Abstract

We report a novel, highly sensitive, and selective non-enzymatic glucose sensor fabricated by electrodepositing Cu microdendrites onto single-walled carbon nanohorn (SWCNH)-modified glassy carbon electrode. This sensor combined the advantages of SWCNHs and Cu microdendrites and exhibited high electrocatalytic activity toward glucose in 0.2 mol L−1 NaOH alkaline solution. Cyclic voltammetry and amperometric current-time curve were used to investigate the performance of the glucose sensor. We also optimize its preparation and test conditions. At an applied potential of 0.35 V, the oxidation peak current of glucose was good proportional to glucose concentration in the range from 0.04 to 12.6 mmol L−1 with a detection limit of 17 μmol L−1 (S/N = 3). In addition, the sensor showed long-term stability and good reproducibility and can resist the interference of coexistent species efficiently.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, diabetes has attracted widespread attention and become a public health problem that does not allow to be ignored. As we all know, glucose is a kind of simple sugars distributed in nature widely. It is the major source of energy of living organisms and closely associated with metabolism. Thus, it is important to maintain blood glucose level in a reasonable range for human health, too high or too low both causing a series of diseases. The glucose content in normal human body is 3–8 mmol L−1 [1]. High blood glucose level can lead to diabetes and other complications such as heart diseases, kidney failure, and blindness [2, 3]. On the contrary, it can make people dizzy, weak, and insensible when the blood glucose level is too low. Glucose is widely used in the fields of biology, clinical diagnosis, environment, and food analysis. A close monitoring of glucose concentration in human blood plays a significant role in the diagnosis, treatment and control of disease. At present, there are several methods proposed for the determination of glucose [4], including high-performance liquid chromatography [5], gas chromatography, spectrophotometry, optical techniques [6], capacitive detection [7], coulometric measurement [8] and amperometric method [9, 10], etc. Among these strategies, the amperometric method has aroused people’s great interest because of its unique advantages, such as high sensitivity, good selectivity, and low detection limit. Amperometric glucose biosensors can be divided into two types according to whether it uses glucose oxidase or not. Electrochemical biosensors based on glucose oxidase have the characteristics of high specificity and fast response. However, the catalytic activity of glucose oxidase can be easily affected by temperature, humidity, pH value, and toxic chemicals [11–13]. In addition, glucose oxidase sensor is restricted in practical applications because of its high cost, poor stability, and easy poisoning. Therefore, it is essential to develop good stability and high selective and sensitive non-enzymatic electrochemical sensor for glucose determination.

Traditionally, bulky bare metal electrode was used to prepare non-enzymatic glucose sensor, such as platinum, gold, copper, and nickel. But it was restricted in applications because of its low sensitivity and poor selectivity. Nagy et al. reported a Cu electrode and studied electrochemical oxidation of the as-prepared electrode towards glucose in alkaline solution [14]. In recent years, some nanomaterials with catalytic properties were widely used in the preparation of non-enzymatic glucose sensors [15]. The nanomaterials used to build non-enzymatic glucose sensor mainly include carbon nanotubes, transition metal nanoparticles, nanocomposite materials, and magnetic nanomaterials. Carbon nanotubes possess excellent advantages of high mechanical strength and good conductivity and stability, and their surface can be functionalized. However, some impurities are introduced inevitably, because metal catalyst is used during the production of carbon nanotubes [16]. So, it must be disposed by concentrated acid before use in order to remove these metal particles, but the procedure is complicated and the mechanical, electronic properties or chemical activity of carbon nanotubes may be damaged [17]. In 1999, Iijima reported a new type of carbon nanomaterial that is single-walled carbon nanohorns (SWCNHs) [18]. SWCNHs are produced without using any metal catalyst with a high purity of about 95 % and can be used directly without purification. Also, SWCNHs possess good electrical conductivity, great specific surface area, and internal spaces. Due to these unique performances, SWCNHs are used broadly in various fields since they arose, especially in the field of sensor. According to literatures, the electrochemical sensors based on SWCNHs have detected a variety of substrates [19–22]. SWCNHs loaded with metal nanoparticles can catalyze many chemical reactions originating from the synergistic effect of SWCNHs and metal nanoparticles. Recently, dendritic materials receive significant attention in catalysis and technological fields [23].

Herein, we report a simple method to fabricate non-enzymatic glucose biosensor-combined SWCNHs and Cu microdendrites. SWCNHs were first dropped on the surface of glassy carbon electrode. And then, Cu microdendrites were electrodeposited on the above electrode by potentiostatic technique. The Cu/SWCNH-modified electrode shows high electrocatalytic activity to glucose oxidation in alkaline solution, and it exhibits the advantages of wide linear range, good stability, and high selectivity for glucose detection.

Experimental

Materials

Single-walled carbon nanohorns (SWCNHs, dahlia-like) were generously provided by Professor Zujin Shi in the Nanocarbon Materials Chemistry Group of Peking University (China). Dopamine hydrochloride and Nafion were purchased from Sigma-Aldrich (China). Uric acid was obtained from Sangon Biotechnology Co. Ltd. (China). l-Cysteine, Cu(NO3)2, and NaOH were purchased from Tianjin Bodi Chemical Co., Ltd (China), Tianjin Hongyan Chemical Reagent Company (China), and Tianjin Beifang Tianyi Chemical Reagent Factory (China), separately. All other chemicals of analytical grade such as glucose, ascorbic acid, ethanol, and KCl were supplied by Sinopharm Chemical Reagent Co., Ltd. (China) without further purification. Deionized water was used throughout the experiments.

Instruments

Electrochemical experiments were performed on a CHI760D electrochemical workstation (Shanghai Chenhua, China) in a conventional three-electrode cell. A saturated calomel electrode (SCE) and a Pt wire were used as reference and counter electrode, respectively. The working electrode was a bare glassy carbon electrode (GCE, 3 mm diameter) or the modified glassy carbon electrode. Cyclic voltammetric measurements were carried out under static condition, while amperometric i-t curve measurements need stir to make molecule spread evenly. All experiments were performed in NaOH solutions at room temperature. Scanning electron microscopy (SEM) images were recorded with a Hitachi S-3400N (Japan). X-ray diffraction (XRD) was collected using an X’Pert Pro diffractometer (PANalytical Co., Holland) using Cu Kα radiation.

Preparation of oxidized SWCNHs

The oxidized SWCNHs were synthesized as our previous report [24]. Typically, 40 mg SWCNHs was first dispersed in 50 mL 30 % H2O2 aqueous solution. Then, the mixture was stirred at 100 °C and irradiated with an ultraviolet lamp for 2 h finally. To obtain 2 mg mL−1 SWCNHs suspension, 4.0 mg oxidized SWCNHs were dispersed in 2 mL deionized water and sonicated for 30 min. After treated with H2O2 aqueous solution, the dispersibility of SWCNHs was improved.

Fabrication of Nafion/Cu/SWCNH-modified electrode

Prior to modification, the GCE was polished successively with 1.0, 0.3, and 0.05 μm alumina slurry to obtain a clean surface. After each polishing step, the electrode was rinsed with deionized water and sonicated in deionized water and ethanol alternately for three times. The processed electrode was dried with N2 for the following usage. A 6 μL of SWCNHs suspension was dropped on the surface of the glassy carbon electrode and dried at room temperature to obtain a SWCNH-modified GCE electrode. Then, potentiostatic technique was used to fabricate Cu/SWCNH-modified electrode: a constant potential of −0.35 V was applied to the SWCNH-modified electrode in a solution of 50 mmol L−1 Cu(NO3)2 for 15 min. In the end, 3 μL of 0.5 wt% Nafion was spread on the surface of modified GCE electrode. So, the Nafion/Cu/SWCNHs/GCE-modified electrode was prepared and stored at room temperature when not being in use.

Results and discussion

Morphological characterization and crystallographic analysis

The surface morphology of the prepared Cu/SWCNHs/GCE was studied by means of SEM. Figure 1a displays the SEM image of Cu/SWCNHs/GCE. A layer of three-dimensional hierarchical dendritic Cu microstructures could be observed. The SWCNH layer is crucial for the formation of the dendritic structure. The SWCNH layer as a preformed matrix can adjust the morphology of Cu deposits in the process of electrochemical deposition. The obtained Cu microdendrites were further characterized by XRD experiment to confirm the crystal structures (Fig. 1b). The peaks are located at 43.5, 50.5, and 74.2°, which are indexed to the cubic Cu crystal planes of (111), (200), and (220), respectively [23]. Particularly, the intensity ratio (2.3) of the (111) to the (200) diffraction line indicates that the deposited cupreous microstructure has the tendency to grow with the surfaces dominated by the lowest energy (111) facets. And no impurities could be detected in this pattern.

Voltammetric characterization

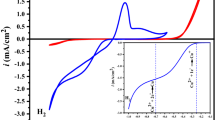

The response of modified electrode to glucose was investigated using cyclic voltammetry. Figure 2 shows the cyclic voltammograms (CVs) of (a) bare GCE, (b) Cu/GCE, (c) Nafion/Cu/SWCNHs/GCE, and (d) Cu/SWCNHs/GCE in 0.2 mol L−1 NaOH solution containing 5 mmol L−1 glucose with the scan rate of 50 mV s−1. As can be seen from CV a, there was no obvious oxidation peak at bare GCE, indicating that no glucose was oxidized in the potential range of 0.0–0.6 V because of high oxidation overpotential. However, an obvious oxidation peak appeared at 0.47 V at Cu/GCE and the peak current was 0.8 mA (CV b); this suggests that Cu can catalyze the oxidation of glucose. Cu can transfer electrons quickly and reduce the oxidation overpotential of glucose observably in alkaline medium. Although there is no definite conclusion about the oxidation mechanism, people generally believe that it is related to the Cu(II)/Cu(III) redox couple [25–28]. When Cu/SWCNHs/GCE was used as working electrode as shown in CV d, the oxidation peak was at 0.42 V and the peak potential was 50 mV negative compared to Cu/GCE. This may attribute to good electrical conductivity of SWCNHs. And the peak current increased to 1.3 mA, which was over 1.6-fold enhancement of that at Cu/GCE. It was because the hyperbranched structures greatly enlarged the surface coverage of the electrode and hence increased the amount of effective reaction sites, which reflected the synergistic effect of Cu microdendrites and SWCNHs. Nafion is a kind of cation exchanger with sulfonic group and is widely used in the modification of electrode surface to enhance the stability because of its unique good dispersity, biological compatibility, the ability of ion exchange, and molecule recognition. Meanwhile, it can also improve the selectivity of electrode in the detection of glucose [29]. The oxidation peak current at Nafion/Cu/SWCNHs/GCE decreased compared to that at Cu/SWCNHs/GCE, which is shown in Fig. 2 CV c, and it is due to Nafion film blocking the electron transfer on the surface of electrode.

Under the same experimental conditions, the Nafion/Cu/SWCNHs/GCE shows remarkable response to the concentration changes of glucose (Fig. S1). As seen, the oxidation peak current increased linearly with increasing glucose concentration. Therefore, glucose is effectively detected by oxidation on the Nafion/Cu/SWCNHs/GCE.

Cyclic voltammograms of Nafion/Cu/SWCNHs/GCE in 0.2 mol L−1 NaOH containing 5 mmol L−1 glucose at different scan rates (from 10 to 80 mV s−1) were recorded in Fig. 3. Figure 3a shows that the oxidation peak current was increased and the peak potential was shifted slightly towards the positive direction with the scan rate increasing. Furthermore, as can be seen from Fig. 3b, the peak current of glucose oxidation was proportional to the square root of scan rate between 10 and 80 mV s−1. The linear regression equation was I p (mA) = 7.9108ν 1/2 − 0.3704 (V1/2 s−1/2), and its correlation coefficient was 0.998, indicating a diffusion-controlled electrode process in the electrochemical oxidation of glucose [30].

Optimization of glucose sensor

SWCNHs act as the carrier of Cu microdendrites, so their amount can affect the morphology of the Cu deposits and the oxidation peak current of glucose at the modified electrode. The thickness of SWCNHs can be controlled by the volume of SWCNHs suspension dropped on the electrode surface. Figure 4 shows the amperometric responses of Nafion/Cu/SWCNH-modified electrodes with different quantity of SWCNHs (3 to 6 μL) to glucose oxidation in 0.1 mol L−1 NaOH containing 5 mmol L−1 glucose. The oxidation peak current of glucose first increased and then decreased with increasing volume of SWCNH suspension, and 6 μL was the optimal volume. In the range of 3 to 6 μL, the current response increased gradually, because SWCNHs increased the surface area of electrode and more active sites could catalyze the oxidation of glucose. When the volume of SWCNH suspension was over 6 μL, the oxidation peak current decreased continuously; this was because the SWCNHs on the electrode surface had reached saturation, and excess SWCNHs would increase the thickness of membrane layer and hinder electron transfer.

The catalytic performance of Cu microstructures for the oxidation of glucose is affected by their size and morphology [12, 23, 31]. Deposition time can control the amounts of Cu deposits being deposited onto electrode surface, varying the morphology of modified electrode. We investigated the electrochemical behavior of prepared modified electrode with different deposition time between 5 and 30 min towards glucose; the results are shown in Fig. 5. The oxidation peak current of glucose increased when the deposition time extended from 5 to 15 min. The surface density of Cu microdendrites increased with the extension of deposition time, which made more effective reaction site catalyze glucose oxidation, so the current response increased. However, when the deposition time was over 15 min, the peak current decreased with increasing deposition time. This may result from the extension of the deposition time which could thicken the Cu film and damage the hierarchical dendritic Cu microstructures. Thus, the amount of reaction active sites decreased and hence decreased the oxidation current. Thus, it can be seen that 15 min was the optimal deposition time of Cu microdendrites. The deposition process was characterized by SEM (Fig. S2).

Like deposition time, deposition potential can also affect the size and morphology of Cu microstructures being deposited onto electrode surface, and its selection is related to overpotential. Deposition potential of Cu microstructures has important influence on the current response of Nafion/Cu/SWCNH-modified electrode for glucose detection [23]. Figure 6 shows the change of the oxidation peak current of modified electrode in 0.1 mol L−1 NaOH solution containing 5 mmol L−1 glucose when the deposition potential was between −0.55 and −0.15 V. With increasing the deposition potential from −0.55 to −0.35 V, the oxidation peak current of glucose increased and reached a maximum at −0.35 V; then, the current response decreased observably. Cu microstructures are easier to be deposited under a more negative potential, so more Cu microstructures can catalyze glucose oxidation. But if the deposition potential was too negative, the oxidation peak current of glucose decreased; this may attribute to deposition potential that changed the surface morphology of Cu microstructures and lowered the catalytic efficiency. Thus, −0.35 V was selected as the optimal potential to deposit Cu microstructures.

According to literatures [4, 13], the electrocatalytic oxidation of Cu microstructures towards glucose must be performed in alkaline medium. Glucose molecule is more easily absorbed on the surface of electrode in the presence of OH−, and it can reduce the activation energy of glucose oxidation [32]. Dependence of the glucose sensor performance on the hydroxide concentration was studied in a series of NaOH solutions of different concentrations between 0.05 and 0.30 mol L−1, as shown in Fig. 7. With the increase of NaOH concentration, the oxidation peak current of glucose increased gradually because glucose is more easily to be oxidized in higher pH value [25] and the current response of modified electrode was up to maximum in 0.2 mol L−1 NaOH solution. Then, the concentration of NaOH solution continued to increase from 0.2 to 0.3 mol L−1; the current response decreased; this may be due to some other substances that react with electrode materials and hinder glucose reaction [33]. So, 0.2 mol L−1 NaOH solution was chosen as the reaction medium in the subsequent experiments.

Applied potential can affect the amperometric response of the modified electrode to detect glucose significantly [4]. In order to improve the electroanalysis performance of the glucose sensor, we investigated the impact of applied potential on the current response. Figure 8 shows that the response signal of glucose oxidation increased with the applied potential increasing, but the noise signal also increased at the same time. When the applied potential was 0.35 V, the current response was larger with a good signal/noise ratio. In addition, some substances which were stable under low potential may react under high potential and affect the determination result. Considering the above factors, we chose 0.35 V as the applied potential of amperometric current-time curve to detect glucose.

Amperometric response of the sensor towards glucose

Under the optimized experimental conditions, amperometric current-time curve was used to study the amperometric response of non-enzymatic sensor towards glucose. Figure 9a displays the current-time curve of Nafion/Cu/SWCNHs/GCE in 0.2 mol L−1 NaOH solution with successive addition of glucose. The current response increased rapidly with the addition of glucose and reached a stable value within 4 s, attributing to high electron transfer efficiency on electrode surface. The oxidation peak current of glucose showed a good linear relationship with its concentration in the range of 0.04–12.6 mmol L−1, and the linear regression equation was I (mA) = 0.0066 + 0.0148c (mmol L−1) with a correlation coefficient of 0.996 (Fig. 9b). The analytical performance of our proposed Nafion/Cu/SWCNH sensor is comparable to or better than that of other non-enzymatic glucose sensors. The linear calibration range is larger than carbon nanotube paste electrode (0.7–3.5 mmol L−1) [34]. CuO nanorod electrode (0.004–8 mmol L−1) [35] and copper nanocubes modified multi-wall carbon nanotube (MWCNT) array electrode (up to 7.5 mmol L−1) [12]. From calibration curve, the detection limit of 17 μmol L−1 was obtained (S/N = 3), which is lower than that of 50 μmol L−1 at bimetallic PtM (M = Ru, Pd, and Au)-carbon nanotube-ionic liquid composite film-modified electrode [36], 160 μmol L−1 at NiO/MWCNT-modified electrode [37]. Large specific surface area of modified electrode makes more active sites absorb more glucose molecule to be oxidized [12], resulting in a wide linear range. Due to the content of glucose in normal blood which is between 3.0 and 8.0 mmol L−1, this non-enzymatic glucose sensor is expected to be applied to detect glucose in human serum samples.

Selectivity, reproducibility, and stability

The ability of discrimination determinand and interfering species is an important indicator to evaluate the performance of sensor. Some oxidizable compounds such as uric acid, ascorbic acid, dopamine, l-cysteine, and other carbohydrate compounds such as lactose, fructose, and sucrose may coexist with glucose in actual samples and affect the determination of glucose. We studied the interference effect of 0.1 mmol L−1 interfering species on the response of 1 mmol L−1 glucose in 0.2 mol L−1 NaOH solution. As shown in Fig. 10, there was no obvious current response for uric acid, ascorbic acid, dopamine, l-cysteine, α-lactose, d-fructose, and sucrose; thus, we think that their interferences can be ignored, proving a good selectivity of this glucose sensor. The Nafion membrane on modified electrode surface was negatively charged, repelling anion in solution because of electrostatic interaction, and it can penetrate certain electroactive substances selectively. So, Nafion can effectively eliminate the interference of anion, improving the selectivity of modified electrodes [38].

The reproducibility and stability of the proposed sensor were also investigated by measuring the current response of 5 mmol L−1 glucose in 0.2 mol L−1 NaOH solution. A relative standard deviation of 0.6 % was obtained for 11 successive measurements using the same modified electrode, indicating a good repeatability. We use the same procedure to modify the same glassy carbon electrode repeatedly, and the 11 sensors showed a good reducibility with a relative standard deviation of 2.7 % to test 5 mmol L−1 glucose. Compared to its initial measurement, the current response of the glucose only decreased 6 % after stored at room temperature for a month, which revealed that the sensor has long-term stability.

Real sample analysis

To illustrate the feasibility of the Nafion/Cu/SWCNHs/GCE in practical analysis, it was applied to detect glucose in human serum utilizing the standard addition method. The sample from one donor was diluted 50-fold by 0.2 mol L−1 NaOH to ensure that the glucose concentration falls in the working range of the calibration curve. The results are given in Table 1. The result corresponded well with the value of 4.8 mmol L−1 measured by the spectrophotometric method in the hospital. The results validate the potential of the Nafion/Cu/SWCNHs/GCE to be used for routine blood glucose sensing.

Conclusion

In this paper, we proposed a novel non-enzymatic glucose electrochemistry sensor using a constant potential technology to electrodeposit Cu microdendrites onto SWCNH-modified electrode and Nafion as stabilizer. The sensor combined the characters of SWCNHs and Cu microdendrites and showed good electrocatalysis towards glucose oxidation in alkaline medium, overcoming the disadvantage of enzyme instability and easy inactivation. Cyclic voltammetry and amperometric i-t curve measurements showed that the non-enzymatic glucose sensor has the attractive features of wide linear range, low detection limit, high selectivity, and good stability and reproducibility. Additionally, the Nafion/Cu/SWCNHs/GCE can also be used as an amperometric biosensor for the routine analysis of glucose in human serum sample.

References

Bai Y, Sun YY, Sun CQ (2008) Biosens Bioelectron 24:579–585

Park S, Park S, Jeong RA, Boo H, Park J, Kim HC, Chung TD (2012) Biosens Bioelectron 31:284–291

Li F, Feng Y, Yang LM, Li L, Tang CF, Tang B (2011) Biosens Bioelectron 26:2489–2494

Lu LM, Zhang XB, Shen GL, Yu RQ (2012) Anal Chim Acta 715:99–104

Bouchard J, Chornet E, Overend RP (1988) J Agric Food Chem 36:1188–1192

Barone PW, Parker RS, Strano MS (2005) Anal Chem 77:7556–7562

Cheng ZL, Wang EK, Yang XR (2001) Biosens Bioelectron 16:179–185

Morris NA, Cardosi MF, Birch BJ, Turner APF (1992) Electroanalysis 4:1–9

Huang FY, Wang F, Feng SQ, Li Y, Li SX, Li YC (2013) J Solid State Electrochem 17:1295–1301

Lee SR, Lee YT, Sawada K, Takao H, Ishida M (2008) Biosens Bioelectron 24:410–414

Wilson R, Turner APF (1992) Biosens Bioelectron 7:165–185

Yang J, Zhang WD, Gunasekaran S (2010) Biosens Bioelectron 26:279–284

Wu HX, Cao WM, Li Y, Liu G, Wen Y, Yang HF, Yang SP (2010) Electrochim Acta 55:3734–3740

Nagy L, Nagy G, Hajos P (2001) Sens Actuators B 76:494–499

Park S, Boo H, Chung TD (2006) Anal Chim Acta 556:46–57

Ma YW, Hu Z, Huo KF, Lu YN, Hu YM, Liu Y, Hu JH, Chen Y (2005) Carbon 43:1667–1672

Zhu SY, Xu GB (2010) Nanoscale 2:2538–2549

Iijima S, Yudasaka M, Yamada R, Bandow S, Suenaga K, Kokai F, Takahashi K (1999) Chem Phys Lett 309:165–170

Wen D, Deng L, Zhou M, Guo SJ, Shang L, Xu GB, Dong SJ (2010) Biosens Bioelectron 25:1544–1547

Shi LH, Liu XQ, Niu WX, Li HJ, Han S, Chen J, Xu GB (2009) Biosens Bioelectron 24:1159–1163

Zhu SY, Li HJ, Niu WX, Xu GB (2009) Biosens Bioelectron 25:940–943

Zhu SY, Niu WX, Li HJ, Han S, Xu GB (2009) Talanta 79:1441–1445

Chen DJ, Lu YH, Wang AJ, Feng JJ, Huo TT, Dong WJ (2012) J Solid State Electrochem 16:1313–1321

Li J, He YJ, He Z, Zeng P, Xu SK (2012) Anal Biochem 428:4–6

Kang XH, Mai ZB, Zou XY, Cai PX, Mo JY (2007) Anal Biochem 363:143–150

Zhuang ZJ, Su XD, Yuan HY, Sun Q, Xiao D, Choi MMF (2008) Analyst 133:126–132

Farrell ST, Breslin CB (2004) Electrochim Acta 49:4497–4503

Wang J, Chen G, Wang M, Chatrathi MP (2004) Analyst 129:512–515

Wang J, Musameh M, Lin YH (2003) J Am Chem Soc 125:2408–2409

Zhao G, Feng JJ, Zhang QL, Li SP, Chen HY (2005) Chem Mater 17:3154–3159

Luo J, Zhang HY, Jiang SS, Jiang JQ, Liu XY (2012) Microchim Acta 177:485–490

Adzic RR, Hsiao MW, Yeager EB (1989) J Electroanal Chem 260:475–485

Yang J, Jiang LC, Zhang WD, Gunasekaran S (2010) Talanta 82:25–33

Valentini F, Amine A, Orlanducci S, Terranova ML, Palleschi G (2003) Anal Chem 75:5413–5421

Wang X, Hu CG, Liu H, Du GJ, He XS, Xi Y (2009) Sens Actuators B 144:220–225

Xiao F, Zhao FQ, Mei DP, Mo ZR, Zeng BZ (2009) Biosens Bioelectron 24:3481–3486

Shamsipur M, Najafi M, Hosseini MRM (2010) Bioelectrochemistry 77:120–124

Liu XQ, Shi LH, Niu WX, Li HJ, Xu GB (2008) Biosens Bioelectron 23:1887–1890

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities (N130405004, N110805001) and the Science and Technology Projects of Liaoning Province (2011225003, 2010220003-1).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 1354 kb)

Rights and permissions

About this article

Cite this article

Zhao, S., Wang, T., Wang, L. et al. A non-enzymatic glucose amperometric biosensor based on a simple one-step electrodeposition of Cu microdendrites onto single-walled carbon nanohorn-modified electrode. J Solid State Electrochem 19, 831–839 (2015). https://doi.org/10.1007/s10008-014-2688-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2688-4