Abstract

Qualitative and quantitative determination of amino acid composition using amino acid analysis (AAA) is an important quality attribute and considered an identity of therapeutic peptide drugs by the regulatory agencies. Although huge literature is available on pre- and post- column derivatization AAA methods, arriving at an appropriate hydrolysis protocol coupled with adequate separation of the derivatized/underivatized amino acids is always challenging. Towards achieving a facile and comprehensive protocol for AAA, the present work is geared towards developing a deeper understanding of the extent of hydrolysis of peptide, and the nature and stability of amino acids present in the peptide backbone. This defines the suitability of the method in meeting the end goals and the regulatory requirement. Analysis of historical data generated during the method optimization of AAA for icatibant acetate (ICT) using head space oven hydrolysis (HSOH) and microwave-assisted hydrolysis (MAH) methods helped in arriving at fast (< 1 h) and efficient hydrolysis (0.9–1.1 of theoretical residue) conditions. Better separations for the natural and unnatural amino acids were achieved using 3.45 ≤ pH ≤ 10.85, and a column oven gradient program. This approach was useful in meeting the method quality attributes [resolution (Rs) > 2.0; plate count (N) > 5600; and USP tailing factor < 1.2] with a target analytical method profile of relative amino acid mole ratios (RAAMR) in the range of 0.9–1.1 for Ser, Oic, Tic, Hyp, Ala (Thi), Gly and Pro, and between 2.7 and 3.3 for Arg. The developed method was validated as per the ICH guidelines and is precise, accurate, linear and robust.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent times, therapeutic peptides (TP) are of immense interest for enhanced target specificity, safety, and efficacy profiles, relative to small molecules (Di 2015; Fosgerau and Hoffmann 2015; Lau and Dunn 2018). Commercially, TP are manufactured using chemical synthesis routes (e.g., solid or solution phase peptide synthesis) or through a recombinant DNA technology path using living systems such as bacteria. Synthetic peptides are an important class of TP that use natural and unnatural amino acids, and their derivatives are the building blocks in the design of peptide backbone (Qvit et al. 2017). Structural identity (Wu 2013) of these backbone peptides are assessed using a combination of analytical techniques based on mass spectrometry, amino acid analysis (AAA), Edman degradation, nuclear magnetic resonance spectroscopy (NMR), peptide mapping, and Ellman test, to name a few (Lobas et al. 2013; Williamson 1993; Guthals and Bandeira 2012; Ellman 1959; Rutherfurd and Gilani 2009; Fürst et al. 1990; Moore and Stein 1951).

AAA is regarded as an identification and characterization test in the structural identification of TP by regulatory agencies, based on method complementarity (Eggen et al. 2014). AAA is used as one of the release identification tests of published peptide [e.g., bivalirudin, exenatide, octreotide] monographs, and is useful in determining peptide content in the sample quantitatively. In structure confirmation analysis of unknown peptides, peptide mapping studies are strategized through the support of AAA. AAA also serves as an important tool in non-pharmaceutical industries such as food technology, proteomics, and metabolomics (Fierabracci et al. 1991; Qureshi and Qureshi 1989; Ishida et al. 1981; Blundell and Brydon 1987), in the determination of concentrations in native or derivatized form of amino acids using pre- or post-column derivatization methods.

Despite the availability of literature on AAA, the choice of hydrolysis temperature, hydrolysis time, chromatographic conditions to separate derivatized or underivatized amino acids, and selection of suitable derivatizing reagent, is specific to individual peptide sequence and their constituent amino acids. Moreover, many hydrolysis protocols are laborious and time-consuming and could lead to loss of sensitive amino acids (such as serine, cysteine, and threonine) during the hydrolysis step, resulting in lower recoveries. Therefore, it is challenging to arrive at a suitable, facile hydrolysis and derivatization procedure along with an adequate chromatographic separations method for accurate quantification of amino acids in a given peptide. Some of the published methods on AAA of therapeutic peptides containing proteinogenic amino acids used hydrolysis of procedures at elevated temperatures (> 130 °C for 3 h), additive-free, and microwave-assisted methods (Akhlaghi et al. 2015; Hsieh et al. 1999; Zhong et al. 2005). However, there is no known literature on therapeutic peptides having non-proteinogenic amino acids.

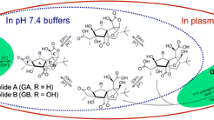

Icatibant acetate (ICT) (Firazyr) is a synthetic decapeptide with five non-proteinogenic amino acids and structurally similar to bradykinin. It is a selective, competitive antagonist at the bradykinin type 2 (B2) receptor, and is used in the treatment of acute attacks of hereditary angioedema (HAE) in adults (with C1-esterase-inhibitor deficiency). The three letter IUPAC code is given by H-DArg-Arg-Pro-Hyp-Gly-Thi-Ser-D-Tic-Oic-Arg-OH, and its structure is represented in Fig. 1. CHMP assessment report for Firazyr contains AAA as one of the proposed identification tests for the control of the active ingredient, ICT. To the best of our knowledge, there is no published reports on the AAA of ICT and no known literature on the qualitative or quantitative AAA of TPs containing non-proteinogenic amino acids.

In this work, we focused on developing an appropriate and facile post-column derivatization (Po-CDT) AAA method using ninhydrin reagent to determine the RAAMR of natural and unnatural amino acids present in ICT. Non-conventional gas chromatography head space oven hydrolysis (HSOH) and microwave-assisted hydrolysis (MAH) methods were used to hydrolyze ICT. Analysis of historical data using regression tool of response surface methodology (RSM) helped in understanding the impact of hydrolysis temperature and time on RAAMR, and in arriving at the final hydrolysis conditions using both methods of hydrolysis. Adequate separation (Rs > 2) between the adjacent eluting amino acids prior to ninhydrin derivatization was achieved using cation-exchange chromatography. Further, the optimized HSOH method was validated according to ICH guidelines (Reason 2003), and is found to be precise, accurate, rugged, and robust. This approach can be used as a chemical identification and characterization test in quality control laboratories to determine the amino acid composition of proteinogenic and non-proteinogenic amino acids present in ICT (Fig. 2).

Materials and methods

HPLC-grade reagents of sodium hydroxide, methanol, isopropyl alcohol, and ethanol were purchased from Merck, Mumbai, India, and used directly in mobile phase preparations. Ninhydrin reagent, buffer solution A (pH 3.45; sodium citrate buffer − 0.12 N), buffer solution B (pH 10.85; sodium citrate buffer − 0.2 N), mobile phase C (used as regeneration solution, 0.5 N sodium hydroxide) and sample dilution buffer were procured from Sykam, Germany. All the natural amino acid standards were purchased from Sigma-Aldrich, India. Unnatural amino acid standards and icatibant acetate samples were generously provided by Dr. Reddy’s Laboratories, Integrated Product Development Organization, India. Hydrochloric acid and sodium hydroxide were procured from Sigma-Aldrich. Design-Expert ® software version 11 is used for the statistical analysis of historical data generated using HSOH and MAH hydrolysis methods.

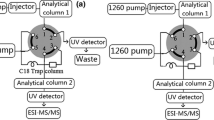

Instrumentation and chromatographic conditions

The Sykam amino acid analyzer equipped with solvent pump, auto sampler, and visible detector at 570 nm and 440 nm detector, and Clarity amino software for data acquisition and elaboration were used. Separation of all the natural and unnatural amino acids of ICT were achieved by employing the cation (sodium form) exchange separation column (Cat No: LCA K06/Na, 150 × 4.6 mm, and 7 µm particle size) using a combination pH gradient of mobile phase A, mobile phase B, and mobile phase C [time (min)/%B] 0.00/0.0, 3.00/0.0, 9.0/15, 16/20, 22/33, 26/80, 28/80, 31/100, 41/100, [time (min)/%C] 41.01/100, 44/100, [time (min)/%B] 44.01/0.0, 56/0.0, 56.01/0.0, 58/0.0 operated at a flow rate of 0.45 mL/min. The column oven temperature was maintained using the program 0/57, 20/57, 25/74, 47/74, 52/57, 57/57. Ninhydrin reagent flow was maintained at 0.25 mL/min and injection volume of 50 µL was used. The post-column derivatization was carried out at 130 °C (reactor coil temperature). Derivatized natural and unnatural amino acids were monitored at 570 and 440 nm.

Standard and sample preparation

The amino acid standard solutions were prepared at 180 nmol/mL concentration for each of these amino acids: Ser, Gly, Pro, Hyp, Ala(thi), Tic, and Oic, and 540 nmol/mL of Arg, and was directly used for the derivatization. The sample was hydrolyzed in an Agilent GC head space vial containing 5 mg of ICT in 0.8 mL of 6N HCl reagent, and purged and sealed under nitrogen environment for the HSOH method. Hydrolysis using the MAH method was conducted at the same concentration using Anton-Paar to make 5 mL digestion vials. After the hydrolysis, 140 µL of sample was neutralized with 194 µL of sodium hydroxide solution (4 N) followed by further dilution of 140 µL in 1060 µL of sample dilution buffer (pH 2.2, sodium citrate 0.12 N) and this solution was used for the derivatization using ninhydrin by post-column derivatization.

Method optimization

AAA involves hydrolysis of peptide sample to its constituent-free amino acids in a suitable reagent (an acid or a base) at elevated temperatures for several hours. These free amino acids are blind to UV–visible region and are derivatized either by pre-column derivatization (Pr-CDT) (Zhang et al. 2012; Zhao et al. 2007) or post-column derivatization (Po-CDT) methods (Rigas 2013; Adriaens et al. 1977; Wainer 1967; Moore and Stein 1948) using a suitable derivatizing agent (e.g., 9-fluorenylmethyl-chloroformate (F-moc), orthophthalaldehyde (OPA), phenylisothiocyanate (PITC), Ninhydrin, dimethylamino-naphthalenesulfonyl chloride, dimethylaminoazobenzene sulfonylchloride). Several analytical techniques such as gas chromatography (Blundell and Brydon 1987; Kataoka et al. 1994; Moodie et al. 1989; Lewis et al. 1980; Kataoka et al. 1997; Matsumura et al. 1996; Duncan and Poljak 1998), high-performance liquid chromatography (Fekkes et al. 2000; Xia et al. 2016; Nakano et al. 2017; Buiarelli et al. 2013; Campanella et al. 1999; Fürst et al. 1990; Fierabracci et al. 1991), ion-exchange chromatography, and capillary electrophoresis (Zunić and Spasić 2008; Omar et al. 2017; Skelley and Mathies 2003; Zahou et al. 2000) have been used in the literature to estimate the derivatized or underivatized forms of amino acids.

Pr-CDT AAA procedures are highly influenced by derivatization conditions such as pH, temperature, time, sample matrix (e.g., buffers, salts) and solvent extraction procedures (to remove the excess reagent and extract the derivatized amino acids) (Ng and Anderson 1998). Pr-CDT methods are sensitive due to manual interventions and pose significant challenges while validating and quality control analysis. On the other hand, most of these difficulties are addressed by automation of some or all of the manual operations in Po-CDT methods. It also involves separation of free amino acids from the hydrolysate solution using ion-exchange chromatography prior to derivatization by ninhydrin/o-phthaldialdehyde (Le Boucher et al. 1997; Heftmann 2004). Hence, Po-CDT AAA methods are advantageous in achieving better quantitative and qualitative analysis results, compared to Pr-CDT methods.

Quality by design approach was followed during the development of the Po-CDT AAA method and finalizing the method conditions to determine the RAAMR of ICT. AAA by the Po-CDT procedure involves three important steps: peptide hydrolysis, chromatographic separation of amino acids from hydrolysate solution, and derivatization using ninhydrin reagent. The critical parameters associated with each step are summarized in the fishbone diagram (Fig. 3; bold font).

The influence of each key method parameter on the hydrolysis step was quantified by the extent of peptide hydrolysis (EOH) in understanding the hydrolysis efficiency, and was considered as a figure of merit (FOM) for the hydrolysis step. The efficiency of chromatographic separation was determined by peak tailing (Tf), resolution (Rs) and theoretical plate count (N), and was considered as FOM for the chromatographic separation step. Relative mole ratios (RAAMR) of each of the amino acids in ICT were considered as FOM for the hydrolysis and derivatization steps of the Po-CDT method. Other method parameters (non-bold) in Fig. 3 at each step of Po-CDT AAA were unaltered based on their potential impact on the selected figure of merits of the method. Further details are discussed in the following section.

Optimization of peptide hydrolysis

The success of the Pr-CDT or Po-CDT AAA method was majorly defined by the peptide hydrolysis step. The choice of hydrolysis temperature and time always depends on the type of amino acid present in the peptide. Conventionally, peptide samples were subjected to hydrolysis in suitable hydrolysis reagents (acid or base) at elevated temperatures (> 100 °C) for several hours (~ 20 h) under inert (nitrogen) atmosphere. This could lead to degradation/oxidation of sensitive amino acids during hydrolysis. As part of the continuous development in peptide hydrolysis protocols, we attempted non-conventional peptide hydrolysis methods based on HSOH and MAH to accelerate the hydrolysis process and reduce the time of exposure for the amino acids to harsh conditions. This will minimize the degradation of sensitive amino acids with improved recoveries and shortening cycle time for the analysis.

Head space oven hydrolysis (HSOH)

Gas chromatography head space oven (HSOH) was used as a source of temperature to hydrolyze the peptide as it provides accurate and homogeneous temperature for hydrolysis in the range of ±1 °C. GC head space crimp vials were used for the hydrolysis of peptide in 6 M HCl under inert atmosphere and these are inert to acid hydrolysis conditions with no leakages during hydrolysis. Optimization experiments were conducted using variable hydrolysis temperature (110–150 °C) and time (3–6 h) using 5 mg of ICT sample in 6 M HCl. The details of the experiments and results are summarized in Table 1.

Microwave-assisted hydrolysis (MAH)

Microwave digestion technique was used to accelerate the rate of hydrolysis of the peptide and achieve complete hydrolysis in a short interval of time. This provides minimum exposure for the liberated amino acids to harsh conditions of hydrolysis, and hence low degradation with improved recoveries (Hesse and Weller 2016). The hydrolysis of the ICT sample was carried in specialized 5 mL (Anton Par) microwave digestion vials under N2 atmosphere using 5 mg of sample in 800 µL of 6 M HCl in the temperature range 80–180 °C and time of exposure between 0.25 and 4.0 h (Table 2). The hydrolyzed samples from both HSOH and MAH were directly used for Po-CDT using ninhydrin derivatization after neutralization and pH adjustment using diluent buffer at room temperature.

Optimization of the chromatographic method

Mobile phase and reagent flow rate

The mobile phase and ninhydrin reagent pump flow rates were considered as fixed parameters during the optimization of the chromatographic method and were operated in the allowed instrument tolerance ranges. Chromatographic separation of all the natural and unnatural amino acids of ICT was ensured with a minimum resolution factor (Rs) > 2.0, with the mobile phase flow rate of 0.45 mL/min, while varying the pH and temperature gradient. Also, the reagent flow rate of 0.25 mL/min ensured continuous flow derivatization of all the amino acids under the optimized pH and column oven temperature gradient program discussed in the following sections.

pH and column oven temperature gradient

Under acidic pH conditions, amino acids possess positive charge and absorb on the negatively charged stationary phases (sulfonated cation-exchange resins) (Csapó et al. 2008). The strength of absorption of amino acids depend on net charge on the respective amino acid and will elute from the column at higher pH and ion strength mobile phases after reaching the isoelectric point. Amino acids possess no net charge at the isoelectric point (pI) and the attraction toward the negatively charged stationary phase ceases and hence elutes from the column. Also, usage of higher pH and ion strength aqueous buffers leads to higher column back pressures during the pH change from acidic to basic under the gradient elution mode (Moore and Stein 1951, 1958). Hence, a pH gradient in combination with higher column oven temperature (> 75 °C) gradients help in reducing the column back pressures during the pH changeover and influences the affinity of respective amino acids toward cation-exchange stationary phase. It also helps in achieving acceleration of the elution of amino acids with better resolutions.

During the pH gradient optimization, column oven temperature program was initially fixed to understand the effect of pH on the elution behavior of natural and unnatural amino acids. Further chromatographic separation is improved by using optimum temperature gradient to achieve a resolution Rs > 2.0 between each of the adjacent amino acids.

The initial pH gradient program-1 [time (min)/%B] 0.00/15 3.00/15, 7.0/15, 12/40, 16/90, 20/90, 27/100, 27.01/0.00, 32/0.00, 32.01/15, 40.00/15. [Time (min)/%C] 27.01/100, 32/100 with temperature program time (min)/temperature °C, 0/57, 3/57, 15/74, 30/74, 33/57, 40/57 yielded broad peak shape for the Oic peak and ammonia peak eluted just at the end of the chromatogram leading to baseline instability in successive injections (Fig. 4a).

To address the above, the pH gradient was slowed down to [time (min)/%B] 0.00/0.0 3.00/0.0, 9.0/15, 16/20, 22/33, 26/80, 28/80, 29/100, 41/100, [time (min)/%C] 41.01/100, 44/100, [time (min)/%B] 44.01/0.0, 56/0.0, 56.01/0.0, 58/0.0 with a change in temperature program time (min)/temperature °C, 0/57, 20/57, 25/74, 47/74, 52/57, 57/57. The above combination of change in pH along with temperature gradient program resulted in higher retention time for all the amino acids. The peak response for Ser was found to be reduced with an improved peak shape for the Oic peak. These chromatographic conditions were found to be resolving all the eight amino acids; however, the presence of negative peak at the peak tailing of Tic amino acid leads to variation in areas from injection to injection. Hence, the gradient program was slightly modified as [time (min)/%B] 0.00/0.0 3.00/0.0, 9.0/15, 16/20, 22/33, 26/80, 28/80, 31/100, 41/100, [time (min)/%C] 41.01/100, 44/100, [time (min)/%C] 44.01/0.0,56/0.0, 56.01/0.0, 58/0.0, and temperature program time (min)/temperature °C, 0/57, 20/57, 25/74, 47/74, 52/57, 57/57, to address the negative peak. Using the above pH gradient and temperature gradient programs, all the amino acids present in ICT were resolved with a resolution factor Rs > 2 and USP tailing factor 1.1, and the % RSD for the areas were found to be < 1.0% (Fig. 4b). Further, the robustness of the column temperature gradient was verified in the range of ± 2 °C of the target temperature during the validation.

Derivatization

The free amino acids obtained from the acid hydrolysis of ICT were subjected to ninhydrin Po-CDT. Samples were obtained from HSOH and MAH hydrolysis procedures after ion-exchange chromatographic separation. Primary amino acids such as Ser, Gly, Thi and Arg, gave blue-purple product and were monitored in the visible region at 570 nm. Secondary amino acids such as Hyp, Tic, Oic, and Pro, gave yellow-orange product and were monitored at 440 nm of visible region Fig. 5 (Troll and Lindsley 1955; Chinard 1952; Bates et al. 1973; Friedmann 2004; Fosgerau and Hoffmann 2015; Wu 2013). The reactor coil temperature and ninhydrin (reagent) flow are important in ensuring the completeness of derivatization of amino acids. The optimum reactor temperature 130 ± 2 °C and reagent flow of 0.25 mL/min were followed as per the Sykam amino acid analyzer recommendation to ensure continuous derivatization of all the amino acids present in ICT.

Results and discussion

Ensuring complete hydrolysis with the minimum loss of amino acids during hydrolysis was measured by EOH, as determined by the ratio of experimentally obtained concentration of the amino acid to that of the theoretical concentration of the amino acid present in ICT. RAAMR of individual amino acids was determined by the ratio of the obtained concentration of the individual amino acid to the total concentration of all the amino acids multiplied by the number of amino acids in the peptide (Tables 1, 2).

Hydrolysis by HSOH at 110 °C for 10 h gave complete hydrolysis of the peptide as measured by EOH (0.91–1.03), with relative molar ratio 2.87 for Arg, and 0.98–1.02 for all other amino acids. Hydrolysis at 120 °C for 6 h gave better EOH (0.89–1.01) for all the amino acids, with 3.04 relative mole ratio for Arg, and 0.94–1.08 for others. Peptide hydrolysis was found to be incomplete at 120 °C for 2 h and the measured EOH for Oic, Tic and Ser were 0.58, 0.62 and 0.80, respectively. However, at 120 °C for 3 h, EOH was improved for all the amino acids (> 0.9). Hydrolysis at high temperature (150 °C) for 3 h led to peptide degradation, and the order of degradation was Thi > Ser > Oic > Hyp. Hydrolysis was complete, and no degradation was noticed at 150 °C, after 0.5 h and 1 h. The results of EOH were between 0.89 and 1.04, with RAAMR for Arg within 2.95–3.04, and 0.92–1.09 for rest of the amino acids.

Experiments conducted using MAH at 150°C for 0.25 h and 0.5 h gave complete peptide hydrolysis. The EOH values were between 0.87 and 1.00, and RAAMR was 2.89 for Arg and 0.95–1.06 for all other amino acids. Increase in hydrolysis time from 0.5 h to 1 h at 150°C led to degradation of serine. Pronounced degradation was noticed at 180 °C and the relative order of degradation is Ser > Th (≈ Oic) > Hyp. Complete peptide hydrolysis was observed at 120 °C for 4 h and the EOH values ranged between 0.91 and 1.08, with 2.89 RAAMR for Arg, and between 0.91 and 1.07 for the rest of the amino acids.

The empirical relationship between hydrolysis time and temperature was predicted through analysis of historical data on HSOH and MAH methods independently using the regression tool of Design-Expert ® software version 11 intended for the response surface methods (RSM). RAAMR for each of the amino acid was used as a response (Table 1, 2) for the bivariate analysis to arrive at the confirmation location for the optimum conditions (Table 3). Ser, Thi, Oic and Hyp were highly sensitive to higher temperature (> 150 °C) and high time of exposure (> 1 h) under MAH conditions as well as HSOH conditions. The 2D plots of temperature vs. time (Fig. 6c) using the HSOH mode of hydrolysis revealed that the target RAAMR (2.7–3.3 for Arg and 0.9–1.1 for all other amino acids) could be achieved with a combination of lower temperature (between 125–110 °C) and high hydrolysis time (3–10 h), or with a combination of higher temperature (150 °C) and low hydrolysis time (1 h), and predicted the confirmation location (optimum) for the hydrolysis using HSOH at 150°C for 1 h (Fig. 6a). Similarly, the 2D plots of temperature vs. time presented in Fig. 6d revealed that using MAH as the mode of hydrolysis, the target RAAMR for all the amino acids was found to be in the temperature range 150–120 °C and hydrolysis time between 0.25 and 4 h. The confirmation location (optimum) using MAH is 126 °C for 2.3 h (Fig. 6b). Though the desired RAAMR and EOH were achieved using the MAH method within 15–30 min at 150 °C, it is highly sensitive to Ser and Ala(thi) amino acids at temperature higher than 150 °C and time > 30 min. HSOH using HSGC is a general laboratory equipment in quality control laboratories and requires no extra investment compared to MAH, and complete hydrolysis could be achieved in 1 h with the target RAAMR for all the amino acids. Hence, HSOH method is taken up for validation of AAA of ICT using ninhydrin Po-CDT.

Overlay plot of amino acid response contours for both the hydrolysis methods (a HSOH, and b MAH) to predict the optimum region of operation for the variables temperature and hydrolysis time. The yellow region represents the design space (region showing the optimal conditions for hydrolysis time and temperature) predicted by Design-Expert ® software version 11 for the HSOH and MAH methods with the RAAMR of all the amino acids within acceptance range (0.9–1.1); gray region represents regions of the RAAMR values outside the acceptance range. c Contour graphs for Ser, Gly, Ala(thi), Arg, Hyp, Pro, Oic, and Tic amino acids representing the design points (experimentally measured) and flags (optimal point predicted by predicted by Design-Expert ® software version 11) for the HSOH hydrolysis method. In these graphs, the graduated color scale indicates the predicted RAAMR for each amino acid, with lower RAAMR values represented by blue and higher RAAMR values by red. The flag on the graphs represents the optimal point against method variables: hydrolysis temperature and time. d Countour graphs for Ser, Gly, Ala(thi), Arg, Hyp, Pro, Oic, and Tic amino acids representing the design points (experimentally measured) and flags (optimal point predicted by Design-Expert ® software version 11) for the MAH hydrolysis method. In these graphs, the graduated color scale indicates the predicted RAAMR for each amino acid, with lower RAAMR values represented by blue and higher RAAMR values by red. The flag on the graphs represents the optimal point against the method variables: hydrolysis temperature and time (color figure online)

Method validation

System suitability and specificity

The system suitability of the method was performed to ensure consistent and reliable performance of the system as well as the method throughout the experiment. In this study, the system suitability of the method was assessed by injecting five replicates of amino acid standard solution containing Ser, Gly, Ala (thi), Hyp, Pro, Oic, and Tic, at a concentration of 180 nmol/mL and Arg at 540 nmol/mL. The retention times, relative standard deviation, and peak tailing were monitored for all the ninhydrin-derivatized amino acids as part of system suitability and the results are summarized in Table 4. Typical chromatograms of the amino acid standard from the system suitability and batch analysis of ICT analysis are shown in Fig. 4.

Precision

The closeness of agreement between the sequences of measurement achieved by multiple sampling of the homogeneous sample at the proposed condition is described as precision of the method (ICH Q2A Text on Validation of Analytical Procedures 1995). In this study, precision (repeatability) was conducted at three levels (50, 100 and 150%) along with intermediate precision. The intermediate precision helped in standardizing the method. The % RSD of RAAMR of natural and unnatural amino acids present in ICT was measured using six replicates of the sample prepared from the same homogeneous sample after subjecting to hydrolysis and derivatization as per the method conditions. The results of the precision and intermediate precision study are summarized in Table 5.

Linearity

The linearity of the analytical method is the ability (in the range of concentration) of the method to ensure that the test results are directly proportional to the concentration of the analyte in the sample (ICH Q2A Text on Validation of Analytical Procedures 1995). Here, the linearity study was performed in the concentration range between 25% to 150% (six concentrations: 25, 50, 75, 100, 125 and 150%) of the target sample concentration (180 nmol/mL) and the method was found to be linear (R2 > 0.999). The results of linearity data for all the natural and unnatural amino acids of ICT are summarized in Table 5.

Accuracy

The accuracy of the method demonstrates how the experimental and reference (true) values are close to each other. In this study, accuracy was tested at three different concentrations (50, 100, 150%) of the target sample concentration of 5 mg/mL and the measured RAAMR of all natural and unnatural amino acids in ICT were found to be within 0.9–1.1 of theoretical residue values for Ser, Hyp, Pro, Gly, Ala (thi), Tic, and Oic, and within 2.7–3.3 for Arg. The results are summarized in Table 6.

Mobile phase, standard and test solution stability

Mobile phase, standard, and test solution stability are crucial to obtain accurate and consistent results. Here, we studied the standard and sample solution stability for 48 h under refrigerator and room temperature conditions. Since mobile phase and ninhydrin reagents were stored and maintained at 2–8 °C, the stability of these solutions was verified at refrigerator conditions alone and found to be stable for a week from the date of opening under nitrogen atmosphere. The results of the mobile phase, standard, and test solution stabilities are summarized in Table 7.

Robustness

Robustness is the measure of the capability of an analytical method to remain unchanged or unaffected by small, but deliberate change in the method parameters (ICH Q2A Text on Validation of Analytical Procedures 1995). In this study, the column oven temperature (in the range of ± 2 °C), hydrolysis time (± 0.5 h), and temperature (± 5°C) were considered as part of robustness and the data are summarized in Tables 7 and 8.

Batch analysis

The batch analysis study of ICT was performed for the two different batches, and RAAMR of natural and unnatural amino acids of ICT were found to be between 2.7 and 3.3 for Arg, and 0.9–1.1 for the rest of the amino acids (Table 9).

Conclusions

Peptide hydrolysis was found to be important among other steps involved in the optimization of the Po-CDT method, for the determination of RAAMR of natural and unnatural amino acids in ICT. RSM analysis of historical data generated on HSOH and MAH modes of hydrolysis methods coupled with EOH of the peptide helped in arriving at the operational design space for both HSOH and MAH digestion methods. Peptide hydrolysis using he HSOH technique employing a temperature of 150 °C for 1 h was found to be optimal among all other HSOH conditions. Similarly, peptide hydrolysis using the MAH method was found to optimal at 126 °C for 2.3 h, based on RMS analysis (Table 3). Under these hydrolysis conditions, complete peptide hydrolysis was achieved along with the RAAMR in the range of 0.9–1.1 for Ser, Hyp, Gly, Pro, Ala(thi), Oic and Tic, and for Arg between 2.7 and 3.3. Though the desired RAAMR and EOH were achieved using the MAH method within 15–30 min at 150 °C, it is highly sensitive to Ser, Ala(thi) amino acids at temperatures > 150 °C and time > 30 min. The relative order of degradation measured by EOH was found to be similar for both the methods of hydrolysis (Ser > Ala > Oic > Hyp). Being a general quality control laboratory equipment, HSGC requires no additional cost for the execution of the hydrolysis protocol using the HSOH method, unlike the microwave-assisted digestion method. Also, the HSOH procedure meets the objective of facile hydrolysis within 1 h, and hence considered for the method validation as per ICH guidelines. The method was found to be facile, specific, precise (< 1.0%), accurate (0.9–1.1 of number of residues of amino acid), and linear in the test concentration range (0.00015–0.00046 mg/µL) of icatibant acetate. It could be used for the estimation of RAAMR of natural and unnatural amino acids present in ICT.

Abbreviations

- AAA:

-

Amino acid analysis

- ICT:

-

Icatibant acetate

- HSOH:

-

Head space oven hydrolysis

- MAH:

-

Microwave-assisted hydrolysis

- RAAMR:

-

Relative amino acid mole ratios

- R s :

-

Resolution

- USP:

-

United States pharmacopeia

- Ser:

-

Serine

- Gly:

-

Glycine

- Ala(thi):

-

Thienylalanine

- Arg:

-

Arginine

- Hyp:

-

Hydroxy-proline

- Pro:

-

Proline

- Oic:

-

Octahydro-1H-indole-2-carboxylic acid

- Tic:

-

D-1, 2, 3, 4-Tetrahydroisoquinoline-3-carboxylic acid

- TP:

-

Therapeutic peptides

- NMR:

-

Nuclear magnetic resonance spectroscopy

- IUPAC:

-

International Union of Pure and Applied Chemists

- CHMP:

-

Committee for Medicinal Products for Human Use

- Pr-CDT:

-

Pre-column derivatization

- Po-CDT:

-

Post-column derivatization

- RSM:

-

Response surface methodology

- F-moc:

-

9-Fluorenylmethyl-chloroformate

- OPA:

-

Orthophthalaldehyde

- PITC:

-

Phenylisothiocyanate

- Tf:

-

Peak tailing

- Rs:

-

Resolution

- N:

-

Theoretical plate count

- FOM:

-

Figure of merit

- EOH:

-

Extent of hydrolysis

- HSGC:

-

Head space gas chromatography

- GC:

-

Gas chromatography

- ICH:

-

International Conference on Harmonization

- RSD:

-

Relative standard deviation

References

Adriaens P, Meesschaert B, Wuyts W, Vaderhaeghe H, Eyssen H (1977) Separation of ninhydrin-positive compounds on a single-column amino acid analyzer using lithium buffers. J Chromatogr 140:103–108

Akhlaghi Y, Ghaffari S, Attar H, Alamir HA (2015) A rapid hydrolysis method and DABS-Cl derivatization for complete amino acid analysis of octreotide acetate by reversed phase HPLC. Amino Acids 47(11):2255–2263

Bates LS, Waldren RP, Teare ID (1973) Rapid determination of free proline for water-stress studies. Plant Soil 39:205–207

Blundell G, Brydon WG (1987) High performance liquid chromatography of plasma aminoacids using orthophthalaldehyde derivatisation. Clin Chim Acta 170(1):79–83

Buiarelli F, Gallo V, Di Filippo P, Pomata D, Riccardi C (2013) Development of a method for the analysis of underivatized amino acids by liquid chromatography/tandem mass spectrometry: application on Standard Reference Material 1649a (urban dust). Talanta 115:966–972

Campanella L, Crescentini G, Avino P (1999) Simultaneous determination of cysteine, cystine and 18 other amino acids in various matrices by high-performance liquid chromatography. J Chromatogr A 833(2):137–145

Chinard FP (1952) Photometric estimation of proline and ornithine. J Biol Chem 199(1):91–95

Csapó J, Albert C, Lóki K, Csapó-Kiss Z (2008) Separation and determination of the amino acids by ion exchange column chromatography applying postcolumn derivatization. Acta Universitatis Sapientiae Alimentaria 1(5–2):9

Di L (2015) Strategic approaches to optimizing peptide ADME properties. AAPS J 17(1):134–143

Duncan M, Poljak A (1998) AAA of peptides and proteins on the femtomole scale by gas chromatography/mass spectrometry. Anal Chem 70:890–896

Eggen I, Gregg B, Verlander M, Swietlow A, Rode H, Szajek A (2014) Control strategies for synthetic therapeutic peptide APIs—part I: analytical consideration. BioPharm Int 27(3):16–21

Ellman GL (1959) Tissue sulfhydryl groups. Arch Biochem Biophys 82(1):70–77

Fekkes D, Voskuilen-Kooyman A, Jankie R, Huijmans J (2000) Precise analysis of primary amino acids in urine by an automated high-performance liquid chromatography method: comparison with ion-exchange chromatography. J Chromatogr B Biomed Sci Appl 744(1):183–188

Fierabracci V, Masiello P, Novelli M, Bergamini E (1991) Application of amino acid analysis by high-performance liquid chromatography with phenyl isothiocyanate derivatization to the rapid determination of free amino acids in biological samples. J Chromatogr 570(2):285–291

Fosgerau K, Hoffmann T (2015) Peptide therapeutics: current status and future directions. Drug Discov Today 20(1):122–128

Friedmann M (2004) Applications of the ninhydrin reaction for analysis of amino acids, peptides and proteins to agricultural and biomedical sciences. J Agric Food Chem 52:385–406

Fürst P, Pollack L, Graser TA, Godel H, Stehle P (1990) Appraisal of four pre-column derivatization methods for the high-performance liquid chromatographic determination of free amino acids in biological materials. J Chromatogr 499:557–569

Guthals A, Bandeira N (2012) Peptide identification by tandem mass spectrometry with alternate fragmentation modes. Mol Cell Proteom 11(9):550–557

Heftmann E (2004) Chromatography: fundamentals and applications of chromatography and related differential migration methods—part A: fundamentals and techniques, vol 69A, 6th edn. Elsevier Science, Amsterdam, Netherlands

Hesse A, Weller MG (2016) Protein quantification by derivatization-free high-performance liquid chromatography of aromatic amino acids. J Amino Acids 2016:7374316

Hsieh HP, Wu YT, Chen ST, Wang KT (1999) Direct solid-phase synthesis of octreotide conjugates: precursors for use as tumor-targeted radiopharmaceuticals. Bioorg Med Chem Lett 7:1797–1803

ICH Q2A Text on Validation of Analytical Procedures (1995) In: International conference on harmonization of technical requirements for registration of pharmaceuticals for human use, Geneva, Switzerland, 1995

Ishida Y, Fujita T, Asai K (1981) New detection and separation method for amino acids by high-performance liquid chromatography. J Chromatogr 204:143–148

Kataoka H, Tanaka H, Fujimoto A, Noguchi I, Makita M (1994) Determination of sulphur amino acids by gas chromatography with flame photometric detection. Biomed Chromatogr 8(3):119–124

Kataoka H, Matsumura S, Makita M (1997) Determination of amino acids in biological fluid by capillary gas chromatography with nitrogen phosphorus selective detection. J Pharm Biomed Anal 15:1271–1279

Lau JL, Dunn MK (2018) Therapeutic peptides: historical perspectives, current development trends, and future directions. Bioorg Med Chem 26(10):2700–2707

Le Boucher J, Charret C, Coudray-Lucas C, Giboudeau J, Cynober L (1997) Amino acid determination in biological fluids by automated ion-exchange chromatography: performance of Hitachi L-8500A. Clin Chem 43(8):1421–1428

Lewis AM, Waterhouse C, Jacob LS (1980) Whole blood and plasma amino acid analysis- Gas chromatography and ion exchange chromatography compared. Clin Chem 26(2):271–276

Lobas AA, Verenchikov AN, Goloborodko AA, Levitsky LI, Gorshkov MV (2013) Combination of Edman degradation of peptides with liquid chromatography/mass spectrometry workflow for peptide identification in bottom-up proteomics. Rapid Commun Mass Spectrom 27(3):391–400

Matsumura S, Kataoka H, Makita M (1996) Determination of amino acids in human serum by capillary gas chromatography with nitrogen phosphorus selective detection. J Chromatogr B 681:375–380

Moodie IM, Hough BJ, Labadarios D (1989) Determination of amino acids in urine by gas chromatography. J Sep Sci 12(7):437–441

Moore S, Stein WH (1948) Photometric ninhydrin method for use in the chromatography of amino acids. J Biol Chem 176(1):367–388

Moore S, Stein WH (1951) Chromatography of amino acids on sulfonated polystyrene resins. J Biol Chem 192(2):663–681

Moore S, Stein WH (1958) Chromatographie determination of amino acids by the use of automatic recording equipment. Methods Enzymol 6:819–831

Nakano Y, Konya Y, Taniguchi M, Fukusaki E (2017) Development of a liquid chromatography-tandem mass spectrometry method for quantitative analysis of trace d-amino acids. J Biosci Bioeng 123(1):134–138

Ng LT, Anderson GH (1998) Analysis of O-phthaldialdehyde precoloumn derivatized physiological amino acids. Malays Appl Biol 27(1–2):13–20

Omar MMA, Elbashir AA, Schmitz OJ (2017) Capillary electrophoresis method with UV-detection for analysis of free amino acids concentrations in food. Food Chem 214:300–307

Qureshi GA, Qureshi AR (1989) Determination of free amino acids in biological samples: problems of quantitation. J Chromatogr 491(2):281–289

Qvit N, Rubin SJS, Urban TJ, Mochly-Rosen D, Gross ER (2017) Peptidomimetic therapeutics: scientific approaches and opportunities. Drug Discov Today 22(2):454–462

Reason AJ (2003) Validation of amino acid analysis methods. Methods Mol Biol 211:181–194

Rigas PG (2013) Post-column labeling techniques in amino acid analysis by liquid chromatography. Anal Bioanal Chem 405(25):7957–7992

Rutherfurd SM, Gilani GS (2009) Amino acid analysis. Curr Protoc Protein Sci 58(1):11.9.1–11.9.37

Skelley AM, Mathies RA (2003) Chiral separation of fluorescamine-labeled amino acids using microfabricated capillary electrophoresis devices for extraterrestrial exploration. J Chromatogr A 1021:191–199

Troll W, Lindsley J (1955) A photometric method for the determination of proline. J Biol Chem 215:655–660

Wainer A (1967) The chromatography of ninhydrin negative compounds on an amino acid analyzer column. J Chromatogr 26(1):48–53

Williamson MP (1993) Peptide structure determination by NMR. Methods Mol Biol 17:69–85

Wu LC (2013) Regulatory considerations for peptide drug products. In: Paper presented at the 2013 GPhA/FDA CMC Workshop

Xia T, Gao S, Shu C, Wen Y, Yun Y, Tao X, Chen W, Zhang F (2016) Analysis of amino acids in human blood using UHPLC-MS/MS: potential interferences of storage time and vacutainer tube in pre-analytical procedure. Clin Biochem 49(18):1372–1378

Zahou E, Jornvall H, Bergman T (2000) AAA by capillary electrophoresis after phenylthiocarbamylation. Anal Biochem 281:115–122

Zhang L, Li Y, Zhou H, Li L, Wang Y, Zhang Y (2012) Determination of eight amino acids in mice embryonic stem cells by pre-column derivatization HPLC with fluorescence detection. J Pharm Biomed Anal 66:356–358

Zhao XE, You JM, Liu HZ, Suo YR (2007) Pre-column derivatization high performance liquid chromatography tandem mass spectrometric determination of trace level of amino acids in rat serum. Chin J Anal Chem 35(7):938–944

Zhong H, Marcus SL, Li L (2005) Microwave-assisted acid hydrolysis of proteins combined with liquid chromatography MALDI MS/MS for protein identification. J Am Soc Mass Spectrom 16(4):471–481

Zunić G, Spasić S (2008) Capillary electrophoresis method optimized with a factorial design for the determination of glutathione and amino acid status using human capillary blood. J Chromatogr B Anal Technol Biomed Life Sci 873(1):70–76

Acknowledgements

Two of the authors (KYKK and DVGR) thank the management of Dr. Reddy’s Laboratories Ltd., Hyderabad, India, for supporting this work. Support from colleagues in Research and Development, and Analytical Research and Development of Dr. Reddy’s Laboratories Ltd. is appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors Yagnakirankumar Komaravolu, Venugopala Rao Dama, and Thirumala Chary Maringanti declare that they have no conflicts of interest.

Ethical statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Handling Editor: F. Albericio.

Rights and permissions

About this article

Cite this article

Komaravolu, Y., Dama, V.R. & Maringanti, T.C. Novel, efficient, facile, and comprehensive protocol for post-column amino acid analysis of icatibant acetate containing natural and unnatural amino acids using the QbD approach. Amino Acids 51, 295–309 (2019). https://doi.org/10.1007/s00726-018-2665-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00726-018-2665-9