Abstract

Dark fermentative biohydrogen production (DFBHP) has potential for utilization of rice starch wastewater (RSWW) as substrate. The hydrogen production of Enterobacter aerogenes MTCC 2822 and Clostridium acetobutylicum MTCC 11274, in pure culture and co-culture modes, was evaluated. The experiments were performed in a 2 L bioreactor, for a batch time of 120 h. The co-culture system resulted in highest cumulative hydrogen (1.13 L H2/L media) and highest yield (1.67 mol H2/mol glucose). Two parameters were optimized through response surface methodology (RSM)—substrate concentration (3.0–5.0 g/L) and initial pH (5.5–7.5), in a three-level factorial design. A total of 11 runs were performed in duplicate, which revealed that 4.0 g/L substrate concentration and 6.5 initial pH were optimal in producing hydrogen. The metabolites produced were acetic, butyric, propionic, lactic and isobutyric acids. The volumetric H2 productions, without and with pH adjustments, were 1.24 L H2/L media and 1.45 L H2/L media, respectively.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the present scenario, pollution from fossil fuel combustion persists and alternative fuels have recently emerged to replace the expensive and non-renewable conventional fuels. Hydrogen is known to possess multiple benefits as a fuel, including reduction of carbon emissions, decreased environmental pollution hazards and a high energy density (143 kJ/g) which is more than thrice the energy density of gasoline (46 kJ/g) [1, 2]. Fermentative techniques of biohydrogen production are popular due to their minimal energy requirements, sustainability and an added advantage of waste-to-energy conversion [3, 4]. Dark fermentative biohydrogen production (DFBHP) is characterized by the simplicity of the process, high hydrogen production rates and valorization of organic wastes [5]. In this regard, a range of substrates have emerged, having the potential to generate biohydrogen. Carbohydrate rich substrates such as starchy [6], cellulosic and lignocellulosic feedstock [7] can act as carbon source for the hydrogen production by the bacteria. Among these, starchy wastes have proven to be excellent substrates due to their ease of availability and degradation, high carbohydrate content and low price. Different types of starchy wastes are in common use for hydrogen production, from sources such as rice, wheat, cassava, potato, sago etc. [8]. Industrial wastewaters with sufficient starch content can also be deployed in the process.

India is the second-most rice consuming country next to China with around 103.5 million metric tons of consumption in the period 2020–2021 [9]. Rice starch wastewater (RSWW) obtained after straining of boiled rice is one among the wastes generated in huge amounts from households, mess halls and restaurants. RSWW has high chemical oxygen demand (COD), which makes water bodies smelly and harms aquatic life. RSWW can be utilized with or without pretreatment, depending on the type of bacteria used in the process and their hydrolytic ability on starch.

Anaerobic bacteria are the commonly used group of microorganisms in DFBHP processes, which can grow in the absence of light to metabolize the substrates for biohydrogen generation. These bacteria are further classified into strict and facultative anaerobes, following distinct metabolic pathways resulting in different hydrogen productivities. The strict anaerobes used in DFBHP process belong to the genera of Clostridium, Thermoanaerobacterium, Ethanoligenens and Desulfovibrio; whereas, the facultative anaerobes are represented by the genera Enterobacter, Klebsiella and Citrobacter [10]. Some bacterial genera have varying tolerance to oxygen during hydrogen production such as Thermotogales and Bacillus. Generally, hydrogen production occurs by the transfer of electrons to protons from reduced ferredoxin (Fdred), the latter being accumulated in the cell via pyruvate or NADH oxidation [11]. This reaction is mediated by the enzyme hydrogenase, which is divided into two major types—[FeFe] hydrogenase and [NiFe] hydrogenase.

Enterobacter aerogenes and Clostridium acetobutylicum are apt choices of bacteria for hydrogen production studies. Despite resulting in hydrogen yields (HYs) lower than the theoretical HY, hydrogen production by E. aerogenes is characterized by high hydrogen production rates (HPR) and increased bacterial growth. Besides their oxygen tolerance and ease of handling, these bacteria show acid resistance which directly influences the pH of culture medium, in maintenance of suitable fermentation conditions [12]. C. acetobutylicum, being an obligate anaerobe, is extremely sensitive to oxygen. However, the bacteria produce a higher yield of hydrogen in comparison to E. aerogenes. Theoretically, facultative anaerobes such as Enterobacter species produce 2 mol H2/mol glucose, whereas, obligate anaerobes such as Clostridium species produce 4 mol H2/mol glucose through acetic acid pathway [13]. C. acetobutylicum shows high cellular growth and substrate consumption, resulting in high hydrogen productivity. An interesting feature of the bacterium is its dual stages of growth, i.e., the acidogenesis phase and the solventogenesis phase. During acidogenesis, the bacteria utilize the substrate to produce hydrogen and volatile fatty acids (VFAs) such as acetate, butyrate, propionate and lactate. Once the pH drops due to acids production, the metabolism is shifted to solventogenesis phase, whereby, production of organic solvents such as acetone, butanol and ethanol takes place.

Co-culture of bacteria is an innovative strategy to uplift the DFBHP process. Bacterial cells in co-culture exist in synergy to consume the substrate and produce biohydrogen. Various researches have utilized bacterial cells in co-culture to improve the hydrogen production process [14,15,16]. Bacterial cells in co-culture can consist of two or more facultative anaerobes, obligate anaerobes or a combination of facultative and obligate anaerobes. Co-culture systems possess multiple advantages such as rapid cell divisions, increased hydrogen production (as compared to mono-cultures), prevention of the necessity of substrate pretreatment and usage of expensive reducing agents such as L-cysteine·HCl or Na2S, facilitating a cost-effective fermentation process [17]. In spite of these advantages, it is also essential to consider a number of factors while employing co-culture systems. Some of the factors to be taken into consideration include optimization of the combination of substrate degrading bacteria and hydrogen producing bacteria, allowance for scale-up of fermentation process and inclusion of low cost pretreatment steps for the substrate [18]. E. aerogenes and C. acetobutylicum have been subjects of co-culture in a few hydrogen production studies [19, 20]. Both the bacterial species have been found to exist symbiotically, which ultimately benefits the DFBHP process.

Biohydrogen production using these bacteria are dependent on optimal values of different parameters such as pH, temperature, hydrogen partial pressure and substrate concentration etc. Values of parameters such as pH and substrate type and concentration are time-dependent and show a non-linear behavior, which cannot be defined by classical model based approach [21]. These parameters affect each other either singly, or in combination with other parameters. pH is a parameter of utmost importance, as it directly affects the metabolic pathway followed by the bacteria and the activity of their hydrogen producing enzymes. Biohydrogen production by E. aerogenes requires a pH which is equal or close to the neutral value [22]. C. acetobutylicum requires an optimal pH of 6.0–6.8, for growth and hydrogen production [23]. Another most important factor influencing biohydrogen production is the substrate concentration. A lower or higher concentration of substrate than the optimal could result in reduced production of the gas. Lower the substrate concentration, the more complete is its degree of metabolism, but the reaction would be characterized by a reduced efficiency [24]. Similarly, a high substrate concentration could lead to an inhibitory action. Hence, it is necessary to maintain balanced pH and substrate concentration in DFBHP process. A suitable way of resolving the issues related to the extremities of pH and substrate concentration, is to optimize these parameters. Optimization can be performed through one-factor-at-a-time (OFAT) or response surface methodology (RSM) approach. OFAT works by keeping the value of all, except one parameter, constant and varying the latter; while RSM is a quadratic modeling technique developed to study and represent the interactive effect among the variables concerned [25].

Pretreatment is an essential step prior to hydrogen production while using complex substrates in DFBHP. This helps to degrade their complex structure to release utilizable sugars for ease of hydrogen production. Dilute acid pretreatment is characterized by its cost effectiveness and sustainability, and thus, it is an effective process. During this process, biomass hydrolysis occurs under extreme physicochemical conditions, giving rise to a solution with high monomeric sugar content. Enzymatic pretreatment is a highly efficient technique to release simple sugars from composite feedstock, as they can be carried out under gentle reaction conditions and low energy requirements, resulting in reduced microbial inhibitor production [26]. α-amylase is a lytic enzyme which catalyzes the hydrolysis of α-1,4 linkages of glucose polymers internally through an endo-attack while retaining the anomeric configuration of the polymer [27]. This enzyme has the ability to break down starch, which is a complex carbohydrate and cannot be degraded by E. aerogenes. The enzyme can also degrade soluble starch giving rise to glucose, maltose and limited dextrin. The end products of α-amylase digestion of starch are suitable substrates that can be readily utilized by the anaerobic microorganisms to produce hydrogen.

To the best of the authors’ knowledge, DFBHP studies on RSWW which combines experiments on pure and co-cultures of E. aerogenes and C. acetobutylicum have not been reported earlier. This novel study lucidly compares the hydrogen production capabilities of the two bacteria and identifies the most influential parameters of the process. In this study, two bacterial strains—E. aerogenes MTCC 2822 and C. acetobutylicum MTCC 11274—were utilized for biohydrogen from RSWW. This paper is intended to highlight the results of three main objectives—(i) DFBHP from RSWW using pure culture of E. aerogenes MTCC 2822, (ii) DFBHP from RSWW using pure culture of C. acetobutylicum MTCC 11274 and (iii) Optimization of DFBHP from RSWW using co-culture of E. aerogenes MTCC 2822 and C. acetobutylicum MTCC 11274 in 1:1 ratio of bacterial cells.

Materials and methods

Materials

RSWW was collected from the student hostel mess of NIT Jalandhar. After collection, the sample was brought to the laboratory and immediately stored in a refrigerator in an airtight container at 4 °C, till further use. The sample requires refrigeration to prevent the deterioration of carbohydrates.

Bacteria and culture maintenance

The two dark fermentative bacterial strains E. aerogenes MTCC 2822 and C. acetobutylicum MTCC 11274 were procured from Microbial Type Culture Collection (MTCC), Chandigarh, India. E. aerogenes MTCC 2822 cells were grown in nutrient broth media, consisting of the following components in g/L: beef extract—0.5, yeast extract—1, peptone—5, NaCl—0.5. The initial pH of the media was set to 7.0 ± 0.2 and was sterilized in an autoclave at 121 °C, 15 psi for 20 min prior to inoculation. The bacterial cells were cultured at a temperature of 30 °C with continuous shaking at 180 rpm. C. acetobutylicum MTCC 11274 cells were grown in a media consisting of glucose [1% (w/v)], tryptone [1% (w/v)], yeast extract [0.4% (w/v)] and L-cysteine HCl [0.1% (w/v)]. The initial pH of the media was set to 6.8 ± 0.2 and was sterilized in an autoclave at 121 °C, 15 psi for 20 min, before inoculation. These cells were grown at a temperature of 37 °C with continuous shaking at 180 rpm. Both the culture flasks were sparged with nitrogen gas (99.99% purity) for 5 min to remove oxygen present in the headspace and maintain strict anaerobic environment. The growth characteristics of both the bacteria were studied and routine sub-culturing was performed when the cells reached the exponential phase.

Acid and enzyme pretreatment of starch

The substrate was acid pretreated by varying the H2SO4 concentration between 0.5% and 2.5% (v/v) [28]. To 6.7 mL of substrate taken in test tubes, 10 mL of varying concentrations of H2SO4 were added. The mixture was incubated at a temperature of 90 °C for a period of 40 min in a water bath [29]. The mixture was then neutralized by addition of few drops of 1 M NaOH. In the enzyme pretreatment experiments, α-amylase from malt having an enzyme activity of 1:2000 IP units was used on the RSWW by varying the enzyme concentration between 0.05 and 0.5% (w/v). To 200 mL of substrate solution, 20 mL of varying concentration of α-amylase (dissolved in distilled water) was added. The pH of the enzyme–substrate mixture was adjusted to 5.8 ± 0.2 to facilitate the catalysis. The mixture was incubated in a shaker incubator at 37 °C and 45 rpm for 4 h [30]. The effectiveness of both the pretreatments were assessed by measuring the concentration of reducing sugars released through 3, 5-dinitrosalicylic acid assay.

Fermentation media for biohydrogen production

RSWW was pretreated with 0.5% (w/v) α-amylase enzyme solution, prepared from a stock solution of 2% (w/v) of α-amylase enzyme in distilled water, to release the monosaccharides, oligosaccharides and dextrins. For this, RSWW was treated with the enzyme solution (10% volume of the RSWW) at 37 °C at 45 rpm in a shaker incubator (Innova® 42). The fermentation media for biohydrogen production from pretreated RSWW using E. aerogenes MTCC 2822 consists of total carbohydrate (6.5 g/L), reducing sugar (4.8 g/L), beef extract (0.75 g/L), yeast extract (1.5 g/L), peptone (7.5 g/L) and NaCl (0.75 g/L). The pH of the production media was set to 7.0 and autoclaved at 121 °C and 15 psi for 20 min. 10% (v/v) of the bacterial cells in exponential phase were transferred to the production media for growth and hydrogen production. Similarly, the hydrogen production media for C. acetobutylicum MTCC 11274 consist of total carbohydrate (6.5 g/L), reducing sugar (4.8 g/L), yeast extract (4 g/L), tryptone (10 g/L) and L-cysteine HCl (1 g/L). Though C. acetobutylicum possess amylase enzyme that degrades starch, the substrate was pretreated, as otherwise, the cells would be forced to enzymatically hydrolyze the substrate, rather than produce hydrogen [31]. The pH of the media were adjusted using 1.0 M NaOH. The sterilization and inoculation procedures followed were similar to that adopted for E. aerogenes MTCC 2822. After inoculation, the culture flasks were sparged with nitrogen gas of 99.99% purity to remove any traces of oxygen. For the co-culture study, 5% (v/v) of each of the bacterial cells (1:1 ratio) were inoculated into the autoclaved media consisting of pretreated RSWW as carbon source, 3 g/L peptone and 1 g/L yeast extract, supplemented with 1% (v/v) P2 stock solution. The P2 stock solution was a filter-sterilized mixture of buffer (50 g/L KH2PO4, 50 g/L K2HPO4, 220 g/L C2H3O2NH4), minerals (20 g/L MgSO4.7H2O, 1 g/L MnSO4.H2O, 1 g/L FeSO4.7H2O, 1 g/L NaCl), vitamins (0.1 g/L thiamin, 0.001 g/L biotin) [19].

Experimental setup for biohydrogen production

The DFBHP production experiments were carried out in a 2 L bioreactor of working volume 1.5 L [32]. After inoculation and sparging of the media with nitrogen gas of 99.99% purity in the bioreactor, these were connected to the experimental setup for hydrogen production (Fig. 1). The experimental set up is same as that of our previous publication [32]. The total batch time of the experiments were 120 h and the samples were collected for analysis at an 8 h interval, starting from 0 h. All the experiments were performed at a temperature of 37 °C.

Analyses of samples

Various analyses were performed on the RSWW and on the fermentation broth after it was subjected to hydrogen production. Total reducing sugar content in RSWW was measured through 3, 5-dinitrosalicylic acid (DNSA) assay, using glucose solution (1 mg/mL) as standard and the absorbance was measured at 540 nm [33]. The total carbohydrates in RSWW was measured by phenol–sulfuric acid method, using glucose solution (1 mg/mL) as standard and measurement of absorbance at 490 nm [34]. The optical density (OD) measurements were performed in a UV–visible spectrophotometer by Eppendorff, after setting the path length to 10 mm. Estimation of total dissolved solids (TDS), total suspended solids (TSS), fixed solids (FS), volatile solids (VS) and COD were performed according to the protocols mentioned in Standard Methods for the Examination of Water and Wastewater by American Public Health Association (APHA) [35]. The pH measurements of RSWW and the samples after every 8 h of fermentation, were performed using pH meter with glass electrode (MAC, India). The results of qualitative and quantitative analyses of RSWW is presented in Table 1.

The growth characteristics of the microbial cells were studied through OD and cell biomass concentration measurements. To measure the OD, 10 mL of the fermentation broth was collected periodically and subject to centrifugation at 7000 rpm for 10 min in a refrigerated centrifuge (Eppendorf). After washing the cell pellets twice and resuspending them in distilled water, the OD was measured at 600 nm in the UV–visible spectrophotometer. The bacterial cell OD was measured against distilled water as blank to avoid the heterogeneity, if any, caused by the media components [36]. The cell biomass concentration was measured in g/L, after centrifugation of 10 mL fermentation broth and drying of the cell pellets thus obtained, until a constant dry weight was obtained. The cell dry weight was measured in an analytical balance (Aczet).

The major liquid metabolites produced during fermentation, i.e., the VFAs, were analyzed through reverse phase-high performance liquid chromatography (RP-HPLC) in Agilent 1260 Infinity Series reverse phase HPLC (RP-HPLC) system. The samples were prepared by centrifugation of 10 mL of the broth followed by filtration of the supernatant through a 0.22 µm filter paper. 0.005 M H2SO4 was used as mobile phase, at a flow rate of 0.6 mL/min. The RP-HPLC system consisted of Hi-Plex H column (7.7 × 300 mm, ion exclusion/ligand exchange column with sulfonated styrene/di vinyl benzene matrix, pore size of 8 µm) and diode array detector (DAD) with λ = 205 nm. Prior to the analysis of samples, standard solutions of differing concentrations of VFAs were run and analyzed in the RP-HPLC system.

The produced hydrogen gas was quantitatively detected in a gas chromatograph (GC) by PerkinElmer, USA containing a thermal conductivity detector (TCD) having 80/100 Porapak-Q column (3.2 mm diameter, 2 m length). The temperature of oven, gas injection port and detector were set and controlled at 80 °C, 150 °C and 200 °C, respectively. Nitrogen was employed as a carrier gas at a flow rate of 20 mL/min. The total runtime for gas analysis in the GC was 15 min.

The volumetric hydrogen production rate (VHPR), signifying the production performance, was evaluated. It is the ratio of volume of hydrogen (Vhydrogen) produced in mL to the product of working volume of the bioreactor (Vworking) in L and time in h. The equation is given as follows:

Another important parameter, HY, is measured as the ratio of moles of hydrogen produced to the moles of substrate (carbohydrate or fatty acid) used in the medium [37]. The equation to measure HY is as follows:

The moles of hydrogen produced is determined from the ideal gas law equation, given as:

where p denotes the atmospheric pressure at mean sea level (1 atm), V is the volume of hydrogen gas produced at the end of batch time, n is the number of moles of hydrogen produced, R is the universal gas constant and T is the temperature in kelvin.

Mathematical models to study hydrogen production and substrate consumption

Modeling of DFBHP is essential to delineate real-time production along with feasibility studies and schedule a cost-effective energy extraction process. Mathematical models assess the performance efficiency of the hydrogen production process. Various mathematical models such as modified Gompertz model and Monod model have been developed to describe the events occurring in DFBHP. Substrate consumption and hydrogen production potential are the phenomena replicated in these models.

The kinetics of hydrogen production by E. aerogenes MTCC 2822 and C. acetobutylicum MTCC 11274 in a batch DFBHP process could be best modeled by modified Gompertz equation [38]. The model relates cumulative volume of hydrogen production to lag time and is given as:

Hcv signifies the cumulative volume of hydrogen produced (mL), Rmax is the maximum rate of hydrogen production (mL/L/h), Hmax is the maximum volume of cumulative hydrogen, tlag is the duration of lag phase (h) and tinc is the incubation time (t). The value of e in the above equation is 2.718.

The Monod model describes the correlation between specific growth rate of cells (µ) and substrate concentration [S], which is represented as follows [39]:

The kinetic parameters in Monod equation are maximum specific growth rate (\(\mu\)max) and half-saturation constant (KS).

Two-parameter optimization study of DFBHP using co-culture

RSM with CCD matrix was used in the optimization study. The two parameters chosen were initial pH and substrate concentration, having imperative effect on the process. The levels of the two parameters and their corresponding coded values are mentioned in Table 2. RSM with CCD matrix created a rational number of experimental runs, while taking into account the interactive effects between the chosen parameters. The CCD approach generated three runs on the central point, 2n number of factorial runs and 2n axial runs, where n is the number of parameters that were optimized. A total of 11 runs were, thus, suggested by the design technique, as represented in Table 2. The range of pH values chosen for optimization was between 5.5 and 7.5 with an increment of 1.0, in accordance with certain research studies [40, 41]. The substrate concentration was varied between 3 and 5 g/L, with an increment value of 1.0, to study its effect. This was done after precursory evaluation of previous research (data not represented). A second-order polynomial (Eq. 6) which gives the linear, quadratic and vector product relationship of the chosen parameters was generated, where the output variable was the hydrogen production in mL/L.

In the above equation, R symbolizes the response variable (hydrogen production, mL/L); α0 is the constant; α1, α2 are the linear coefficients; α11, α22 are the quadratic coefficients, α12 is the interactive coefficient, A and B represent the studied parameters, substrate concentration and initial pH, respectively. Analysis of variance (ANOVA), a part of statistical model which is a combination of estimation procedures, was used to analyze differences among group means in tests [42]. R2 and adjusted R2 values, varying between 0 and 1, statistically measured the agreement of experimental data to the fitted regression line of various models.

The kinetic parameters of the models studied were determined in the method of least square, using the software. Design Expert version 13 (Stat Ease, Inc., USA; trial version) was used for optimization studies. RSM with CCD matrix encompassing a three-level factorial design (− 1, 0, + 1) for the parameters pH and substrate concentration was chosen for this purpose. The data used and obtained in this study were fitted non-linearly in the respective curves, using OriginPro software (version: 8.5).

Results and discussion

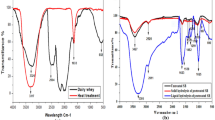

Comparison of acid and enzyme pretreatment on starch

It was observed that, with increasing concentration of the enzyme, the concentration of reducing sugar released also increases. α-amylase cleaves both the amorphous and the crystalline regions of starch, thus releasing an appreciable amount of reducing sugars. Thus, albeit the slow reaction time as compared to acid pretreatment, better hydrolysis was observed with α-amylase pretreatment. The reducing sugar release was linearly dependent on the concentration of enzyme used, with the highest release (4.8 g/L) at highest concentration of enzyme (0.5% v/v). After α-amylase pretreatment, there was a tremendous increase in reducing sugar concentration from 0.1 to 4.8 g/L. It was observed that the concentration of reducing sugar released increases with increasing H2SO4 concentration and the highest concentration of reducing sugar (0.5 g/L) was released at the usage 2.5% H2SO4. However, the concentration of reducing sugar released was comparatively lower than that of enzyme pretreatment. This was due to the preferential hydrolysis of the amorphous regions of starch by the dilute acid [43]. The reducing sugar concentration increased from 0.1 to 0.5 g/L with the acid pretreatment.

DFBHP from RSWW using pure culture of E. aerogenes MTCC 2822

The variation of hydrogen production and pH with time is shown in Fig. 2(a). It was observed that hydrogen production began in a short span after inoculation, which was reflected in the drop of culture medium pH and downward displacement of 5% potassium dichromate solution. An important observation was the sharp pH decline in the initial hours of fermentation. The pH dropped to a value of 5.7 at the end of 16 h, which necessitated the adjustment of the system pH using 1.0 M NaOH. A similar observation was reported by Das and Basak [44], during the initial 24 h of dark-photo combined fermentation from potato starch employing E. aerogenes and R. sphaeroides [44]. pH was adjusted twice in this study, at 16 h (5.7–6.4) and at 68 h (5.1–6.4). Beyond 100 h, the system pH decreased to values less than 5.0, due to which the hydrogen production almost ceased. The final cumulative volume of hydrogen produced was 0.67 L H2/L of media, at a final pH of 4.70. This value of hydrogen production was greater than the value reported in the study by Ulhiza et al., where sago wastewater was used as substrate for hydrogen production using E. aerogenes cells [45]. The cumulative volume of hydrogen production was also modeled non-linearly in modified Gompertz equation [Fig. 2(a)], resulting in an adjusted R2 value of 99.7% showing a goodness of fit. The predicted value of 0.73 L H2/L of media, adequately agrees with the experimental value.

Graph of variations of pH and cumulative volume of hydrogen (mL/L) with respect to time (h) by E. aerogenes (a), C. acetobutylicum (b) and co-culture system (c); Mathematical modeling of experimental values of cumulative volume of hydrogen to modified Gompertz equation has been represented in the graphs

From the substrate consumption profile in Fig. 3(a), it can be observed that the reducing sugars were consumed starting from 0 h, which was concomitant with hydrogen production. The active substrate consumption in the initial hours of fermentation correlates to the rapid growth and hydrogen production by the bacterial cells in the media. There was almost complete substrate consumption, owing to the pH adjustment which helped the bacteria to utilize the substrate for growth and hydrogen production. The slowed rate of substrate consumption at around 60 h could be due to the decline in pH. The kinetics of substrate consumption in the experiment was modeled on Monod equation which gave a reasonable fit, with an adjusted R2 value of 99.2%.

The production of organic acids during the metabolic activity of the E. aerogenes cells were analyzed every 24 h, starting from 0 h. Lactic acid is one of the prime metabolite of E. aerogenes under anaerobic conditions. The high concentration of lactic acid produced, along with the generation of other organic acids, in the initial 48 h of fermentation is responsible for the sharp decline of pH. After 48 h, there was a sharp decline in the concentration of lactic acid, which could be due to its conversion to acetic and butyric acids, alongside an increment in the hydrogen volume. A similar observation was reported by Stavropoulos et al. when mixed anaerobic sludge was used to produce hydrogen from end-of-life dairy products (EoL-DPs) [46]. The degradation of lactic acid to butyric and propionic acids could be confirmed as there was a decrease in concentration of lactic acid and corresponding increase in butyric acid and propionic acid contents. Another important metabolite produced was acetic acid, in the range of 0.6–1.0 g/L. Even though propionic acid concentration was high at 72 h, there was complete consumption of the acid at the end of 120 h. Figure 4(a) shows the various organic acids produced and their concentrations at different time intervals.

DFBHP from RSWW using pure culture of C. acetobutylicum MTCC 11274

The hydrogen production (mL/L) and pH profiles with respect to time (h) is represented in Fig. 2(b). Biohydrogen production by C. acetobutylicum started within 8 h inoculation, which was evident in the abrupt pH decrease. After 16 h of inoculation, hydrogen production exponentially increased. The production of organic acids during fermentation caused a severe pH drop, from 5.7 to 4.9 in 8 to 16 h. Mitra et al. reported a similar finding, where the pH dropped to 4.7 during the acidogenesis phase of Clostridium acetobutylicum using starchy wastewater as substrate [47]. To maintain a favorable pH for the bacteria to continue hydrogen production, the operating pH was adjusted thrice in the system, at 16 h, 68 h and at 96 h, respectively. Compared to the hydrogen production by E. aerogenes, nearly 1.6 times higher volume of hydrogen was produced. Active hydrogen production almost ceased after 96 h, which could be attributed to the entry of the bacterial cells into stationary phase. It was seen that the bacterial cells were continuously maintained at their acidogenesis phase until the end of fermentation process, as seen in the pH profile. The kinetics of cumulative volume of hydrogen production was studied by fitting the experimental data to modified Gompertz equation, which resulted in an adjusted R2 value of 99.3% showing a goodness of fit [Fig. 2(b)]. The predicted value of hydrogen production (1.21 L H2/L media) is in reasonable agreement with that of the actual value (1.05 L H2/L media). This study resulted in a HY of 1.6 mol H2/mol glucose, which is a higher value in comparison to the study by Bagy et al., where molasses spent media was used as substrate (HY 1.3 mol H2/mol glucose) [48]. However, in comparison to DFBHP studies using C. acetobutylicum on substrates such as cassava processing wastewater [49] and beet molasses [50], the HY reported in our study was lower. The lower HY could be due to the difference in the type of substrates used and the high COD content (16 g/L) in RSWW. Though pH was adjusted in the present study, the effect of high partial pressure in bioreactor headspace by hydrogen accumulation at high COD concentration could be a reason for the lower yield [51].

Cells of C. acetobutylicum displayed a minimal lag time in substrate uptake. After 8 h of growth, the substrate uptake rate increased and was maintained throughout the exponential phase. The slowed rate of utilization could be reasoned to the pH fall that proved detrimental to the cells. However, after pH adjustment, substrate usage continued fairly well until stationary phase was reached (after 96 h). Similar to E. aerogenes, the pH adjustment helped the cells to consume a maximum proportion of substrate. At the end of 120 h, the concentration of reducing sugars decreased to 0.2 g/L. Substrate consumption kinetics was modeled in Monod equation, giving an appropriate non-linear curve fit, with an adjusted R2 value of 99.8% [Fig. 3(b)].

The major organic acids produced during the process were lactic acid, acetic acid and butyric acid. Among these, acetic and butyric acids favored hydrogen production, while lactic acid production caused pH reduction and did not benefit the process. Butyric acid was produced in slightly more concentrations (1.8 g/L) as compared to acetic acid (0.9 g/L). Khamaiseh et al. also reported that, in majority cases, the production of butyric acid occurs in higher amounts as compared to that of acetic acid, by C. acetobutylicum [52]. However, beyond 72 h when the butyric acid concentration almost became constant, the acetic acid production continued to increase steadily upto 0.9 g/L at the end of 120 h. Lactic acid production also ceased after 96 h, depicting the entry of cells into stationary phase. There was complete absence of propionic acid in the process, meaning that there was no consumption of hydrogen. Figure 4(b) shows the various organic acids produced in the process.

DFBHP from RSWW using co-culture of E. aerogenes MTCC 2822 and C. acetobutylicum MTCC 11274

The co-culture system established several advantages, as compared to the mono-culture system of the two bacteria. A gradual decrease of pH, in contrast to sudden drop as that in pure culture system, was one of the key finding in this study. A study by Geng et al., where C. thermocellum and C. thermopalmarium were co-cultured to produce hydrogen from cellulose, also supported this finding. According to their research, a severe pH drop occurred after 32 h, due to the increase in growth of C. thermocellum and its hydrolytic activity [53]. pH was adjusted thrice in this experiment, at 32 h (4.8–6.5), 68 h (4.8–6.0) and 96 h (4.9–5.4). Reduction of pH was accompanied by surge in hydrogen volume. Hydrogen production almost ceased after 100 h. At the end of 120 h, a maximum cumulative volume of 1.13 L H2/L was obtained. Ramprakash and Muthukumar studied DFBHP from rice mill wastewater using co-culture of E. aerogenes and C. freundii, to obtain a HY of 1.6 mol H2/mol sugars [54], and Pachapur et al. co-fermented apple pomace hydrolysate with crude glycerol, using co-culture of E. aerogenes and C. butyricum, to obtain 26.0 ± 1.6 mmol H2/L medium [55]. In comparison to these previously mentioned studies, this study resulted in a HY of 1.7 mol H2/mol glucose. This signifies that the choice of substrate and the bacteria in our co-culture study is apt to improve HY. Table 3 lists a few DFBHP studies, involving either E. aerogenes, C. acetobutylicum or both in comparison with the present study.

Compared to DFBHP processes employing pure cultures of the two bacteria, highest production was achieved in co-culture systems. The higher productivity in the co-culture system is attributed to two reasons: (i) the activity of E. aerogenes which could utilize traces of oxygen, if any, present in the media, and provide a strict anaerobic environment for hydrogen production by C. acetobutylicum; and (ii) the synergism between the two bacteria having similar growth rates, which lead to equal productivities and not a competition for substrate [59]. The time-dependent changes of cumulative volume of hydrogen (mL H2/L media) and pH are depicted in Fig. 2(c). Hydrogen production data were modeled in modified Gompertz equation, which resulted in an adjusted R2 value of 98.1%, depicting a good non-linear curve fit [Fig. 2(c)].

Substrate consumption began shortly after inoculation of the cells in the production media. Instead of a rapid uptake, there was a gradual utilization of the carbon source, which was also evident in the pH profile of the system. Active utilization was observed in the phase between 16 and 72 h, which meant that the cells were in their highly functional state. Beyond 80 h, the substrate consumption rate slowed down which could be due to the reduced availability of reducing sugars. Due to the combined activity of both the bacteria and pH adjustments, most of the reducing sugars were consumed. Kinetics of substrate utilization, modeled in Monod equation showed a close exactness of fit, with an adjusted R2 value of 99.9% [Fig. 3(c)]. Mishra et al. also arrived at a similar conclusion, using pure and co-cultures K. pneumonia and C. ferundii for distillery effluent-based hydrogen production [60].

Two major organic acids were produced in this process—lactic acid and acetic acid. There was no trace of butyric acid or propionic acid produced in the process denoting that the bacteria in co-culture primarily followed acetic acid pathway in hydrogen production. Cheng and Zhu also stated that in a co-culture system of C. thermocellum and T. aotearoense, acetic acid was the major end product, when sugarcane bagasse was used as substrate [61]. The maximum concentration of acetic acid produced was 1.0 g/L, at the end of 120 h. The concentration of lactic acid produced increased from 0 h of production, with the maximum concentration at the end of 72 h of production, after which its concentration decreased in small amounts. This could be due to the consumption of lactic acid. Figure 4(c) shows the concentrations of different organic acids produced with respect to time.

Co-culture system displayed higher hydrogen production rates than pure culture of E. aerogenes. The highest VHPR value was reported at 32 h (7.9 mL/L/h), during the exponential phase of hydrogen production. After 32 h, the VHPR values dropped, which could be due to the reduction in pH. VHPRs in further hours were maintained between 6.3 and 7.3 mL/L/h, till the end of fermentation. In the case of pure culture systems, the VHPR profile of E. aerogenes showed a steady increase within 8 h of fermentation. High hydrogen production rate is an inherent characteristic of DFBHP. The highest VHPR was obtained at 48 h (7.2 mL/L/h), which is around the mid-log phase of E. aerogenes. This emphasizes that hydrogen production is highly favored during the exponential phase of bacterial growth. Beyond 48 h, the VHPR decreased gradually until 100 h. After 100 h (precisely around 112 h), the VHPR dropped to values below 5, and at the end of fermentation (120 h), the VHPR value was 4.9 mL/L/h. In contrast to the VHPR profile of E. aerogenes, a high VHPR was seen in the initial hours of fermentation by C. acetobutylicum, with the highest value (9.1 mL/L/h) at 8 h of fermentation. This showed the high activity of the culture and quick establishment in the production media, directing the metabolic pathway towards hydrogen production. In the exponential phase, the VHPR values swayed between 6.8 and 7.3 mL/L/h. After 96 h, VHPR values gradually decreased until 120 h, where the lowest value of 5.9 mL/L/h was observed. Compared to that of E. aerogenes, higher VHPR values were reported for C. acetobutylicum. A comparison of cumulative volume of hydrogen production, substrate consumption profiles and VHPR profiles of pure culture and co-culture systems are shown in Fig. 5. Table 4 represents the results of mathematical modeling of experimental data in modified Gompertz equation and Monod equation.

Optimization of process parameters for enhanced hydrogen production

Two most influential parameters were chosen for process optimization of co-culture DFBHP study—substrate concentration and initial pH. The substrate concentration values were varied in three levels – 3 g/L, 4 g/L and 5 g/L, respectively coded as − 1, 0 and + 1. Similarly, the effects of initial pH values were studied in three levels – 5.5, 6.5 and 7.5, coded as − 1, 0 and + 1, respectively. The CCD method generated a quadratic regression model, which helped in understanding the individual, quadratic and interactive effects of the variables. The maximum value of hydrogen production was obtained at the central point, i.e., at initial pH of 6.5 and substrate concentration 4 g/L, while the least hydrogen production was obtained at the axial point (4 g/L substrate concentration, initial pH 5.1).

ANOVA study of hydrogen production during co-culture process

ANOVA study is a culmination of various tests to analyze the significance of the model and the difference of various parameters. The model F value, which is the ratio of average of squares due to the regression, to that of residues [62], was obtained as 38.8, which signifies the model. A p value less than 0.0001 also proves that the model is significant. The linear, quadratic and interactive effects of the variables had p values < 0.05, indicating the significance of all these effects. In addition to this, the experimental data had a lack of fit p value of 0.096, which means that the lack of fit of actual data to the model was insignificant. The R2 and adjusted R2 values of the model were measured to be 95.9% and 91.9% respectively, implying the goodness of fit of experimental data with that of the model. The predicted R2 value of 74.7% was in reasonable agreement with that of the adjusted R2 value. Table 5 shows the results of ANOVA studies on the DFBHP co-culture optimization.

Collaborative effects of different parameters on hydrogen production and validation of optimized conditions

The 2D contour and 3D surface plot for parameter optimization of hydrogen production is given in Fig. 6(a) and (b). As evident in the 2D plot, an elliptical-shaped curve symbolizes that the interactive effect of substrate concentration and initial pH is significant. The 3D contour plot reveals that initial pH had crucial effect on hydrogen production, as compared to substrate concentration. This is due to the sharper changes in the curvature in the pH axis of the 3D plot. Drastic changes in hydrogen production i.e., 225–1235 mL/L, was also observed when the initial pH was varied from 5.1 to 6.5, with constant value of substrate concentration (4 g/L). At very high initial pH of 7.91, the hydrogen production was limited to 800 mL/L at substrate concentration of 4 g/L, which could be either attributed to the decreased microbial activity or due to the pathway shift of C. acetobutylicum from acidogenesis to solventogenesis [63]. In the two runs employing substrate concentration of 5 g/L each, and initial pH values 5.5 and 7.5, higher hydrogen production was found in the run with pH 7.5 (980 mL/L). This could be due to the slower drop of pH to a highly acidic value, which would hamper hydrogen production. A similar effect was observed in two runs with substrate 3 g/L, and initial pH values 5.5 and 7.5.

Substrate concentration also had significant influence on hydrogen production. When the initial pH value was kept constant at 7.5, and substrate concentration was varied in two levels, i.e., at 3 g/L and 5 g/L, lower production was obtained 3 g/L of the substrate concentration. Similar was the effect at 3 g/L and 5 g/L substrate concentrations, at initial pH 5.5. These phenomena could have occurred due to the depletion of the available substrate, which could not sustain the growth of bacteria. Values of substrate concentration above or below the central point, i.e., 5.41 g/L and 2.59 g/L respectively, showed lesser hydrogen production. Hydrogen production at + α point of substrate concentration (5.41 g/L) was higher as compared to that of—α point (2.59 g/L), mandating the maintenance of a minimum level of substrate concentration for reasonable hydrogen production. Table 2 lists the actual and predicted hydrogen production values at different operational parameters.

Figure 7 shows the closeness of experimental values of hydrogen production to the predicted values. The degree of closeness was determined statistically through linear curve fitting analysis. An adjusted R2 value of 95.5% symbolizes a high accuracy between experimental and predicted values. Table 6 sums up a few optimization studies which utilized mixed or co-culture system.

The optimized substrate concentration was 4.0 g/L and initial pH 6.5. The hydrogen production, substrate consumption, pH profile and metabolite production were validated through a confirmation experiment, run for a batch time of 120 h. A final volume of 1.24 L H2/L media was produced, when operating pH was not adjusted to optimal value [Fig. 8(a)]. A striking observation was that, hydrogen production ceased after 96 h, and the experiment was continued till 120 h, to confirm the end of production. This could be due to the drop of pH below a value of 4.9. A research by Rao and Basak encountered a similar phenomenon, where hydrogen production was reduced when the pH declined to 4.3 [68]. Beyond 72 h, the pH decreased to values < 5.0, but the hydrogen production continued, which could be due to the activity of E. aerogenes. The concentration of reducing sugar reduced gradually, declining to a value of 0.7 g/L at the end of 120 h. Even though hydrogen production stopped at 96 h, the residual sugars could have been used for organic acids production. On the contrary, when the operational pH was adjusted to the optimal value, the hydrogen produced continued to a value of 1.45 L H2/L media [Fig. 8(b)]. The profiles of cumulative volume of hydrogen production (mL/L), pH and concentration of reducing sugars (g/L) with respect to time is given in Fig. 8(a).

The organic acids profile showed that the major acids produced were acetate, butyrate, propionate and isobutyrate (Fig. 9). There was no production of lactic acid at any hour of fermentation. The butyric acid concentration increased to 1.1 g/L at 48 h and further decreased, which could be due to its conversion to acetic acid. The increase in acetic acid concentration with time showed that the bacteria primarily followed acetic acid pathway for hydrogen production. The sharp increase in the concentration of acetic acid after 96 h was also revealed in the simultaneous pH drop. Isobutyric acid concentration also increased from 0 to 120 h. Even though propionic acid was produced in significant amounts during the reaction, the co-production of butyric, acetic and isobutyric acids, is thought to have overcome the inhibitory effects of the former on hydrogen production. After 72 h, it was also observed that propionic acid concentration decreased, which might be due to its conversion to acetic acid.

Future prospects and conclusion

DFBHP processes are known for their process simplicity, high HPRs and potential to use a wide range of wastes as substrates, thus, a nexus of waste conversion and energy generation. A comparative study on DFBHP from α-amylase pretreated RSWW using pure cultures of E. aerogenes MTCC 2822 and C. acetobutylicum MTCC 11274, and co-culture of the two bacteria were performed. This novel research analyzed the hydrogen production potentials of the two bacteria in different modes, discovered the parameters that significantly affected the process and further optimized them. The pure culture of E. aerogenes gave the lowest HY and cumulative volume of hydrogen values, while co-culture system, displaying the advantages of synergism between the bacteria, gave the best results of hydrogen production.

Being the highest producer of hydrogen in the former studies, the co-culture system was further chosen for optimization studies using RSM-CCD matrix to enhance hydrogen production. Two important parameters—substrate concentration and pH were selected and varied at three levels (− 1, 0, 1) and their optimal values were found to be 4.0 g/L and 6.5, respectively. Some of the striking findings from the optimization studies were on hydrogen and metabolites production. Hydrogen production completely stopped, once the pH became unfavorable for both the bacteria, around 96 h. This reminds that a lower pH has impending effects on DFBHP. It was also observed that instead of an exponential increase in organic acids production with time, some of these acids (such as butyric and propionic) could be converted to acetic and/or isobutyric acids, which is a key finding of this study.

The utmost aim of any DFBHP study is to raise the technique to an industrial level with appreciable market returns. Maintaining strict anaerobic conditions on a large scale is strenuous task, which can be resolved by co-culture systems. There has been challenges associated with scale-up of co-culture systems, a major problem to overcome being the difficulty of maintenance of a balanced co-culture system with increasing number of strains [69]. Like several studies mentioned in this paper, employing only two strains of comparable growth rates, could lead to equal productivity, rather than competition for substrate. A major challenge to be overcome is the pH imbalance, which should be timely adjusted to the optimal value. Employing a buffering system or using bacteria that can tolerate the acidic environment in the system are plausible solutions for pH imbalance. From the present study, it can be understood that the co-metabolites (organic acids) have been produced in sufficient amounts, which could be channeled as substrates in a secondary or integrated stage of hydrogen production such as photofermentation [70] or microbial electrolysis. It could be analyzed from this study that, the HYs were only slightly close to the theoretical maximum yield of DFBHP. Design considerations of the bioreactor including studies on computational fluid dynamics could help in improving the yield of the process [71]. For enhancing hydrogen productivity, novel strategies such as metabolic engineering, modular co-culture engineering, nanotechnology and microbial bioaugmentation could be trialed in the future to achieve yields equal or close to the Thauer limit of DFBHP.

Data availability

Not applicable.

Abbreviations

- DFBHP:

-

Dark fermentative biohydrogen production

- RSWW:

-

Rice starch wastewater

- RSM:

-

Response surface methodology

- CCD:

-

Central composite design

- COD:

-

Chemical oxygen demand

- VHPR:

-

Volumetric hydrogen production rate

- HY:

-

Hydrogen yield

- TDS:

-

Total dissolved solids

- TSS:

-

Total suspended solids

- FS:

-

Fixed solids

- VS:

-

Volatile solids

References

Basak N, Jana AK, Das D, Saikia D (2014) Photofermentative molecular biohydrogen production by purple-non-sulfur (PNS) bacteria in various modes: the present progress and future perspective. Int J Hydrogen Energy 39:6853–6871. https://doi.org/10.1016/j.ijhydene.2014.02.093

Basak N, Das D (2006) The prospect of purple non-sulfur (PNS) photosynthetic bacteria for hydrogen production: the present state of the art. World J Microbiol Biotechnol 23:31–42. https://doi.org/10.1007/s11274-006-9190-9

Rao R, Basak N (2020) Development of novel strategies for higher fermentative biohydrogen recovery along with novel metabolites from organic wastes: the present state of the art. Biotechnol Appl Biochem 68:421–444. https://doi.org/10.1002/bab.1964

Rao R, Basak N (2021) Fermentative molecular biohydrogen production from cheese whey: present prospects and future strategy. Appl Biochem Biotechnol 193:2297–2330. https://doi.org/10.1007/s12010-021-03528-6

Jayachandran V, Basak N, De Philippis R, Adessi A (2022) Novel strategies towards efficient molecular biohydrogen production by dark fermentative mechanism: present progress and future perspective. Bioprocess Biosyst Eng. https://doi.org/10.10007/s00449-022-02738-4

Lin C-Y, Chang C-C, Hung C-H (2008) Fermentative hydrogen production from starch using natural mixed cultures. Int J Hydrogen Energy 33:2445–2453. https://doi.org/10.1016/j.ijhydene.2008.02.069

Reginatto V, Antônio RV (2015) Fermentative hydrogen production from agroindustrial lignocellulosic substrates. Braz J Microbiol 46:323–335. https://doi.org/10.1590/S1517-838246220140111

Das SR, Basak N (2020) Molecular biohydrogen production by dark and photo fermentation from wastes containing starch: recent advancement and future perspective. Bioprocess Biosyst Eng 44:1–25. https://doi.org/10.1007/s00449-020-02422-5

Shahbandeh M (2022) Rice consumption worldwide in 2021/2022, by country (in 1000 metric tons). Statista. https://www.statista.com/statistics/255971/top-countries-based-on-rice-consumption-2012-2013/. Accessed 27 July 2022

Castelló E, Ferraz-Junior ADN, Andreani C, Anzola-Rojas MdP, Borzacconi L, Buitrón G, Carrillo-Reyes J, Gomes SD, Maintinguer SI, Moreno-Andrade I, Palomo-Briones R, Razo-Flores E, Schiappacasse-Dasati M, Tapia-Venegas E, Valdez-Vazquez I, Vesga-Baron A, Etchebehere MZC (2020) Stability problems in the hydrogen production by dark fermentation: possible causes and solutions. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2019.109602

Cardoso V, Romao BB, Silva FTM, Santos JG, Batista FRX (2014) Hydrogen production by dark fermentation. Chem Eng Trans 38:481–486. https://doi.org/10.3303/CET1438081

Jing Y, Li F, Li Y, Jin P, Zhu S, He C, Zhao J, Zhang Z, Zhang Q (2020) Statistical optimization of simultaneous saccharification fermentative hydrogen production from corn stover. Bioengineered 11:428–438. https://doi.org/10.1080/21655979.2020.1739405

Yoshida A, Nishimura T, Kawaguchi H, Inui M, Yukawa H (2006) Enhanced hydrogen production from glucose using ldh- and frd-inactivated Escherichia coli strains. Appl Microbiol Biotechnol 73:67–72. https://doi.org/10.1007/s00253-006-0456-9

Maru BT, López F, Kengen SWM, Constantí M, Medina F (2016) Dark fermentative hydrogen and ethanol production from biodiesel waste glycerol using a co-culture of Escherichia coli and Enterobacter sp. Fuel 186:375–384. https://doi.org/10.1016/j.fuel.2016.08.043

Zhang S-C, Lai Q-H, Lu Y, Liu Z-D, Wang T-M, Zhang C, Xing X-H (2016) Enhanced biohydrogen production from corn stover by the combination of Clostridium cellulolyticum and hydrogen fermentation bacteria. J Biosci Bioeng 122:482–487. https://doi.org/10.1016/j.jbiosc.2016.03.014

Patel SKS, Kumar P, Mehariya S, Purohit HJ, Lee J-K, Kalia VC (2014) Enhancement in hydrogen production by co-cultures of Bacillus and Enterobacter. Int J Hydrogen Energy 39:14663–14668. https://doi.org/10.1016/j.ijhydene.2014.07.084

Pachapur VL, Sarma SJ, Brar SK, Bihan YL, Buelna G, Verma M (2016) Hydrogen production from biodiesel industry waste by using a co-culture of Enterobacter aerogenes and Clostridium butyricum. Biofuels 8:651–662. https://doi.org/10.1080/17597269.2015.1122471

Li Q, Liu C-Z (2012) Co-culture of Clostridium thermocellum and Clostridium thermosaccharolyticum for enhancing hydrogen production via thermophilic fermentation of cornstalk waste. Int J Hydrogen Energy 37:10648–10654. https://doi.org/10.1016/j.ijhydene.2012.04.115

Tondro H, Musivand S, Zilouei H, Bazarganipour M, Zargoosh K (2020) Biological production of hydrogen and acetone- butanol-ethanol from sugarcane bagasse and rice straw using co-culture of Enterobacter aerogenes and Clostridium acetobutylicum. Biomass Bioenerg. https://doi.org/10.1016/j.biombioe.2020.105818

Ebrahimian F, Karimi K, Angelidaki I (2022) Coproduction of hydrogen, butanol, butanediol, ethanol, and biogas from the organic fraction of municipal solid waste using bacterial cocultivation followed by anaerobic digestion. Renewable Energy 194:552–560. https://doi.org/10.1016/j.renene.2022.05.067

Ozyurt B, Soysal F, Hitit ZY, Camcioglu S, Akay B, Ertunc S (2019) An efficient dark fermentative hydrogen production by GMV control of pH. Int J Hydrogen Energy 44:19709–19718. https://doi.org/10.1016/j.ijhydene.2019.06.048

Abd-Alla MH, Gabra FA, Danial AW, Abdel-Wahab AM (2018) Enhancement of biohydrogen production from sustainable orange peel wastes using Enterobacter species isolated from domestic wastewater. Int J Energy Res 43:391–404. https://doi.org/10.1002/er.4273

Iyyappan J, Bharathiraja B, Varjani S, PraveenKumar R, Kumar SM (2022) Anaerobic biobutanol production from black strap molasses using Clostridium acetobutylicum MTCC11274: media engineering and kinetic analysis. Biores Technol. https://doi.org/10.1016/j.biortech.2021.126405

Li Z, Wang H, Tang Z, Wang X, Bai J (2008) Effects of pH value and substrate concentration on hydrogen production from the anaerobic fermentation of glucose. Int J Hydrogen Energy 33:7413–7418. https://doi.org/10.1016/j.ijhydene.2008.09.048

Wang J, Wan W (2009) Optimization of fermentative hydrogen production process using genetic algorithm based on neural network and response surface methodology. Int J Hydrogen Energy 34:255–261. https://doi.org/10.1016/j.ijhydene.2008.10.010

Sriyod K, Reungsang A, Plangklang P (2021) One-step multi enzyme pretreatment and biohydrogen production from Chlorella sp. biomass. Int J Hydrogen Energy 46:39675–39687. https://doi.org/10.1016/j.ijhydene.2021.09.232

Derde LJ, Gomand SV, Courtin CM, Delcour JA (2012) Characterisation of three starch degrading enzymes: thermostable β-amylase, maltotetraogenic and maltogenic α-amylases. Food Chem 135:713–721. https://doi.org/10.1016/j.foodchem.2012.05.031

Ramprakash B, Muthukumar K (2014) Comparative study on the production of biohydrogen from rice mill wastewater. Int J Hydrogen Energy 39:14613–14621. https://doi.org/10.1016/j.ijhydene.2014.06.029

Puad NIM, Rahim NFA, Azmi AS (2018) Acid Pretreatment of Sago Wastewater for Biohydrogen Production. International Conference on Civil & Environmental Engineering (CENVIRON 2017) 34. https://doi.org/10.1051/e3sconf/20183402012

Leaño EP, Babel S (2012) Effects of pretreatment methods on cassava wastewater for biohydrogen production optimization. Renewable Energy 39:339–346. https://doi.org/10.1016/j.renene.2011.08.030

Orozco RL, Redwood MD, Leeke GA, Bahari A, Santos RCD, Macaskie LE (2012) Hydrothermal hydrolysis of starch with CO2 and detoxification of the hydrolysates with activated carbon for bio-hydrogen fermentation. Int J Hydrogen Energy 37:6545–6553. https://doi.org/10.1016/j.ijhydene.2012.01.047

Rao R, Basak N (2021) Optimization and modelling of dark fermentative hydrogen production from cheese whey by Enterobacter aerogenes 2822. Int J Hydrogen Energy 46:1777–1800. https://doi.org/10.1016/j.ijhydene.2020.10.142

Sengupta S, Jana ML, Sengupta D, Naskar AK (2000) A note on the estimation of microbial glycosidase activities by dinitrosalicylic acid reagent. Appl Microbiol Biotechnol 53:732–735. https://doi.org/10.1007/s002530000327

Nielsen SS (2009) Phenol-sulfuric acid method for total carbohydrates. In: Coupland J, Ferruzzi M, Hartel RW, Morawicki RM, Nielsen SS, Silva JL (eds) Food analysis laboratory manual. Springer. https://doi.org/10.1007/978-1-4419-1463-7_6

Gilcreas FW (1966) Standard methods for the examination of water and waste water. Am Public Health Assoc. https://doi.org/10.2105/AJPH.56.3.387

Hu Y, Zhao N, Gan T, Duan J, Yu HJ, Meng D, Liu J, Liu W (2017) Analytic method on characteristic parameters of bacteria in water by multiwavelength transmission spectroscopy. J Spectrosc 2017:7. https://doi.org/10.1155/2017/4039048

Tao Y, Chen Y, Wu Y, He Y, Zhou Z (2007) High hydrogen yield from a two-step process of dark- and photo-fermentation of sucrose. Int J Hydrogen Energy 32:200–206. https://doi.org/10.1016/j.ijhydene.2006.06.034

Chen C-C, Lin C-Y, Lin M-C (2002) Acid–base enrichment enhances anaerobic hydrogen production process. Appl Microbiol Biotechnol 58:224–228. https://doi.org/10.1007/s002530100814

Malik SN, Pugalenthi V, Vaidya AN, Ghosh PC, Mudliar SN (2013) Kinetics of nano-catalysed dark fermentative hydrogen production from distillery wastewater. Energy Procedia 54:417–430. https://doi.org/10.1016/j.egypro.2014.07.284

Chaitanya N, Kumar BS, Himabindu V, Lakshminarasu M, Vishwanadham M (2017) Strategies for enhancement of bio-hydrogen production using mixed cultures from starch effluent as substrate. Biofuels 9:341–352. https://doi.org/10.1080/17597269.2016.1271626

Singh N, Rai P, Pandey A, Pandey A (2022) Exploring the potential of Bacillus licheniformis AP1 for fermentive biohydrogen production using starch substrate: BBD based process parameter optimization. Fuel. https://doi.org/10.1016/j.fuel.2022.123668

Hossain MS, Rahim NA, Aman MM, Selvaraj J (2019) Application of ANOVA method to study solar energy for hydrogen production. Int J Hydrogen Energy 44:14571–14579. https://doi.org/10.1016/j.ijhydene.2019.04.028

Miao M, Jiang B, Zhang T, Jin Z, Mu W (2011) Impact of mild acid hydrolysis on structure and digestion properties of waxy maize starch. Food Chem 126:506–513. https://doi.org/10.1016/j.foodchem.2010.11.031

Das SR, Basak N (2022) Optimization of process parameters for enhanced biohydrogen production using potato waste as substrate by combined dark and photo fermentation. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-02588-w

Ulhiza TA, Puad NIM, Azmi AS (2018) Optimization of culture conditions for biohydrogen production from sago wastewater by Enterobacter aerogenes using response surface methodology. Int J Hydrogen Energy 43:22148–22158. https://doi.org/10.1016/j.ijhydene.2018.10.057

Stavropoulos KP, Kopsahelis A, Zafiri C, Kornaros M (2016) Effect of pH on continuous biohydrogen production from end-of-life dairy products (EoL-DPs) via dark fermentation. Waste Biomass Valorization 7:753–764. https://doi.org/10.1007/s12649-016-9548-7

Mitra R, Balachandar G, Singh V, Sinha P, Das D (2017) Improvement in energy recovery by dark fermentative biohydrogen followed by biobutanol production process using obligate anaerobes. Int J Hydrogen Energy 42:4880–4892. https://doi.org/10.1016/j.ijhydene.2017.01.183

Bagy MMK, Abd-Alla MH, Morsy FM, Hassan EA (2014) Two stage biodiesel and hydrogen production from molasses by oleaginous fungi and Clostridium acetobutylicum ATCC 824. Int J Hydrogen Energy 39:3185–3197. https://doi.org/10.1016/j.ijhydene.2013.12.106

Cappelletti BM, Reginatto V, Amante ER, Antônio RV (2011) Fermentative production of hydrogen from cassava processing wastewater by Clostridium acetobutylicum. Renewable Energy 36:3367–3372. https://doi.org/10.1016/j.renene.2011.05.015

Avcı A, Kılıç NK, Dönmez G, Dönmez S (2013) Evaluation of hydrogen production by Clostridium strains on beet molasses. Environ Technol 35:278–285. https://doi.org/10.1080/09593330.2013.826251

Sharma Y, Li B (2009) Optimizing hydrogen production from organic wastewater treatment in batch reactors through experimental and kinetic analysis. Int J Hydrogen Energy 34:6171–6180. https://doi.org/10.1016/j.ijhydene.2009.06.031

Khamaiseh EI, Hamid AA, Abdeshahian P, Yusoff WMW, Kalil MS (2014) Enhanced butanol production by Clostridium acetobutylicum NCIMB 13357 grown on date fruit as carbon source in P2 medium. Sci World J 2014:7. https://doi.org/10.1155/2014/395754

Geng A, He Y, Qian C, Yan X, Zhou Z (2010) Effect of key factors on hydrogen production from cellulose in a co-culture of Clostridium thermocellum and Clostridium thermopalmarium. Biores Technol 101:4029–4033. https://doi.org/10.1016/j.biortech.2010.01.042

Ramprakash B, Muthukumar K (2018) Influence of sulfuric acid concentration on biohydrogen production from rice mill wastewater using pure and coculture of Enterobacter aerogenes and Citrobacter freundii. Int J Hydrogen Energy 43:9254–9258. https://doi.org/10.1016/j.ijhydene.2018.03.198

Pachapur VL, Sarma SJ, Brar SK, Bihan YL, Buelna G, Verma M (2015) Biohydrogen production by co-fermentation of crude glycerol and apple pomace hydrolysate using co-culture of Enterobacter aerogenes and Clostridium butyricum. Biores Technol 193:297–306. https://doi.org/10.1016/j.biortech.2015.06.095

Fabiano B, Perego P (2002) Thermodynamic study and optimization of hydrogen production by Enterobacter aerogenes. Int J Hydrogen Energy 27:149–156. https://doi.org/10.1016/S0360-3199(01)00102-1

Choonut A, Saejong M, Sangkharak K (2014) The production of ethanol and hydrogen from pineapple peel by Saccharomyces cerevisiae and Enterobacter aerogenes. Energy Procedia 52:242–249. https://doi.org/10.1016/j.egypro.2014.07.075

Ren Y, Wang J, Liu Z, Ren Y, Li G (2009) Hydrogen production from the monomeric sugars hydrolyzed from hemicellulose by Enterobacter aerogenes. Renewable Energy 34:2774–2779. https://doi.org/10.1016/j.renene.2009.04.011

Hasibar B, Ergal İ, Moser S, Bochmann G, Rittmann SK-MR, Fuchs W (2020) Increasing biohydrogen production with the use of a co-culture inside a microbial electrolysis cell. Biochem Eng J. https://doi.org/10.1016/j.bej.2020.107802

Mishra P, Roy S, Das D (2015) Comparative evaluation of the hydrogen production by mixed consortium, synthetic co-culture and pure culture using distillery effluent. Biores Technol 198:593–602. https://doi.org/10.1016/j.biortech.2015.09.074

Cheng J, Zhu M (2013) A novel anaerobic co-culture system for bio-hydrogen production from sugarcane bagasse. Biores Technol 144:623–631. https://doi.org/10.1016/j.biortech.2013.07.018

Mu Y, Zheng X-J, Yu H-Q (2009) Determining optimum conditions for hydrogen production from glucose by an anaerobic culture using response surface methodology (RSM). Int J Hydrogen Energy 34:7959–7963. https://doi.org/10.1016/j.ijhydene.2009.07.093

Abdeshahian P, Al-Shorgani NKN, Salih NKM, Shukor H, Kadier A, Hamid AA, Kalil MS (2014) The production of biohydrogen by a novel strain Clostridium sp. YM1 in dark fermentation process. Int J Hydrogen Energy 39:12524–12531. https://doi.org/10.1016/j.ijhydene.2014.05.081

Fan Y, Li C, Lay J-J, Hou H, Zhang G (2004) Optimization of initial substrate and pH levels for germination of sporing hydrogen-producing anaerobes in cow dung compost. Biores Technol 91:189–193. https://doi.org/10.1016/S0960-8524(03)00175-5

Bao H, Chen C, Jiang L, Liu Y, Shen M, Liu W, Wang A (2015) Optimization of key factors affecting biohydrogen production from microcrystalline cellulose by the co-culture of Clostridium acetobutylicum X9 + Ethanoigenens harbinense B2. RSC Adv 6:3421–3427. https://doi.org/10.1039/C5RA14192C

Wang S, Ma Z, Zhang T, Bao M, Su H (2017) Optimization and modeling of biohydrogen production by mixed bacterial cultures from raw cassava starch. Front Chem Sci Eng 11:100–106. https://doi.org/10.1007/s11705-017-1617-3

Islam MS, Zhang C, Sui K-Y, Guo C, Liu C-Z (2017) Coproduction of hydrogen and volatile fatty acid via thermophilic fermentation of sweet sorghum stalk from co-culture of Clostridium thermocellum and Clostridium thermosaccharolyticum. Int J Hydrogen Energy 42:830–837. https://doi.org/10.1016/j.ijhydene.2016.09.117

Rao R, Basak N (2022) Sequential dark-photo batch fermentation and kinetic modelling for biohydrogen production using cheese whey as a feedstock. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-022-03958-w

Zhang H, Wang X (2016) Modular co-culture engineering, a new approach for metabolic engineering. Metab Eng 37:114–121. https://doi.org/10.1016/j.ymben.2016.05.007

Rao R, Basak N (2021) Process optimization and mathematical modelling of photo-fermentative hydrogen production from dark fermentative cheese whey effluent by Rhodobacter sphaeroides O.U.001 in 2-L cylindrical bioreactor. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-01377-1

Basak N, Jana AK, Das D (2021) Photofermentative biohydrogen generation from organic acids by Rhodobacter sphaeroides O.U.001: Computational fluid dynamics modeling of hydrodynamics and temperature. Biotechnol Appl Biochem 69:783–797. https://doi.org/10.1002/bab.2151

Acknowledgements

The authors are thankful to the Ministry of Education (MoE), Government of India, for providing post-graduation fellowship to the first author. The authors are extremely grateful to the facilities and support provided by the Department of Biotechnology, Dr. B R Ambedkar National Institute of Technology, Jalandhar, India, for the conduct of experiments and completion of this work.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Conceptualization, Investigation, Validation of results and Writing—original draft: VJ. Conceptualization, Validation of results and interpreted data, Writing—review and editing, and overall supervision of study: NB. All authors have reviewed and approved the final version of the manuscript for submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no competing financial interests or personal relationship that influence the work in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jayachandran, V., Basak, N. Optimization of dark fermentative biohydrogen production from rice starch by Enterobacter aerogenes MTCC 2822 and Clostridium acetobutylicum MTCC 11274. Bioprocess Biosyst Eng 46, 535–553 (2023). https://doi.org/10.1007/s00449-022-02838-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-022-02838-1