Abstract

In this review, an introduction is given to provide the fundamental principles of magnetic droplet microfluidics. This is followed by a thorough discussion of methods that have been developed for the continuous generation of magnetic droplets and their controlled and precise manipulation by using external magnetic fields. Next, attention is given to techniques devised for the continuous fabrication of magnetic materials in droplets with an emphasis on the synthesis and modification of magnetic nanoparticles (MNPs), magnetic microstructures, Janus microparticles and magnetic hydrogels. In addition, selected applications of continuous magnetic droplets in (bio)assays and detection methods are discussed. The review (with 113 refs.) ends with concluding remarks and a discussion of current challenges and the future outlook for the field of continuous magnetic droplet microfluidics.

Continuous generation of magnetic droplets in microfluidic devices has the advantage of producing droplets at high frequencies and therefore has been exploited for the synthesis and generation of magnetic microparticles, manipulation, performing (bio)assyas and detection of magnetic contents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A sub-branch of the field of microfluidics, the science of manipulating and controlling fluids, focuses on multiphase systems containing droplets. Droplet microfluidic systems have significant advantages over their single-phase counterparts and, as a result, they become attractive and versatile alternatives for several key applications [1]. Droplets are spheres or plugs of fluid dispersed in other immiscible fluids (or simply air), where all or parts of the channel are blocked without actually being in direct contact with the channel walls [2, 3]. Typically, droplets are referred to as the dispersed phase (inner phase) in a surrounding continuous carrier phase (outer phase). Droplets have incredibly small volumes that range from picolitres (pL) to microlitres (μL), and dimensions usually in the micrometer (μm) range. [3]. Continuous generation at high frequencies (ca. tens of KiloHertz, KHz) enables the production of more than 500 monodispersed droplets per second with size coefficient deviations (CV) of less than 2% [4]. While over the past two decades, droplet microfluidic systems have been extensively utilized by many research groups to study protein crystallization [5], optimize screening conditions [6] and detect bacteria [7].

Compared to conventional methods, microfluidic devices are capable of producing large quantities of monodispersed droplets [8]. As a result, use of these droplets for screening processes are both cost-effective and significantly less time consuming. In addition, rapid mixing to homogenize reagents within droplets can be achieved by using two mechanisms including diffusion and chaotic advection [9]. Heat transfer and dissipation, critical for the success of processes such as the polymerase chain reaction (PCR), can be highly controlled in small droplets owing to their high surface area-to-volume ratio [10]. Droplets are surrounded by an inert and immiscible fluid layer that isolates them from channel walls, thus, eliminating cross-contamination of contents between droplets and preventing droplet evaporation [6, 11]. Furthermore, manipulation of droplets inside microchannels requires minimal force. The force on a small amount of liquid in a microfluidic channel can be determined using the Stokes’ drag (Fd in N) equation (Eq. 1),

where η is the dynamic viscosity of the continuous phase (in kg m−1 s−1), r is the radius of the droplet (in m) and v is the droplet velocity (in m s−1). Since the values of r and v are small the force exerted on the droplet is estimated to be in the range of tens nanonewtons (nN) to piconewtons (pN) [12], which can be easily achieved for example by using magnetic fields.

A number of dimensionless values such as the Reynolds number (Re), Weber number (We), Bond number (Bo) and capillary number (Ca) are commonly employed to describe the behavior of fluids in the microscale [13]. Among these, Bo and Ca are significant to describe the influence of physical forces on droplets formation and stability within the microchannels. Bo relates the effect of gravitational force on interfacial tension through Eq. 2,

where Δρ is the difference between the densities of the dispersed and continuous phases (Kg m−3), g is the acceleration of gravity (m s−2), l is a characteristic length scale (m) and γ is the interfacial tension (N m−1). In droplet microfluidics, Bo is preferably maintained below unity (Bo < < 1) so that the effect of gravitational force is negligible.

In contrast, Ca relates the interfacial tension to viscosity through Eq. 3

where η is the viscosity of the most viscous phase (Kg m−1 s−1) and ν is the velocity of that phase (m s−1). When Ca is much less than unity, interfacial forces dominate and, consequently, spherical droplets are normally formed as a result of surface area minimization. On the other hand, when Ca is much larger than unity (Ca > > 1), deformed and asymmetrical droplets are produced because of the dominance of viscous forces [14].

Introduction to magnetic droplets

A methods for continuous generation and handling of discrete magnetic liquids within microfluidic channels was first developed in 2004 by Pekas et al. [15]. The protocol was uniquely applied to monitor the velocity and size of moving magnetic droplets. A magnetic droplet is defined as a small volume of liquid that possesses a magnetic core and responds to an external magnetic field. Introduction of magnetic functionality into a droplet was achieved by incorporating a ferrofluid (FF) comprised of magnetic nanoparticles (MNPs) or microparticles (sometimes referred to as beads) into the dispersed phase. FFs are suspensions of MNPs, which have typical dimensions of approximately 10 nm. These particles possess superparamagnetic properties and are normally coated with a surfactant or charge in order to give them stability in the carrier liquid [16]. FFs are either water or oil based and are commercially available with a range of magnetic properties from companies such as Ferrotec (www.ferrotec.co.uk) [17, 18]. On the other hand, magnetic microparticles composed of iron oxide nanoparticles (NPs) embedded in polymeric or a silica shell in the μm range are commercially available (for example from www.invitrogen.com) and can be suspended in liquids to produce magnetic droplets [19].

Magnetic components are incorporated into droplets to promote actuation, prepare novel magnetic materials and/or perform bio-analysis process. Microfluidic platforms used to generate magnetic droplets range from simple capillary assemblies to more complex setups incorporating connected sealed microdevices comprised of different substrates. Tables 1, 2, 3, and 4 contain overviews of the various types of substrates, with methods for surface modification, magnetic materials, continuous phase and surfactants used to produce magnetic droplets. Moreover, Table 5 lists the common types of substrates used in the fabrication of microfluidic devices for magnetic droplet generation and their advantages and disadvantages.

The term micro-magnetofluidics has been utilized in the current literature to describe platforms which combine magnetism and microfluidics [20]. Although this term is not new, it has been used recently for systems which employ magnetic fluids for sensing and actuation purposes. More broadly, this term refers to devices in which flowing magnetic fluids on the microscale are used for actuation, manipulation and detection applications. This topic has been covered in a detailed review recently prepared by Nam-Trung Nguyen [20].

Unlike nonmagnetic droplets, which require relatively complex methods for manipulation [21, 22], their magnetic analogs have several advantageous features when generated in microfluidic devices. For example, introducing magnetic control directly into droplet microfluidics can be simply accomplished and actuation of the droplets does not require integrated mechanical components such as pumps and valves or special channel designs [23]. Moreover, magnetic droplets are relatively insensitive to changes in pH, ionic strengths and surface charge [24]. Actuation of these droplets can be affected by temperature, viscosity and the magnetic properties of the magnetic moiety [25]. The key parameters that influence the behavior of magnetic droplets subjected to magnetic fields are their volume, the difference between the magnetic susceptibility of the droplet and surrounding medium and the strength and gradient of the applied magnetic field [24]. Thus, The magnetic force acting on magnetic droplets, (Fmag, in N), is defined in Eq. 4:

where Δχ is the difference in magnetic susceptibility between the magnetic droplet and the carrier phase (dimensionless), V is the volume of the droplet (in m3), N is the number of magnetic particles in each droplet (dimensionless), B is the magnetic flux density (in T),∇ B is the magnetic field gradient (in T m−1) and μ0 is the permeability of vacuum (4π × 10−7 H m−1) [25]. Therefore, by selecting ∇ B and Δχ the magnetic force on the droplet can be controlled.

A moving magnetic droplet (or bead) in a magnetic field experiences an equal but opposing force due to the influence of the hydrodynamic flow. Under this condition, the sum of Fmag and Fdrag (Eq. 5) equals zero [26]:

therefore, the velocity of the magnetic droplet can be calculated by using Eq. 6, which arises by combining Eqs. 1, 4 and 5.

The methods employed to generate non-magnetic and magnetic droplets are similar, typically incorporating T-junction [27], flow focusing configurations [28], capillary/tubing assembly [29], pipetting [30], electrowetting on dielectric (EWOD) [31] or less common designs such as electrospray devices [32]. The term “digital microfluidics” (DMF) is often used in the literature to denote the manipulation of discrete and relatively large volumes (ca. μL) of liquids on a surface using various mechanisms, such as EWOD [33], dielectrophoresis (DEP) [34], thermocapillary transport [35], electromagnetic pillar arrays [36], and surface acoustic waves (SAWs) [37]. DMF refers to techniques for microscale electrostatic fluid-handling that enables the control of discrete droplets on an electrode array and, as a result, it is beyond the scope of this review.

Key processes, including transporting, merging, splitting, mixing, sorting and detecting magnetic droplets, can be accomplished in microfluidic platforms using several interesting approaches [38]. For example, several publications by Nguyen and his co-authors have focused on the formation and manipulation of magnetic droplets in microfluidic systems [27, 39, 40]. In several of the approaches, surfactants were added to the dispersed or the carrier phase to reduce interfacial tension between the two phases, which facilitates droplet formation and stability. In other techniques, surfactants were used to assist droplet splitting [41] or to reduce magnetic bead aggregation, which would lead to a decrease in the available surface for binding [42]. Baret prepared a detailed review discussing the roles surfactants play in droplet microfluidics [43].

Thus far, several reviews have appeared covering recent advances made in the generation, maneuvering and application of droplet micorfluidics [44, 45]. Additionally, numerous reviews have focused on the utilization of magnetic particles in single-phase microfluidic devices including those that discuss microfluidics and magnetism [24] for bio-analysis [46], catalysis [47] and micromixers [48], and the interactions occurring between magnetism and fluid flow on the microscale [20]. Furthermore, the integration of droplet microfluidics and magnetism was the focus of one review dedicated to DMF [49]. However, a survey of the literature shows that no reviews have been published that discuss the growing number of applications of continuous magnetic droplets in microfluidics. Thus, this review fills that gap by providing a detailed overview of studies carried out on continuous magnetic droplets within sealed microfluidic systems. The review is divided into five sections that discuss (1) magnetic droplet generation, (2) magnetic droplet manipulation, (3) synthesis of magnetic materials, (4) assay-based magnetic droplets and (5) magnetic droplet detection.

Continuous magnetic droplet generation

Generation of droplets having uniform sizes and distributions is one of the most important advantages of microfluidics. Since the time of their discovery, droplets have been generated mainly by using pressure [18], electric [50] and centrifugal forces [51]. The use of magnetic forces alone or in combination with others to generate monodispersed droplets has emerged as a new tool to control the sizes, magnetic contents and frequencies of generated droplets.

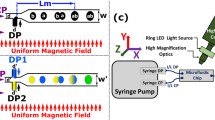

Tan et al. [27] demonstrated that FF droplets can be generated at a T-junction (Fig. 1a) in the absence and presence of a permanent magnetic field. In the absence of a magnetic field, the size of the droplets decreased as the flow rate of the continuous phase (Qc) is increased and the size of the FF droplets decreased as the capillary number (Ca) is increased (Fig. 1b). However, in the presence of a magnetic field, the size of the droplets depended on the factors affecting magnetic force including the magnetic field strength (B) and gradient (∇B), and the magnetization of the FF (M). At fixed dispersed flow rates (Qd) and Qc, when the magnetic field was positioned upstream from the droplet generation point, the droplet size increased as B increased. In contrast, when the field was located downstream, the droplet size decreased as B increased. These phenomena are a consequence of the effect of the magnetic force on the droplet as it emerges at the T-junction, which retarded its movement and delayed the breakup process. Furthermore, increasing both B and Qc led to the production of smaller magnetic droplets. The influence of a uniform magnetic field on the generation of FF droplets in a flow focusing configuration rather than a T-junction has been elucidated [39, 40].

a) Experimental setup for the formation of FF droplets at a microfluidic T-junction. The microfluidic device used to generate the FF droplet in silicone oil and the PDMS layer separating the glass and magnet with the flow direction are indicated. b) The effect of the continuous phase flow rate on Ca and the FF droplet size (the dispersed phase flow rate was maintained constant), the sizes are illustrated in photographs. Reprinted with permission from ref. [27]. Copyright (2010), IOP Science

A magnetic tweezers based approach for continuous magnetic droplet generation and manipulation was also developed by Yan et al. [52]. In this technique, Fe3O4 NPs were prepared off-chip using a solvothermal method and characterized using TEM and by analyzing a magnetization curve which showed that they are superparamagnetic. Using a flow-focusing geometry, the FF, comprised of a deioinzed water dispersion of the NPs, was fed and merged with the continuous phase to form magnetic droplets. The microfluidic device was placed in the gap between the middle of the tweezers so that the dispersed phase was aligned perpendicular to the magnetic field. The influence of increasing the outer magnetic field on the droplet size and generation frequency, formed at a fixed flow rate, can be seen by viewing the micrograph sequences of FF droplet shown in Fig. 2a. The findings demonstrated that the diameter of the droplets decreased when B increased. However, the sizes of the droplets remained at an average diameter of 100 μm when B was increased further, but at B ca. 60 mT secondary droplets were generated and monodispersion of the droplets no longer existed. The influence of inner phase viscosity was also explored by comparing water and FF droplets under the same flow rate conditions. At a constant inner phase flow rate (Qi), as the flow rate of the outer phase (Qo) increased the droplet diameter decreased linearly. However, when Qo/Qi was higher than 7.5, the sizes of both water and FF droplets decreased slowly reflecting an independent behavior on the droplet size. The relationship between the maximum contraction positions of the FF tip and magnetic flux densities was also investigated (illustrated in Fig. 2b). A decrease in the distance between the maximum contraction position of the FF tip and the entrance of the throat (Cmax) occurred initially as the magnetic flux density increases and then it reached a nearly constant value as the magnetic flux density was further increased. A smaller distance to the entrance throat resulted in a faster droplet formation frequency and, hence, a smaller droplet size. Additionally, these authors demonstrated that the magnetic droplets with different size distribution can be obtained utilizing different square wave signals. Using a low level area of the signal, larger droplets were generated, while smaller droplets were formed at a high level area of the signal. Thus, this method can be used to generate FF droplets with predetermined sizes and distributions. Ray et al. [53] investigated the effect of magnetic field on FF droplet size, produced by using re-pumping mechanism which utilized an external magnetic field to generate FF droplets with tuned sizes. In this approach, a permanent magnet was placed at a certain distance from the droplet generation nozzle, defined as x = 0, and the distance between x = 0 and the droplet generation point was –x (0 - –5 mm) and a distance beyond the magnet is +x (0 − +5 mm). Droplets generated at the nozzle were called the initial FF droplet (IFD) whereas after merging at x = 0 they are called the final FF droplet (FFD). As the IFD approached a non-uniform magnetic field, several droplets merged and formed a slug because the hydrodynamic force created a larger FFD. The IFD size was governed by varying Qd/Qc, η, γ and diameter of the channel, and the FFD size was controlled by the applied magnetic field (H), Qd, Qc and the viscosity of the continuous phase. As H increased the size of FFD increased and reached a plateau at 10 mT, which was attributed to Ms and Fmag. Increasing Qd and Qc caused increase in the velocity and Fdrag resulting in the formation of smaller FFDs. Furthermore, the FFD size was larger for silicone oil (85 mPa s) compared to heavy mineral oil (118 mPa s) due to the smaller Fdrag. FF droplet generation and optimization using a pump-free approach was first described by Kakheshani and Di Carlo [54]. In this protocol, FF droplets were generated from a reservoir connected to multiple small channels solely using an external magnet placed underneath the device. The magnet dragged the FF stream towards an oil reservoir with dimensions larger than the channels in a pattern that mimics a ‘step’ in the terrace region (Fig. 3a–c). Droplets generated at the terrace region were a result of the presence of the magnetic force and the abrupt change in the interfacial tension at the FF/oil interface, which was caused by the increase in the channel dimensions. Due to the low flow rate and Re in this system, the inertial forces were negligible. The study focused on the size, generation frequency and mixing of droplets generated using only magnetic gradient. In comparison to effects arising from changes in the surface tension and magnetic field strength, the size of the droplets was found to be significantly influenced by the channel dimensions. The droplet size could be also controlled by modifying the length of the terrace. Specifically, when the terrace length increases from 60 to 90 μm the diameter of the generated droplets increased from 85 to 125 μm (Fig. 3d). While the droplet generation frequency was influenced by factors such as the interfacial tension, viscosity of the oil, volume fraction of the magnetic material, strength of the magnetic field and the number of channels connected to the FF reservoir. Furthermore, the results showed that interfacial forces were more important than viscous forces, as demonstrated by the observation that at Ca < <0.05 (equivalent to a flow rate 1 μL min−1) droplet formation occured, whereas at Ca > 0.1 (equivalent to a flow rate 2 μL min−1) the FF stream did not breakup and it stretched into the channel. Two different oils were used to investigate the effect of viscosity. The droplet generation frequency was found to be higher with Novec 7500 (η = 1.24 cP) than with FC-40 (η = 3.5 cP). Additionally, the device was modified to contain two and three inlets for introduction of the dispersed phase and studying mixing of reagents with the FF stream. For example, water and fluorescein were fed from separate inlets and then mixed with ferumoxytol (a type of FF) to enable droplet generation. The intensity of fluorescein fluorescence intensity of the generated droplets was used to monitor the efficiency of mixing. The authors showed that the system had guaranteed mixing and can be employed to produce droplets of different sizes at different frequencies with controlled generation times (seconds to minutes). One limitation of this protocol was that magnetic properties must be incorporated in both dispersed phase streams in order to achieve droplet generation and complete mixing. Although significant studies have been conducted, methods for the continuous generation of magnetic droplets using magnetic forces still require further investigations that focus on other approaches including diamagentophresis [55] and magnetic pumps [56].

(a) Micrographs of FF droplet under different magnetic flux densities. The red arrow demonstrates the effect of increasing the outer magnetic field on the droplet size and generation frequency (b) Maximum contraction position of the FF tip under the influence of different magnetic flux densities. The arrows indicate the distance between the maximum contraction position the entrance of the throat (Cmax). Reprinted with permission from ref. [52]. Copyright (2015), Springer

a) A 3D schematic of the magnetically driven droplet generation design displaying all the components, b) A photograph showing a FF droplet generated using a magnet by pulling from the reservoir, c) Front and top views of the platform showing the dimensions of the device, d) An image of the generated droplet, the droplet size was influenced by the size of the terrace as illustrated in the graph, scale bar 250 μm. Reprinted with permission from ref. [54]. Copyright (2016), the Royal Society of Chemistry (RSC)

Manipulation of magnetic droplets

Methods for continuous generation and downstream manipulation of magnetic droplets are very appealing in that they enable rapid processing and screening of hundreds/thousands of droplets per minute with a high degree of control and precision. In this regard, approaches to controlled droplet generation, attraction, repulsion, sorting, trapping, splitting and coalescence in a continuous mode have been developed. In this regard, the on-chip free-flow magnetophoresis (FFM) principle has been applied for the first time to droplets [57]. Often, FFM is performed to sort particles/cells in continuous flow system with very high throughput [58], which makes the application of this technique ideal for processing hundreds/thousands of droplets in short time periods. This goal can be achieved by manipulating the magnetic field gradient and differences in magnetic susceptibilities between the magnetic objects and the carrier phases.

FFM, is a technique that utilizes magnetic forces to separate magnetic particles from each other or from nonmagnetic particles using a rectangular chamber, laminar flow and magnetic field [49]. The chamber has a number of inlets and outlets in the x-direction to maintain parallel flow with minimum mixing between the laminar streams, and a nonhomogenous magnetic field is applied in the y-direction (perpendicular to the streams). The magnetic force exerted on a magnetic particle introduced into the chamber causes it to experience a deflection of its path and to exit from one of the outlets close to the magnet. The particle will be dragged at a velocity (udefl) equal to the sum (Eq. 5) of the hydrodynamic flow velocity uhyd and the magnetically induced velocity umag, which is the ratio of Fmag (Eq. 4) and Fdrag (Eq. 1) shown in Eq. 7 [25, 49]:

Therefore, the magnetically induced velocity can be calculated from:

Zhang et al. [59,60,61] developed three systems for the continuous generation and manipulation of droplets in sealed microfluidic devices. The first system was designed for magnetic droplet attraction. In this system, a T-junction polydimethylsiloxane (PDMS) microfluidic device was used for generation, mixing and manipulation of magnetic droplets [59]. Superparamagnetic droplets containing Fe3O4 NPs suspended in water were synthesized by chemical co-precipitation method. The microfluidic device consisted of a T-junction with two inlets to introduce the dispersed phase and a 400 μm chamber connected to three sub-microchannel outlets. In the absence of a magnetic field, the magnetic droplets followed a straight path (laminar flow direction) and exited via sub-microchannel 1. On the other hand, in the presence of a magnetic field generated by using a Nd-Fe-B magnet the droplets were deflected from the laminar flow direction at an angle (θ) and exit via sub-channels 2 or 3. The deflection angle can be calculated using the Eq. 9:

where C is the concentration of the magnetic NPs (in kg m−3), r is the radius of the magnetic droplet (in m) and ρ is the density of the magnetic NPs (5.18 × 103 kg m−3). The results of experimental studies showed that θ was proportional to the magnetic field gradient and MNPs concentration and was greatly affected by the position of the magnet. Superparamagnetic droplets and non-magnetic water droplets can be generated in an alternating manner using this platform. The two droplets were separated in the chamber by applying a magnetic field, which did not influence the flow path of the non-magnetic droplets so that they exited through sub-microchannel 1. In contrast, the magnetic droplets were deflected and exited via either sub-microchannels 2 and 3. This platform is suitable for rapid processing of superparamagnetic droplets and, thus, it finds potential utility in drug delivery/screening and immunoassays. Zhang et al. [61] also described the first magnetic repulsion systems to manipulate pL water droplets, which were modified versions of the platform previously used in droplet deflection [59]. While the original systems were utilized for splitting, dispensing, continuous-phase exchange, trapping, releasing and demulsification of water droplets, the continuous phase used in Zhang’s system was magnetic [60, 61]. A similar system for deflection of the flow of magnetic droplets in a chamber and subsequent exiting via a desired outlet was also investigated by Al-Hetlani et al. [18]. In the deflection device, droplets of an aqueous FF were generated at a T-junction and deflected in a 2 mm wide and 6 mm long chamber using a small permanent magnet. The authors demonstrated that the field strength, position of the magnet, and magnetic loading influenced the degree of deflection. Another magnetic deflection platform was devised to sort single cells of Thalassiosira eccentric microalgae within magnetic droplets using magnetophoretic sorting method [62]. The system was designed to handle magnetic droplets of the same size (69.9 ± 1.1 μm) under the same conditions, containing the same number of MNPs at the same magnetic field strength. Upon introduction of cells into the droplet, the number of MNPs was reduced due to the displacement of the MNPs. Thus, the magnetic force acting on the droplet was decreased. In this device, the cells and MNPs were mixed off-chip and introduced from the same inlet to generate droplets at a T-junction. The droplets then entered a ‘focusing region’ to direct them to the side of the wall. After they exited in this area, the droplets were introduced into the 10 mm ‘magnetophoretic separation region’ causing them to deflect towards the opposite channel wall. The magnetic flux density in the system was enhanced by locating a nickel microstructure between the device and the magnet. This enabled separation of droplets containing both MNPs and single cells from pure magnetic droplets which were more greatly affected by the strong applied magnetic field. The authors showed that only 4.9% of the droplets contained single cells. The authors attributed this low level of encapsulation to the cylindrical shape of the microalgae giving them a diameter of 39.9 ± 3.1 μm. Therefore, further improvement of this technique is required to develop a system for encapsulation of angulated and larger microalgae of Thalassiosira eccentric. An approach to deflect FF droplets across two immiscible streams having different interfacial tensions was investigated by Banerjee and co-workers [63]. The authors reported that the degree of deflection depended on an interplay between Fmag, non-inertial lift force (Fl) and interfacial tension force (Fi). Three flow regimes were designed based on varying the lift force ratio (KL = Fl/ Fi) and magnetic force ratio (KM = Fmag/Fi), including no migration (KL < < 0.44 and 0 < KM ≤ 0.14), partial migration (0.44 < KL ≤ 0.46 and 0.14 < KM ≤ 0.16) or 3) and complete migration from high to low interfacial tension (KL > 0.46 and KM > 0.16). The deflection of the droplets and migration length (Lmig*) was found to depend on the location of the magnet (xm*) and the net force (FR,net), which can be estimated using Eq. 10:

At constant xm*, as FR,net increased Lmig* decreased, whereas at constant FR,net, increasing xm* resulted in an increasing Lmig*. The effect of droplet size on droplet trajectory in the presence and absence of a magnetic field was also assessed. Interestingly, in both cases small droplets did not have a tendency to migrate to the second immiscible phase, while larger droplets moved across the boundary and entered the second phase. This phenomenon was attributed to the dependence of FR,net on the size of the droplet. This platform has the potential of being further expanded to studies of the migration of droplets between various streams of different interfacial tensions and viscosities related to drug deliver applications.

A method for continuous generation and downstream manipulation of magnetic droplets was also developed by Al-Hetlani et al. [18]. In this system, FF magnetic droplets were manipulated by using simple Nd-Fe-B magnets generated in a glass microfluidic device hydrophobized with a fluorosilane reagent. Droplets generated using a flow focusing design were split downstream at a T-junction to produce two daughter droplets, one magnetically enriched and the other magnetically depleted. In the absence of a magnetic field, the generated droplets approached the T-junction and split into two daughter droplets of equal size and content (Fig. 4a). When a magnetic field was placed near one of the T-junction arms, the MNPs within the mother droplet were attracted to the field and accumulate on one side of the droplet. Thus, splitting of these mother droplets at the junction creates pairs of magnetically enriched and depleted daughters (Fig 4b). The dynamics for splitting FF droplets at a T-junction microfluidic device under the influence of uniform (UM) and non-uniform magnetic fields was investigated by Wu et al. [64]. The system was comprised of a flow focusing device with magnets placed at the two sides in order to form a UM and non-uniform (NM) magnetic field. Four droplet breakup regimes were explored including 1) permanent obstruction (BPO), 2) temporary obstruction (BTO), 3) without obstruction (BNO) and 4) non-breakup (NB). The difference between the breakup process of FF droplets using the BPO regime and under the influence of UM and NM was not clear. In these cases, the two dumbbell-like parts of the FF droplets break-up uniformly at the T-junction to form two daughter droplets. However, breakup of FF droplets using the BTO regime under a UM was associated with a much larger channel compared to that occurring under a NM. Following stretching caused by the magnetic field, the droplets broke into two symmetric daughter droplets. Additionally, the breakup process using the BNO regime displayed similar behavior under both UM and NM conditions. In this case, the droplets stretched at the T-junction, moved to the wall opposite to the feed channel and upon impact broke up into two daughter droplets. In the case of the NB condition, droplets emerged from the T-junction and enter either of the bifurcations based on feedback formed by the preceding droplet. Breakup at the T-junction was mainly affected by the droplet size (L) or the dimensionless droplet length (ε = L/πWc, Wc is the width of the channel), and Ca. Therefore, the behavior of the droplet as a function of Ca was probed using four magnetic flux densities. The results showed that as the magnetic flux density increased, the BTO region gradually enlarged towards BPO. This phenomenon was attributed to elongation of FF droplets due to the effect of the magnetic field [40, 65]. The FF droplet stretched in the direction of the uniform magnetic field, which is parallel to the branches of the T-junction. Hence, the two dumbbell-like parts separated from the wall enabling a higher flow of the continuous phase into the bifurcations. B0 was also introduced to determine the stability of the shape of the droplets. Moreover, the authors substantiated that the uniform magnetic field cannot only influence the type of breakup but also the breakup process. The results of this effort demonstrated that the breakup of FF droplets in the presence of a non-uniform magnetic field generated two daughters of different sizes into either side of the bifurcation. Moreover, the volume ratio of the droplets flowing in the right and left branches (VR/VL) was influenced by the total flow rate Qt = Qc + Qd. Therefore, this study has provided an insight into the behavior and mechanism for breakup of FF droplets and has demonstrated how to control the size of the droplet using an additional and controllable external force. Controllable breakup of FF droplets at a simple Y-junction in a microfluidic device was investigated by Li et al. [66] using a magnetofluid technique. At the Y-junction divergence in the system, the mother droplet split into two identical daughter droplets, which was in agreement with the previously reported observations [67]. However, placing an external magnet on the side of the upper arm of the microchannel caused asymmetric breakup of the mother droplet to occur, in which the forefront was pulled up into the upper arm due to strong non-uniform magnetic attraction. Subsequently, the size of the daughter droplet in the upper arm increased gradually as the injection liquid continued to flow (Fig. 5a). A probe of the influence of the flow rate ratio (Qd/Qc) showed that respective symmetric and asymmetric size distributions were obtained in the presence and absence of an external magnetic field (Fig. 5b). Additionally, the size of mother droplet decreased as Qd/Qc decreased while the asymmetric size distribution increased. Furthermore, the volume ratio of the daughter droplets (Vu/Vl) as a function of Qd/Qc at various magnetic flux densities was explored. The findings indicated that the influence of Qd/Qc was insignificant in the absence of the magnetic field and Vu/Vl remained 1. However, in the presence of an external magnetic field, Vu/Vl decreased as Qd/Qc increased and remained almost constant when Qd/Qc > 1. The latter observation was ascribed to the large length of the mother droplet, which retarded the rupture of the droplets thereby slowing their growth rate. Additionally, it was found that when Qc increased to 20 mL h−1, the droplets did not breakup and are instead pulled towards the external magnet while undesired satellite droplets moved into the lower arm. Finally, theoretical simulation based on Bo was carried out to predict the size of the daughter droplets. The numerical values arising from this treatment showed that FF droplets with desired sizes can be generated by optimizing the fluid flow rate and the magnetic flux density [66]. Further details of asymmetric FF droplet splitting at a T-junction have been elucidated using theoretical numerical investigations [68]. Analysis and optimization of factors that influence the extraction of magnetic particles at a splitting fork were carried out by Brouzes et al. [44]. The principle of the system was to marginalize the magnetic microparticles within moving droplets by using an external magnetic field prior to their split at a fork (rather than T- or Y-junction). The authors determined the optimal position of the splitting fork relative to the magnet. For this purpose, an imaginary “midline” was drawn across the middle of the droplet, which split the droplet into an upper or “waste” and lower or “enriched” parts. The results showed that the enclosed magnetic particles tend to aggregate at the upper and lower parts of the droplet as it moved past the magnet resulting in concentrating the majority of the particles in the lower part of the droplet. Next, a determination of the fraction of particles in the midsection of the droplet as a function of the droplet velocity and magnetic force showed that the particle fraction and magnetic field strength was not linearly related, which was difficult to interpret due to the formation of particle chains within the droplets. A 1:1 symmetric split fork with “upper” and “lower” branches was used to study splitting and enriching efficiencies as a function of droplet velocity and magnetic force. Using a splitting fork width that was half that of the main channel led to production of identical sizes of the droplets. At 20 and 60 pN, the approximate number of particles in the “waste” droplet was small at low velocities (< 2%), but increases (>6%) as the velocity increased. The efficiency of particle separation at the 1:1 symmetric splitting fork depended on the droplet velocity and generation frequency. To minimize the amount of particles deposited in the “waste”, the droplet size was reduced by adjusting the splitting ratio and profile. The splitting ratio was controlled by using an asymmetric splitting fork whereas the profile was controlled by manipulating Ca (lower values being more favorable). At low Ca and constant velocity, the fork design highly influenced the enrichment of the particles with optimal enrichment occurring when a 1:3”upper” and “lower” branch ratio, 50 μm hydraulic resistance and along box, was utilized. Moreover, the enrichment increased as Ca increased and then plateaued at 0.27, which corresponded to the value at which interfacial tension can be neglected. The authors proposed that their system can be employed for the detection of a threshold of highly expressed genes and supported it by comparing the theoretical predictions with earlier experimental findings those found earlier [45]. However, no experimental data was provided to substantiate the proposal.

Flow focusing manifold utilized in continuous generation and subsequent splitting of magnetic droplets using EMG 507 FF. a) Droplets generated and split in the absence of the magnet. b) Droplets generated and split in the presence of the magnet to produce magnetically enriched and magnetically depleted droplets. Reprinted with permission from ref. [18]. Copyright (2010), American Institute of Physics (AIP)

a–b) The breakup of FF mother droplet at a constant flow rate (Qd = 1 mL h−1 and Qc = 2 mL h−1) at the Y-junction a) without and b) with the external magnet. C-D) The effect of the flow rate ratio on the FF droplet distribution at Qd = 1 mL h−1 a symmetric distribution was obtained in the absence of magnetic field and D) An asymmetric distribution was generated in the presence of a magnetic field. Reprinted with permission from ref. [66]. Copyright (2016), the Royal Society of Chemistry

Generation of magnetic double emulsion was first explored by Sander et al. [69]. Nanoliter magnetic droplets have been generated using a commercially available FF in the form of a single or double emulsion in a microfluidic device. The magnetic cargo containing emulsions were transported, collected and coalesced by controlling the external magnetic field. The emulsions used in this study were oil-in-water (O/W) droplets and double emulsions of water-in-oil-in-water droplets (W/O/W) and the cargo was contained in the inner oil, water droplet or the intermediate oil phase of the double emulsion generated within the device. The FF was mixed with the inner phase of the single emulsion (MO/W), and the intermediate (W/MO/W) or inner phase (MW/O/W) of the double emulsion by introducing magnetic particles into different fluids in the emulsification step. MO/W droplets were too stable to enable rupture of the droplets, which was ascribed to the presence of a surfactant in the commercial FF. However, the use of high concentrations of CaCl2 in combination with a strong magnetic field enabled more proficient droplet coalescence. The coalescence force was estimated to be 50 nN for the MO/W in the presence of CaCl2 and the magnetic field required to achieve coalescence was ca. 75 Oe. On the other hand, destabilization was not required for the MW/O/W and W/MO/W and the aqueous magnetic droplets in these cases broke through the oil layer and entered the continuous phase. Furthermore, a fluorescent reagent was incorporated into the double emulsion system in a manner that leads to creation of a magnetic core and a fluorescent intermediate layer to avoid mixing. At high magnetic fields, the thin films separated into individual droplets that led to coalescence into one large droplet. Another double emulsion platform devised by Misuk et al. [70] involved the use of an organic solvent (toluene or cyclohexane) and paramagnetic ionic liquid (MIL). In a surfactant-free approach, the magnetic inner sphere of the emulsion droplets, composed of 1-butyl-3-methylimidazolium cation and a paramagnetic anion of iron, manganese, nickel or dysprosium, were synthesized in an off-chip manner using a previously reported procedure [71,72,73]. Merging the MIL with the organic phase at the first T-junction produced MIL droplets, which then travelled through the inner capillary where they merged with a perfluorinated solvent at the second T-junction to generate the double emulsion of organic phase/MIL/FC-40. A magnetic field simulation was used to gain information about the effect of the strength of the magnetic field on the flow behavior of the double emulsion droplets. The use of two external Nd-Fe-B magnets enabled controllable manipulation of individual emulsion droplets including capture, release, pair-merging, coalescence, separation and reunification. Moreover, the efficiency of pair-merging was visualized by utilizing two commercially available ink containing colored streams of the double-emulsion droplets within a Y-junction. Unlike in microfluidic devices, in the capillary-microreactor using organic solvents pre-treatment of the device surface was not required and low and high flow rates of the solvents were achieved [70]. A coaxial capillary microfluidic system comprised of MIL of [bmin]FeCl4 was used to generate magnetic droplets [29]. The coaxial device consisted of a capillary, used for injection of the dispersed phase, coaxially aligned with a second capillary (inner diameter = 0.70 mm) with tapered orifice of approximately 70 μm inserted into a second larger capillary (inner diameter = 1.05 mm) to pump the continuous phase. The effect of magnetic field strength and flow rates on the flow pattern and droplet size was assessed and a mathematical model for predicting the droplet size was developed. Additionally, the ability to control coalescence of the generated MIL droplets by tuning the applied magnetic field was demonstrated. In the absence of a magnetic field, the MIL droplets behaved like normal Newtonian fluids and dripping (at low Qc and Qd) or jetting regimes (at high Qc and Qd) was observed depending on Qc and Qd. Dripping was used in experiments employing inhomogeneous magnetic fields along the coaxial capillaries. The effect of the magnetic field strength on droplet generation was influenced by the distance between the frontier of the magnet and the capillary orifice (x). Increasing magnetic field strengths caused acceleration in droplet breakup and generation of small fast-moving droplets. The effect of Qc on the droplet was investigated by fixing Qd and x, and varying Qc between 100 to 300 μL min−1. Compared to those created in the absence of a magnetic field, droplets created using Qc = 100 and 300 μL min−1 had diameters reduced by 27.5% and 8.3%, respectively. This finding showed that the effect of magnetic field strength has a more pronounced effect on droplet size than viscous forces. In the presence of the magnetic field, smaller droplets were obtained due to the accelerated rate of droplet formation. A modification of this device was developed that enabled injection of two dispersed phases (magnetic and non-magnetic) for in situ generation and coalescence of droplets. In the process, the magnetic droplets were trapped by use of the magnetic field and subsequently merged with the flowing non-magnetic droplets. Due to viscous forces, the mixed droplets were released from the influence of the magnet and moved in the direction of the hydrodynamic flow. Despite the fact that double (or more) emulsions exhibit interesting structures and can be formed in droplets with high precision, thus far they have not been employed in any applications. Furthermore, double emulsions can be converted to solid particles (as will be discussed in section 3.2) and can be used as potential drug carriers.

Lin et al. [74] developed the concept of hybrid magnetic-optical joint barcoding and decoding droplets in a magnetofluidic device. The device was comprised of an encoding area, storage pool and magnetic decoding area containing integrated giant magnetoresistive (GMR) sensors. The optical component employed in the system was a fluorescently labeled penicillin (P) derivative serving as a model drug and MNPs were used as the magnetic component. In addition, P, MNPs and water were encapsulated within droplets in the encoding area using mineral oil. After their formation, the droplets were first directed into a reservoir (pool) to enable the optical observation, and were moved into the decoding area with the aid of an additional oil stream arising from a side channel. This protocol was used to avoid optical interferences when collecting the GMR signal. Final decoding of the magnetic and optical barcoded droplets was achieved using respective fluorescence (a.u.) and magnetic voltage (μV) signals for the quantification of the MNPs and P the signals were measured simultaneously as the droplets passed through the decoding area. The intensities of the recorded signals varied with the amount of the MNPs and P in the droplet, which were controlled by Qc and Qd. The sensitivity of the system was determined using standard deviation values (σ) which were found to be ca. 1.5 μV and ca. 1.6 a.u. for the magnetic voltage and fluorescence intensity, respectively. These values indicated that ca. 96% of the droplets were produced within a confidence interval of 2σ. Although in this effort the detection frequency of the formed droplets was 10 droplets per second it can be increased by increasing the Qc and Qd. For instance, increasing Qc from 30 to 900 nL s−1 and MNPs stream from 10 to 100 nL s−1 reduced the droplets size from 150 to 80 μm, which caused the detection frequency to increase to ca. 240 droplets per second. Moreover, the amplitude of the GMR signal was decreased by a decrease in the droplet size so that a minimum droplet size of 60 μm can be detected by the GMR. This coded magnetofluidic device has the capability of dual fluorescence and magnetic detection of multiple components present in the same droplet, and, as a result, it can be further utilized to perform assays like those quantifying the amount of fluorescently labeled cells compared to the amount of MNPs located in a single droplet.

Microfluidic devices that utilize a combination of conventional PDMS and replica molding techniques were developed by Teste et al. [75] for selective treatment of magnetic droplets. In the fabrication process, a PDMS pre-polymer was mixed with ferromagnetic iron microparticles (6–8 μm) and poured into an aluminum mold (Fig. 6i a). After degassing, a soft silicon blade was used to remove excess magnetic PDMS followed by spreading the PDMS pre-polymer on top of the mold. Following incubation of the system at 70 °C for 15 h (Fig. 6i b-c), the resulting structures were peeled off and planarized by adding fresh PDMS using a salinized glass slide with a scotch tape spacer (Fig. 6i d-e). The system was then kept at 70 °C for 2 h before the bottom of the structure was integrated in the magnetic rail and bonded to the microchamber. Finally, the inlet and outlet of the device were connected via Teflon tubing (Fig. 6i f-i) and the thickness of the final PDMS layer on the top of the rail was 50 μm. The microsystem was inserted into a home-made electromagnetic coil controlled by a tunable power supply to generate a homogenous magnetic field at the center of the coil. In the absence of the external magnetic field, the trajectory of the magnetic droplets in this devise was linear, indicating that the droplets were dragged by the oil flow only. However, when the external magnetic field was on, the rails induced an attractive force that stimulated formation of magnetic clusters, which caused the motion of the droplets to deviate from their linear path. Furthermore, droplet sorting, parking and merging were performed using a microdevice that combined the magnetic rail network and an array of physical traps (Fig. 6ii). Switching on the external magnetic field allowed the droplet to pass over the first rail (r1) and be trapped. Similarly, the following droplets can be sorted and trapped in rails r2-r4 and by reversing the flow, the droplets can be made to flow back to the inlet streamline. Additionally, merging of the droplets can be performed using the same concept. For example, after trapping the first droplet, a train of additional droplets can then be introduced. Once the droplets are in contact, increasing the flow rate to >15 μL s−1 caused the droplets to merge. A study using an enzymatic reaction was performed to demonstrate the potential use of the system for monitoring of processes occurring within a single droplet. Although the system enables controlled sorting, parking and merging of droplets, as well as performing enzymatic reactions, fabrication of the device was complicated and time consuming.

(i) A detailed schematic representation of the microfluidic platform where the bottom part was integrated with the magnetic rail structures. (ii) Schematic representation of the microdevice used to sort, park and merge the magnetic droplets showing integrating a magnetic rails network and physical traps array . Reprinted with permission from ref. [75]. Copyright (2015), Springer

Varma et al. [76] was the first to conduct an experimental and modeling investigation of uniform magnetic field induced merging of FF droplets. The use of uniform magnetic fields enabled contact-free, wireless programmable control of magnetic droplets. In the device, FF droplets were generated at a T-junction configuration utilizing a squeezing regime (i.e. Ca < 10−2) and alternating droplets were generated at the T-junction by having two inlets for the dispersed phase facing each other. The uniform magnetic field was generated using a water cooled DEXING electromagnet system with an air gap of 4 cm between the magnet poles, and the microfluidic device was mounted in the middle of the poles. Independent dye and FF droplets were generated at a constant flow rate ratio in the absence and presence of the uniform magnetic field. Due to the attraction force of the magnetic field, a decrease in the generation time took place. On the other hand, an increase in the droplet size occurred as H increased to 500 mT. However, a further increase in H to 1000 mT caused the field to become non-uniform which resulted in elongation and an increase in the surface tension of the FF droplets. An assessment of the FF droplets merging in the presence of a uniform magnetic field was carried out by varying H and merging length (Lm), which is the distance from the T-junction to the center of the droplet at the droplet merging point. In the presence of the field, a competition existed between fluidic pressure, which depends on Qp and Qc, surface tension and magnetic force. Merging will take place only when the magnetic force exceeds the sum of the two other forces. Droplet merging was studied at a constant H of 500 mT and different droplet velocities, particularly at flow rate ratios of 2 and 5. Assuming that two consecutive droplets with velocities Va and Vb merge to form a droplet with velocity of Vab, three scenarios can exist for successful merging of two droplets with respect to variations in Va and Vb, including i) both droplets moving in the same flow direction and Va < Vb, ii) both droplets moving in the opposite flow direction and – Va > − Vb, and iii) both droplets flow towards each other. At t = 0 the transition merging point, Vb – Va, reached a maximum value and droplets are then merged. The results of time variation simulations of velocity were found to be in agreement with the experimental results. Application of the magnetically induced merging technique was demonstrated by generating FF and blue dye droplets in oil. In the absence of the magnetic field, no droplet merging tooke place while at H = 1000 mT the droplets merge to form green FF droplets. The authors suggest that the system can be used for biosensing, bioassays and determining reaction kinetics.

Fabrication of magnetic materials in droplets

The synthesis of magnetic materials within droplets has received great attention. The fabricated magnetic materials have been found to have small and narrow size distributions, in addition to interesting morphologies. Among the materials that have been prepared in this manner are MNPs [77], magnetic microstructures [78], magnetic Janus particles [79] and magnetic hydrogels [28].

Synthesis and modification of MNPs

Due to the existence of highly controlled mixing and reaction conditions within droplets, it was believed that it would be possible to generate particles with small sizes and monodispersities in this environment, Table 6. This proposal was initially explored by Frenz et al. in 2008 [77] in the context of continuous synthesis of iron oxide NPs using controlled electrocoalescence of two droplets. Mixing of the first droplet containing a mixture of Fe2+ and Fe3+ precursors with the second containing ammonium hydroxide produced iron oxide NPs. The electrocoalescence device employed for this purpose consisted of two hydrodynamically coupled nozzles and a central oil channel. When the first primary droplet was formed, the aqueous stream blocked the oil channel causing an increase in the flow of oil through the second nozzle to produce a secondary droplet. Once the secondary droplet was generated, the oil flow moved back to the first nozzle enabling the formation of the second primary droplet. Within the PDMS device, electrodes were programmed to pair the droplets and promote electrocoalescence, which was effectively accomplished when the droplets were generated at flow rate ratios of 1:1 and up to 1:5. A preliminary evaluation of the efficiency of electrocoalescence and mixing of the two alternating produced droplets was conducted by mixing using two fluorescent dyes. The results showed that droplet pairing occured to the extent of 99.99%. The results of off-chip characterization of the MNPs prepared using this system by TEM showed that they had an average particle size of 4 ± 1 nm, in addition to displaying hysteresis in the magnetization curve, which confirmed their superparamagnetic nature. Another droplet-based microfluidic system for synthesizing biogenic FeMn MNPs was described by Jung et al. [80]. In this system, a flow-focusing configuration was used to generate nL droplets containing E. coli cells and a mixture of FeSO4·7H2O and MnCl2·4H2O. The droplet contents were thoroughly mixed, using a device having a serpentine channel design, and then incubated on-chip in a chamber for 5 min and off-chip for 18 h at 37 °C. Laser-induced confocal microscope analysis showed that while the size of the droplets remained constant and that the color of the cells changed to brown as a result of formation of biogenic NPs were in their interiors. After droplet breakage, the E. coli containing FeMn NPs were collected in eppendorf tube. The cells were then isolated by using a magnet, washed by using ultracentrifugation and calcinated to eliminate any proteins that might have bound to the NPs. The biogenic NPs were characterized off-chip using TEM and a vibrating sample magnetometer (VSM). The size of the on-chip prepared NPs was determined to be 5.17 ± 0.24 nm, compared to the smaller yet slightly polydispersed off-chip NPs that have a size of 3.04 ± 0.68 nm. The magnetization profile of the NPs obtained in the range of −5.0 to +5.0 kOe did not display saturation or loss of their magnetism, confirming the paramagnetic nature of the particles. Interestingly, a capillary based microfluidic device that enables droplet mixing, flocculation, magnetic decantation, colloidal re-dispersion, washing, surface functionalization, heating and colloidal assembly was developed for the synthesis of MNPs by Ferraro et al. [81]. Using this device, fluorescence labeled and amine functionalized silica NPs (SiO2 NPs, 200 nm) were coupled with citrate functionalized FF (γ-Fe2O3, 9 nm) under pH controlled conditions using a trapping mechanism. Initially, a droplet containing γ-Fe2O3 NPs was trapped using magnetic tweezers and then merged with another droplet containing trisodium citrate. This caused destabilization and precipitation of the NPs within the droplet. A homemade heater was used to enhance diffusion and grafting of the citrate molecules on the surface of the NPs. Then, a droplet of functionalized γ-Fe2O3 NPs was formed, trapped in a capillary using the magnetic tweezers, and subjected to washing steps with droplets containing a mixture of acetone/water and two droplets of water. Then, the NPs cluster was added to 3-(N-morpholino)propanesulfonic acid (MOPS) buffer droplet. Finally, the citrate functionalized MNPs suspended in MOPS were trapped and merged with a droplet, containing the fluorescent material Rhodamine B isothiocyanate-SiO2 (RITC-SiO2 NPs), to form a droplet containing magnetic nanoassembly of RITC-SiO2@ γ-Fe2O3. Inspection of fluorescence images demonstrated that the nanoassemblies present in the droplet were randomly oriented in the absence of a magnetic field while in the presence of the magnetic field the NPs became aligned along with the direction of the field. Moreover, TEM analysis proved that γ-Fe2O3 NPs were attached to the surfaces of the RITC-SiO2 NPs.

Synthesis of magnetic microstructures

In 2011, magnetochromatic microcapsules were prepared using droplet microfluidics by Zhu et al. [82] for array display applications (Fig. 7a–c). The microcapsules, composed of an aqueous suspension of magnetic nanospheres covered with a transparent layer of ethoxylated trimethylolopropane triacrylate (ETPTA) resin. ETPTA was chosen for this purpose due to its fast solidification time when exposed to UV radiation, transparency and density which closely matches that of water. In an off-chip procedure, oleic acid modified Fe3O4 nanocrystals were mixed with styrene, methacrylic acid, hexadecane, water and sodium dodecyl sulfate (SDS) to form magnetic nanospheres, which were then suspended in water. The magnetochromaic microcapsules were produced using a droplet platform composed of a double T-junction channel with three syringe pumps to deliver the three reagent streams. The inner aqueous phase was composed of magnetic nanospheres, the middle phase contained ETPTA and a photoinitiator, and the outer phase was comprised of water mixed with surfactant (4% polyvinyl alcohol, PVA). This system generated monodispersed magnetic core-ETPTA shell double emulsion droplets, which were subsequently collected off-chip in a glass dish and exposed to UV light for 15 min to promote solidification. The magnetochromatic microcapsules were then formed with an average size of ca. 138 nm (Fig. 7b) by placing the microcapsules into a single layer, close-packed hexahedral array and adding a boiling aqueous solution of agarose to fill the gaps between the microcapsules. Upon cooling to room temperature, microcapsules having different colors and patterns were formed. Characterization of the formed microcapsules was conducted using optical techniques including digital microscopy and scanning electron microscopy (SEM) to assess their magnetochromatic behavior, shape and morphology (Fig. 7a). The change in color of the array was completely reversible process, the coloration of the array changed under different magnetic stimulations and returned to its original state when the field was removed, as shown in Fig. 7c. One dimensional chains of connected soft droplets were synthesized for the first time within a single microfluidic device by Jiang et al. [83]. The simple platform was comprised of a T-junction to form aqueous chitosan droplets in oil and surfactant, and a side channel to deliver a mixture of an incubation phase of glutaraldehyde (GA), oil and surfactant. The role of the surfactant was to stabilize the droplets and that of GA was to covalently crosslink the chitosan droplets as they flowed through the serpentine channel to form a chain, which was eventually collected in a reservoir. The optimum conditions for preparation of 150 μm droplets involved a generation rate of one droplet per second, although higher frequency and larger sizes can be obtained. This strategy was employed to fabricate magnetic, magnetically fluorescent and fluorescent/non-fluorescent alternating chains. Magnetic chains were obtained by adding γ-Fe2O3 NPs (average surface area ca. 42 m2 g−1) to the chitosan solution and incubating the chains within the microchannel for 24 h. The stiffness of the chains was found to depend on the time for incubation of the droplets in GA, with longer incubation times (24 h) leading to rigid rodlike chains and a short 5 min incubation time resulting in production of flexible chains. The presence of magnetic functionality enabled the chains to be controlled using an external magnet (Fig. 8).

a) SEM image of the magnetic nanospheres encapsulated in microcapsules, the inset is a TEM image of the nanospheres (scale bar 200 nm), b) Size distribution of the synthesized magnetic nanospheres and c) Digital photograph of the coloration of the array as the strength of the magnetic stimulation changes. All scale bars are 2 mm. Reprinted with permission from ref. [82]. Copyright (2011), Wiley

Successive photographs of semiflexible magnetic chains generated in droplet microfluidics in continuous flow moving under the influence of the magnetic field. Reprinted with permission from ref. [83]. Copyright (2011), Wiley

Bokharaei et al. generated non-magnetic and magnetic polymeric droplets using a flow focusing device [84]. The dispersed phase used in this system was 10% poly(L-lactic acid) (PLL) in chloroform and the continuous phase was 2% PVA in water. The PLL droplets were collected off-chip in a 2% solution of PVA followed by solvent removal using an 8 h air flow. Addition of MNPs to the dispersed phase required a re-optimization of the flow rates due to irregularities in Qd, mainly as a result of the change in phase rheological properties. Different amounts of the MNPs were incorporated to produce droplets with different sizes and magnetic properties. The particle sizes were found to be in the range of 24.06–31.66 μm and their saturation magnetization (Ms) occurred between 11.1–13.1 emu g−1. A determination of their heat generation capability, also known as specific absorption rates (SAR), at a constant frequency displayed a small decrease as the number of the MNPs decreased. Inspection of SEM images showed that the non-magnetic microparticles were spherical and had smooth surfaces. On the other hand, the magnetic microparticles had porous and uneven surfaces. These phenomena can be attributed to the rate and mechanism of solvent removal or drug release during the solidification process. Furthermore, the authors developed a 3D computational multiphase droplet generation model, which produced results that correlated well with the experimental data. The microparticles produced in this manner had a high potential for magnetic hyperthermia applications and drug delivery. In another effort, a droplet microfluidic platform for the synthesis of magnetic microspheres with controlled macroporosity was developed by Paquet et al. in 2012 [78]. By combining MNPs with a polymer, it was possible to form functional magnetic microparticles with controlled sizes, porosities and narrow size distributions without the need for chemical transformations such as polymerization. The formed droplets, containing a mixture of iron oxide NPs, poly(styrene/maleic anhydride) and an organic solvent, were collected off-chip in a solution of SDS, where the solvent diffused out of the droplet. The results showed that the diameter of the microparticles was influenced by Qc/Qd and had a CV of 2–3%. Two critical factors affecting the morphology of the generated microspheres include the concentration of SDS in the collection solution and the nature of the solvent. Inspection of SEM images of microspheres created using SDS concentrations between 0 and 250 mM revealed the existence of large differences in the morphology depending on the SDS concentration (Fig. 9a–f). For example, with SDS concentration ≤ 10 mM the microparticles were densely compact composites of the NPs and polymer, whereas at SDS concentrations >100 mM the microspheres had denser channel-like structures. Additionally, the sizes and stabilities of the collected droplets were found to depend on SDS concentration (Fig. 9g and h). The effect of solvent was investigated using chloroform, toluene, hexane and a mixture of tetrahydrofuran (THF) and toluene. The droplets were observed to form particles after a few minutes when chloroform was used, whereas longer times were required for particle formation when other solvents were utilized. However, a denser pore structure was formed when hexane or a THF/toluene mixture was used. The results of nitrogen isotherm measurements and Brunauer-Emmett-Teller (BET) calculations on the magnetic microparticles produced using 25 mM SDS showed that the surface contained macropores (d > 50 nm) and a total surface area of 5.2 m2 g−1. This method can be used to prepare novel and versatile materials, such as porous magnetic microspheres, without the need to use light- or heat-sensitive materials to initiate a polymerization process. It has also been shown that droplet microfluidics can be used to form interesting morphologies. For example, tadpole-shaped Fe3O4-chitosan composite particles were prepared using a flow focusing device by Yang et al. [85] (Fig. 10a-b). In this system, a solution of chitosan, and a mixture of FeCl2 and FeCl3 was injected into a sun flower seed oil stream to generate magnetic droplets (Fig. 10a). The droplets formed on-chip were solidified off-chip in a NaOH solution as soon as they exited the channel. The dimensions of the Fe3O4-chitosan composite particles can be controlled by varying Qd. When Qc was maintained at 0.5 mL min−1 and Qd was varied from 0.02, 0.2 and 0.3 mL h−1, composites were generated with respective length/diameter (D/L) ratios of 2.2, 2.1 and 1.9. SEM images of the composite particles confirmed the formation of tadpole-like structures (Fig. 10b). Mitoxantrone, serving as a model drug, was mixed with chitosan, FeCl2 and FeCl3 to generate composite particles. An assessment of the efficiency of drug release from the magnetic composite showed that the prepared composite had an encapsulation rate of 69% compared to 71% for the native chitosan particles. However, the magnetic composite displayed a larger drug release rate (41.6%) over 180 min compared to that for native chitosan (24.6%). The high efficiency of drug release rate was attributed to the increased porosity of the composites. Despite being able to generate this unique composite shape, the authors do not mention if this shape has any advantages over spherical or disk-shaped particles that can be prepared using droplet microfluidics. Additionally no in vivo study was conducted to probe the applicability of this method for encapsulation and release. Porous magnetic beads were prepared using droplet microfluidics for separating oil/organic solvent contaminants in water [86, 87]. A suspension of acidified multi-wall carbon nanotubes (aMWCNTs), polystyrene (PS) microspheres and Fe3O4 NPs was used as the dispersed phase and dimethyl silicone oil as the continuous phase [86]. Porous aMWCNTs are well-known adsorbents, while PS served as a hard and porous template for the droplets and Fe3O4 NPs enabled remote and wireless control of the beads after solidification. The droplets were collected off-chip and hardened at 60 °C for 12 h, washed and then heated at 750 °C for 2 h to form porous magnetic beads. The beads were characterized using SEM, Fourier-transform infrared spectroscopy (FTIR), X-ray powder diffraction (XRD), X-ray photon spectroscopy (XPS), surface area and Raman spectroscopy. After exposing the beads to oils or organic solvents, they can be isolated using an external magnet (Fig. 11a1-a6), and the adsorption can be monitored by digital imaging. In addition, the beads were recyclable using combustion and distillation approaches. A reduction by only 4.3% in their absorption capacity occured following their use for 6 cycles when using the combustion recovery approach and negligible loss recorded when using the distillation recovery protocol. No information was provided regarding the features (eg. quantities, and concentrations) of oil/organic solvent removal. The same group described the use of the same strategy to generate magnetic porous graphene oxide/multi-walled carbon nanotube beads (MPGCBs) in the same capillary microdevice [87]. In this case, the beads were formed on-chip in a continuous flow mode by injecting a mixture of graphene oxide (GO), aMWCNTs, polystyrene beads (PS) and Fe3O4 NPs in dimethyl silicone oil. The GO/aMWCNTs/PS/ Fe3O4 droplets were collected and solidified in the manner described above to yield magnetic beads. The MPGCBs were characterized using SEM, FTIR, XRD, XPS, Raman and UV-Vis spectroscopy. The results of the XRD and XPS studies confirmed the magnetic properties of the formed beads, and the presence of iron, carbon and oxygen. The contaminant absorption capacity of the beads was assessed by exposing them to a series of oils/organic solvents. The results showed that the beads can absorb 8–25 times their own weight. By placing the MPGCBs between two Nylon filters, several water-in-oil emulsions can be separated, because the oil passed through the MPGCBs while the water was repelled by the hydrophobic MPGCBs and, thus, remained on the membrane surface. However, the authors did not mention the advantage of adding GO to the MPGCBs, nor did they carry out surface area measurements of the formed beads in order to obtain information about their adsorption behavior for comparison to previously described systems.

SEM micrographs of the interior of the microspheres made from solutions of SPIONs and copolymer in toluene and collected in (a) 0, (b) 10, (c) 25, (d) 50, (e) 100 and (f) 250 mM SDS solutions (scale bar 1 μm). (g) Variation in droplet size as a function of time for droplets collected in difference SDS concentration. (h) Changes in the porosity of particles as a function of the SDS concentration solution. Reprinted with permission from ref. [78]. Copyright (2012), American Chemical Society (ACS)

a) A descriptive schematic of the microfluidic setup for the production of tadpole-like iron oxide-chitosan composite. b) SEM images of the formed tadpole-like composites prepared at Qd = 0.3 mL h−1 and Qc = 0.02 mL h−1. Reprinted with permission from ref. [85]. Copyright 2014, Elsevier

Photographs of the adsorption process of pump oil (yellow) in water, the adsorption was completed within 40 s then the magnetic porous aMWCNTs were collected using a magnet. Reprinted with permission from ref. [86]. Copyright (20116), the Royal Society of Chemistry (RSC)