Abstract

Many aerospace applications involve complex multiphysics in compressible flow regimes that are challenging to model and analyze. Fluid–structure interaction (FSI) simulations offer a promising approach to effectively examine these complex systems. In this work, a fully coupled FSI formulation for compressible flows is summarized. The formulation is developed based on an augmented Lagrangian approach and is capable of handling problems that involve nonmatching fluid–structure interface discretizations. The fluid is modeled with a stabilized finite element method for the Navier–Stokes equations of compressible flows and is coupled to the structure formulated using isogeometric Kirchhoff–Love shells. To solve the fully coupled system, a block-iterative approach is used. To demonstrate the framework’s effectiveness for modeling industrial-scale applications, the FSI methodology is applied to the NASA Common Research Model (CRM) aircraft to study buffeting phenomena by performing an aircraft pitching simulation based on a prescribed time-dependent angle of attack.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The aerospace industry has invested a considerable amount of time and resources into various research areas over the last few decades to advance the performance, efficiency, and safety of aircraft. Some notable efforts include enhancing external aerodynamic designs [1], improving the structural strength of aircraft materials [2], integrating lightweight structural components [3], and advancing the approaches for dynamic load prediction [4,5,6], fatigue damage evaluation [7, 8], and aeroelastic modeling and analysis [9,10,11,12,13]. The advancement of these primary research areas often relies on high-fidelity computational modeling, such as computational fluid dynamics (CFD), computational structural mechanics (CSM), and fluid–structure interaction (FSI) analysis. In aerospace applications, an FSI analysis is typically conducted through a loosely coupled scheme [14,15,16] to find the final equilibrium solution and configuration. This approach, however, tends to have convergence problems and may fail to accurately capture the nonlinear forces acting at the fluid–structure interface in complex situations, such as the aircraft buffeting problems [4,5,6] discussed in this paper.

Aircraft buffeting is a complex loading phenomenon characterized by random pressure oscillations on aircraft structures caused by unsteady airflow. Turbulent flow, normal shocks, and stalls can cause the flow to separate from the wing, which may lead to a buffeting response. This can occur in the wing itself or the empennage or tail region when unsteady flow excites a dynamic response from these surfaces. For aircraft operating under certain conditions, flow can also separate from external structures such as radomes, causing the turbulent wake to impinge on tail structures. Buffet load analysis is usually updated using regression methods based on flight test data, such as peak-valley tables and Mach number-dynamic pressure usage data, but these methods heavily rely on real flight test data [5]. On the other hand, computational modeling of aircraft buffeting is challenging due to aerodynamic nonlinearities and complex structural components of the aircraft.

To model and predict aircraft tail buffeting phenomena, this work adopts a validated fully coupled nonmatching interface-based compressible flow FSI methodology developed by Rajanna et al. [17] based on the augmented Lagrangian approach [18]. The FSI framework makes use of the stabilized finite element-based Navier–Stokes equation of compressible flow [19, 20] to model the fluid, and the isogeometric analysis (IGA) based rotation-free Kirchhoff–Love thin-shell structural formulation [21,22,23] to model the structure. The combined use of finite elements for fluids and IGA for structures has proven to provide an effective balance between accuracy, robustness, and speed for FSI simulations [24,25,26,27].

The present work uses this FSI formulation to simulate the unsteady flow around the NASA Common Research Model (CRM) aircraft [28,29,30]. A time-dependent simulation for varying angles of attack (AOAs) is performed to study and understand the initiation and effects of buffeting as a function of the angle of attack. Different flow and structural quantities of interest have been analyzed at different time instances during the FSI simulation. The fluid flow around the aircraft is modeled using linear finite elements, and only the aircraft’s horizontal stabilizer is modeled using cubic non-uniform rational B-splines (NURBS) to study its structural response. The aircraft aerodynamic modeling has been validated using 3D flow simulations over the NASA CRM wing-body configuration at transonic conditions in Rajanna et al. [20].

This paper is outlined as follows. Section 2 presents the FSI framework for compressible flows, summarizes the fluid and structural formulations, and concludes with a discussion of time integration and FSI coupling techniques. In Sect. 3, the compressible flow FSI framework is applied to simulate flow around the CRM aircraft and predict the structural response of its horizontal tail due to the induced buffeting phenomena. Conclusions are drawn in Sect. 4.

2 FSI formulation for compressible flows

The fully coupled FSI formulation for compressible flow problems with nonmatching fluid–structure interface discretizations is presented here. In what follows, superscripts “f” and “s” denote quantities associated with the fluid and structural subproblems, respectively. \(\varOmega ^\text {f}_t\) and \(\varOmega ^\text {s}_t \in {\mathbb {R}}^d\), \(d\in \{2,3\}\) denote the spatial domains of the fluid and structural mechanics problems, respectively, at time t, with \(\varGamma ^\text {f}_t\) and \(\varGamma ^\text {s}_t\) representing their boundaries. \(\varGamma ^\text {I}_t\in {\mathbb {R}}^d\) represent the interface between the fluid and structural domains. \({\textbf{Y}}^\text {f}=[p\; {\textbf{u}}^\text {f}\; T^\text {f}]^\text {T}\) is the vector of pressure-primitive variables, where \(p, {\textbf{u}}^\text {f},\) and \(T^\text {f}\) are the pressure, velocity and temperature of the fluid, respectively. \({\textbf{y}}^\text {s}\) denotes the structural displacement, with \({\textbf{u}}^\text {s}\) being its velocity defined as the material time derivative of \({\textbf{y}}^\text {s}\). Let \({\mathcal {S}}^\text {f}\) and \({\mathcal {S}}^\text {s}\) be the trial function spaces for the fluid and structural mechanics variables, respectively, with \({\mathcal {V}}^\text {f}\) and \({\mathcal {V}}^\text {s}\) being the corresponding test function spaces. Let the superscript h denote the corresponding variable in the discrete space. The semi-discrete variational problem for the compressible flow FSI system is given by: Find \({\textbf{Y}}^{\text {f},h}=[p^h\; {\textbf{u}}^{\text {f},h}\; T^{\text {f},h}]^\text {T}\in {\mathcal {S}}^{\text {f},h}\) and \({\textbf{y}}^{\text {s},h}\in {\mathcal {S}}^{\text {s},h}\) such that for all test functions \({\textbf{W}}^{\text {f},h}=[q^h\; {\textbf{w}}^{\text {f},h}\; w_T^{\text {f},h}]^\text {T}\in {\mathcal {V}}^{\text {f},h}\) and \({\textbf{w}}^{\text {s},h}\in {\mathcal {V}}^{\text {s},h}\),

where \(B^\text {f}\), \( B^\text {s}\), \(F^\text {f}\), and \(F^\text {s}\) are the semi-linear forms and linear functionals corresponding to the fluid and structural mechanics problems, respectively. Their detailed expressions are given below.

For the fluid mechanics part of the FSI problem, let \(\varOmega ^\text {f}_t\) be divided into \(N_\text {el}\) spatial finite elements, each denoted by \(\varOmega ^\text {f}_e\), and let \(\varGamma ^\text {f}_t\) be decomposed into \(N_\text {eb}\) surface elements, where the bth element is denoted by \(\varGamma ^\text {f}_b\). Let the mesh defined by \(\bigcup _e \overline{\varOmega ^\text {f}_e}\) deform with a velocity field \(\hat{{\textbf{u}}}\), and let the boundary \(\varGamma ^\text {I}_t\) move with velocity \({\textbf{u}}^\text {s}\). Note that \(\varOmega ^\text {f}_e\) and \(\varGamma ^\text {f}_b\) remain time dependent, but the subscript t is omitted for notational convenience.

\(B^\text {f}_\text {STAB}\) in Eq. (1) is the stabilized discretizations of \(B^\text {f}\) using both streamline upwind/Petrov–Galerkin (SUPG) [31,32,33,34,35,36,37,38,39,40,41,42,43,44] and discontinuity-capturing (DC) [45,46,47,48,49,50,51,52,53,54,55,56] operators and is given by

where \(i = 1, \ldots , d\) for a spatial domain of dimension d, \({\hat{u}}_i\) is the \(i^{\textrm{th}}\) component of the domain velocity \(\hat{{\textbf{u}}}\), \({\textbf{A}}\)’s and \({\textbf{K}}_{ij}\) are the arbitrary Lagrangian–Eulerian (ALE) version of the Euler Jacobian and diffusivity matrices, respectively, for the Navier–Stokes equations of compressible flows [17], \((\cdot )_{,i}\) denotes a spatial gradient, and \((\cdot )_{,t}\) denotes a partial time derivative taken with respect to a fixed spatial coordinate in the referential domain. The convention used for i applies to j, k, and l, and the Einstein summation convention on repeated indices is used throughout. In Eq. (2), \(\textbf{Res}\) is the fluid residual, \(\hat{\pmb {\tau }}_{\text {SUPG}}\) is the SUPG stabilization matrix, and \({\hat{\kappa }}_{\text {DC}}\) is the DC parameter. Their details can be found in Rajanna et al. [17].

The weak boundary condition operator \(B^\text {f}_\text {WBC}\) in Eq. (1) is defined at the fluid–structure interface as

where \(\pmb {\sigma }^\text {f}\) is the fluid Cauchy stress and \(\delta \pmb {\sigma }^\text {f}\) is its corresponding variation, \({\textbf{n}}^\text {f}\) is the unit outward normal vector to the fluid domain, \(\rho ^\text {f}\) is the fluid density, \(T^\text {B}\) is the prescribed temperature on the structure boundary, and \(\kappa ^\text {f}\) is the thermal conductivities of the fluid. A calorically perfect gas is assumed in this work, and the fluid thermal conductivity is calculated by \(\kappa ^\text {f} = {\mu }c_p/Pr\), where \(\mu \) is the fluid dynamic viscosity, \(c_p = \gamma c_\text {v}\) is the specific heat at constant pressure, \(c_\text {v} = R/(\gamma -1)\) is the specific heat at constant volume, \(\gamma \) is the heat capacity ratio, R is the ideal gas constant, and Pr is the Prandtl number.

In Eq. (3), \(\varGamma ^\text {I}_b=\varGamma ^\text {f}_b\bigcap \varGamma ^\text {I}_t\), \((\cdot )^-\) denotes the “inflow” part of \(\varGamma ^\text {I}\), where \(({\textbf{u}}^\text {f}-\hat{{\textbf{u}}})\cdot {\textbf{n}}^\text {f} < 0\), \(\varPi ^\text {f}\) is a projection operator onto the space spanned by the fluid basis functions restricted to the fluid–structure interface, the mesh velocity \(\hat{{\textbf{u}}}\) is obtained using \(\hat{{\textbf{u}}} = \varPi ^\text {f}{\textbf{u}}^\text {s}\), and \(\tau _\mu ^\text {B} = C^\text {B}_I\mu /h_n \), \(\tau _\lambda ^\text {B} = C^\text {B}_I |\lambda |/h_n \), and \(\tau _\kappa ^\text {B} = C^\text {B}_I\kappa /h_n\) are stabilization parameters for the symmetric Nitsche’s method, where \(C^\text {B}_I\) is a positive constant obtained from an inverse estimate, \(\lambda = - 2 \mu /3\) is the second coefficient of viscosity, and \(h_n\) is the element size in the direction normal to the wall.

\(F^\text {f}\) in Eq. (1) is given by

where \({\textbf{S}}^\text {f}\) is the fluid source term, and \(\varGamma ^{\text {f},{\textbf{H}}}_t\) denotes the portion of \(\varGamma ^\text {f}_t\) where the fluid traction and heat flux boundary conditions \({\textbf{H}}^\text {f}\) are enforced.

For the structural mechanics part of the FSI problem, this work incorporates an isogeometric Kirchhoff–Love thin-shell formulation [21,22,23]. \(B^\text {s}_\text {KL}\) and \(F^\text {s}_\text {KL}\) in Eq. (1) are given by

and

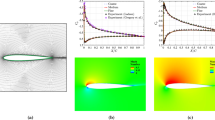

a Left half of the wing-body-tail CRM CAD geometry model used to simulate the tail buffeting problem. b CAD geometry and computational structural mechanics mesh of the horizontal tail based on NURBS. The connection between the horizontal tail root and the fuselage is simulated using a clamped boundary condition. c Computational domain and boundary conditions to simulate aircraft pitching. Freestream conditions are applied to all outer boundary surfaces of the fluid domain

where \({\mathcal {S}}^\text {s}_0\) is the shell midsurface in the reference configuration, \(\varGamma ^\text {I}_t\) is the shell midsurface in the deformed configuration, \({h_\text {th}}\) is the shell thickness, \(\rho ^\text {s}\) is the density of the structure, \(\left. \frac{\partial (\cdot )}{\partial t}\right| _{\textbf{X}}\) is the time derivative holding the material coordinates \({\textbf{X}}\) fixed, \({\textbf{E}}\) is the Green–Lagrange strain tensor, \(\delta {\textbf{E}}\) is the variation of \({\textbf{E}}\) corresponding to displacement variation \({\textbf{w}}^\text {s}\), \({\textbf{S}}\) is the second Piola–Kirchhoff stress tensor, \(\xi ^3 \in [-{h_\text {th}}/2,{h_\text {th}}/2]\) is the through-thickness coordinate, \({\textbf{f}}^\text {s}\) is the body force, \({\mathcal {S}}^{\text {s},{\textbf{h}}}_0\) denotes the portion of \({\mathcal {S}}^{\text {s}}_0\) where only the traction boundary condition \({\textbf{h}}^\text {s}\) is enforced, \(\varPi ^\text {s}\) is a projection operator onto the space spanned by the structural basis functions restricted to the fluid–structure interface, and \({\textbf{t}}^\text {f}\) is the discrete counterpart of the fluid traction vector defined as

Throughout this work, the St. Venant–Kirchhoff material model is used; the stress–strain relationship is expressed as \({\textbf{S}} = {\mathbb {C}}{\textbf{E}}\), where \({\mathbb {C}}\) is the constitutive material tensor.

In this work, both \(\varPi ^\text {f}\) and \(\varPi ^\text {s}\) are defined to be \(L^2\)-projection operators, which globally conserve forces and moments acting on the fluid and structure [18]. For the time integration of the FSI equations and coupling strategies, this work applies the generalized-\(\alpha \) method [57,58,59] to integrate the semi-discrete ALE formulation for compressible flow problems and the Lagrangian formulation for structural mechanics applications. The combined fluid, structure, and mesh motion discrete residuals are converged to zero at each time step using a block-iterative FSI coupling approach [18, 60,61,62], which is highly efficient for problems with nonmatching fluid and structural discretizations. Newton–Raphson iterations are repeated until convergence to an appropriately coupled discrete solution is achieved.

3 Application to simulating aircraft buffeting

The compressible flow FSI formulation for nonmatching interface discretizations presented in Sect. 2 was thoroughly validated in Rajanna et al. [17]. To demonstrate its high-fidelity modeling capability for a full-scale aircraft subject to an aggressive operational condition, we select the Common Research Model (CRM) [30] to study the occurrence of buffeting events when performing maneuvers. In this section, we use the proposed FSI framework to simulate a time-dependent varying angle of attack simulation of the CRM aircraft and study the effects of buffeting phenomena by observing different flow and structural quantities of interest. The aerodynamic modeling of the aircraft was validated in Rajanna et al. [20] using flow simulations of a CRM wing-body configuration at transonic conditions.

3.1 Problem setup

To model the aircraft buffeting problem, we assume the aircraft is flying under cruise conditions at a specified speed and performs a consecutive pitch-up and pitch-down maneuver. The aircraft is assumed to be rigid everywhere except for the horizontal tail, which is flexible and cantilevered (clamped) to the fuselage. The pitching maneuver is executed in two stages. First, the aircraft is positioned at a zero-degree angle of attack, and uniform freestream (far-field) conditions are prescribed on all outer boundaries of the fluid mechanics domain to simulate cruising conditions. Once the flow is fully developed, the pitching motion is prescribed for the entire computational domain while keeping the freestream conditions fixed. The far-field air velocity, pressure, and temperature are set to \(u_1^\text {f} = 168\) m/s, \(p=56.688\) kPa, and \(T^\text {f}=258.4\) K, respectively, which result in a Mach number of 0.52. The no-slip velocity and stagnation temperature of \(T^\text {B} = 272.4\) K are imposed on the aircraft surface as weak boundary conditions. The stagnation temperature is calculated by \(T^\text {B} = (1+0.5(\gamma -1)M^2_\infty )T_\infty \), where \(M_\infty \) and \(T_\infty \) are the far-field Mach number and temperature, respectively. Standard air properties of Pr = 0.72, \(\gamma = 1.4\), and R = 288.293 J/(kg\(\cdot \)K) are used. The viscosity of the air is assumed to be constant and is set to \(\mu = 1.758 \times 10^{-5}\) kg/(m\(\cdot \)s). The pitching motion is prescribed by rotating the entire fluid domain about the quarter-chord pitch axis of the mean aerodynamic chord of the aircraft at a rate of 4\(^{\circ }\)/s and \(-2^{\circ }\)/s while pitching up and down, respectively. During the maneuver, the aircraft is subjected to a maximum angle of attack of 20\(^{\circ }\).

Figure 1 illustrates the geometry model of an idealized aircraft, horizontal stabilizer tail, and the computational domain used to perform this study. The aircraft model has a fuselage length of 62.74 m, a wing semispan of 29.38 m, and a tail semispan of 10.67 m. In this study, the FSI simulation is performed by assuming only the left horizontal tail of the aircraft as the structural part of the FSI problem. The tail deformation is governed by the isogeometric Kirchhoff–Love shell formulation with a St. Venant–Kirchhoff material model. Figure 1b shows the geometry of the horizontal tail, defined as the combination of a stabilizer and an elevator in this work. The tail structure is idealized (without internal spars and ribs) and has a root chord length of 5.3 m and tip chord length of 2.23 m. The NURBS surface mesh of the stabilizer is comprised of 2144 cubic elements and 2450 control points. The material is assumed to be linearly elastic with Young’s modulus of E = 70 GPa, a Poisson’s ratio of \(\nu \) = 0.35, a density of \(\rho ^\text {s}\) = 2700 kg/m\(^3\), and a thickness of \(h_\text {th}\) = 8 cm. Figure 2 shows the computational volume mesh generated using tetrahedral elements. The computational mesh is comprised of 6,486,616 linear tetrahedral elements. An element size of 0.1 m is used to discretize the wing and tail surfaces of the fluid domain, and an element size of 0.2 m is used for the remaining aircraft surfaces. The maximum element size in the mesh refinement zone is 5 m with an element growth ratio of 1.15. A time step size of \(\varDelta t = 0.5\times 10^{-3}\text { s}\) is used in this simulation.

During the aircraft pitching simulation, the motion of the horizontal tail and the fluid domain are dominated by the rotational motion due to pitching. This type of large rotational motion can be common in maneuvering simulations when rotating about yaw, roll, and pitch axes. For structures, solving for large rotations can become harder to converge, especially for long-term integration. In the case of the fluid domain, the linear elastostatics problem [63,64,65] is solved to determine the interior mesh motion, which may lead to undesired mesh distortion for large rotations. To circumvent this difficulty, following the procedure in Bazilevs et al. [66], the displacements of the structure and the fluid domain interior can be decomposed into their respective rotation and deflection components. The rotational motion is handled exactly based on the prescribed pitch angle for both the fluid domain and the structure, and the deflection part is solved using the Kirchhoff–Love shell for the structure and linear elastostatics for the fluid domain interior. We combine the exact rotations and time-discrete deflections to get a total discrete solution at each time step.

3.2 Computational results

Figure 3 shows the prescribed input angle of attack to perform the pitch maneuver and the time history of the tip displacement of the left horizontal tail obtained using the proposed FSI formulation. The tip displacement results demonstrate severe tail vibration at higher aircraft angles of attack. The amplitude of the tip oscillation is almost negligible during the pitching up motion between 0\(^{\circ }\) and 12\(^{\circ }\) angle of attack, but it experiences a sudden and nonlinear rise in magnitude beyond the 12\(^{\circ }\) angle. The significant displacement can be attributed to the turbulent wake produced by the wing that directly impacts the tail. This wake is particularly intense at higher angles of attack and can further increase the vibration of the tail. The vibration is exacerbated when a second wave of turbulent wake flow from the wing strikes the tail at an angle of 18\(^{\circ }\) during downward pitching, resulting in the highest recorded displacement of the tip. Figure 4 illustrates the deformation of the horizontal tail in comparison with the reference configuration at different time points, including the instances where the highest and lowest displacements are observed at angles of attack of 18.21\(^{\circ }\) and 17.98\(^{\circ }\), respectively. To visually demonstrate the flow behavior, Fig. 5 displays the fluid velocity distribution along the mid-span of the horizontal tail, and Fig. 6 presents the fluid traction magnitude exerted on the tail structure at different time instances and angles of attack. These findings exhibit the consistent airflow around the wing and tail regions when the angle of attack is below 12\(^{\circ }\). However, when the angle of attack surpasses 12\(^{\circ }\), significant airflow detachment from the wing and related flow disruptions in the aircraft’s tail region become apparent. The same phenomena can also be observed in Fig. 6, which shows the irregular variation of traction magnitude on the tail beyond 12\(^{\circ }\) angle. After 15 s into the pitch-down maneuver, the flow over the wings becomes fully attached at an angle of attack of 8\(^{\circ }\), as depicted in Fig. 5; however, the vibration in the tail still exists, as illustrated in Fig. 3. The vibration in the tail after the flow re-attaches can be primarily categorized as damped vibration, as the clamped horizontal tail acts as an under-damped system. The oscillation dissipates on its own as the aerodynamic damping acts steadily on the tail after the aircraft returns to its original position at the zero-degree angle of attack. The behavior of the horizontal tail from 12\(^{\circ }\) while pitching up to 8\(^{\circ }\) while pitching down is observed as aircraft tail buffeting [5].

The fluid velocity contour and streamlines along the midspan of the horizontal tail are shown in Fig. 7, which provide insights into the formation of unsteady vortex cores as the flow separates behind the wing. The interaction between these vortices and the empennage of the aircraft results in the appearance of the observed buffeting phenomena. The turbulent wake violently impinges upon the horizontal tail during the pitch-down maneuver, as depicted in Fig. 7, at angles of attack of 18.21\(^{\circ }\) and 17.98\(^{\circ }\), which correspond to the maximum and minimum displacement of the tail, respectively. Additionally, Fig. 8 shows the top view of the aircraft colored with pressure contour, demonstrating the non-uniform pressure distribution behind the wing and on the tail at different angles of attack. These findings are consistent with the effects of the separated flow behind the wing, as shown in Fig. 7, that induce the observed buffeting phenomenon.

4 Conclusions

This work presents a compressible flow FSI framework that is fully coupled and designed for nonmatching interface discretizations. The methodology’s effectiveness for industrial-scale applications is demonstrated by simulating a full-scale aircraft’s pitching movement to investigate tail buffeting phenomena. The simulation based on a prescribed angle of attack input has been successfully carried out using an ALE approach. The study presents both fluid and structural quantities of interest as a function of time and angle of attack. Based on the simulation results, it is evident that the unsteady dynamic flow behind the wing can cause nonlinear oscillations of the horizontal tail, especially at higher angles of attack. The tip displacement results indicate that at these angles, the tail experiences severe vibration, which is further amplified by dynamic fluid loads. Significant flow separation behind the wing can be seen from the airflow visualizations, which leads to flow disturbances observed in the tail region of the aircraft. The complex flow dynamics in the wake behind the wing result in the buffeting phenomenon, particularly at higher angles of attack, and understanding the dynamics of the wake is essential for developing effective methods to mitigate buffeting and enhance aircraft performance and safety. Further research is also necessary to investigate the effects of this phenomenon on structural fatigue and aircraft stability. Future work includes extending the framework to incorporate complex isogeometric fluid discretizations [67,68,69,70,71,72] to improve flow predictions especially in boundary layers, and to employ point cloud analysis methods to enable direct handling of as-manufactured or in-use objects and structures [73,74,75].

References

Abbas A, Vicente J, Valero E (2013) Aerodynamic technologies to improve aircraft performance. Aerosp Sci Technol 28:100–132

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, Miller WS (2000) Recent development in aluminium alloys for aerospace applications. Mater Sci Eng, A 280:102–107

Immarigeon J-P, Holt RT, Koul AK, Zhao L, Wallace W, Beddoes JC (1995) Lightweight materials for aircraft applications. Mater Charact 35:41–67

Lee BHK (2000) Vertical tail buffeting of fighter aircraft. Prog Aerosp Sci 36:193–279

Sharma V, Walker J, Sweet M, Weimerskirch T (2001) P-3 aircraft buffet response characterization. In 39th AIAA Aerospace Science Meeting & Exhibition, AIAA 2001-0711, Reno, Nevada

Giannelis NF, Vio GA, Levinski O (2017) A review of recent developments in the understanding of transonic shock buffet. Prog Aerosp Sci 92:39–84

Molent L, Jones R, Barter S, Pitt S (2006) Recent developments in fatigue crack growth assessment. Int J Fatigue 28:1759–1768

Liu N, Rajanna MR, Johnson EL, Lua J, Phan N, Hsu M-C (2022) Isogeometric blended shells for dynamic analysis: simulating aircraft takeoff and the resulting fatigue damage on the horizontal stabilizer. Comput Mech 70:1013–1024

Marshall JG, Imregun M (1996) A review of aeroelasticity methods with emphasis on turbomachinery applications. J Fluids Struct 10:237–267

Dowell EH, Hall KC (2001) Modeling of fluid-structure interaction. Annu Rev Fluid Mech 33:445–490

Kamakoti R, Shyy W (2004) Fluid-structure interaction for aeroelastic applications. Prog Aerosp Sci 40:535–558

Shyy W, Aono H, Chimakurthi SK, Trizila P, Kang C-K, Cesnik CES, Liu H (2010) Recent progress in flapping wing aerodynamics and aeroelasticity. Prog Aerosp Sci 46:284–327

Lee-Rausch EM, Batina JT (1995) Wing flutter boundary prediction using unsteady Euler aerodynamic method. J Aircraft 32(2):416–422

Farhat C, Lesoinne M (2000) Two efficient staggered algorithms for the serial and parallel solution of three-dimensional nonlinear transient aeroelastic problem. Comput Methods Appl Mech Eng 182:499–515

Smith MJ, Hodges DH, Cesnik CES (2000) Evaluation of computational algorithms suitable for fluid-structure interactions. J Aircraft 37(2):282–294

Abras JN, Lynch CE, Smith MJ (2012) Computational fluid dynamics-computational structural dynamics rotor coupling using an unstructured Reynolds-averaged Navier-Stokes methodology. J Am Helicopter Soc 57(1):1–14

Rajanna MR, Johnson EL, Liu N, Korobenko A, Bazilevs Y, Hsu M-C (2022) Fluid-structure interaction modeling with nonmatching interface discretizations for compressible flow problems: computational framework and validation study. Math Models Methods Appl Sci 32:2497–2528

Bazilevs Y, Hsu M-C, Scott MA (2012) Isogeometric fluid-structure interaction analysis with emphasis on non-matching discretizations, and with application to wind turbines. Comput Methods Appl Mech Eng 249–252:28–41

Xu F, Moutsanidis G, Kamensky D, Hsu M-C, Murugan M, Ghoshal A, Bazilevs Y (2017) Compressible flows on moving domains: Stabilized methods, weakly enforced essential boundary conditions, sliding interfaces, and application to gas-turbine modeling. Comput Fluids 158:201–220

Rajanna MR, Johnson EL, Codoni D, Korobenko A, Bazilevs Y, Liu N, Lua J, Phan N, Hsu M-C (2022) Finite element methodology for modeling aircraft aerodynamics: development, simulation, and validation. Comput Mech 70:549–563

Kiendl J, Bletzinger K-U, Linhard J, Wüchner R (2009) Isogeometric shell analysis with Kirchhoff–Love elements. Comput Methods Appl Mech Eng 198:3902–3914

Kiendl J, Hsu M-C, Wu MCH, Reali A (2015) Isogeometric Kirchhoff–Love shell formulations for general hyperelastic materials. Comput Methods Appl Mech Eng 291:280–303

Herrema AJ, Johnson EL, Proserpio D, Wu MCH, Kiendl J, Hsu M-C (2019) Penalty coupling of non-matching isogeometric Kirchhoff-Love shell patches with application to composite wind turbine blades. Comput Methods Appl Mech Eng 346:810–840

Hsu M-C, Bazilevs Y (2012) Fluid-structure interaction modeling of wind turbines: simulating the full machine. Comput Mech 50:821–833

Wu MCH, Kamensky D, Wang C, Herrema AJ, Xu F, Pigazzini MS, Verma A, Marsden AL, Bazilevs Y, Hsu M-C (2017) Optimizing fluid-structure interaction systems with immersogeometric analysis and surrogate modeling: Application to a hydraulic arresting gear. Comput Methods Appl Mech Eng 316:668–693

Xu F, Johnson EL, Wang C, Jafari A, Yang C-H, Sacks MS, Krishnamurthy A, Hsu M-C (2021) Computational investigation of left ventricular hemodynamics following bioprosthetic aortic and mitral valve replacement. Mech Res Commun 112:103604

Neighbor GE, Zhao H, Saraeian M, Hsu M-C, Kamensky D (2023) Leveraging code generation for transparent immersogeometric fluid-structure interaction analysis on deforming domains. Eng Comput 39:1019–1040

Vassberg J, Dehaan M, Rivers M, Wahls R (2008) Development of a Common Research Model for applied CFD validation studies. In AIAA 2008-6919, Honolulu, Hawaii. 26th AIAA Applied Aerodynamics Conference

Rivers MB, Dittberner A (2014) Experimental investigations of the NASA Common Research Model. J Aircr 51:1183–1193

NASA Common Research Model. https://commonresearchmodel.larc.nasa.gov/. [Accessed 31 March 2022]

Shakib F, Hughes TJR, Johan Z (1991) A new finite element formulation for computational fluid dynamics: X. The compressible Euler and Navier-Stokes equations. Comput Methods Appl Mech Engrg 89:141–219

Le Beau GJ, Ray SE, Aliabadi SK, Tezduyar TE (1993) SUPG finite element computation of compressible flows with the entropy and conservation variables formulations. Comput Methods Appl Mech Eng 104:397–422

Aliabadi SK, Tezduyar TE (1993) Space-time finite element computation of compressible flows involving moving boundaries and interfaces. Comput Methods Appl Mech Eng 107:209–223

Tezduyar TE, Aliabadi SK, Behr M, Mittal S (1994) Massively parallel finite element simulation of compressible and incompressible flows. Comput Methods Appl Mech Eng 119:157–177

Hauke G, Hughes TJR (1994) A unified approach to compressible and incompressible flows. Comput Methods Appl Mech Eng 113:389–396

Wren GP, Ray SE, Aliabadi SK, Tezduyar TE (1995) Space-time finite element computation of compressible flows between moving components. Int J Numer Meth Fluids 21:981–991

Wren GP, Ray SE, Aliabadi SK, Tezduyar TE (1997) Simulation of flow problems with moving mechanical components, fluid-structure interactions and two-fluid interfaces. Int J Numer Meth Fluids 24:1433–1448

Mittal S, Tezduyar T (1998) A unified finite element formulation for compressible and incompressible flows using augumented conservation variables. Comput Methods Appl Mech Eng 161:229–243

Ray SE, Tezduyar TE (2000) Fluid-object interactions in interior ballistics. Comput Methods Appl Mech Eng 190:363–372

Hauke G (2001) Simple stabilizing matrices for the computation of compressible flows in primitive variables. Comput Methods Appl Mech Eng 190:6881–6893

Hughes TJR, Scovazzi G, Tezduyar TE (2010) Stabilized methods for compressible flows. J Sci Comput 43:343–368

Takizawa K, Tezduyar TE, Kanai T (2017) Porosity models and computational methods for compressible-flow aerodynamics of parachutes with geometric porosity. Math Models Methods Appl Sci 27:771–806

Kanai T, Takizawa K, Tezduyar TE, Tanaka T, Hartmann A (2019) Compressible-flow geometric-porosity modeling and spacecraft parachute computation with isogeometric discretization. Comput Mech 63:301–321

Takizawa K, Otoguro Y, Tezduyar TE (2023) Variational multiscale method stabilization parameter calculated from the strain-rate tensor. Math Models Methods Appl Sci 33:1661–1691

Tezduyar TE, Park YJ (1986) Discontinuity capturing finite element formulations for nonlinear convection-diffusion-reaction equations. Comput Methods Appl Mech Eng 59:307–325

Hughes TJR, Mallet M, Mizukami A (1986) A new finite element formulation for computational fluid dynamics: II. Beyond SUPG. Comput Methods Appl Mech Eng 54:341–355

Hughes TJR, Mallet M (1986) A new finite element formulation for computational fluid dynamics: IV. A discontinuity-capturing operator for multidimensional advective-diffusive systems. Comput Methods Appl Mech Eng 58:329–339

Almeida RC, Galeão AC (1996) An adaptive Petrov–Galerkin formulation for the compressible Euler and Navier-Stokes equations. Comput Methods Appl Mech Eng 129:157–176

Hauke G, Hughes TJR (1998) A comparative study of different sets of variables for solving compressible and incompressible flows. Comput Methods Appl Mech Eng 153:1–44

Tezduyar TE, Senga M (2006) Stabilization and shock-capturing parameters in SUPG formulation of compressible flows. Comput Methods Appl Mech Eng 195:1621–1632

Tezduyar TE, Senga M, Vicker D (2006) Computation of inviscid supersonic flows around cylinders and spheres with the SUPG formulation and YZ\(\beta \) shock-capturing. Comput Mech 38:469–481

Tezduyar TE, Senga M (2007) SUPG finite element computation of inviscid supersonic flows with YZ\(\beta \) shock-capturing. Comput Fluids 36:147–159

Rispoli F, Saavedra R, Corsini A, Tezduyar TE (2007) Computation of inviscid compressible flows with the V-SGS stabilization and YZ\(\beta \) shock-capturing. Int J Numer Meth Fluids 54:695–706

Rispoli F, Saavedra R, Menichini F, Tezduyar TE (2009) Computation of inviscid supersonic flows around cylinders and spheres with the V-SGS stabilization and YZ\(\beta \) shock-capturing. J Appl Mech 76:021209

Rispoli F, Delibra G, Venturini P, Corsini A, Saavedra R, Tezduyar TE (2015) Particle tracking and particle-shock interaction in compressible-flow computations with the V-SGS stabilization and YZ\(\beta \) shock-capturing. Comput Mech 55:1201–1209

Takizawa K, Tezduyar TE, Otoguro Y (2018) Stabilization and discontinuity-capturing parameters for space-time flow computations with finite element and isogeometric discretizations. Comput Mech 62:1169–1186

Chung J, Hulbert GM (1993) A time integration algorithm for structural dynamics with improved numerical dissipation: The generalized-\(\alpha \) method. J Appl Mech 60:371–75

Jansen KE, Whiting CH, Hulbert GM (2000) A generalized-\(\alpha \) method for integrating the filtered Navier-Stokes equations with a stabilized finite element method. Comput Methods Appl Mech Eng 190:305–319

Bazilevs Y, Calo VM, Hughes TJR, Zhang Y (2008) Isogeometric fluid-structure interaction: theory, algorithms, and computations. Comput Mech 43:3–37

Tezduyar TE, Sathe S, Keedy R, Stein K (2006) Space-time finite element techniques for computation of fluid-structure interactions. Comput Methods Appl Mech Eng 195:2002–2027

Tezduyar TE, Sathe S, Stein K (2006) Solution techniques for the fully-discretized equations in computation of fluid-structure interactions with the space-time formulations. Comput Methods Appl Mech Eng 195:5743–5753

Tezduyar TE, Sathe S (2007) Modelling of fluid-structure interactions with the space-time finite elements: Solution techniques. Int J Numer Meth Fluids 54(6–8):855–900

Johnson AA, Tezduyar TE (1994) Mesh update strategies in parallel finite element computations of flow problems with moving boundaries and interfaces. Comput Methods Appl Mech Eng 119:73–94

Stein K, Tezduyar T, Benney R (2003) Mesh moving techniques for fluid-structure interactions with large displacements. J Appl Mech 70:58–63

Stein K, Tezduyar TE, Benney R (2004) Automatic mesh update with the solid-extension mesh moving technique. Comput Methods Appl Mech Eng 193:2019–2032

Fluid-structure interaction modeling with composite blades (2011) Y. Bazilevs, M.-C. Hsu, J. Kiendl, R. Wüchner, K.-U. Bletzinger. 3D simulation of wind turbine rotors at full scale. Part II. Int J Numer Meth Fluids 65:236–253

Takizawa K, Tezduyar TE, Uchikawa H, Terahara T, Sasaki T, Yoshida A (2019) Mesh refinement influence and cardiac-cycle flow periodicity in aorta flow analysis with isogeometric discretization. Comput Fluids 179:790–798

Terahara T, Takizawa K, Tezduyar TE, Tsushima A, Shiozaki K (2020) Ventricle-valve-aorta flow analysis with the Space-Time Isogeometric Discretization and Topology Change. Comput Mech 65:1343–1363

Bazilevs Y, Takizawa K, Wu MCH, Kuraishi T, Avsar R, Xu Z, Tezduyar TE (2021) Gas turbine computational flow and structure analysis with isogeometric discretization and a complex-geometry mesh generation method. Comput Mech 67:57–84

Aydinbakar L, Takizawa K, Tezduyar TE, Matsuda D (2021) U-duct turbulent-flow computation with the ST-VMS method and isogeometric discretization. Comput Mech 67:823–843

Kuraishi T, Xu Z, Takizawa K, Tezduyar TE, Yamasaki S (2022) High-resolution multi-domain space-time isogeometric analysis of car and tire aerodynamics with road contact and tire deformation and rotation. Comput Mech 70:1257–1279

Bazilevs Y, Takizawa K, Tezduyar TE, Korobenko A, Kuraishi T, Otoguro Y (2023) Computational aerodynamics with isogeometric analysis. J Mech 39:24–39

Kudela L, Kollmannsberger S, Almac U, Rank E (2020) Direct structural analysis of domains defined by point clouds. Comput Methods Appl Mech Eng 358:112581

Balu A, Rajanna MR, Khristy J, Xu F, Krishnamurthy A, Hsu M-C (2023) Direct immersogeometric fluid flow and heat transfer analysis of objects represented by point clouds. Comput Methods Appl Mech Eng 404:115742

Wang X, Jaiswal M, Corpuz AM, Paudel S, Balu A, Krishnamurthy A, Yan J, Hsu M-C (2023) Photogrammetry-based computational fluid dynamics. Comput Methods Appl Mech Eng 417:116311

Acknowledgements

This work is supported by the Naval Air Systems Command (NAVAIR) Funding Agreement No. N68335-20-C-0899. This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rajanna, M.R., Jaiswal, M., Johnson, E.L. et al. Fluid–structure interaction modeling with nonmatching interface discretizations for compressible flow problems: simulating aircraft tail buffeting. Comput Mech 74, 367–377 (2024). https://doi.org/10.1007/s00466-023-02436-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-023-02436-2