Abstract

A weak interlayer zone (WIZ) is a poor rock mass system with loose structure, weak mechanical properties, variable thickness, random distribution, strong extension, and high risk due to the shear motion of rock masses under the action of tectonism, bringing many stability problems and geological hazards, especially representing a potential threat to the overall stability of rock masses with WIZs in large underground cavern excavations. Focusing on the deformation and failure problems encountered in the process of excavation unloading, this research proposes comprehensive in situ observation schemes for rock masses with WIZs in large underground cavern on the basis of the collection of geological, construction, monitoring, and testing data. The schemes have been fully applied in two valuable project cases of an underground cavern group under construction in the southwest of China, including the plastic squeezing-out tensile failure and the structural stress-induced collapse of rock masses with WIZs. In this way, the development of rock mass failure, affected by the step-by-step excavations along the cavern’s axis and the subsequent excavation downward, could be observed thoroughly. Furthermore, this paper reveals the preliminary analyses of failure mechanism of rock masses with WIZs from several aspects, including rock mass structure, strength, high stress, ground water effects, and microfracture mechanisms. Finally, the failure particularities of rock masses with WIZs and rethink on prevention and control of failures are discussed. The research results could provide important guiding reference value for stability analysis, as well as for rethinking the excavation and support optimization of rock masses with WIZs in similar large underground cavern under high geostress.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A weak interlayer zone (WIZ) is a permanent deformation zone with different thickness and spacing in hard stratified rock masses in areas where regional geotectonic movement has been historically active. It is a poor rock mass system susceptible to water softening and weathering, with loose structure, weak mechanical properties, variable thickness, random distribution, strong extension, and high risk, due to the shear movement of soft, weak rock masses under the action of tectonism (Jia 1994; Feng and Wang 1995; Wang 1996; Xu et al. 2012). Hence, because of the poor mechanical properties of rock masses with a WIZ, it is inevitable that they induce many engineering stability problems including a number of dam foundation instabilities and dam breaks as well as rock mass shear slip failures in foundation pits. For example, the famous Italian Vajont dam reservoir landside event (Hendron and Patton 1987), the failure of the Austin Dam foundation in Texas, USA (Wang 1990), the dam break at the Malpasset Dam in France (Wang 1990), the Niagara mineral foundation pit groove damage (Bruneau et al. 2003), and the foundation pit wall rock shear dislocation in Gezhouba Dam hydropower station (Chu 1997), are all noteworthy. Additionally, its threat to the stability of large deep underground caverns could not be neglected, and it is now attracting widespread concern.

Unlike shallow engineering works, deeply buried underground engineering shows the characteristics of high side walls, large spans, high geostress, and complex geological conditions, which makes the rock masses with WIZ tend to have a series of complex and special engineering characteristics, such as the preconsolidation, the initial shear, the soft and hard interbedded rocks, and water softening or clay generation (Feng 1998; Wang et al. 2003; Lan and Tang 2008; Jiang et al. 2011; Xu et al. 2012; Indraratna et al. 1999, 2008, 2010). As a result, a variety of deformation and failure problems controlled by rock masses with WIZs are often met in excavation unloading of underground engineering in high geostress areas (Duan et al. 2016). The failures mainly include the relatively large deformation of upper and lower rock masses, plastic squeezing-out failure, and anchor bolt or anchor cable overload events (Jiang et al. 2011). During the construction of the powerhouse on the right bank in Xiangjiaba Hydropower Station in China, a shear dislocation occurred in the soft rock of the arch, causing adverse effects on powerhouse stability (Feng 1998). Due to the high geostress and high sidewall on the left-bank powerhouse in Xiluodu Hydropower Station, rock masses on the upstream sidewall formed a staggered displacement of 2–10 cm along the rock/WIZ interface (Lan and Tang 2008; Wang et al. 2003). Besides, a series of collapses have occurred in the arch and high sidewall due to the excavation unloading in the Baihetan Hydropower Station, making the excavation and support design of rock masses with WIZ become very difficult (Duan et al. 2016).

However, the current study of the failure mechanism of rock masses with WIZs is relatively simple, and the observational schemes of the failure process are rarely mentioned. Zhao and Sun (1978) propose that the failure mechanism of rock masses with WIZs is compression-extrusion. That is, under normal pressure, the WIZ is crushed to form a plastic zone, and the increased lateral pressure pushed the crushed material to the uncompressed elastic zone. Xu et al. (2012) adopted rock mass structure controlling theory to categorize the failure modes of rock masses with WIZs into tension crack failure, block-fall, and contact shear slip failure. The mechanical behavior analysis focuses on the shear strength and shear-strength-related models of the WIZ, mainly from the point of view of laboratory and field shear tests (Sun et al. 1981; Guo 1982; Xiao and Argelov 1991; Xu et al. 2012, 2013; Ladanyi and Archambault 1977; Lama 1978; Barla et al. 1987; Phien-wej et al. 1990; De Toledo and De Freitas 1993; Papaliangas et al. 1993; Indraratna et al. 1999, 2008, 2010). However, due to the complexity, differences, and particularities of the geological conditions in large underground cavern, the above researches have not given due weight to any study of the failure process of rock masses with WIZs. The limitations mainly manifest themselves in two aspects. For one thing, there are still lacking effective observation schemes to monitor the development process of failure, including the relationship between failure behaviors and excavation and support, and the correspondence between fracture evolution and failure development of rock masses with WIZs. For another, the failure mechanism of rock masses with WIZs mainly concerns the shear behaviors through the laboratory tests. That is, typical failure modes such as plastic squeezing-out tensile failure and structural stress-induced collapse in macro- and microscales have not been systematically revealed and explained by combining in situ observation and measurement with physical and mechanical tests. Consequently, based on the above researches, design and construction could not match the mechanical behaviors of rock masses with WIZs in high geostress conditions, which inevitably has brought great uncertainty and security risks to the project.

On account of the above, this research attempts to reveal the failure process of rock masses with WIZs in large underground cavern excavation. On the basis of the collection of geological, construction, monitoring, testing, and numerical analysis of data, the comprehensive in situ observation schemes for rock masses with WIZs are first proposed, consisting of observation content, observational instrumentations, and layout schemes of observation boreholes. Ulteriorly, the observation schemes have been fully applied in typical project cases, and the failure mechanism of rock masses with WIZs is explained on the macro- and microscales. Finally, the particularities of failure of rock masses with WIZs and the rethink on prevention and control of failures are discussed. According to the research results, the failure mechanism of plastic squeezing-out tensile failure and the structural stress-induced collapse under complex excavation process could be better understood. Support optimization in the area controlled by WIZs could also be dynamically adjusted.

2 In Situ Observation of Rock Mass Failure Controlled by WIZs

2.1 Observation Purpose

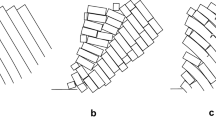

The instability failure of rock masses with a slightly inclined WIZ is controlled by the engineering characteristics, the high geostress, the scale of the cavern, the excavation blasting, the geological conditions, the supports, and so on, resulting in more complicated failure processes. With the advancing working face along cavern axis and the subsequent excavation downwards, several typical failure types would occur, key among which are three typical failure modes: plastic squeezing-out tensile failure, structural stress-induced collapse/fall blocks, and contact shear slip failure (see Fig. 1). However, there are few reports of the testing and analysis of the formation and evolution of the whole failure process of rock masses with WIZs. Lessons learned from failures shown in Fig. 1 tell us that the excavation and support design demands a full comprehension of the failure behavior of rock masses with WIZs near excavations. It is urgent to find practical and effective measures to record the development characteristics of rock mass failure controlled by WIZs, that is, the high-risk area near WIZs in underground excavations needs to be regularly observed.

Typical failure of rock masses with weak interlayer zones in a large underground cavern a plastic squeezing-out failure of the side wall in an underground powerhouse, b hanging wall rock collapse of WIZ in a transformer room, c contact shear slip of WIZ in the downstream sidewall of a main powerhouse (Ding et al. 2008)

2.2 Comprehensive Observational Instrumentations and Contents

A feasible in situ observation scheme should be able to detect the key warning signs of failures in rock masses with WIZs. Through good field practice, the authors have discovered that distinctive multi-information observations are direct and effective to study the formation and development process of failures, as shown in Fig. 2. Based on the site-specific geological and geotechnical conditions, the geostress distribution and the excavation schemes, the location where the failure is most likely to occur must be first estimated as soon as possible. Afterward, in order to capture the co-evolution of the key warning signs including internal rock displacement, stress changes, geological structure, and excavation damage zones of rock masses with WIZs, the associated observation instrumentations (i.e., acoustic velocity testing, multi-point extensometers, cable dynamometers, bolt stressmeters, a digital panoramic borehole camera system, shear dislocation distance monitoring device, and a microseismic monitoring system) are arranged in vicinity of the potential failure areas per suggested methods (Li et al. 2013; Wang et al. 2002; Hansmire 1978; Takahashi et al. 2006; Shen et al. 2008; Sun et al. 2010).

The observational instrumentations and their outputs are shown in Fig. 2. They could offer guiding significance to the research into the failure processes and mechanisms of rock masses with WIZs, even though they might not include all the monitoring of failures therein during cavern construction. It should be noted that the contact shear slip failure (an overall instability) rarely occurs in the current cavern excavations, and so the shear dislocation distance and microseismic monitoring system used for monitoring this kind of failure are not discussed here. Plastic squeezing-out tensile failure and structural stress-induced collapse are the main failure modes during excavation. They therefore become the focus of this research, with multi-point extensometers, bolt stressmeters, cable dynamometers, and a digital panoramic borehole camera system (see Fig. 3) included.

2.3 Layout Schemes of Observation Boreholes

During the staged excavation of a large underground cavern, rock masses with WIZs would continue to show all kinds of deformation and failure problems because of the continuously adjusted geostress and the high sidewall effect. When the WIZ is exposed near the arch roof or the arch foot, the rock masses become potentially dangerous, with collapse and shotcrete spalling occurring with the advancing working face along cavern axis and the subsequent excavation downwards (see Fig. 4a, b). When the WIZ cuts across the high sidewall, the relaxation of rock masses with WIZs would be sharply increased under the influence of layer-by-layer excavation unloading, leading to the development of large deformation, plastic squeezing-out tensile failure, and structural stress-induced collapse. Hence, to monitor such high-risk areas (see Fig. 4a–c) dynamically with the excavation of the cavern, the emphasis is that observation boreholes should always be arranged in the high-risk failure areas within WIZs.

Typical observation schemes of failure processes in rock masses with WIZs exposed in different locations by different observational instrumentations a WIZ exposed above the arch roof. b WIZ cutting though both upstream and downstream roof of the cavern/arch foot, c WIZ cutting though the side wall (numbers such as D-1 denote borehole numbers of different observational instrumentations)

Commonly, branch tunnels or other auxiliary tunnels (i.e., anchorage-monitoring tunnels, drainage tunnels) are usually designed and excavated around the large cavern for functional needs or guaranteeing the stability during construction and operation periods. These pre-excavated tunnels around the cavern become very useful to the layout of observation predrilled boreholes in rock masses with WIZs, since they could improve the accuracy and operability of instrumentations (see Fig. 4a–c). In addition, when some unexpected new potential failure areas arise during excavation, new observation boreholes need to be added.

-

(a)

Digital camera observation boreholes

Predrilled and follow-up boreholes are adopted for digital camera observation: they are required to pass through the potential failure area (see Fig. 4a–c). When the WIZ is exposed in the arch roof, boreholes need to be arranged before the excavation of the potential failure area of the top arch, drilled through the anchorage-monitoring tunnel, branch tunnel, and drainage gallery toward the upper and lower risk areas of arch roof and arch foot (see Fig. 4a). It is a similar case when the WIZ cuts through both upstream and downstream roof of the cavern/arch foot. However, for borehole D-2 in Fig. 4b, the follow-up borehole drilled in the failure area directly after the adjacent excavation could also be used, if construction conditions are not permitted. When the WIZ cuts across the high sidewall, relatively flexible follow-up boreholes, such as boreholes D-1 and D-2 in Fig. 4c, are usually adopted, since the exposed failure areas always change with the excavation of the cavern. There is no doubt that a predrilled borehole is a better choice since it can be used as a long-term observation hole to observe the whole failure process of the rock mass with a WIZ. And yet, only the failure development of rock masses with WIZs after excavation can be captured through use of follow-up boreholes.

-

(b)

Multi-point extensometer

The multi-point extensometer is a simple yet reliable device. It is relatively easy to install, which could be buried in the horizontal and vertical borehole or those in different directions for the automatic deformation monitoring of rock masses with WIZs in different depths and along any direction. The layout bears much resemblance to that used for digital camera observation. Preinstalled and follow-up boreholes are both adopted in the observation process. Extensometers need to be preinstalled passing through the potential failure area before the excavation such as extensometer B-2 in Fig. 4a–c, or installed subsequently as close as possible to the dangerous areas near the working face during excavation such as extensometer B-1 in Fig. 4c, so as to monitor the main deformation state and changes in rock masses with a WIZ.

-

(c)

Bolt stressmeters and cable dynamometers

The bolt stressmeter can be applied to automatically monitor the internal stress in rock masses with a WIZ, with the anchor rod being used as the transmission rod. Stressmeters are better placed near the WIZ or passing through the WIZ at an angle (see Fig. 4a–c). The load change and loss rate of cable dynamometer can be used to judge the stability of rock mass with a WIZ and the operating conditions of any anchor cables. When the WIZ is exposed in the arch roof or arch foot, the dynamometer could be preinstalled on the prestressed anchor cables (see Fig. 4a, b) to allow load monitoring. When the WIZ cuts across the high sidewall, the cable dynamometers could be directly installed on pressure-dispersive anchor cables in the concerned area of the cavern immediately after the adjacent excavation for convenience of monitoring, such as the dynamometer C-2 in Fig. 4c.

It should be emphasized that the above observation schemes are all chronically tracked and dynamic. The frequency of observations is recommended to increase, especially when there are construction activities such as the current or subsequent excavations and supporting works occurring nearby. Only when the rock fracturing stops growing in the digital camera borehole and the deformation and stress would not change, can the frequency of observation be decreased. At least one or two observation instrumentations must be chosen in the construction and should also be used simultaneously if construction conditions allow.

3 Engineering Cases Study

3.1 Engineering Background

Currently, there is a typical underground cavern group with high side wall and great burial depth at a hydropower station under construction, located in the upstream mountain of the dam abutment on both sides of the valley in the southwest of China. The underground cavern is mainly composed of a main powerhouse, a main transformer chamber, and four surge shafts, the dimensions of which are (length × span × height) 438 m × 34/31 m × 86.7 m, 368 m × 21 m × 39.5 m, and about 49 m × 100 m, respectively. The burial depths of the caverns on the left bank and right bank are 260–330 and 420–540 m, respectively. Meanwhile, the horizontal distances from the caverns to the foot of the mountain are 600–1000 m on the left and 420–800 m on the right, to ensure that the caverns are far from the unloading zones induced by river erosion. The geostress on both sides mainly arise as a result of tectonic stress, with the horizontal stress exceeding the vertical stress. Among the three principal stresses, the maximum and intermediate principal stresses are sub-horizontal, and the minimum principal stress is sub-vertical. For the geostresses on the left bank, the maximum principal stress is within 15.0–23.0 MPa with the orientation of N30°–50°W and the dip angle of 5°–13°. The intermediate principal stress is within 13.0–16.0 MPa and the minimum principal stress is approximately 8.0–12.0 MPa, a rough equivalent of the gravity stress of overlying strata. For the geostresses on the right bank, the maximum principal stress is within 22.0–26.0 MPa with the orientation of N0°–20°E and the dip angle of 2°–11°. The intermediate principal stress is within 14.0–18.0 MPa and the minimum principal stress is approximately 13.0–16.0 MPa. The ratio of the laboratory uniaxial compressive stress to the maximum stress on both sides is about 2–6, which indicates that the caverns are in a high geostress area.

From the engineering geological point of view, rock masses are generally rock masses of class III1 and partly of classes III2 or IV according to the China National Standards GB 50218-94 (The Ministry of Water Resources of China 1994). And if more widely known rock mass rating system of RMR is adopted, rock masses mostly belong to class III (Bieniawski 1973, 1989), as shown in Table 1. Hence, the strength of surrounding rock is much higher than that of WIZs with the same inclination. Six slightly inclined WIZs (No. 2, No. 3, No. 3-1, No. 411, No. 4, and No. 5) are commonly developed around caverns. It can be seen that the main weak tectonic zone of WIZ No. 2 crosses the side wall of the left caverns with thicknesses ranging from 5 to 60 cm (see Fig. 5a), and the WIZs of No. 3, No. 3-1, No. 411, No. 4, and No. 5 outcrop in the upper part of the high wall, or arch, of the right caverns (see Fig. 5b).

Two typical engineering cases, including plastic squeezing-out tensile failure in the transformer chamber on the left bank and structural stress-induced collapse in the main powerhouse on the right bank, are selected to elaborate the failure formation and development in rock masses with WIZs and the corresponding failure mechanism.

3.2 Process Observation and Mechanism of Structural Stress-Induced Collapse

3.2.1 Basic Conditions

Generally speaking, a structural stress-induced collapse tends to occur when a series of unstable rock blocks are formed due to the combination of the slightly inclined WIZ cutting through the high wall or arch, the dominant structural planes or concentrated joints and free face influenced by excavation unloading and blasting under high geostress. Up to now, it is the most common failure mode seen during cavern excavation, posing a serious threat to the stability of the rock masses. Hence, it is of vital importance to master the failure process in a timeous manner by use of the observation schemes presented in Sect. 2.

The excavation of the right main powerhouse and main transformer room, from the top to bottom layers is based on the drilling and blasting method with small steps and weak-vibration blasting. Each excavation round along the cavern axis is generally within 2–5 m. The support of shotcrete layer during the excavation is installed immediately after one blasting round, following by systematic support priority together with locally reinforced support. That is, the distance between support and each working face (i.e., I1–VI2) is approximately within 5 m.

By the end of August 2016, the main powerhouse and the main transformer chamber in the concerned area controlled by WIZ No. 4 have been excavated to layer III and layer IV, respectively. The detailed excavation steps and sequence of which are shown in Fig. 6, and the main supports are as follows.

-

As for the support in the cavern roof, the surface of surrounding rock masses was first covered by the preliminary steel-fiber shotcrete layer of CF30 with thickness of 50 mm. And then the prestressed rockbolts were installed, the diameter, length, spacing and prestress of which are 32 mm, 9 m, 1.2 × 1.2 m, and 100 kN, respectively. Afterward, the reinforcing fabric (conventional rebar meshes) was installed, with the diameter and spacing of 8 mm and 150 × 150 mm. The secondary steel-fiber shotcrete layer of C25 with thickness of 150 mm was finally finished. Considering that WIZ No. 4 poses a serious threat to the stability of the rock masses in the arch (see Fig. 6), four rows of anchor cables (2000 kN in prestress) were installed through the anchorage-monitoring tunnels to the top of the upstream and downstream sides of the arch roof. The length of each anchor cable is 29–30 m and the row spacing along the cavern axis is 3.6–4.8 m.

-

As for the support in the arch foot, there were two rows of systematic anchor cables installed in the upstream and downstream arch foot. The length, the row spacing along the cavern axis and the prestress are 25, 3.6–4.8 m and 2000 kN, respectively.

-

As for the support design of high sidewall during the excavation, the systematic support was almost similar to the above. Prestressed anchor cables were installed in the upstream and downstream high sidewall, the length, spacing, and prestress of which are 35 m, 3.6 m × 3.8/6.0 m, and 2500 kN, respectively.

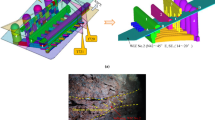

The slightly inclined WIZ No. 4 with an inclination of N40°E, SE18°, developing in the lower part of the volcanic tuff, was exposed in the excavation of the south area. According to the rock mass rating system of RMR (Bieniawski 1973, 1989), the upper and lower host rocks have poor rock mass integrity and may be classified as rock mass class IV with concentrated joints (see Fig. 7). Meanwhile, there is one set of relaxed fissures with an inclination of N50°W, SE70° developing in the arch of the powerhouse at the chainage of K0-60–K0-40, the spacing of which is 15–30 cm. During excavation from layer I to layer III, a series of structural stress-induced collapses and shotcrete spalling events of different sizes occurred at the chainage of K0-75.4–K0-35 in the main powerhouse and at chainage of K0-49.4–K0+10 in the transformer chamber (see Fig. 8).

3.2.2 Observation Schemes

To observe the spatial and temporal evolution of collapses mentioned in Sect. 3.3.1, the specific observation schemes were timeously arranged after the excavation of the central pilot tunnel (I1), using the observation means proposed in Sect. 2. It should be first explained that, although collapses occurred in both the powerhouse and the transformer chamber (see Fig. 8), the layout of monitoring instruments focuses on the potential failure areas of rock masses with WIZs exposed in the arch roof and arch foot of the main powerhouse, due to its larger span, higher side walls, and greater risk.

The profile and plane distributions of observation boreholes thereof are shown in Fig. 9a, b, respectively. From chainage K0-35 to chainage K0-75, two predrilled boreholes for digital camera observation (D-1 and D-2), five multi-point extensometers (M-1, M-2, M-3, M-4, and M-5) for deformation monitoring, four bolt stress meters (B-1, B-2, B-3, and B-4) and three cable dynamometers (C-1, C-2, and C-3) for stress monitoring were arranged.

Sketch of observation schemes of potential failure areas in rock masses with WIZ No. 4 during excavation of the section from K0-75 to K0-35 for the powerhouse on the right bank a profile of observation instruments (note D-1, D-2, and M-4 were installed at the chainage of K0-40, and the others are near the chainage of K0-55), b plane distribution map showing observation instruments (note Outline 1 denotes the main powerhouse, Outline 2, the auxiliary powerhouse)

-

As for failure evolution monitoring, when the WIZ has a certain distance to the arch roof of the main powerhouse, it would constitute a more powerful threat to the stability of the arch of the main powerhouse. Once collapse occurs, the scope and depth would be larger. Therefore, two digital camera observation boreholes were arranged at the chainage of K0-40 with a distance of 7–8 m from the WIZ to the arch, which had a certain distance from the first collapse area occurring at K0-75–K0-62. In other words, boreholes D-1 and D-2 were symmetrically tilted downwards through the anchor tunnel to the top of the upstream and downstream sides of the arch before the excavation of layer I3 (see Fig. 9a). The boreholes have a diameter of 110 mm and depth of 26.5 m. It could be seen that the bottom of the boreholes are closed, with a distance of 1.5 m to the arch wall of the main powerhouse, which could be used for digital panoramic borehole camera and acoustic velocity testing. The failure evolution characteristics of rock masses with WIZ No. 4 in the arch during excavation of layer I and subsequent layers of the main powerhouse can be timely monitored via observation boreholes D-1 and D-2. The frequency of observation can be adjusted based on the actual conditions of construction and can be increased when there are construction activities nearby.

-

As for deformation monitoring, three multi-point extensometers (M-1, M-2, and M-3) were arranged in the upstream arch, top arch, and downstream arch of the cross section at K0-55, respectively (see Fig. 9a). Since further collapses of rock masses with WIZ No. 4 continued to happen during the expanding excavation of layer I3, the multi-point extensometer M-4 was also embedded in the top arch at the chainage of K0-40. Considering that the downstream side wall was also a potential failure area subject, as it was, to intensity stress adjustment, the multi-point extensometer M-5 near the chainage of K0-55 was installed through the drainage tunnel to the downstream side wall (see Fig. 9a). The distances from the measured points of extensometers, including M-1, M-2, M-3, and M-5, to the powerhouse wall are 1.5, 3.5, 6.5, and 11 m. But for extensometer M-4, the distances are 0, 2.5, 6.5, and 11 m, respectively. The deformation evolution process of rock masses with WIZ No. 4 can be monitored comprehensively by use of the schemes described above.

-

As for stress monitoring, three bolt stress meters (B-1, B-2, and B-3) and two cable dynamometers (C-1 and C-2) were arranged in the arch roof and downstream arch at the chainage of K0-55 when layer I was finished. Afterward, stressmeter B-4 and dynamometer C-3 were also arranged after excavation of layer II (see Fig. 9). The distances from the measured points of stress meters, including B-1, B-2, and B-3, to the powerhouse wall, are 1.5, 3.5, and 6.5 m, respectively, but for bolt stressmeter B-4, the distances are 1.5 and 6.5 m, respectively. The layout of the above bolt stressmeters and cable dynamometers could realize the real-time automatic stress monitoring in potential failure areas of rock masses with WIZ No. 4.

In addition, it is also of vital importance to collect the engineering geology, construction, and destruction of rock masses with WIZs.

3.2.3 Observation of Collapse Processes

When the working face of the central pilot tunnel (I1) (see Fig. 9a) advanced to the cavern section from chainage K0-35 to chainage K0-75.4, a structural stress-induced collapse of rock masses with WIZ No. 4 occurred in the arch roof of the pilot tunnel within the section at the chainage of K0-75–K0-62. Subsequently, with the advance of the working faces of I2, I3, and I4 (see Fig. 9a), different degrees of collapse continued to appear in the area of concern. When the support to layer I was completed, the subsequent excavation of layer II and layer III again resulted in shotcrete spalling and fall blocks of the arch and spandrel in the area of concern. Figure 10 shows photographs of collapses evolving with construction. Figures 11 and 12 show the temporal and spatial evolution of deformation and stress during excavation of layer I to layer III, respectively. Figure 13 illustrates the failure evolution of rock masses near the powerhouse wall and near the WIZ No. 4 at the chainage of K0-40, observed by the digital panoramic borehole camera system. From Figs. 9, 10, 11 and 12, it can be seen that rock masses with WIZ No. 4 gradually deteriorate under the action of excavation unloading. That is to say, during the whole process of these collapses, the deformation and stress tend to increase, and there is generation of new cracking, opening, propagation and connection of both existing and new cracks in the vicinity of WIZ No. 4. The specific failure process is discussed below.

Deformation characteristics of rock masses with WIZ No. 4 in the arch and downstream spandrel at K0-35–K0-75 during excavation of layer I to layer III and its relationship with the construction activities [notes (1) excavation elevation in the figure indicates the highest excavation elevation in a certain period of time. (2) Sequence numbers b–e indicate the corresponding collapses shown in Fig. 17, and positions b–e correspond to the respective times and elevations at which collapses occurred. (3) “ ”in Fig. 11 indicates support installation in different excavation stages]

”in Fig. 11 indicates support installation in different excavation stages]

Bolt and anchor stress characteristics of rock masses with WIZ No. 4 in the arch and downstream spandrel at K0-35–K0-75 during the excavation of layer I to layer III in the auxiliary powerhouse and its relationship with on-going construction activities [notes (1) excavation elevation in the figure indicates the highest excavation elevation in a certain period of time. (2) The sequence b–e indicates the corresponding collapses shown in Fig. 17, and the positions of b–e correspond to the respective times and elevations at which collapses occurred. (3) “ ” in Fig. 11 indicates support installation in different excavation stages]

” in Fig. 11 indicates support installation in different excavation stages]

The monitored failure evolution of rock masses near the powerhouse wall and near the WIZ No. 4 in borehole D-2 in the arch at K0-40 during excavation of layer I–layer III in the auxiliary powerhouse (notes numbers such as 2014/6/28 denote the observation time, and 8.0 m denotes the distance from the powerhouse wall)

-

(a)

By the end of January 2014, the working face of the central pilot tunnel (I1) advanced to the area of concern affected by WIZ No. 4 from north to south. The WIZ No. 4 in the top arch of the section at K0-75–K0-62 intersects steeply inclined structural planes, leading to the lower host rock’s relaxation and collapse along the WIZ. The dimensions of the collapsed zone were 6 m × 11 m × 0.5–1.5 m, and the diameter of the maximum fall block was 1.5 m (see Fig. 10a). Then at the start of February, the initial support of steel-fiber shotcrete layer with 50 mm in thickness was applied, as shown in Fig. 10a.

-

(b)

As of early April 2014, four rows of anchor cables were installed through the anchorage-monitoring tunnels to the top of the upstream and downstream sides of the arch roof. The length of each anchor cable is 25–30 m, and the row spacing along the cavern axis is 3.6–4.8 m. Prestressed rockbolts (Φ32 mm, L = 9 m, T = 100 KN, @1.2 m × 1.2 m) and steel mesh reinforcement supports (Φ8 mm, @15 cm × 15 cm) had also been finished in the arch roof of the central pilot tunnel (see Fig. 10b). However, at this point, the deformation of M-3-1.5 and M-3-3.5 m, embedded in the downstream arch of chainage K0-55, showed a little increase, as seen in Fig. 11. Soon afterward, fall blocks measuring 3 m × 2 m × 0.4–0.8 m were seen after long-term relaxation in the downstream arch of the central pilot tunnel at K0-70–K0-65 (see Fig. 10b). There were no supporting measures taken in the downstream arch foot of the central pilot tunnel. The stress concentration area, with an approximate right angle, became the main reason for the collapse. Then from mid-April to early August, the deformation remained stable. However, the upper and lower host rocks of WIZ No. 4 in borehole D-2, at a distance of 8 m from the arch wall, generated new cracks and rock falling, making the spacing between the upper host rock and the lower host rock increase to 29.4 cm, as shown in Fig. 13b.

-

(c)

In mid-August 2014, the working face of I3 advanced to the area of concern affected by WIZ No. 4. Then, the deformation of M-3-1.5 and M-3-3.5 m embedded in the downstream arch of chainage K0-55 showed a significant, rapid increase. When the working face of I3 advanced through chainage K0-55, the measurement point at M-3-1.5 m was destroyed, due to the large deformation of those rock masses near the wall (see Fig. 11). Moreover, the accumulated load of cable dynamometers C-1 (see Fig. 9), installed in the arch roof of chainage K0-56, increased by about 170 KN during this month (see Fig. 12). The stress in the bolt stress meters at B-2-6.5 and B-3-6.5 m suddenly increased by 110 and 90 MPa, as shown in Fig. 12. When the working face of I3 advanced from chainage K0-60 to change K0-75.4, another collapse controlled by WIZ No. 4 occurred in the downstream arch foot at chainage K0-60–K0-68. This collapse measured 8 m × 5 m × 0.3–1.0 m, and the diameter of the maximum fall block was 0.8 m (see Fig. 10c). Before the collapse occurred, digital camera borehole observation at chainage K0-40 showed that the crack initiation and propagation of rock masses within a depth of 3.5 m from the arch wall appeared, and the upper and lower host rocks of WIZ No. 4, with the distance of 8 m from the arch wall, continued to generate fall blocks. The spacing increased to 50.7 cm through the observation in borehole D-2, as shown in Fig. 13a, b.

-

(d)

In mid-September 2014, the excavation of I3 had been completed. Shotcrete layer with 200 mm in total thickness, reinforcing fabric (Φ8 mm, @15 cm × 15 cm) and prestressed rockbolts (Φ32 mm, L = 9 m, T = 100 KN, @1.2 m × 1.2 m) were applied. At this moment, the working faces of I4 and I2 advanced to the concerned area affected by WIZ No. 4. In the meantime, the measurement point of M-3-1.5 m was restored and brought back into use. Deformation and stress monitoring results in Figs. 11 and 12 show that deformations at M-3-1.5 and M-3-3.5 m slowly increased by 4.5 cm. The stresses in the bolt stressmeters at B-1-3.5 m embedded in the arch and B-3-6.5 m in the downstream arch, respectively, increased by 10, 12, and 40 MPa. The accumulated load in the cable dynamometer C-1 increased to 2004 KN exceeding the design load, which made the rock masses with WIZ No. 4 potentially very dangerous. Moreover, the cracks in those rock masses within a depth of 3.5 m from the arch wall continued to increase, as seen in Fig. 13a. Therefore, from late September to early October, collapses measuring 3 m × 3 m × 0.5 m occurred in the downstream arch of the powerhouse from chainage K0-75 to chainage K0-72, because of the slow stress adjustment of rock masses within WIZ No. 4 (see Fig. 10d). After this collapse, the deformation and stress entered a relatively stable period, with no obvious new failures occurring. And then, up to December 2014, the spacing between the upper rock mass and the lower rock mass slowly increased to 56.2 cm (see Fig. 13b).

-

(e)

In early March 2015, the excavation of layer II of the main powerhouse began. Yet, the influence on the stability of rock masses with WIZ No. 4 seemed small, owing to its low excavation height of 4 m. Support installation in the upstream and downstream sidewall of layer II was done by the end of June 2015, including shotcrete layer with 200 mm in total thickness, prestressed rockbolts (Φ32 mm, L = 9 m, T = 100 KN, @1.2 m × 1.2 m), reinforcing fabric (Φ8 mm, @15 cm × 15 cm), and prestressed anchor cables (L = 25/30 m, T = 2500 KN, @3.6 m × 3.8/6.0 m), as shown in Figs. 11 and 12. Layer III in the concerned area started in October 2015 with an excavation height of 11 m, and in November 2015, shotcrete spalling and fall blocks appeared in the arch of the powerhouse at K0-75 to K0-40 (see Fig. 10e). More importantly, there were noteworthy signals indicating failure, as shown in Figs. 11 and 12. Before this failure, the deformation at M-4-0 m, embedded in the arch of chainage K0-40, underwent a rapid increase in nearly 20 cm. The load on the cable dynamometer C-2 increased by 550 KN, and the stress at B-1-3.5 m also increased by 30 MPa. Besides, the spacing between the upper rock mass and the lower rock mass increased to 62.3 cm (see Fig. 13b). Thereafter, the deformation and stress entered a longer-term period of stability.

-

(f)

From March to July 2016, to prevent new cracks or new shotcrete spalling in the area of concern, more than 200 prestressed anchor rockbolts (Φ32 mm, L = 9 m, T = 100KN, @1.2 m × 1.2 m) and anchor cables (L = 30 m, T = 2500 KN, @3.6 m × 3.8 m) were added in the arch and downstream sidewall (see Fig. 10f). And the flexible protective support net was also installed to further restrain the movement of fall blocks (see Fig. 10f). The deformation and stress in Figs. 11 and 12 trended to be stable. So far, the collapse remained under control, with no new failure occurring.

Based on the above analyses, it may be concluded that, in the excavation of layer I to layer III, the failure process of structural stress-induced collapse of rock masses with WIZ No. 4 shows significant progressive characteristics, as follows.

-

In general, under high geostress unloading effect and construction disturbance, the dramatic increase in deformation and stress and the crack initiation and propagation would always appear before the collapse of rock masses with WIZs.

-

The collapses are mainly distributed in the arch roof, the upstream and downstream arch and high side wall of the powerhouse, with different scales and depths.

-

Collapse might occur repeatedly over a period of a few minutes to a few days, with the advancing working face along cavern axis and the subsequent excavation downwards, especially before support installation, or when the supports are relatively weak.

-

Besides, through observation of the failures, not only could the possible time of each collapse be qualitatively predicted at some level, but also effective supporting measures may be provided before the next collapse failure occurs, if the deformation, stress, and crack initiation and propagation are fully observed and understood.

3.2.4 Preliminary Analysis of Mechanism of Structural Stress-Induced Collapse

Based on field investigation and laboratory physical and chemical experiments, the mechanism of the structural stress-induced collapses of rock masses with WIZ No. 4, elaborated in Sect. 3.2.3, could be explained from the following viewpoints:

-

(1)

Relationship between structure of rock masses with WIZ No. 4 and collapse

Objectively, rock mass structure affects the stability of any surrounding rock: This is a basic cause of collapse. Field observations show that the rock mass with WIZ No. 4 is a soft/hard interbedded rock with the interlayer material of WIZ No. 4. The upper and lower host rocks are volcanic tuff and basalt/breccia lava, respectively (see Figs. 7, 14). The volcanic tuff is much more fractured than the basalt or breccia lava. Moreover, the WIZ No. 4 has a slightly inclined double-layer structure according to the report by Wang et al. (1983). WIZ No. 4, near the WIZ/tuff interface, would be muddied under the long-term effect of strong tectonic motion and frequent groundwater activity (see Fig. 14), and the width of the mud zone could reach 10 mm, whereas the WIZ No. 4, in its middle to lower part, is a silted cataclastic structure of about 5–60 cm, in which it is cut into pieces of debris of different sizes and shapes by all kinds of structural planes with mud filling in the interstices between rock fragments (see Fig. 7). Figure 15 shows the grain size distribution curves of WIZ No. 4 in the collapse area obtained by grain analysis test, and the main physical property indices of WIZ No. 4 are shown in Table 2. The results show that WIZ No. 4 is a highly fractured coarse-grained material in which the clay fraction is about 10%, and the coarse fraction is about 40%, showing flaky or angular rock fragments with different sizes ranging from 3 to 10 mm.

Significant differences exist between the host rocks and WIZ No 4 especially with regard to their strength and stiffness. Laboratory mechanical testing revealed that the strength ratio of the host rocks (volcanic tuff, basalt, and breccia lava) and WIZ No 4 could be greater than 10 (see Fig. 16), leading to the incoordination in deformation and failure process between host rocks and WIZ No 4. Meanwhile, the cohesion of the WIZ No. 4/rock interface decreases to some very low value because of the specialized structure of such rock masses with features such as WIZ No. 4.

Therefore, the collapse of rock masses with WIZ No. 4, elaborated in Sect. 3.2.3, is mainly controlled by the fracture of soft and hard interbedded rocks, including the extremely fractured double-layer of WIZ No. 4 and the weak interface. Once WIZ No. 4 in the arch is exposed during excavation, there would be enough space and free surface for large unstable rock mass collapse to occur along the WIZ No. 4/rock interface, with cracks opening and coalescence occurring under the action of high geostress. The collapse depth is determined by the exposure height in the arch or spandrel.

-

(2)

Relationship between geostress and collapse

The stress magnitudes and orientations are significantly affected by geological structures, especially such large inclined WIZs. It is particularly true that stress magnitudes can increase significantly near WIZs. In other words, areas near the WIZs are prone to correlate to areas of high geostress. This is basically coincident with the research findings compiled from triaxial overcore results proposed by Martin (1990) and Martin and Chandler (1993). The corollary also holds true: The initial and secondary stress magnitudes and orientations affect the stability of rock masses with WIZs in cavern excavation, leading to failures such as the structural stress-induced collapse.

The mechanism of collapses, elaborated in Sect. 3.2.3, is interpreted in Fig. 17, expounding the spatial relationship between geostress and collapse. The stress adjustment and redistribution of rock masses with WIZ No. 4 cutting through the arch and spandrel become severe, due to the exposure of a free surface (see Fig. 17). On the one hand, the maximum stress parallel to the plane of WIZ No. 4 increase significantly, further degrading the mechanical properties of the WIZ No. 4/rock interface with a decrease in the adhesive force acting thereon. On the other hand, the stress perpendicular to the WIZ No. 4 plane drops rapidly due to excavation unloading, making the rock masses with WIZ No. 4 lose the constraint imposed by any confining pressure (see Fig. 17).

Therefore, when excavated, WIZ No. 4 and its fractured host rocks are liable to be damaged, with reduced adhesive force on the interface, confining pressure unloading, and self-weight stresses. This would not only arouse intensive relaxation, coalescence, and slip along the preexisting structural planes in the lower host rock, but also result in the generation of new cracking, opening, expansion, and interconnection of both existing and new cracks under high geostress, which leads to the continuous collapse of the rock masses with WIZ No. 4 toward the free surface. The WIZ No. 4/rock interface tends to be the main controlling boundary for a collapse, and the collapse bodies may meanwhile take on the features of wedges dominated by the interface and joints in the host rocks (see Fig. 10).

Additionally, when WIZ No. 4 cuts through the high sidewall of the powerhouse, the relaxation of the surrounding rocks would also be intensified, resulting in large deformation or collapse of the upper and lower host rocks. The mechanism is consistent with the above analysis, and will not be explored further in this article.

-

(3)

Microscopic failure mechanism of structural stress-induced collapse

Typical fall blocks in the collapse area in the south of powerhouse (see Fig. 10) were sampled to interpret the microscopic mechanism of collapse by scanning electron microscope (SEM) investigation. Considering that fall blocks with different sizes and shapes are dominated by the interface and the joints in host rocks, they need to be wrapped in clear plastic and sealed with adhesive tape before storage. To minimize sample disturbance during transportation and reduce the disturbance to primary or new cracks, sponge layers were placed in the bottom of the storage box and bubble wrap sheets were placed between the fall blocks. Typical SEM microstructures are shown in Fig. 18.

According to the macroscopic and microscopic morphology of the fracture surface shown in Fig. 18, there are two main types of failure mechanism including shear and tensile failure. The shear fracture plane is mainly located near the WIZ No. 4/rock interface and represents intergranular, transgranular, and mixed abrasion at a microscopic scale. The fracture plane takes on a step-like morphology accompanied by conjugate scratches and shearing traces of the crystal edges and the crystal materials being abraded into rock powder (see Fig. 18a). In addition, some of the fracture planes show typical tensile failure characteristics, as shown in Fig. 18b. The scanning fracture is quite fresh, assuming a stepped shape. The mineral grains are columnar or acicular with an oriented arrangement. The particles open significantly along the mineral border, and the mineral itself is partially destroyed through abrasion by mineral particles. That is, the transcrystalline and intercrystalline fractures occur almost simultaneously, showing obvious characteristics of a tension–torsion rupture.

Hence, it is found that the structural stress-induced collapse of rock masses with WIZs has obvious tension and shear characteristics on the microscale, with shear movement of the WIZ/rock interface and crack initiation and propagation prevalent on the macroscopic scale. Finally, the adhesive force and internal friction are overcome, causing rock masses with a WIZ to develop a dynamic instability, thereby causing their collapse.

3.3 Process Observation and Mechanism of Plastic Squeezing-Out Failure

3.3.1 Basic Conditions

As of October 2016, the main transformer chamber on the left bank has been excavated to its layer V, the excavation steps and sequence of which are shown in Figs. 19 and 20. Drilling and blasting method with the excavation round of 2–5 m is also adopted. During the excavation of layer III and layer IV, the slightly inclined WIZ No. 2 developed from chainage K0 + 210 to chainage K0 + 320.45 in the north area with an inclination of N42°–45°E, SE14°–20° (see Fig. 19). According to the geological conditions around the excavation, the lithology is mainly composed of basalt and volcanic tuff of rock mass classes III, whereas the host rocks of WIZ No. 2 are relatively fractured with joint fissures and faults and thus belong to rock mass class IV (Bieniawski 1973, 1989).

Based on this field survey, it was identified that a continuous plastic squeezing-out tensile failure of WIZ No. 2 ranging from K0 + 220 to K0 + 268 appeared since the excavation of layer III (III1 and III2) on the north side of the main transformer chamber (see Figs. 19, 21). The extrusion width ranged from 1 cm to 20 cm, not only causing significant water seepage in rock masses (see Fig. 21a), but also leading to a series of problems with shotcrete spalling and bolt plate separation from sidewall surfaces or bolt failure (see Fig. 21b), which affected the safety and progress of construction. Afterward, to explain further the spatial and temporal evolution of the plastic squeezing-out failure process with excavation and support works on-going, a bolt stressmeter was arranged at an elevation of 607.24 m in the downstream sidewall (see Fig. 20) in early March 2016, permitting real-time and automatic stress monitoring of the failure area. Meanwhile, the excavation and supporting schedule, as well as the extrusion width, were tracked and recorded in real time. Measurement of the WIZ plastic extrusion width is shown in Fig. 21c.

3.3.2 Observation of Squeezing-Out Tensile Failure Process

When the working face of III2 (see Fig. 20) advanced to K0 + 228, the near-surface WIZ No. 2 suffered from strong unloading action and began to show obvious squeezing-out behavior. Afterward, with slow stress adjustment and the advance of working face IV2 from south to north, the extent of the squeezing-out failure gradually deepened in the area of concern. It can be seen in Fig. 22 that both the bolt stress and the plastic extrusion width changed with construction and time since March 2016, as presented below.

-

(a)

On March 3, 2016, the bolt stressmeter at K0 + 228 was just embedded, and thus the stress at A (see Fig. 20) with a distance of 3 m from the sidewall was only 6.2 MPa. However, at this point, the extrusion width had reached 50 mm in two days after the working face III2 passed the area (see Fig. 20). By the end of March 17, 2016, the stress at A and B, with distances of 3 and 6 m from the sidewall, increased to 82.75 and 26.45 MPa, respectively. The width of the squeezing-out zone also increased to 68 cm (see Fig. 22). At that moment, only the initial support of shotcrete layer with 50 mm in thickness had been applied over the monitoring area, as shown in Fig. 22.

-

(b)

From March 18–31, 2016, the WIZ No. 2 continued to fail, with the width of the squeezing-out zone rising to 82 mm under the influence of the self-weight stress imposed by the upper host rock, concentrated stresses, and fissure water. During this period, working face IV2 (see Fig. 20) advanced to the monitoring area over a distance of 40 m from south to north, and then prestressed rockbolts (Φ32 mm, L = 9 m, T = 100 KN, @1.2 m × 1.2 m) were installed (see Fig. 22).

-

(c)

Since then, and to April 20, 2016, the excavation of IV2 in the downstream area was temporarily halted. The bolt stress in the area of concern underwent slow increase with the width of the squeezing-out zone gradually going up to about 89 mm. In this stage, the squeezing-out failure developed mainly due to the stress adjustment. It might show some degree of aging characteristics, but it is less obvious.

-

(d)

From 21 April to 12 May, 2016, working face IV2 (see Fig. 20) continued to advance to the monitoring area over a distance of 60 m. Affected by excavation disturbance and water seepage (see Fig. 21a), the width of the squeezing-out zone increased by 12 mm, and the stress at A increased by about 76 MPa, which destroyed the support system including bolt plate separation from the sidewall surface and spalling of the shotcrete layer on May 11, 2016 (see Fig. 21b).

-

(e)

From 13 May to 4 June, 2016, working face IV2 (see Fig. 20) continued to advance to the monitoring area over a distance of 40 m, intensifying the stress adjustment therein. Accordingly, the width of the squeezing-out zone increased to about 108 mm, and the stress at A also increased by about 45 MPa. Owing to the destroyed support system and continued squeezing-out failure, there would still be some security risks in the area during subsequent excavation. Redisposal of the plastic squeezing-out zone was undertaken on June 5, 2016, including the removal of rock masses suffering from squeezing-out failure and the installation of secondary supports including shotcrete layer with 150 mm in thickness, prestressed rockbolts (Φ32 mm, L = 9 m, T = 100 KN, @1.2 m × 1.2 m), and anchor cables (L = 25 m, T = 2500 KN, @3.6 m × 3.8 m) (see Fig. 22).

-

(f)

Fortunately, up to now, rock masses with WIZ No. 2 in the area of concern remain relatively stable and squeezing-out failures remain under control due to the supplementary support works applied on June 5, 2016.

From the above observation of the failure process of plastic squeezing-out failure, the key characteristics of deformation and failure can be concluded as below.

-

For a cavern with a large span and high sidewalls, plastic squeezing-out failure often appears as a gradual failure process. Progressive failure is one of the most important deformation and stress behaviors. It develops with the time–space of cavern excavation and the associated long-term stress adjustment.

-

With the development of squeezing-out failure, the supporting system may be difficult to adapt to the large deformation of WIZ No. 2, leading to problems such as concrete cracking and anchor overloading. However, if given timely and effective support (see Fig. 22), the failure could be restrained to some extent.

3.3.3 Preliminary Analysis of Mechanism of Squeezing-Out Failure

Likewise, through in situ monitoring and laboratory experiments, the mechanism of squeezing-out failure of rock masses with WIZ No. 2, as elaborated in Sect. 3.3.2, is explained as follows:

-

(1)

Excavation unloading under high geostress

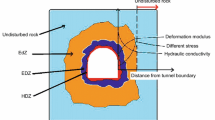

The spatial relationship between the location of squeezing-out failure and the orientation of maximum principal stress is given in Fig. 23. Generally speaking, the surrounding rock failure is controlled by high geostress, and the direction of the initial maximum stress is correlated with the rock mass (Hoek et al. 1995). During the excavation of layer III and layer IV of the main transformer chamber, the orientation of the maximum principal stress in the cross section shown in Fig. 23 would result in the stresses being concentrated on the plastic squeezing-out failure area. The tangential stress parallel to the sidewall tends to increase dramatically, whereas the normal stress perpendicular to the sidewall would decrease sharply, or fall to zero due to stress redistribution. Hence, with the action of the secondary compressive stress σ θ, the WIZ No. 2 would be compressed and lateral expansion takes place simultaneously, producing expansive stress σ S (see Fig. 23b). This would make the plastic squeezing-out failure move toward free surface where possible. Meanwhile, over its geological history, the three-dimensional confining pressure states, composed of the self-weight and the bidirectional construction stress field, cause compaction of the WIZ, allowing an accumulation of elastic strain energy. Then, due to excavation unloading, the energy is quickly released, accelerating the squeezing-out failure. Moreover, the uncoordinated deformation between the host rocks and WIZ No 2 further induces the deepening of this failure, leading to support system damage.

Mechanism of plastic squeezing-out failure of WIZ No. 2 a relationship between plastic squeezing-out failure of WIZ No. 2 and principal stress during excavation of layer III, b stress analysis of WIZ plastic squeezing-out failure (note σ θ, σ S, σ e, and τ indicate compressive stress, expansive stress, elastic strain energy stress, and shear strength, respectively)

Therefore, the increase of compressive stress σ θ, the generation of expansive stress σ S, and the release of elastic strain energy σ e, induced by excavation unloading under high geostress, become prerequisites for the plastic squeezing-out failure of WIZ No. 4.

Furthermore, the undisturbed natural WIZ No. 2, where thicker than 10 cm, was sampled in the area of concern area (see Fig. 24), and then samples were placed into galvanized iron cylinders and taken to the laboratory, after being sealed with clear plastic wrap and adhesive tape. Afterward, the standard cylindrical specimens, with diameters of 50 mm and heights of 100 mm, were formed and placed in sealed plastic bags at 22 °C in readiness for testing (see Fig. 24).

The stress path adopted in Fig. 25a could generally reflect the stress redistribution in the unloading excavation of the cavern (see Fig. 23). The triaxial test can be divided into four phases. In phase I, the axial pressure and the confining pressure are applied synchronously at a definite loading rate. And then the pressures are stabilized for a moment in phase II. Afterward, in phase III, the confining pressure remains unchanged and the axial pressure is applied continuously. Finally, in phase IV, the maximum stress σ 1 increases while the minimum stress σ 3 decreases at a certain rate until the specimens are damaged or reach their limiting displacement.

Typical results from WIZ No. 2 under unloading conditions a stress path adopted in the test, b failure modes of staggered zone specimens in a triaxial unloading test, c typical stress–strain curve of WIZ specimen (note the consolidation stage is not included in Fig. 25c, and only phase III and phase IV are included)

Figure 25c shows typical stress–strain curves of staggered zone specimens. The curve takes the deformation under a hydrostatic stress state as the origin of the strain axis, with the initial confining pressure of 15 MPa. The unloading begins when (σ 1–σ 3) rises to around 70% of the maximum deviator stress, which corresponds to the inflection point of volumetric strain (see Fig. 25c). The growth in circumferential deformation accelerated at the beginning of unloading, and its increasing rate is greater than that of the axial strain. Moreover, the volumetric strain curve turns left quickly with an intense spring-back deformation. The post-peak stress–strain curve in the unloading process decreases slightly, showing obvious plastic flow. In addition, the WIZ No. 2 shows typical tensile failure characteristics, with tension cracks and strongly expanding toward the unloading direction (see Fig. 25b). The above results could prove that the plastic squeezing-out tensile failure, occurring under the action of high stress, was subjected to unloading to a certain extent.

-

(2)

Softening and dilation of WIZ No. 2

Based on field observations, rock masses near WIZ No. 2 are fractured with dense fissures, accompanied by clear water seepage or groundwater flow (see Fig. 21). Groundwater activity exerts an important influence on the particle size distribution of WIZ No. 2. The more frequent the groundwater activity, the greater the softening degree therein, the higher the corresponding clay content, and the lower the corresponding coarse-grained content, as also explained by Xiao and Argelov (1991) and Xu (2011). The water content and grain analysis testing of WIZ No. 2 samples taken from the plastic squeezing-out area were carried out: the main physical property indices of WIZ No. 2 are shown in Table 3. It can be seen that the WIZ No. 2 samples may be classified as a well-graded geotechnical material, the clay fraction of which amounts to about 10–20%, and the coarse fraction of which is about 10–30%. In other words, for WIZ No. 2, the angular, flaky rock debris is wrapped by mud, and locally oriented. WIZ No. 2 is usually in a plastic state and would be softened into a clay when the groundwater is more active (see Fig. 26).

The whole rock mineral and clay mineral components of the plastic squeezing-out WIZ No. 2 are tested by X-ray diffractometer, as shown in Fig. 27. The compositional analysis data show that the main minerals present were hematite, titanite, and clay minerals. The content of clay minerals accounts for more than 60% of the total sample mass, in the form of montmorillonite and illite smectite (I/S). Montmorillonite and I/S are composed of many parallel crystal cells, and the crystal cells are connected with an oxygen layer. The combination of them is sufficiently spaced, and the connection strength is quite low. The crystal cells have very weak bonds and good cleavage, which increases its permeability to water. Moreover, the cations in crystal cells can be exchanged with ions in the water, thus expanding crystal lattices and increasing the hydrophilicity of the minerals. Thus the montmorillonite and I/S have strong water sensitivity, and the minerals can be expanded rapidly after water absorption, causing the WIZ to expand.

The excavation of layer III of the main transformer chamber exposes the rock mass with WIZ No. 2. On the one hand, the exposure causes a react with water molecules penetrating through the cracks, resulting in the expansion and softening of the WIZ. The strength decreases with increasing exposure time, further weakening the rock mass with its WIZ. On the other hand, the WIZ No. 2 itself expands to a significant extent due to water absorption, continuing to produce a strong additional expansive stress as shown in Fig. 23b. On the basis of these two aspects, the large squeezing-out deformation is aggravated and the local relaxed failure zone is formed, making the rock masses with WIZ No. 2 gradually lose their bearing capacity. Hence, the easy softening and strong expansion are important factors behind the plastic squeezing-out failure of WIZ No. 2.

-

(3)

Microscopic mechanism of plastic squeezing-out failure

The engineering properties of rock and soil are controlled by their microstructure to a great extent (Hu and Li. 1999). The undisturbed natural WIZ No. 2 and the damaged WIZ No. 2 with plastic squeezing-out failure are sampled in the area at the chainage of K0 + 225–K0 + 270 for SEM scanning. The mechanism of the plastic squeezing-out failure is studied from the microscopic point of view, and typical scanning results are shown in Fig. 28.

As is shown in Fig. 28a, c, the SEM scanning results from undisturbed natural samples from WIZ No. 2, imply that the basic structural units are mainly irregular flakes, some of which are random, and some of which are flower-like structures, with diameters reaching 20 μm. Laminations of schistose minerals are usually seen in the form of edge–face, edge–edge, and face–face, constituting flocculated, and coagulated, structures. Moreover, the laminations constitute the pores with a relatively large porosity and less obvious orientation therein.

The SEM scanning results of the damaged WIZ No. 2 with plastic squeezing-out failure are shown in Fig. 28b, d at 800 × and 5000× magnifications. It can be found that the basic structural units are changed to form a clay-based structure with face–face polymers. The structural units and the gaps become smaller than those of the undisturbed natural WIZ No. 2, and the structure becomes more compact. Meanwhile, the directionality of orientation and alignment are becoming more obvious for most face–face polymers, which exerts a significant influence on the expansion of WIZ No. 2. Additionally, the tensile fractures, with stepped and herringbone patterns, can be seen in the scanning results at 5000× magnification (Fig. 28b, d). Due to the presence of defects in the crystal cells, the transcrystalline fracture is not only formed along a crystallographic plane, but also along a cluster of planes parallel to each other at different heights.

Therefore, the microscopic mechanism of plastic squeezing-out failure of WIZ No. 2 under high geostress is the result of a certain degree of particle orientation, particle breakage, and transcrystalline fracture.

4 Discussion

4.1 Particularities of Failure of Rock Masses with a Slightly Inclined WIZ in a Large, Deeply Buried Underground Cavern

This research shows that, compared with conventional shallow engineering works of relatively small size, the large underground cavern discussed in this paper has the characteristics of a large span, high side walls, and great depth, and is more likely to experience rock masses with WIZs with poor mechanical properties, and plastic deformation or displacements, triggering a series of more serious failures. The failure process and mechanism show significant differences with those seen in shallow engineering, mainly reflected in the following aspects:

-

(1)

Particularity in the initial geostress

For the underground caverns described in the paper, the initial geostress tends to be very high due to the large horizontal tectonic stress and the large burial depth, with the average principal stress generally being 15.4–23.0 MPa on the left bank and 22.0–26.0 MPa on the right bank. Thus, the larger elastic strain energy stored in rock masses with WIZs could be released suddenly, and violently, due to strong excavation unloading. A variety of much more serious failure problems would then occur, including structural stress-induced collapse (Sect. 3.2) and plastic squeezing-out tensile failure (Sect. 3.3) and large contact shear slip, particularly that with directional arrangement and particle of the coarse particles (see Fig. 28). However, these serious failure problems are generally not prevalent in shallow workings. The failure in shallow engineering is mainly dominated by shear slip with obvious dilation, and the collapse mainly occurs under the action of gravity and is less affected by the influence of tectonic stress.

-

(2)

Particularity in the cavern dimensions and the combination of a WIZ and a cavern

The characteristics of stress redistribution in the surrounding rock and the range of the disturbed zone after excavation are greatly affected by the shape and dimensions, especially the span. The rock looseness range of underground caverns with large spans and high side walls is far greater than that of tunnels with small spans, especially in large cavern influenced by rock masses with WIZs. The increased excavation span will increase the possibility of the works suffering from large inclined WIZ effects which bring about changes in the combination of WIZ and cavern, thus causing many more different types of failure such as more massive collapses or contact shear slip, as shown in Fig. 29b, c. Moreover, when rock masses with WIZ are combined with other large faults or dominant structural planes to form a large unstable bulk structure, an increased span will render it more dangerous as a rock mass structure with larger structural stress-induced collapse risk (see Fig. 29b).

-

(3)

Particularity in the excavation method

Compared to the one-time advance of a small cavern, the excavation method, of multilayer, pilot tunnel first, expanding excavation, small footage, and multiple working faces, is adopted in a large deeply buried underground cavern. Thus, various types of failure would occur, not only due to the advance of a single working face in the current layer of excavation, but also due to the later advance of multiple working faces or subsequent excavation of the downward layers. The continuous exposure of rock masses with WIZs tends to cause several adjustments to the geostress field, leading to further development of failure depth and scope, which in turn will result in collapse or plastic squeezing-out failure on several occasions (see Figs. 10, 21). What is worse, shotcrete spalling and support failure also occur when failure problems develop in a slow gradual failure process (see Figs. 10, 21).

In view of the above particularities, the prevention and control of failure problems of rock masses with WIZ in large deeply buried underground caverns could be very difficult, making it seem more important to observe the formation and evolution of the whole failure process by use of the in situ observation proposed in Sect. 2 and to explain the mechanism through in situ monitoring and laboratory experiments (at least qualitatively). A more quantitative analysis of the mechanism of a WIZ and the WIZ/rock interface, including a constitutive model thereof, is suggested as a future research project.

4.2 Rethink on Prevention and Control of Failure of Rock Masses with WIZs

The prevention and control of failure of rock masses with WIZs in large underground caverns is an important scientific problem and is worthy of study. The observed failure process and the analysis shown in Sects. 3.2 and 3.3 could help us rethink on prevention and control of failures. The key points are as below.

-

For an underground cavern with a large span and high sidewalls, failures often appear as gradual failure processes. They tend to occur repeatedly and continuously over a period of a few hours to a few days, with the advancing working face along cavern axis and the subsequent excavation downwards. Hence, it provides valuable time for the prevention and control of the next collapse thereof.

-

In the influence of high geostress unloading and construction disturbance, deformation, stress, and the crack initiation and propagation would always appear a few days ahead of new failures. This offers dynamic early prewarning for the occurrence of failures and provides guidelines on when to take support measures to prevent the failures.

-

The gradual development of failures may destroy the supporting system, leading to problems such as shotecrete cracking and anchor overloading. Hence, the observations help us to recognize two key problems in the rock design: One is that the support strength and parameters should be dynamically adjusted to guarantee the stability of rock masses with WIZ. The other is that the supporting time should be dully optimized.

Therefore, lessons learned from the observations and mechanisms tell us that support design of rock masses with WIZs in such large underground excavations must be made to fit the associated failure behaviors, and vice versa. Prevention and control of rock masses with WIZs are discussed preliminarily, with respect to the optimization of supporting parameters and supporting time.

-

(1)

Rethink on the support of structural stress-induced collapse shown in Sect. 3.2.3

-

Throughout the whole collapse process from stage (a) to stage (f) (Figs. 10, 11, 12), we can see that shotcrete spalling and fall blocks in the arch still occurred in layer III excavation. The supplement supports in the arch had to be installed again, which made lots of trouble for construction. This illustrates that the reasonable support design for rock masses with WIZs in the arch and high sidewall are particularly important. Considering the long-term stability of the cavern, the early installed supports must have enough strength to steadily match the failure behaviors in the downward excavation.

-

In stage (a), as for the collapse shown in Figs. 10a, the collapse occurred at the moment of excavation with little time for self-stabilization (see Fig. 10a). Here, there are some important inspirations for the support of arch roof.

-

Presupporting If presupport measures (i.e., spilling, canopy tubes, pipe umbrella with lattice girders/steel sets) are taken in the cavern roof before excavation, the collapse may be temporarily avoided, or the scope could be reduced.

-

Shotcrete layer supporting for surface retention Once the working face I1 passes through the high-risk area, thicker nanosteel-fiber-reinforced concrete is recommended to be immediately sprayed for initial support. This is because the early strength of nanosteel-fiber-reinforced concrete developed more rapidly than the conventional concrete. In this way, some cracks and joints in the rock masses with WIZs could be filled more quickly, and the surrounding rock surface could be given enough confining support to form a three-dimensional stress state.

-

Rockblots and anchor cables support optimization for suspension/holding action As for support parameters in the arch roof, the prestressed rockbolts and anchor cables should pass though the WIZs in the arch and the length of rockbolts are set to at least 9 m here. The reason is that, even when the distance from the WIZ to the top arch of the main powerhouse was more than 8.5 m, there remains some growth in the spacing between the upper and lower host rocks (see Fig. 13b). Hence, the length of adopted rockbolts (Φ32 mm, L = 9 m, T = 100 KN, @1.2 m × 1.2 m) and prestressed anchor cables (L = 25/30 m, T = 2500 KN, @3.6 m × 3.8/6.0 m) could basically meet the requirement in projects. However, the support strength is not enough, and the support time is a little late, with about 1-month delay. These are what indirectly cause the occurring of subsequent collapses.

-

-

In stage (b), the reason why collapse occurred was because no supporting measures were taken in the downstream arch foot of central pilot tunnel (see Figs. 10b, 11, 12). Although the downstream sidewall of layer I1 would be excavated in layer I2, simple presupport measures still needed to be taken, such as shotcrete and resin rockbolts with at least 6 m length. In this way, maybe this collapse could be avoided, reducing the effect on the arch shape and construction progress.

-

In stage (c), what should be pointed out is that, the collapse may be reduced if the nano steel-fiber shotcrete layer in the downstream arch was timely installed, not later than the time when the deformation, stress and crack propagation sharply increased (see Figs. 10c, 11, 12). The support strength and parameters could refer to the rethink on the support of collapse in stage (a).

-

In stage (d), the collapse occurred a few days although some supports of layer I3 have been installed (see Fig. 10d, 11, 12). This once again illustrates the importance of support strength and parameters optimization. The number of rockbolts in the downstream arch foot should be increased, and the support time of anchor cables should be earlier before the failure accelerated.

-

In stage (e), shotcrete spalling and fall blocks occurred during the excavation of layer III because of stress adjustment and insufficient support in the arch. This has been discussed at the beginning.

-

In order to make the supports (i.e., support parameters, rockbolt length, spacing, and shotcrete thickness) more scientific, the possible ultimate depth or extent of collapse controlled by WIZs should be estimated at the early stage of the excavation of the cavern, based on numerical simulation and back analysis. During the excavation, the supports should be dynamically adjusted based on the in situ observation and numerical simulation, to ensure that earlier supports could match the changing failure behaviors in the layer-to-layer downward excavation.

-

(2)

Rethink on the support of squeezing-out failure shown in Sect. 3.3.2

-

Throughout the observed whole squeezing-out process from stage (a) to stage (f) (Figs. 21, 12), we can see that the squeezing-out failure occurred soon after the working face III2 passed the concerned area. Afterward, the width of squeezing-out had been growing, although the support of shotcrete layer and prestressed rockbolts were installed after the excessive deformation. This illustrates two keys: One is that the initial support strength cannot guarantee the stability of rock masses with WIZ No. 2. The other is that the support time is too late. Hence, these initial support measures have not played a due role in preventing the squeezing-out failure.

-

However, till now, rock masses with WIZ No. 2 in the area of concern remain relatively stable and squeezing-out failures remain under control due to the supplementary support works applied on June 5, 2016. This illustrates that although the supplementary support works were late, they ultimately had engineering impact, preventing the development of failure.

-

According to the observation shown in Fig. 22, it is suggested that, supports with enough strength should be installed before the stress and the width of squeezing-out accelerated. That is, supports in stage (b) could be optimized, by adding prestressed anchor cables together with prestressed rockbolts. And the support time should be not later than the end of March 2016. In this way, the squeezing-out failure may be controlled earlier, reducing problems such as shotcrete spalling and bolt plate separation from sidewall surfaces.

-