Abstract

Halophilic archaea offer a potential source for production of polyhydroxyalkanoates (PHAs). Hence, the experiments were carried out with five extremely halophilic archaeal isolates to determine the highest PHA-producing strain. PHA production of each isolates was separately examined in cheap carbon sources such as corn starch, sucrose, whey, apple, melon and tomato wastes. Corn starch was found to be a fairly effective substrate for PHA production. Among the strains studied here, the strain with the highest capability for PHA biosynthesis was found to be 1KYS1. Phylogenetic analysis based on 16S rRNA gene sequence comparison showed that 1KYS1 closely related to species of the genus Natrinema. The closest phylogenetic similarity was with the strain of Natrinema pallidum JCM 8980 (99 %). PHA content of 1KYS1 was about 53.14 % of the cell dry weight when starch was used as a carbon source. The formation of large and uniform PHA granules was confirmed by transmission electron microscopy and the biopolymer was identified as poly(3-hydroxybutyrate-co-hydroxyvalerate) (PHBV). PHBV produced by 1KYS1 was blended with low molar mass polyethylene glycol (PEG 300) to prepare biocompatible films for drug delivery. Rifampicin was used as a model drug and its release from PHBV films was investigated at pH 7.4, 37 °C. It was found that PHBV films obtained from 1KYS1 were very effective for drug delivery. In conclusion, PHBV of 1KYS1 may have a potential usage in drug delivery applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biodegradable polymers such as polyhydroxyalkanoates (PHA) have attracted enormous attention due to expanding range of potential applications and have been proposed as a solution for the waste problem (Luengo et al. 2003). Biodegradable poly(3-hydroxybutyrate) (PHB) and its copolymers with 3-hydroxyvalerate (PHBV) are the best known members of the PHAs (Bonartsev et al. 2007). PHAs are produced intracellularly and stored as carbon and energy reservoir by several bacteria. This cell inclusion, found in the cell cytoplasm, is mobile, amorphous, liquid granule allowing microbial survival under stress conditions usually when cellular growth is restricted by the lack of nutrients and in the presence of excess carbon source (Rodriguez-Valera and Lillo 1992).

PHB and PHBV are synthesized by numerous microorganisms including extremely halophilic Archaea (Grant et al. 2001; Quillaguamán et al. 2005; Verlinden et al. 2007). These microorganisms which belong to the family Halobacteriaceae are aerobic heterotrophic organisms that require at least 12 % (w/v) NaCl for growth in most cases (Lillo and Rodriguez-Valera 1990). They inhabit natural environments containing high salt concentrations, e.g., salt lakes, salt mines, crystallizer ponds of solar salterns or artificial habitats such as salted fish, vegetables, meat and hides (Rodriguez-Valera et al. 1983; Anderson and Dawes 1990; Oren 1994; Birbir et al. 2004).

PHB has been usually studied as a model product in the development of fermentation strategies (Lee 1996; Choi and Lee 1999). Although PHB exhibits physical properties that resemble those of widely used synthetic polymers such as polyethylene and polypropylene (Vroman and Tighzert 2009), its usage is limited by the high production cost. Therefore, many studies have focused on the reduction of production costs by using inexpensive carbon sources and/or developing more economical fermentation and separation processes (Koller et al. 2007). Also, since PHB is highly crystalline, when used in controlled release devices poor (inhomogeneous) distribution of drugs within its structure may occur. Its low degradation rate in the absence of hydrolytic enzymes is another disadvantage (Gursel et al. 2002). However, when the copolymers containing hydroxyvalerate are used, the crystallinity of material decreases and its degradability increases (Gursel and Hasirci 1995). Furthermore, since PHBV copolymers are more amorphous than the homopolymer PHB, it is expected to show decreased resistance to the diffusing drug molecules which results in enhanced release rates when compared with those from PHB (Hasirci 2000).

Industrial production of PHA is currently achieved by using recombinant Escherichia coli (Reddy et al. 2003), but recent research has shown that halophiles also have a great potential to produce PHA (Quillaguamán et al. 2010). It has been stated that several haloarchaeal species in the genera Haloferax and Haloarcula may synthesize PHA from cheap sources and isolation of PHA from these extremely halophilic Archaea is easier than that of Bacteria (Koller et al. 2007, 2008; Lu et al. 2008). Due to the increasing demand for biodegradable PHA such as PHBV, the potential strain, substrate and optimum conditions must be investigated for a high-yield production. Thus, the production of PHA by fermentation of agricultural waste products with low-cost and high-energy carbon sources is promising (Huang et al. 2006).

As far as we are aware, production of PHA by the extremely halophilic archaeal isolates, obtained from Tuzkoy salt mine, Tuz lake and its saltern of Kayacik, in cheap substrates such as corn starch, sucrose, whey, apple, melon and tomato wastes has not been reported. Therefore, the goal of this study was to determine the highest PHA-producing isolate obtained from Turkish salt sources in cheap substrates. Synthesis of PHA by the highest PHA-producing strain was confirmed by transmission electron microscope (TEM) analysis and the biopolymer was characterized as PHBV using FTIR and 1HNMR. A model drug, rifampicin (RIF), was introduced into PHBV, and then, this mixture was plasticized with PEG300 to form PHBV films. Later, drug-loading and drug-releasing characteristics of these prepared PHBV films were further investigated by Fourier transform infrared (FTIR) and UV–Vis spectroscopies.

Materials and methods

Test Isolates

2KYS1, 3TL4, 5TL6 (Birbir et al. 2007), 1TK1 (Birbir et al. 2004) and a novel isolate 1KYS1 were obtained from salt lake (TL), Tuzkoy Salt Mine (TK) and Kayacik saltern (KYS), respectively. All test isolates were maintained at 4 °C on Brown agar medium containing 250 g NaCl, 2.0 g MgSO4∙7H2O, 2.0 g KCl, 3.0 g C6H5Na3O7∙5H2O, 5 g yeast extract and 2 g agar per liter (Brown 1963; Vreeland 1993).

Shake flask cultivations of isolates for production of PHA

Extremely halophilic archaeal isolates were separately inoculated into 1 L liquid Brown medium. Then, these cultures were incubated in a shaking incubator (120 rpm) at 39 °C for 10 days. After the incubation period, 15 mL of the culture broth was transferred into a 100 mL of basal minimal medium containing 0.375 g/L KH2PO4, 0.2 g/L NH4Cl, 0.00838 g/L FeCl3∙6H2O, 250 g/L NaCl and 20 g/L only one carbon source (corn starch, sucrose, whey, apple, melon or tomato wastes) with pH 7.5 (Lillo and Rodriguez-Valera 1990). Later, these culture media were incubated at 39 °C in a shaking incubator (120 rpm). Maximum turbidity was determined by measuring the optical density of the samples at 550 nm at the end of 10 days of incubation time.

Isolation and quantitative analysis of PHA

Archaeal isolates containing PHA were harvested from 100 mL of the culture broth by centrifuging at 10,000×g for 10 min, washed once with sterile water, and finally resuspended in water and dried at 40 °C for 24 h until constant weight was obtained. Archaeal cells were suspended in 5 mL of 0.2 % (w/v) sodium hypochloride for 1.5–2 h at 37 °C to allow the total lysis of the suspension. PHA granules were collected by centrifugation (2,000×g, 10 min) (Lillo and Rodriguez-Valera 1990). Each pellet was washed with distilled water, acetone and finally 96 % ethanol and the final pellet was dissolved in hot chloroform. After the chloroform had been evaporated, the residue was hydrolyzed and dehydrogenated with concentrated sulfuric acid to obtain crotonic acid, which can be quantified by its absorbance at 235 nm (Law and Slepecky 1961; Lillo and Rodriguez-Valera 1990). Samples were analyzed in duplicates from shake flasks, and the standard curve was drawn by using PHA obtained. Residual cell mass concentration was calculated as the difference between the cell concentration and PHA concentration, while PHA content was calculated as the ratio of PHA concentration to cell concentration according to the definition by Lee et al. (1994). PHA isolated from 1KYS1 was characterized by FTIR and 1HNMR analysis.

Phenotypic characterization of 1KYS1

Biochemical tests of 1KYS1

The phenotypic characterization of 1KYS1 was performed according to the recommendations of the proposed minimal standards for describing new taxa in the order Halobacteriales (Oren et al. 1997). The morphology of colonies, their size and pigmentation were examined on the Brown agar medium after 4 weeks of incubation at 39 °C (Brown 1963; Vreeland 1993). Cell morphology and motility of exponentially growing liquid culture of 1KYS1 were examined on freshly prepared wet mounts by light microscopy. Gram staining was performed by using acetic acid-fixed samples as described by Dussault (1955). Growth rates at different salt concentrations were examined by using Brown medium prepared with 0, 3, 5, 10, 15 and 25 % (w/v) NaCl (Arahal et al. 1996). The pH tolerance range for the isolate was examined in Brown medium adjusted to pH values of 4.5, 6.0, 7.0 and 7.5. 1KYS1 for the various biochemical tests was prepared by growing the isolate in Brown medium at 39 °C for 7 days. The optimum ionic content (per liter: 20 g of MgSO4∙7H2O, 2 g of KCl, 250 g of NaCl) was added to all biochemical test media (Birbir et al. 2004). All biochemical tests of the isolate were carried out at 25 % NaCl and 39 °C. Oxidase, catalase, β-galactosidase and DNase activities, indole production and methyl red experiments were conducted by using standard procedures (Gonzalez et al. 1978; Quesada et al. 1982). 1KYS1 was tested for the degradation of gelatin, casein, starch, cellulose and Tween 80 by standard methods (Gonzalez et al. 1978; Quesada et al. 1982; Bailey and Birbir 1993) using 2 % (w/v) gelatin, 1 % (w/v) casein, 1 % (w/v) soluble starch, 0.2 % (w/v) carboxymethylcellulose and 0.1 % (w/v) Tween 80, respectively. Peptone broth was used to detect conversion of organic nitrogen to ammonia by the isolate (Birbir et al. 2007; Ogan et al. 2012).

Antibiotic susceptibility test

Antibiotic susceptibility of 1KYS1 was examined by spreading the archaeal suspensions (108 CFU/mL) on plates containing Brown medium and applying antibiotic disks of bacitracin (10 U), cefadroxil (30 µg), novobiocin (5 µg), penicillin G (10 U), spiramycin (100 µg) and streptomycin (25 µg). The results were recorded as susceptible or resistant after 14 days of incubation at 40 °C (Benola et al. 1984; Birbir et al. 2004).

DNA extraction and PCR amplification

Nucleic acid extraction was performed using Bio 101 FastDNA® SPIN kit (Q-BIOgene) (Aktan et al. 2012). Samples were agitated in a 2-mL screw-capped microcentrifuge tube using a FastPrep-24 bead-beating system (Bio 101) set at maximum speed for 45 s. The amount and purity of DNA was estimated using Quant-iT™ PicoGreen® dsDNA reagent kit (Molecular Probes) according to the manufacturer’s protocol with a few modifications. Fluorescence was measured with the Lightcycler Instrument (Roche, Mannheim, Germany). For calibration, a serial dilution of lambda DNA standard ranging from 50 to 2000 ng/mL was prepared with TE buffer. After DNA extraction, partial 16S rDNA fragments were amplified for the cloning experiments with 16S rDNA primers [Ar109f (ACK GCT CAG TAA CAC GT) and Ar915r (GTG CTC CCC CGC CAA TTC CT)].

The PCR amplification reaction was performed in a Progene thermocycler (Techne, Cambridge, UK) and the following program was used: pre-denaturation (95 °C, 5 min), 35 cycles of denaturation (95 °C, 60 s), annealing (56 °C, 90 s), elongation (72 °C, 90 s) and post-elongation (72 °C, 10 min). The reactions were subsequently cooled to 4 °C. Amplifications were performed in accordance with the manufacturer’s recommendations by using 0.5 µM of each primer, 1.5 U of Taq DNA polymerase (MBI Fermentas), 1× PCR buffer, 1.5 mM MgCl2, and 1.25 mM of each dNTP. The template DNA was diluted 10× in order to obtain possible PCR-inhibiting compounds and obtain suitable PCR amplicons (Aktan et al. 2012).

Cloning and sequencing analysis

The phylogenetic analysis was achieved by the purification of PCR products of partial 16S rRNA genes by using the QIAquick PCR purification kit (Qiagen) prior to cloning. Then, the purified amplicons were cloned in EZ competent cells with the Qiagen PCR Cloning plus kit (Qiagen) with ampicillin selection and blue/white screening following the manufacturer’s protocol. White colonies were picked up from each cloned sample and reamplified. Before DNA sequencing, the plasmids of selected transformants were purified using the Fermentas PCR purification kit. DNA sequences were analyzed in Iontek Laboratories (Istanbul, Turkey). Afterward, with the derived partial 16S rRNA sequences from the clones, a similarity search was performed in the GenBank database using the BLAST search program of the National Center for Biotechnology Information sequence search service (http://www.ncbi.nlm.nih.gov). Sequences were analyzed using Chromas-Pro software (Technelysium Pty Ltd., Eden Prairie, MN) and aligned by the multiple alignment Clustal W2 program. Phylogenetic trees were constructed with the neighbor-joining method using molecular evolutionary genetics analysis package (MEGA version 2.1). The robustness of the phylogeny was tested by bootstrap analysis with 1,000 iterations (Aktan et al. 2012).

Characterization of PHB from 1KYS1

The 1H nuclear magnetic resonance (NMR) spectrum of obtained PHA was recorded at 500 MHz with a Bruker Avance III Spectrometer at room temperature using deuterated chloroform as internal reference solvent. The FTIR spectrum was recorded on a PerkinElmer spectrum 100 ATR–FTIR spectrophotometer.

Transmission electron microscope (TEM) analysis

Among the isolates, 1KYS1 cells displaying the maximum PHA content were separated by centrifugation at 4000×g for 10 min and fixed for 4 h at room temperature in a solution of 4 % (v/v). The cells were then rinsed with 100 mM phosphate buffer (pH 7.4) and followed by an overnight treatment in 3.5 % osmium tetroxide solution at 4 °C for 30 min and subsequently transferred to 3.5 % uranyl acetate solution for 30 min at 4 °C (Quillaguamán et al. 2006). Later, the cells were rinsed with 2 % acetic acid solution for 5 min to remove the salts. The cells were dehydrated through a graded series of ethanol–water solutions with a final treatment in propylene oxide, and embedded into an epon/araldite resin that was then cut with a diamond knife. The fine sections of 50 nm were placed on formvar-coated copper grids, contrasted with a 2 % aqueous solution of uranyl acetate and examined under a JEOL Jem-1011 transmission electron microscope (JEOL, Massachusetts, USA) (Tian et al. 2005; Han et al. 2007; Van-Thuoc et al. 2012).

Preparation of drug-loaded PHBV films

Among the isolates tested, 1KYS1 produced the maximum amount of PHA, and therefore, this isolate was selected and used for production of PHBV films. Isolated PHBV from 1 L culture of 1KYS1, the plasticizer PEG300 and the model drug, RIF, were dissolved in chloroform at a ratio of 100:10:25, respectively. Homogeneous mixtures were then poured into cylinder-shaped Teflon® molds and left to cure at room temperature overnight (Savenkova et al. 2000).

Fourier transform infrared spectroscopy (FTIR) and release studies

FTIR spectra of pure drug and drug-loaded films were recorded on PerkinElmer Spectrum 100 ATR–FTIR spectrophotometer. Biofilms were dried before FTIR analysis. The conditions of analysis were as follows; resolution 2 cm−1 and a frequency range of 400–4000 cm−1 (Hong et al. 1999).

RIF-loaded PHBV film was suspended in a glass vessel containing 10 mL of phosphate buffer (pH 7.4) and incubated on a shaking water bath at 37 °C. At appropriate time intervals, 3 mL of the solutions were withdrawn and the amount of RIF released from the drug-loaded films were evaluated by using the Helios Zeta UV–Vis spectrophotometer (Thermo Scientific, Waltham, MA, USA) at 334 nm. RIF concentration was calculated according to a calibration curve obtained from standard RIF solutions at different concentrations (Kassab et al. 1997; Gursel et al. 2002).

Results and discussion

Effect of carbon sources on the PHA production

In the present study, the effects of corn starch, whey, melon, apple and tomato wastes and sucrose as carbon source were evaluated on PHA production. Dry weights, PHA concentrations in g/L and percentage of PHA yields of isolates are shown in Table 1.

It was found that corn starch positively affected PHA production than all the isolates. Among the tested isolates, 1KYS1 was found to be the highest PHA-producing strain. This isolate accumulated 53.14 % PHA the cell dry weight (CDW) when corn starch was used as a carbon source. As shown in Table 1, PHA yield of isolates 5TL6 and 1TK1 was also comparably high, 41.38 and 47.69 %, respectively. These strains are able to produce high levels of PHA while utilizing whey as their primary source. Due to its low cost and abundance in nature, use of corn starch as a carbon source is an important advantage compared with other sugars such as glucose and sucrose (Rodriguez-Valera and Lillo 1992). Although all carbon sources tested were used by the isolates for PHA production and cell growth, isolates that grew in the media containing sucrose produced the lowest amount of PHA (Table 1). This may be due to the low intake of the sucrose by the isolates. When 2 g/L starch was used as carbon source, maximum yield of PHA for H. mediterranei was reported by Lillo and Rodriguez-Valera (1990).

It was shown that H. mediterranei accumulated 50 wt % of PHA from whey-containing culture media (Koller et al. 2008). Recently, researchers studied the usage of vegetable wastes as growth media of extremophilic microorganisms for producing biopolymers and found that biomass fermentation provides a cheaper way (Di Donato et al. 2011).

The Haloterrigena hispanica strain FP1 cells grown on carrot wastes as sole carbon source were able to produce a comparable amount of PHB (0.13 % of CDW) with respect to that produced when the growth was carried out on complex standard media (0.14 % of CDW) and thus suggesting an alternative and low environmental impacting method for vegetable wastes management (Poli et al. 2011).

Phenotypic characterization of 1KYS1

1KYS1 was Gram negative and non-motile. It was able to grow in media containing 10–25 % NaCl (w/v) and optimally in medium containing 25 % (w/v) NaCl. The isolate did not grow in the absence of NaCl and Brown medium containing 3 and 5 % NaCl. According to salt requirement for growth and antibiotic test results, this isolate can be considered as an extremely halophilic archaea. Other phenotypic features of 1KYS1 are presented in Table 2.

Characterization of PHBV from 1KYS1

The structure and mole fractions of HB and HV units in the copolyester samples were investigated by the 500 MHz 1HNMR spectra recorded at 27 °C in a CDCl3 solution of polyester and are given in Fig. 1a. 1HNMR (CDCl3, 500 MHz): δ (ppm): 0.78–0.83 (m, –CH3), 1.20–1.24 (m, –CH3), 1.56 (m, –CH2), 2.32–2.61 (m, –CH2), 5.18–5.23 (m, –CH), 7.20 (s, –CHCl3). The 1HNMR spectral data of the PHA obtained by cultivating 1KYS1 in 2 % corn starch matched with the 1HNMR spectrum of PHBV acquired by Bloembergen and Holden (1986). The copolymer composition, expressed as the mole percent P-hydroxyvalerate, is a ratio of peak areas due to the HV methyl resonance and the sum of the HB and HV methyl resonances. Compositions were determined by integration of the fully expanded spectra of the two methyl resonances of HB and HV units and found to be containing approximately 25 mol % HV Bloembergen and Holden (1986).

FTIR composition analysis of sample was performed in chloroform and results are given in Fig. 1b. The IR spectrum of PHBV produced by 1KYS1, when grown on 2 % corn starch, was similar to that previously reported (Cai et al. 2013; Bloembergen and Holden 1986). From the chemical structure of PHBV, peaks in IR spectrum should be assigned as: 2943, 2926, 2854 cm−1, CH2, CH3 stretching mode; 1721 cm−1, C=O stretching vibration; 1453 cm−1, CH2 scissoring; 1379 cm−1, CH3 symmetric scissoring; 1276 and 1227 cm−1, –CH2 wagging, 1300–1000 cm−1, C–O–C stretching mode and 979 cm−1, CH2 in-plane bending mode.

Antibiotic susceptibility test

1KYS1 was sensitive to bacitracin (10 U) and novobiocin (5 µg), but resistant to cefadroxil (30 µg), penicillin G (10 U), spiramycin (100 µg) and streptomycin (25 µg).

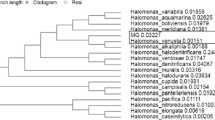

The phylogenetic analysis

The phylogenetic analysis, based on the neighbor-joining method, revealed that strain 1KYS1 was placed into genus Natrinema. The closest phylogenetic similarity was with the strains of Natrinema pallidum JCM 8980 (99 %). The phylogenetic tree constructed using the 16S rRNA gene sequences is given in Fig. 2. The phylogenetic analysis of other strains has been previously reported by us (Birbir et al. 2004, 2007).

The microorganisms used for industrial production of PHA are generally pathogenic bacteria (Poli et al. 2011). Industrial production of PHB has been achieved by using genetically engineered Escherichia coli which accumulates 90 % PHB of its dry weight (Lee et al. 1994). Studies on halophiles have shown a remarkable potential for biotechnological production of PHA, especially PHBV, with certain advantages (Margesin and Schinner 2001; Koller et al. 2008; Quillaguamán et al. 2010). These organisms grow on media containing high salt concentrations, and under these conditions very few organisms can survive; therefore, the requirement for sterilization is greatly reduced (Poli et al. 2011). It has been stated that the genera Haloferax, Haloarcula, Natrialba, Haloterrigena, Halococcus, Haloquadratum, Halorubrum, Natronobacterium, Natronococcus and Halobacterium are capable of synthesizing PHA (Poli et al. 2011).

Haloferax mediterranei is so far the best PHBV producer of family Halobacteriaceae. This species is able to accumulate up to 55 wt % PHA with respect to its CDW using starch or glucose as carbon source grown under phosphorous-limited conditions (Quillaguamán et al. 2010). The species that belong to genus Natrinema are promising PHA producers. In another study, it was shown that 18 strains from 12 genera in the family of Halobacteriacea could synthesize PHB and PHBV with the levels ranging from 5.4 to 22.9 % of CDW (Han et al. 2010). It was noteworthy that 1KYS1 which was closely similar to species of Natrinema pallidum JCM 8980 (99 %) can be a potential PHBV producer with 53.14 % CDW.

Transmission electron micrograph analysis

As shown in Fig. 3, TEM of 1KYS1 revealed that most of the PHA granules were localized at or close to the cytoplasmic membrane. As seen in the micrograph images, most of the PHA granules synthesized by 1KYS1 isolate are spherical in shape and its boundary is clearly seen. However, ovoid- and elongated-shaped granules can also be observed in the same cell. The formation of large and uniform PHA granules is suggested to be advantageous for the purification and quality of the polymer (Steinbüchel et al. 1995).

Preparation of drug-loaded PHBV films

Since PHB is a hydrophobic polymer, its biodegradation in PBS at pH 7.4 and 37 °C is very slow (Bonartsev et al. 2007). Slow degradation rate of PHB avoids sepsis caused by rapid degradation as a result of acidic product accumulation and decrease in pH. Therefore, its usage is preferred compared with other biodegradable polymers (Gursel et al. 2002). In our study, PEG300 usage was especially regarded due to its strengthening effect on the mechanical properties of PHBV which is of more brittle nature by itself (Chan et al. 2011).

The FTIR spectra of neat PHBV, RIF and RIF-loaded PHBV films are given in Fig. 4. In the FTIR spectrum of PHBV, the peak at 1721 cm−1 is due to the characteristic ester carbonyl stretching vibrations. The peaks at around 2926 and 2854 cm−1 are related to the aliphatic –CH2 groups. In the FTIR spectrum of the drug-loaded PHBV film, the peaks that belong to RIF is not observed due to its low content in the formulation. However, it can be seen that the characteristic ester carbonyl of the PHBV in the drug-loaded films shifted to 1723 cm−1, which might suggest an interaction between PHBV and RIF.

The amount of RIF released from the drug-loaded films was evaluated at 334 nm by UV–Vis spectrophotometer. The drug-release profile of RIF from PHBV films is shown in Fig. 5. Within 2 h, 17 % of drug was released which could be attributed to the loosely held drug molecules on the surface. Then, the rate of RIF release from the PHBV films slowed down. The drug release was sustained for 10 days. This might be due to the occurrence of microcracks on the surface of PHBV with time. This effect caused the slow diffusion of the drug from the PHBV film, and the release rate of the entrapped drug inside the bulk polymer slowed down after the initial burst of release. In a study of Kassab et al. (1997), RIF release from PHB microspheres were considerably high where almost the entire initial drug was released within 24 h. However, the PHBV films prepared in our study by blending PHBV and PEG300 had a release duration of over 10 days. The number of drug administrations required during the medical treatments can be reduced, and the effectiveness of the drug therapy can be improved by the PHBV films prepared.

Conclusion

PHBV can be synthesized by a variety of nonpathogenic haloarcheal species which avoid the risk of microbial contamination during cultivation. Corn starch positively affected PHBV production when compared with other carbon sources. Finally, our results suggest that 1KYS1 may be a good candidate for the production of PHBV. The use of highly biocompatible PHBV produced by the extremely halophilic archaea with minimum sterility demands is an attractive option for the development of therapeutic systems of sustained drug delivery.

References

Aktan CK, Yapsakli K, Mertoglu B (2012) Inhibitory effects of free ammonia on Anammox bacteria. Biodegradation 23:751–762

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Arahal DR, Dewhirst FE, Paster BJ, Volcani BE, Ventosa A (1996) Phylogenetic analyses of some extremely halophilic archae isolated from dead sea water. Determined on the basis of their 16S rRNA sequences. Appl Environ Microbiol 62:3779–3786

Bailey M, Birbir DG (1993) A study of the extremely halophilic microorganisms found on commercially brine-cured cattle hides. J Am Leather Chem Assoc 88:285–293

Benola G, Ventosa A, Megias M, Berraquero F (1984) The sensitivity of Halobacteria to antibiotics. FEMS Microbiol Lett 21:341–345

Birbir M, Ogan A, Calli B, Mertoglu B (2004) Enzyme characteristics of extremely halophilic archaeal community in Tuzkoy Salt Mine, Turkey. World J Microb Biot 20:613–621

Birbir M, Calli B, Mertoglu B, Bardavid RE, Oren A, Ogmen MN, Ogan A (2007) Extremely halophilic Archaea from Tuz Lake, Turkey, and the adjacent Kaldirim and Kayacik salterns. W J Microb Biotech 23:309–316

Bloembergen S, Holden DA (1986) Studies of composition and crystallinity of bacterial poly(β-hydroxybutyrate-co-β-hydroxyvalerate). Macromolecules 19:2865–2871

Bonartsev AP, Myshkina VL, Nikolaeva DA, Furina EK, Makhina TA, Livshits VA, Boskhomdzhiev AP, Ivanov EA, Iordanskii AL, Bonartseva GA (2007) Biosynthesis, biodegradation, and application of poly(3-hydroxybutyrate) and its copolymers—natural polyesters produced by diazotrophic bacteria. In: Mendez-Villas A (ed) Communicating current research and educational topics and trends in applied microbiology, 2007th edn. Formatex, Spain, pp 295–307

Brown AD (1963) The peripheral structures of Gram-negative bacteria. IV. The cation-sensitive dissolution of the cell membrane of the halophilic bacterium Halobacterium halobium. Biochim Biophys Acta 75:425–435

Cai Y, Lv J, Feng J (2013) Spectral characterization of four kinds of biodegradable plastics: poly (lactic acid), poly (butylenes adipate-co-terephthalate), poly (hydroxybutyrate-co-hydroxyvalerate) and poly (butylenes succinate) with FTIR and raman spectroscopy. J Polym Environ 21:108–114

Chan RTH, Marcal H, Russel RA, Holden PJ, Foster LJR (2011) Application of polyethylene glycol to promote cellular biocompatibility of polyhydroxybutyrate films. Int J Polymer Sci 2011:1–9

Choi J, Lee SY (1999) Efficient and economical recovery of poly(3-hydroxybutyrate) from recombinant Escherichia coli by simple digestion with chemicals. Biotechnol Bioeng 62:546–553

Di Donato P, Fiorentino G, Anzelmo G, Tommonaro G, Nicolaus B, Poli A (2011) Re-use of vegetable wastes as cheap substrates for extremophile biomass production. Waste Biomass Valor 2:103–111

Dussault HP (1955) An improved technique for staining red halophilic bacteria. J Bacteriol 70:484–485

Gonzalez C, Gutierrez C, Ramirez C (1978) Halobacterium vallismortis sp. nov. An amylolytic and carbohydrate-metabolizing, extremely halophilic bacterium. Can J Microbiol 24:710–715

Grant WD, Kamekura M, McGenity TJ, Ventosa A (2001) Order Halobacteriales. In: Boone DR, Castenholz RW, Garrity GM (eds) Bergey’s manual of systematic bacteriology, 2nd edn. Springer, New York, pp 294–334

Gursel I, Hasirci V (1995) Properties and drug release behavior of PHB and various PHBV copolymer microcapsules. J Microencapsul 12:185–193

Gursel I, Yagmurlu F, Korkusuz F, Hasırcı V (2002) In vitro antibiotic release from poly(3-hydroxybutyrate-co-3-hydroxyvalerate) rods. J Microencapsul 19:153–164

Han J, lu Q, Zhou L, Zhou J, Xiang H (2007) Molecular characterization of the phaECHm genes, required for biosynthesis of poly(3-hydroxybutyrate) in the extremely halophilic archaeon Haloarcula marismortui. Appl Environ Microbiol 73:6058-6065

Han J, Hou J, Liu H, Cai S, Feng B, Zhou J, Xiang H (2010) Wide distribution among halophilic archaea of a novel polyhydroxyalkanoate synthase subtype with homology to bacterial type III synthases. Appl Environ Microbiol 76:7811–7819

Hasirci V (2000) Biodegradable biomedical polymers: a review of degradation of and in vivo response to polylactides and polyhydroxyalkanoates. In: Wise DL (ed) Biomaterials and bioengineering handbook Marcel Dekker Inc, New York, pp 141–155

Hong K, Sun S, Tian W, Chen GQ, Huang W (1999) A rapid method for detecting bacterial polyhydroxyalkanoates in intact cells by Fourier transform infrared spectroscopy. Appl Microbiol Biotechnol 51:523–526

Huang TY, Duan KJ, Huang SY, Chen CW (2006) Production of polyhydroxyalkanoates from inexpensive extruded rice bran and starch by Haloferax mediterranei. J Ind Microbiol Biotechnol 33:701–706

Kassab AC, Xu K, Denkbas EB, Dou Y, Zhao S, Piskin E (1997) Rifampicin carrying polyhydroxybutyrate as a potential chemoembolization agent. J Biomater Sci Polymer Edn 8:947–961

Koller M, Hesse P, Bona R, Kutschera C, Atlic A, Braunegg G (2007) Potential of various archae- and eubacterial strains as industrial polyhydroxyalkanoate producers from whey. Macromol Biosci 7:218–226

Koller M, Altic A, Gonzales-Garcia Y, Kutschera C, Braunegg G (2008) Polyhydroxyalkanoate (PHA) biosynthesis from whey lactose. Macromol Symp 272:87–92

Law JH, Slepecky RA (1961) Assay of poly-β-hydroxybutyric acid. J Bacteriol 82:33–36

Lee SY (1996) Bacterial polyhydroxyalkanoates. Biotechnol Bioeng 49:1–14

Lee SY, Yim KS, Chang HN, Chang YK (1994) Construction of plasmids, estimation of plasmid stability, and use of stable plasmids for the production of poly(3-hydroxybutyric acid) by recombinant Escherichia coli. J Biotechnol 32:203–211

Lillo JG, Rodriguez-Valera F (1990) Effects of culture conditions on poly(β-hydroxybutyric acid) production by Haloferax mediterranei. Appl Environ Microbiol 56:2517–2521

Lu Q, Han J, Zhou L, Zhou J, Xiang H (2008) Genetic and biochemical characterization of the poly(3-hydroxybutyrate-co-3-hydroxyvalerate) synthase in Haloferax mediterranei. J Bacteriol 190:4173–4180

Luengo J, Garcia B, Sandoval A, Naharro G, Oliver E (2003) Bioplastics from microorganisms. Current Opin Biotechnol 6:51–260

Margesin R, Schinner F (2001) Potential of halotolerant and halophilic microorganisms for biotechnology. Extremophiles 5:13–83

Ogan A, Danis O, Gozuacik A, Cakmar E, Birbir M (2012) Production of cellulase by immobilized whole cells of Haloarcula. Appl Biochem Microbiol 48:440–443

Oren A (1994) Characterization of the halophilic archaeal community in saltern crystallizer ponds by means of polar lipid analysis. Int J Salt Lake Res 3:15–29

Oren A, Ventosa A, Grant WD (1997) Proposed minimal standards for description of new taxa in the order Halobacteriales. Int J Syst Bacteriol 47:233–238

Poli A, Di Donato P, Abbamondi GR, Nicolaus B (2011) Synthesis, production, and biotechnological applications of exopolysaccharides and polyhydroxyalkanoates by archaea. Archaea 2011:1–13

Quesada E, Ventosa A, Valera FR, Cormenzana AR (1982) Types and properties of some bacteria isolated from hypersaline soils. J Appl Bacteriol 53:155–161

Quillaguamán J, Hashim S, Bento F, Mattiasson B, Hatti-Kaul R (2005) Poly(β-hydroxybutyrate) production by a moderate halophile, Halomonas boliviensis LC1 using starch hydrolysate as substrate. J Appl Microbiol 99:151–157

Quillaguamán J, Delgado O, Mattiasson B, Hatti-Kaul R (2006) Poly(β-hydroxybutyrate) production by a moderate halophile, Halomonas boliviensis LC1. Enzyme Microb Tech 38:148–154

Quillaguamán J, Guzmán H, Van-Thuoc D, Hatti-Kau R (2010) Synthesis and production of polyhydroxyalkanoates by halophiles: current potential and future prospects. Appl Microbiol Biotechnol 85:1687–1696

Reddy CSK, Ghai R, Kalia VC (2003) Polyhydroxyalkanoates: an overview. Bioresour Technol 87:137–149

Rodriguez-Valera F, Lillo AG (1992) Halobacteria as producers of polyhydroxyalkanoates. FEMS Microbiol Rev 103:181–186

Rodriguez-Valera F, Juez G, Kushner DJ (1983) Halobacterium mediterranei spec. nov., a new carbohydrate-utilizing extreme halophile. Syst Appl Microbiol 4:369–381

Savenkova L, Gercberga Z, Nikolaeva V, Dzene A, Bibers I, Kalnin M (2000) Mechanical properties and biodegradation characteristics of PHB-based films. Process Biochem 35:573–579

Steinbüchel A, Aerts K, Babel W, Folner C, Leibergesell M, Wieczorek R (1995) Considerations on the structure and biochemistry of bacterial polyhydroxyalkanoic acid inclusions. Can J Microbiol 41(Suppl. 1):94–105

Tian J, He A, Lawrence AG, Liu P, Watson N, Sinskey AJ, Stubble J (2005) Analysis of transient polyhydroxybutyrate production in Wautersia eutropha H16 by quantitative Western Analysis and transmission electron microscopy. J Bacteriol 187:3825–3832

Van-Thuoc D, Huu-Phong T, Thi-Binh N, Thi-Tho N, Minh-Lam D, Quillaguamán J (2012) Polyester production by halophilic and halotolerant bacterial strains obtained from mangrove soil samples located in Northern Vietnam. Microbiologyopen 1:395–406

Verlinden RAJ, Hill DJ, Kenward MA, Williams CD, Radecka I (2007) Bacterial synthesis of biodegradable polyhydroxyalkanoates. J Appl Microbiol 102:1437–1449

Vreeland RH (1993) Taxonomy of Halophilic Bacteria. In: Vreeland RH, Hochstein LI (eds) The biology of halophilic bacteria. CRS Press, Baco Raton, pp 115–134

Vroman I, Tighzert L (2009) Biodegradable polymers. Materials 2:307–344

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by A. Driessen.

Rights and permissions

About this article

Cite this article

Danis, O., Ogan, A., Tatlican, P. et al. Preparation of poly(3-hydroxybutyrate-co-hydroxyvalerate) films from halophilic archaea and their potential use in drug delivery. Extremophiles 19, 515–524 (2015). https://doi.org/10.1007/s00792-015-0735-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00792-015-0735-4