Abstract

Objectives

This study investigated the antibacterial, cytotoxicity, and mechanical properties of a dental adhesive modified with quaternary ammonium monomer ((2-acryloyloxyethyl)dimethyldodecylammonium bromide) and cross-linker (bis(2-acryloyloxyethyl)methyldodecylammonium bromide).

Materials and methods

Monomer (M), cross-linker (C), or a combination of these (M + C) were incorporated into adhesive Adper Single Bond Plus (SB) in 5, 10, or 25% (as wt%). A colony-forming unit and MTT assays were used to evaluate antibacterial properties against Streptococcus mutans and cell viability. Resin-dentin beams (0.9 ± 0.1 mm2) were evaluated for micro-tensile bond strength (μTBS) after 24 h, 6 months, and 3 years. Hourglass specimens were evaluated for ultimate tensile strength (UTS) after 24 h, 1 week, and 6 months. Micro-hardness measurements after softening in ethanol were taken as an indirect assessment of the polymer cross-linking density. Kruskal-Wallis, one-way ANOVA, two-way ANOVA, and Student’s t test were used for analysis of the antibacterial, cytotoxicity, μTBS, UTS, and hardness data, all with a significance level of p < 0.05.

Results

10%M and 25%M demonstrated a significant reduction in S. mutans relative to SB (p < 0.001). No differences in cytotoxicity were detected for any of the groups. After 6 months, no changes in μTBS were shown for any of the groups. After 3 years, all groups evidenced a significant decrease in μTBS (p < 0.05) except 5%M, 5%C, and 5%M + 5%C. All groups demonstrated either stable or significantly increased UTS after 6 months. Except for the cross-linker groups, a significant decrease in micro-hardness was shown for all groups after softening in ethanol (p < 0.05).

Conclusions

A 5–10% of monomer may render the resin antibacterial without a compromise to its mechanical and bonding properties.

Clinical relevance

Biomodification of a resin adhesive with an antibacterial monomer and cross-linker may help improve the life span of adhesive restorations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dental caries is a pandemic disease affecting millions of people. According to the Center for Disease Control and Prevention, in 2015, 91% of Americans over twenty had dental caries at some point [1]. Despite the popularity of tooth-colored restorations, their limited longevity remains an issue. Compared with amalgams, resin restorations are more prone to plaque accumulation and micro-leakage around the margins, providing a pathway for acid-producing bacteria to dissolve tooth substrates [2,3,4]. Resins have thus a greater replacement rate than amalgams, with recurrent caries representing the primary reason for replacement [5]. Several strategies have been proposed to overcome this issue with limited success. Modification of resin biomaterials with antibacterial compounds has been the focus of research for many groups. Released agents, such as fluoride, zinc, silver or antibiotics, iodine, chlorhexidine, and quaternary ammonium (QA) salts, have an effect that is mainly limited to their initial burst release [6,7,8,9]. Moreover, voids left in the cross-linked structure after elution of the agent may further compromise the material’s mechanical integrity [10, 11]. QA-containing polymers are probably the most extensively investigated biocides for a wide range of applications [12]. In recent years, considerable efforts have been made to improve their polymerization capacity by incorporation of one or more methacrylate functionalities. QA monomethacrylate monomers only undergo linear polymerization, whereas QA dimethacrylate monomers can also be used as cross-linking agents [13]. Immobilized agents such as QA dimethacrylate (QADM) [14] have been shown to provide long-lasting antibacterial benefits [7], but they lack strong and remote antibacterial action. Despite considerable research efforts in the field, the necessary balance between sustained antibacterial efficacy, without a compromise to other biomedical-relevant properties, is yet to be achieved.

In this study, we propose incorporating a monomer and cross-linker containing an antibacterial QA functionality [15, 16] into a commercially available dental adhesive. Their mechanism of action is by disruption of the bacterial cell membranes via their cationic quaternary amine group. QA-based monomers have been extensively investigated as antibacterial additives for dental materials [13]. In these studies, however, the presence of cross-linkers without QA groups was responsible for the material’s cross-linking. Several types of QA-based cross-linkers (QA dimethacrylate monomers) have also been reported and used for the fabrication of dental materials without the use of QA-based monomethacrylate monomers [12, 17,18,19,20,21,22]. In principle, the use of QA-based monomers, together with QA-based cross-linkers, may potentially endow the resulting dental materials with enhanced antibacterial performance and cross-linking-related properties, which may in turn result in a stronger hybridization with the underlying dentin. To the best of our knowledge, the combined copolymerization of the proposed antibacterial QA-containing monomer and cross-linker with resin monomers has not been studied. Such copolymerization is expected to provide sustained benefits to the material properties. The long-term antibacterial efficacy, along with an enhanced hybridization, is expected to render an interface with improved mechanical integrity and resistance to bacterial and enzymatic degradation. Evaluation of the antibacterial and cytotoxicity properties of the proposed structures, along with their tensile strength and adhesion to tooth structure, was investigated. Furthermore, since polymer cross-linking density is known to play a major role on properties such as fracture strength and wear resistance [23], hardness measurements of the polymerized resin after softening in ethanol were also investigated as an indirect assessment of the polymer cross-linking density. The null hypotheses investigated in this study were the following: (1) there would be no effect of the monomer and cross-linker on the antibacterial properties against S. mutans; (2) the additives would have no effect on the cytotoxicity, bonding, and mechanical properties of the parent adhesive.

Materials and methods

Synthesis of antibacterial monomer and cross-linker

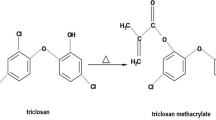

The chemical structures of the monomer and cross-linker are shown in Fig. 1. All reactants and solvents were obtained from Sigma-Aldrich, St. Louis, MO, USA. 1H NMR analysis was used to characterize the synthesized chemicals. 1H NMR spectra were recorded at 500 MHz on solutions in deuterated chloroform (CDCl3) on a Varian INOVA-500 Spectrometer at 25 °C, with tetramethylsilane (TMS) as an internal standard.

Schematic representation of the incorporation of monomer and cross-linker surfactants into the commercial adhesive single bond. Here, a monomer and cross-linker containing a quaternary amine group convey antibacterial characteristics to the functional surfactant. Blue light irradiation was applied for 20 s to induce radical polymerization. In the resulting copolymer product, the concentration of antibacterial quaternary amine group is determined by the sum of x and y; cross-linking density is determined by y; and the fraction of base dental materials gives z

The antibacterial monomer was prepared by quaternization reaction following a literature approach [24, 25]: 1H NMR: δ 0.88 (3H, CH3-CH2), 1.18–1.50 (18H, CH2), 1.76 (2H, CH2), 3.53 (6H, CH3-N+-CH3), 3.61 (2H, CH2-N+), 4.18 (2H, N+-CH2-CH2-O), 4.67 (2H, N+-CH2-CH2-O), 5.95 (1H, CH=CH2), 6.14 (1H, CH=CH2), 6.48 (1H, CH=CH2). The antibacterial cross-linker was prepared by two-step organic synthesis based on a literature method [24, 25]: 1H NMR: δ 0.88 (3H, CH3-CH2), 1.20–1.40 (18H, CH2), 1.78 (2H, CH2), 3.53 (3H, CH3-N+), 3.60 (2H, CH2-N+), 4.10–4.32 (4H, N+-CH2-CH2-O), 4.72 (4H, N+-CH2-CH2-O), 5.96 (2H, CH=CH2), 6.13 (2H, CH=CH2), 6.51 (2H, CH=CH2).

Incorporation of the antibacterial monomer and cross-linker into a dental adhesive

Experimental adhesives were prepared by measuring different weight concentrations of monomer, cross-linker, or a combination of both on a laboratory balance (AGCN 200, Fulcrum Inc., Clifton, NJ, USA) and incorporating them into a commercially available adhesive Adper Singe Bond Plus (SB, 3M ESPE, Saint Paul, MN, USA) (Fig. 1). Single bond is a two-step, ethanol-based, etch-and-rinse adhesive composed of bisphenol A diglycidyl ether dimethacrylate (BisGMA), silane-treated silica, 2-hydroxyethyl methacrylate (HEMA), 2-hydroxy-1,3-dimethacryloxypropane, copolymer of acrylic and itaconic acids, diurethane dimethacrylate (UDMA), water, and diphenyliodonium hexafluorophosphate. The following groups, with mass of added monomer (M) and/or cross-linker (C) relative to 1 mg of SB, were evaluated: (1) 0.05 mg M (5%M), (2) 0.1 mg M (10%M), (3) 0.25 mg M (25%M), (4) 0.05 mg C (5%C), (5) 0.1 mg C (10%C), (6) 0.25 mg C (25%C), (7) 0.05 mg M + 0.05 mg C (5%M + 5%C), (8) 0.1 mg M + 0.1 mg (10%M + 10%C). SB alone was used as a control. To ensure uniform dissolution of the mixture, an ultrasonic bath powered by a probe tip sonicator was used for 15 s in dark conditions to avoid undue photo-polymerization. All samples were prepared immediately before the start of each experiment and vortexed (Scientific Industries Inc., Bohemia, NY, USA) for 1 min prior to use to ensure appropriate dispersion.

Assessment of the antibacterial activity and cytotoxicity of the modified adhesives

Assessment of the antibacterial activity

Disc specimens of 8 × 1 mm were prepared by micro-pipetting the adhesive into a circumferential polytetrafluoroethylene (PTFE) mold against a polyester strip, which was placed on a microscope glass slab, covered with another strip and slab, and polymerized with LED unit (VALO, Ultradent, South Jordan, UT, USA) with a power density of 1,400 mW/cm2 for 10 s per manufacturer’s recommendations. The discs were then incubated in distilled water (DW) at 37 °C for 24 h to allow post-cure polymerization, and polished using silicon carbide abrasive papers of #1500 (SiC, Buehler, Lake Bluff, IL, USA) per reported protocols [26, 27]. This experiment was conducted following the International Organization for Standardization (ISO) standards for the testing of biomedical devices [28]. The discs were sterilized by immersion in 70% ethanol and allowed to dry at room temperature for 48 h. The selection of this chemical sterilization method followed the US FDA recommendations for extraction studies [29]. Streptococcus mutans ATCC 25175 (Gift from Dr. Stefan Ruhl, University at Buffalo) was streaked on a brain heart infusion (BHI) (Sigma-Aldrich, St Louis, MO, USA) agar and incubated in an anaerobic chamber at 37 °C. Five milliliters of BHI broth was inoculated with S. mutans and grown overnight anaerobically at 37 °C, followed by sub-cultured (0.5 ml culture in 5 ml BHI) and incubated for 4–6 h until the culture reached an OD600 reading of 0.3. A total of 100 μl of the culture was pipetted directly onto the surface of each disc in a sterile 24-well plate. In this method, the entire 100 μl volume remains on the disc surface, with no overflow or loss of media to the surrounding containment, such that all bacteria in the suspension remain in contact with the disc. One milliliter of DW was added next to each well containing a disc to provide a hydrated environment with anaerobic incubation for 18 h. Each disc was aseptically removed from the well, placed in 9.9 ml of BHI, and vortexed for 3 min to disperse any bacteria on the surface of the disc. The media was then serially diluted in 1:10 dilutions to obtain countable CFUs. All plates were then incubated in the anaerobic chamber at 37 °C for 24 h after which colonies were counted. The average colony-forming units (CFU) of three replicate experiments (n = 3, duplicate plates) were determined following exposure to the discs.

Assessment of the cell viability

Human gingival fibroblasts (HGFs) were isolated from discarded healthy gingival tissue collected from subjects undergoing surgery at the University at Buffalo clinics, using an explant outgrowth method (IRB protocol 663292-1). The tissue was washed in minimum essential media (MEM) containing 10X antibiotics followed by three washes in media containing 1X antibiotics. Tissues were minced into small pieces and allowed to attach to the wells of a 6-well plate for 30 min, followed by the addition of 1 ml of fresh MEM + 10% FBS with antibiotics. Explants were incubated at 37 °C, 5% CO2 until migration of cells from the tissue explant could be observed. Media were replaced every 3 days. To maintain routine culture, HGFs were grown to 80% confluence in MEM + 10% FBS and passaged using trypsin/EDTA. The 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) cell viability assay (Sigma-Aldrich, St Louis, MO, USA) was used to assess the cell metabolic function based on mitochondrial dehydrogenase activity. Three discs (5 × 2 mm) per group were fabricated per methods described in the “Assessment of the antibacterial activity” section, incubated for 24 h in DW at 37 °C, and sterilized in 70% ethanol prior to testing. The discs were incubated in 24-well plates in 1 ml of gingival fibroblast growth medium (alpha-MEM + 10% FBS + 1% antimycotic; pH 7.4; Gibco, Life Technologies, Grand Island, NY, USA) for 24 h. An additional group, containing gingival fibroblast medium only and no disc, was used as control whose survival rates were set to represent 100% viability. To prepare disc-conditioned media, three discs per group were incubated for 24 h in 350 μl of gingival fibroblast growth media per recommended ratio of specimen surface area to media volume [28]. The MTT assay was performed by aspirating the disc test media, followed by incubation of the HGFs with 100 μl of clear MEM and 10 μl MTT assay reagent (Invitrogen, Thermo Fischer Scientific, Eugene, OR, USA) for 4 h at 37 °C in 5% CO2. After removal of 75 μl of medium from the wells, 50 μl of DMSO was added to each well, mixed by pipetting, and allowed to incubate for 10 min after which the plate was measured at an absorbance of 540 nm (Flexstation 3, Molecular Devices, Sunnyvale, CA, USA). Groups were plated in triplicate (n = 3).

Assessment of the mechanical and bonding properties of the modified adhesives

Assessment of the micro-tensile bond strength

Dentin was obtained from thirty-six recently extracted, healthy human molars (IRB protocol no. 00000133). Four teeth were assigned to each of the study groups. Superficial occlusal dentin was revealed using a water-cooled lab trimmer (Whip Mix, Louisville, KY, USA), and a standardized smear layer created with SiC papers to 800-grit. All adhesives were applied and polymerized per manufacturer’s recommendations. Resin composite (Filtek Z100, 3M ESPE, Saint Paul, MN, USA) was applied in 2-mm increments and polymerized for 40 s. The teeth were incubated in DW at 37 °C for 24 h and then sectioned into beams of cross-sectional area of 0.9 ± 0.1 mm [30]. Forty beams per group were obtained, ten per tooth. A research design balanced by tooth dependency was used for this part of the investigation [31]; that is, beams derived from each tooth were equally assigned to one of three study periods (24 h, 6 months, and 3 years). At each time period, twenty beams (n = 20) were tested for μTBS. Additional beams were used to obtain representative SEM observations of the study groups. The individual beams were stabilized on a jig with cyanoacrylate (Zapit, Dental Ventures of America, Corona, CA, USA) and stressed to failure with a universal testing machine (Micro-tester, Bisco, Schaumburg, IL, USA) at a cross-head speed of 1 mm/min. The load required to fracture the specimen was expressed in megapascals (MPa). The rest of the beams were incubated in DW with the media replaced weekly. One-mm slabs were set aside for interfacial characterization with SEM (SU-70, Hitachi, Tokyo, Japan). The slabs were polished with SiC papers to 800-grit, allowed to dry for 24 h, placed on aluminum stubs, coated with carbon, and placed in a vacuum evaporator (Denton DV-502, Douglasville, PA, USA) for 20 min. Different areas of one slab were analyzed at 20 kV and images generated using backscattered electron mode.

Assessment of the ultimate tensile strength

Ten hourglass adhesive specimens per group (n = 10) were made using a rubber mold (10 mm long × 2 mm wide at neck × 1 mm deep). The adhesive was micro-pipetted into the mold, which was covered with a polyester strip and microscope glass slab and then polymerized with LED unit. All specimens were incubated in DW at 37 °C and evaluated for ultimate tensile strength (UTS) after 24 h, 1 week, or 6 months with a universal testing machine as described in the previous section and expressed in megapascals (MPa).

Assessment of the micro-hardness after softening in ethanol

It is generally accepted that highly cross-linked polymers are more resistant to degradation and solvent uptake, whereas linear polymers allow greater diffusion of solvent molecules within their structure [32]. This could result in increased softening, which can be assessed by a hardness test [33]. To determine the degradation in solvent, the specimens were subjected to softening in absolute ethanol per protocol by Leitune et al. [34]. Five discs (5 × 1 mm) were made for each experimental condition (n = 5) with a PTFE mold, which was sandwiched between two glass slabs as described in previous sections. After polymerization, the samples were incubated for 24 h in DW at 37 °C. The discs were then embedded in acrylic resin and polished with SiC discs to 1200-grit. The specimens were then allowed to dry for 24 h, and subjected to a Knoop micro-hardness test. Five indentations (50 g/15 s), one central and four radial approximately 100 μm apart, were recorded using a digital micro-hardness tester (HMV 2, Shimadzu, Tokyo, Japan), where the Knoop hardness number (KHN) = 14228 × c/d2, 14228 is a constant, c is the load in grams, and d is the length of the longer diagonal in μm. For each specimen, the initial KHN1 was recorded as the average of the five values. The specimens were then subjected to softening in absolute ethanol for 4 h at 37 °C, the test repeated, and recorded as KHN2. The difference between KHN1 and KHN2 in percent was calculated.

Statistical analysis

The normality of data was evaluated using the Kolmogorov-Smirnov test and equal variance with the Brown-Forsythe test. Antibacterial data was analyzed with a Kruskal-Wallis and Dunn’s post hoc test. The cytotoxicity data was first normalized and then analyzed with a one-way ANOVA and Tukey’s post hoc test. A two-way ANOVA and Tukey’s post hoc test were used for analysis of μTBS and UTS data. For analysis of the softening in ethanol, a paired Student’s t test (KHN1 and KHN2) was used. A significance level of p < 0.05 was used for all tests. All statistical analyses were performed with the statistical software (SigmaStat Version.3.5, San José, CA, USA).

Results

Assessment of the antibacterial activity and cytotoxicity of the modified adhesives

Assessment of the antibacterial activity

The mean log viable cell concentrations are summarized in Fig. 2. There was a significant effect of the treatment group on antibacterial activity against S. mutans (p < 0.001). No significant differences in log viable cell concentration were detected among any of the cross-linker groups or combined groups and the SB control. Of the monomer groups, only 10%M and 25%M demonstrated significantly lower log viable cell concentration than the SB control.

Assessment of the cell viability

Figure 3 summarizes the MTT assay results. There was no significant effect of the treatment group on cell viability, with no significant variations in cell viability values observed among any of the experimental groups and the SB control.

Assessment of the mechanical and bonding properties of the modified adhesives

Assessment of the micro-tensile bond strength

There was a significant effect of the treatment group (p < 0.001) and group × time interaction (p < 0.001), but no effect of time on μTBS values. No significant differences in bond strength values were detected among the experimental groups and the SB control when evaluated at 24 h or 6 months (Fig. 4). Evaluation of all the experimental groups against the control SB after 3 years of storage revealed no differences between any of the experimental groups and the control SB, except for 5%M, 5%C, and 5%M + 5%C, which evidenced significantly higher μTBS values relative to the control SB (p < 0.001). Assessment of the bond degradation for each individual group overtime revealed no significant degradation for any of the groups after 6 months. After 3 years, a significant decrease in mean μTBS values was observed for all groups including the control SB (p < 0.001). Only groups 5%M, 5%C, and 5%M + 5%C remained stable with no significant degradation after the 3-year period. Representative SEM images of the hybrid layer interfaces for the different treatment groups are provided in Fig. 5a–i.

Mean micro-tensile bond strength (μTBS) values for all study groups at 24 h and 6 months of incubation. Bars represent mean values; brackets indicate SD values. Groups identified by different letters are significantly different (Tukey’s test, p < 0.05). n = 20. Upper case denotes differences between 24 h and 6 months for each group. Lower case denotes differences among groups for each testing time

Scanning electron microscopy (SEM) representative micrographs of adhesives modified with monomer and cross-linking surfactant; magnification × 2.00 k. Monomer groups (0.05 mg M, 0.1 mg M, 0.25 mg M), cross-linker groups (0.05 mg C, 0.1 mg C, 0.25 mg C), combined groups (0.05 mg MC, 0.1 mg MC), and control single bond (SB)

Assessment of the ultimate tensile strength

A significant effect of the treatment group (p = 0.032), time (p < 0.001), and their interaction (p < 0.001) was evidenced on UTS values. No significant differences were found among the groups when they were evaluated at 24 h or 1 week (Fig. 6). When evaluated after 6 months, only 25%M and 25%C showed significantly higher UTS values than the SB control (p = 0.005 and p < 0.001, respectively). Evaluation of each individual group after 6 months revealed a significant increase in UTS values for 25%M and 25%C relative to their 24-h values (p = 0.029 and p = 0.001, respectively). All other groups demonstrated no significant variations overtime.

Mean ultimate tensile strength (UTS) values for all groups at 24 h, 1 week, and 6 months of incubation. Bars represent mean values; brackets indicate SD values. Different letters indicate significant differences between groups (Tukey’s test, p < 0.05). n = 10. Upper case letters denote differences among testing times for each study group. Lower case letters denote differences among study groups for each testing time

Assessment of the micro-hardness after softening in ethanol

With exception of 5%C, 10%C, and 25%C, all other groups demonstrated a significant reduction in micro-hardness values after incubation in ethanol (p < 0.05). 10%C and 25%C demonstrated a significant increase in micro-hardness (p < 0.05) after ethanol incubation (Fig. 7).

Discussion

The present study investigated incorporation of a monomer and cross-linker, each containing a quaternary amine group, into a commercially available resin-based adhesive for their antibacterial, cytotoxicity, mechanical, and bonding properties. While multispecies microbial models continue to become more prevalent for the antibacterial screening of novel therapies, the data remains consistent with the prominent role of S. mutans in caries development [35]; hence, culture with a single microbial strain of S. mutans was selected for this investigation. The strain of S. mutans used in this study was ATCC 25175 as this is a well-investigated strain in the study of biomodified dental materials [36]. The first null hypothesis was rejected since groups 10%M and 25%M evidenced greatly reduced S. mutans counts relative to the control SB. While the other monomer and cross-linker groups also showed reduced microbial counts relative to the control SB, these differences remained not significant. Both the monomer and cross-linker used in this study have a 12-carbon chain. We speculate that the favorable results for the monomer groups may be ascribed to the easily accessible cationic group in the monomer [37], as opposed to the more tightly bound quaternary ammonium functionality [15, 16] in the cross-linker groups, which may have restricted access to its antibacterial properties. Incorporation of a quaternary ammonium-containing monomer and cross-linker is known to provide sustained antibacterial characteristics to resins, while also allowing copolymerization via formation of covalent bonds with the polymer network [38]. The antibacterial efficacy of resins modified with quaternary ammonium dimethacrylates is well established [39]. The mechanism is known to be by bacteria lysis when positively charged N+ sites of the quaternary ammonium compounds contact the negatively charged bacterial cell wall disturbing its electric balance causing the bacteria to lyse under its own osmotic pressure [37]. The length of the monomer is important as the carbon chain needs to be long enough to penetrate the cell membrane. A study by Zhou et al. demonstrated that increasing the chain length from 6 to 12 carbons increased antibacterial activity [38]. Differently from that study, our results demonstrated significantly reduced bacterial counts only for 10%M and 25%M, but not for the rest of the groups.

Incorporation of antibacterial monomer and cross-linker led to no changes in the inherent cytotoxicity of the parent adhesive SB leading to a partial acceptance of the second null hypothesis. The findings of no differences in cell viability of gingival fibroblasts between the experimental and control groups indicate that the proposed additives are thus considered safe for in vivo use. Cell viability value of 70% is as a well-accepted threshold to describe cytotoxicity of biomaterials [40]. A study by Pupo et al. [41] reported cell viability values of 73% for SB. Similarly, our study reported cell viability values of 72% for SB. It is well accepted that the inherent cytotoxicity of SB is the result of the BisGMA, UDMA, TEGDMA, and HEMA monomers present in the resin [42, 43]. MTT has been regarded as the gold standard for the preliminary screening of the in vitro cytotoxicity of new biomaterials as it is simple, inexpensive, and reliable [44]. The favorable results of no cytotoxicity for any of the experimental groups point to the need for further investigation of the proposed structures with more clinically relevant tests such as the use of a dentin barrier for a more accurate representation of in vivo conditions. Such barrier has been shown to reduce the adhesive’s diffusion, with the consequent reduction in toxicity [45].

An effect of the antibacterial monomer and cross-linker on bond strength, bond degradation, UTS, and micro-hardness after softening in ethanol was also demonstrated, thus partially rejecting the second null hypothesis. The absence of differences between the control and experimental groups when compared at the early incubation periods—24 h and 6 months—may be the result of a myriad of factors. First, the alterations proposed to the parent adhesive are minor and as such not likely to alter considerably the viscosity, degree of conversion, and overall clinical handling and bonding performance of the material (internal unpublished observations). In addition, bond strength tests of macro-specimens are typically not able to discern the effect of subtle variations in the chemical composition of the adhesive, especially after short incubation periods. They are, however, well-accepted screening tests to determine variations in the initial bonding performance of the modified adhesives. The SEM images obtained at baseline confirm that all groups show very similar hybrid layer micro-morphologies (Fig. 5). Only when evaluating the study groups after 3 years of storage, some differences became apparent, with only the groups with the lowest concentration of monomer, cross-linker, or the combination of both showing bond strength values that were significantly higher than those of the control SB. Similarly, evaluation of each individual group overtime revealed no apparent bond degradation for any of the groups after 6 months. The International Organization for Standardization (ISO) still regards 6 months as long-term incubation for bond strength studies [46], and our study validates the need for longer-term incubation periods for a more accurate representation of the potential effects of hydrolytic degradation of adhesive interfaces. Nonetheless, in a fast-paced market with very quick product turnover, this is unfortunately not always possible, and thus valuable information may still be derived from 6-month aging studies [47]. In this study, SEM observations for interfacial characterization intended only to provide a qualitative assessment of the hybrid layer micro-morphology created with the different modified adhesives. As expected, similar interfacial morphological features were observed in all groups with well-defined resin tags, and relatively uniform hybrid layers. After 3 years, all groups, including the control SB, evidenced significant decreases in bond strength relative to their 24-h values ranging from 19 to 48%. These findings are not unexpected considering that bond strengths of resin-based adhesives are known to fall a 30–40% during the first 6–12 months [48]. Interestingly, only 5%M, 5%C, and 5%M + 5%C demonstrated stable bond strength values with no significant bond degradation after 3 years. Further studies evaluating these polymers’ glass transition temperature and degree of conversion need to be conducted to elucidate the effect of these structures, when incorporated into resin adhesives, on their mechanical and physical properties, as well as their interaction with the tooth structure in the hybrid zone.

Because of the complex anatomy of the teeth and 3-dimensional nature of the jaw mechanics, single axial loading is almost never encountered in the oral cavity. ISO standard 4049 for dental composites recommends flexural test for the evaluation of the mechanical properties of these materials perhaps based on their brittleness, and the development of tensile, shear, and compressive stresses during the test. Recently, the Academy of Dental Materials critically appraised several methods used in the evaluation of specific properties. While flexural and tensile were ranked equally based on being the most useful, applicable, and supported by the literature, the authors suggested that tensile may be the most appropriate testing modality when attempting to understand the mechanical behavior of these materials since it represents the most challenging mechanical situation [49]. Thus, a tensile test was selected for this investigation to determine if incorporation of the monomer and cross-linker had an effect in the mechanical behavior of the parent adhesive. No variations in UTS values were observed after 6 months for any of the groups, indicating that there was no effect of the monomer and cross-linker on the mechanical properties of the parent adhesive. An exception was shown for 25%M and 25%C, both of which evidenced a significant increase in UTS after 6 months. While not significant, SB evidenced the greatest decrease in UTS values after 6 months.

The cross-linking density of a polymer is a critical factor that can be directly correlated to its mechanical properties [50, 51], and can be evaluated by tests such as dynamic mechanical thermal analysis (DMTA), swelling measurements, and glass transition temperature. These tests, however, require complex protocols and equipment, so softening tests have been used, instead as an indirect assessment of the cross-linking density for the preliminary screening of new polymers [52, 53]. In this study, changes in micro-hardness values after immersion in absolute ethanol were used as an indirect estimation of the polymer cross-linking density. While micro-hardness tests can only provide information regarding the surface characteristics of the polymer, which may be different from its bulk properties, useful information can still be derived from these tests. Plasticization was determined on the basis of the softening effect of ethanol. It is well accepted that when a polymer is immersed in a solvent, the solvent enters the polymer network through the intermolecular spaces developing secondary bonds with the polymer, pulling apart the polymer grid and reducing the interchain interactions [53]. The reduction in hardness is thus a consequence of polymer plasticization [32]. In this study, most groups demonstrated a significant decrease in micro-hardness after immersion in ethanol, expected outcome considering the plasticizing effect of the solvent [54]. Conversely, none of the cross-linker groups showed signs of degradation. Furthermore, a significant increase in hardness values was shown for the higher concentrations of cross-linker groups—10%C and 25%C—after immersion in ethanol. These results, while unexpected, are in line with a more tightly bound network, which was less susceptible to the effects of solvent plasticization. Dimethacrylates (cross-linker groups) are known to form cross-linked polymeric structures, while mono-methacrylates (monomer groups) form linear polymers, with cross-linked networks allowing less solvent uptake than linear polymers [13]. While there is no consensus regarding incubation time and concentration of ethanol required to identify differences, absolute ethanol is considered an important weathering agent as it is known to mimic and accelerate the normal degradation expected to occur clinically from food and saliva [29]. The concentration of ethanol in the media is certainly critical since some sterilization protocols call for the use of 70–75% ethanol. In the present study, absolute ethanol was selected based on a study by Schneider et al. who was able to demonstrate differences in cross-linking density when polymers were incubated in absolute ethanol, but not when they were incubated in 75% ethanol [55]. Based on this study, ethanol concentrations under 75% may still be appropriate for specimen sterilization as they did not generate changes in cross-linking density of the polymers. A 4-h immersion period was selected in the present study following a protocol by Rodrigues et al. [56]. While this period may seem insufficient for the polymer swelling to reach equilibrium, it was enough to detect hardness variations between groups. Further investigation by direct assessment methods such as dynamic mechanical thermal analysis, swelling measurements, or glass transition temperature will be able to provide information regarding the time and temperature dependence of the cross-linking densities of these materials. The solubility parameter describes the ease with which a molecule can penetrate and dissolve another substance, with a maximum softening expected when there is minimal magnitude mismatch between the solvent and the polymer itself [23]. The solubility parameter of absolute ethanol is known to be 2.6 × 10−4 (J1/2m−3/2) [23]. While the exact composition of single bond is proprietary, it is likely that alterations in the organic matrix components, resulting from the incorporation of different concentrations of monomer and cross-linker, may have altered the solubility parameter of the material to a magnitude that could have interfered with the softening effect promoted by ethanol. This could help explain the unexpected increase in hardness values observed for groups 10%C and 25%C.

Table 1 depicts a summary of the results. Only 10%M and 25%M evidenced reduced S. mutans counts, none of the groups showed increased cytotoxicity, and only interfaces bonded with 5%M, 5%C, and 5%M + 5%C remained stable after the 3-year incubation period with no signs of bond degradation. Incorporation of the monomer and cross-linker led to no variations in the UTS of the parent adhesive with exception of 25%M and 25%C, both of which evidenced a significant increase. Softening in absolute ethanol led to a significant decrease in hardness values for all groups except the cross-linker groups. Evaluation of the combined results makes a few trends apparent. First, while higher concentrations of the monomer and cross-linker may be beneficial to improve the mechanical strength of the adhesive, strength values above certain level may not be clinically relevant in their ability to derive an improved longevity of these restorations. Second, since only 10%M and 25%M demonstrated antibacterial efficacy and only interfaces bonded with 5%M, 5%C, and 5%M + 5%C remained stable after 3 years, a range between 5 and 10% of the monomer may be able to achieve the necessary balance between deriving antibacterial efficacy against S. mutans and an enhanced bond stability long term, perhaps resulting in restorations with improved life span. Moreover, the results of no cytotoxicity and stable mechanical properties for QA-based monomer in concentrations ranging between 5 and 10% further support an optimal balance.

With the main goals of contemporary restorative dentistry centered around the promotion of minimal intervention, while delivering longer-lasting esthetic restorations, efforts shall remain focused on finding an optimal balance between a material’s ability to convey long-term antibacterial characteristics without a compromise to their mechanical and bonding properties or biocompatibility. Future studies should be undertaken to evaluate the proposed QA-based monomer in a concentration range between 5 and 10% incorporated into adhesives of different chemistries. Also, future studies on these additives should incorporate incubating solutions containing minerals and enzyme components that will more closely resemble in vivo conditions, as well as an evaluation of the degree of conversion, and more complex protocols for a direct evaluation of the polymer’s cross-linking density. More in-depth information is needed to understand the apparent favorable behavior of these additives. Only then, we may be able to speculate as to how their mechanism of action and effect in the host resin may translate into an improved clinical longevity of these restorations. Evaluation of antimicrobial behavior against multiple other cariogenic bacteria including Streptococcus oralis, Streptococcus mitis, and Streptococcus gordonii is also recommended either in a single or multiple-specie bacterial model to further confirm their potential to combat bacterial biofilm formation intra-orally.

Conclusions

Within the limitations of this study, it can be concluded that, while a promising approach in principle, the combination of QA-based monomers with QA-based cross-linkers did not yield materials with the expected combined benefits of enhanced antibacterial and mechanical performance. Only the higher concentrations of QA-based monomer—10%M and 25%M—exhibited enhanced antibacterial performance against S. mutans without an adverse effect on cytotoxicity and mechanical properties of the material relative to the control. While other groups demonstrated enhanced mechanical and bonding properties relative to the control (5%M, 5%C, and 5%M + 5%C showed stable bond strengths after 3 years; 25%M and 25%C evidenced increased UTS values after 6 months; and 10%C and 25%C showed increased hardness values after immersion in ethanol), none of them demonstrated antibacterial efficacy against S. mutans.

References

Raible R (2015) ADA statement: new CDC statistics show need for increased access to dental care, with a greater emphasis on preventing disease

Bohaty BS, Ye Q, Misra A, Sene F, Spencer P (2013) Posterior composite restoration update: focus on factors influencing form and function. Clin Cosmet Investig Dent 5:33–42. https://doi.org/10.2147/CCIDE.S42044

Fabianelli A, Pollington S, Davidson CL, Cagidiaco MC, Goracci C (2007) The relevance of micro-leakage studies. Inter Dent SA 9(3):64–74

Kubo S (2011) Longevity of resin composite restorations. Jpn Dent Sci Rev 47(1):43–55. https://doi.org/10.1016/j.jdsr.2010.05.002

Ferracane JL (2017) Models of caries formation around dental composite restorations. J Dent Res 96(4):364–371. https://doi.org/10.1177/0022034516683395

Xie D, Weng Y, Guo X, Zhao J, Gregory RL, Zheng C (2011) Preparation and evaluation of a novel glass-ionomer cement with antibacterial functions. Dent Mater 27(5):487–496. https://doi.org/10.1016/j.dental.2011.02.006

Imazato S, J-h C, Ma S, Izutani N, Li F (2012) Antibacterial resin monomers based on quaternary ammonium and their benefits in restorative dentistry. Jpn Dent Sci Rev 48(2):115–125. https://doi.org/10.1016/j.jdsr.2012.02.003

Wiegand A, Buchalla W, Attin T (2007) Review on fluoride-releasing restorative materials--fluoride release and uptake characteristics, antibacterial activity and influence on caries formation. Dent Mater 23(3):343–362. https://doi.org/10.1016/j.dental.2006.01.022

Chatzistavrou X, Velamakanni S, DiRenzo K, Lefkelidou A, Fenno JC, Kasuga T, Boccaccini AR, Papagerakis P (2015) Designing dental composites with bioactive and bactericidal properties. Mater Sci Eng C Mater Biol Appl 52:267–272. https://doi.org/10.1016/j.msec.2015.03.062

Kasraei S, Sami L, Hendi S, Alikhani MY, Rezaei-Soufi L, Khamverdi Z (2014) Antibacterial properties of composite resins incorporating silver and zinc oxide nanoparticles on Streptococcus mutans and Lactobacillus. Restor Dent Endod 39(2):109–114. https://doi.org/10.5395/rde.2014.39.2.109

Tavassoli Hojati S, Alaghemand H, Hamze F, Ahmadian Babaki F, Rajab-Nia R, Rezvani MB, Kaviani M, Atai M (2013) Antibacterial, physical and mechanical properties of flowable resin composites containing zinc oxide nanoparticles. Dent Mater 29(5):495–505. https://doi.org/10.1016/j.dental.2013.03.011

Antonucci JM, Zeiger DN, Tang K, Lin-Gibson S, Fowler BO, Lin NJ (2012) Synthesis and characterization of dimethacrylates containing quaternary ammonium functionalities for dental applications. Dent Mater 28(2):219–228. https://doi.org/10.1016/j.dental.2011.10.004

Makvandi P, Jamaledin R, Jabbari M, Nikfarjam N, Borzacchiello A (2018) Antibacterial quaternary ammonium compounds in dental materials: a systematic review. Dent Mater 34(6):851–867. https://doi.org/10.1016/j.dental.2018.03.014

Zhang K, Cheng L, Imazato S, Antonucci JM, Lin NJ, Lin-Gibson S, Bai Y, Xu HH (2013) Effects of dual antibacterial agents MDPB and nano-silver in primer on microcosm biofilm, cytotoxicity and dentine bond properties. J Dent 41(5):464–474. https://doi.org/10.1016/j.jdent.2013.02.001

Cheng L, Weir MD, Zhang K, Arola DD, Zhou X, Xu HH (2013) Dental primer and adhesive containing a new antibacterial quaternary ammonium monomer dimethylaminododecyl methacrylate. J Dent 41(4):345–355. https://doi.org/10.1016/j.jdent.2013.01.004

Li F, Weir MD, Chen J, Xu HH (2014) Effect of charge density of bonding agent containing a new quaternary ammonium methacrylate on antibacterial and bonding properties. Dent Mater 30(4):433–441. https://doi.org/10.1016/j.dental.2014.01.002

Cheng L, Weir MD, Xu HH, Antonucci JM, Kraigsley AM, Lin NJ, Lin-Gibson S, Zhou X (2012) Antibacterial amorphous calcium phosphate nanocomposites with a quaternary ammonium dimethacrylate and silver nanoparticles. Dent Mater 28(5):561–572. https://doi.org/10.1016/j.dental.2012.01.005

He J, Soderling E, Lassila LV, Vallittu PK (2015) Preparation of antibacterial and radio-opaque dental resin with new polymerizable quaternary ammonium monomer. Dent Mater 31(5):575–582. https://doi.org/10.1016/j.dental.2015.02.007

Huang L, Xiao YH, Xing XD, Li F, Ma S, Qi LL, Chen JH (2011) Antibacterial activity and cytotoxicity of two novel cross-linking antibacterial monomers on oral pathogens. Arch Oral Biol 56(4):367–373. https://doi.org/10.1016/j.archoralbio.2010.10.011

Makvandi P, Ghaemy M, Mohseni M (2016) Synthesis and characterization of photo-curable bis-quaternary ammonium dimethacrylate with antimicrobial activity for dental restoration materials. Eur Polym J 74:81–90. https://doi.org/10.1016/j.eurpolymj.2015.11.011

Weng Y, Guo X, Chong V, Howard L, Gregory R, Xie D (2011) Synthesis and evaluation of a novel antibacterial dental resin composite with quaternary ammonium salts. J Biomed Sci Eng 4(3):147–157. https://doi.org/10.4236/jbise.2011.43021

Punyani S, Singh H (2006) Preparation of iodine containing quaternary amine methacrylate copolymers and their contact killing antimicrobial properties. J Appl Polym Sci 102(2):1038–1044. https://doi.org/10.1002/app.24181

McKinney JE, Wu W (1985) Chemical softening and wear of dental composites. J Dent Res 64(11):1326–1331. https://doi.org/10.1177/00220345850640111601

Li Y, Themistou E, Das BP, Christian-Tabak L, Zou J, Tsianou M, Cheng C (2011) Polyelectrolyte nanocages via crystallized miniemulsion droplets. Chem Commun (Camb) 47(42):11697–11699. https://doi.org/10.1039/c1cc14298d

Sun B, Sun H, Li Y, Cui H, Cheng C (2019) A systematic synthetic study of polyelectrolyte nanocapsules via crystallized miniemulsion nanodroplets. Eng Sci 5:39–45. https://doi.org/10.30919/es8d536

Lee MJ, Kim MJ, Kwon JS, Lee SB, Kim KM (2017) Cytotoxicity of light-cured dental materials according to different sample preparation methods. Materials (Basel) 10 (3). https://doi.org/10.3390/ma10030288

Barot T, Rawtani D, Kulkarni P (2020) Physicochemical and biological assessment of silver nanoparticles immobilized Halloysite nanotubes-based resin composite for dental applications. Heliyon 6(3):e03601. https://doi.org/10.1016/j.heliyon.2020.e03601

ISO Standard 10993. Biological evaluation of medical devices. International Organization for Standardization Geneva, Switzerland

Lagocka R, Mazurek-Mochol M, Jakubowska K, Bendyk-Szeffer M, Chlubek D, Buczkowska-Radlinska J (2018) Analysis of base monomer elution from 3 flowable bulk-fill composite resins using high performance liquid chromatography (HPLC). Med Sci Monit 24:4679–4690. https://doi.org/10.12659/MSM.907390

Shonol Y, Ogawal T, Terashital M, Carvalho RM, Pashley EL, Pashley DH (1999) Regional measurement of resin-dentin bonding as an array. J Dent Res 78(2):699–705. https://doi.org/10.1177/00220345990780021001

Armstrong S, Breschi L, Ozcan M, Pfefferkorn F, Ferrari M, Van Meerbeek B (2017) Academy of Dental Materials guidance on in vitro testing of dental composite bonding effectiveness to dentin/enamel using micro-tensile bond strength (muTBS) approach. Dent Mater 33(2):133–143. https://doi.org/10.1016/j.dental.2016.11.015

Ferracane JL (2006) Hygroscopic and hydrolytic effects in dental polymer networks. Dent Mater 22(3):211–222. https://doi.org/10.1016/j.dental.2005.05.005

Asmussen E, Peutzfeldt A (2001) Influence of pulse-delay curing on softening of polymer structures. J Dent Res 80(6):1570–1573. https://doi.org/10.1177/00220345010800061801

Leitune V, Collares F, Trommer R, Andrioli D, Bergmann C, Samuel S (2013) The addition of nanostructured hydroxyapatite to an experimental adhesive resin. J Dent Res 41:321–327

Banas JA, Drake DR (2018) Are the mutans streptococci still considered relevant to understanding the microbial etiology of dental caries? BMC Oral Health 18(1):129. https://doi.org/10.1186/s12903-018-0595-2

Xiao YH, Chen JH, Fang M, Xing XD, Wang H, Wang YJ, Li F (2008) Antibacterial effects of three experimental quaternary ammonium salt (QAS) monomers on bacteria associated with oral infections. J Oral Sci 50(3):323–327. https://doi.org/10.2334/josnusd.50.323

Namba N, Yoshida Y, Nagaoka N, Takashima S, Matsuura-Yoshimoto K, Maeda H, Meerbeek BV, Suzuki K, Takashiba S (2009) Antibacterial effect of bactericide immobilized in resin matrix. Dent Mater 25(4):424–430. https://doi.org/10.1016/j.dental.2008.08.012

Zhou C, Weir MD, Zhang K, Deng D, Cheng L, Xu HH (2013) Synthesis of new antibacterial quaternary ammonium monomer for incorporation into CaP nanocomposite. Dent Mater 29(8):859–870. https://doi.org/10.1016/j.dental.2013.05.005

Cheng L, Weir M, Zhang K, Xu S, Chen Q, Zhou X, Xu H (2012) Antibacterial nanocomposite with calcium phosphate and quaternary ammonium. J Dent Res 91(5):460–466. https://doi.org/10.1177/0022034512440579

Gsib O, Duval J-L, Goczkowski M, Deneufchatel M, Fichet O, Larreta-Garde V, Bencherif SA, Egles C (2017) Evaluation of fibrin-based interpenetrating polymer networks as potential biomaterials for tissue engineering. Nanomaterials 7(12):436. https://doi.org/10.3390/nano7120436

Pupo Y, Bernardo C, Fd S, Michél M, Ribeiro C, Germano S, Maluf DF (2017) Cytotoxicity of etch-and-rinse, self-etch, and universal dental adhesive systems in fibroblast cell line 3T3. Scanning 2017:1–7. https://doi.org/10.1155/2017/9650420

Geurtsen W (1998) Cytotoxicity of 35 dental resin composite monomers/additives in permanent 3T3 and three human primary fibroblast cultures. J Biomed Mater Res 41(3):474–480. https://doi.org/10.1002/(SICI)1097-4636(19980905)41:3

Geurtsen W (1999) Aqueous extracts from dentin adhesives contain cytotoxic chemicals. J Biomed Mater Res 48(6):772–777. https://doi.org/10.1002/(sici)1097-4636(1999)48:6

Mosmann T (1983) Rapid colorimetric assay for cellular growth and survival: application to proliferation and cytotoxicity assays. J Immunol Methods 65(1-2):55–63. https://doi.org/10.1016/0022-1759(83)90303-4

Elias ST, Santos AF, Garcia FCP, Pereira PNR, Hilgert LA, Fonseca-Bazzo YM, Guerra ENS, Ribeiro APD (2015) Cytotoxicity of universal, self-etching and etch-and-rinse adhesive systems according to the polymerization time. Braz Dent J 26(2):160–168. https://doi.org/10.1590/0103-6440201300294

ISO/TS 11405, Dental materials—Testing of adhesion to tooth structure (2003). International Organization for Standardization, Geneva, Switzerland

Rêgo HMC, Alves TS, Bresciani E, Niu L, Tay FR, Pucci CR (2016) Can long-term dentine bonding created in real life be forecasted by parameters established in the laboratory? Sci Report 6:1–8. https://doi.org/10.1038/srep37799

Pashley DH, Tay FR, Imazato S (2011) How to increase the durability of resin-dentin bonds. Compend Contin Educ Dent 32(7):60–66

Ilie N, Hilton TJ, Heintze SD, Hickel R, Watts DC, Silikas N, Stansbury JW, Cadenaro M, Ferracane JL (2017) Academy of Dental Materials guidance-resin composites: Part I-mechanical properties. Dent Mater 33(8):880–894. https://doi.org/10.1016/j.dental.2017.04.013

Sideridou I, Tserki V, Papanastasiou G (2003) Study of water sorption, solubility and modulus of elasticity of light-cured dimethacrylate-based dental resins. Biomaterials 24(4):655–665. https://doi.org/10.1016/s0142-9612(02)00380-0

St-Georges AJ, Swift EJ, Thompson JY, Heymann HO (2003) Irradiance effects on the mechanical properties of universal hybrid and flowable hybrid resin composites. Dent Mater 19(5):406–413. https://doi.org/10.1016/s0109-5641(02)00084-2

Asmussen E, Peutzfeldt A (2003) Two-step curing: influence on conversion and softening of a dental polymer. Dent Mater 19(6):466–470. https://doi.org/10.1016/s0109-5641(02)00091-x

Soh MS, Yap AU (2004) Influence of curing modes on crosslink density in polymer structures. J Dent 32(4):321–326. https://doi.org/10.1016/j.jdent.2004.01.012

Filho JD, Poskus LT, Guimaraes JG, Barcellos AA, Silva EM (2008) Degree of conversion and plasticization of dimethacrylate-based polymeric matrices: influence of light-curing mode. J Oral Sci 50(3):315–321. https://doi.org/10.2334/josnusd.50.315

Schneider LF, Moraes RR, Cavalcante LM, Sinhoreti MA, Correr-Sobrinho L, Consani S (2008) Cross-link density evaluation through softening tests: effect of ethanol concentration. Dent Mater 24(2):199–203. https://doi.org/10.1016/j.dental.2007.03.010

Rodrigues SB, Collares FM, Leitune VC, Schneider LF, Ogliari FA, Petzhold CL, Samuel SM (2015) Influence of hydroxyethyl acrylamide addition to dental adhesive resin. Dent Mater 31(12):1579–1586. https://doi.org/10.1016/j.dental.2015.10.005

Acknowledgments

The authors wish to thank Mr. Peter Bush, Mr. Stephen Vanyo, and Mr. Steve Makowka for their assistance with SEM, MTT assay, and hardness testing, respectively and Dr. Stefan Ruhl for donating the cells for the antibacterial study. This paper is based on the thesis dissertation submitted in partial fulfillment of the requirements for the degree of Master of Sciences in Forensic Science in the Chemistry Department of Buffalo State College at SUNY (thesis major advisor: Associate Professor Camila Sabatini).

Funding

This work was supported by the Innovative Micro-Programs Accelerating Collaboration in Themes (IMPACT) award from the University at Buffalo to Dr. Camila Sabatini.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

N/A. Research did not involve human participants.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moussa, H., Jones, M.M., Huo, N. et al. Biocompatibility, mechanical, and bonding properties of a dental adhesive modified with antibacterial monomer and cross-linker. Clin Oral Invest 25, 2877–2889 (2021). https://doi.org/10.1007/s00784-020-03605-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-020-03605-w