Abstract

Considering the increasing importance of fluorinated peptides, the development of efficient and reliable synthetic methods for the incorporation of unnatural fluorinated amino acids into peptides is a current matter of interest. In this study, we report the convenient Boc/benzyl and Cbz/tert-butyl protection of both enantiomers of the quaternarized amino acid α-trifluoromethylalanine [(R)- and (S)-α-Tfm-Ala]. Because of the deactivation of the nitrogen atom of this synthetic amino acid by the strong electron withdrawing trifluoromethyl group, the peptide coupling on this position is a challenge. In order to provide a robust synthetic methodology for the incorporation of enantiopure (R)- and (S)-α-trifluoromethylalanines into peptides, we report herein the preparation of dipeptides ready to use for solid phase peptide synthesis. The difficult peptide coupling on the nitrogen atom of the α-trifluoromethylalanines was performed in solution phase by means of highly electrophilic amino acid chlorides or mixed anhydrides. The synthetic effectiveness of this fluorinated dipeptide building block strategy is illustrated by the solid phase peptide synthesis (SPPS) of the Ac-Ala-Phe-(R)-α-Tfm-Ala-Ala-NH2 tetrapeptide.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the last decades, the incorporation of non-natural fluorinated amino acids into peptides or proteins became a thematic of major concern since the fluorine atom allows to beneficially modify the chemical and biological properties of these molecules of high biological and medicinal interest (Salwiczek et al. 2012). Depending on the fluorine substitution site and (or) the nature of the fluorine-containing amino acid, different issues are observed. For examples, fluorinated analogues of aromatic amino acids have been used to stabilize protein–protein interactions by electrostatic attraction in a model peptide (Zheng and Gao 2010) and to stabilize the folded secondary structure of a nuclease by increasing the hydrogen bond donor character of a tyrosine (Thorson et al. 1995). The substitution of the methyl group by a trifluoromethyl group on the side chain of an aliphatic amino acid (Leu, Val) has been used to increase the thermal stability of “leucine zipper” type dimers by fluorine–fluorine interactions (Bilgicer et al. 2001; Tang et al. 2001) or increase the stability of an alpha helix (Gottler et al. 2008a) or a beta strand (Gerling et al. 2014; Horng and Raleigh 2003; Chiu et al. 2009) by increasing the hydrophobicity and the steric hindrance of the residues. Moreover it has been demonstrated than the replacement of leucines and isoleucines of the antimicrobial peptide pexiganan could increase its metabolic stability in the presence of a lipid bilayer (Gottler et al. 2008b). The authors hypothesized a strong peptide-lipids auto assembly favored by the presence of the fluorinated residues. In other respect it has been shown that the 14-helix stability of a model beta peptide could be greatly reinforced by the presence of trifluoromethyl groups in β3 position, increasing the H-bond donor character of the amide functional group (Cho et al. 2014). Among the panel of fluorinated amino acids reported in the literature, the Cα trifluoromethyl substituted amino acids (α-Tfm-AAs) are of particular interest. The trifluoroalanine is quite unstable and readily epimerizes because of the increased acidity of the proton in α-position of both the trifluoromethyl and the carboxylic groups. This important drawback is solved by the quaternarization of the α-carbon avoiding the amino acid racemization and the dehydrofluorination reaction. However, because of the poor nucleophilicity of the vicinal Nα limiting the use of classical coupling reactions, there are only few examples of peptides where the trifluoromethyl group is introduced directly on the peptide backbone. Nevertheless, the connection of the strong electron withdrawing and sterically hindered trifluoromethyl group directly on the backbone provides important modifications in terms of hydrophobicity, preferred conformations and increased hydrogen bonding donating effect. Firstly synthesized in their racemic form (Osipov et al. 1986; Burger and Gaa 1990; Burger and Sewald 1990; Kukhar et al. 1990), α-Tfm-AAs can now be prepared in their enantiopure form (Smits et al. 2008; Acena et al. 2012). However, α-Tfm-AAs have mainly been incorporated into peptides in their racemic form. The poor nucleophilicity of the Nα and the steric hindrance brought by the trifluoromethyl group require harsh coupling conditions or completely new coupling strategies (Hollweck et al. 1997; Burger et al. 1998) limiting their use by the peptide chemists community. To our knowledge, the incorporation of an enantiopure α-Tfm-AA at its C and N position in a peptide chain has been very scarcely reported in the literature (Koksch et al. 2004; Chaume et al. 2009; Botz et al. 2015). Considered as an aminoisobutyric acid (Aib) fluorinated analogue, the α-trifluoromethylalanine provided an improved resistance towards chymotrypsin digestion when incorporated into a model peptide (Koksch et al. 1997). This fluorinated amino acid has also been used as a 19F NMR probe to study the structuration and the orientation of the antimicrobial peptide alamethicin in membranes (Maisch et al. 2009). For this study, the α-trifluoromethylalanine has been incorporated in racemic form in tripeptide building blocks. After separation via chromatography on silica gel and identification of their configuration, these tripeptides were engaged in the SPPS of the antimicrobial peptide. Since several years, we are involved in the synthesis of enantiopure α-Tfm-AAs (Huguenot and Brigaud 2006; Caupene et al. 2009; Simon et al. 2011; Chaume et al. 2009) in order to investigate the physicochemical and biological consequences of their incorporation into peptides. In this context we showed that the incorporation of a α-Tfm-proline at the N-terminal position of a MIF-1 analogue increased its biological activity (Jlalia et al. 2013; Bocheva et al. 2013). We wish now to develop convenient and efficient synthetic routes for the incorporation of enantiopure α-Tfm-alanine in peptides by solution or solid phase peptide synthesis (SPPS). For this purpose we report herein the convenient Boc/benzyl and Cbz/tert-butyl protection of both enantiomers of α-Tfm-alanine and the synthesis of various Fmoc-AA-α-Tfm-Ala-OH and Fmoc-AA-α-Tfm-Ala-OtBu dipeptide building blocks ready to use for SPPS. Finally, this strategy was illustrated by the SPPS incorporation of (R)-α-Tfm-Ala into a model tetrapeptide.

Results and discussion

Orthogonal protection of (R)-and (S)-α-Tfm-alanine

Boc/benzyl protection

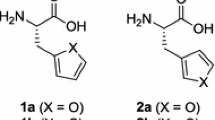

Multigram quantities of unprotected enantiopure (R)- and (S)-α-Tfm-Ala ( R)-1 and ( S)-1 were conveniently prepared following our previously described procedure involving a Strecker-type reaction on (R)-phenylglycinol derived trifluoromethyloxazolidines (Chaume et al. 2009). Surprisingly, the direct esterification of the unprotected ( R)-1 and ( S)-1 α-Tfm-Ala with benzyl alcohol in various standard conditions only proceeded in extremely low yields. Thus we chose to protect first the amino group with a Boc group since the Boc/benzyl strategy is the most convenient for liquid phase coupling reactions. The poor nucleophilicity of the nitrogen atom did not allow the classical Boc protection in the presence of Boc2O and an organic or an inorganic base. After a short screening of solvents and bases, we found out than the activation of Boc2O with a submolar amount of DMAP was necessary to obtain the Boc protected α-Tfm-Ala ( R)-2 and ( S)-2 in high yields (Scheme 1). As the esterification of the Boc protected α-Tfm-alanines with benzyl alcohol in various standard conditions did not proceeded cleanly, we decided to take advantage of the high acidity of the fluorinated carboxylic acid to perform the alkylation of the carboxylate formed in mild basic conditions. The benzylic esters ( R)-3 and ( S)-3 were obtained in good yields by treatment of the Boc protected α-Tfm-alanines with a slight excess of benzyl bromide in the presence of potassium carbonate (Wipf and Heimgartner 1987; Brasca et al. 2007; Li et al. 2011) (Scheme 1).

Having in hand suitably protected α-Tfm-alanines useful for peptide synthesis in solution, we directed our efforts towards the solid phase peptide synthesis (SPPS). Although we succeeded in the coupling of the unprotected (R)-α-Tfm-Ala ( R)-1 on the N-terminal position of a leucine attached on a Wang resin, to date we failed in the coupling of another Fmoc-amino acid on the deactivated nitrogen atom of the fluorinated amino acid. To circumvent this lack of reactivity of the Tfm-alanine amino group on resin, we designed to perform this difficult peptide coupling in solution phase and to elaborate dipeptide building blocks suitably protected for solid phase peptide synthesis. In order to synthesize these dipeptides we decided first to prepare each orthogonally protected enantiomer of Cbz-Tfm-Ala-OtBu.

Cbz/tert-butyl protection

Unexpectedly, the tert-butylation reaction of the α-Tfm-alanines 1 with isobutene or tert-butanol using standard procedures of the literature failed to give the corresponding esters in reasonable yield. Thus, the Cbz protection of the nitrogen atom was achieved first (Li et al. 2013). The α-Tfm-alanines ( R)-1 and ( S)-1 were N-protected in excellent yields using benzyl chloroformate and potassium carbonate in a water/dioxane mixture (Lai et al. 2005) to give the Cbz-Tfm-Ala-OH ( R)-4 and ( S)-4 (Scheme 2). As observed for the Boc protected α-Tfm-Ala, the standard protocols for the amino acids esterification reaction using alcohols in acidic conditions were ineffective starting from N-carboxybenzoyl protected Tfm-Ala ( R)-4 or ( S)-4. However the alkylation of the amino acid carboxylate by methyl iodide provided the Cbz-Tfm-Ala-OMe ( R)-5 in a good yield. Encouraged by this result we tried the substitution on the sterically more hindered tert-butyl bromide. Finally, this reaction took place in excellent yield using a large excess of tert-butyl bromide and potassium carbonate in the presence of one equivalent of triethylbenzylammonium chloride (TEBAC) used to generate a looser and more reactive ion pair (Ginisty et al. 2006) (Scheme 2).

Synthesis of α-Tfm-Ala containing dipeptides designed for solid phase peptide synthesis

The coupling on the N-terminal position of the trifluoromethylalanine could be performed in high yield on the unprotected fluorinated amino acid (Scheme 3). However this reaction required the prior preparation of highly electrophilic Fmoc-protected amino acid chlorides (Patil and Babu 2002; Chaume et al. 2013) and specific reaction conditions (3 h at 100 °C in a sealed tube in acetonitrile). After a reverse phase semi-preparative HPLC purification the corresponding dipeptides ( R)-7, ( R)-8 and ( R)-9 were obtained in 85, 78 and 90 %, respectively (Scheme 3).

Although the dipeptides were obtained in good yields, the main drawbacks of this methodology are: (1) it necessitate a preliminary amino acid chloride preparation, (2) the separation of the target free carboxylic dipeptide from the remaining Fmoc-amino acid resulting from the amino acid chloride hydrolysis is difficult and requires tedious reverse phase preparative HPLC purifications. For these reasons we designed to perform the peptide coupling reactions at the amino group on (R)- and (S)-α-trifluoromethylalanines protected as their tert-butyl esters. The (R)-and (S)-α-Tfm-Ala tert-butyl esters ( R)-10 and ( S)-10 were obtained in nearly quantitative yields by hydrogenolysis of the Cbz-protected α-Tfm-Ala ( R)-6 and ( S)-6. The highly volatile tert-butyl esters were isolated as their hydrochlorides by a short bubbling of gaseous hydrogen chloride in the crude solution. Because of their low stability, the latter compounds were directly engaged in the next coupling step. The coupling reactions of various Fmoc-protected amino acids was performed through mixed anhydride activation of the carboxylic acids with isobutylchloroformate in the presence of N-methylmorpholine (Koksch et al. 1997; Maisch et al. 2009). This activation mode is experimentally more convenient to implement than the amino acid chloride handling. The corresponding dipeptides were obtained in quite good yields (Table 1). We can note that the yields are similar regardless the enantiomer of the Tfm-Ala tert-butyl ester (entries 1 and 2). Yields are also satisfactory in the case of a cyclic amino acid such as proline (entries 4 and 5) or bulky amino acid such as Aib (entry 7).

Solid phase peptide synthesis of a tetrapeptide

In order to demonstrate the practicability of the trifluoromethylalanine containing dipeptide building blocks, a model tetrapeptide was prepared by SPPS. The dipeptide Fmoc-Phe-(R)-Tfm-Ala-OtBu ( R)-12 was treated with a TFA/CH2Cl2 mixture (Scheme 4) to give quantitatively the Fmoc-Phe-(R)-Tfm-AlaOH building block ( R)-16 which was engaged without further purification in the SPPS of the tetrapeptide 17 (Scheme 5).

The Rink amide resin is commonly used in SPPS protocols to prepare peptide amides from Fmoc-protected amino acids. The peptide sequence is assembled under basic or neutral conditions on Rink amide resin, and then the completed peptide is cleaved from the Rink resin under acidic conditions. We have used these conditions for the synthesis of the tetrapeptide Ac-Ala-Phe-(R)-Tfm-Ala-Ala-NH2 17. After the Fmoc deprotection of the Fmoc-Rink-amide resin using piperidine in DMF, the coupling of Fmoc-Ala-OH was carried out with the standard HATU activation in the presence of DIPEA. A second Fmoc deprotection step followed by the coupling of the dipeptide block ( R)-16 allowed the efficient incorporation α-Tfm-Ala by SPPS. After the coupling of the last amino acid, the acetylation reaction with acetic anhydride and the cleavage from the resin in TFA/TIS conditions gave the target tetrapeptide Ac-Ala-Phe-(R)-Tfm-Ala-Ala-NH2 17 which was obtained in 53 % yield after semi-preparative HPLC purification (Scheme 5).

Conclusion

We have reported the convenient Boc/benzyl and Cbz/tert-butyl protection of both enantiomers of the fluorinated quaternary amino acid α-trifluoromethylalanine (α-Tfm-Ala). A strategy for the challenging SPPS incorporation of these hindered and deactivated amino acids into peptides has been developed. Fmoc-protected dipeptides incorporating the (R)- or (S)-α-trifluoromethylalanine were efficiently prepared in solution phase and proved to be highly valuable building blocks for the incorporation of α-trifluoromethylalanines into peptides by SPPS. This strategy was exemplified by the synthesis of a model tetrapeptide. The use of the dipeptide block strategy constitutes a nice alternative to circumvent the weak reactivity of the amino group of α-Tfm-amino acids in peptide coupling reactions and will be useful for the incorporation of various α-Tfm-amino acids in more complex peptides.

Materials and methods

Unless otherwise mentioned, all the reagents were purchased from commercial source. All glassware was dried in an oven at 100 °C prior to use. THF was distilled under nitrogen from sodium/benzophenone prior to use. CH2Cl2 was distilled under nitrogen from CaH2 prior to use. 1H NMR spectra, 13C NMR spectra and 19F NMR spectra were recorded on a JEOL ECX-400 (400 MHz 1H, 100.5 MHz 13C and 376.2 MHz 19F). Chemical shift values (δ) were reported in ppm downfield from Me4Si (δ 0.0 ppm), CDCl3 (δ 77.0 ppm) or C6F6 (δ −164.9 ppm) as internal standard. Data are reported as follows: chemical shift (δ ppm), multiplicity (s = singlet, d = doublet, t = triplet, q = quartet, p = pentet, m = multiplet), coupling constant (Hz), integration. Infrared (IR-FT) spectra were performed on a Brucker Tensor 27. Specific rotations were measured on a JASCO P1010 or an Anton Paar MCP 200 polarimeter. Microanalysis and HRMS analyses were performed by the Service Central d’Analyses of CNRS, or by IMAGIF/ICSN-CNRS. Melting points (uncorrected) were measured in capillary tubes on a Büchi apparatus. Column chromatography was performed on 60A (40–63 μm) silica gel, employing mixture of specified solvent as eluent. Silica TLC plates were visualized under UV light, by a 10 % solution of phosphomolybdic acid in ethanol followed by heating.

Boc-(R)-α-Tfm-Ala-OH, ( R)-2

To a solution of (R)-α-Tfm-Ala-OH ( R)-1 (700 mg, 4.5 mmol, 1.0 equiv) in THF (15 mL) was added DMAP (163 mg, 1.3 mmol, 0.3 equiv). The resulting mixture was stirred for 10 min at room temperature. Di-tert-butyldicarbonate (1.24 mL, 5.4 mmol 1.2 equiv) was then added slowly and the solution was stirred for 3 h at room temperature. After completion of the reaction, the reaction mixture was evaporated under vacuum and dissolved in AcOEt (15 mL). The mixture was washed with a 1 M HCl solution (10 mL) and the aqueous layer was then extracted three times with AcOEt (3 × 15 mL). The combined organic layers were dried over anhydrous MgSO4, and evaporated under vacuum to give Boc-(R)-α-Tfm-Ala-OH ( R)-2 (1.102 g, 4.3 mmol) as a white solid in 96 % yield. Mp: 107–108 °C. [α] 20D = −5.7 (c = 0.7, MeOH). 1H NMR (CD3OD, 400 MHz): δ 1.47 (s, 9H, tBu); 1.62 (s, 3H, Hβ). 13C NMR (CD3OD, 100.5 MHz): δ 20.4 (Cβ); 29.4 (CtBu); 63.4 (q, J = 27.8 Hz, Cα); 82.1 (CtBu); 126.9 (q, J = 284.7 Hz, CF3); 156.9 (CO tBu); 171.4 (COOH). 19F NMR (CD3OD, 376.2 MHz): δ −80.3 (s, 3F, CF3). IR (neat/cm−1): 3325, 3249, 2974, 1730, 1699, 1652, 1396, 1382, 1370, 1155. MS (EI): m/z = 256.1 [M−H]−. HRMS (EI) m/z calcd for C9H13F3NO4 [M−H]− 256.0797 found 256.0788.

Boc-(S)-α-Tfm-Ala-OH, ( S)-2

By means of the procedure described for ( R)-2 starting from ( S)-α-Tfm-Ala-OH ( S)-1 (800 mg, 5.1 mmol, 1.0 equiv), the compound ( S)-2 (5.0 mmol) was obtained as a white solid in 98 % yield and was then used without purification. Mp: 100–102 °C. [α] 20D = +5.4 (c = 1.0, MeOH). 1H NMR (CD3OD, 400 MHz): δ 1.47 (s, 9H, tBu); 1.61 (s, 3H, Hβ). 13C NMR (CD3OD, 100.5 MHz): δ 20.4 (Cβ); 29.4 (CtBu); 63.4 (q, J = 27.8 Hz, Cα); 82.1 (CtBu); 126.9 (q, J = 284.7 Hz, CF3); 156.9 (CO tBu); 171.4 (COOH). 19F NMR (CD3OD, 376.2 MHz): δ −80.3 (s, 3F, CF3). IR (neat/cm−1): 3325, 3249, 2974, 1730, 1699, 1652, 1396, 1382, 1370, 1155.

Boc-(R)-α-Tfm-Ala-OBn, ( R)-3

To a solution of Boc-(R)-α-Tfm-Ala-OH ( R)-2 (770 mg, 3.0 mmol, 1.0 equiv) in DMF (8 mL) were successively added K2CO3 (497 mg, 3.6 mmol, 1.2 equiv) and benzyl bromide (427 μL, 1.2 equiv). The reaction mixture was stirred at room temperature for 3 h and then diluted with water (15 mL). The aqueous mixture was extracted with AcOEt (3 × 30 mL) and the combined organic extracts were dried over anhydrous MgSO4 and evaporated under vacuum. The crude product was purified by silica gel chromatography (cyclohexane/AcOEt, 98/2–95/5) to afford Boc-(R)-α-Tfm-Ala-OBn ( R)-3 (854 mg, 2.46 mmol) as a white solid in 82 % yield. R f: 0.72 (cyclohexane/AcOEt, 8/2). Mp: 94–95 °C. [α] 20D = +3.7 (c = 1.0, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.41 (s, 9H, HBoc); 1.74 (s, 3 H, Hβ); 5.24 (s, 2H, CH2bzl); 7.35 (m, 5H, Haro). 13C NMR (CDCl3, 100.5 MHz): δ 18.9 (Cβ); 28.4 (CHBoc); 62.5 (q, J = 28.8 Hz, Cα); 68.5 (Cbzl); 81.5 [C(CH3)3]; 124.4 (q, J = 286.6 Hz, CF3); 128.6–128.9; 135.1 (Cq bzl); 154.0 (CO bzl); 167.2 (CO tBu). 19F NMR (CDCl3, 376.2 MHz): δ −79.6 (s, 3F, CF3). IR (neat/cm−1): 3363, 3008, 1739, 1720, 1588. MS (EI): m/z = 370.1 [M+Na]+. HRMS (EI) m/z calcd for C16H20F3NO4Na [M+Na]+ 370.1242 found 370.1233.

Boc-(S)-α-Tfm-Ala-OBn, ( S)-3

By means of the procedure described for ( R)-3 starting from ( S)-α-Tfm-Ala-OH ( S)-2 (775 mg, 3.0 mmol, 1.0 equiv), the compound ( S)-3 (900 mg, 2.6 mmol) was obtained as a white solid in 86 % yield. R f: 0.72 (Cyclohexane/AcOEt, 8/2). Mp: 94–95 °C. [α] 20D = –3.8 (c = 1.0, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.36 (s, 9 H, HBoc); 1.74 (s, 3 H, Hβ); 5.24 (s, 2 H, CH 2 bzl); 7.35 (m, 5 H, Haro). 13C NMR (CDCl3, 100.5 MHz): δ 18.7 (Cβ); 28.4 (CHBoc); 62.5 (q, J = 28.8 Hz, Cα); 68.5 (Cbzl); 81.5 [C(CH3)3]; 124.4 (q, J = 286.6 Hz, CF3); 128.6–128.9; 135.1 (Cq bzl);154.0 (CO bzl); 167.2 (CO tBu). 19F NMR (CDCl3, 376.2 MHz): δ −79.6 (s, 3 F, CF3). IR (neat/cm−1): 3363, 3008, 1739, 1720, 1588. MS (EI): m/z = 370.1 [M+Na]+. HRMS (EI): m/z calcd for C16H20F3NO4Na [M+Na]+ 370.1242 found 370.1259.

Cbz-(R)-α-Tfm-Ala-OH, ( R)-4

To a solution of enantiopure (R)-α-Tfm-Ala-OH ( R)-1 (500 mg, 3.2 mmol, 1.0 equiv) and K2CO3 (1.76 g, 12.7 mmol, 4.0 equiv) in water (9 mL) at 0 °C was added dropwise CbzCl (1.14 mL, 8.0 mmol, 2.5 equiv, 1.4 M in dioxane). The solution was stirred for 10 min at 0 °C and 3 h at room temperature. Another 2.5 equivalent (1.4 M in dioxane) of CbzCl were added following the same procedure. After completion of the reaction, the solution was washed with dichloromethane (3 × 3 mL). The aqueous layer was acidified with 10 % HCl solution to pH 1–2 and extracted with ethyl acetate (3 × 40 mL). The organic layers were combined, dried over MgSO4, filtered and evaporated under reduced pressure. The crude product was purified by silica gel chromatography (DCM/MeOH 98/2) to afford Cbz-(R)-α-Tfm-Ala-OH ( R)-4 (850 mg, 2.94 mmol) as a white solid in 92 % yield. Mp = 70–72 °C. [α] 20D = +67.2 (c = 1.3, MeOH). 1H NMR (CD3OD, 400 MHz): δ 1.68 (s, 3H, Hβ); 5.09 (m, 2H, CH2bzl); 7.28–7.41 (m, 5H, Haro). 13C NMR (CD3OD, 100.5 MHz): δ 19.5 (Cβ); 62.7 (q, J = 30.7 Hz, Cα); 67.8 (Cbzl); 126.0 (q, J = 284.7 Hz, CF3); 127.9; 128.8; 129.4; 137.7; 156.8 (CO Bzl); 170.1 (COOH). 19F NMR (CD3OD, 376.2 MHz): δ −80.1 (s, 3F, CF3). IR (neat/cm−1): 3324, 3036, 2952, 1720, 1627, 1247. MS (EI): m/z = 292.1 [M+H]+. HRMS (EI) m/z calcd for C12H13F3NO4 [M+H]+ 292.0797 found 292.0801. Anal. calcd: %C: 49.49; %H: 4.15; %N: 4.81 found: %C: 49.27; %H: 4.04; %N: 4.71.

Cbz (S)-α-Tfm-Ala-OH, ( S)-4

By means of the procedure described for ( R)-4 starting from ( S )-α-Tfm-Ala-OH ( S)-1 (470 mg, 3.0 mmol, 1.0 equiv), the compound ( S)-4 (835 mg, 2.9 mmol) was obtained as a white solid in 96 % yield. Mp: 71–73 °C. [α] 20D = –65.4 (c = 1.2, MeOH). 1H NMR (CD3OD, 400 MHz): δ 1.68 (s, 3H, Hβ); 5.09 (m, 2H, CH2bzl); 7.28–7.41 (m, 5H, Haro). 13C NMR (CD3OD, 100.5 MHz): δ 19.5 (Cβ); 62.7 (q, J = 30.7 Hz, Cα); 67.8 (Cbzl); 126.0 (q, J = 284.7 Hz, CF3); 127.9; 128.8; 129.4; 137.7; 156.8 (CO Bzl); 170.1 (COOH). 19F NMR (CD3OD, 376.2 MHz): δ −80.1 (s, 3F, CF3). IR (neat/cm−1): 3324, 3036, 2952, 1720, 1627, 1247. MS (EI): m/z = 290.1 [M−H]−. HRMS (EI) m/z calcd for C12H11F3NO4 [M−H]− 290.0640 found 290.0653.

Cbz-(R)-α-Tfm-Ala-OMe ( R)-5

To a solution of N-Cbz-(R)-α-Tfm-Ala-OH ( R)-4 (1.5 g, 5.1 mmol, 1.0 equiv) in DMF (13 mL) was added K2CO3 (1.07 g, 6.1 mmol, 1.2 equiv). The mixture was stirred for 10 min at 0 °C and MeI (6.6 mmol, 1.3 equiv) was then added slowly. The reaction mixture was stirred for 30 min at 0 °C and 1 h at room temperature and was then diluted with water (20 mL). The diluted mixture was extracted with AcOEt (3 × 20 mL) and the combined organic layers were dried over anhydrous MgSO4 and evaporated under vacuum. The crude product was purified by silica gel chromatography (cyclohexane/AcOEt: 95/5–80/20) to afford desired Cbz-(R)-α-Tfm-Ala-OMe ( R)-5 (1.43 g, 4.7 mmol, 92 %) as a yellow oil. R f: 0.68 (cyclohexane/AcOEt, 7/3). [α] 20D = +2.4 (c = 1.0, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.78 (s, 3H, Hβ); 3.80 (s, 3H, OMe); 5.12 (s, 2H, CH 2 bzl); 6.00 (s, 2H, NH); 7.37–7.39 (m, 5H, Har). 13C NMR (CDCl3, 100.5 MHz): δ 18.2 (Cβ); 53.2 (CO2 CH3); 61.9 (q, J = 28.8 Hz, Cα); 67.2 (Cbzl); 123.9 (q, J = 285.6 Hz, CF3); 128.0; 128.2; 128.3; 135.5 (Car); 154.3 (CO Bzl); 167.3 (CO2CH3). 19F NMR (CDCl3, 376.2 MHz): δ −79.8 (s, 3F, CF3). IR (neat/cm−1): 3450–3250, 1710, 1730, 1524, 1450. MS (EI): m/z = 306.1 [M+H]+. HRMS (EI): m/z calcd for C13H15F3NO4 [M+H]+ 306.0953 found 306.0960. Anal. calcd: %C: 51.15; %H: 4.62; %N: 4.59 found: %C: 51.17; %H: 4.63; %N: 4.74.

Cbz-(R)-α-Tfm-Ala-OtBu ( R)-6

To a solution of enantiopure Cbz-(R)-α-Tfm-Ala-OH ( R)-4 (650 mg, 2.2 mmol, 1.0 equiv) in acetonitrile (20 mL) were successively added benzyl triethylammonium chloride (505 mg, 2.2 mmol, 1.0 equiv), K2CO3 (6.17 g, 44.7 mmol, 20 equiv) and tert-butyl bromide (8.8 mL, 78.2 mmol, 35 equiv) at room temperature. The reaction mixture was then heated to 48 °C and stirred for 20 h at 48 °C. The mixture was cooled to room temperature and evaporated under vacuum. The crude product was diluted with water (20 mL) and extracted with AcOEt (3 × 20 mL). The combined organic layers were dried over anhydrous MgSO4, and concentrated under vacuum. The crude product was purified by silica gel chromatography (cyclohexane/AcOEt, 90/10) to afford enantiopure Cbz-(R)-α-Tfm-Ala-OtBu ( R)-6 (729 mg, 2.1 mmol) as a white solid in 94 % yield. R f: 0.78 (cyclohexane/AcOEt, 8/2). Mp: 103–104 °C. [α] 20D = +5.2 (c = 1.0, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.46 (s, 9H, HtBu); 1.79 (s, 3H, Hβ); 5.10 (s, 2H, CH2bzl); 5.67 (s, 1H, NH); 7.33–7.35 (m, 5H, Haro). 13C NMR (CDCl3, 100.5 MHz): δ 18.0 (Cβ); 27.8 (CHtBu); 63.0 (q, J = 28.8 Hz, Cα); 67.4 (Cbzl); 84.6 [C(CH3)3]; 124.5 (q, J = 286.6 Hz, CF3); 128.5; 128.6; 128.8; 136.2; 154.6 (CObzl); 166.0 (COtBu). 19F NMR (CDCl3, 376.2 MHz): δ −79.4 (s, 3F, CF3). IR (neat/cm−1): 3278, 1745, 1700, 1543. MS (EI): m/z = 370.1 [M+Na]+. HRMS (EI) calcd for C16H20F3NO4Na [M+Na]+ 370.1242 found 370.1232. Anal. calcd: %C: 55.33; %H: 5.80; %N: 4.03 found: %C: 55.27; %H: 5.81; %N: 3.89.

Cbz-(S)-α-Tfm-Ala-OtBu, ( S)-6

By means of the procedure described for (R )-6 starting from (S)-4 (579 mg, 2.0 mmol), the compound ( S)-6 (635 mg, 1.8 mmol) was obtained as a white solid in 92 % yield. R f: 0.78 (cyclohexane/AcOEt, 8/2). Mp: 102–103 °C. [α] 20D = −6.7 (c = 1.0, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.46 (s, 9H, HtBu); 1.80 (s, 3H, Hβ); 5.10 (s, 2H, CH 2 bzl); 5.60 (s, 1H, NH); 7.26–7.37 (m, 5H, Haro). 13C NMR (CDCl3, 100.5 MHz): δ 18.0 (Cβ); 27.9 (CHtBu); 63.1 (q, J = 28.8 Hz, Cα); 67.5 (Cbzl); 84.7 [C(CH3)3]; 124.5 (q, J = 286.6 Hz, CF3); 128.5; 128.6; 128.9; 136.3; 154.6 (CO bzl); 166.0 (COtBu). 19F NMR (CDCl3, 376.2 MHz): δ −79.5 (s, 3F, CF3). IR (neat/cm−1): 3281, 1744, 1701, 1542. MS (EI): m/z (%) = 370.1 [M+Na]+. HRMS (EI) m/z calcd for C16H20F3NO4Na [M+Na]+ 370.1242 found 370.1239. Anal. calcd: %C: 55.33; %H: 5.80; %N: 4.03 found: %C: 55.53; %H: 5.88; %N: 3.91.

Syntheses of Fmoc-AA-(R)-α-Tfm-Ala-OH dipeptides

The Fmoc-amino acid chlorides were prepared according to previously reported procedures (Patil and Babu 2002; Chaume et al. 2013).

Fmoc-Ala-(R)-α-Tfm-Ala-OH, ( R)-7

To a suspension of (R)-α-Tfm-Ala-OH ( R)-1 (100 mg, 0.64 mmol, 1.0 equiv) in THF (4 mL), were added Fmoc-Ala-Cl (250 mg, 0.76 mmol, 1.2 equiv) and K2CO3 (176 mg, 1.27 mmol, 2.0 equiv). The reaction mixture was heated at 100 °C in a sealed tube for 1 h. The crude mixture was then cooled to room temperature, and the K2CO3 was filtered. The filtrated product was evaporated under vacuum and purified by semi-preparative HPLC (water/acetonitrile 90/10–70/30) to afford the desired dipeptide Fmoc-Ala-(R)-α-Tfm-Ala-OH ( R)-7 (262 mg, 0.59 mmol, 92 %) as a white hygroscopic solid. Mp: 148 °C. [α] 20D = +17.9 (c = 0.9, HCl). 1H NMR (400 MHz, CD3OD): δ 1.36 (d, 3 J = 7 Hz, 3 H, Hβ1); 1,72 (s, 3 H, Hβ2); 4,18 (t, 3 J = 7 Hz, 1 H, CHFmoc); 4,23 (q, 3 J = 7 Hz, 1 H, Hα1); 4,33 (t, 3 J = 7 Hz, 2 H, CH 2Fmoc); 7,29 (t, 3 J = 7 Hz, 2 H, HFmoc); 7,36 (t, 3 J = 7 Hz, 2 H, HFmoc); 7,64 (t, 3 J = 8 Hz, 2 H, HFmoc); 7,76 (d, 3 J = 8 Hz, 2 H, HFmoc); 8,74 (s, 1 H, NH) ppm. 13C NMR (100.5 MHz, CD3OD): δ 19.1 (Cβ1), 19.7 (Cβ2); 47.1 (CHFmoc); 50,2 (Cα1), 61.2 (Cα2, J = 28,8 Hz); 68.8 (CH2Fmoc); 121.7 (Car Fmoc); 124.6 (CF3, J = 284.7 Hz); 127.1 (Car Fmoc); 141.5 (Car Fmoc); 143.8 (Car Fmoc); 144.0 (Car Fmoc); 156.9 (CO); 168.2 (CO)173.6 (CO2H) ppm. 19F NMR (376.2 MHz, D2O): δ −80.3 (s, 3 F, CF3) ppm. IR (neat/cm−1): 3246, 2840, 2250, 2238, 1500. MS (EI): m/z (%) = 450.1 [M]+.

Fmoc-Leu-(R)-α-Tfm-Ala-OH, ( R)-8

To a suspension of (R)-α-Tfm-Ala-OH ( R)-1 (80 mg, 0.51 mmol, 1.0 equiv) in THF (4 mL), were added Fmoc-Leu-Cl (216 mg, 0.61 mmol, 1.2 equiv) and K2CO3 (141 mg, 1.02 mmol, 2.0 equiv). The reaction mixture was heated at 100 °C in a sealed tube for 1 h. The crude mixture was then cooled to room temperature, and the K2CO3 was filtered. The filtrated product was evaporated under vacuum and purified by semi-preparative HPLC (water/acetonitrile 90/10–70/30) to afford the desired dipeptide Fmoc-Leu-(R)-α-Tfm-Ala-OH ( R)-8 (221 mg, 0.45 mmol, 88 %) as a white hygroscopic solid. [α] 20D = +6.3 (c = 0.9, MeOH). 1H NMR (400 MHz, CD3OD): δ 0.88 (d, 3 J = 5,5 Hz, 3 H, Hδ1); 0,91 (d, 3 J = 5,5 Hz, 3 H, Hδ1′); 1,60 (m, 3 H, Hβ1 et Hγ1); 1,69 (s, 3 H, Hβ2); 4,17 (t, 3 J = 6.9 Hz, 1 H, HFmoc); 4,36 (m, 3 H, Hα1 et CH 2 Fmoc); 6,02 (s, 1 H, NH); 7,27 (t, 3 J = 7.3 Hz, 2 H, HFmoc); 7,37 (t, 3 J = 7.3 Hz, 2 H, HFmoc); 7,54 (t, 3 J = 8.2 Hz, 2 H, HFmoc); 7,72 (d, 3 J = 7.3 Hz, 2 H, HFmoc) ppm. 13C NMR (100.5 MHz, CD3OD): δ 18.6 (Cβ2), 22,1 (Cδ1); 22,9 (Cδ1′); 24,8 (Cγ1); 41,0 (Cβ1); 47,2 (CH Fmoc); 53,5 (Cα1); 62.1 (q, J = 29.7 Hz, Cα2), 68,1 (CH2Fmoc); 120,4 (Car Fmoc); 124,1 (q, J = 282.8 Hz, CF3); 125,4 (Car Fmoc); 127.5 (Car Fmoc); 128.2 (Car Fmoc); 141.6 (Cq ar Fmoc); 143.8 (Cq ar Fmoc); 157.4 (CO); 168.6 (CO); 173.7 (CO); 168.2 (CO2H) ppm. 19F NMR (376.2 MHz, CD3OD): δ −79.0 (s, CF3) ppm. IR (neat/cm−1): 3402, 2937, 1645, 1611, 1545.

Fmoc-Pro-(R)-α-Tfm-Ala-OH, ( R)-9

To a suspension of (R)-α-Tfm-Ala-OH ( R)-1 (99 mg, 0.64 mmol, 1.0 equiv) in THF (4 mL), were added Fmoc-Pro-Cl (259 mg, 0.76 mmol, 1.2 equiv) and K2CO3 (176 mg, 1.27 mmol, 2.0 equiv). The reaction mixture was heated at 100 °C in a sealed tube for 1 h. The crude mixture was then cooled to room temperature, and the K2CO3 was filtered. The filtrated product was evaporated under vacuum and purified by semi-preparative HPLC (water/acetonitrile 90/10–70/30) to afford the desired dipeptide Fmoc-Pro-(R)-α-Tfm-Ala-OH ( R)-9 (270 mg, 0.57 mmol, 90 %) as a white hygroscopic solid. [α] 20D = +23.4 (c = 0.9, MeOH). 1H NMR (400 MHz, CD3OD): δ 1.71 (s, 3 H, Hβ2); 1.92 (m, 2 H, Hγ1 and Hγ1′); 2.19 (m, 1 H, Hβ1); 2.39 (m, 1 H, Hβ1′); 3.44 (m, 1 H, Hδ1); 3.25 (m, 1 H, Hδ1′); 4.32 (t, 3 J = 6.9 Hz, 1 H, HFmoc); 4.36–4.46 (m, 3 H, Hα1 et CH 2 Fmoc); 6.70 (s, 1 H, NH); 7.32 (t, 3 J = 7.3 Hz, 2 H, HFmoc); 7.41 (t, 3 J = 7.3 Hz, 2 H, HFmoc); 7.60 (d, 3 J = 7.3 Hz, 2 H, Hfmoc); 7.65 (s, 1 H, NH); 7.77 (d, 3 J = 7.3 Hz, 2 H, HFmoc). 13C NMR (100.5 MHz, CD3OD): δ 18.3 (Cβ2); 26.0 (Cγ1); 29.2 (Cβ1)′; 47.4 (CHFmoc); 47.9 (δ1); 60.7 (Cα1); 62.6 (q, J = 28.8 Hz, Cα2); 68.2 (CH2 Fmoc); 121.1 (Car Fmoc); 123.9 (q, J = 285.6 Hz, CF3); 125.2 (Car Fmoc); 127.2 (Car Fmoc); 128.1 (Car Fmoc); 141.6 (Cqar Fmoc); 144.0 (Cqar Fmoc); 156.8 (CO); 165.6 (CO); 170.8 (CO). 19F NMR (376.2 MHz, CD3OD): δ −79.1 (s, CF3) ppm. IR (neat/cm−1): 3506, 3257, 2959, 2592, 1650, 1607, 1532, 1156.

General procedure for the synthesis of the α-Tfm-Ala containing dipeptides (11– 15)

HCl.(R)-α-Tfm-Ala-OtBu, ( R)-10

Pd/C (250 mg, 0.23 mmol, 0.2 equiv) was added to a solution of enantiopure N-Cbz-(R)-α-Tfm-Ala-OtBu ( R)-6 (345 mg, 1.0 mmol, 1.0 equiv) in AcOEt (15 mL) under a nitrogen atmosphere. The reaction mixture was stirred under a hydrogen atmosphere (three bars) for 2 h. The catalyst was separated by filtration and HCl gas was bubbled through the solution for 10 min. The resulting solution was evaporated under vacuum to afford enantiopure HCl.(R)-α-Tfm-Ala-OtBu ( R)-10 (210 mg, 0.99 mmol) as a white solid in 99 % yield which was directly used in the next step without further purification after 1H NMR checking. 1H NMR (CD3OD, 400 MHz): δ 1.60 (s, 9H, tBu); 1.82 (s, 3H, Hβ). 19F NMR (CD3OD, 376.2 MHz): δ −80.0 (s, 3F, CF3).

HCl.(S)-α-Tfm-alanine-OtBu, ( S)-10

By means of the procedure described for ( R)-10 starting from ( S)-6 (345 mg, 1.0 mmol), the compound ( S)-10 (206 mg, 0.97 mmol) was obtained as a white solid in 97 % yield. 1H NMR (CD3OD, 400 MHz): δ 1.60 (s, 9H, tBu); 1.82 (s, 3H, Hβ). 19F NMR (CD3OD, 376.2 MHz): δ −80.0 (s, 3F, CF3).

To a solution of Fmoc-AA-OH (0.9 mmol, 1.0 equiv) in THF (15 mL) at −20 °C was added N-methylmorpholine (1.1 equiv) and isobutylchloroformiate (1.1 equiv). After 10 min at −20 °C, a solution of enantiopure HCl.α-Tfm-Ala-OtBu 10 (0.9 equiv) and N-methylmorpholine (1.1 equiv) in THF (10 mL) was added to the reaction mixture and the resulting mixture was stirred 1 h at −20 °C and 2 h at room temperature. The reaction was evaporated under vacuum and diluted with water (15 mL). The aqueous solution was extracted with AcOEt (3 × 15 mL) and the combined organic extracts were dried with anhydrous MgSO4, and evaporated under vacuum. The crude product was purified by silica gel chromatography (cyclohexane/AcOEt 90/10–70/30) to afford the dipeptide Fmoc-AA-α-Tfm-Ala-OtBu.

Fmoc-Ala-(R)-α-Tfm-Ala-OtBu, ( R)-11

According to the general procedure described above starting from ( R)-10 (182 mg, 0.9 mmol), the compound ( R)-11 (190 mg, 0.6 mmol) was obtained as a white solid in 67 % yield. R f: 0.35 (cyclohexane/AcOEt, 7/3). Mp: 53–55 °C. [α] 20D = +12.7 (c = 0.9, MeOH). 1H NMR (CDCl3, 400 MHz): δ 1.41 (d, 3 J = 6.9 Hz, 3H, Hβ1,); 1.47 (s, 9H, HtBu); 1.73 (s, 3H, Hβ2); 4.20 (t, 3 J = 6.9 Hz, 1H, Hfmoc); 4.38–4.39 (m, 3H, CH 2 Fmoc et Hα1); 5.61 (d, 3 J = 7.3 Hz, 1H, NH); 7.22 (s, 1H, NH); 7.31 (t, 3 J = 7.8 Hz, 2H, Fmoc); 7.40 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.58 (d, 3 J = 7.3 Hz, 2H HFmoc); 7.76 (d, 3 J = 7.3 Hz, 2H, Fmoc). 13C NMR (CDCl3, 100.5 MHz): δ 18.1 (Cβ2); 19.0 (Cβ1); 27.9 (CtBu); 47.3 (CH Fmoc); 50.6 (Cα1); 62.9 (q, J = 28.8 Hz, Cα2); 67.5 (CH2 Fmoc); 84.2 (CtBu); 120.3; 124.5 (q, J = 285.6 Hz,CF3); 125.4; 127.4; 128.0; 141.6; 143.9; 156.4 (CO); 165.4 (CO); 172.0 (CO). 19F NMR (CDCl3, 376.2 MHz): δ −79.1 (s, 3F, CF3). IR (neat/cm−1): 3400, 1747, 1673, 1538. MS (EI): m/z = 507.2 [M+H]+. HRMS (EI) m/z calcd for C26H30F3N2O5 [M+H]+: 507.2107 found 507.2111. Anal. calcd: %C: 61.65; %H: 5.77; %N: 5.53 found: %C: 61.97; %H: 6.00; %N: 5.11.

Fmoc-Ala-(S)-α-Tfm-Ala-OtBu, ( S)-11

By means of the general procedure described above starting from ( S)-10 (145 mg, 0.7 mmol), the compound ( S)-11 (238 mg, 0.5 mmol) was obtained as a white solid in 69 % yield. R f: 0.45 (cyclohexane/AcOEt, 7/3). Mp: 51–54 °C. [α] 20D = −23.5 (c = 0.5, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.40 (d, 3 J = 6.9 Hz, 3H, Hβ1,); 1.47 (s, 9H, HtBu); 1.73 (s, 3H, Hβ2); 4.20 (t, 3 J = 6.9 Hz, 1H, HFmoc); 4.33–4.43 (m, 3H, CH 2 Fmoc et Hα1); 5.60 (d, 3 J = 6.9 Hz, 1H, NH); 7.18 (s, 1H, NH); 7.30 (t, 3 J = 6.9 Hz, 2H, Fmoc); 7.40 (t, 3 J = 7.3 Hz, 2H, Fmoc); 7.57 (d, 3 J = 7.3 Hz, 2H, HFmoc); 7.76 (d, 3 J = 7.3 Hz, 2H, HFmoc). 13C NMR (CDCl3, 100.5 MHz): δ 18.3 (Cβ2); 18.7 (Cβ1); 27.9 (CtBu); 47.3 (CH Fmoc); 50.7 (Cα1); 62.7 (q, J = 28.8 Hz, Cα2); 67.6 (CH2 Fmoc); 84.2 (CtBu); 120.3; 124.5 (q, J = 285.6 Hz,CF3); 125.3; 127.4; 128.1; 141.6; 143.9; 156.5 (CO); 165.5 (CO); 172.0 (CO). 19F NMR (CDCl3, 376.2 MHz): δ −78.9 (s, 3F, CF3). IR (neat/cm−1): 3301, 2981, 1745, 1680, 1508.

Fmoc-Phe-(R)-α-Tfm-Ala-OtBu, ( R)-12

By means of the general procedure described above starting from ( R)-10 (215 mg, 1.0 mmol), the compound ( R)-12 (342 mg, 0.59 mmol) was obtained as a white solid in 59 % yield. Mp: 170 °C. 1H NMR (CDCl3, 400 MHz): δ 1.48 (s, 9H, HtBu); 1.69 (s, 3H, Hβ2); 3.08 (s, 2H, Hβ1); 4.18 (t, 3 J = 7.3 Hz, 1H, HFmoc); 4.28 (t, 3 J = 6.9 Hz, 1H, CH 2Fmoc); 4.37 (t, 3 J = 8.2 Hz, 1H, CH 2Fmoc); 4.57 (m, 1H, Hα1); 5.66 (d, 3 J = 7.3 Hz, 1H, NH); 7.14–7.27 (m, 5H, HarPhe); 7.31 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.41 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.54 (m, 2H, HFmoc); 7.77 (d, 3 J = 7.3 Hz, 2H, HFmoc). 13C NMR (CDCl3, 100.5 MHz): δ 17.9 (Cβ2); 27.9 (CtBu); 38.7 (Cβ1); 47.2 (CH Fmoc); 56.4 (Cα1); 62.7 (q, J = 28.8 Hz, Cα2); 67.5 (CH2 Fmoc); 84.2 (CtBu); 120.3; 124.3 (q, J = 285.6 Hz, CF3); 125.4; 127.4; 128.1; 141.6; 144.0; 156.4 (CO); 165.4 (CO); 170.8 (CO). 19F NMR (CDCl3, 376.2 MHz): δ −78.7 (s, 3F, CF3). IR (neat/cm−1): 3428, 3303, 3290, 1750, 1746, 1495.

Fmoc-Pro-(R)-α-Tfm-Ala-OtBu, ( R)-13

By means of the general procedure described above starting from ( R)-10 (150 mg, 0.7 mmol), the compound ( R)-13 (232 mg, 0.44 mmol) was obtained as a white solid in 62 % yield. Mp: 162–163 °C. [α] 20D = −78.8 (c = 1.2, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 1.44 (s, 9H, HtBu); 1.71 (s, 3 H, Hβ2); 1.95 (m, 2H, Hγ1 and Hγ1′); 2.19 (m, 1H, Hβ1); 2.39 (m, 1H, Hβ1′); 3.44 (m, 1H, Hδ1); 3.55 (m, 1H, Hδ1′); 4.28 (t, 3 J = 6.9 Hz, 1H, HFmoc); 4.36–4.46 (m, 3H, Hα1 et CH 2 Fmoc); 6.70 (s, 1H, NH); 7.32 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.41 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.60 (d, 3 J = 7.3 Hz, 2H, fmoc); 7.65 (s, 1H, NH); 7.77 (d, 3 J = 7.3 Hz, 2H, Fmoc). 13C NMR (CDCl3, 100.5 MHz): δ 17.9 (Cβ2); 24.7 (Cγ1); 27.6 (CtBu and Cβ1)′; 47.1 (CHFmoc); 47.5 (δ1); 60.3 (Cα1); 62.2 (q, J = 28.8 Hz, Cα2); 67.9 (CH2 Fmoc); 83.4 (CtBu); 120.0; 124.1 (q, J = 285.6 Hz, CF3); 125.0; 127.0; 127.8; 141.2; 143.7; 156.4 (CO); 165.2 (CO); 170.4 (CO). 19F NMR (CDCl3, 376.2 MHz): δ –79.1 (s, 3F, CF3). IR (neat/cm−1): 3354, 2975, 1735, 1709, 1693. MS (EI): m/z = 533.2 [M+H]+. HRMS (EI) m/z calcd for C28H32F3N2O5 [M+H]+ 533.2263 found 533.2266.

Fmoc-Pro-(S)-α-Tfm-Ala-OtBu, ( S)-13

By means of the general procedure described above starting from ( S)-10 (157 mg, 0.63 mmol), the compound ( S)-13 (255 mg, 0.48 mmol) was obtained as a white solid in 76 % yield. Mp: 158–159 °C. 1H NMR (CDCl3, 400 MHz): δ 1.46 (s, 9H, HtBu); 1.76 (s, 3H, Hβ2); 1.96 (m, 2H, Hγ1 and Hγ1′); 2.19 (m, 1H, Hβ1); 2.42 (m, 1H, Hβ1′); 3.44 (m, 1H, Hδ1); 3.55 (m, 1H, Hδ1′); 4.27 (t, 3 J = 6.9 Hz, 1H, HFmoc); 4.36–4.46 (m, 3H, Hα1 et CH 2 Fmoc); 6.70 (s, 1H, NH); 7.32 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.41 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.60 (d, 3 J = 7.3 Hz, 2H, fmoc); 7.65 (s, 1H, NH); 7.77 (d, 3 J = 7.3 Hz, 2H, Fmoc). 13C NMR (CDCl3, 100.5 MHz): δ 17.7 (Cβ2); 24.6 (Cγ1); 27.4 (CtBu and Cβ1)′; 47.0 (CHFmoc); 47.9 (δ1); 60.1 (Cα1); 62.5 (q, J = 28.8 Hz, Cα2); 67.9 (CH2 Fmoc); 83.2 (CtBu); 119.9; 124.1 (q, J = 285.6 Hz, CF3); 124.9; 127.0; 127.7; 141.2; 143.5; 143.7; 156.4 (CO); 165.1 (CO); 170.5 (CO). 19F NMR (CDCl3, 376.2 MHz): δ −79.4 (s, 3F, CF3). IR (neat/cm−1): 3350, 2977, 1738, 1710, 1690.

Fmoc-Leu-(R)-α-Tfm-Ala-OtBu, ( R)-14

By means of the general procedure described above starting from ( R)-10 (170 mg, 0.8 mmol), the compound ( R)-14 (355 mg, 0.65 mmol) was obtained as a white solid in 81 % yield. Mp: 147–148 °C. [α] 20D = –25.0 (c = 0.6, CHCl3). 1H NMR (CDCl3, 400 MHz): δ 0.94 (s, 6H, Hδ1 et Hδ1′); 1.45 (s, 9H, HtBu); 1.53 (m, 1H, Hγ1); 1.73 (m, 2H, Hβ1); 1.74 (s, 3H, Hβ2); 4.20–4.28 (m, 2H, Hα1 et HFmoc); 4.41 (d, 3 J = 6.9 Hz, 2H, CH 2 Fmoc); 5.25 (d, 3 J = 7.8 Hz, 1H, NH); 6.96 (s, 1H, NH); 7.31 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.40 (t, 3 J = 7.8 Hz, 2H, HFmoc); 7.58 (d, 3 J = 7.3 Hz, 2H, HFmoc); 7.77 (d, 3 J = 7.3 Hz, 2H, HFmoc). 13C NMR (CDCl3, 100.5 MHz): δ 18.1 (Cβ2); 22.2 (Cδ1); 23.2 (Cδ1′); 24.9 (Cγ1); 27.9 (CtBu); 41.4 (Cβ1); 47.4 (CH Fmoc); 53.8 (Cα1); 62.9 (q, J = 28.8 Hz, Cα2); 67.5 (CH2 Fmoc); 84.3 (CtBu); 120.4; 124.5 (q, J = 285.6 Hz, CF3); 125.4; 127.4; 128.1; 128.7; 141.6; 144.0; 156.7 (CO); 165.4 (CO); 171.8 (CO). 19F NMR (CDCl3, 376.2 MHz): δ −79.1 (s, 3F, CF3). IR (neat/cm−1): 3432, 3297, 1750, 1748, 1497. MS (EI): m/z = 549.3 [M+H]+. HRMS (EI) m/z calcd for C29H36F3N2O5 [M+H]+ 549.2576 found 549.2579.

Fmoc-Aib-(R)-α-Tfm-Ala-OtBu ( R)-15

By means of the general procedure described above starting from ( R)-10 (0.8 mmol), the compound ( R)-15 (0.5 mmol) was obtained as a white solid in 63 % yield. Mp: 146–149 °C. 1H NMR (CDCl3, 400 MHz): δ 1.47 (s, 9H, HtBu); 1.53 (s, 6H, Hβ1 et Hβ1′); 1,78 (s, 3H, Hβ2); 4,22 (t, 3 J = 6.4 Hz, 1H, HFmoc); 4,44 (d, 3 J = 5.0 Hz, 2H, CH 2 Fmoc); 5,29 (s, 1H, NH); 7.33 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.42 (t, 3 J = 7.3 Hz, 2H, HFmoc); 7.60 (m, 2H, HFmoc); 7.77 (d, 3 J = 7.3 Hz, 2H, HFmoc). 13C NMR (CDCl3, 100.5 MHz): δ 17.3 (Cβ2); 25.2 (Cβ1 et Cβ1′); 27,5 (CtBu); 47.0 (CH Fmoc); 57,2 (Cα1); 62.5 (q, J = 28.8 Hz, Cα2); 66.7 (CH2 Fmoc); 84.9 (CtBu); 119.9; 120.0; 124.2 (q, J = 285.6 Hz, CF3); 124.9; 127.0; 127.7; 141.3; 143.6; 143.7; 155.3 (CO); 165.5 (CO); 173.4 (CO). 19F NMR (CDCl3, 376.2 MHz): δ −79.2 (s, 3F, CF3). IR (neat/cm−1): 3420, 3293, 1747, 1752, 1490.

Ac-Ala-Phe-(R)-α-Tfm-Ala-Ala-NH2, 17

A sample of N-Fmoc-Rink-amide resin (loading 0.64 mmol/g, 0.13 mmol, 1.0 equiv) was placed in a dried 15 mL glass reaction vessel, stirred in a mixture of dry DCM (2 mL) and DMF (2 mL) for 30 min, and drained. The Fmoc group was removed by treatment with 10 ml of 20 % piperidine in DMF (3 × 10 min) and the resin was washed with DMF (3 × 1 min) and DCM (3 × 1 min). To the resin were added a solution of N-Fmoc-Ala-OH (0.65 mmol, 5.0 equiv), DIPEA (0.65 mmol, 5.0 equiv) and HATU (0.65 mmol, 5.0 equiv) in DMF (4 mL). The coupling reaction was shaken for 2 h at room temperature, after which the resin was washed with 5 mL of DMF (3 × 2 min) and 5 mL of DCM (3 × 2 min). The Fmoc group was removed with 10 ml of 20 % piperidine in DMF (3 × 10 min) and the resin was washed with DMF (3 × 1 min) and DCM (3 × 1 min). Independently, the dipeptide ( R)-12 (0.26 mmol) was treated with a solution of trifluoroacetic acid in CH2Cl2 (4 M, 3 mL) for 3 h at room temperature and evaporated to dryness to give the N-Fmoc-Phe-(R)-α-Tfm-Ala-OH dipeptide ( R)-16 which was used in the next step without further purification. To the resin were then added the dipeptide ( R)-16 (0.26 mmol, 2.0 equiv), DIPEA (0.26 mmol, 2.0 equiv) and HATU (0.26 mmol, 2.0 equiv) in DMF (2 mL). The coupling reaction was shaken for 3 h at room temperature, after which the resin was washed with 5 mL of DMF (3 × 2 min) and 5 mL of DCM (3 × 2 min). The same procedure was repeated for the coupling of the Fmoc-Ala-OH (0.65 mmol, 5.0 equiv). A 10 ml solution of acetic anhydride/pyridine/DMF (1:2:3) was transferred to the peptidyl resin and was reacted at room temperature (2 × 60 min). The resin was drained, washed with DMF (3 × 1 min) and DCM (3 × 1 min). A total of 6 ml of TFA/TIS/water/EDT (94:1:2.5:2.5) was added to the acetylated peptidyl resin (0.26 mmol) and shaked at room temperature for 3 h. The resin was then removed by filtration and washed twice with 100 % TFA. The filtrate was evaporated under vacuum and purified by semi-preparative HPLC (water/acetonitrile 90/10–70/30) to afford the desired tetrapeptide Ac-Ala-Phe-(R)-α-Tfm-Ala-Ala-NH2 17 (341 mg, 0.07 mmol, 53 %) as a white hygroscopic solid. [α] 20D = −1.6 (c = 0.5, MeOH). 1H NMR (CD3OD, 400 MHz): δ 1.27 (d, 3 J = 7.3 Hz, 3H, Hβ1 or Hβ4); 1.40 (d, 3 J = 6.9 Hz, 3H, Hβ1 or Hβ4); 1,68 (s, 3H, Hβ3); 1.96 (s, 3H, CH 3 CO); 2.99 (dd, 2 J = 14.2 Hz, 3 J = 9.2 Hz, 1H, Hβ2); 3.18 (dd, 2 J = 14.2 Hz, 3 J = 6.0 Hz 1H, Hβ2′); 4,31 (m, 2H, Hα1 and Hα4); 4,57 (m, 1H, Hα2); 7.24–7.33 (m, 5H, Har). 13C NMR (CD3OD, 100.5 MHz): δ 18.5 (Cβ1 or Cβ4); 18.6 (Cβ1 or Cβ4); 20.0 (Cβ3); 23.3 (CH3CO); 38.6 (Cβ2); 51.3 (Cα1 or Cα4); 51.7 (Cα1 or Cα4); 57.3 (Cα2); 64.4 (q, J = 25.9 Hz, Cα3); 126.7 (q, J = 283.7 Hz, CF3); 128.8; 130.4; 131.2;138.8; 168.9 (CO); 174.2 (CO); 174.6 (CO);176.5 (CO); 178.2 (CO). 19F RMN (CD3OD, 376.2 MHz): δ −79.1 (s, 3F, CF3). IR (neat/cm−1): 3402, 3350, 3250, 1740, 1628, 1550. MS (EI): m/z = 488.2 [M+H] +. HRMS (EI) m/z for C21H29F3N5O5 [M+H]+: 488.2121 found 488.2122.

Abbreviations

- α-Tfm-AAs:

-

α-Trifluoromethylamino acids

- Boc:

-

Tert-butyloxycarbonyl

- Cbz:

-

Carboxybenzyl

- Fmoc:

-

Fluorenylmethoxy carbonyl

- DIPEA:

-

N,N-Diisopropylethylamine

- DMAP:

-

4-Dimethylaminopyridine

- HPLC:

-

High performance liquid chromatography

- HATU:

-

N-[(dimethylamino)-1H-1,2,3-triazolo[4,5-b]pyridino-1-ylmethylene]-N-methylmethanaminium hexafluorophosphate

- IBCF:

-

Isobutyl chloroformate

- NMM:

-

N-Methylmorpholine

- SPPS:

-

Solid phase peptide synthesis

- TFA:

-

Trifluoroacetic acid

- TIS:

-

Triisopropylsilane

References

Acena JL, Sorochinsky AE, Soloshonok VA (2012) Recent advances in the asymmetric synthesis of α-(trifluoromethyl)-containing α-amino acids. Synthesis 44:1591–1602. doi:10.1055/s-0031-1289756

Bilgicer B, Fichera A, Kumar K (2001) A coiled coil with a fluorous core. J Am Chem Soc 123:4393–4399. doi:10.1021/ja002961j

Bocheva A, Nocheva H, Jlalia I, Lensen N, Chaume G, Brigaud T (2013) Effects of enantiopure (S)-α-trifluoromethyl proline containing MIF-1’s analogue on stress-induced analgesia. Med Chem 03:206–209. doi:10.4172/2161-0444.1000140

Botz A, Gasparik V, Devillers E, Hoffmann ARF, Caillon L, Chelain E, Lequin O, Brigaud T, Khemtemourian L (2015) (R)-α-Trifluoromethylalanine containing short peptide in the inhibition of amyloid peptide fibrillation. Biopolymers (Pept Sci) 104:601–610. doi:10.1002/bip.22670

Brasca MG, Albanese C, Amici R et al (2007) 6-Substituted pyrrolo[3,4-c]pyrazoles: an improved class of CDK2 inhibitors. Chem Med Chem 2:841–852. doi:10.1002/cmdc.200600302

Burger K, Gaa K (1990) Synthesis of α-(trifluoromethyl)-substituted α-amino acids. Part 7. An efficient synthesis for α-trifluoromethyl-substituted ω-carboxy α-amino acids. Chem Ztg 114:101–104

Burger K, Mütze K, Hollweck W, Koksch B (1998) Incorporation of α-trifluoromethyl substituted α-amino acids into C-and N-terminal position of peptides and peptide mimetics using multicomponent reactions. Tetrahedron 54:5915–5928. doi:10.1016/S0040-4020(98)00291-9

Burger K, Sewald N (1990) Synthesis of trifluoromethyl-substituted amino acids. 6. α-Trifluoromethyl-substituted amino acids with acetylene functions in the side chain. Synthesis. doi:10.1055/s-1990-26803

Caupene C, Chaume G, Ricard L, Brigaud T (2009) Iodocyclization of chiral CF3-allylmorpholinones: a versatile strategy for the synthesis of enantiopure α-Tfm-prolines and α-Tfm-dihydroxyprolines. Org Lett 11:209–212. doi:10.1021/ol8024567

Chaume G, Lensen N, Caupene C, Brigaud T (2009) Convenient synthesis of N-terminal Tfm-dipeptides from unprotected enantiopure α-Tfm-proline and α-Tfm-alanine. Eur J Org Chem. doi:10.1002/ejoc.200900768

Chaume G, Simon J, Caupene C, Lensen N, Miclet E, Brigaud T (2013) Incorporation of CF3-pseudoprolines into peptides: a methodological study. J Org Chem 78:10144–10153. doi:10.1021/jo401494q

Chiu HP, Kokona B, Fairman R, Cheng RP (2009) Effect of highly fluorinated amino acids on protein stability at a solvent-exposed position on an internal strand of protein G B1 domain. J Am Chem Soc 131:13192–13193. doi:10.1021/ja903631h

Cho J, Sawaki K, Hanashima S et al (2014) Stabilization of β-peptide helices by direct attachment of trifluoromethyl groups to peptide backbones. Chem Commun 50:9855–9858. doi:10.1039/c4cc02136c

Ginisty M, Gravier-Pelletier C, Le Merrer Y (2006) Chemical investigations in the synthesis of O-serinyl aminoribosides. Tetrahedron Asymmetry 17:142–150. doi:10.1016/j.tetasy.2005.11.019

Gerling UIM, Salwiczek M, Cadicamo CD, Erdbrink H, Czekelius C, Grage SL, Wadhwani P, Ulrich AS, Behrends M, Haufe G, Koksch B (2014) Fluorinated amino acids in amyloid formation: a symphony of size, hydrophobicity and α-helix propensity. Chem Sci 5:819–830. doi:10.1039/C3SC52932K

Gottler LM, de la Salud Bea R, Shelburne CE, Ramamoorthy A, Marsh ENG (2008a) Using fluorous amino acids to probe the effects of changing hydrophobicity on the physical and biological properties of the beta-hairpin antimicrobial peptide protegrin-1. Biochemistry 47:9243–9250. doi:10.1021/bi801045n

Gottler LM, Lee HY, Shelburne CE, Ramamoorthy A, Marsh ENG (2008b) Using fluorous amino acids to modulate the biological activity of an antimicrobial peptide. ChemBioChem 9:370–373. doi:10.1002/cbic.200700643

Hollweck W, Sewald N, Michel T, Burger K (1997) C-terminal incorporation of a-trifluoromethyl-substituted amino acids into peptides via in-situ deprotection of N-Teoc derivatives. Liebigs Ann. doi:10.1002/jlac.199719971219

Horng JC, Raleigh DP (2003) Sigma-values beyond the ribosomally encoded amino acids: kinetic and thermodynamic consequences of incorporating trifluoromethyl amino acids in a globular protein. J Am Chem Soc 125:9286–9287. doi:10.1021/ja0353199

Huguenot F, Brigaud T (2006) Concise synthesis of enantiopure alpha-trifluoromethyl alanines, diamines, and amino alcohols via the Strecker-type reaction. J Org Chem 71:7075–7078. doi:10.1021/Jo0607717

Jlalia I, Lensen N, Chaume G, Dzhambazova E, Astasidi L, Hadjiolova R, Bocheva A, Brigaud T (2013) Synthesis of a MIF-1 analogue containing enantiopure (S)-α-trifluoromethyl-proline and biological evaluation on nociception. Eur J Med Chem 62:122–129. doi:10.1016/j.ejmech.2012.12.041

Koksch B, Quaedflieg PJLM, Michel T, Burger K, Broxterman QB, Schoemaker HE (2004) Enzymatic resolution of Cα-fluoroalkyl substituted amino acids. Tetrahedron Asymmetry 15:1401–1407. doi:10.1016/j.tetasy.2004.02.027

Koksch B, Sewald N, Hofmann HJ, Burger K, Jakubke HD (1997) Proteolytically stable peptides by incorporation of alpha-Tfm amino acids. J Pept Sci 3:157–167. doi:10.1002/(SICI)1099-1387(199705)3:3<157:AID-PSC94>3.0.CO;2-W

Kukhar VP, Yagupolskii YL, Soloshonok VA (1990) β-Fluoro-substituted aminoacids. Russ Chem Rev 89:89–102

Lai MYH, Brimble M, Callis DJ et al (2005) Synthesis and pharmacological evaluation of glycine-modified analogues of the neuroprotective agent glycyl-l-prolyl-l-glutamic acid (GPE). Bioorganic Med Chem 13:533–548. doi:10.1016/j.bmc.2004.10.004

Li H, Hong Y, Nukui S et al (2011) Identification of novel pyrrolopyrazoles as protein kinase C β II inhibitors. Bioorg Med Chem Lett 21:584–587. doi:10.1016/j.bmcl.2010.10.032

Li T-W, Shang P-H, Cheng C-M, Zhao Y-F (2013) A convenient one-pot synthesis of (R)-2-amino-3,3,3-trifluoro-2-methyl-N-phenylpropanamide derivatives. Tetrahedron Lett 54:134–137. doi:10.1016/j.tetlet.2012.10.086

Maisch D, Wadhwani P, Afonin S, Bottcher C, Koksch B, Ulrich AS (2009) Chemical labeling strategy with (R)- and (S)-trifluoromethylalanine for solid state 19F NMR analysis of peptaibols in membranes. J Am Chem Soc 131:15596–15597. doi:10.1021/ja9067595

Osipov SN, Chkanikov ND, Kolomiets AF, Fokin AV (1986) Synthesis and c-alkylating properties of methyl 2-(benzenesulfonylimino)-3,3,3-trifluoropropionate. Bull Acad Sci USSR Div Chem Sci 35:1256–1259. doi:10.1007/BF00956610

Patil KBS, Babu VVS (2002) Synthesis of Fmoc-amino acid chlorides assisted by ultrasonication, a rapid approach. Lett Pept Sci 9:227–229. doi:10.1007/BF02538388

Salwiczek M, Nyakatura EK, Gerling UIM, Ye S, Koksch B (2012) Fluorinated amino acids: compatibility with native protein structures and effects on protein-protein interactions. Chem Soc Rev 41:2135–2171. doi:10.1039/c1cs15241f

Simon J, Nguyen TT, Chelain E, Lensen N, Pytkowicz J, Chaume G, Brigaud T (2011) Concise synthesis of enantiopure (S)- and (R)-α-trifluoromethyl aspartic acid and α-trifluoromethyl serine from chiral trifluoromethyl oxazolidines (Fox) via a Strecker-type reaction. Tetrahedron Asymmetry 22:309–314. doi:10.1016/j.tetasy.2011.01.007

Smits R, Cadicamo CD, Burger K, Koksch B (2008) Synthetic strategies to alpha-trifluoromethyl and alpha-difluoromethyl substituted alpha-amino acids. Chem Soc Rev 37:1727–1739. doi:10.1039/b800310f

Tang Y, Ghirlanda G, Vaidehi N et al (2001) Stabilization of coiled-coil peptide domains by introduction of trifluoroleucine. Biochemistry 40:2790–2796. doi:10.1021/bi0022588

Thorson JS, Chapman E, Murphy EC, Schultz PG, Judice JK (1995) Linear free energy analysis of hydrogen bonding in proteins. J Am Chem Soc 117:1157–1158. doi:10.1021/ja00108a044

Wipf P, Heimgartner H (1987) Selektive Amidspaltung bei Peptiden mit α, α-disubstituierten α-Aminosauren. Helv Chim Acta 70:354–368. doi:10.1002/hlca.19870700213

Zheng H, Gao J (2010) Highly specific heterodimerization mediated by quadrupole interactions. Angew Chem Int Ed 49:8635–8639. doi:10.1002/anie.201002860

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Communicated by J. Bode.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Devillers, E., Pytkowicz, J., Chelain, E. et al. Synthesis of protected enantiopure (R) and (S)-α-trifluoromethylalanine containing dipeptide building blocks ready to use for solid phase peptide synthesis. Amino Acids 48, 1457–1468 (2016). https://doi.org/10.1007/s00726-016-2200-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00726-016-2200-9