Abstract

A novel conductive filament based on graphite (Gr) dispersed in polylactic acid polymer matrix (PLA) is described to produce 3D-electrochemical devices (Gr/PLA). This conductive filament was used to additively manufacture electrochemical sensors using the 3D pen. Thermogravimetric analysis confirmed that Gr was successfully incorporated into PLA, achieving a composite material (40:60% w/w, Gr and PLA, respectively), while Raman and scanning electron microscopy revealed the presence of defects and a high porosity on the electrode surface, which contributes to improved electrochemical performance. The 3D-printed Gr/PLA electrode provided a more favorable charge transfer (335 Ω) than the conventional glassy carbon (1277 Ω) and 3D-printed Proto-pasta® (3750 Ω) electrodes. As a proof of concept, the ciprofloxacin antibiotic, a species of multiple interest, was selected as a model molecule. Thus, a square wave voltammetry (SWV) method was proposed in the potential range + 0.9 to + 1.3 V (vs Ag|AgCl|KCl(sat)), which provided a wide linear working range (2 to 32 µmol L−1), 1.79 µmol L−1 limit of detection (LOD), suitable precision (RSD < 7.9%), and recovery values from 94 to 109% when applied to pharmaceutical and milk samples. Additionally, the sensor is free from the interference of other antibiotics routinely employed in veterinary practices. This device is disposable, cost-effective, feasibly produced in financially limited laboratories, and consequently promising for evaluation of other antibiotic species in routine applications.

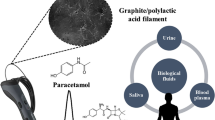

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently additive manufacturing (AM), popularly known as 3D printing has played an important role in the scientific scenario, acting as a promising tool for building equipment, spare parts, and electronic components [1,2,3]. In fact, such technology has been enabling the advancement of several areas of science, such as engineering, medicine, dentistry, aerospace, electronics, and food [4,5,6,7]. The area of chemistry, specifically, in electrochemistry, has also benefited greatly, considering the rapid prototyping of electrochemical devices (cells and electrodes) on a large scale with varied designs, sizes, and compositions, often under specific analytical demand [8,9,10,11,12].

The construction of electrochemical devices is generally based on fusion deposition modeling (FDM) manufacturing employing polymeric (thermoplastic) filaments, which are extruded and deposited layer by layer until three-dimensional structures are obtained [13]. Commercially available, conductive filaments are based on mixtures of polymeric materials, usually polylactic acid (PLA), and a conductive carbon-based material such as graphene (Black Magic®) and carbon black (Proto-pasta®) [14, 15]. However, 3D-printed sensors obtained by both filaments commonly exhibit poor electrochemical performance when they are used “as printed,” probably due to their composition, which contains between 10 and 20% wt. of conductive material [9]. Furthermore, its performance has been associated with shelf-life and storage conditions [16].

Different approaches involving surface treatment/activation procedure, such as mechanical polishing, heating, chemical/electrochemical activation, immersion in organic solvents, and the use of enzymes, have been used to improve the electrochemical response of these 3D printed electrodes [17,18,19,20,21,22,23]. Overall, these procedures aim to consume the polymeric matrix of insulating material (PLA) exposing the carbon black or graphene electroactive sites [24]. It is worth emphasizing that most of these procedures are labor intensive, time consuming, and require the use of toxic reagents. In this context, other research groups have reported the development of lab-made conductive filaments, reducing costs and pretreatment steps, improving electroanalytical performance and practicality of analysis. The synthesis of filaments based on copper nanowires (5% wt.) and polycaprolactone (PCL) [25], nanographite (25% wt.) [26], graphite (40% wt.) [27], carbon black (28.5% wt.) [28] mixed with PLA has been recently proposed and successfully used for 3D printing of electrodes for electrochemical sensing proposals. This research line has been gaining prominence by the scientific community, considering that the development of eco-friendly synthesis protocols to obtain new thermostable materials with higher amount of conductive content are promising alternatives to achieve cost-effective 3D-printing electrochemical devices with improved analytical performance. Of the filaments mentioned above, the developed by Stefano and colleagues based on graphite dispersed in PLA matrix (Gr-PLA, 40:60% w/w) [27] has been little explored for electroanalytical purposes.

Indeed, such material has only been used as working electrode for biosensing of SARS-CoV-2 [27], tetracycline [29], and pesticide monitoring, as carbendazim, in food [30, 31]. To the best of our knowledge, its performance has not yet been reported for detecting other antibiotics, such as the fluoroquinolone derivatives, whose species are of interest in several areas (pharmaceutical, environmental, and food) [32, 33].

Hence, in this work we synthesized and characterize Gr/PLA material to print “ready-to-use” electrodes using 3D pen. Unlike FDM 3D printers, the 3D pen is cheaper and require less material to print the device, and moreover provides electrodes with similar analytical performance to the ones obtained by the FDM 3D printer [13]. This 3D-printed Gr/PLA electrode was coupled with square wave voltammetry (SWV) for simple and fast detection of ciprofloxacin (CIP), a third-generation fluoroquinolone widely used in human and veterinary medicine for the treatment of infectious bacterial manifestations and prophylactic purposes [32, 34], in complex milk samples (cow and goat) and pharmaceutical formulations.

Materials and methods

Instruments

A magnetic stirrer with heating system IKA, model lab disc (Staufen, Germany), and a temperature-controlled oven Mylabor, model SSD150L (São Paulo, Brazil), were used for the synthesis and drying of the conductive filaments, respectively. An extruder Filmaq 3D, model CV (Curitiba, Brazil), was used to extrude the filaments for 3D printing. Customized cylinders were printed using insulating acrylonitrile butadiene styrene (ABS) filament on a 3D printer GTMax3D CORE, model A2V2 (Americana, Brazil), and used as supports for the working electrodes. The conductive material was manually extruded at one end of the holder using 3D pen Sanmersen (China). The pH values of the solutions were adjusted using a pH meter Digimed, model DM-22 (São Paulo, Brazil). High-purity deionized water was obtained from a Milli-Q purification system Millipore, model Direct-Q3 UV (Burlington, USA). Scanning electron microscopy (SEM) images were obtained using a microscope FEI, model Quanta 250 (Eindhoven, the Netherlands), with a 20 kV accelerating voltage. Thermogravimetric analysis (TGA) was carried out on a Shimadzu TG/DTA 60 (Kyoto, Japan) using approximately 5 mg of each sample in alumina crucibles heated from 25 to 1000 °C (heating rate 10 °C min−1) under an atmosphere of synthetic air at a flow rate of 50 mL min−1. Raman spectra were acquired on a LabRam HR Evolution Spectrophotometer Horiba (Kyoto, Japan) in the wavelength range between 4000 and 240 cm−1, using a source laser of 532 nm at 50 mW potency. Fourier transform infrared spectroscopy (FTIR) was performed with a spectrometer model Cary 630 (Agilent Technologies, USA) coupled to an attenuated total reflection (ATR) element. The spectrum was recorded in the range of 4000 to 500 cm−1 at a resolution of 4 cm−1. All electrochemical measurements (cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS), chronoamperometry (CA), and SWV) were performed using a potentiostat/galvanostat Metrohm Autolab B.V., model PGSTAT-128N (Herisau, Switzerland), interfaced by NOVA software (version 2.1.6) to a desktop computer. All SWVs data were presented after baseline correction (moving average mode and window size at level 1). Electrochemical experiments were performed in a 5-mL glass cell containing a three-electrode system: platinum wire and an Ag|AgCl|KCl(Sat), as auxiliary and reference electrodes, respectively; and 3D-printed Gr/PLA, 3D-printed Proto-pasta®, and a commercial glassy carbon electrode (GCE, Metrohm, 3 mm diameter) were used as working electrode.

Reagents and solutions

Analytical standard of CIP (98% w/w), ampicillin (AMP, 96% w/w), tetracycline (TET, 98% w/w), sulfanilamide (SFA, 99% w/w), sulfamethoxazole (SFX, 98% w/w), chloramphenicol (CHL, 98% w/w), and levofloxacin (LEV, 98% w/w) were purchased from Sigma-Aldrich (St. Louis, USA). Acetone (92% v/v), ethanol (95% v/v), and chloroform (99.8% v/v) were obtained from Qhemis (Indaiatuba, Brazil). Glacial acetic acid (99.9% w/v), phosphoric acid (85% w/v), sodium hydroxide (99% w/w), potassium ferricyanide (99% w/w), and potassium chloride (99% w/w) were obtained from Synth (Diadema, Brazil). Boric acid (99.8% w/w) was obtained from MP Biomedicals (Irvine, USA). The in natura PLA pellets were purchased from 3DLab (Betim, Brazil), whereas the graphite powder was obtained from Sigma-Aldrich (St. Louis, USA). Carbon black/polylactic acid (CB/PLA) thermoplastic filament (Proto-Pasta®) was obtained from ProtoPlant Inc. (Vancouver, USA).

Britton-Robinson (BR) buffer solution (0.1 mol L−1) was used as the supporting electrolyte for the electrochemical measurements. This solution was prepared using an equimolar mixture of acetic, boric, and phosphoric acids and the pH values (2.0 to 10.0) were adjusted using a sodium hydroxide solution (1 mol L−1). The stock solution of CIP (5 mmol L−1) was prepared daily in deionized water.

Conductive filament synthesis

Gr/PLA filaments were synthesized following the procedure described by Stefano et al. [27]. In short, 30 g of PLA pellets was dissolved in 250 mL of a mixture of acetone and chloroform (3:1) under stirring and reflux (about 70 °C) for 2 h. Then, 20 g of graphite powder was added to the reaction medium, and the system was kept under the same conditions for 1.5 h. After this, the obtained material (Gr/PLA) was recrystallized in ethanol, filtered, and dried in an oven at 50 °C for 24 h. Subsequently, the composite was cut in small pieces (< 2 cm) using scissors and extruded, resulting in a filament of approximately 1.75 mm in diameter, which was inserted into a 3D pen for posterior printing of the working electrodes.

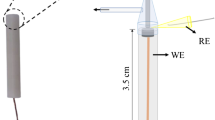

Electrochemical sensor manufacturing

A 3D-printed cylindrical support (40 mm length and 8 mm diameter) was modeled using Solidworks® 3DCAD software by inserting a concentric cylinder of 2 mm diameter to introduce a copper wire and thus establish the electrical contact with potentiostat. In addition, a conical opening (3 mm high and 5 mm in diameter) was modeled at one end of the cylinder allowing the deposition of the Gr/PLA filament in contact with the copper wire. Simplify3D® software was used to slice the 3D models to enable additive manufacturing performed on a GTMax3D CORE printer, model A2V2. The cylindrical support was printed on ABS filament, while the synthesized conductive filament was manually extruded using a 3D pen. Finally, the electrodes were polished on water sandpaper (400 and 2000 grt).

The 3D-printed Proto-pasta® electrode surfaces were polished with sandpaper (600 grit followed by 1200 grit) and electrochemically treated by amperometry with application of a potential of + 1.4 V for 200 s, followed by − 1.0 V (vs Ag|AgCl|KCl(Sat)) for the same time using NaOH solution (0.5 mol L−1) as supporting electrolyte [20].

Samples

Two pharmaceutical formulation samples of different brands (marketed as 500 mg ciprofloxacin hydrochloride) were purchased in tablet form from local pharmacies (Juiz de Fora, Brazil). The tablets were weighed and pulverized, then aliquots of 10 mg were dissolved into 10.00-mL volumetric flasks. Thereafter the pharmaceutical formulation solutions were diluted 2000-fold in the electrochemical cell for measurements. Milk samples (cow and goat) were purchased from local markets and diluted 100-fold in 10.00-mL volumetric flask for the electrochemical measurements. All samples were spiked with three levels of CIP concentration and then diluted in supporting electrolyte (BR buffer 0.1 mol L−1, pH 4.0); the spiking was performed so that, after the dilution step, the concentrations reached were 5, 10, and 15 µmol L−1 for the pharmaceutical formulation samples and 10, 15, and 20 µmol L−1 for the milk samples in the electrochemical cell, in order to check the accuracy of the method. All samples were diluted in supporting electrolyte (BR buffer 0.1 mol L−1, pH 4.0) and analyzed by external calibration curve.

Electrochemical measurements

The sensors were electrochemically characterized by EIS and CA measurements to calculate charge transfer resistance (Rct) and electroactive area, respectively. EIS method was employed with frequency ranging from 10,000 to 0.1 Hz, signal amplitude of 10 mV, 10 data points per frequency, and potential applied of + 0.25 V (vs Ag|AgCl|KCl(sat)). A redox probe of [Fe(CN)6)]−3/−4 (5 mmol L−1 in 100 mmol L−1 KCl medium) was used for both methods.

CV was used to study the effect of pH values of the supporting electrolyte (BR buffer 0.1 mol L−1) on the redox process of CIP, in the potential range of + 0.6 to + 1.4 V (vs Ag|AgCl|KCl(sat)). The pH values ranging from 2.0 to 10.0 were evaluated. Additionally, the mass transport process of the electroactive CIP species during the redox reactions was also studied by varying the scan rate from 25 to 250 mV s−1. SWV method was optimized to perform the CIP determinations on the samples studied, in the potential range of + 0.9 to + 1.3 V (vs Ag|AgCl|KCl(sat)). The instrumental parameters, such as step potential, amplitude, and frequency, were optimized. The analytical concentrations of CIP (in electrochemical cell) for the CV and SWV studies were 300 µmol L−1 and 25 µmol L−1, respectively.

Analytical validation by UV–Vis spectrophotometry

All samples were also analyzed by UV–Vis spectrophotometry using a Shimadzu UV-1800 ultraviolet spectrophotometer equipped with quartz cuvettes and wavelengths ranging from 200 to 400 nm. The samples of pharmaceutical formulations were pulverized using a pistil and mortar and prepared according to the protocol reported by Cazedey and Salgado [35]. A 10 mg aliquot was weighed and diluted in a 10.00-mL volumetric flask. The samples were diluted 200-fold in 10.00-mL volumetric flasks. An external calibration curve was constructed from 6 to 30 µmol L−1. The standard solutions and samples were diluted in water and required no filtration step.

Results and discussions

Characterization of the synthesized Gr/PLA filaments

In order to understand the thermal stability of the Gr/PLA composite material and also to check the percentage of graphite incorporated into the polymer matrix (PLA), TGA measurements were performed (Fig. 1A). As can be seen, for the raw biopolymer, a weight loss at around 305 °C was noted (Fig. 1A, green line), which corresponds to its decomposition to carbon oxides and cyclic oligomers, until the monomer unit [36]. On the other hand, Gr presents a high thermal stability (Fig. 1A, black line), attested by its mass loss between 632 and 800 °C [37]. After the addition of Gr content, the filament exhibited a considerable improvement in thermal stability, probably due to the increased heat conduction that inhibits the decomposition of the material at low temperatures. The proposed Gr/PLA filament (Fig. 1A, red line) underwent 60% and 40% mass loss around 305 and 625 °C, respectively, suggesting that the graphite incorporation was successfully accomplished. Moreover, it is noted that such material did not decompose before 250 °C, indicating that printing temperature used (190 °C) is suited for 3D printing of the electrodes.

Raman spectra of the 3D-printed Gr/PLA electrode surface were also obtained (Fig. 1B). Characteristic bands of graphitic materials were found, such as D-band (at 1348 cm−1) related to sp3 and sp carbon networks, edge defects and heteroatom presence, G-band (at 1570 cm−1) associated to sp2 hybridized carbon, and 2D-band (2710 cm−1), a combination of D and G-bands of graphitic structures [38,39,40]. Additionally, SEM image of the Gr/PLA electrode (Fig. 1C) revealed non-uniformly distributed graphite sheets on the composite material, resulting in a highly porous surface, which consequently provides more active sites for enhanced interaction of electroactive species at the electrode/solution interface.

In addition, FTIR spectrum of the Gr/PLA filament is presented in Supplementary Material (Fig. S1 of the Supplementary Material), whose results indicate characteristic bands of PLA and Gr in the composite structure. In fact, the peaks located between 2820 and 3050 cm−1 are associated with aliphatic chains present in the PLA structure [41]. On the other hand, oxygenated compounds (carboxyl, carbonyl, and epoxy groups) are evidenced by peaks between 1000 and 1850 cm−1 [36, 41]. More specifically, the vibrations of carboxyl and/or carbonyl groups of the polymeric matrix are indicated at around 1740 and 1448 cm−1, respectively [41]. Other peaks at 1044 and 1170 cm−1 are assigned to the vibration of epoxy groups (C–O–C) [42], while a relatively low-intensity peak at 1580 cm−1 is related to the vibration of sp2 hybridized carbons (double bond) of graphitic structures [43].

Electrochemical characterization of the 3D-printed Gr/PLA surface

Initially, the proposed 3D-printed Gr/PLA device was compared to a commercial glassy carbon electrode (GCE) and the 3D-printed sensor using commercial CB/PLA filament from Proto-pasta® in terms of electroactive area (n = 5) and Rct values (n = 5) using 5 mmol L−1 [Fe(CN)6)]−3/−4 as redox probe and 0.1 mol L−1 KCl as supporting electrolyte. With regard to geometric area, GCE has 7.1 mm2, whereas the both 3D-printed electrodes with Gr/PLA and Proto-pasta® filaments have approximately 19.6 mm2. However according to the Cottrell equation [44], electroactive areas of (3.8 ± 0.2) mm2, (11.1 ± 0.2) mm2, and (4.8 ± 0.3) mm2 were found for GCE, 3D-printed Gr/PLA, and 3D-printed Proto-pasta®, respectively, indicating that 3D-printed Gr/PLA device provided a slightly more porous surface, which agrees with SEM images. The Rct values of both surfaces were determined using EIS measurements, as shown in Fig. 2A. A significant difference between the Rct values was observed, where GCE showed (1266 ± 37) Ω, 3D-printed Gr/PLA (335 ± 5) Ω, and 3D-printed Proto-pasta® (3750 ± 180) Ω, indicating a more favored charge transfer over the proposed 3D-printed platform. Besides having higher Rct value and poorer electrochemical response compared to the proposed filament, the Proto-pasta® filament requires an additional electrode surface treatment step (electrochemical activation) as reported in the literature [45]. In fact, a better-defined electrochemical profile (two oxidation peaks around + 1.15 and + 1.30 V) was obtained for CIP (300 µmol L−1) using 3D-printed Gr/PLA compared to 3D-printed GCE and Proto-pasta® (Fig. 2B), which showed only one oxidation peak (+ 1.25 and + 1.36 V, respectively). Furthermore, for the first CIP oxidation process, a higher peak current (1.5-fold and 2.5-fold compared to 3D-printed GCE and Proto-pasta®, respectively) and a potential advance of approximately 110 mV and 210 mV were also observed when compared to the other two sensors, which characterizes an electrocatalytic effect caused by the 3D-printed Gr/PLA electrode. This effect can be associated with the porous carbon structures (e.g., graphite, carbon nanotubes, and graphene), which provide significant electrocatalytic effects (potential shift) for CIP detection, as reported in previous studies [46,47,48]. The presence of structural defects, evidenced by the D-band in the Raman spectrum (such as sp3 and sp carbon networks, vacancies, edge sites, and oxygen functional groups) shown in Fig. 1B, which provide more sites for better molecular interaction with the target antibiotic can also be attributed as a preponderant factor for observing the electrocatalytic effects.

A Nyquist diagrams of GCE (black points), 3D-printed Proto-pasta® (blue points), and 3D-printed Gr/PLA (red points) in presence of 5 mmol L−1 of [Fe(CN)6)]−3/−4 redox probe in 0.1 mol L−1 KCl medium. The insert graph shows CV voltammograms of the same redox probe. B CV voltammograms obtained for a solution of CIP 300 µmol L−1 in BR buffer (0.1 mol L−1, pH 4.0) using GCE (black line), 3D-printed Proto-pasta® (blue line), and 3D-printed Gr/PLA (red line). The dashed lines represent the respective blanks

CV studies

CV was also used to promote a study at different pH values of the electrochemical behavior of CIP on the surface of the 3D-Gr electrode (Fig. 3A). As mentioned earlier, two irreversible oxidation processes at + 1.15 and + 1.30 V (vs Ag|AgCl|KCl(Sat)) were observed for CIP at values starting at pH 4.0. Similar behavior was observed by Rkik and colleagues for levofloxacin, another antibiotic of the fluoroquinolone class [49]. The first signal proved to be more sensitive and was, therefore, selected for the optimizations of the analytical conditions. The highest peak current signal for the CIP oxidation process was observed at pH 4.0, as shown in the inserted graph in Fig. 3A; thus, this pH value was chosen for performing the remaining measurements. Furthermore, a linear behavior (R2 = 0.991) was found between the oxidation peak potential (Ep) as a function of pH of the supporting electrolyte (Fig. 3B). The correlation between Ep and pH showed a slope value of 0.056 V pH−1, extremely close to the theoretical value for Nernstinian systems (0.059 mV pH−1), which indicates an equality between the number of protons and electrons involved in the CIP oxidation process on the 3D-printed electrode surface, as observed for other carbon-based sensors [47, 50]. Thus, it can be assumed that the mechanism of oxidation of CIP (Fig. S2 in the Supplementary Material) occurs in different steps on the sensor surface; in a first step two oxidation processes (1 electron in each) of the piperazine portion are responsible for the peak shown at + 1.15 V (vs Ag|AgCl|KCl(Sat)), while the oxidation of this intermediate leads to the final product and the presence of a second oxidation peak at + 1.30 V (vs Ag|AgCl|KCl(Sat)), behavior similar to that observed by Rkik and colleagues for levofloxacin oxidation on carbon-based electrodes [49].

A pH study by CV using BR buffer (0.1 mol L−1) with pH values ranging from 2.0 to 10.0. Inserted graph showing the relationship between the peak current and the pH value of the supporting electrolyte. B Peak potential versus pH with linear equation Ep = − 0.056pH + 1.36 (R2 = 0.983). C CV mass transport study with scan rate ranging from (a) 50 to (i) 250 mV s−1

The mass transport regime of the CIP electroactive species during the electrooxidation process was also evaluated by CV, as shown in Fig. 3C. Linear adjustments between peak current and square root of scan rate (R2 = 0.997, Fig. S3A), and peak current and scan rate (R2 = 0.998, Fig. S3B) suggest that the oxidation process of CIP is controlled by both adsorption and diffusion of the species on the 3D-printed Gr/PLA electrode surface. To confirm this hypothesis, the relationship between logarithm of the peak current and logarithm of the scan rate was investigated, where the following linear equation was obtained: Log(Ip) = (0.881 ± 0.002)Log(v) − (3.548 ± 0.019), R2 = 0.998 (Fig. S3C). Slope value of 0.88 confirmed that a dual mechanism (diffusion and adsorption) governs the electrochemical oxidation of CIP species.

SWV parameters and figures of merit

The instrumental parameters regarding the SWV technique (step potential (1 to 2 mV), amplitude (10 to 50 mV), and frequency (10 to 20 Hz)) were optimized in a univariate manner using a 25 µmol L−1 CIP solution in BR buffer solution (0.1 mol L−1, pH 4.0). Measurements by SWV also showed two oxidation peaks, a first at + 1.05 and the second (of lower sensitivity) at + 1.15 V (vs Ag|AgCl|KCl(Sat)). Thus, optimizations were performed in order to maintain the separation of the two peaks and establish the optimal analytical condition for the peak of highest sensitivity. The most appropriate conditions for this purpose were achieved when step potential of 1 mV, amplitude of 30 mV, and frequency of 10 Hz were used.

An analytical curve for CIP was constructed using the previously optimized instrumental conditions with concentrations ranging from 2 to 32 µmol L−1 (n = 3) in BR buffer solution (0.1 mol L−1, pH 4.0), as shown in Fig. 4. The first oxidation peak showed more sensitive behavior with a linear adjustment (R2 = 0.993) expressed by the equation Ip (µA) = (0.122 ± 0.008)[CIP] (µmol L−1) − (0.206 ± 0.066), while the second oxidation peak (R2 = 0.998) was expressed by the following equation Ip (µA) = (0.042 ± 0.002)[CIP] (µmol L−1) + (0.020 ± 0.026). The analytical precision was measured at two concentration levels (2 and 32 µmol L−1). The relative standard deviation (RSD) of the measurements was calculated for both oxidation peaks, where RSD of 7.9 and 7.2% were found for the first peak (low and high levels, respectively), while 6.2 and 5.6% were reached for the second oxidation peak (low and high levels, respectively).

A SWV voltammograms of the CIP analytical curve with concentrations varying in the range from blank (a) to 32 (e) µmol L−1 in BR buffer solution (0.1 mol L.−1, pH 4.0). B Linear adjustment of the correlation between oxidation peak current and CIP concentration (n = 3). Instrumental conditions: 1 mV step potential, 30 mV amplitude, and 10 Hz frequency. The baseline correction was performed using moving average mode and window size at level 1

The limit of detection (LOD) was calculated from the data obtained by linear adjustment of the analytical curve of the first oxidation peak, which presented the highest analytical sensitivity (threefold higher than the second oxidation process). The calculations were performed using the formula LOD = 3.3sB/A, where sB is the standard deviation of the linear coefficient and A is the slope of the calibration curve, following the guidelines of the International Union of Pure and Applied Chemistry (IUPAC). Thus, the LOD of the optimized method for the CIP determination was estimated at 1.79 µmol L−1.

The analytical performance of the proposed sensor was compared to the GCE and the 3D-printed Proto-pasta® electrode using the same previously optimized instrumental conditions. Analytical curves were also constructed in the range of 2 to 32 µmol L−1 (shown in Fig. S4 of the Supplementary Material), and the sensitivities, oxidation peak potential, and LOD achieved are described in Table 1. Overall, the proposed device showed similar electroanalytical performance compared to the other sensors. Furthermore, it is remarkable that only our sensor showed two oxidation processes with linear behavior in the working range studied, which is an advantage in terms of selectivity. Unlike the 3D-printed Proto-pasta® electrode, the electrode proposed here requires no chemical/electrochemical surface treatment steps and can be used “as printed.”

Application of the SWV method to pharmaceutical samples and foodstuffs

Two samples of pharmaceutical formulation in tablet form (A and B), marketed as 500 mg ciprofloxacin hydrochloride, were analyzed. The results obtained (n = 3) for CIP determination using the 3D-printed Gr/PLA sensor were 493 ± 31 mg and 502 ± 51 mg for samples A and B, respectively. Meanwhile, two other milk samples (cow and goat) were also examined and showed concentration values below the LOD. The accuracy of the method was then evaluated by spiked tests at three concentration levels (5, 10, and 15 µmol L−1 for the pharmaceutical formulation samples and 10, 15, and 20 µmol L−1 for the milk samples). The average percent recovery ranged from 94 to 104% for the pharmaceutical formulation samples and from 103 to 109% for the milk samples (Table 2), which indicates that the proposed sensor has suitable characteristics for the determination of CIP in complex samples simply diluted in supporting electrolyte, with excellent accuracy. Additionally, the SWV voltammograms of the samples are shown in Fig. S5 of the Supplementary Material.

CIP presents a band with a maximum absorbance near 276 nm, which allows its monitoring by spectrophotometric methods. Thus, the CIP content in the pharmaceutical formulation samples was determined using an analytical curve from 6 to 30 µmol L−1, shown in Fig. S6 of the Supplementary Material. Excellent linear fitting (R2 = 0.998) expressed by the equation Abs (a.u.) = (0.0286 ± 0.002)[CIP] (µmol L−1) + (0.019 ± 0.014) was observed. The results obtained for samples A and B were 518 ± 12 mg and 472 ± 11 mg, respectively. The comparison of the results in detail can be checked in Table S1. The variances of the results obtained by the electrochemical (SWV) and spectrophotometric methods were compared using the F-test at a 95% confidence level. No significant differences were observed between the variances of the methods, since the Fcalculated value (1.27) is smaller than the Fcritical value (5.05). Furthermore, the means were compared at the same significance level using Student’s t-test. The results observed for tcalculated (0.13) and tcritical (2.57) indicated that at a 95% confidence level, no significant differences were observed between the results obtained by SWV and UV–Vis, which attests to the reliability of the proposed method for CIP monitoring.

Interference tests

Different antibiotics (AMP, TET, SFA, SFX, CHL, and LEV) used in both human and veterinary medicine were used to perform an interference study and verify the selectivity of the 3D-printed sensor (Fig. 5). The studies were conducted using a 1:1 ratio between CIP and each interfering agents at a concentration level of 32 µmol L−1. The variation in the electroanalytical response of CIP was less than 5.4%, indicating that the sensor showed excellent selectivity for CIP measurements in the presence of other antibiotics frequently monitored in milk samples. Additionally, the SWV voltammograms were inserted in Fig. S7 of the Supplementary Material. Regarding the results obtained for the LEV interference test, a fluoroquinolone of similar chemical structure, two peaks were observed at close oxidation potentials, + 0.96 V and + 1.03 V (vs Ag|AgCl|KCl(Sat)) for LEV and CIP (Fig. S7C), respectively, which does not affect the discrimination of the antibiotics using the 3D-printed Gr/PLA sensor. The results were statistically compared using analysis of variance (ANOVA single factor) at a 95% confidence level. The Fcalculated value (0.71) was lower than the Fcritical value (2.85), suggesting that the results do not present significant differences in the level of reliability evaluated, which demonstrates that the selectivity study of the sensor is robust and it does not present significant interferences in its electroanalytical responses to the presence of other antibiotics commonly used in the treatment of infectious manifestations in humans and animals.

The performance of the 3D-printed Gr/PLA sensor proposed in this work was compared with other sensors reported in the scientific literature, as shown in Table 3. Initially, the other sensors described in the literature identified only one oxidation process for CIP, while the developed 3D-printed Gr/PLA sensor provided two peaks at + 1.05 and + 1.15 V (vs Ag|AgCl|KCl(Sat)), which can be an interesting tool for CIP monitoring even under interference effect with other electroactive species. Moreover, the linear working range of the device was comparable to the other reported sensors. In some cases, wider linear range (9.9 to 220 µmol L−1) is reported, but in terms of detectability our sensor was is significantly more effective (1.79 versus 4.96 µmol L−1). Other works report lower LOD values; however, they use more costly electrodes like GCE that require laborious and time-consuming surface modifications. On the other hand, the 3D-printed electrode is easily produced in large scale (at low cost) in laboratories with minimal infrastructure and is ready for use after simple mechanical polishing. It is also noteworthy that such a sensor is free from matrix interference, even when applied to complex samples (milk), involving simple sample preparation (dilution in electrolyte), being interesting for other routine applications. Additionally, the sensor allows modifications of its surface, which can significantly improve its performance.

Conclusion

In this paper the synthesis and extrusion of conductive filaments based on graphite and PLA, as well as the printing of electrochemical sensors using 3D pen for CIP monitoring, were reported for this first time. The 3D-printed Gr/PLA electrode was properly characterized and compared to commercial GCE and 3D-printed Proto-pasta® electrodes. The results indicated a better electrochemical performance attested by anticipation of the CIP oxidation peak potential and increase in current compared to GCE and 3D-printed Proto-pasta®. Moreover, an altered electrochemical behavior compared to other studies reported in the literature was observed (two oxidation peaks were checked for CIP, while usually only one is reported), both with linear behavior in the concentration range of 2 to 32 µmol L−1.

When combined with SWV detection, the sensor showed detectability and linear working range similar to other expensive sensors reported in the literature. In addition, excellent precision, accuracy, and selectivity were also obtained. The synthesized filaments present a slightly more brittle characteristic compared to commercially available filaments (Proto-pasta® and Black magic®), a property associated with a higher amount of conductive material. However, this aspect is not a limiting factor for its use in 3D printers and pens. Additionally, the devices manufactured with this filament are ready to use after the printing process, unlike commercially available filaments. The simplicity large-scale manufacturing, low cost associated with the enhanced performance demonstrates the feasibility and robustness of this 3D-printed platform for monitoring other classes of antibiotics.

Data Availability

The authors of the paper entitled “Cost-effective protocol to produce 3D-printed electrochemical devices using a 3D pen and lab-made filaments for ciprofloxacin sensing” declare that they are available to provide any information and data about this work upon request.

References

Neumaier JM, Madani A, Klein T, Ziegler T (2019) Low-budget 3D-printed equipment for continuous flow reactions. Beilstein J Org Chem 15:558–566. https://doi.org/10.3762/bjoc.15.50

Flowers PF, Reyes C, Ye S et al (2017) 3D printing electronic components and circuits with conductive thermoplastic filament. Addit Manuf 18:156–163. https://doi.org/10.1016/j.addma.2017.10.002

Tully JJ, Meloni GN (2020) A scientist’s guide to buying a 3D printer: how to choose the right printer for your laboratory. Anal Chem 92:14853–14860. https://doi.org/10.1021/acs.analchem.0c03299

BG PK, Mehrotra S, Marques SM, et al (2023) 3D printing in personalized medicines: a focus on applications of the technology. Mater Today Commun 105875.https://doi.org/10.1016/j.mtcomm.2023.105875

Shen D, Zhang M, Mujumdar AS, Li J (2023) Advances and application of efficient physical fields in extrusion based 3D food printing technology. Trends Food Sci Technol 131:104–117. https://doi.org/10.1016/j.tifs.2022.11.017

Vasamsetty P, Pss T, Kukkala D et al (2020) 3D printing in dentistry – exploring the new horizons. Mater Today Proc 26:838–841. https://doi.org/10.1016/j.matpr.2020.01.049

Prasad KV, Vasugi V, Senthil Kumaran G (2023) Application of 3D printing concepts in the architecture engineering and construction (AEC) industry - a scientometric review. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.02.158

Hamzah HH, Shafiee SA, Abdalla A, Patel BA (2018) 3D printable conductive materials for the fabrication of electrochemical sensors: a mini review. Electrochem commun 96:27–31. https://doi.org/10.1016/j.elecom.2018.09.006

Veloso WB, Paixão TRLC, Meloni GN (2023) 3D printed electrodes design and voltammetric response. Electrochim Acta 449:142166. https://doi.org/10.1016/j.electacta.2023.142166

Gross B, Lockwood SY, Spence DM (2017) Recent advances in analytical chemistry by 3D printing. Anal Chem 89:57–70. https://doi.org/10.1021/acs.analchem.6b04344

Abdalla A, Patel BA (2020) 3D-printed electrochemical sensors: a new horizon for measurement of biomolecules. Curr Opin Electrochem 20:78–81. https://doi.org/10.1016/j.coelec.2020.04.009

Stefano JS, Kalinke C, da Rocha RG et al (2022) Electrochemical (bio)sensors enabled by fused deposition modeling-based 3D printing: a guide to selecting designs, printing parameters, and post-treatment protocols. Anal Chem 94:6417–6429. https://doi.org/10.1021/acs.analchem.1c05523

Cardoso RM, Rocha DP, Rocha RG et al (2020) 3D-printing pen versus desktop 3D-printers: fabrication of carbon black/polylactic acid electrodes for single-drop detection of 2,4,6-trinitrotoluene. Anal Chim Acta 1132:10–19. https://doi.org/10.1016/j.aca.2020.07.034

O’Neil GD, Ahmed S, Halloran K et al (2019) Single-step fabrication of electrochemical flow cells utilizing multi-material 3D printing. Electrochem Commun 99:56–60. https://doi.org/10.1016/j.elecom.2018.12.006

Vaněčková E, Bouša M, NovákováLachmanová Š et al (2020) 3D printed polylactic acid/carbon black electrodes with nearly ideal electrochemical behaviour. J Electroanal Chem 857:113745. https://doi.org/10.1016/j.jelechem.2019.113745

Kalinke C, de Oliveira PR, Neumsteir NV et al (2022) Influence of filament aging and conductive additive in 3D printed sensors. Anal Chim Acta 1191:339228. https://doi.org/10.1016/j.aca.2021.339228

Cardoso RM, Mendonça DMH, Silva WP et al (2018) 3D printing for electroanalysis: From multiuse electrochemical cells to sensors. Anal Chim Acta 1033:49–57. https://doi.org/10.1016/j.aca.2018.06.021

Browne MP, Novotný F, Sofer Z, Pumera M (2018) 3D printed graphene electrodes’ electrochemical activation. ACS Appl Mater Interfaces 10:40294–40301. https://doi.org/10.1021/acsami.8b14701

Cardoso RM, Castro SVF, Silva MNT et al (2019) 3D-printed flexible device combining sampling and detection of explosives. Sensors Actuators, B Chem 292:308–313. https://doi.org/10.1016/j.snb.2019.04.126

Richter EM, Rocha DP, Cardoso RM et al (2019) Complete additively manufactured (3D-printed) electrochemical sensing platform. Anal Chem 91:12844–12851. https://doi.org/10.1021/acs.analchem.9b02573

Novotný F, Urbanová V, Plutnar J, Pumera M (2019) Preserving fine structure details and dramatically enhancing electron transfer rates in graphene 3D-printed electrodes via thermal annealing: toward nitroaromatic explosives sensing. ACS Appl Mater Interfaces 11:35371–35375. https://doi.org/10.1021/acsami.9b06683

Gusmão R, Browne MP, Sofer Z, Pumera M (2019) The capacitance and electron transfer of 3D-printed graphene electrodes are dramatically influenced by the type of solvent used for pre-treatment. Electrochem Commun 102:83–88. https://doi.org/10.1016/j.elecom.2019.04.004

Koterwa A, Kaczmarzyk I, Mania S et al (2022) The role of electrolysis and enzymatic hydrolysis treatment in the enhancement of the electrochemical properties of 3D-printed carbon black/poly(lactic acid) structures. Appl Surf Sci 574:151587. https://doi.org/10.1016/j.apsusc.2021.151587

Wirth DM, Sheaff MJ, Waldman JV et al (2019) Electrolysis activation of fused-filament-fabrication 3D-printed electrodes for electrochemical and spectroelectrochemical analysis. Anal Chem 91:5553–5557. https://doi.org/10.1021/acs.analchem.9b01331

Cruz MA, Ye S, Kim MJ et al (2018) Multigram synthesis of Cu-Ag core–shell nanowires enables the production of a highly conductive polymer filament for 3D printing electronics. Part Part Syst Charact 35:1700385. https://doi.org/10.1002/ppsc.201700385

Foster CW, Elbardisy HM, Down MP et al (2020) Additively manufactured graphitic electrochemical sensing platforms. Chem Eng J 381:122343. https://doi.org/10.1016/j.cej.2019.122343

Stefano JS, Guterres e Silva LR, Rocha RG et al (2022) New conductive filament ready-to-use for 3D-printing electrochemical (bio)sensors: towards the detection of SARS-CoV-2. Anal Chim Acta 1191:339372. https://doi.org/10.1016/j.aca.2021.339372

Stefano JS, e Silva LRG, Janegitz BC (2022) New carbon black-based conductive filaments for the additive manufacture of improved electrochemical sensors by fused deposition modeling. Microchim Acta 189:414. https://doi.org/10.1007/s00604-022-05511-2

Lopes CEC, de Faria LV, Araújo DAG et al (2023) Lab-made 3D-printed electrochemical sensors for tetracycline determination. Talanta 259:124536. https://doi.org/10.1016/j.talanta.2023.124536

Guterres Silva LR, Santos Stefano J, Cornélio Ferreira Nocelli R, Campos Janegitz B (2023) 3D electrochemical device obtained by additive manufacturing for sequential determination of paraquat and carbendazim in food samples. Food Chem 406:135038. https://doi.org/10.1016/j.foodchem.2022.135038

Silva LRG, Stefano JS, Crapnell RD et al (2023) Additive manufactured microfluidic device for electrochemical detection of carbendazim in honey samples. Talanta Open 7:100213. https://doi.org/10.1016/j.talo.2023.100213

de Faria LV, Lisboa TP, da Campos NS et al (2021) Electrochemical methods for the determination of antibiotic residues in milk: a critical review. Anal Chim Acta 1173:338569. https://doi.org/10.1016/j.aca.2021.338569

Joshi A, Kim K-H (2020) Recent advances in nanomaterial-based electrochemical detection of antibiotics: challenges and future perspectives. Biosens Bioelectron 153:112046. https://doi.org/10.1016/j.bios.2020.112046

Rudnicki K, Sipa K, Brycht M et al (2020) Electrochemical sensing of fluoroquinolone antibiotics. TrAC Trends Anal Chem 128:115907. https://doi.org/10.1016/j.trac.2020.115907

Cazedey E, Salgado H (2012) Spectrophotometric determination of ciprofloxacin hydrochloride in ophthalmic solution. Currículo Lattes 2:74–79. https://doi.org/10.5923/j.aac.20120206.01

Mofokeng JP, Luyt AS, Tábi T, Kovács J (2012) Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J Thermoplast Compos Mater 25:927–948. https://doi.org/10.1177/0892705711423291

Hansen G, Næss E, Kristjansson K (2015) Sintered nickel powder wicks for flat vertical heat pipes. Energies 8:2337–2357. https://doi.org/10.3390/en8042337

Pimenta MA, Dresselhaus G, Dresselhaus MS et al (2007) Studying disorder in graphite-based systems by Raman spectroscopy. Phys Chem Chem Phys 9:1276–1290. https://doi.org/10.1039/B613962K

Reich S, Thomsen C (2004) Raman spectroscopy of graphite. Philos. Trans. R. Soc A Math Phys Eng Sci 362:2271–2288

Bokobza L, Bruneel J-L, Couzi M (2015) Raman spectra of carbon-based materials (from graphite to carbon black) and of some silicone composites. C 1:77–94. https://doi.org/10.3390/c1010077

Weng Y-X, Jin Y-J, Meng Q-Y et al (2013) Biodegradation behavior of poly(butylene adipate-co-terephthalate) (PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym Test 32:918–926. https://doi.org/10.1016/j.polymertesting.2013.05.001

dos Santos PL, Katic V, Loureiro HC et al (2019) Enhanced performance of 3D printed graphene electrodes after electrochemical pre-treatment: role of exposed graphene sheets. Sensors Actuators B Chem 281:837–848. https://doi.org/10.1016/j.snb.2018.11.013

Ţucureanu V, Matei A, Avram AM (2016) FTIR spectroscopy for carbon family study. Crit Rev Anal Chem 46:502–520. https://doi.org/10.1080/10408347.2016.1157013

Franco Guzmán M, Álvarez-Romero GA, Mendoza Huizar LH et al (2018) Influence on the electroactive area of the electrode’s nature and the transformed redox molecule. ECS Trans 84:235–242. https://doi.org/10.1149/08401.0235ecst

Lisboa TP, Alves GF, de Faria LV et al (2022) 3D-printed electrode an affordable sensor for sulfanilamide monitoring in breast milk, synthetic urine, and pharmaceutical formulation samples. Talanta 247:123610. https://doi.org/10.1016/j.talanta.2022.123610

Martin Santos A, Wong A, Araújo Almeida A, Fatibello-Filho O (2017) Simultaneous determination of paracetamol and ciprofloxacin in biological fluid samples using a glassy carbon electrode modified with graphene oxide and nickel oxide nanoparticles. Talanta 174:610–618. https://doi.org/10.1016/j.talanta.2017.06.040

de Faria LV, Lisboa TP, Alves GF et al (2020) Electrochemical study of different sensors for simple and fast quantification of ciprofloxacin in pharmaceutical formulations and bovine milk. Electroanalysis 32:2266–2272. https://doi.org/10.1002/elan.202060211

Rahimpour R, Sabeti B, Chekin F (2021) Electrochemical sensor based on nitrogen doped porous reduced graphene oxide to detection of ciprofloxacin in pharmaceutical samples. Russ J Electrochem 57:654–662. https://doi.org/10.1134/S1023193520120186

Rkik M, Ben BM, Samet Y (2017) Electrochemical determination of levofloxacin antibiotic in biological samples using boron doped diamond electrode. J Electroanal Chem 794:175–181. https://doi.org/10.1016/j.jelechem.2017.04.015

de Souza CC, Alves GF, Lisboa TP et al (2022) Low-cost paper-based electrochemical sensor for the detection of ciprofloxacin in honey and milk samples. J Food Compos Anal 112:104700. https://doi.org/10.1016/j.jfca.2022.104700

Tajeu KY, Ebunang DVT, Tonleu RCT et al (2021) Electroanalytical application of thiol-grafted laponite to the sensitive quantification of ciprofloxacin antibiotic. J Appl Electrochem 51:435–446. https://doi.org/10.1007/s10800-020-01508-y

Pollap A, Baran K, Kuszewska N, Kochana J (2020) Electrochemical sensing of ciprofloxacin and paracetamol in environmental water using titanium sol based sensor. J Electroanal Chem 878:114574. https://doi.org/10.1016/j.jelechem.2020.114574

Hernández P, Aguilar-Lira GY, Islas G, Rodriguez JA (2021) Development of a new voltammetric methodology for the determination of ciprofloxacin in beef samples using a carbon paste electrode modified with nafion and fullerenes. Electroanalysis 33:1539–1546. https://doi.org/10.1002/elan.202060525

Garbellini GS, Rocha-Filho RC, Fatibello-Filho O (2015) Voltammetric determination of ciprofloxacin in urine samples and its interaction with dsDNA on a cathodically pretreated boron-doped diamond electrode. Anal Methods 7:3411–3418. https://doi.org/10.1039/C5AY00625B

Acknowledgements

This research was supported by CNPq (National Council for Scientific and Technological Development, process: 303815/2022-1 and 150604/2022-0), CAPES (Coordination for the Improvement of Higher Education Personnel, financial code 001), FAPERJ ((E-26/211.465/2019, E-33/201.429/2022, E-26/205.806/2022, and 205.807/2022), and PROPESQ/UFJF.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lisboa, T.P., de Faria, L.V., de Oliveira, W.B.V. et al. Cost-effective protocol to produce 3D-printed electrochemical devices using a 3D pen and lab-made filaments to ciprofloxacin sensing. Microchim Acta 190, 310 (2023). https://doi.org/10.1007/s00604-023-05892-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-023-05892-y