Abstract

Objectives

The aim of this study was to determine and correlate the degree of conversion (DC) with Vickers hardness (VH) and translucency parameter (TP) with the depth of cure (DoC) of five bulk-fill composites.

Materials and methods

Six specimens per group, consisting of Tetric EvoCeram Bulk Fill (“TEC Bulk,” Ivoclar Vivadent), SonicFill (Kerr), SDR Smart Dentin Replacement (“SDR,” Dentsply), Xenius base (“Xenius,” StickTech; commercialized as EverX Posterior, GC), Filtek Bulk Fill flowable (“Filtek Bulk,” 3M ESPE), and Tetric EvoCeram (“TEC,” control), were prepared for DC and VH: two 2-mm-thick layers, each light-cured for 10 s; one 4-mm bulk-fill, light-cured for 10 or 20 s; and one 6-mm bulk-fill, cured for 20 s. DC was measured using a Fourier-transform infrared spectrometer, VH using a Vickers hardness tester. DoC and TP were measured using an acetone-shaking test and a spectrophotometer, respectively. Data were analyzed using ANOVA and Pearson’s correlation (α = 0.05).

Results

DC and VH ranged between 40–70 % and 30–80 VHN, respectively. TEC Bulk, Xenius, and SonicFill, bulk-filled as 4-mm-thick specimens, showed bottom-to-top hardness ratios above 80 % after 20 s curing. A positive linear correlation was found for bottom DC and VH. An average DC ratio of 0.9 corresponded to a bottom-to-top VH ratio of 0.8.

Conclusions

Sculptable bulk-fills require 20 s, whereas 10 s curing time was sufficient for flowable bulk-fills using a high-intensity LED unit.

Clinical relevance

Clinicians should be aware that longer curing times may be required for sculptable than flowable bulk-fill composites in order to achieve optimal curing characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Direct composite is today the material of choice to restore small-to-medium sized occlusal and proximal cavities in posterior teeth on the condition that the bonding and filling procedures can be adequately performed [1]. To fill posterior cavities, an incremental filling or layering technique, generally involving the placement and curing of composite in layers with a maximum thickness of 2 mm, has been favored over a bulk-fill technique or the filling of the entire cavity with a single composite portion [2]. The main advantages of the layering technique include the more optimal cure throughout the depth of composite and lower polymerization shrinkage with the associated reduced shrinkage stress [2]. On the other hand, layering is more time-consuming and technique-sensitive than bulk-fill placement with the additional risk of void entrapment between layers as well as operative field contamination due to the prolonged working time. There is a constant need to simplify the clinical procedure for direct posterior composite restorations.

It is important to highlight that there are inconclusive laboratory data and insufficient clinical evidence to support either placement technique for conventional composites [2, 3]. Computer simulations have even shown reduced shrinkage effects related to the bulk-fill technique [3]. The layering technique has been reported to maintain hardness throughout the material depth [4, 5] and remains the preferred placement method for conventional and low-shrinking composites [6, 7].

Recent improvements in dental composite technology led to the development of the so-called “bulk-fill” composites, specifically designed for placement in single layers of 4 to 5 mm. According to manufacturer’s data, bulk-fill composites maintain optimal curing efficiency and mechanical properties in layers exceeding 2 mm based on several mechanisms: (1) “booster” photoinitiators, benzoyl germanium derivatives, with a higher photocuring activity resulting in increased polymerization rate and depth of cure [8]; (2) “polymerization modulators,” i.e., high molecular weight, urethane-based, dimethacrylate monomers responsible for reduced shrinkage stress [9]; (3) increased flowability for better adaptation; and (4) increased translucency compared to conventional composites [10] through the use of mixed oxide fillers with matching refractive index to that of the resin matrix, or glass fibers which also favor light penetration through composite [11, 12].

Previous papers have reported on different curing and mechanical properties of various bulk-fill composites such as the degree of conversion (DC) and flexural strength [13], shrinkage behavior, hardness, modulus of elasticity and elastic-plastic indentation work [9], creep deformation [14], cuspal deflection and microleakage [15], marginal quality [16], and surface morphology [17]. Viscoelastic properties of a flowable bulk-fill composite (SDR, Dentsply, Konstanz, Germany) have been used to develop a predictive mathematical model for different flow conditions [18]. An experimental composite containing short glass fibers, recommended to restore the restoration base in bulk, has been characterized in terms of DC, water sorption and solubility, mechanical properties [19], shrinkage stress and marginal adaptation [20], depth of cure (DoC), and microhardness [21]. A positive linear correlation was found between Vickers hardness (VH) and the filler loading of bulk-fill composites [22]. Commercial bulk-fill composites showed inferior mechanical properties compared to the conventional highly filled nano-hybrid composites and comparable to flowable materials [23]. A downside of bulk-fill composites was reported to be a significant decrease of hardness after short-term storage in 75 % ethanol/water [24].

The aim of this study was to determine the DC, VH, and DoC of five bulk-fill composites and to relate these data to translucency, curing time, and layer thickness. The null hypotheses investigated were that (1) there were no differences in the tested properties between the different bulk-fill composites, (2) there were no differences in DC and VH for each composite as a function of filling procedure and curing time, and (3) there was no correlation between DC and VH.

Materials and methods

Sample preparation

Details on the materials used in this study are presented in Table 1. Six specimens for each of the four experimental filling procedures, involving five bulk-fill composites and the conventional composite, were prepared to measure DC and VH as follows:

-

The composite was applied in two 2-mm-thick layers or layer-filled, with each layer individually light-cured for 10 s; this experimental mode has further been referred to as “2 + 2 mm_2 × 10 s.”

-

The composite was applied in one 4-mm layer or bulk-filled and light-cured for 10 s (“4 mm_10 s”).

-

The composite was applied in one 4-mm layer or bulk-filled and light-cured for 20 s (“4 mm_20 s”).

-

The composite was applied in one 6-mm layer or bulk-filled and light-cured for 20 s (“6 mm_20 s”); this condition served as the extreme bulk-filling procedure, although not recommended by any of the composite manufacturers.

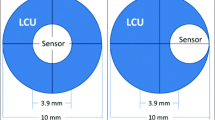

Standardized prefabricated molds made of polyethylene plastic were used to prepare specimens 5 mm in diameter and either 4 or 6 mm thick, as illustrated in Fig. 1. Each mold was placed on a celluloid matrix strip on a glass microscope slide, filled with composite following one of the four filling procedures, after which another glass slide was pressed on top of the composite to extrude excess material. For the layer-filling procedure, the first layer was applied, leaving a 2-mm space on top and separately light-cured for 10 s.

The composite was light-cured through the slide for either 10 or 20 s, using a polywave LED light-curing unit (Bluephase 20i, Ivoclar Vivadent, Schaan, Liechtenstein) in “high” mode. Spectral irradiance was determined using a NIST-referenced USB4000 Spectrometer (MARC, Ocean Optics Inc., Dunedin FL, USA) (Fig. 2).

All specimens were stored dry, in light-proof containers at 37 °C for 24 h. The same specimens were used to measure DC and VH, enabling to correlate the two properties.

DC, VH, DoC, and TP measurements

DC was measured using a Fourier-transform infrared spectrometer (FTIR) equipped with a platinum ATR single reflection crystal (Vertex 70, Bruker Optik, Ettlingen, Germany). Thirty-two scans were taken in the absorbance mode within the 4500–400 cm−1 range at a resolution of 4 cm−1. Three measurements each were made on the top and bottom surface of each specimen. Uncured composite served as a reference. DC was calculated using the following formula:

where R is the ratio of intensities of the 1639 and 1609 cm−1 peaks, associated with the aliphatic and aromatic groups in the spectra of tested composites, respectively.

VH was measured using a Vickers hardness tester (FV-700, Future-Tech, Kawasaki-ku, Japan) equipped with a computer-controlled XY stage, which allowed automatic indentation at pre-selected points on the surface. Five measurements were made on the top and bottom surface of each specimen by applying a 1-kg load for 10 s under ×10 magnification.

DoC was measured using the acetone-shaking test according to the protocol previously described by Kleverlaan and de Gee [25] as a modification of the ISO/DIS 4049 (2008) standard [26]. Briefly, cylindrical samples were prepared in a stainless steel mold, 8 mm in diameter and 10 mm deep, and light-cured through a glass slide for 20 s using the Bluephase 20i (Ivoclar Vivadent) light-curing unit. Five minutes post-curing, each specimen was removed from the mold, immersed in 1 ml of acetone in an amalgam capsule, and shaken for 15 s in a mixing device (RotoMix, 3M ESPE, Seefeld, Germany) to facilitate dissolution of the uncured material. Following shaking, DoC was determined by measuring the residual specimen thickness using a digital caliper (CD-15CPX, Mitutoyo, Kanagawa, Japan) and dividing this value by two, in accordance with the requirements of the ISO/DIS 4049 (2008) standard [26].

Translucency parameter (TP) was measured for 4-mm-thick specimens using a dental spectrophotometer (SpectroShade Micro, MHT Optic Research, Niederhasli, Switzerland). Each specimen was analyzed against a black and white background. Three measurements per specimen per background were averaged prior to the calculation of the TP for each composite, using the following equation:

where L1 and L2 are the L values against the black and white background, respectively; a1 and a2 are the a values against the black and white background, respectively; and b1 and b2 are the b values against the black and white background, respectively.

Statistical analysis

Two linear mixed-effects models were constructed (nlme package, R3.1.0, R Foundation for Statistical Computing, Vienna, Austria) to assess DC and VH separately. DC and VH were modeled by means of a full factorial design of the six different composites, four filling techniques, and two surfaces. Each composite block was considered as a random effect. To assess the differences between the different filling techniques, specific contrasts were calculated within each group (contrast package, R3.1.0, R Foundation for Statistical Computing, Vienna, Austria). Additionally, contrasts were calculated to assess the difference between top and bottom surface. To assess the relation between VH and DC, a Pearson correlation analysis between the top-bottom ratios of DC and VH was calculated. All tests were performed at a significance level of α = 0.05.

Results

DC varied between 4.2 % (SD 2.3 %) for the 6-mm bulk-filled conventional composite TEC when measured at the specimen bottom, and 69.0 % (SD 2.1 %) for the 6-mm bulk-filled flowable bulk-fill composite SDR when measured at the specimen top (Fig. 3). Overall, significantly, the highest DC (p = 0.0012) was measured for the flowable bulk-fill composite SDR, irrespective of the filling procedure and top or bottom measurement. Although lower than the DC of SDR, the DC of the flowable bulk-fill composite Filtek Bulk was similar at the specimen top and bottom, except for the extreme 6-mm bulk-filled procedure (“6 mm_20 s”) when measured at the specimen bottom (−7.7 % DC, p < 0.0001). For both the so-called sonic-activated bulk-fill composite SonicFill and the sculptable bulk-fill composite TEC Bulk, DC was significantly lower at the bottom than at the top surface. In particular, when SonicFill was employed following the 6-mm deep bulk-filling procedure (“6 mm_20 s”), DC was significantly lower at the bottom surface (−27.1 % DC, p < 0.0001). Significantly, the lowest DC was measured at both the top and bottom for the fiber-reinforced composite Xenius and the conventional composite TEC (p < 0.05).

Predictions and 95 % confidence intervals for the DC of the tested composites. The predictions used in the graph are extracted from the linear mixed-effects model and are very close to the respective means. These predictions can be considered an estimate of the mean fitted value for the variable under consideration adjusted for all other variables in the analysis. Groups of which the whiskers do not overlap are significantly different (p < 0.05). Within each composite brand, groups below the dotted line are significantly lower than their respective control (top surface of the layered group) (p < 0.05)

The highest VH (p < 0.0001) was measured for the sonic-activated bulk-fill composite SonicFill at the specimen top surface (Fig. 4). This high VH was approached at the specimen bottom when SonicFill was applied following the layered filling procedure (“2 + 2 mm_2 × 10 s”), and, though somewhat less, following the 4-mm bulk-filling and 20-s light-curing procedure (“4 mm_20 s”). A light-curing time of 10 s is clearly insufficient (−22.1 VHN, p < 0.0001) for the 4-mm bulk-filling procedure (“4 mm_10 s”) and even much more insufficient to reach a sufficient hardness was the extreme 6-mm bulk-filling in combination with 20-s light-curing procedure (“6 mm_20 s,” −54.9 VHN, p < 0.0001). VH of TEC Bulk and TEC exceeded 60 VHN at the specimen top surface, though was significantly lower than the VH of SonicFill. Again at the specimen bottom, the top VH of both the bulk-fill and conventional composite TEC Bulk and TEC was best approached following the layered filling procedure (“2 + 2 mm_2 × 10 s”), and, though somewhat less, following the 4-mm bulk-filling in combination with the 20-s light-curing procedure (“4 mm_20 s”). Significantly lower VH was again achieved for “4 mm_20 s” and “6 mm_20 s” (−8.8 and −49.248 VHN respectively, p < 0.0001), following the latter procedure TEC remained soft. The fiber-reinforced composite Xenius performed in terms of VH somewhat in between that of the other composites. Noteworthy is that a significantly higher VH was reached at the specimen top surface for the 20-s 4- and 6-mm bulk-filling procedures (“4 mm_20 s” and “6 mm_20 s”). VH was somewhat less consistent, as at the specimen bottom surface the highest VH was achieved for “2 + 2 mm_10 s” and “4 mm_20s.” Both flowable bulk-fill composites SDR and Filtek Bulk achieved the lowest VH; not much difference in VH was recorded for both composites, except for the extreme 6-mm bulk-filling procedure (“6 mm_20 s”) that resulted in significantly lower VH at the specimen bottom surface.

Predictions and 95 % confidence intervals for VH of the tested composites. Groups of which the whiskers do not overlap are significantly different (p < 0.05). Within each composite brand, groups below the dotted line are significantly lower than their respective control (top surface of the layered group) (p < 0.05)

Bottom-to-top VH ratios approximated 1 (Fig. 5), indicating no difference in VH between the specimen top and bottom surface and thus achieving its best VH, for the flowable bulk-fill composites SDR and Filtek Bulk in case of all filling procedures, except the extreme 6-mm bulk-filling procedure (“6 mm_20 s”). The ratio exceeded at least 0.8, indicating that at least 80 % of the top VH was reached at the specimen bottom, for all composites when applied following the layered (“2 + 2 mm_2 × 10 s”) and the 20-s 4-mm bulk-filling (“4 mm_20 s”) procedure, except for the conventional composite TEC. The lowest ratios, far below 0.8, were recorded for the extreme 6-mm bulk-filling procedure (“6 mm_20 s”), except for SDR and Filtek Bulk, whose bottom-to-top VH ratios approached the 0.8 threshold.

Table 2 presents the Pearson correlation coefficient values between DC and VH. When measured at the specimen top surface, DC and VH correlated positively only for Xenius (r 2 = 0.724, p < 0.001). Conversely, DC and VH measured at the specimen bottom surface correlated positively for all composites tested.

Figure 6 presents the relation between the VH and DC ratios. An average DC ratio of 0.9 was found to correspond to a VH ratio of 0.8 between bottom and top surfaces (p < 0.001). It was further calculated that TEC Bulk showed the lowest (0.7869) and Xenius the highest DC ratio (0.9478) that corresponded to a VH ratio of 0.8. The highest DC ratio corresponding to 0.8 VH ratio of all tested composites was found for TEC control (0.9621). However, it should be highlighted that this DC to VH ratio was calculated only for the layered group (2 × 2 mm), since the bulk groups of TEC control all showed a bottom-to-top VH ratio below 0.8.

The DoC threshold of 4 mm was reached for all composites, except for the sonic-activated SonicFill and the control conventional composite TEC (Fig. 7). A DoC above 5 mm was even achieved by the bulk-fill composites SDR, Xenius, and Filtek Bulk, thereby being significantly higher than the DoC of the remaining three composites (p < 0.05).

All composites significantly differed in terms of TP (Fig. 8) (p < 0.05), except for the flowable bulk-fill composite SDR and the bulk-fill composite TEC, of which their respective TPs were not significantly different. The highest TP was recorded for the fiber-reinforced composite Xenius (mean 36.6, SD 2.0), while the lowest TP was measured for the sonic-activated composite SonicFill (mean 14.6, SD 0.3).

Discussion

In order to make the application of posterior composite clinically less cumbersome, bulk-fill composites were introduced. Such bulk-fill technology promotes the effective use of 4-mm instead of the classical 2-mm composite increments generally recommended for conventional composites. Bulk-filling was made possible thanks to an improved depth of cure in combination with reduced polymerization shrinkage characteristics. Today, two kinds of bulk-fill composites exist. “Flowable” bulk-fill composites are applied to basically replace dentin in one single layer of maximum 4 mm; this “bulk-fill base” needs to be over-layered by a conventional composite to restore the tooth’s outer anatomy. We tested in this study the flowable bulk-fill composites SDR and Filtek Bulk. A newer generation of non-flowable “full-depth” bulk-fill composites enables to restore the whole cavity in one single increment, thereby being “sculptable” to the natural tooth topography. We included in this study the sculptable bulk-fill composite TEC Bulk. Most bulk-fill composites are, per manufacturer’s instructions, limited to be applied in a maximum 4-mm layer thickness. According to the manufacturer’s instructions, the sonic-activated bulk-fill composite SonicFill we tested can be applied up to a 5-mm layer thickness in a single increment and does not require an additional high-viscosity composite on top. Sonic activation lowers the viscosity enabling void-less and easy cavity-wall adaptation; after application, the composite consistency returns to a sculptable state. We also included the experimental fiber-reinforced composite Xenius (later commercialized as EverX Posterior by GC), which is to be used as a 4- to 5-mm bulk-fill dentin replacement in conjunction with a conventional composite as enamel replacement on top. The short fibers are claimed to prevent and stop crack propagation through the filling; this fiber-reinforced composite is particularly recommended for large-sized cavities and so to extend the indication area of direct composites to restore also severely weakened teeth in a more economically affordable manner, such as teeth with extremely deep cavities, endodontic cavities, large amalgam cavities, and cavities with missing cusps. As control, the conventional so-called “universal nano-hybrid” composite TEC, instructed to be applied in maximum 2-mm-thick increments, was finally tested as well.

Overall, significant differences in the tested properties were found between different bulk-fill composites as well as for each composite as a function of filling procedure and curing time, by which both the first and second hypotheses were rejected. The third null hypothesis was also rejected as correlation was established between DC and VH.

The flowable bulk-fill composites SDR scored highest and most consistent for DC, this even when applied following the extreme 6-mm bulk-filling (“6-mm_20 s”) procedure and when DC was measured at the specimen bottom surface. This was confirmed by the consistent VH data, with only a slightly reduced VH for “6-mm_20 s.” Besides the latter filling procedure, the VH bottom-to-top ratio was 1 or closely approached it; an almost 0.8 VH bottom-to-top ratio was even recorded for “6-mm_20 s.” DoC exceeded 5 mm, being thus safely above the manufacturer’s recommended maximum 4-mm single increment. Besides the relatively high translucency with a TP above 20 allowing light to penetrate sufficiently deep, the superior curing efficiency should most likely be attributed to its efficient polymerization-initiation system. The generally lower VH, as compared to that of the “full-depth” bulk-fill (SonicFill, TEC Bulk) and the control conventional composite (TEC), must be ascribed to its lower mechanical properties and to a large degree to its lower filler loading. This superb curing efficiency is combined with favorable polymerization shrinkage characteristics, as SDR was found to preserve the adhesive interface integrity and to achieve the highest bond strength at the cavity-bottom dentin of high C-factor class-I cavities, this in contrast to a conventional flowable and a conventional paste-like composite [27]. Most likely, a higher flow with shrinkage stress relief prior to reaching the gel point accounts for the more favorable polymerization shrinkage characteristics [28, 29].

DC of SDR measured in our study was higher than that of the North American version Surefil SDR in the study of Czasch and Ilie [13]. Their specimens were tested 5 min versus 24 h post-curing in our study, potentially explaining the difference in DC measured. Although previous studies reported a post-curing increase in conversion of about 2–3 % for conventional composites [30, 31], another study reported greater variability in DC for both bulk-fill composites following dry storage [32]. Relatively low hardness values have been reported for Surefil SDR in previous studies [13, 33], even lower than our findings for SDR, when a hardness of about 35 VHN was measured.

The second flowable bulk-fill composite we tested, Filtek Bulk, performed similar to SDR for VH, VH bottom-to-top ratio, and DoC; it slightly underperformed SDR for DC, while it appeared more translucent. Self-evidently, because of the lower VH measured and thus their mechanical properties, the flowable composites SDR and Filtek Bulk must be over-capped with a conventional composite, as recommended by their respective manufacturers.

DC of the sculptable bulk-fill composite TEC Bulk was lower than that of the flowable bulk-fill composite SDR and about the same as DC of Filtek Bulk, when measured at the specimen top surface. DC then dropped significantly from about 55 % to about 40 % (or below) for the four different filling procedures. A similar, but less pronounced, trend was recorded in terms of VH, with a VH bottom-to-top ratio reaching 0.8 or slightly above only for “2 + 2 mm_2 × 10 s” and “4 mm_20 s.” A reduced curing efficiency with a VH bottom-to-top ratio of about 0.7 was recorded when TEC Bulk was bulk-filled in a 4-mm layer but only light-cured for 10 s. Although not recommended by the manufacturer, the VH bottom-to-top ratio reached only about 0.47 for the 6-mm bulk-fill procedure. A 10-s curing time is recommended by the manufacturer when using the light-curing device Bluephase 20i in “high” mode, as done in this study. Hence, based on our data, an extended curing time of 20 s should be recommended. This is confirmed by the DoC measured for TEC Bulk, being just below 5 mm when the composite was light-cured for 20 s, while TP was not significantly different from that of SDR. As compared to its conventional “sister” composite TEC, DC was higher at the specimen top surface, but not at the specimen bottom surface, except for the extreme 6-mm bulk-filling protocol; for “6 mm_20 s,” a reasonable DC approaching 40 % was recorded, versus only about 5 % for the conventional nano-hybrid composite. TEC and TEC Bulk share the same underlying manufacturer’s philosophy regarding filler type and size, the presence of prepolymers, and similar resin matrix. TEC and TEC Bulk contain the same Ba-Al-glass fillers of a mean size of 0.4 and 0.7 μm, prepolymerized and milled mixture of monomer, ytterbium fluoride, and glass fillers well as 160-nm-sized mixed oxide fillers. Nevertheless, greater filler and lower prepolymer content, according to technical information of the manufacturer, and increased curing efficiency based on the new “booster” photoinitiator likely resulted in the generally greater VH of TEC Bulk than TEC control. The new germanium-based photoinitiator has shown a more intense absorption in the visible light spectrum, albeit at lower wavelengths than camphorquinone with a potential for faster and deeper polymerization. Other reported properties of this photoinitiator are good solubility in methacrylate monomers, low water solubility, low toxicity, and lower yellowing effect than camphorquinone [8]. Superior hardness of TEC Bulk compared to TEC is corroborated by previous Knoop microhardness measurements 24 h post-irradiation [34]. All the curing characteristics measured in this study, among which also the significantly lowest DoC of all composites was investigated, confirm that the conventional TEC composite should be applied in layers.

A special bulk-fill composite is the sonic-activated composite SonicFill. DC revealed that SonicFill should be cured sufficiently, at least 20 s for a 4-mm bulk layer and longer for the (non-recommended) 6-mm bulk layer. These findings correspond to the minimum curing times recommended by the manufacturer (technical information of Kerr); a 20-s cure for an up to 5-mm bulk layer is recommended for high-power light-curing devices and programs, and even a 40-s curing time when curing in a “regular” mode. Additional curing from buccal and lingual for class-I cavities and also after matrix removal for class-II cavities is safely recommended following the manufacturer’s instructions. The highest VH values of all composites investigated were recorded for SonicFill, at least when measured at the specimen top surface. As the DC of SonicFill at the specimen top surface significantly underscored that of the flowable bulk-fill composite SDR, the significantly highest VH of SonicFill must, to a great extent, be attributed to the high filler loading and thus superior mechanical properties. Increased VH was previously reported for bulk-fill composites with higher filler content [10]. The lower curing efficiency, requiring longer curing times, also appears from the VH bottom-to-top ratios. Only a layered filling procedure (“2 + 2 mm_2 × 10 s”) reached a bottom-to-top ratio above 0.9. Of all tested bulk-fill composites (thus except for the conventional control composite), the lowest bottom-to-top ratio (only 0.2) was measured for the 6-mm bulk-fill procedure, being only 1 mm above the recommended maximum curing depth. Since also the second lowest DoC, being below 4 mm for a 20-s curing time, was measured for SonicFill (only the conventional composite scored worse), higher light-power programs and/or longer curing times are indeed recommended, as mentioned above as well as instructed by the manufacturer. It is not clear if the sonic activation on itself, perhaps generating internal heat, may positively influence curing efficiency. Finally, the significantly lowest translucency in terms of TP was recorded for SonicFill, which is in agreement with the results of Bucuta and Ilie [10]. This self-evidently leads to reduced light penetration through the bulk and thus contributes to the need for more powerful and longer curing regimes. This was in particular corroborated by the decrease in DC for the 6-mm versus 4-mm bulk layers, which was greater for SonicFill than for any other bulk-fill composite (thus except for the conventional composite control) (Fig. 2).

DC was quite consistent for the fiber-reinforced bulk-fill base composite Xenius, this for the four different filling procedures and when measured at the specimen top and bottom surface. More varying VH data were however measured, indicating that a longer 20-s curing time is definitely needed with increased bulk-fill depth, as also appeared from the VH bottom-to-top ratios. Nevertheless, DoC was highest of all composites tested, not significantly different from that of the flowable bulk-fill composites SDR and Filtek Bulk. Most striking was the translucency of Xenius, reaching by far the highest TP of all composites tested. This must most likely be associated with the glass fibers with an average length of 1.3–2 mm [12]. Previously, the presence of these fibers in experimental fiber-reinforced composite materials has been associated with improved flexural strength and load-bearing capacity [19], and reduced shrinkage stress and microleakage [20].

Differences were observed between the present results for DC and VH of bulk-fill composites and those reported for the same materials tested in a previous study [23]. These differences may be due to the different specimen geometry and curing conditions between the two studies, i.e., we used 4-mm-thick specimens cured once for 10 or 20 s, whereas Leprince et al. used 2 × 2 × 25 mm specimens cured by four 40-s overlapping irradiations [23].

Regarding test methodology, DoC was determined using the acetone-shaking test [25] as a modification of the hand-scrapping test recommended by the ISO/DIS 4049 (2008) standard [26]. Unpolymerized resin was removed by dissolution in acetone, as an organic solvent, through standardized mixing, thereby eliminating the non-standardized hand scrapping with a spatula. The flowable bulk-fill composite SDR revealed a similar DoC and the sculptable bulk-fill composite TEC Bulk a larger DoC than that measured in the study by Flury et al. [33]. Specimen preparation and curing were similar, but Flury et al. [33] used the hand-scrapping method with a plastic spatula to remove the uncured material. DoC of all tested bulk-fill composites was higher in our study, even by up to 1 mm, compared to the study of Garoushi et al. [35], who also used the hand-scrapping method. The non-standardized hand-scrapping technique may account for the large variation in DoC measured in different studies, suggesting the need to introduce a more controllable method such as the acetone-shaking test employed in our study. Moreover, using the acetone-shaking test, DoC of SonicFill remained below 4 mm. This result was not in close agreement with the DC and VH measurements, which showed about 50 % conversion at the specimen bottom surface and a bottom-to-top ratio of 0.8 for the 4-mm bulk layer and when cured for 20 s. The reason for this discrepancy could be that DoC is determined by dividing the remaining sample thickness by 2 as required by the ISO/DIS 4049 (2008) standard, which in this case may have led to an underestimation of DoC.

With a safety margin of 1 mm, the manufacturer’s instructions of most bulk-fill composites limiting the single-layer increment to a thickness of 4 mm seem justified. The translucency of the flowable bulk-fill composites SDR and Filtek Bulk, although significantly lower than that of Xenius, appeared sufficient for light to reach the specimen bottom in order to properly cure at the 4-mm depth and for SDR also at the 6-mm depth. The initial flowable nature of these composites may have contributed to this finding, as the non-flowable bulk-fill composite TEC Bulk, possessing a similar translucency as SDR, revealed a significantly lower DC and VH at the specimen bottom surface. Furthermore, imino groups (-NH-) in UDMA have been considered responsible for continued polymerization through chain-transfer reactions and increased mobility of radical sites [36], which, combined with the low viscosity of Filtek Bulk and SDR, may have contributed to monomer conversion in these two materials. DoC and TP of the sonic-activated bulk-fill composite Sonicfill however appears less favorable by being in the range of TP and DoC recorded for the control conventional composite TEC.

Longer curing time (20 s versus 10 s) improved monomer conversion to a much lower extent than surface hardness, the latter being significantly higher upon 20-s curing for the non-flowable bulk-fill composites Xenius, TEC Bulk, and SonicFill. Improved surface hardness has been associated with higher monomer to polymer conversion for conventional composites [37, 38]. A recent study reported increased microhardness of bulk-fill composites following 24 h of dry storage but a significant decrease of this property following the same period of storage in 75 % ethanol/water solution [24]. The current experiments were taken after 24 h storage to allow polymer post-cure effects which lead to increased double bond conversion as shown previously [32]. Dry storage is especially important prior to DC measurements using FTIR or micro-Raman spectroscopy because any liquid storage medium could facilitate monomer elution resulting in artificially high DC values. This experimental setup allowed accurate assessment of initial polymer properties while any long-term evaluation of clinically relevant material performance would require water storage for longer intervals.

The relation between DC and VH showed that an average 0.9 DC ratio between bottom and top surface corresponded to a 0.8 VH ratio of the tested composites. This suggests that a decrease in microhardness of the bulk-fill composites is not followed by the same decrease in the double bond conversion (Fig. 6). Furthermore, the Pearson correlation showed a positive linear correlation between DC and VH values only for the bottom surfaces of all tested composites. Looking at the top surfaces, DC linearly correlated with VH only for the fiber-reinforced bulk-fill base composite Xenius (Table 2). These findings indicate that additional cross-linking tests of bulk-fill composites are required to elucidate the relation between hardness and physical rearrangement of the polymeric units and/or additional conversion of pendant double bonds across the bulk polymer.

Conclusions

The “flowable” and “sculptable,” the “base” and “full-depth,” the “sonic-activated,” and the “fiber-reinforced” bulk-fill composites differ for DC, VH, DoC, and TP following the four different filling procedures, this depending on curing time and bulk-fill depth. For flowable bulk-fill composites, 10 s light-curing with a high-intensity LED light-curing unit appears sufficient, while non-flowable or sculptable bulk-fill composites are best cured for at least 20 s. DC and VH positively correlated at the deeper portions of the bulk-fill composites. Significantly lower VH and bottom-to-top VH ratios below 80 % suggest that no bulk-fill composite is recommended for a 6-mm bulk-fill placement.

References

Momoi Y, Hayashi M, Fujitani M, Fukushima M, Imazato S, Kubo S, Nikaido T, Shimizu A, Unemori M, Yamaki C (2012) Clinical guidelines for treating caries in adults following a minimal intervention policy—evidence and consensus based report. J Dent 40:95–105

Ferracane JL (2011) Resin composite—state of the art. Dent Mater 27:29–38

Versluis A, Douglas WH, Cross M, Sakaguchi RL (1996) Does an incremental filling technique reduce polymerization shrinkage stresses? J Dent Res 75:871–878

Ilie N, Hickel R (2007) Quality of curing in relation to hardness, degree of cure and polymerization depth measured on a nano-hybrid composite. Am J Dent 20:263–268

Lazarchik DA, Hammond BD, Sikes CL, Looney SW, Rueggeberg FA (2007) Hardness comparison of bulk-filled/transtooth and incremental-filled/occlusally irradiated composite resins. J Prosthet Dent 98:129–140

Van Ende A, De Munck J, Mine A, Lambrechts P, Van Meerbeek B (2010) Does a low-shrinking composite induce less stress at the adhesive interface? Dent Mater 26:215–222

Van Ende A, Mine A, De Munck J, Poitevin A, Van Meerbeek B (2012) Bonding of low-shrinking composites in high C-factor cavities. J Dent 40:295–303

Moszner N, Fischer UK, Ganster B, Liska R, Rheinberger V (2008) Benzoyl germanium derivatives as novel visible light photoinitiators for dental materials. Dent Mater 24:901–907

Ilie N, Hickel R (2011) Investigations on a methacrylate-based flowable composite based on the SDR technology. Dent Mater 27:348–355

Bucuta S, Ilie N (2014) Light transmittance and micro-mechanical properties of bulk fill vs. conventional resin based composites. Clin Oral Investig 18:1991–2000

Ivoclar Vivadent. Tetric evoceram bulk fill—scientific documentation 2011.

Garoushi S, Sailynoja E, Vallittu PK, Lassila L (2013) Physical properties and depth of cure of a new short fiber reinforced composite. Dent Mater 29:835–841

Czasch P, Ilie N (2012) In vitro comparison of mechanical properties and degree of cure of bulk fill composites. Clin Oral Investig 17:227–235

El-Safty S, Silikas N, Watts DC (2012) Creep deformation of restorative resin-composites intended for bulk-fill placement. Dent Mater 28:928–935

Moorthy A, Hogg CH, Dowling AH, Grufferty BF, Benetti AR, Fleming GJ (2012) Cuspal deflection and microleakage in premolar teeth restored with bulk-fill flowable resin-based composite base materials. J Dent 40:500–505

Roggendorf MJ, Kramer N, Appelt A, Naumann M, Frankenberger R (2011) Marginal quality of flowable 4-mm base vs. conventionally layered resin composite. J Dent 39:643–647

Salerno M, Derchi G, Thorat S, Ceseracciu L, Ruffilli R, Barone AC (2011) Surface morphology and mechanical properties of new-generation flowable resin composites for dental restoration. Dent Mater 27:1221–1228

Petrovic LM, Zorica DM, Stojanac I, Krstonosic VS, Hadnadjev MS, Atanackovic TM (2013) A model of the viscoelastic behavior of flowable resin composites prior to setting. Dent Mater 29:929–934

Garoushi S, Vallittu PK, Lassila LV (2007) Short glass fiber reinforced restorative composite resin with semi-inter penetrating polymer network matrix. Dent Mater 23:1356–1362

Garoushi S, Vallittu PK, Watts DC, Lassila LV (2008) Polymerization shrinkage of experimental short glass fiber-reinforced composite with semi-inter penetrating polymer network matrix. Dent Mater 24:211–215

Garoushi S, Vallittu PK, Lassila LV (2008) Depth of cure and surface microhardness of experimental short fiber-reinforced composite. Acta Odontol Scand 66:38–42

Alrahlah A, Silikas N, Watts DC (2014) Post-cure depth of cure of bulk fill dental resin-composites. Dent Mater 30:149–154

Leprince JG, Palin WM, Vanacker J, Sabbagh J, Devaux J, Leloup G (2014) Physico-mechanical characteristics of commercially available bulk-fill composites. J Dent 42:993–1000

Alshali RZ, Salim NA, Satterthwaite JD, Silikas N (2015) Post-irradiation hardness development, chemical softening, and thermal stability of bulk-fill and conventional resin-composites. J Dent 43:209–218

Kleverlaan CJ, de Gee AJ (2004) Curing efficiency and heat generation of various resin composites cured with high-intensity halogen lights. Eur J Oral Sci 112:84–88

ISO 4049 (2009) Dentistry—polymer-based restorative materials

Van Ende A, De Munck J, Van Landuyt KL, Poitevin A, Peumans M, Van Meerbeek B (2013) Bulk-filling of high C-factor posterior cavities: effect on adhesion to cavity-bottom dentin. Dent Mater 29:269–277

Feilzer AJ, De Gee AJ, Davidson CL (1990) Quantitative determination of stress reduction by flow in composite restorations. Dent Mater 6:167–171

Shah PK, Stansbury JW (2014) Role of filler and functional group conversion in the evolution of properties in polymeric dental restoratives. Dent Mater 30:586–593

Miletic V, Santini A (2012) Micro-Raman spectroscopic analysis of the degree of conversion of composite resins containing different initiators cured by polywave or monowave LED units. J Dent 40:106–113

Truffier-Boutry D, Demoustier-Champagne S, Devaux J, Biebuyck JJ, Mestdagh M, Larbanois P, Leloup G (2006) A physico-chemical explanation of the post-polymerization shrinkage in dental resins. Dent Mater 22:405–412

Par M, Gamulin O, Marovic D, Klaric E, Tarle Z (2014) Effect of temperature on post-cure polymerization of bulk-fill composites. J Dent 42:1255–1260

Flury S, Hayoz S, Peutzfeldt A, Husler J, Lussi A (2012) Depth of cure of resin composites: is the ISO 4049 method suitable for bulk fill materials? Dent Mater 28:521–528

Tarle Z, Attin T, Marovic D, Andermatt L, Ristic M, Taubock TT (2015) Influence of irradiation time on subsurface degree of conversion and microhardness of high-viscosity bulk-fill resin composites. Clin Oral Investig 19:831–840

Chang MC, Lin LD, Chan CP, Chang HH, Chen LI, Lin HJ, Yeh HW, Tseng WY, Lin PS, Lin CC, Jeng JH (2009) The effect of BisGMA on cyclooxygenase-2 expression, PGE2 production and cytotoxicity via reactive oxygen species- and MEK/ERK-dependent and -independent pathways. Biomaterials 30:4070–4077

Sideridou I, Tserki V, Papanastasiou G (2002) Effect of chemical structure on degree of conversion in light-cured dimethacrylate-based dental resins. Biomaterials 23:1819–1829

Santini A, Miletic V, Swift MD, Bradley M (2012) Degree of conversion and microhardness of TPO-containing resin-based composites cured by polywave and monowave LED units. J Dent 40:577–584

Bouschlicher MR, Rueggeberg FA, Wilson BM (2004) Correlation of bottom-to-top surface microhardness and conversion ratios for a variety of resin composite compositions. Oper Dent 29:698–704

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

Dr. Miletic’s research at KU Leuven was funded by a CED-IADR Visiting Scholar Stipend, the G.0496.10 grant of the Research Foundation-Flanders (FWO), and the Research grant ON172007 from the Ministry of Education, Science and Technological Development, Republic of Serbia.

Conflict of interest

Authors VM, PP, JDM, NRB, and BVM declare that they have no conflict of interest. Research grants and/or speaker honoraria have been received by KU Leuven and/or UZ Leuven, who employ the authors BVM and JDM, these from the companies, of which products have been investigated in this study, but they were however not directly related with the current research reported in this paper. The authors are grateful to all of the named companies for generous donations of materials used in this study.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Not applicable. No human participants were involved in the present study. No biological tissue (e.g., extracted teeth) was used in the present study.

Rights and permissions

About this article

Cite this article

Miletic, V., Pongprueksa, P., De Munck, J. et al. Curing characteristics of flowable and sculptable bulk-fill composites. Clin Oral Invest 21, 1201–1212 (2017). https://doi.org/10.1007/s00784-016-1894-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-016-1894-0