Abstract

A new heterogeneous nanocatalyst containing Cu–dimethylglyoxime complex grafted to an MCM-41 matrix was synthesized. This recoverable nanocomposite was applied as a highly effective, green, thermally stable catalyst in the one-pot reductive cyclization of aromatic aldehydes with 2-aminobenzamide. 2,3-Dihydroquinazolin-4(1H)-ones were obtained in 80–98% yield. The MCM-41-silylcyclopropyl-dimethylglyoxime-Cu heterogeneous nanocomposite was well identified using X‐ray diffraction, field emission scanning electron microscopy, Fourier transform infrared spectroscopy, energy‐dispersive X‐ray spectroscopy, Brunauer–Emmett–Teller technique, and thermogravimetric analysis. The eco-friendly nanocatalyst demonstrated excellent recyclability: it could be reused for at least six successive cycles without any notable decrease in its catalytic function.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, nanoporous materials have a superior role in green chemistry and have received a lot of attention amongst the industrial and academic scientific society, owing to facile recovery, high surface area, and their fundamental influence on the human life quality and economic advance [1, 2]. Also, these nanostructures have versatile applications in materials science owing to shape and size-selective different usages. Among them, mesoporous silica materials like MCM‐41 as the typical representative of the M41S material family has attracted much attention because of their several unique properties including large pore volume (normally over 0.8 cm3/g), unique channel structure, well thermal stability, large surface area (∼1000 m2/g), and good biocompatibility as well as ready surface functionalization [3, 4]. Due to unique properties these mesoporous creating suitable properties such as controllable, morphologies, narrow pore size distribution, structural simplicity, and ease synthesis with insignificant pore obstruction and pore networking [5,6,7,8]. These properties have made MCM-41 frequent support for heteropoly acids [9], immobilizing acids [10], complexes [11, 12], metal oxides [13], etc. Also, these mesoporous have been used for several applications such as adsorption [14], support of various catalysts [15], environmental science [16], sensors [17], drug delivery [18], etc. Finally, there is also the possibility of presentation transition metals including Cr [19], Pd [20], Mn [21], Cu [22], VO [23], Ni [15, 24], Mo [25], V [26], Co [27], and Fe [28] in the MCM-41 matrix to preparing different redox heterogeneous catalysts.

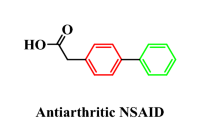

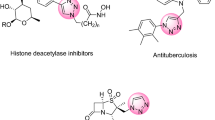

From a long time ago, copper-dimethylglyoxime complexes have been examined due to their possible utilization in organic and catalysis reactions [29]. Its catalytic property increases by grafting of the copper-dimethylglyoxime complex onto the MCM-41 matrix. 2,3-Dihydroquinazolinones, six-membered heterocyclic compounds, are of interest to many chemists owing to extensive range of different biological and pharmacological activities, anticancer, antifertility, antihistaminic, antibiotic, cytotoxicity, antibacterial, antitumor, painkiller, angiotensin II AT1 receptor antagonists, and mono amine oxidase inhibition [30,31,32]. Generally, various methods have been presented for the synthesis of 2,3-dihydroquinazolinones [33,34,35,36]. Among them, 2,3-dihydroquinazolin-4(1H)-one derivatives were synthesized via reductive cyclization of 2-aminobenzamide with various ketones or aldehydes in the presence of acid catalysts [32, 37]. In this synthetic process, many methods have been developed using different catalytic systems under different conditions [38,39,40,41]. Nevertheless, most of these catalytic processes have unfavorable reaction conditions such as harsh reaction conditions, longer reaction time, use of a major amount of poisonous and costly catalysts, unpleasant yields, and frustrating workup. So one of the goals of organic chemists is to develop better reaction conditions for the synthesis of these compounds using novel catalysts.

Herein, we synthesized a complex of copper-dimethylglyoxime based on MCM-41 nanoparticles and utilized it for the preparation of 2,3-dihydroquinazolin-4(1H)-one derivatives using cyclocondensation of aromatic aldehydes with 2-aminobenzamide under conditions of reflux in ethanol solvent with excellent yields, low reaction time, and easy workup.

Results and discussion

In our examinations on the use of heterogeneous nanocatalysts in organic reactions [42], herein, we synthesized a novel copper-dimethylglyoxime complex supported on MCM-41. We also checked its function as an effective heterogeneous and recoverable nanocatalyst in the preparation of 2,3-dihydroquinazolin-4(1H)-one derivatives. The details of the nanocatalyst preparation method were presented in Scheme 1.

Catalyst characterization

The nanocatalyst was fully characterized by XRD (X‐ray diffraction), FESEM (field emission scanning electron microscopy), FT-IR (Fourier transform infrared spectroscopy), EDS (energy‐dispersive X‐ray spectroscopy), BET (Brunauer–Emmett–Teller technique), and TGA (thermogravimetric analysis). The FT-IR spectra of MCM-41-dimethylglyoxime-Cu were shown in Fig. 1. As is depicted in Fig. 1, for the MCM-41, the absorption peaks at 1652, 1085, 805, and 459 cm−1 are related to stretching vibrations (symmetric and asymmetric) of Si–O-Si. Also, the peak at 3409 cm−1 indicates the presence of O─H groups stretching vibration. Stretching vibrations at 2953 and 3305 cm−1 attributed to the C─H of the chloropropylsilyl group. The existence of the grafted complex of Cu–dimethylglyoxime to functionalized MCM-41 can be confirmed by the presence of peaks at 1395 and 579 cm−1 that are allocated to stretching vibrations of C─N and Cu─N (Fig. 1) [43, 44].

The spherical morphology of MCM-41 and Cu(II)‐dimethylglyoxime‐MCM‐41 was studied using FESEM images (Fig. 2). The FESEM images confirm that MCM‐41 has almost spherical and regular morphology. The size distribution histogram for MCM‐41 and Cu(II)‐dimethylglyoxime‐MCM‐41 nanoparticles (Fig. 2) was shown a mean of 89.8 ± 2.4 nm and 86.8 ± 2.0 nm, respectively. It confirmed that these structures maintain their high monodispersity profile even after immobilization on the support.

As shown in Fig. 3, the EDX has confirmed the presence of every anticipated element in the produced Cu(II)‐dimethylglyoxime‐MCM‐41, including O, C, Si, N, and Cu with the relative weight percents 30.0, 20.5, 39.30, 1.3, and 8.9%, respectively. Moreover, the presence of the element of nitrogen in elemental analysis demonstrates dimethylglyoxime ligand has fully bonded onto MCM-41, and the metal of Cu has coordinated successfully to the ligand of dimethylglyoxime. These results indicate that the new nanocatalyst was constructed successfully.

Figure 4 demonstrates the low-angle powder XRD patterns of Cu(II)-dimethylglyoxime/MCM-41 and MCM-41 samples. The XRD pattern of MCM-41 illustrates the presence of three reflection peaks corresponding to (200), (110), (100) and planes at 2θ = 4.33°, 3.87°, and 2.41°, respectively. These patterns confirm the presence of ordered hexagonal mesoporous structure of MCM-41 (Fig. 4a). As shown in Fig. 4b, during the functionalization steps, a remarkable decline in the severity of XRD peaks was seen. It is due to decrease of dispersion contrast between the channel wall of complex and framework of silicate, or may be because of the alterations in the thickness of the wall. Thus, it can be found out that the preparation of the nanocatalyst has been accomplished on the internal pore channels of the MCM-41/Si.

Thermal stability of Cu(II)-dimethylglyoxime/MCM-41 mesoporous was determined using the TGA and TGA/DTA analysis. TGA (Fig. 5, top) and TGA/DTA (Fig. 5, bottom) curves showed primary weight decrease at temperatures under 200 °C owing to desorption of organic solvent and water molecules. Furthermore, raising the temperature from 200 to 800 °C, the major weight decrease was observed due to the thermal decomposition of organic functional groups located inside the framework.

The N2 adsorption–desorption isotherm of the Cu(II)-dimethylglyoxime/MCM-41 nanocomposite was shown in Fig. 6. The pore features of the prepared nanocomposite were investigated using the Brunauer–Emmett–Teller (BET) technique. The BET entire cavity capacity and surface areas for the nano composites were 0.1819 m3 g−1 and 1.400 m2 g−1, respectively. By using the technique of Barrett-Joyner-Halenda (BJH), the corresponding pores diameter distributions of Cu(II)-dimethylglyoxime/MCM-41 were specified as 1.21 nm (Fig. 7). The structure of the porous medium contains pores more than 2 nm (Dv > 2 nm) which demonstrates a mesoporous structure.

Catalytic activity of the Cu(II)-dimethylglyoxime/MCM-41

We examined the catalytic activity of Cu(II)-dimethylglyoxime/MCM-41 as a novel, stable, and recyclable heterogeneous nanocatalyst in preparation of 2,3-dihydroquinazolin-4(1H)-one derivative (Scheme 2). In this regard, the one-pot reaction of benzaldehyde and 2-aminobenzamide was performed to find the optimal conditions. The optimized conditions were shown in Table 1 for preparing the quinazoline in the presence of different catalytic quantities of Cu(II)-dimethylglyoxime/MCM-41.

The various parameters such as the reaction temperature, the amount of catalyst, time, and various solvents were studied, and the results were summarized in Table 1. The best results were obtained with 1.0 mmol benzaldehyde and 1.0 mmol 2-aminobenzamide in the presence of 5 mg Cu(II) dimethylglyoxime/MCM-41 and 5 cm3 ethanol as solvent at 80 ºC (Table 1, entry 12). Furthermore, with the utilization of further quantities of 8 mg catalyst and fewer quantities of 4 mg catalyst, the favored results and desired yields did not obtain (Table 1, entries 13 and 2, respectively).

After optimization experiments, the optimized conditions (ethanol solvent, 5 mg catalyst, and reflux conditions) were applied for the preparation of 2,3-dihydroquinazolin-4(1H)-ones (Table 2). The reaction of 2-aminobenzamide (1) with various aromatic aldehydes derivatives was carried out. It can be observed that a broad range of aldehyde derivatives 2 react with 2-aminobenzamide readily and give compounds 3 in suitable yields. It is also notable that only small condensation rate differences occur between aldehydes substituted with electron-donating and electron-attracting groups.

The proposed mechanism for the preparation of quinazolines derivatives was presented in Scheme 3. According to this mechanism, Cu(II)-dimethylglyoxime/MCM-41 is an active catalyst for the production of 2,3-dihydroquinazoline-4(1H) ones. First, the proposed catalyst coordinated to aldehyde oxygen to produce intermediate a, then imine b generated by nucleophilic attack of primary amine to intermediate a with loss of water. Afterward, under an intramolecular cyclization by the attack of amide nitrogen on the activated imine carbon, the desired 2,3-dihydroquinazoline-4(1H) one 3 is formed. It is noteworthy that the mechanism for the reaction has not been studied. We suggest the following possibility. We have not determined whether or not the catalyst functions in both steps as shown.

Further, the efficiency of the prepared catalyst was compared with other nanoparticle-based metal catalysts for the synthesis of the model product. To have a more precise comparison, the reaction condition, time, temperature, and solvent for each protocol were considered in Table 3. As obvious, our procedure is comparable with those of previously reported catalytic systems in terms of yields of the products, reaction temperature, and time. In addition to this, the present catalyst is more effective than the others due to some important benefits such as its eco-friendly, stability, recyclability, etc.

Recyclability of the catalyst

Finally, the stability and reusability of the catalyst were significant parameters in the potential application of organic transformation. To survey this trait, the reusability of the Cu(II)-DMG@MCM-41 was examined in the reaction of aromatic aldehydes with 2-aminobenzamide as a model reaction according to optimal conditions (Fig. 8).

At the end of each reaction cycle, the catalyst was separated using centrifugation and dried after washing with distilled water and ethanol. Then the catalyst is utilized for the next run. The results in Fig. 8 indicate that the proposed catalyst is recycled up to six successive runs. Furthermore, after six runs, the nature of the recycled nanocomposite was examined by SEM (Fig. 9). The conclusions of the analyses showed that the recycled nanocomposite after six periods had no significant decrease in catalytic activity that the structure of the mesoporous silica did not change significantly.

Conclusion

In summary, a new complex of Cu–dimethylglyoxime anchored to MCM-41 nanostructure was synthesized using the sol–gel method. It developed as an innovative promise catalyst and effectively green recyclable catalytic system in the synthesis of 2,3-dihydroquinazolin-4(1H)-ones. Advantages of the catalytic system are simple preparation, high reaction speed, green conditions, simple workup, excellent yields of products, excellent stability, and reusability of the catalyst.

Experimental

The used solvents and chemicals were obtained from Fluka, Aldrich, and Merck and used without further purification. The particle morphology and size of nanoparticles were checked using FESEM (Day Petronic Company, Tehran, Iran) with a TESCAN MIRA3, also EDS analysis was accomplished by a TESCAN MIRA3 (Day Petronic Company, Tehran, Iran). The FT‐IR spectra were taken by KBr pellets utilizing a Nexus 670 FT‐IR spectrometer (Urmia University, Urmia, Iran). Thin-layer chromatography was used for monitoring reaction over silica gel 60 F254 aluminum sheet. 1H NMR spectrum (300 MHz) and 13C NMR spectrum (75 MHz) were recorded by a Bruker NMR spectrometer (Urmia University, Urmia, Iran). The crystalline structures were checked by powder XRD measurements with a wavelength of 1.54 Å and several templates of diffraction were entered in the 2θ confine (1–80°) (Day Petronic Company, Tehran, Iran). Melting points were recorded using an IA9200 melting point device. Curves of TGA were collected using an STA 1500 appliance from Scientific American Rheometric (Day Petronic Company, Tehran, Iran).

Synthesis of siliceous MCM-41

Firstly, 1.0 g surfactant cetyltrimethylammonium bromide (CTAB, 2.74 mmol) was mixed with a solution containing 3.5 cm3 NaOH (2 M) and 480 cm3 deionized water under stirred at 80 °C. After homogenizing the mixture, 5 cm3 tetraethyl orthosilicate (TEOS) was slowly added dropwise into the solution, it gives a mixture of white suspension. The mixture of reaction was refluxed for 2 h at 80 °C. The product was filtered and dried at 70 °C after being washed with deionized water, then it was calcined at 550 °C for 5 h to eliminate the surfactants of remain. Eventually, Si-MCM-41 was prepared.

Synthesis of MCM-41-(CH2)3Cl

The prepared MCM-41 nanoparticles (4.8 g) with 5.0 g 3-chloropropyltrimethoxysilane (CPTMS) was mixed with 96 cm3 of n-hexane and the reaction mixture was stirred under N2 atmosphere and reflux conditions for 24 h. The outcome sediments were gathered by filtration, after washing with ethanol. The resulting MCM-41-(CH2)3-Cl was dried under vacuum.

Synthesis of MCM-41-(CH2)3Cl functionalized with dimethylglyoxime (MCM-41-CPTMS-DMG)

In a 50 cm3 round-bottomed flask equipped with a magnetic stirrer, 0.5 g dimethylglyoxime (DMG), 0.5 g MCM-41-(CH2)3Cl, 1.0 cm3 triethylamine (TEA), and 25 cm3 ethanol were mixed and refluxed for 24 h under N2 atmosphere. After washing with ethanol, it was dried under vacuum at 60 °C for 12 h.

Synthesis of MCM-41-CPTMS-DMG-Cu

Finally, a mixture of 0.8 g MCM-41-CPTMS-DMG, 0.4 g CuCl2·2H2O, and 20 cm3 ethanol was refluxed for 24 h under N2 atmosphere. The purified resulting precipitate was washed with EtOH and dried at 60 °C for 12 h to product MCM-41-CPTMS-DMG-Cu.

General synthesis for the preparation of 2,3-dihydroquinazolin-4(1H)-ones

A mixture of 0.136 g 2-aminobenzamide (1 mmol), aldehyde (1 mmol), and 5 mg MCM-41-CPTMS-DMG-Cu was stirred in 5 cm3 ethanol and heated at 80 °C. The reaction progression was controlled using TLC (acetone:n-hexane, 2:8, V/V). After the completion of reaction, the mixture of reaction was cooled until room temperature, then nanocatalyst was filtered by centrifuge and reused for the subsequent reactions. The filtered solution was evaporated to remove the solvent, then obtained product was washed with ethanol, 80–98% yields.

References

Ng EP, Mohd Subari SN, Marie O, Mukti RR, Juan JC (2013) Appl Catal A Gen 450:34

Polshettiwar V, Varma RS (2010) Green Chem 12:743

Munoz B, Ramila A, Perez-Pariente J, Diaz I, Vallet-Regi M (2003) Chem Mater 15:500

Manzano M, Aina V, Arean CO, Balas F, Cauda V, Colilla M, Delgado MR, Vallet-Regi M (2008) Chem Eng J 137:30

Rath D, Rana S, Parida KM (2014) RSC Adv 4:57111

Ando R, Ono H, Yagyu T, Maeda M (2004) Inorg Chim Acta 357:817

Nikoorazm M, Ghorbani-Choghamarani A, Noori N (2015) J Porous Mater 22:877

Nikoorazm M, Ghorbani-Choghamarani A, Khanmoradi M (2016) Appl Organomet Chem 30:236

Karthikeyan G, Pandurangan A (2009) J Mol Catal A Chem 311:36

Hu X, Chuah GK, Jaenicke S (2001) Appl Catal A Gen 217:1

Mandal M, Nagaraju V, Sarma B, Karunakar GV, Bania KK (2015) ChemPlusChem 80:749

Jana S, Dutta B, Bera R, Koner S (2007) Langmuir 23:2492

Hajjami M, Shiri L, Jahanbakhshi A (2015) Appl Organomet Chem 29:668

Zhang L, Li Y, Zhou H (2018) Energy 149:414

Batmani H, Noroozi Pesyan N, Havasi F (2018) Micropor Mesopor Mat 257:27

Qi F, Chu W, Xu B (2013) Appl Catal B Environ 134–135:324

Abu-Zied BM, Alam MM, Asiri AM, Schwieger W, Rahman MM (2019) Colloid Surf A Physiochem Eng Asp 562:161

Vallet-Regi M, Balas F, Arcos D (2007) Angew Chem Int Ed 46:5748

Wang X, Wu G, Xue Y, Zhang F, Liu X, Ding K (2013) Catal Lett 143:219

Batmani H, Noroozi Pesyan N, Havasi F (2018) Appl Organomet Chem 32:1

Mahdavi V, Mardani M, Malekhosseini M (2008) Catal Commun 9:2201

Sreyashi J, Buddhadeb D, Rajesh B, Subratanath K (2007) Langmuir 23:2492

Bhunia S, Saha D, Koner S (2011) Langmuir 27:15322

Qiu S, Zhang X, Liu Q, Wang T, Zhang Q, Ma L (2013) Catal Commun 42:73

Higashimoto S, Tsumura R, Zhang SG, Matsuoka M, Yamashita H, Louis C, Che M, Anpo M (2000) Chem Lett 29:408

Canepa AL, Elias VR, Vaschetti VM, Sabre EV, Eimer GA, Casuscelli SG (2017) Appl Catal A Gen 545:72

Tang K, Hong X (2016) Energ Fuel 30:4619

Jiang Y, Lin K, Zhang Y, Liu J, Li G, Sun J, Xu X (2012) Appl Catal A Gen 445–446:172

Parrey IR, Hashmi AA (2014) J New Develop Chem 1:20

Narasimhulu M, Lee YR (2011) Tetrahedron 67:9627

Na YH, Hong SH, Lee JH, Park WK, Baek DJ, Koh HY, Cho YS, Choo H, Pae AN (2008) Bioorg Med Chem 16:2570

Ghorbani-Choghamarani A, Azadi G (2015) RSC Adv 5:9752

Dabiri M, Salehi P, Otokesh S, Baghbanzadeh M, Kozehgary G, Mohammadi AA (2005) Tetrahedron Lett 46:6123

Ghorbani-Choghamarani A, Norouzi M (2014) J Mol Catal A Chem 395:172

Chen J, Wu D, He F, Liu M, Wu H, Ding J, Su W (2008) Tetrahedron Lett 49:3814

Aalinejad M, Noroozi Pesyan N, Heidari N, Batmani H, Danandeh Asl A (2019) Appl Organomet Chem 33:1

Darvatkar NB, Bhilare SV, Deorukhkar AR, Raut DG, Salunkhe MM (2010) Green Chem Lett Rev 3:301

Vahdat SM, Chekin F, Hatami M, Khavarpour M, Baghery S, Roshan-Kouhi Z (2013) Chin J Catal 34:758

Nasr-Esfahani M, Hoseini SJ, Montazerozohori M, Mehrabi R, Nasrabadi H (2014) J Mol Catal A Chem 382:99

Chen BH, Li JT, Chen GF (2015) Ultrason Sonochem 23:59

Noroozi Pesyan N, Danandeh Asl A, Namdar S (2020) Appl Organomet Chem 34:e5710

Hassanloie N, Noroozi Pesyan N, Sheykhaghaei G (2019) Appl Organomet Chem 34:1

Sarkar B, Kwek W, Verma D, Kim J (2017) Appl Catal A Gen 545:148

Bigotto A, Galasso V, deAlti G (1971) Spectrochim Acta A Mol Biomol Spect 27:1659

Labade VB, Shinde PV, Shingare MS (2013) Tetrahedron Lett 54:5778

Rostamizadeh S, Amani AM, Aryan R, Ghaieni HR, Shadjou N (2008) Synth Commun 3:3567

Chen JX, Wu HY, Su WK (2007) Chin Chem Lett 18:536

Sharma M, Pandey S, Chauhan K, Sharma D, Kumar B, Chauhan PMS (2012) J Org Chem 77:929

Qiao RZ, Xu BL, Wang YH (2007) Chin Chem Lett 18:656

Shaterian HR, Oveisi AR (2009) Chin J Chem 27:2418

Ding QS, Zhang JL, Chen JX, Liu MC, Ding JC, Wu HY (2012) J Heterocycl Chem 49:375

Davoodnia A, Allameh S, Fakhari AR, Tavakoli-Hoseini N (2010) Chin Chem Lett 21:550

Ojaghi Aghbash K, Noroozi Pesyan N (2020) J Porous Mater 27:1087

Rostami A, Tavakoli A (2011) Chin Chem Lett 22:1317

Shiri L, Ghorbani-Choghamarani A, Kazemi M (2016) Appl Organomet Chem 31:1

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hassanloie, N., Noroozi Pesyan, N., Sheykhaghaei, G. et al. Anchoring of Cu–dimethylglyoxime complex in MCM-41 matrix: a new, recyclable, and highly efficient nanocatalyst for the green preparation of 2,3-dihydroquinazolin-4(1H)-ones. Monatsh Chem 152, 833–844 (2021). https://doi.org/10.1007/s00706-021-02793-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-021-02793-9