Abstract

The authors describe a magnetic nanoadsorbent consisting of magnetite nanoparticles coated first with titanium dioxide and then with polypyrrole (PPy). It is shown to be a viable material for magnetic solid-phase extraction of trace amount of Pb(II). The magnetic titanium dioxide nanoparticles were synthesized first and then modified with PPy via in-situ electropolymerization. The properties, morphology, and composition of the sorbent were characterized by FTIR, scanning electron microscopy, energy-dispersive X-ray analysis and vibrating sample magnetometry. The effects of pH value, extraction time, type and concentration of eluent, and of sample volume were optimized. Under the optimum conditions, the limit of detection (for S/N = 3) is 0.28 μg⋅L−1. The maximum adsorption capacity of the adsorbent is 126 mg⋅g−1 of Pb(II). The accuracy of the method was investigated by analysis of a Certified Reference Material and the obtained value (0.119 μg⋅g−1) was in good agreement with the certified value (0.120 μg⋅g−1). The method was successfully applied to the determination of Pb(II) in a gastropod and spiked environmental and marine water samples. It gave recoveries in the range from 94.4 to 103.1%.

Magnetic titanium dioxide nanoparticles were synthesized and modified with PPy via in situ polymerization. The Fe3O4/TiO2/PPy nanocomposite was used for solid-phase extraction and pre-concentration of trace amount of lead(II) ions in complex matrices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sample pretreatment is a fundamental and essential step in almost all analytical procedures, especially for environmental samples with complex matrix [1]. Also, in some samples the analytes cannot be accurately detected because of their extremely low concentrations in those samples [2]. Therefore, to improve the detection accuracy, sensitivity and selectivity of measuring analytes, sample pretreatment is needed before instrumental analysis. Based on the matrix complexity and analyte properties, various materials and procedures have been employed for sample pretreatment [3].

Metal oxides with a wide range of surface reactivity have been applied in sample pretreatment (especially for magnetic solid-phase extraction, MSPE) in a variety of occasions due to their advantages of high binding capacity, good selectivity, and extraordinary stability [4]. Due to the unsaturated surface atoms of metal oxides, they can easily bind with other metal ions and adsorb them selectively from sample solutions [5, 6]. In addition the metal oxides supports can be modified or coated with suitable materials to give novel applications in sample pretreatment [1]. In the other hand, polymers have been widely used for sample preparation because of their plenty adsorption sites, high pH stability and flexibility for modification [7]. Combining of these materials adds new functional groups to the surfaces of both metal oxide and polymer and provides improved and unprecedented advantages over one single component as adsorbent in sample pretreatment [8].

Among the metal oxides, TiO2 nanoparticles have great potential and advantages due to their relatively low cost, simple preparation, nontoxic nature and high specific surface area [9, 10]. Different publications have focused on the adsorption of organic or inorganic analytes on TiO2 nanoparticles [11, 12]. Although TiO2 magnetic nanoparticles are mesopore as well, they can easily aggregate in their loose and random states, which it decrease their magnetic efficiency [13]. So, modification of its surface usually results in improvements of its properties, particularly its stability and adsorption capacity [9, 10]. One of the main approaches to overcome these limitations is to combine TiO2 with polymers such as polypyrrole (PPy). PPy is a promising material for extraction application because of its easy preparation through chemical or electrochemical routes and also it shows good stability in acidic and neutral solution [14, 15].

Environmental pollution by heavy metal ions is increased due to the rapid industrialization in the worldwide which threatens the environment and human life [16, 17]. Among these heavy metals, lead is considered to play a key role in its translocation in biogeochemical cycles. It is non-biodegradable and enters into the food chain, so can accumulate in living organisms and cause serious disorders such as poisoning, renal impairment, neuronal cell injury and brain disorders, and cancer [18, 19]. Therefore, the trace analysis of these metals is necessary.

Since the quest for new adsorbents is an important factor in improving analytical sensitivity and precision in MSPE techniques, we prepared the Fe3O4/TiO2/PPy nanocomposite and use it for the extraction and preconcentration of trace amounts of Pb2+ ions from different environmental samples. The Fe3O4/TiO2/PPy sorbent with the specific properties of both TiO2 and PPy was proven to be a quick, simple, and efficient adsorbent for enrichment of lead ions in trace levels.

Experimental

Instruments

Spectrometric measurements were carried out with a GBC 932+ (Australia) Atomic Absorption Spectrophotometer with deuterium lamp for background correction. The hollow cathode lamp for lead was used as the radiation source operated at 20 mA and the wavelength was set at 434 nm resonance line. All measurements were carried out in an air/acetylene flame. A Metrohm model 713 (Herisau, Switzerland) pH-meter with a combined glass electrode was used for pH adjustments. Heidolph heater stirrer model MR3001 (Germany) was used for heating and stirring the solutions. A Bruker VerTex 70 instrument was used to obtain the Fourier transform infrared (FTIR) spectra of KBr powder-pressed pellets. The surface morphology and size of the nanoparticles were observed using a KYKY-EM3200–26 kV scanning electron microscope (SEM). The composition and the magnetic property of the synthesized composite was investigated using an Energy-dispersive X-ray analysis (EDX, Sirius SD, England) and vibrating sample magnetometer (VSM, Meghnatis Daghigh Kavir Co., Kashan, Iran).

Reagents and solutions

Analytical grade chemical reagents from Sigma-Aldrich (Steinheim, Germany, www.sigmaaldrich.com) and Merck (Darmstadt, Germany, www.merck.com) were used for the preparation of all standard and sample solutions. Stock solutions were prepared from Pb2+ standard solutions of 1000.0 mg L−1 (Merck, Germany) by serial dilution with deionized water. Pyrrole (98%) was purified by vacuum distillation before being used. The ultra- pure water was used throughout the study.

Synthesis of Fe3O4

Fe3O4 nanoparticles were prepared using a co-precipitation method. First, 4.72 g FeCl3.6H2O and 1.7 g FeCl2.4H2O were added to 100 mL of distilled water under 80 °C and the solution was stirred for 30 min. Then, 10 mL ammonia (25% v/v) was dropped into the mixed solution and stirred under nitrogen gas purge for 30 min. A large amount of black precipitates was prepared. The Fe3O4 precipitates were separated with an external magnet (1.4 T) and washed with distilled water and ethanol several times until the pH value was about 7 [20].

Synthesis of Fe3O4/TiO2 nanocomposite

The Fe3O4/TiO2 nanocomposite particles were prepared via sol-gel technology. According to the literature [21], 0.01 mol (2.315 g) of Fe3O4 nanoparticles were dispersed in the mixture solution of water-ethanol with a volume ratio of 1:20. Then the mixture sonicated for 5 min. The pH value of the mixture was adjusted at 4–5. Then, 0.08 mol (23.68 mL) of tetrabutyl titanate (TBOT) dissolved in ethanol and acetic acid under 40 °C water bath, was slowly dropped into the above suspension. The suspension was sonicated and vigorously stirred for 30 min to ensure a uniform composition. The precipitates were separated by a strong magnet and washed with ethanol and deionized water until the pH value was about 7. The particles were aged for 5 h and then dried in an oven at 60 °C for 1 h. Finally, the prepared composite particles were calcinated at 450 °C for 3 h.

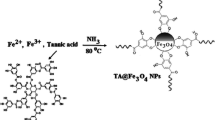

Synthesis of Fe3O4/TiO2/PPy nanocomposite

Schematic diagram of the preparation of Fe3O4/TiO2 and Fe3O4/TiO2/PPy is illustrated in Fig. 1. The Fe3O4/TiO2 powder was dispersed in 50 mL deionized water by bath-sonication for 30 min. Then, 71.5 μL of pyrrole was added into the 0.5 mol L−1 HCl solution, and 10 mL of this solution was added into the above prepared suspension and sonicated for about 5 min. The solution was polymerized through the chemical oxidation of the pyrrole monomers with ammonium persulfate (APS) as an oxidant. Thus, 10 mL APS (0.1 mol L−1) aqueous solution was slowly added drop by drop into the above reaction system, after stirring for 2 h, the solution was filtered and the residual was washed with double distilled water and ethanol, and then dried in an oven at 60 °C [22].

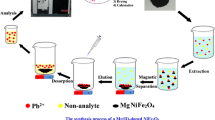

Magnetic solid-phase extraction procedure

The MSPE procedure was carried out as follows: Fe3O4/TiO2/PPy (45 mg) was added to 100 mL of Pb2+ solution in a 250 mL beaker, the pH value of the solution was adjusted to 6 using 0.1–1.0 mol L−1 HCl and/or NaOH solutions. The mixture was stirred for 20 min, and then the adsorbent was magnetically separated from the solution with the assistance of an external magnet. The residual solution and Fe3O4/TiO2/PPy adsorbent were totally transferred to a 10 mL beaker, and then the solution was completely discarded. The magnetic sorbent was eluted with 1.5 mL of 2.0 mol L−1 HNO3 solution for 2 min to desorb the adsorbed analyte. Finally, the magnetic adsorbent was separated using a magnet and the supernatant HNO3 solution was collected and analyzed using the AAS system.

For reusability tests, the residual sorbent was washed with 3 mL of HNO3 and 5 mL of ultrapure water in turn, and then used for the next extraction process.

Real samples preparation

The gastropod, Trochus erythraeus, samples were collected from the costs of Bushehr (Persian Gulf, Iran) and then, stored and transferred to the laboratory in clean polyethylene sample bags. In the laboratory, the hard and soft tissues of the samples were separated. The soft tissue was freeze-dried at −40 °C and 100 tors for 48 h, and the homogenized with a blender. 0.25 g of the sample was placed in a 100 mL beaker containing 9 mL HNO3 and 3 mL H2O2 and it was digested for 4 h at 80 °C. The solution was cooled to room temperature and filtered. Sample was then diluted with deionized water to 300 mL and the pH of solution was adjusted to 6 by adding sodium hydroxide (1 mol L−1).

Two real environmental water samples were used for evaluating feasibility of the method in real aqua samples. Water samples were collected from Caspian Sea (Babolsar,Iran) and Chabahar Bay (Chabahar,Iran). The samples were filtered through a filter paper (Whatman No. 40), acidified with 1 mol L−1 HCl (pH = 6) and stored in glass bottles at 4 °C for subsequent usage.

Reference material

The Certified Reference Material (CRM) IAEA-407 was heated in an oven for 2 h at 200 °C before analysis to ensure a stable weighing form. Then, 1.3 g CRM was weighed into a 100 mL beaker, and 15 mL HNO3 and 5 mL H2O2 were added. Then, it was digested for 4 h at 80 °C. After that, the solution was cooled and filtered. Sample was then diluted with distilled water to 300 mL and the pH was adjusted to 6 and then, the preconcentration procedure was performed.

Results and discussion

Choice of materials

Magnetic nanoparticles (especially Fe3O4) as MSPE adsorbents has received considerable attention due to their excellent properties. However, for analytical purpose, Fe3O4 nanoparticles have been modified by different materials, because bare Fe3O4 forms large aggregation easily in solutions and lacks selectivity for the complicated samples [8].

Titanium dioxide has great potential as a sorbent material because insolubility, nontoxic nature and high specific surface area [9, 10, 23]. Moreover, the hydroxyl groups on the surface of TiO2 can interact with the target analytes to do the adsorption process [23].

To improve the stability, adsorption and regeneration capacities of TiO2, PPy can be considered as a potential modifier material because of its high thermal stability and non-toxicity [24]. PPy can prevent the aggregation of magnetic TiO2 nanoparticles, and also enhance the effective surface area of the nanoparticles. It can improve the adsorption of lead ions due to the sharing of an electron pair of N groups on PPy with the empty orbitals of lead ions. Comparison of the adsorption efficiencies of the Fe3O4@TiO2 and Fe3O4@TiO2@PPy for Pb+2 showed the uptake percentages of 74.0% and 92.5% for them, respectively. It demonstrated the role of using PPy in enhancing of the extraction efficiency of Fe3O4@TiO2. Therefore, we immobilized PPy on the surface of magnetic TiO2 nanoparticles during in situ polymerization and introduce a new surface for effective preconcentration of Pb2+ ions in different samples with the complicated matrices.

Characterization of the magnetic sorbent

The FT-IR spectra of Fe3O4/TiO2 and Fe3O4/TiO2/PPy are shown in Fig. 2. The peak in the range of 400–600 cm−1 is assigned to Ti–O–Ti stretching (Fig. 2a) [25]. The peak in 641.3 cm−1 is due to the Fe–O vibration of magnetite. Fe3O4/TiO2/PPy nanocomposite shows characteristic peaks of polypyrrole (Fig. 2b). The peaks at 1624.7 and 1425.2 cm−1 correspond to the C═C and C═N in-plane vibrations respectively, and the broad peak at approximately 3421.3 cm−1 is the typical N–H stretch in the pyrrole structures [26]. The absorption bands at 1516.1, 1153.5 and 1044.3 cm−1 are assigned to C═C symmetric stretching vibration and the C–H bending in pyrrole rings, respectively [27, 28].

The surface morphology of Fe3O4/TiO2/PPy was determined by SEM (Fig. 3a). The SEM image shows that the magnetic nanocomposite has approximately homogeneous and spherical structure that plays an effective role in the enhancement of the adsorption capacity. As can be clearly seen from Fig. 3a, the Fe3O4/TiO2 surface was completely coated with PPy during in situ polymerization and the average diameter of nanoparticles estimated from the SEM micrograph was approximately 60 nm.

A typical EDX spectrum taken from the synthesized sorbent is showed in Fig. 3b, where peaks associated with C, O, Fe, N, Ti and Cl can be distinguished. The quantitative analysis gives weight ratios of Fe (38.35%), Ti (25.51%), C (20.74%), O (8.98%), N (4.84%) and Cl (1.39%). The above results are consistent with the results obtained from FT-IR.

Magnetic property of the sorbent was analyzed using a vibrating sample magnetometer (VSM) at room temperature. The magnetization curve in Fig. 4 illustrates that the Fe3O4/TiO2/PPy sorbent is super-paramagnetic with magnetization saturation of 28 emug−1. Compared with the Fe3O4, the saturation magnetization of Fe3O4/TiO2/PPy reduced, but it was sufficient for magnetic separation from the solution with a conventional magnet.

Optimization of extraction conditions

In order to achieve an optimal extraction efficiency of the MSPE procedure, several parameters that could affect the extraction efficiency were investigated and optimized, such as (a) pH value; (b) sorbent dosage; (c) extraction time; (d) eluent type and (e) concentration; (f) elution volume; (g) desorption time and (h) sample volume. Respective data and Figures are given in the Electronic Supporting Material as Fig. S1. The following experimental conditions were selected to obtain the best analytical performance: (a) a pH value of 6; (b) a sorbent dosage of 45 mg; (c) an extraction time of 20 min; (d) an eluent type of HNO3; (e) an elution concentration of 2 mol L−1; (f) an elution volume of 1.5 mL; (g) a desorption time of 2 min and (h) a sample volume of 300 mL.

Effect of interfering ions

Matrix effect is a critical problem in determination of metals in real samples. Under optimized conditions, the interference of common cations and anions on the recovery of lead ions was investigated. For this purpose, a solution of 100 μg L−1 of Pb2+ containing the corresponding interfering ions were prepared and operated according to the procedure. The tolerance limit was defined as the largest amount of potentially interfering ions that reduce the recoveries of Pb2+ to less than 85%. According to Table 1, the results demonstrate that the sorbent can extract Pb2+ ions with good recoveries and the interfering ions have no significant effect on preconcentration.

Adsorption capacity

The adsorption capacity is the maximum analyte quantity taken up by 1.0 g of adsorbent. In order to determine this factor, 45 mg of the nanoadsorbent were subjected to several solutions containing various concentrations (0.2–40.0 mg L−1) of Pb2+ and the solutions stirred for 20 min at room temperature using a magnetic stirrer, followed by the determination of retained analyte using flame atomic absorption spectrometer (FAAS). The adsorption capacity of the Fe3O4/TiO2/PPy sorbent toward lead ions was calculated by the following equation:

where qe is the adsorption capacity (mg g−1), Ci and Ce are initial and equilibrium concentrations (mg L −1) of lead ions in aqueous solutions respectively, V (L) and W (g) are volume of aqueous solution and weight of the sorbent, respectively. The values of adsorption capacity increased with the increase of initial concentrations of lead ions and then it reached a plateau (Figure 2Sa). The static adsorption capacity of 126 (±2, n = 3) mg g−1 was obtained for lead ions.

Adsorption isotherm

The Langmuir and Freundlich isotherm models were employed to investigate the adsorption process of lead ions by the synthesized sorbent.

Table 1 S displays the equilibrium adsorption isotherm parameters of Pb2+ ions onto the Fe3O4/TiO2/PPy. The adsorption mechanism of lead ions was well fitted to the Langmuir isotherm model with the higher correlation coefficients (0.913). The theoretical q m value (129 mg g−1) calculated from the Langmuir adsorption model was close to the experimental value (126 mg g−1). As a result, the adsorption of Pb2+ ions onto the magnetic nanocomposite showed good agreement with the Langmuir isotherm model.

Sorbent reusability

The reusing ability of the adsorbent in several successive adsorption processes was investigated. Based on the result Figure 2Sb, no obvious changes were observed in the recoveries after 8 times. It indicates that the adsorbent is reusable and stable with no analyte carryover during MSPE procedure.

Analytical performance

To evaluate the analytical performance of the established method, under the optimized experimental conditions, a series sample solutions in the concentration range of 0.5–400 μg L−1 were prepared and applied to the MSPE procedures. According to the results, the calibration curve for lead was found to be linear with the correlation coefficient of 0.999 in the range of 0.6–100 μg L−1. The LOD (defined as 3Sb/m, where Sb is the standard deviation of the blank readings for three replicate analysis and m is the slope of the calibration curve) was 0.21 μg L−1. Also, the resultant repeatability expressed as relative standard deviations (RSD) was 3.9% (C = 1 μg L−1, n = 5).

The enrichment factor of 200 was calculated as the ratio of initial volume to the final. In Table 2, a comparison of the analytical performance data of the introduced method with the other reported preconcentration methods [29–35] for determination of Pb2+ was done. Compared with the other techniques, the present work has the good LOD for the target analyte. As can be seen from Table 2, our method has generally the highest PF value and adsorption capacity. So, our method is comparable with most of the methods used in the published reports.

Analysis of the real samples

In order to verify the accuracy of the method, it was tested to the determination of Pb2+ in CRM IAEA-407 and also by different samples, and the analytical results along with the recoveries at two spiked concentrations were given in Table 3. All of the Trochus erythraeus gastropodsample and water samples were spiked with 2, 5 μg g−1 and 2, 5 μg L−1 of Pb2+ ions, respectively. The results show the determined values were in good agreement with the certified values, indicating the high accuracy and suitability of the method for analysis of Pb2+ ions in real samples.

Conclusions

Fe3O4/TiO2/PPy nanocomposite was successfully applied to solid-phase extraction and preconcentration of Pb2+ ions as a simple and effective adsorbent. The magnetic sorbent was prepared by a simple procedure and the feasibility of the method was demonstrated by application to different samples. The method was simple, quick and sensitive. Compared with the other reported methods, our method is characterized by relatively lower LOD, higher adsorption capacity and PF values prior to determination by flame atomic absorption spectrometric. So, it can be applied for the analysis of trace/ultratrace Pb2+ in even complex matrices.

References

Xu J, Wu P, Ye EC, Yuan BF, Feng YQ (2016) Metal oxides in sample pretreatment: a review. Trends Anal Chem 80:41–56. doi:10.1016/j.trac.2016.02.027

Habila M, Yilmaz E, ALOthman ZA, Soylak M (2014) Flame atomic absorption spectrometric determination of Cd, Pb, and Cu in food samples after preconcentration using 4-(2-thiazolylazo) resorcinol-modified activated carbon. J Ind Eng Chem 20:3989–3993. doi:10.1016/j.jiec.2013.12.101

Nawrocki J, Dunlap C, McCormick A, Carr PW (2004) Part I. Chromatography using ultra-stable metal oxide-based stationary phases for HPLC. J Chromatogr A 1028:1–30. doi:10.1016/j.chroma.2003.11.052

Figueroa A, Corradini C, Feibush B, Karger BL (1986) High-performance immobilized-metal affinity chromatography of proteins of iminodiacetic acid silica-based bonded phases. J Chromatogr A 371:335–352. doi:10.1016/S0021-9673(01)94717-X

Liang P, Ding Q, Liu Y (2006) Speciation of chromium by selective separation and preconcentration of Cr(III) on an immobilized nanometer titanium dioxide microcolumn. J Sep Sci 29:242–247. doi:10.1002/jssc.200500301

Liang P, Qin Y, Hu B, Li C, Peng T, Jiang Z (2000) Study of the adsorption behavior of heavy metal ions on nanometer-size titanium dioxide with ICP-AES. Fresenius J Anal Chem 368:638–640. doi:10.1007/s00216000054

Li XS, Xu LD, Shan YB, Yuan BF, Feng YQ (2012) Preparation of magnetic poly(diethyl vinylphosphonate-co-ethylene glycol dimethacrylate) for the determination of chlorophenols in water samples. J Chromatogr A 1265:24–30. doi:10.1016/j.chroma.2012.09.083

Huang D, Deng C, Zhang X (2014) Functionalized magnetic nanomaterials as solid- phase extraction adsorbents for organic pollutants in environmental analysis: a review. Anal Methods 6:7130–7141. doi:10.1039/C4AY01100G

Manzoori JL, Amjadi M, Hallaj T (2009) Preconcentration of trace cadmium and manganese using 1-(2-pyridylazo)-2-naphthol-modified TiO2 nanoparticles and their determination by flame atomic absorption spectrometry. Int J Environ Anal Chem 89:749–758. doi:10.1080/03067310902736955

Ma X, Huang B, Cheng M (2007) Analysis of trace mercury in water by solid phase extraction using dithizone modified nanometer titanium dioxide and cold vapor atomic absorption spectrometry. Rare Metals 26:541–546. doi:10.1016/S1001-0521(08)60004-2

Zhou J, Hou W, Qi P, Gao X, Luo Z, Cen K (2013) CeO2–TiO2 sorbents for the removal of elemental mercury from syngas. Environ Sci Technol 47:10056–10062. doi:10.1021/es401681y

Lian N, Chang X, Zheng H, Wang S, Cui Y, Zhai Y (2005) Application of dithizone-modified TiO2 nanoparticles in the Preconcentration of trace chromium and lead from sample solution and determination by inductively coupled plasma atomic emission spectrometry. Microchim Acta 151:81–88. doi:10.1007/s00604-005-0381-0

Yang Y, Wen J, Wei J, Xiong R, Shi J, Pan C (2013) Polypyrrole-decorated Ag TiO2 nanofibers exhibiting enhanced photocatalytic activity under visible light illumination. ACS Appl Mater Interfaces 5:6201–6207. doi:10.1021/am401167y

Zhang Z, Yuan Y, Liang L, Cheng Y, Xu H, Shi G, Jin L (2008) Preparation and photoelectrochemical properties of a hybrid electrode composed of polypyrrole encapsulated in highly ordered titanium dioxide nanotube array. Thin Solid Films 516:8663–8667. doi:10.1016/j.tsf.2008.04.079

Alumaa A, Hallik A, Sammelselg V, Tamm J (2007) On the improvement of stability of polypyrrole films in aqueous solutions. Synth Met 157:485–491. doi:10.1016/j.synthmet.2007.05.006

Farooq U, Khan MA, Athar M, Kozinski JA (2011) Effect of modification of environmentally friendly biosorbent wheat (Triticum aestivum) on the biosorptive removal of cadmium (II) ions from aqueous solution. Chem Eng J 171:400–410. doi:10.1016/j.cej.2011.03.094

Bianchin JN, Martendal E, Mior R, Alves VN, Araújo CST, Coelho NMM, Carasek E (2009) Development of a flow system for the determination of cadmium in fuel alcohol using vermicompost as biosorbent and flame atomic absorption spectrometry. Talanta 78:333–336. doi:10.1016/j.talanta.2008.11.012

Musico YLF, Santos CM, Dalida MLP, Rodrigues DF (2013) Improved removal of lead (II) from water using a polymer-based graphene oxide nanocomposite. J Mater Chem A 11:3789–3796. doi:10.1039/C3TA01616A

Wang Y, Chen H, Tang J, Ye G, Ge H, Hu X (2015) Preparation of magnetic metal organic frameworks adsorbent modified with mercapto groups for the extraction and analysis of lead in food samples by flame atomic absorption spectrometry. Food Chem 181:191–197. doi:10.1016/j.foodchem.2015.02.080

Mehdinia A, Kayyal TB, Jabbari A, Aziz-Zanjani MO, Ziaei E (2013) Magnetic molecularly imprinted nanoparticles based on graftingpolymerization for selective detection of 4-nitrophenol in aqueous samples. J Chromatogr A 1283:82–88. doi:10.1016/j.chroma.2013.01.093

Li Y, Zhang M, Guo M, Wang X (2009a) Preparation and properties of a nano TiO2/Fe3O4 composite superparamagnetic photocatalyst. Rare Met 28:423–427. doi:10.1007/s12598-009-0082-7

Mehdinia A, Asiabi M, Jabbari A (2015) Trace analysis of Pt (IV) metal ions in roadside soil and water samples by Fe3O4/graphene/polypyrrole nanocomposite as a solid-phase extraction sorbent followed by atomic absorption spectrometry. Int J Environ Anal Chem 95:1099–1111. doi:10.1080/03067319.2015.1085523

Li J, Feng J, Yan W (2013) Synthesis of polypyrrole-modified TiO2 composite adsorbent and its adsorption performance on acid red G. J Appl Polym Sci 128:3231–3239. doi:10.1002/app.38525

Cheng Q, He Y, Pavlinek V, Li C, Saha P (2008) Surfactant-assisted polypyrrole/titanate composite nanofibers: Morphology, structure and electrical properties. Synth Met 158:953–957. doi:10.1016/j.synthmet.2008.06.022

Xu JC, Liu WM, Li HL (2005a) Titanium dioxide doped polyaniline. Mater Sci Eng C Mater Biol Appl 25:444–447. doi:10.1016/j.msec.2004.11.003

George S (2000) Infrared and Raman characteristic group frequencies tables and charts, third edn. Wiley, New York

Xie Y, Du H (2012) Electrochemical capacitance performance of polypyrrole–titania nanotube hybrid. J Solid State Electrochem 16:2683–2689. doi:10.1007/s10008-012-1696-5

Xu JC, Liu WM, Li HL (2005b) Titanium dioxide doped polyaniline. Mater Sci Eng C 25:444–447. doi:10.1016/j.msec.2004.11.003

Behbahani M, Bide Y, Bagheri S, Salarian M, Omidi F, Nabid MR (2016) A pH responsive nanogel composed of magnetite, silica and poly(4-vinylpyridine) for extraction of Cd(II), Cu(II), Ni(II) and Pb(II). Microchim Acta 183:111–121. doi:10.1007/s00604-015-1603-8

Pytlakowska K (2016) Dispersive micro solid-phase extraction of heavy metals as their complexes with 2-(5-bromo-2-pyridylazo)-5-diethylaminophenol using graphene oxide nanoparticles. Microchim Acta 183:91–99. doi:10.1007/s00604-015-1596-3

Suleiman JS, Hu B, Peng H, Huang C (2009) Separation/preconcentration of trace amounts of Cr, Cu and Pb in environmental samples by magnetic solid phase extraction with bismuthiol-II-immobilized magnetic nanoparticles and their determination by ICP-OES. Talanta 77:1579–1583. doi:10.1016/j.talanta.2008.09.049

Barbosa AF, Segatelli MG, Pereira AC, Santos AS, Kubota LT, Luccas PO, Tarley CRT (2007) Solid-phase extraction system for Pb2+ ions enrichment based on multiwall carbon nanotubes coupled on-line to flame atomic absorption spectrometry. Talanta 71:1512–1519. doi:10.1016/j.talanta.2006.07.026

Li Z, Chang X, Hu Z, Huang X, Zou X, Wu Q, Nie R (2009b) Zincon-modified activated carbon for solid-phase extraction and preconcentration of trace lead and chromium from environmental samples. J Hazard Mater 166:133–137. doi:10.1016/j.jhazmat.2008.11.006

Karimi M, Shabani AM, Dadfarnia S (2015) Deep eutectic solvent-mediated extraction for ligand-less preconcentration of lead and cadmium from environmental samples using magnetic nanoparticles. Microchim Acta 183:563–571. doi:10.1007/s00604-015-1671-9

Pirouz MJ, Beyki MH, Shemirani F (2015) Anhydride functionalised calcium ferrite nanoparticles: a new selective magnetic material for enrichment of lead ions from water and food samples. Food Chem 170:131–137. doi:10.1016/j.foodchem.2014.08.046

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOCX 84 kb)

Rights and permissions

About this article

Cite this article

Mehdinia, A., Shoormeij, Z. & Jabbari, A. Trace determination of lead(II) ions by using a magnetic nanocomposite of the type Fe3O4/TiO2/PPy as a sorbent, and FAAS for quantitation. Microchim Acta 184, 1529–1537 (2017). https://doi.org/10.1007/s00604-017-2156-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-017-2156-9