER.

a LSV polarization curves for NiO-NiS/N-C, NiO, NiS, NiO-NiS/XC-72R mixture, and bare CFP in 1 M KOH solution. Inset is the current per mass of catalyst vs potential. b Tafel plots and c Nyquist plots of electrodes in 1 M KOH for NiO-NiS/N-C, NiO, NiS, and NiO-NiS/XC-72R mixture with the potential of 1.64 V vs RHE. d The compared polarization curves of NiO-NiS/N-C catalyst before and after 10 h chronopotentiometric test. Inset is the chronopotentiometric response at a constant current density of 10.0 mA cm−2 of NiO-NiS/N-C nanocomposite catalysts

It was commonly accepted that the activity was evaluated by the potential at current density 10 mA cm−2, which is another benchmark for OER catalysts. The NiO-NiS/N-C nanocomposite afforded an overpotential of 374 mV to deliver a current density of 10 mA cm−2, which is better than the overpotential of NiO NP (422 mV), NiS NP (410 mV), and mixture NiO-NiS/XC-72R (428 mV), which reveal the advantageous architecture of NiO coupled with NiS supported on N-doped carbon. We further compared the operating potentials of different catalysts to deliver a 10-mA cm−2 current density. It even showed superior performance to those of previously reported OER catalysts with the same configuration, such as NiCo2S4@N/S-graphene [30], CoxSy@N/S-C [46], NiO nanosheets [47], and FeNC sheets/NiO [48], which demonstrates that NiO-NiS/N-C is among the most efficient.

The pyrolyzed Ni complex mixed with thiourea for the OER activity could be attributed to the additional sulfur and nitrogen from decomposing thiourea, and active component would be resulted. The sulfur and oxygen elements were combined with Ni to form NiS, NiO, here which has been proven to be a good OER catalyst. Meanwhile, the nitrogen-doped carbon substrate facilitated the electrolyte penetration and diffusion of ionic species, enhancing the electrical conductivity between substrate and active species, and resulting in favorable charge and mass transport, which in turn accelerated the kinetics for OER.

To examine the kinetics for catalytic OER, the linear fitting of Tafel plot lead to a low Tafel slope 44.7 mV dec−1 (Fig. 6b), smaller than those of NiO (75.3 mV dec−1), mixture NiO-NiS/XC-72R (64.1 mV dec−1), and NiS (60.3 mV dec−1). The decreased Tafel slope for NiO-NiS/N-C compared with mixture NiO-NiS/XC-72R implies an efficient OER process and favorable reaction kenetics, coinciding with the higher current density for NiO-NiS/N-C.

The EIS investigations for NiO-NiS/N-C, NiO, NiS, and NiO-NiS/XC-72R mixture were carried out at the same applied potential (1.64 V vs RHE) to further explore OER kinetics with catalytic activity, as illustrated in Fig. 6c. The ohmic resistance R s arising from the electrolyte as well as all the contact and charge transfer resistance R ct at the interface between the catalysts and the electrolyte were well correlated to electrocatalytic kinetics, and thus, the electrocatalytic kinetics can be determined from the diameter of the semicircles in the low-frequency zone. It is generally accepted that small values of R s correspond to close contact between current collector and catalysts and that small values of R ct give rise to rapid charge transfer kinetics. From Fig. 6c, it can be seen that all our four catalysts exhibit almost the same small R s . Furthermore, the semicircular diameter represented the R ct for catalysts, and the smallest diameter for NiO-NiS/N-C manifested minimum charge transfer resistance and rapid charge transfer kinetics, which is consistent with the lower overpotential associated with large current density, showing that outstanding activity of NiO-NiS/N-C originates not simply from the increased electrical conductivity but also from a synergistic effect between NiO, NiS nanoparticles, and N-doped carbon.

Superior durability toward OER is of great significance for energy conversion and storage systems. The inset shown in Fig. 6d is the chronopotentiometric response. An activation process could occur in the initial 2 h of durability tests. The operating potential of NiO-NiS/N-C catalyst was decreased by about 15 mV, suggesting that the catalyst can be activated by electrochemical reaction due to the change of interaction between active species and the solution during the OER process with the conversion of surface NiO-NiS/N-C to OER active Ni oxide species [26, 49]. Hereafter, NiO-NiS/N-C catalyst demonstrated a scarcely operating potential increase (only ∼5 mV), representing strong durability in alkaline electrolyte during 10 h test at constant current density (10.0 mA cm−2). As Fig. 6d shown, there was slight attenuation of the current density for NiO-NiS/N-C catalyst before and after 10 h chronopotentiometric test, confirming that this catalyst had a superior stability in an alkaline medium.

The activity of NiO-NiS/N-C is significantly greater than NiO and other Ni-based catalysts for OER in alkaline media, which can be ascribed to rapid charge transfer based on analyses of EIS results, and also the well-dispersed NiO, NiS NPs with N-doped carbon substrate benefiting transportation of electrons proven by aforementioned SEM. To verify the superior activity of our nickel-based catalysts, the corresponding C dl were also measured, which are proportional to the electrochemical surface area (ESCA). As the inset has shown in Fig. 7a surprisingly, the obtained C dl value for NiO-NiS/N-C was estimated to be 2.52 mF cm2, which was almost the same as that of NiO-NiS/XC-72R (2.55 mF cm−2; Fig. 7b) but larger than NiO (1.28 mF cm−2; Fig. 7c) and NiS (0.71 mF cm−2; Fig. 7d). Since the C dl was proportional to the ESCA of the catalysts, the results showed that the NiO-NiS/N-C hybrids and NiO-NiS/XC-72R had more active surface area than NiO and NiS, seperately, which may be induced by the synergetic effect between active component and substrate. The surface roughness factor R f was calculated dividing C dl by the capacitance of ideal planar metal oxides having smooth surface, normally taken to be 60 uF cm−2 [50, 51], and they are 42 for NiO-NiS/N-C, 42.5 for NiO-NiS/XC-72R, 21 for NiO, and 12 for NiS, which along with the Cdl values for each catalyst stayed the same with the activity test.

Double-layer capacitance measurements for determining electrochemically active surface area for a NiO-NiS/N-C, b NiO, c NiS, and d NiO-NiS/XC-72R mixture in 1 M KOH. Cyclic voltammograms were measured in a non-Faradaic region of the voltammogram at the scan rates from 2 to 10 mV s−1. All current is assumed to be due to capacitive charging. All insets in Fig. 7 were capacitive currents at 1.14 V vs scan rate

Based on the above results, the excellent OER catalytic performance for NiO-NiS/N-C nanocomposites should be explained according to the following analysis. First, the unique characteristic of electroactive hybrid composition endowed NiO-NiS/N-C with excellent OER catalytic activity. The NiO and NiS nanoparticles embedded in carbon species were obtained by the pyrolysis of Ni-vanillin thiosemicarbazone complex with thiourea as an additional sulfur source, and the frame of the complex was converted to N-doped carbon substrate, which made evenly distributed configuration and the strong interaction between catalyst and substrate that is favorable to the OER and further enhance the stability of catalysts. Second, the carbon supporter formed in situ could increase the dispersion and utilization of the active catalysts, and improve the entire conductivity of NiO-NiS/N-C, providing paths for the flow of electrons so that catalytic activity could be improved. Finally, another reason taken into account was doping effect. The N-doped carbon layer, containing pyridinic N, pyrrolic N, and graphite N, played an important role to the promotion of OER activity through structure and electronic modification. For N-doped carbon species, N impurities were electron donor and could increase the electron density at carbon substrate; meanwhile, due to different properties of N and C atoms, electronic uneven distribution occurred in the vicinity of N atoms, which was said to be active for OER [52]. Thus, our Ni complex structure supplied an easier path to fabricate the active catalyst supported on N-doped carbon substrate through one step, which is a promising method for water-splitting catalysts’ preparation.

Conclusions

In summary, we have developed a highly efficient self-supporting NiO-NiS/N-C OER electrocatalyst by pyrolysis, a complex precursor (Ni-vanillin thiosemicarbazone) with thiourea. These complex-derived NiO-NiS/N-C hybrids exhibit excellent electrocatalytic OER activity in alkaline electrolyte with a low onset potential and large current density. The durability of the hybrids is also very excellent, and catalytic activity is not reduced after galvanostatic OER measurement at 10 mA cm−2 for 10 h. The high performance of the as-obtained electrocatalyst is associated with well-dispersed active NiO, NiS nanoparticles, and the strong interaction with carbon substrate. The vanillin thiosemicarbazone containing N-based ligand is regarded to benefit the formation of N-doped carbon, which also played a great role in improving the performance of OER. Our findings supply an easier path to fabricate the active catalyst through one-step preparation way and are promising for use in energy conversion systems and also yield new impetus for exploring other non-noble metal catalysts.

References

Thomas IL, Dresselhaus MD (2001) Alternative energy technologies. Nature 414(6861):332–3372

Zeng K, Zhang D (2010) Recent progress in alkaline water electrolysis for hydrogen production and applications. Prog Energy Combust Sci 36(3):307–326

Cheng F, Chen J (2012) Metal-air batteries: from oxygen reduction electrochemistry to cathode catalysts. Chem Soc Rev 41(6):2172–2192

Suntivich J, May KJ, Gasteiger HA, Goodenough JB, Shao-Horn Y (2011) A perovskite oxide optimized for oxygen evolution catalysis from molecular orbital principles. Science 334(6061):1383–1385

Bediako DK, Surendranath Y, Nocera DG (2013) Mechanistic studies of the oxygen evolution reaction mediated by a nickel-borate thin film electrocatalyst. J Am Chem Soc 135(9):3662–3674

Hu J (2004) Oxygen evolution reaction on IrO2-based DSA® type electrodes: kinetics analysis of Tafel lines and EIS. Int J Hydrog Energy 29(8):791–797

Over H (2012) Surface chemistry of ruthenium dioxide in heterogeneous catalysis and electrocatalysis: from fundamental to applied research. Chem Rev 112(6):3356–3426

Burke LD (1986) The formation and stability of hydrous oxide films on iron under potential cycling conditions in aqueous solution at high pH. J Electroanal Chem 198(2):347–368

Corrigan DA (1987) The catalysis of the oxygen evolution reaction by iron impurities in thin film nickel oxide electrodes. J Electrochem Soc 134(2):377–384

Lyons ME, Doyle RL, Brandon MP (2011) Redox switching and oxygen evolution at oxidized metal and metal oxide electrodes: iron in base. Phys Chem Chem Phys 13(48):21530–21551

Robinson DM, Yong BG, Greenblatt M, Dismukes GC (2010) Water oxidation by λ-MnO2: catalysis by the cubical Mn4O4 subcluster obtained by delithiation of spinel LiMn2O4. J Am Chem Soc 132(33):11467–11469

Ramírez A, Bogdanoff P, Friedrich D, Fiechter S (2012) Synthesis of Ca2Mn3O8 films and their electrochemical studies for the oxygen evolution reaction (OER) of water. Nano Energy 1(2):282–289

Subbaraman R, Tripkovic D, Chang KC, Strmcnik D, Paulikas AP, Hirunsit P, Chan M, Greeley J, Stamenkovic V, Markovic NM (2012) Trends in activity for the water electrolyser reactions on 3d M (Ni, Co, Fe, Mn) hydr(oxy)oxide catalysts. Nat Mater 11(6):550–557

Wang J, Zhong HX, Qin YL, Zhang XB (2013) An efficient three-dimensional oxygen evolution electrode. Angew Chem Int Ed 52(20):5248–5253

Lin L, Zhu Q, Xu AW (2014) Noble-metal-free Fe-N/C catalyst for highly efficient oxygen reduction reaction under both alkaline and acidic conditions. J Am Chem Soc 136(31):11027–11033

Ma TY, Dai S, Jaroniec M, Qiao SZ (2014) Metal–organic framework derived hybrid Co3O4-carbon porous nanowire arrays as reversible oxygen evolution electrodes. J Am Chem Soc 136(39):13925–13931

Xu K, Chen P, Li X, Tong Y, Ding H, Wu X, Chu W, Peng Z, Wu C, Xie Y (2015) Metallic nickel nitride nanosheets realizing enhanced electrochemical water oxidation. J Am Chem Soc 137(12):4119–4125

Shalom M, Ressnig D, Yang X, Clavel G, Fellinger TP, Antonietti M (2015) Nickel nitride as an efficient electrocatalyst for water splitting. J Mater Chem A 3(15):8171–8177

Li X, Walsh FC, Pletcher D (2011) Nickel based electrocatalysts for oxygen evolution in high current density, alkaline water electrolysers. Phys Chem Chem Phys 13(3):1162–1167

Ratcliff EL, Meyer J, Steirer KX, Garcia A, Berry JJ, Ginley DS, Olson DC, Kahn A, Armstrong NR (2011) Evidence for near-surface NiOOH species in solution-processed NiOx selective interlayer materials: impact on energetics and the performance of polymer bulk heterojunction photovoltaics. Chem Mater 23(22):4988–5000

Gao M, Sheng W, Zhuang Z, Fang Q, Gu S, Jiang J, Yan Y (2014) Efficient water oxidation using nanostructured alpha-nickel-hydroxide as an electrocatalyst. J Am Chem Soc 136(19):7077–7084

Trotochaud L, Young SL, Ranney JK, Boettcher SW (2014) Nickel-iron oxyhydroxide oxygen-evolution electrocatalysts: the role of intentional and incidental iron incorporation. J Am Chem Soc 136(18):6744–6753

Gong M, Li Y, Wang H, Liang Y, Wu JZ, Zhou J, Wang J, Regier T, Wei F, Dai H (2013) An advanced Ni-Fe layered double hydroxide electrocatalyst for water oxidation. J Am Chem Soc 135(23):8452–8455

Diaz-Morales O, Ledezma-Yanez I, Koper MTM, Calle-Vallejo F (2015) Guidelines for the rational design of Ni-based double hydroxide electrocatalysts for the oxygen evolution reaction. ACS Catal 5(9):5380–5387

Zhou W, Wu X-J, Cao X, Huang X, Tan C, Tian J, Liu H, Wang J, Zhang H (2013) Ni3S2 nanorods/Ni foam composite electrode with low overpotential for electrocatalytic oxygen evolution. Energy Environ Sci 6(10):2921–2924

Lu X, Yim WL, Suryanto BH, Zhao C (2015) Electrocatalytic oxygen evolution at surface-oxidized multiwall carbon nanotubes. J Am Chem Soc 137(8):2901–2907

Tian J, Liu Q, Asiri AM, Alamry KA, Sun X (2014) Ultrathin graphitic C3N4 nanosheets/graphene composites: efficient organic electrocatalyst for oxygen evolution reaction. ChemSusChem 7(8):2125–2130

Mao S, Wen Z, Huang T, Hou Y, Chen J (2014) High-performance bi-functional electrocatalysts of 3D crumpled graphene–cobalt oxide nanohybrids for oxygen reduction and evolution reactions. Energy Environ Sci 7(2):609–616

Liang Y, Li Y, Wang H, Dai H (2013b) Strongly coupled inorganic/nanocarbon hybrid materials for advanced electrocatalysis. J Am Chem Soc 135(6):2013–2036

Liu Q, Jin J, Zhang J (2013) NiCo2S4@graphene as a bifunctional electrocatalyst for oxygen reduction and evolution reactions. ACS Appl Mater Interfaces 5(11):5002–5008

Li J, Tang S, Lu L, Zeng HC (2007) Preparation of nanocomposites of metals, metal oxides, and carbon nanotubes via self-assembly. J Am Chem Soc 129(30):9401–9409

Wu J, Xue Y, Yan X, Yan W, Cheng Q, Xie Y (2012) Co3O4 nanocrystals on single-walled carbon nanotubes as a highly efficient oxygen-evolving catalyst. Nano Res 5(8):521–530

Sasan K, Kong A, Wang Y, Chengyu M, Zhai Q, Feng P (2015) From hemoglobin to porous N–S–Fe-doped carbon for efficient oxygen electroreduction. J Phys Chem C 119(24):13545–13550

Tian T, Ai L, Jiang J (2015) Metal–organic framework-derived nickel phosphides as efficient electrocatalysts toward sustainable hydrogen generation from water splitting. RSC Adv 5(14):10290–10295

Wu R, Zhang J, Shi Y, Liu D, Zhang B (2015) Metallic WO2-carbon mesoporous nanowires as highly efficient electrocatalysts for hydrogen evolution reaction. J Am Chem Soc 137(22):6983–6986

Liang J, Jiao Y, Jaroniec M, Qiao SZ (2012) Sulfur and nitrogen dual-doped mesoporous graphene electrocatalyst for oxygen reduction with synergistically enhanced performance. Angew Chem Int Ed 51(46):11496–11500

Liang J, Du X, Gibson C, Du XW, Qiao SZ (2013a) N-doped graphene natively grown on hierarchical ordered porous carbon for enhanced oxygen reduction. Adv Mater 25(43):6226–6231

Chen S, Duan J, Jaroniec M, Qiao SZ (2014) Nitrogen and oxygen dual-doped carbon hydrogel film as a substrate-free electrode for highly efficient oxygen evolution reaction. Adv Mater 26(18):2925–2930

Kumar S, Dhar DN, Saxena PN (2009) Application of Schiff bases complexes of Schiff bases—a review. J Sci Ind Res 68(3):181–187

Bushra Begum A, Rekha ND, Vasantha Kumar BC, Lakshmi Ranganatha V, Khanum SA (2014) Synthesis, characterization, biological and catalytic applications of transition metal complexes derived from Schiff base. Bioorg Med Chem Lett 24(25):3559–3564

Abram U, Ortner K, Gust R, Sommer K (2000) Gold complexes with thiosemicarbazones: reactions of bi- and tridentate thiosemicarbazones with dichloro[2-(dimethylaminomethyl)phenyl-C 1,N ]gold(III), [Au(damp-C 1,N )Cl2]. Dalton Trans 5:735–744

Meng ZY, Peng YY, Yu WC, Qian YT (2002) Solvothermal synthesis and phase control of nickel sulfides with different morphologies. Mater Chem Phys 74(2):230–233

Zhang HT, Wu G, Chen XH (2005) Synthesis and magnetic properties of NiS1 + x nanocrystallines. Mater Lett 59(28):3728–3731

Chen N, Zhang WQ, Yu WC, Qian YT (2002) Synthesis of nanocrystalline NiS with different morphologies. Mater Lett 55(4):230–233

Xiao M, Zhu J, Feng L, Liu C, Xing W (2015) Meso/macroporous nitrogen-doped carbon architectures with iron carbide encapsulated in graphitic layers as an efficient and robust catalyst for the oxygen reduction reaction in both acidic and alkaline solutions. Adv Mater 27(15):2521–2527

Feng LL, Yu G, Wu Y, Li GD, Li H, Sun Y, Asefa T, Chen W, Zou X (2015) High-index faceted Ni3S2 nanosheet arrays as highly active and ultrastable electrocatalysts for water splitting. J Am Chem Soc 137(44):14023–14026

Cheng NY, Liu Q, Tian JQ, Sun XP, He YQ, Zhai SY, Asiri AM (2015) Nickel oxide nanosheets array grown on carbon cloth as a high-performance three-dimensional oxygen evolution electrode. Int J Hydrog Energy 40(32):9866–9871

Wang J, Li K, Zhong HX, Xu D, Wang ZL, Jiang Z, Wu ZJ, Zhang XB (2015) Synergistic effect between metal-nitrogen-carbon sheets and NiO nanoparticles for enhanced electrochemical water-oxidation performance. Angew Chem Int Ed 54(36):10530–10534

Duan J, Chen S, Jaroniec M, Qiao SZ (2015) Porous C3N4 nanolayers@N-graphene films as catalyst electrodes for highly efficient hydrogen evolution. ACS Nano 9(1):931–940

Da Silva LaDF LM, Boodts JFC (2001) Determination of the morphology factor of oxide layers. Electrochim Acta 47(3):395–403

Mccrory CC, Jung S, Peters JC, Jaramillo TF (2013) Benchmarking heterogeneous electrocatalysts for the oxygen evolution reaction. J Am Chem Soc 135(45):16977–16987

Yang DS, Bhattacharjya D, Inamdar S, Park J, Yu JS (2012) Phosphorus-doped ordered mesoporous carbons with different lengths as efficient metal-free electrocatalysts for oxygen reduction reaction in alkaline media. J Am Chem Soc 134(39):16127–16130

Acknowledgments

This work was supported by Bingtuan Innovation Team in Key Areas (2015BD003), Open Project for Key Laboratory of Materials-Oriented Chemical Engineering of Xinjiang Uygur Autonomous Region (2015BTRC004), and General Project for Natural Science and Technology of Shihezi University (ZRKXYB-02).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 746 kb)

Rights and permissions

About this article

Cite this article

Gao, M., Yang, L., Dai, B. et al. A novel Ni-Schiff base complex derived electrocatalyst for oxygen evolution reaction. J Solid State Electrochem 20, 2737–2747 (2016). https://doi.org/10.1007/s10008-016-3279-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3279-3