Abstract

A new one-pot method has been introduced in this work for the synthesis of symmetrical primary, secondary, and tertiary alkyl amines from alkyl halides and 5-methyl-1,3,4-thiadiazole-2-amine as a nitrogen-transfer reagent. In this method, all three types of amines have been successfully prepared after changing the ratio of substrates and base control. In addition to the introduction of a new nitrogen-transfer reagent, other important features of this work include normal atmospheric conditions and excellent yields under mild reaction conditions.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amines found in a wide range of natural products, bioactive molecules, and industrial materials [1]. They are important building blocks in organic synthesis and the chemical industry. For example, they are used in the synthesis of pharmaceuticals and agrochemicals, and also as building blocks for polymers and dyes [2, 3]. Owing to the numerous applications of amines, their synthesis has perhaps received more attention than the preparation of many other functional groups in organic chemistry [4]. Accordingly, the development of methods for the selective synthesis of amines is an obvious problem in organic chemistry [5].

The most classic method for amine synthesis is Hoffmann alkylation, that is, reaction of ammonia with alkyl halides producing a mixture of primary, secondary, and tertiary amines and ammonium salts [6]. Other methods of formation of amines include catalyzed amination of alcohols [7, 8], and reduction of amides [9, 10] or carboxylic acids [11] in the presence of ammonia. However, there are practical difficulties associated with the use of ammonia, including its storage, handling, and transportation [10, 12]. In addition, this reaction usually results in an over-alkylation that often gives rise to mixtures of primary, secondary, and tertiary amines [1, 13, 14].

There are many interesting approaches for the synthesis of secondary and tertiary amines. These methods traditionally include N-alkylation of amines with alkyl halides (or with dialkyl sulfates or sulfonates) [15,16,17], reductive amination of carbonyl [18, 19] and nitrile compounds [20], or hydroamination of unsaturated hydrocarbons [21, 22]. Unfortunately, the disadvantages of these methods include the use of expensive catalysts and starting materials, low selectivity, concomitant formation of large amounts of wasteful salts, and harsh workup procedures [17].

Moreover, difficulty in working with ammonia has led organic chemists to use nitrogen-transfer reagents to overcome these disadvantages. Compared to the impressive progress being made in the N-alkylation of organic amines, reports dealing with the direct synthesis of amines using nitrogen-transfer reagents are scarcely available. Nitrogen-containing compounds have been evaluated for their ability to transfer nitrogen. Nitrogen-transfer reactions aim for a direct synthesis of primary, secondary, and tertiary amines. Some of the nitrogen-transfer reagents electrophile or nucleophile include: urea [23], N,N-dialkyl-O-aryl sulfonylhydroxylamines [24, 25], azide [26, 27], aziridines [28], and O-alkyloximes [29].

After a successful presentation of sulfur-transfer reagents in our previous works [30,31,32,33], herein, we wish to report an economical and environmental friendly method for synthesis of symmetrical alkyl amines from alkyl halides and 5-methyl-1,3,4-thiadiazole-2-amine (1) as a new nitrogen-transfer reagent. In this process, N-source 1 is a basic, solid reagent that can be easily prepared and handled. In addition, for the first time, in the presence of this reagent, all three types of highly selective amines were successfully prepared (Scheme 1).

Results and discussion

The reaction of benzyl chloride with 5-methyl-1,3,4-thiadiazole-2-amine (1) in the presence of a base and in a mixture EtOH/H2O at room temperature was studied under normal atmospheric conditions to optimize the reaction conditions. According to the results shown in Table 1, it was observed that there was no reaction in the absence of a base (Table 1, entry 1). In addition, the amount of 3 mmol from KOH showed a superior effect on the reaction conversion and reaction in less than 3 mmol from KOH was incomplete (Table 1, entries 2, 3). The selectivity of the N-alkylation is influenced by both the stoichiometric amounts of the starting materials and type of the base. We found that by increasing the stoichiometric amounts of benzyl chloride in the presence of a strong base, the reaction moved forward to production of tertiary amine (Table 1, entries 4, 5). KOH, NaOH, and t-BuOK displayed similar behavior in similar conditions stoichiometry (Table 1, entries 5–7). As expected, in stoichiometric amounts of 1:0.5 from benzyl chloride: 5-methyl-1,3,4-thiadiazole-2-amine and in the presence of an average base, the main product was a dibenzyl amine (Table 1, entries 8, 9).

It is interesting that average bases such as K2CO3 and K3PO4 take a mid-path. The main resultant product is secondary alkyl amine (Table 1, entries 9–11). When a weak base was added, the reaction will be majority converted into primary alkyl amine (Table 1, entries 12, 13). We found that by increasing the stoichiometric amounts of N-source 1 in the presence of a weak base, the reaction progressed to the production of benzyl amine. (Table 1, entries 14–16).

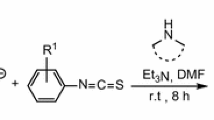

After the optimized reaction conditions were established, a large number of alkyl halides were examined to explore the scope of this reaction. Accordingly, the number of alkyl amine was synthesized in the presence of alkyl halides (1 mmol) using 1.5 mmol of 5-methyl-1,3,4-thiadiazole-2-amine (1) at 25 °C under normal atmospheric conditions and Et3N as base. As shown in Table 2, primary, secondary, and tertiary alkyl halides worked well with this procedure to efficiently yield the corresponding alkyl amines as only product in good-to-excellent yields (Table 2, entries 1–10).

In addition, this protocol efficiently generated symmetric secondary amines. A range of this material were obtained with alkyl halides (1 mmol) using 0.5 mmol of 5-methyl-1,3,4-thiadiazole-2-amine (1) at 25 °C under normal atmospheric conditions using K2CO3 as base (Table 3). As shown in Table 3, primary, secondary, and tertiary alkyl halides worked well with this procedure to efficiently yield the corresponding alkyl amines in good-to-excellent yields (Table 3, entries 1–10). In addition, it was observed that secondary and tertiary alkyl halides generate less than 10% primary amines (Table 3, entries 9–10).

The reaction efficiency for the synthesis of tertiary amines was examined in the presence of alkyl halides (1 mmol) using 0.3 mmol of 5-methyl-1,3,4-thiadiazole-2-amine (1) at 25 °C under normal atmospheric conditions and KOH as base. Various types of primary alkyl halides reacted very well with N-source 1 (Table 4, entries 1–7). It was observed that secondary and tertiary alkylhalides generated tertiary amines in very small amounts. This could be because of steric hindrance. Thus, at the end, a mixture of elimination products, primary, and secondary amines were produced.

Two possible mechanisms have been proposed for this reaction. On using a strong base such as KOH, the reaction mechanism progressed to Scheme 2. When ammonia was generated in situ, trialkylamine was produced in the presence of excess R-X (Scheme 2) [21, 22]. When a weak base such as Et3N was used, N-source 1 seemed to act as a better nucleophile. Given that N-source 1 in excess, all of alkyl halide was converted to 9. Finally, in the presence of the Et3N, primary amines were generated (Scheme 3).

Although we cannot clearly determine the reaction pathway for the synthesis of secondary amines from alkyl halides and N-source 1, it seems reaction can progress through both reaction pathways.

Conclusions

In summary, a novel, effective, and one-pot procedure was developed for the direct synthesis of primary, secondary, and tertiary alkyl amine from various alkyl halides and 5-methyl-1,3,4-thiadiazole-2-amine (1) in mild conditions. The important feature of this method is the introduction of a new nitrogen-transfer reagent. The reagent was a stable and nontoxic solid, which could be used to prepare all three types of amines. This protocol has several advantages: normal atmospheric conditions, catalyst-free systems, easily available and low-cost reagents, using green solvent instead of the usually used organic solvents, simple work up without further purification, and accomplishment reaction at room temperature.

Experimental section

All reagents and starting materials were obtained commercial from Sigma–Aldrich and Merck. Melting points were determined on an Electrothermal 9100 apparatus. Fourier transform infrared (FT-IR) spectra were obtained on a Bruker VERTEX 70 instrument, with samples being dispersed on potassium bromide pellets. The 1H NMR (400 MHz) and 13C NMR (100 MHz) spectra were recorded on a Bruker Avance NMR spectrometer in CDCl3 solution. The progress of the reaction was monitored by TLC using silica-gel SILG/UV 254 plates.

Typical experimental procedure for primary amines synthesis

A mixture of alkyl halide (1.0 mmol) and 5-methyl-1,3,4-thiadiazole-2-amine (1) (1.5 mmol) were added to a flask containing 3 mmol Et3N and 2 cm3 EtOH/H2O (10:1). The reaction continued at room temperature under atmospheric conditions 1 h. The reaction progress was controlled by thin-layer chromatography. Then, crude reaction mixture was purified by column chromatography (petroleum ether/ethyl acetate 1:4) to give the primary amines in good yields.

Typical experimental procedure for secondary amines synthesis

A mixture of alkyl halide (1.0 mmol) and 5-methyl-1,3,4-thiadiazole-2-amine (1) (0.5 mmol) were added to a flask containing 3 mmol K2CO3 and 2 cm3 EtOH/H2O (10:1). The reaction continued at room temperature under atmospheric conditions until 1 h. The reaction progress was controlled by thin-layer chromatography. The solvent was evaporated under vacuum. Then, crude reaction mixture was purified by column chromatography (petroleum ether/ethyl acetate 1:1) to give the secondary amines in good yields.

Typical experimental procedure for tertiary amines synthesis

A mixture of alkyl halide (1.0 mmol) and 5-methyl-1,3,4-thiadiazole-2-amine (1) (0.3 mmol) were added to a flask containing 3 mmol KOH and 2 cm3 EtOH/H2O (10:1). The reaction continued at room temperature under atmospheric conditions until 1 h. The reaction progress was controlled by thin-layer chromatography. The solvent was evaporated under vacuum. Then, crude reaction mixture was purified by column chromatography (petroleum ether/ethyl acetate 8:1) to give the tertiary amines in good yields.

References

Lawrence SA (ed) (2004) Amines: synthesis, properties and application. Cambridge University Press, Cambridge

Wittcoff HA, Reuben BG, Plotkin JS (2004) Industrial organic chemicals, 2nd edn. Wiley, New York

Hartwig JF (2002) Handbook of organopalladium chemistry for organic synthesis. Wiley, New York, p 1051

Brown BR (1994) The organic chemistry of aliphatic nitrogen compounds. Oxford University Press, New York

Salvatore RN, Yoon CH, Jung KW (2001) Tetrahedron 57:7785

Hoffmann AW (1850) Philos Trans 140:93

Bahn S, Imm S, Neubert L, Zhang M, Neumann H, Beller M (2011) ChemCatChem 3:1853

Yang Q, Wang Q, Yu Z (2015) Chem Soc Rev 44:2305

Hanada S, Ishida T, Motoyama Y, Nagashima H (2007) J Org Chem 72:7551

Das S, Wendt B, Möller K, Junge K, Beller M (2012) Angew Chem 124:1694

Sorribes I, Jung K, Beller M (2014) J Am Chem Soc 136:14314

Katz DLV (1959) Handbook of natural gas engineering. McGraw-Hill, New York

Azov V, Beller M, Butenschön H, Börner A, Couty FG (2014) Science of Synthesis: Houben-Weyl methods of molecular transformations, vol 40a: Amines and Ammonium Salts. Georg Thieme Verlag

McKetta JJ Jr (1993) Chemical Processing Handbook. CRC Press, Florida

Castillo J-C, Orrego-Hernández J, Portilla J (2016) Eur J Org Chem 22:3824

Demir S, Damarhan Y, Özdemir I (2015) J Mol Liq 204:210

Watson AJA, Maxwell AC, Williams JMJ (2011) J Org Chem 76:2328

Nayal OS, Bhatt V, Sharma S, Kumar N (2015) J Org Chem 80:5912

Yagafarov NZ, Kolesnikov PN, Usanov DL, Novikov VV, Nelyubina YV, Chusov D (2016) Chem Commun 52:1397

Liu S, Chen R, Deng GJ (2011) Chem Lett 40:489

Artamkina GA, Sergeev AG, Stern MM, Beletskaya IP (2006) Synlett 2006:235

Younis FM, Krieck S, Görls H, Westerhausen M (2016) Dalton Trans 45:6241

He L, Qian Y, Ding RS, Liu YM, He HY, Fan KN, Cao Y (2012) Chemsuschem 5:621

Boche G, Mayer N, Bernheim M, Wagner K (1978) Angew Chem lnt Ed 17:678

Berman AM, Johnson JS (2006) J Org Chem 71:219

Nyffeler PT, Liang CH, Koeller KM, Wong CH (2002) J Am Chem Soc 124:10773

Chandrasekhar S, Prakash SY, Rao CL (2006) J Org Chem 71:2196

Watson ID, Yu L, Yudin AK (2006) Acc Chem Rev 39:194

Beak P, Selling GW (1989) J Org Chem 54:5574

Soleiman-Beigi M, Mohammadi F (2012) Tetrahedron Lett 53:7028

Soleiman-Beigi M, Mohammadi F (2015) Synlett 26:911

Soleiman-Beigi M, Hemmati M (2013) Appl Organometal Chem 27:734

Soleiman-Beigi M, Arzehgar Z (2015) Sulfur Chem 36:395

Bähn S, Imm S, Neubert L, Zhang M, Neumann H, Beller M (2011) Chem Eur J 17:4705

Szostak M, Sautier B, Spain M, Procter DJ (2014) Org Lett 16:1092

Miriyala B, Bhattacharyya S, Williamson JS (2004) Tetrahedron 60:1463

Cui X, Dai X, Deng Y, Shi F (2013) Chem Eur J 19:3665

He J, Kim JW, Yamaguchi K, Mizuno N (2009) Angew Chem 121:10072

Koschabek R, Gleiter R, Rominger F (2006) Eur J Inorg Chem 2006:609

Sachinvala N, Winsor DL, Maskos K, Grimm C, Hamed O, Vigo TL, Bertoniere NR (2000) J Org Chem 65:9234

Peeters A, Claes L, Geukens I, Stassen I, De Vos D (2014) Appl Catal A Gen 469:191

Acknowledgements

We acknowledge the financial support of Ilam University Research Council.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Soleiman-Beigi, M., Mohammadi, F. An improved and one-pot procedure to the synthesis of symmetric amines by domino reactions of 5-methyl-1,3,4-thiadiazole-2-amine, a new nitrogen atom donor, and alkyl halides. Monatsh Chem 148, 2123–2128 (2017). https://doi.org/10.1007/s00706-017-2042-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-017-2042-5