Abstract

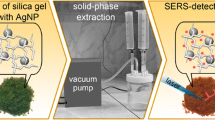

We demonstrate the applicability of ionic liquid-modified silica-coated Mn3O4 nanoparticles (NPs) as a sorbent for solid-phase extraction and preconcentration of Ag(I) ion without a chelating agent. The size, morphology and surface coating of the nano-sorbent were characterized via X-ray diffraction analysis, scanning electron microscopy and Fourier transform IR spectroscopy. Following desorption with HCl, silver was quantified by AAS. Under optimized experimental conditions, the calibration graph is linear in the 0.8 − 320 ng mL−1 concentration range (with an r2 of 0.9970). The limit of detection and limit of quantification are 0.2 and 0.8 ng mL−1, respectively. The relative standard deviation (for n = 6; at an Ag(I) concentration of 60 ng mL−1) and preconcentration factor are 1.9 % and 50, respectively. The method was used to determine Ag(I) in (spiked) water samples and in radiology films. The accuracy of the method was confirmed by successfully analyzing the certified reference material NIST SRM 1566b.

Silica-coated Mn3O4 nanoparticles modified with an ionic liquid are shown to be viable materials for solid phase extraction of silver(I) ions with a preconcentration factor of 50

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silver is widely used in consumer products ranging from disinfecting medical devices and home appliances to water treatment. These widespread applications have resulted in increased silver content of environmental water samples. Exposure to relatively high levels of silver compounds may cause breathing problems, lung and throat irritation, stomach pain and pigmentary disorders. Skin contact with silver compounds has been found to cause allergic reactions in some people [1]. Therefore, highly-sensitive analytical methods for the determination of trace levels of silver need to be established. Up to now, variety of methods including flame atomic absorption spectrometry [2], spectrophotometric methods [3], voltammetry [4], spectrofluorometry [5] inductively coupled plasma optical emission spectrometry [6, 7], inductively coupled plasma mass spectroscopy [8], ion exchange chromatography with chemiluminescence detection [9] Rayleigh light-scattering [10], and capillary zone electrophoresis [11] have been used for trace determination of silver in different samples.

In the all reported analytical procedures, sample preparation is the most critical step, since direct trace determination of elements appears to be difficult task. A successful sample preparation for most analytical techniques has multifarious roles related to analyte extraction, pre-concentration and clean-up from interfering species or to improve the detectability of the analytical techniques [12, 13]. Solid phase extraction (SPE) has become a well-established sample preparation method to pre-concentrate the analyte and separate it from the interferences, because of its simplicity, high pre-concentration factor, minimum eluent volume, reduced disposal cost, rapidity and ability to attain high recoveries [14, 15]. In SPE procedure, the choice of appropriate adsorbent is an important factor to achieve quantitative recoveries and high enrichment factors. So far, several types of SPE sorbents such as dithizone-modified naphthalene [2], polymeric supports [16–18], chelating resin [19], activated carbon [20] and functionalized silica [21] have been reported for the selective pre-concentration and determination of silver.

Recently, nanosized materials have gained more attention due to their highly chemical activity and adsorption capacities to many metal ions. Nanomaterials possess a series of unique physical and chemical properties that make them suitable adsorbents for SPE procedures. Metal oxides nanoparticles as a class of nanosized materials exhibit intrinsic surface reactivity and high surface areas, and can strongly chemisorb many substances [22]. Among metal oxides, nanometer-sized Mn3O4 with notable increased surface area, high sorption capacity and strong acid sites is expected to display better performance as a good sorbent for removing metal ions from aqueous media. However, when packed into a SPE column, Mn3O4 nanoparticles give rise to the formation of flocks or gels due to their high free energy states. Hence, these nanometer-sized metal oxides were not selective and not suitable for samples with complicated matrices [23]. Therefore, a suitable coating is essential to prevent the mentioned limitations. It has been demonstrated that the formation of a passive coating of inert materials such as silica on the surfaces of metal oxide nanoparticles could help to prevent their aggregation, improve their chemical stability and allows achieving reproducible experimental conditions [24]. In addition, surface silanol groups could offer many possibilities for further surface modification such as the introduction of hydroxyl, carboxyl and amino groups.

Ionic liquids (ILs) have many fascinating properties, including wide liquid ranges, low volatilities, good thermal stabilities, electrolytic conductivity, wide range of viscosities, adjustable miscibility, reusability, and non-flammability. Imidazolium-based ILs present a great extraction capability toward different analytes with which they can interact by electrostatic, hydrophobic and π–π interactions. On the other hand, they could covalently bond on silica via n-alkyl chains. Consequently, the surface modifying of silica particles with imidazolium-based ILs can enhance their stability against flocculation in aqueous media due to the additional steric/electrostatic repulsive forces, and increases the versatility of the technique even improving the selectivity of the extraction procedures.

This article describes ionic liquid-modified silica coated Mn3O4 nanoparticles as a new solid phase extractor for separation of Ag(I) ions from aqueous solutions. To the best of our knowledge, this is the first time that ionic liquid-modified silica coated Mn3O4 nanoparticles (Mn3O4@SiO2@IL) have been used as an adsorbent for separation and pre-concentration of Ag(I) ions. The effect of experimental parameters affecting the extraction efficiency was studied and optimized. Under the optimized conditions, the enrichment factor of the method, detection limit and adsorption capacity of the nanosorbent for Ag(I) ion were 50, 0.2 and 56.9 mg g−1, respectively. To evaluate the applicability of the method, it was applied to the determination of Ag(I) ion in different water samples and in radiology films.

Experimental

Apparatus

A SpectrAA 220 (Varian, Australia, http://www.agilent.com) flame atomic absorption spectrometer was used for the determination of silver. It was equipped with a hallow cathode lamp and an air/acetylene burner. The instrumental parameters were as follows: wavelength, 328.1 nm; lamp current, 5 mA; band pass, 0.5 nm. The flame composition was controlled at an acetylene flow rate of 1.5 L min−1 and air flow rate of 3.5 L min−1. A 2 mL polypropylene cartridge (30 × 7 mm i.d.) (Shafa Co., Iran, http://www.shafapharma.com) packed with 320 mg of IL-modified silica coated Mn3O4 was used to pre-concentrate the analyte in SPE procedures. To prevent material losses, a small portion of cotton was used to block both sides of the cartridge. The flow rate of solution through the column was controlled with an air-driven fluid pump model 440 (Rocker Scientific Co., Taiwan, http://www.rocker.com).

To identify the crystal structure of the nanosorbent, powder X-ray diffraction (XRD) measurements were performed at room temperature by employing a D8 Advance (Bruker, Germany, http://www.bruker.com) instrument with Cu-Kα radiation (1.54 Å), an acceleration voltage of 40 kV, and a current of 35 mA. In addition, a Vector 22 (Bruker, Germany) Fourier transform infrared spectrometer was employed to elucidate the functional groups present in the sorbent. FT-IR spectra were recorded in the range of 4000–400 cm−1 at 4 cm−1 resolution using the conventional KBr pellet technique with a ratio sample/KBr of 1:100 by mass. A scanning electron microscope model LEO1430vp (Carl Zeiss, Germany, https://www.microscopy.zeiss.com) was used to examine the morphological characteristics of the sorbent.

The pH values were measured with a digital pH-meter model 827 (Metrohm Ltd., Switzerland, https://www.metrohm.com) supplied with a glass-combined electrode. An EX. 1200–4 L electrical furnace (Exciton Co., Iran) was applied to control the temperature in the sorbent synthesis process. An electronic analytical balance model PB303 (Mettler Toledo, Switzerland, https://www.mt.com) was used to weight the solid materials.

Standard solutions and reagents

All chemicals used were of analytical-reagent grade and all solutions were prepared with high-purity deionized water (Shahid Ghazi Co., Tabriz, Iran, http://www.sgco-infusion.com). A stock solution of 1000 mg L−1 Ag(I) was prepared by dissolving appropriate amount of AgNO3, obtained from Merck (Darmstadt, Germany, http://www.merck.com), in deionized water and stored in a dark place. The working solutions were prepared by stepwise diluting the stock solution. Ethanol, hydrochloric acid, nitric acid, disodium hydrogenophosphate (99 %), tetraethylorthosilicate (TEOS, 98 %), 3-chloropropyltrimethoxysilane, ammonia (25 %), N-methylimidazole, polyethyleneglycol (PEG, 10,000 Da), NaOH solution (32 %) and Mn(NO3)2 · 4H2O (99 %) were purchased from Merck. Toluene, acetone, diethyl ether, acetonitrile and H2O2 (35 %) were purchased from Acros organics (New Jersey, USA, http://www.acros.com). 0.1 mol L−1 phosphate buffer solutions with various pH values were prepared by dissolving an appropriate amount of Na2HPO4 in deionized water and adjusting the pH values with 0.1 mol L−1 HCl or NaOH solutions. A standard reference material, SRM 1566b (Oyster Tissue) (from National Institute of Standards and Technology, Giathersburg, MD, USA, http://www.nist.gov) was used for validation of the presented method. All the plastic and glassware used for the trace analysis were kept in 15 % (v/v) nitric acid at least overnight and rinsed three times with deionized water prior to use.

Synthesis of ionic liquid immobilized on silica coated Mn3O4 nanoparticles

The synthesis of the nanosorbent was carried out following four defined steps. First of all, Mn3O4 nanoparticles were prepared by polyethylene glycol-assisted hydrothermal route according to the procedure described by Durmus & et al. [25]. 1.4 g of PEG (as the surfactant) with a molecular mass of about 10,000 Da was dissolved in 10 mL deionized water and added to a beaker containing 4 g Mn(NO3)2.4H2O. Under continuous stirring, an excessive amount of 2 mol L−1 NaOH was added until the pH of the solution reached around 10 to form Mn(OH)2 gel. Afterwards, a 20 mL of H2O2 (35 %) was dropped into the suspension. Finally, it was transferred into a 100 mL Teflon-lined stainless-steel autoclave and was kept at 160 °C for 16 h, then cooled to room temperature. The brown product was centrifuged and washed three times with deionized water and acetone, then dried at 70 °C for 3 h.

Silica has been considered as one of the most ideal shell materials due to its reliable chemical stability and versatility in surface modification via silanol groups [26]. In a second step, the Mn3O4 nanoparticles were coated with silica following the Stöber process [27] with some modifications. For this purpose, 2.2 g Mn3O4 nanoparticles were dispersed in the mixture of ethanol (160 mL), deionized water (40 mL) and ammonium hydroxide solution (2 mL, 25 %). Then, 2.2 mL of TEOS was added and followed by stirring at 25 °C for 24 h. The produced particles (Mn3O4@SiO2) were washed several times with deionized water to eliminate excess reactants and dried at 65 °C.

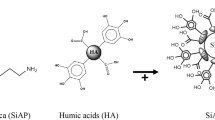

Thirdly, 1-methyl-3-[(3-trimethoxysilyl)propyl] imidazolium chloride [MTMSPIm]+ [Cl]− was synthesized following a procedure described elsewhere [28]. Briefly, N-methylimidazole (2.38 mL) was added to 3-chloropropyltrimethoxysilane (7.22 mL) and then refluxed for 96 h at 90 °C. The resultant mixture was washed with diethyl ether and dried under vacuum at room temperature. The synthesis route was illustrated in Scheme 1.

Finally, in order to prepare ionic liquid immobilized on silica coated Mn3O4 nanoparticles, 1 g of as-prepared ionic liquid was dispersed in 60 mL toluene by ultrasonification for 10 min. Afterward, 1 g Mn3O4@SiO2 was added and the mixture was refluxed at 90 °C for 24 h. The obtained product (Mn3O4@SiO2@IL) was rinsed several times with deionized water and dried at 60 °C [29]. Illustration of the procedure is shown in Scheme 1.

Column preparation

Mn3O4@SiO2@IL was employed as a nanosorbent in the SPE procedure. For this purpose, the SPE column was prepared by introducing 320 mg of the nanosorbent into a 2 mL polypropylene cartridge. The ends of the column were plugged with a small portion of cotton to retain the nanosorbent in the column. Prior to each use, the column should be cleaned with 5 mL of 3 mol L−1 HCl solution and conditioned by passing 5 mL of deionized water.

Sample preparation

Water samples including tap water, mineral water, spring water and well water were collected from local sources. After sampling, they were filtered through 0.45 μm pore-size cellulose filter, transferred to the PTFE container and stored in refrigerator at 4 °C. Then, aliquots of 50 mL of each sample were analyzed by following the procedure described in “General procedure” section.

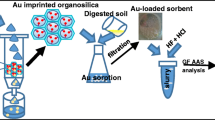

Radiology film samples were dissolved according to the following procedure [2]. 10 mL of concentrated nitric acid was added to 50 mg of radiology film sample in a beaker and boiled for 20 min. The resulting solution was then transferred into a 50 mL volumetric flask and diluted to the mark with deionized water. Finally, the solution was taken for analysis according to the “General procedure”.

An accurately measured amount (25 mg) of the standard reference material (NIST SRM 1566b, Oyster Tissue) was heated on a hot plate at 120 °C for 45 min in the glass beaker containing mixture of concentrated nitric acid 65 % (10 mL) and hydrogen peroxide 35 % (5 mL) after covering with a clock glass [30]. Afterward, the sample was heated at 150 °C for 45 min and the heating process was continued to dryness of the sample at 200 °C. Then, the sample was cooled down to room temperature and the residue was dissolved in a 1.0 mL of HNO3 0.1 mol L−1. After dilution with deionized water, the pH was adjusted to nearly 3 by adding diluted NaOH solution. Finally, the solution was transferred into a 50.0 mL volumetric flask and after dilution to the mark with the deionized water, the concentration of Ag(I) was determined as described in the “General procedure” section.

General procedure

Aliquots of 50.0 mL sample or aqueous standard solution containing silver ions in the range of 0.8 − 320 ng mL−1 (pH 3, adjusted by phosphate buffer solution) was passed through a SPE column, packed with 320 mg of Mn3O4@SiO2@IL nanosorbent, at a controlled flow rate in 5.0 mL min−1 by an air-driven fluid pump. After sample loading, the retained analyte on the column was eluted with 1 mL of 3 mol L−1 HCL solution. Finally, the absorbance of silver atoms as an analytical signal was measured by atomic absorption spectrometer at λ = 328.1 nm. A reagent blank was prepared using a similar procedure but without silver ion.

Results and discussion

Choice of adsorbent

The main requirements for a substance to work effectively as an SPE adsorption material are as follows: it should consist of a stable and insoluble porous matrix having suitable active groups, typically organic groups, which can interact with analytes; it should achieve fast and quantitative sorption; and it should have high adsorption capacity, good regenerability, and surface area accessibility. Recently, metal oxide nanoparticles are widely used in SPE procedures. However, it should be noted that pure metal oxide nanoparticles (such as Fe3O4, Mn3O4, Mn2O3 and Fe2O3) can easily form large aggregates, which may alter their magnetic properties [31]. Moreover, these nanometer-sized metal oxides are not target-selective and not suitable for samples with complicated matrices because of their low capacities. Hence, surface modification can not only improve their dispersibility but also provide an active surface to interact with certain molecules [7].

Silica has been considered as one of the most ideal shell materials due to its reliable chemical stability, biocompatibility and versatility in surface modification. The core–shell silica magnetic nanoparticles have high surface areas. Also, the silica shell can efficiently prevent the aggregation and chemical decomposition of nanoparticles in a harsh environment [32]. On the other hand, silica coated magnetic nanoparticles can be fashioned with a wide range of materials using surface modification techniques and giving rise to highly selective metal ions extraction systems. Although according to the literature, silica-coated Fe3O4 nanoparticles modified with g-mercaptopropyltrimethoxysilane [31] or 1- N-(3-(Triethoxysilyl)propyl)isonicotinamide [33] have been used for SPE of trace amounts of Cd, Cu, Hg, and Pb, there is no report on the use of bare or modified Mn3O4 nanoparticles for the extraction of trace metal ions. Consequently, in the present work, to find the best adsorbent for extraction of silver(I) ion as a target analyte from aqueous solutions, the synthesized adsorbents including SiO2, Mn3O4 nanoparticles, ionic liquid-coated silica (SiO2@IL), silica-coated Mn3O4 (Mn3O4@SiO2) and silica-coated Mn3O4 modified with ([MTMSPIm] Cl) ionic liquid (Mn3O4@SiO2@IL) were individually tested. As can be seen from Fig. 1, the extraction efficiency is negligible in case of unmodified SiO2 and Mn3O4 nanoparticles. Mn3O4@SiO2 core-shell nanostructures are present in an aggregated form. The presence of aggregates could be attributed to the formation of H-bond between the silica shells due to the presence of Si-OH bond over the shell surface. Also, Mn3O4 is a magnetic material and there is an inherent tendency of these metal oxide nanoparticles to agglomerate. Nevertheless, the retention of the analyte on the Mn3O4@SiO2@IL is the highest, indicating that the adsorption amount is positively related with the IL. Accordingly, Mn3O4@SiO2@IL was employed as an adsorbent for further experiments.

Characterization of the nanosorbent

Characterization of the synthesized Mn3O4 nanoparticles, Mn3O4@SiO2 and Mn3O4@SiO2@IL was performed using Fourier transform infrared (FT-IR) spectroscopy, powder X-ray diffraction (XRD) and scanning electron microscopy (SEM). Figure 2a shows XRD pattern of Mn3O4 nanoparticles. It can be observed the characteristic reflections of (112), (200), (103), (211), (004), (220), (204), (015), (312), (303), (321), (224), (116) and (400) planes of a crystalline Mn3O4 which is in agreement with the results reported in literature [25]. To characterize the surface nature of the nanoparticles, the infrared absorption spectroscopy was used. Figure 2b presents the FT–IR spectrum of Mn3O4 nanoparticles synthesized via polyethylene glycol-assisted hydrothermal route. The bands observed in the range 400–600 cm−1 are assigned to the intrinsic stretching vibrations of metal ions in the crystal lattice. The bands with maximum peak at around 1084 and 1151 cm−1 can be ascribed to C–O stretching modes and C–O–C bending vibrations that indicate the presence of linkage in the absorbed molecules due to PEG. A broad band is observed at around 2640 cm−1, which is responsible for the stretching modes of methylene (−CH2–) and methyl (−CH3–). The broad peak around 3422 cm−1 and weak peak around 1637 cm−1 are attributed to the stretching and bending vibration of water molecules [25].

Moreover, FT-IR spectra of Mn3O4@SiO2 (1), [MTMSPIm] [Cl] ionic liquid (2) and Mn3O4@SiO2 modified with [MTMSPIm] [Cl] ionic liquid (Mn3O4@SiO2@IL) (3) are shown in Fig. 3a. For silica coated Mn3O4, the strong bond at around 1100 cm−1 represents Si–O bonds, while the bond at 592 cm−1 corresponds to Mn–O vibrations of the Mn3O4 core, and the bond at around 797 cm−1 is the characteristic of Si–O–Mn, which implies that SiO2 is chemically bonded to Mn3O4. The bonds at 3420 and 1637 cm−1 correspond to the stretching and bending vibrations of Si–OH [28]. The FT-IR spectrum of ionic liquid modified Mn3O4 nanoparticles shows the characteristic bonds of ionic liquids. The introduction of imidazole groups in the Mn3O4 nanoparticles surface involves the appearance of a band around 1635 cm−1, which is assigned to the –NH– stretching vibration of imidazole ring. Slightly intense bands corresponding to the C–H stretching vibrations can be observed at 2922 and 2961 cm−1 [26]. Moreover, the bonds at around 1437 and 1199 cm−1 correspond to the bending vibrations of C − H and/or N − H. FT − IR spectra prove that silica coated Mn3O4 nanoparticles are bonded with imidazolium based [MTMSPIm] [Cl] ionic liquid.

In addition, SEM images were used to obtain information on the particle size and morphology of as-prepared nanoparticles. Figure 3b shows the typical SEM images of Mn3O4@SiO2 nanoparticles before and after modification with the ionic liquid. It can be seen that the particles are mainly spherical with average diameter of 60 nm. The size and morphology of the nano-particles did not significantly change after anchoring the 1-methyl-3-[(3-trimethoxysilyl)propyl] imidazolium chloride ionic liquid onto the silica shell. This finding suggested that Mn3O4@SiO2 nano-particles were coated by a thin layer of the ionic liquid. This type of coating can be provided abundant reaction sites for grafting.

Adsorption/desorption mechanism

Based on findings of Neeraj and coworkers, there is a complexation reaction between transition metal ions and imidazole ring of the ionic liquids [34]. According to the hard–soft-acid–base theory, the atom N in imidazole ring of [MTMSPIm]+ [Cl]− ionic liquid belongs to the soft base and has good affinity for the soft acids. Hence, the silver ion, as a soft acid, could be extracted by the ionic liquid. It seems that an anionic complex is firstly formed between Ag(I), H2PO4 − and [Cl]− in the ionic liquid structure, at pH 3 (phosphate buffer solution). Then, the anionic complex is combined with [MTMSPIm]+ to form a neutral compound, which is extracted by the ionic liquid [35]. On the other hand, the recovery of Ag(I) ion obviously decreased when the pH of sample solution was less than 2.5 (Fig. S1, Electronic Supplementary Material, ESM), indicating a feasibility of desorption with high acidity solution. In the acidic media, the donor atoms in the adsorbent are protonized and the complexes of metal ions and adsorbent become weak. Moreover, desorption of Ag(I) ions from the adsorbent may be due to a complexation reaction between Ag(I) and chloride ions to produce an anionic complex, AgCl2 −, by using high concentrations of HCl solution as an elution reagent.

Optimization of solid phase extraction conditions

To achieve the optimum conditions for selective separation/pre-concentration of silver ions, the effect of several parameters such as pH, the amount of nanosorbent, the sample volume and the elution conditions on the extraction efficiency was studied and discussed in the Electronic Supplementary Material. In all cases, the recovery percentage used as the analytical signal, which was calculated from the amount of silver ions in the starting sample and the amount of silver ions eluted from the column. Method optimization was carried out using the one variable at a time method with a concentration of 60 ng mL−1 of the silver ions. In the impact parameters optimization procedure, the limits marked on the figures were obtained from three experiments that repeated under the same conditions.

Adsorption capacity

The adsorption capacity (q e , mg g−1) of the nanosorbent for Ag(I) ion was calculated using the following equation:

where, C 0 (mg L−1) and C e (mg L−1) are the initial and equilibrium concentrations of the analyte in aqueous solution, respectively, V(L) is the volume of sample solution, and W (g) is the mass of used Mn3O4@SiO2@IL nanocomposite. To determine the adsorption capacity, 100 mL of sample solution containing 250 mg L−1 Ag(I) (pH 3.0) was transferred into a beaker containing 320 mg of the nanosorbent. The solution was shaken for 60 min at room temperature to reach equilibrium. Then, the supernatant is filtered through a filter paper and loaded Ag(I) in the nanosorbent was stripped with 1 mL of 3.0 mol L−1 HCl. Finally, the concentration of the analyte was determined by flame atomic absorption spectrometry after appropriate dilution. As a result, capacity of the Mn3O4@SiO2@IL nanosorbent for Ag(I) was found to be 56.9 mg g−1.

Reusability of the nanosorbent

The potential reusability and stability of the nanosorbent was studied by monitoring the change in recovery of the analyte through several adsorption–elution cycles. It was observed that the column packed with 320 mg of the nanosorbent could be reused up to 300 times without decrease in recovery of the analyte. Based on the obtained results, % CV of absolute recovery values after 300 times adsorption/desorption cycles (for n = 20; at an Ag(I) concentration of 60 ng mL−1) was 3.7 % with an average recovery of 98.0 %, suggesting the good reusability of the sorbent.

Study of interferences

The pre-concentration procedures and thus recoveries of analytes may be affected by the other constituents of the samples. Therefore, the reliability of the presented method should be examined in the presence of some potentially interfering ions. For this purpose, the possible interfering elements were added to 50 mL of aqueous solutions containing 60 ng mL−1 Ag(I) ions as their nitrate salts. The tolerance limit was considered as the highest ion concentration causing ±5 % deviation in recovery of the analyte. As can be seen from Table 1, the tested potential interfering ions have no significant effect on the recovery of Ag(I) ions.

Analytical figures of merits

Under the optimized experimental conditions, the analytical features of the presented method, such as the linear range of the calibration graph, the limit of detection, the accuracy and the precision were examined. The calibration graph was linear in the range of 0.8 − 320 ng mL−1 for silver ions with a correlation coefficient of about 0.9985 applying the preconcentration procedure. However, the calibration graph without using the pre-concentration procedure was linear in the range of 40–16,000 ng mL−1 with the same correlation coefficient. The calibration equations relating to with and without preconcentration procedure were ΔA = 2.439 C + 0.069 and ΔA = 0.048 C + 0.069, respectively, where ΔA is the blank-corrected absorbance and C is the concentration of Ag(I) ion in ng mL−1. The enhancement factor, calculated as the ratio of slope of preconcentrated samples to that obtained without preconcentration, was 50.8. The limit of detection (LOD) and limit of quantification (LOQ) of this method, defined as 3S b /m, and 10S b /m (where S b is the standard deviation of six replicate measurements of the blank and m is the slope of the calibration curve) were 0.2 and 0.8 ng mL−1, respectively. The relative standard deviation resulting from the analysis of six replicates of 50 mL solution containing 60 ng mL−1 of Ag(I) ion under optimum experimental conditions was 1.9 %, showing the good precision of the developed method. The reproducibility of the method was evaluated by repeated analysis of Ag(I) during the course of experimentation by the same adsorbents synthesized on different days under the optimized experimental conditions. For batch to batch variation, solutions of Ag(I) ion at concentrations of 60 ng mL−1 were determined in triplicate, and the RSD (n = 5) was found to be 2.56 %.

Analysis of real samples and method validation

To test the applicability of the method, it was used to determine Ag(I) in radiology film and water samples including tap water, mineral water, spring water and well water. The obtained results are summarized in Table 2. In order to evaluate the accuracy of the presented method, known quantities of Ag(I) ions were added into the real samples, and then the samples were prepared and analyzed according the general procedure described in Experimental section. As can be seen from Table 2, recoveries between 95.0 and 102.4 % were obtained, which confirm the accuracy of the developed method. Furthermore, the accuracy of the method was also verified by determining the content of Ag(I) ions in a certified reference material, NIST SRM 1566b (Oyster Tissue), with certified silver content of 0.666 ± 0.009 μg g−1. The obtained value for silver by using the presented procedure was 0.648 ± 0.008 μg g−1 (mean of three determinations ± standard deviation). It was found that there is no significant difference at 95 % confidence level between result found by the developed method and certified value according to Student t-test. It can be concluded that the presented procedure is reliable for the determination of silver in different real samples including water samples, radiology film and biological samples.

Comparison with other methods

The method was compared with other published techniques for Ag(I) determination in Table 3. Limit of detection, linearity, precision and the recoveries of this method are comparable or better than those of the reported methods. In comparison with the other methods, the developed method has the merits of considerable analysis speed, good separation efficiency and high sensitivity. The method is presented as a suitable alternative to more expensive instruments for Ag determination at trace levels. This methodology is a reproducible, simple and low cost technique and does not require further instrumentation and it can be used with regular FAAS equipment.

Conclusions

In the present work, 1-methyl-3-[(3-trimethoxysilyl)propyl] imidazolium chloride ionic liquid was covalently immobilized on the surface of silica coated Mn3O4 nanoparticles and applied as an adsorbent for the selective solid phase extraction of silver ion from aqueous solutions. The covalent immobilization provides the ionic liquid coating with a high stability avoiding it loses in the extraction and elution process. This aspect is especially interesting since it allows the reuse of the nanosorbent up to 300 times after cleaning with 5 mL of 3 mol L−1 HCl solution and conditioning by 5 mL of deionized water. The enrichment factor (50), detection limit (0.2 ng mL−1) and adsorption capacity (56.9 mg g−1) of the new as-prepared nanosorbent for Ag(I) are satisfactory. Another advantage of the developed method is permitting to study in acidic medium that minimize precipitation of metal hydroxides. This work is a simple and fast method, and reveals the tremendous application potentials of ionic liquids in environmental and biological sample preparation.

References

Agency for toxic substances disease registry (ATSDR) (1990) Toxicological profile for silver. US department of health and human services, Atlanta

Fathi MR, Pourreza N, Purweis S (2009) Determination of silver by flame atomic absorption spectrometry after preconcentration on naphthalene modified with dithizone. J Chinese Chem Soc 56:725–728

Ghaedi M, Daneshfar A, Shokrollahi A, Ghaedi H, Arvin pili F (2007) Highly selective and sensitive spectrophotometric determination of trace amounts of silver ion in surfactant media using 2-mercaptobenzoxazole. Ann Chim 97:971–982

Zejli H, Hidalgo-Hidalgo de Cisneros JL, Naranjo-Rodriguez I, Temsamani KR (2007) Stripping voltammetry of silver ions at polythiophene-modified platinum electrodes. Talanta 71:1594–1598

Xiao Q, Huang S, Ge Y, He Z, Liu Y, Liang J (2010) A novel fluorescent silver ion biosensor based on nucleic acid molecular “light switch. J Fluoresc 20:541–549

Väisänen A, Suontamo R, Silvonen J, Rintala J (2002) Ultrasound–assisted extraction in the determination of arsenic, cadmium, copper, lead, and silver in contaminated soil samples by inductively coupled plasma atomic emission spectrometry. Anal Bioanal Chem 373:93–97

Tahmasebi E, Yamini Y (2014) Polythiophene-coated Fe3O4 nanoparticles as a selective adsorbent for magnetic solid-phase extraction of silver(I), gold(III), copper(II) and palladium(II). Microchim Acta 181:543–551

Jingyu H, Zheng L, Haizhou W (2002) Determination of trace silver in superalloys and steels by inductively coupled plasma-mass spectrometry. Anal Chim Acta 451:329–335

Jones P, Beere HG (1995) Ion chromatography determination of trace silver ions using hydrophilic resins with chemiluminescence detection. Anal Proc Incl Anal Commun 32:169–171

Zhao Y, Cao QE, Hu Z, Xu Q (1999) Synthesis of a new triazene reagent and its application for the determination of silver(I) by the Rayleigh light–scattering. Anal Chim Acta 388:45–50

Aguilar M, Farran A, Martinez M (1993) Determination of gold(I) and silver(I) cyanide in ores by capillary zone electrophoresis. J Chromatogr 635:127–131

Poole CF (2003) New trends in solid phase extraction. Trend Anal Chem 22:362–373

Aguilar M, Cortina JL, Sastre AM (2005) Analytical application of solvent extraction. In: Rydberg J, Cox M, Musikas C, Choppin GR (eds) Solvent extraction principles and practice, second. Taylor and Frans e-library, New York, pp 559–608

Żwir-Ferenc A, Biziuk M (2006) Solid phase extraction technique–trends, opportunities and applications. Pol J Envir Stud 15:677–690

Türker AR (2007) New sorbents for solid phase extraction for metal enrichment. Clean 35:548–557

Absalan G, Akhond M, Ghanizadeh AZ, Abedi ZA, Tamami B (2007) Benzil derivative of polyacrylohydrazide as a new sorbent for separation, preconcentration and measurement of silver(I) ion. Sep Purif Technol 56:231–236

El-Menshawy AM, Kenawy IM, El-Asmy AA (2010) Modification of chloromethylated polystyrene with 2-mercabtobenzothiazole for application as a new sorbent for preconcentration and determination of Ag+ from different matrices. J Hazard Mater 173:523–527

Medveď J, Matúš P, Bujdoš M, Kubová J (2006) Gold and silver determination in waters by SPHERON® thiol 1000 preconcentration and ETAAS. Chem Pap 60:27–31

Hosoba M, Oshita K, Katarina RK, Takayanagi T, Oshima M, Motomizu S (2009) Synthesis of novel chitosan resin possessing histidine moiety and its application to the determination of trace silver by ICP-AES coupled with triplet automated-pretreatment system. Anal Chim Acta 639:51–56

Jankowski K, Jackowska A, Łukasiak P (2005) Determination of precious metals in geological samples by continuous powder introduction microwave induced plasma atomic emission spectrometry after preconcentration on activated carbon. Anal Chim Acta 540:197–205

Wu HY, Chen CT, Hung IM, Liao CH, Vetrivel S, Kao HM (2010) Direct synthesis of cubic benzene-bridged mesoporous organosilica functionalized with mercaptopropyl groups as an effective adsorbent for mercury and silver ions. J Phys Chem C 114:7021–7029

Liu Y, Liang P, Guo L (2005) Nanometer titanium dioxide immobilized on silica gel as sorbent for preconcentration of metal ions prior to their determination by inductively coupled plasma atomic emission spectrometry. Talanta 68:25–30

Tiwari D, Laldanwngliana C, Choi CH, Lee SM (2011) Manganese-modified natural sand in the remediation of aquatic environment contaminated with heavy metal toxic ions. Chem Eng J 171:958–966

Butterworth MD, Illum L, Davis SS (2001) Preparation of ultrafine silica- and PEG-coated magnetite particles. Colloids Surf A Physicochem Eng Asp 179:93–102

Durmus Z, Tomaş M, Baykal A, Kavas H, Toprak MS (2011) PEG-assisted synthesis of Mn3O4 nanoparticles: a structural and magnetic study. Synth React Inorg Met-Org Nano-Metal Chem 41:768–773

Galán-Cano F, Alcudia-León MC, Lucena R, Cárdenas S, Valcárcel M (2013) Ionic liquid coated magnetic nanoparticles for the gas chromatography/mass spectrometric determination of polycyclic aromatic hydrocarbons in waters. J Chromatogr A 1300:134–140

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface 26:62–69

Naka K, Narita A, Tanaka H, Chujo Y, Morita M, Inubushi T, Nishimura I, Hiruta J, Shibayama H, Koga M, Ishibashi S, Seki J, Kizaka-Kondoh S, Hiraoka M (2008) Biomedical applications of imidazolium cation-modified iron oxide nanoparticles. Polym Adv Technol 19:1421–1429

Jiang Y, Guo C, Xia H, Mahmood I, Liu C, Liu H (2009) Magnetic nanoparticles supported ionic liquids for lipase immobilization: Enzyme activity in catalyzing esterification. J Mol Cata B 58:103–109

Silva EGP, Hatje V, Santos WNL, Costa LM, Nogueira ARA, Ferreira SLC (2008) Fast method for the determination of copper, manganese and iron in seafood samples. J Food Comp Anal 21:259–263

Huang C, Hu B (2008) Silica-coated magnetic nanoparticles modified with γ-mercaptopropyltrimethoxysilane for fast and selective solid phase extraction of trace amounts of Cd, Cu, Hg, and Pb in environmental and biological samples prior to their determination by inductively coupled plasma mass spectrometry. Spectrochim Acta B 63:437–444

Afkhami A, Shirzadmehr A, Madrakian T, Bagheri H (2014) Improvement in the performance of a Pb2+ selective potentiometric sensor using modified core/shell SiO2/Fe3O4 nano-structure. J Mol Liq 199:108–114

Behbahani M, Ali Akbari A, Amini MM, Bagheri A (2014) Synthesis and haracterization of pyridine functionalized magnetic mesoporous silica and its application for preconcentration and trace detection of lead and copper ions in fuel products. Anal Methods 6:8785–8792

Neeraj S, Loiseau T, Rao CNR, Cheetham AK (2004) Synthesis and structure of [C3N2H5][Cu(H2PO4)2Cl] H2O with a chain structure: the first example of an organically template copper (II) phosphate. Solid State Sci 6:1169–1173

Cui C, Hu B, Chen B, He M (2013) Ionic liquid-based magnetic solid phase extraction coupled with inductively coupled plasma-optical emission spectrometry for the determination of Cu, Cd, and Zn in biological samples. J Anal At Spectrom 28:1110–1117

Acknowledgments

The financial support from the Research Council of Azarbaijan Shahid Madani University (ASMU, Iran (Grant no. 10799)) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 108 kb)

Rights and permissions

About this article

Cite this article

Abdolmohammad-Zadeh, H., Javan, Z. Silica-coated Mn3O4 nanoparticles coated with an ionic liquid for use in solid phase extraction of silver(I) ions prior to their determination by AAS. Microchim Acta 182, 1447–1456 (2015). https://doi.org/10.1007/s00604-015-1468-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-015-1468-x