Abstract

An investigation was carried out using sugarcane bagasse as the agricultural residue to study the optimization of xylanase production by solid-state fermentation. Maximum xylanase production (20.35 U/g substrate) was achieved by Bacillus substilis subsp. subtilis JJBS250 using ‘one variable at a time approach’ at pH 7.0, 40 °C after 48 h. After statistical optimization by response surface methodology (RSM) there was 4.82-fold improvement in xylanase production (98.16 U/g substrate). Further optimization of untreated and sodium carbonate pretreated sugarcane bagasse enzymatic hydrolysis was carried out using both bacterial (Bacillus substilis subsp. subtilis JJBS250) and fungal (Myceliophthora thermophila BJTLRMDU3) xylanases that showed high amount of reducing sugar liberation from untreated sugarcane bagasse (124.24 mg/g substrate) as compared to pretreated (76.23 mg/g substrate) biomass. Furthermore, biophysical characterization of untreated and sodium carbonate pretreated sugarcane bagasse using Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) and scanning electron microscopy (SEM), revealed the structural changes in the pretreated biomass.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is a major concern of environmental pollution due to the rising of agro-industrial waste generated from sugarcane bagasse, rice straw, wheat straw, wastes of vegetables, oil refinery, coconut husk, groundnut shell, etc. This leads to complexity in utilization and recycling of this waste. It consists of hemicelluloses (25%), lignin (25%) and cellulose (50%), which can be utilized by the microorganisms for the production of xylanases [1]. Solid-state fermentation is one of the eco-friendly alternatives to produce different value-added products (enzymes, biopesticides, bioflavor, biosurfactant, organic acids) via microbial fermentation using these agro-industrial residues which finally results in cleaner and greener environment [2]. Economical hemicellulosic agricultural residues like sugarcane bagasse, rice straw, rice bran, wheat straw, wheat bran, corn cob and others have been reported as ideal solid substrate for the xylanase production using various fungal and bacterial genera including Bacillus, Aspergillus, Clostridium, Rhizopus, Fusarium, Streptomyces, Micrococcus, Staphylococcus, Pseudomonas, Cellulomonas, etc.[3].

Sugarcane bagasse is the major byproduct of the sugarcane industry, which consists of about 25% lignin, 25% hemicelluloses and 50% cellulose. The fibrous nature of sugarcane bagasse with high content of hemicellulose and cellulose induced the xylanase production by microorganisms. Due to huge availability, it is used as a perfect substrate for the production of various value-added products using microbial fermentations [4]. But the high content of lignin hinders the saccharification of sugarcane bagasse using enzymes. Therefore, pretreatment methods have been used to access cellulose and hemicellulose for enzymatic hydrolysis. Pretreatment disrupts the lignocellulosic matrix and removes lignin that is the main barrier of hydrolysis [5]. Xylan, the major constituent of hemicellulose, is a linear backbone of 1,4-β-linked D-xylose units [6]. Xylanases hydrolyse the β-1,4 d-xylopyranosyl linkages of the β-1,4 d-xylans into monomeric and oligomeric sugars [7]. Xylanases are under enormous research due to their prospects in biofuel production, food industries, animal feed, paper and pulp, textiles industries and many others [3].

The economics of a microbial enzyme-based process can be determined by the cost of the enzyme which is one of the major factors. Therefore, optimizing the culture conditions is the main purpose of basic research for industrial applications [8]. RSM is a statistical technique used to design minimum number of experiments for large number of components to improve the enzyme activity. Using this, the connection between a group of controlled experimental factors and the observed results of one or more variables can be assessed [7]. Optimization of xylanase production was carried out in SSF using B. subtilis subsp. subtilis JJBS250. In the present research work, B. subtilis subsp. subtilis JJBS250 utilized low-cost sugarcane bagasse for maximum xylanase production followed by its applicability in saccharification of untreated and sodium carbonate pretreated sugarcane bagasse.

Materials and methods

Source and growth conditions of bacterial and fungal culture

Bacillus subtilis subsp. subtilis JJBS250 was isolated from soil sample and regularly grown on nutrient agar (pH 7.0) medium at 37 °C [9]. The bacterial culture was preserved in glycerol stocks at − 20 °C and on nutrient agar plates at 4 °C [10]. Myceliophthora thermophila BJTLRMDU3 was grown and maintained under conditions as described by Dahiya and Singh [11].

Cultivation in solid state fermentation

Bacterial xylanase cultivation medium containing 5 g of sugarcane bagasse substrate at a ratio of 4:1 with moistening medium [(%w/v) (NH4)2SO4 0.50, MgSO4·7H2O 0.10, K2HPO4 0.10 and NaCl 0.10] was autoclaved for 30 min at 121 °C. After cooling, the flasks were inoculated under sterile conditions and incubated at 35 °C. Similarly, fungal xylanase cultivation medium containing 5 g of substrate at a ratio of 1:7 with moistening medium [(% w/v) NH4NO3 2.0, K2HPO4 0.5, Sucrose 2.0 and Tween 20 3.0] was autoclaved for 30 min at 121 °C. After cooling, the flasks were inoculated under sterile conditions and incubated at 45 °C under static conditions for 4 days.

Extraction of enzymes

After cultivation, 50 ml distilled water containing 0.1% Tween 80 was added to SSF medium and kept under shaking for 30 min at room temperature. Then, the obtained mixture was filtered, squeezed through the muslin cloth and the filtered crude supernatant was used as the xylanase source.

Xylanase assay

The xylanase assay was performed as described by Alokika et al. [9]. Using DNS method, the amount of reducing sugar liberation was estimated as reported by Miller [12]. One enzyme unit (IU) is defined as the amount of xylanase required to liberate 1µmole of xylose per min under the assay conditions.

Optimization of culture conditions for xylanase production

Xylanase production was first optimized by ‘one variable at a time approach’ and then by RSM a statistical approach under solid-state fermentation. Various culture conditions effect such as different substrates (wheat bran, wheat straw, rice bran, rice straw, sugarcane bagasse, cotton oil cake), pH (4.0–8.0), temperatures (30–45 ˚C), moistening media (tap water, distilled water, solution 1 [(% w/v) K2HPO4 0.1, (NH4)2SO4 1.0, MgSO4·7H2O 0.30, CaCl2 0.10, FeSO4·7H2O 0.10 and MnSO4 0.10], solution 2 [(% w/v) (NH4)2SO4 0.50,MgSO4·7H2O 0.10, K2HPO4 0.10 and Nacl 0.10], solution3 [(% w/v) K2HPO4 1.0, Cacl2 0.03, MgSO4·7H2O 0.30 and FeSO4·7H2O 0.03]), different moisture ratio (1:2, 1:2.5, 1:3, 1:4), nitrogen sources (ammonium sulphate, ammonium nitrate, potassium nitrate, beef extract, yeast extract, tryptone, peptone), incubation time (24–96 h), surfactants (Tween 80, Tween 20, Triton X-100, SDS), polyethylene glycols (PEG 400, 4000, 8000, 20000) and water activity (100%, 0.95%, 0.92%, 0.87%, 0.82%).

On the basis of ‘one variable at a time’ approach, three variables viz. tryptone (A), tween 20 (B) and PEG 20000 (C) were selected as the most significant factors which affect xylanase production. The basal medium containing sugarcane bagasse (5 g) optimized in the design was studied with five different levels of each variable at pH 7.0 (Table 1). With a set of 20 experiments, statistical software was used as described earlier [9].

Using quadratic equation, behaviour of the system was explained as follows:

where Y denotes predicted response (Enzyme production), β0 as intercept, β1, β2, β3 as linear coefficient, β11, β22, β33 as squared coefficient, β1,2, β1,3, β2,3 as interaction coefficients and A, B, C, A2, B2, C2, AB, AC, BC as factors.

Pretreatment of sugarcane bagasse with sodium carbonate

Pretreatment of sugarcane bagasse was carried out using 10% (w/v) substrate and sodium carbonate (1% w/v) followed by autoclaving (121 °C) for 60 min. After autoclaving, the pretreated substrate was washed properly with distilled water and used for enzymatic hydrolysis after drying properly at 60 °C overnight.

Optimization of enzymatic hydrolysis

For enzymatic hydrolysis, 0.5 g of untreated and pretreated substrate supplemented with 20 ml potassium phosphate buffer (0.1 M) containing combination of bacterial and fungal xylanase was taken and kept under shaking conditions at 60˚C. Optimization was carried out using different parameters like enzyme doses (5–100 U/g), different pH (5.0, 7.0), different ratios of enzyme doses and different time intervals (0–48 h). Insoluble solids in the samples were removed after centrifugation at 10,000 rpm for 10 min and the amount of reducing sugars was evaluated as described earlier by Alokika et al. [9].

Biophysical characterization of sugarcane bagasse

Biophysical characterization of untreated and sodium carbonate pretreated samples of sugarcane bagasse was carried out using SEM, FTIR and XRD analysis. Surface images of untreated and pretreated sugarcane bagasse were obtained by JSM-6510 (JEOL) scanning electron microscope. For sample preparation, untreated and sodium carbonate pretreated sugarcane bagasse were mounted on aluminium stubs using double-coated tape with gold layer. Images were captured at 500 X magnification and 15.00 kV. FTIR analysis was carried out for the analysis of changes in functional group, morphological and structural modifications after the pretreatment of lignocellulosic biomass. The present work assessed chemical and structural changes of sodium carbonate pretreated sugarcane bagasse in comparison with untreated sugarcane bagasse. FTIR spectrum of samples was recorded between the resolutions of 500–4000 cm−1, at 24 scans per sample [5]. XRD method was used for comparing cellulose crystallinity of untreated and pretreated sugarcane bagasse samples. First of all, the sugarcane bagasse samples were dried in oven at 60 °C overnight and then powdered samples were used for XRD (Rigaku Miniflex 600). Peaks were analysed between 10° to 70° 2-theta (deg) intensities and at a scanning speed of 0.002°/scan. Using following equation, cellulose crystallinity index was calculated [13]:

where Iam and I002 are amorphous phase from the (002) lattice plane and peak intensity of crystalline.

Reducing sugar analysis using high-pressure liquid chromatography (HPLC)

The hydrolysates of untreated and sodium carbonate pretreated sugarcane bagasse of 24 h were evaluated using HPLC for analysing the presence of sugars. Column used for HPLC was Aminex 87hpx (BioRad, USA) using milli Q water as an eluent at flow rate of 0.3 ml/min at room temperature with refractive index (RI) detector.

Results

Culture condition optimization for xylanase production

Bacillus subtilis subsp. subtilis JJBS250 has been reported for xylanase production in submerged fermentation [9]. In the present study, xylanase production was observed using sugarcane bagasse under SSF. Sugarcane bagasse favoured high xylanase production (20.35 U/g substrate) by B. subtilis subsp. subtilis JJBS 250 as compared to other substrates (Fig. 1a) moistened with moistening medium [(% w/v) (NH4)2SO4 0.50, MgSO4·7H2O 0.10, K2HPO4 0.10, NaCl 0.10] with moisture to substrate ratio of 4:1 at 40 °C and pH 7.0 after 48 h. The transport of several enzymes across the cell membrane and the solubility of some medium components is highly influenced by pH [14]. High xylanase production (19.00 U/g substrate) was observed by bacterial culture at pH 7.0 (Fig. 1b). Results revealed maximum xylanase production (26.53 U/g substrate) by bacterial culture at 40 °C followed by decline afterwards (Fig. 1c).

Maximum xylanase production (15.40 U/g substrate) was supported by solution 2 as compared to others (Table 2). Different moisture ratios were tested to check the optimum xylanase production. Results revealed that the moisture ratio of 1:4 was found optimum for high xylanase production (19.98 U/g substrate) (Table 2). The rate of water absorption by different substrates varies from one substrate to another [15]. Among all nitrogen sources, tryptone supported high xylanase titre (33.03 U/g substrate) by B. subtilis subsp. subtilis JJBS250 (Table 2). Using sugarcane bagasse as a substrate, xylanase production was observed maximally after 48 h (32.56 U/g substrate) (Table 2). Among all surfactants, high xylanase titre (32.59 U/g substrate) was observed by the addition of Tween 20 (Table 2). Xyalanse production was enhanced (32.54 U/g substrate) by the addition of PEG 20000 as compared to other (Table 2). Water activity effected xylanase production and high xylanase production (29.89 U/g substrate) was observed at 100% water activity (Table 2).

Optimization of fermentation parameters using statistical design for improved xylanase production

Maximum xylanase production (20.35 U/g substrate) was achieved by B. subtilis subsp. subtilis JJBS250 using ‘one variable at a time approach’ at 40 °C, pH 7.0 after 48 h. To enhance xylanase production, medium components were further optimized using RSM and xylanase production ranged from 61.58 U/g to 98.16 U/g (Table 3). The results were analysed using analysis of variance (ANOVA) and xylanase production (Y) was calculated from regression analysis as a function of these variables using the following equation:

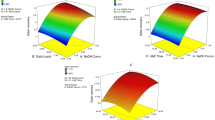

Different criteria like correlation coefficient (predicted R2), coefficient of determination (adjusted R2), adequate precision, model F and values of P > F can be used for interpreting the quality of the model as given in Table 4. All these values justify the significance and variability in the model. The 3D plots of interactions between the variables showed maximum xylanase production upto the optimum level followed by decline afterwards (Fig. 2). The experimental value for xylanase production was observed as 98.16 U/g substrate, whereas predicted value was 97.71 U/g substrate. The experimental and predicted values are very close, hence, revealing that the model is significant for xylanase production. As a result of statistical analysis, there was 4.82-fold improvement in the xylanase production by B. subtilis subsp. subtilis JJBS250 using sugarcane bagasse as a substrate under SSF.

Optimization of enzymatic hydrolysis of untreated and sodium carbonate pretreated sugarcane bagasse

Hydrolysis of untreated and sodium carbonate pretreated sugarcane bagasse was carried out using bacterial and fungal xylanases and reducing sugars were analysed. Results revealed that from the hydrolysis of untreated sugarcane bagasse, high amount of reducing sugars was attained by both bacterial (36.39 mg/g substrate) and fungal xylanases (34.19 mg/g substrate) at 20 U/g (Fig. 3a). Among different pH values, high amount of reducing sugars was released by the synergistic action of bacterial and fungal xylanases at pH 7.0 (37.80 mg/g substrate) (Fig. 3b). A combination comprising of 12 U/g bacterial xylanase and 8 U/g fungal xylanase resulted in enhanced saccharification of sugarcane bagasse (36.17 mg/g substrate). High amount of reducing sugars was released from untreated sugarcane bagasse (124.24 mg/g substrate) as compared to sodium carbonate pretreated biomass (76.23 mg/g substrate) after 48 h (Fig. 3c).

Optimization of enzymatic hydrolysis of untreated sugarcane bagasse at a different enzyme doses, b enzyme doses with different pH, BX and FX represents bacterial xylanase and fungal xylanase, respectively and c effect of reaction time on the saccharification of untreated and sodium carbonate pretreated sugarcane bagasse

Biophysical characterization using SEM, FTIR and XRD analysis

SEM produces images by scanning the surface of samples with a focused beam of electrons. In our study, surface images of untreated and sodium carbonate pretreated sugarcane bagasse were compared. Figure 4a showed rough, compact, rigid, ordered structure of untreated sugarcane bagasse while pretreated sugarcane bagasse showed loosening of fibrous network, with appearance of lignin droplets and pores (Fig. 4b).

Scanning electron microscopy of a untreated and b sodium carbonate pretreated sugarcane bagasse. c Fourier-transform infrared spectra of untreated, pretreated and enzymatic treated sugarcane bagasse. d X-ray diffraction spectra of untreated (blue) and pretreated (red) sugarcane bagasse (color figure online)

FTIR spectroscopy is used to examine morphological, structural changes of untreated and pretreated lignocellulosic biomass [5, 16]. The FTIR spectrum of untreated, sodium carbonate pretreated and enzymatic hydrolyzed sugarcane bagasse showed relative changes in the absorbance at specific band positions (Fig. 4c). According to the previous studies, the region between 3100 and 3600 cm−1 has been assigned to the OH stretching and 2890–2940 cm−1 for C–H stretching. Various other ranges like between, 1660–1630, 1600–1610, 1505–1510 are associated with conjugated C=O stretch aromatic skeletal vibrations. Bands between 1380–1370, 1060–1040 showed C–H deformation in cellulose and hemicelluloses and C-O stretch in cellulose and hemicelluloses, respectively. In our result, untreated and enzyme treated sugarcane bagasse shows highest absorbance but sodium carbonate pretreated ones show smallest absorbance. The absorption bands and corresponding assignments are given in Table 5. Results revealed that the peak around 3330 cm−1 assigned to the OH stretching and 2897 to the C–H stretching. Bands at 1602 cm−1, 1631 cm−1 and 1633 cm−1 are associated with conjugated C=O stretch aromatic skeletal vibrations. Peaks around 1514 cm−1 and 1031 cm−1 attributed to aromatic ring vibrations and C–O stretch (primary alcohol).

X-ray diffraction (XRD) analysis is a suitable technique which revealed the crystallinity index of lignocellulosic biomass. Crystallinity index (Crl, %) is used to measure the relative amount of crystalline material present in the lignocellulosic biomass and it also affects the enzymatic saccharification of biomass [5, 17]. After various pretreatments, cellulose structure and crystallinity in the biomass could change due to disrupting inter and intra chain hydrogen bonding of cellulose fibrils [16]. Our both samples showed typical XRD peaks of cellulose at 2-theta of 20–30o (degree) (Fig. 4d). Sodium carbonate preteated sugarcane bagasse showed more elevated peak in comparison to untreated biomass.

Reducing sugar analysis

HPLC profiles of hydrolysates of untreated and sodium carbonate pretreated sugarcane bagasse showed release of different sugars like glucose, xylose, xylohexose, cellobiose and arabinose (Fig. 5a, b). These sugars can be utilized in many fermentation processes. A good amount of xylose, xylohexose and cellobiose released by untreated bagasse is also advantageous because many microorganisms converted these sugars into value-added products like biofuels.

Discussion

Solid-state fermentation by utilizing less cost agricultural residues provides various economic advantages for the production of enzymes that can be used in various industrial applications [14]. In our study, sugarcane bagasse favoured high xylanase production by Bacillus subtilis subsp. subtilis JJBS250 as compared to other substrates. The high xylanase yield on sugarcane bagasse was due to relatively high levels of hemicellulose in this substrate [15]. Similarly, high xylanase titre was reported by Aspergillus niger [18], Penicillium citrinum [2], Trichoderma viride-IR05 [19] using sugarcane bagasse as a substrate under SSF conditions. High xylanase production was observed by bacterial culture at pH 7.0. Similarly, Ho and Heng [20] observed maximum xylanase production at pH 6.5 by Bacillus subtilis. Some other investigators reported highest xylanase titre at pH 7.0 by Streptomyces sp [21]. and by Bacillus sp. at pH 8.0 under SSF [14]. Maximum xylanase production by B. subtilis subsp. subtilis JJBS250 was recorded at 40 °C that declined afterwards. Similarly, high xylanase production by B. subtilis [20], B. subtilis ASH [22], B. megatherium [23], Bacillus sp. PKD [14] and B. pumilus VLK-1 [24] was attained at 37 ˚C in SSF. Abdel-Sater and El-Said [25] observed high xylanase titre at 35 ˚C using Trichoderma harzianum.

The maximum xylanase production was supported by solution 2 [(% w/v) (NH4)2SO4 0.50, MgSO4·7H2O 0.10, K2HPO4 0.10 and Nacl 0.10]. Ghoshal et al. [2] observed high xylanase titre by P. citrinum using Czapek yeast extract media (201.91 U/gds) as compared to other moistening media. In the study of Sanghi et al. [22] high xylanase production (7988 ± 10.41 U/g) was reported using moistening solution by Bacillus subtilis ASH. The moisture ratio of 1:4 was found optimum for high xylanase production by Bacillus subtilis subsp. subtilis JJBS250 as also reported by Panwar et al. [14]. The available water can be absorbed by substrate particles, which provides best conditions for microbial metabolic activity and growth [4]. There is lower degree of swelling and higher water tension of the nutrients of the solid substrate due to lower moisture content [26]. In some other findings, highest xylanase production was reported at a substrate to moisture ratio of 1:2.5 and 1:2 by B. pumilus VLK-1 [24] and B. subtilis ASH [22], respectively.

Among all nitrogen sources, tryptone supported high xylanase titre by B. subtilis subsp. subtilis JJBS250. Similarly, Irfan et al. [19] found high xylanase production by T. viride-IR05 using tryptone as a nitrogen source. In contrast, Kumar et al. [24] and Shangi et al. [22] observed maximum xylanase production using yeast extract by B. pumilus VLK-1 and B. subtilis ASH, respectively. There was gradual increase in enzyme production upto 48 h by the bacterial culture in SSF as reported by Ho and Heng [20]. After that there was gradual decrease in enzyme activity that could be due to the depletion of essential growth nutrients and accumulation of toxic products in the medium [26]. Duration of incubation time affects the growth rate of microorganism and enzyme production. Therefore, in case of bacteria as compared to fungi, less time is required for enzyme production due to their faster doubling time [22]. In contrast, Poorna and Prema [27] and Sanghi et al. [22] reported high xylanase titre after 72 h by the microorganisms in SSF.

Among all surfactants, high xylanase titre was observed by the addition of Tween 20 as reported in Streptomyces sp. ESRAA-301097 [21]. In some other reports, enhanced xylanase production was observed by addition of Tween 80 under SSF [19, 24, 28]. Xyalanse production by bacterial culture was also enhanced by the addition of PEG 20000 as reported in B. pumilus MK001 by Kapoor et al. [29]. Sharma et al. [30] also observed that addition of PEG improved laccase production from Ganoderma sp. kk-02. Maximum xylanase production by the bacterial culture was observed at 100% water activity (aw 0.99) as reported for xylanase production by Sporotrichum thermophile BJAMDU5 [28]. In contrast, Singh and Satyanarayana [31] and Kumar and Satyanarayana [32] reported high phytase and glucoamylase production by S. thermophile and Thermomucor indicae-seudaticae at low water activity (aw 0.95).

In our study, as a result of RSM, there was 4.82-fold improvement in the xylanase production by B. subtilis subsp. subtilis JJBS250 using sugarcane bagasse as a substrate under SSF. Khusro et al. [7] observed 3.7-fold improvement in xylanase production as a result of RSM by B. subtilis ARMATI. Panwer et al. [14] observed 1.30-fold increase in the production of xylanase by Bacillus sp. PKD after statistical optimization.

Usually high amounts of reducing sugars have been reported after pretreatment of lignocellulosic biomass. But present work showed antagonistic results in terms of liberation of reducing sugars. In this study, high amounts of reducing sugars were liberated from untreated sugarcane bagasse (124.24 mg/g substrate) as compared to sodium carbonate pretreated bagasse (76.23 mg/g substrate). This may be due to pretreatment of bagasse by physical grinding used for reducing particle size. Saccharification of sugarcane bagasse was significantly increased after various pretreatment using xylanolytic and cellulolytic enzymes of S. thermophile [28]. Chong et al. [33] reported that dilute alkali pretreatment enhanced the saccharification of sugarcane bagasse. Similarly, Chandel et al. [17] observed high reducing sugars (48.50 g/l) after acid/base pretreatment of sugarcane bagasse.

Morphological analysis of untreated and pretreated sugarcane bagasse using SEM showed rough, rigid and highly ordered structure of untreated sugarcane bagasse as compared to pretreated one which showed partial deconstruction of biomass surface, exposure of fibres and high disruption [5]. Similarly, untreated sugarcane bagasse showed rigid, highly ordered and compact structures while more fragmented structures were observed in pretreated samples [33]. Chandel et al. [17] reported rough, compact and thick-walled parallel fibres in untreated sugarcane bagasse, while disrupted cell wall with loose matrix and pores was shown in pretreated biomass.

In our result, untreated and enzyme-treated sugarcane bagasse showed higher absorbance values as compared to sodium carbonate pretreated biomass. This is due to the structural changes in the biomass as a result of pretreatments that modifies the structures of all the macromolecules like cellolose, hemicelluloses and lignin present in plat biomass [5, 17, 34]. Bala and Singh [5] observed structural and functional changes in the pretreated biomass. Nosratpour et al. [34] reported reduction in total crystallinity index of sodium carbonate pretreated biomass. Our results revealed that peaks of untreated and pretreated sugarcane bagasse for cellulose was recorded at 2-theta of 20–30°. Sodium carbonate preteated sugarcane bagasse showed more elevated peak as compared to untreated biomass revealing the removal of non-crystalline components after pretreatment. Similar findings have been observed earlier for chemically pretreated sugarcane bagasse [16, 17].

In our study, HPLC profile of enzymatic hydrolysates of untreated and sodium carbonate pretreated sugarcane bagasse showed the release of many sugars like glucose, xylose, xylohexose, cellobiose and arabinose as reported by Bala and Singh [5] In another study, saccharification of green liquor-ethanol pretreated sugarcane bagasse showed the presence of xylose, glucose, glycerol, ethanol and acetic acid using HPLC [35].

Conclusions

Xylanase production by B. subtilis subsp. subtilis JJBS250 in SSF using sugarcane bagasse was enhanced due to optimization. Optimization of three significant variables using RSM resulted in 4.82-fold higher xylanase production. Moreover, sodium carbonate pretreatment does not affect enzymatic hydrolysis of sugarcane bagasse because untreated sugarcane bagasse liberated high amounts of reducing sugars as compared to untreated biomass. Biophysical characterization using SEM, FTIR and XRD analysis showed structural changes in untreated and pretreated sugarcane bagasse. Furthermore, liberation of various reducing sugars in the enzymatic hydrolysate was confirmed by HPLC data.

References

Camassola M, Dillon AJP (2010) Cellulases and xylanases production by Penicillium echinulatum grown on sugarcane bagasse in solid-state fermentation. Appl Biochem Biotechnol 162:1889–1900

Ghoshal G, Banerjee UC, Shivhare US (2015) Utilization of agrowaste and xylanase production in solid state fermentation. J Biochem Technol 6:1013–1024

Burlacu A, Cornea CP, Israel-Roming F (2016) Microbial xylanase: a review. Sci Bull Ser F Biotechnol 20:335–342

Pandey A, Soccol CR, Nigam P, Soccol VT (2000) Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresour Technol 74:69–80

Bala A, Singh B (2019) Development of an environmental-benign process for efficient pretreatment and saccharification of Saccharum biomasses for bioethanol production. Renew Energ 130:12–24

Kumar S, Haq I, Prakash J, Singh SK, Mishra S, Raj A (2017) Purification, characterization and thermostability improvement of xylanase from Bacillus amyloliquefaciens and its application in pre-bleaching of kraft pulp. 3 Biotech 7:20

Khusro A, Kaliyan BK, Al-Dhabi NA, Arasu MV, Agastian P (2016) Statistical optimization of thermo-alkali stable xylanase production from Bacillus tequilensis strain ARMATI. Electron J Biotechnol 22:16–25

Maciel GM, de Souza Vandenberghe LP, Haminiuk CWI, Fendrich RC, Della Bianca BE, da Silva Brandalize TQ, Pandey A, Soccol CR (2008) Xylanase production by Aspergillus niger LBP 326 in solid-state fermentation using statistical experimental designs. Food Technol Biotechnol 46:183–189

Alokika, Singh D, Singh B (2018) Utility of acidic xylanase of Bacillus subtilis subsp. subtilis JJBS250 in improving the nutritional value of poultry feed. 3 Biotech 8:503.

Jain J, Singh B (2016) Phytase production and development of an ideal dephytinization process for amelioration of food nutrition using microbial phytases. Appl Biochem Biotechnol 181:1485–1495

Dahiya S, Singh B (2019) Enhanced endoxylanase production by Myceliophthora thermophile with applicability in saccharification of agricultural substrates. 3 Biotech 9:214

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–429

Kim S, Holtzapple MT (2006) Effect of structural features on enzyme digestibility of corn stover. Bioresour Technol 97:583–591

Panwar D, Srivastava PK, Kapoor M (2014) Production, extraction and characterization of alkaline xylanase from Bacillus sp. PKD-9 with potential for poultry feed. Biocatal Agric Biotechnol 3:118–125

Addela IR, Gujjula R, Surender M, Nyapati S, Rudravaram R, Bhagam R (2015) Production and optimization of xylanase from Penicillium species in solid-state fermentation. Int J Rec Biotechmol 3:15–21

Saratale GD, Saratale RG, Kim SH, Kumar G (2018) Screening and optimization of pretreatments in the preparation of sugarcane bagasse feedstock for biohydrogen production and process optimization. Int J Hydrog Energ 43:11470–11483

Chandel AK, Antunes FA, Anjos V, Bell MJ, Rodrigues LN, Polikarpov I, de Azevedo ER, Bernardinelli OD, Rosa CA, Pagnocca FC, da Silva SS (2014) Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid–base pretreatment and ethanol production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol Biofuels 7:63

Alebiosu FA, Lawal AK, Olatope SO, Suberu YL, Shittu KA, Orji FA, Adelaja OD, Ugbana AI, Esan OA, Dike EN, Elemo GN (2015) Production of xylanases from fungal isolates by solid state fermentation using sugarcane bagasse. Int J Curr Microbiol App Sci 4:323–331

Irfan M, Nadeem M, Syed Q (2014) One-factor-at-a-time (OFAT) optimization of xylanase production from Trichoderma viridea-IR05 in solid-state fermentation. J Radiat Res Appl Sci 7:317–326

Ho LH, Heng KL (2015) Xylanase production by Bacillus subtilis in cost-effective medium using soybean hull as a part of medium composition under submerged fermentation (SmF) and solid-state fermentation (SsF). J Biodivers Bioprospect Dev 2:143

El-Gendy MMA, El-Bondkly AMA (2014) Optimization of solid state fermentation and leaching process parameters for improvement xylanase production by endophytic Streptomyces sp. ESRAA-301097. J Microb Biochem Technol 6:154–166

Sanghi A, Garg N, Sharma J, Kuhar K, Kuhad RC, Gupta VK (2008) Optimization of xylanase production using inexpensive agro-residues by alkalophilic Bacillus subtilis ASH in solid-state fermentation. World J Microbiol Biotechnol 24:633–640

El-Shishtawy RM, Mohamed SA, Asiri AM, Gomaa AM, Ibrahim IH, Al-Talhi HA (2014) Solid fermentation of wheat bran for hydrolytic enzymes production and saccharification content by a local isolate Bacillus megatherium. BMC Biotechnol 14:29

Kumar L, Nagar S, Kumar D, Garg N, Gupta VK (2013) Production of an alkali tolerant extracellular xylanase from Bacillus pumilus VLK-1 in solid state fermentation and its use in tomato juice clarification. Int J Cell Sci Biotechnol 2:1–10

Abdel-Sater MA, El-Said AHM (2001) Xylan-decomposing fungi and xylanolytic activity in agricultural and industrial wastes. Int Biodeterior Biodegrad 47:15–21

Norazlina I, Meenalosani N, Ku Halim KH (2013) Production of xylanase by Trichoderma sp. via solid state culture using sugarcane bagasse. Int J Energ Sci 3:99–105

Poorna AC, Prema P (2007) Production of cellulase-free endoxylanase from novel alkalophilic thermotolerant Bacillus pumilus by solid state fermentation and its application in waste paper recycling. Bioresour Technol 98:485–490

Bala A, Singh B (2017) Concomitant production of cellulase and xylanase by thermophilic mould Sporotrichum thermophile in solid state fermentation and their applicability in bread making. World J Microbiol Biotechnol 33:109

Kapoor M, Nair LM, Kuhad RC (2008) Cost-effective xylanase production from free and immobilized Bacillus pumilus strain MK001 and its application in saccharification of Prosopis juliflora. Biochem Eng J 38:88–97

Sharma KK, Kapoor M, Kuhad RC (2005) In vivo enzymatic digestion, in vitro xylanase digestion, metabolic analogues, surfactants and polyethylene glycol ameliorate laccase production from Ganoderma sp. kk-02. Lett Appl Microbiol 41:24–31

Singh B, Sataynarayana T (2006) A marked enhancement in phytase production by a thermophilic mould Sporotrichum thermophile using statistical designs in a cost-effective cane molasses medium. J Appl Microbiol 101:344–352

Kumar S, Satyanarayana T (2004) Statistical optimization of a thermostable and neutral glucoamylase production by a thermophilic mold Thermomucor indicae-seudaticae in solid-state fermentation. World J Microbiol Biotechnol 20:895–902

Chong G, Di J, Qian J, Wang C, He Y, Huo X, Wu C, Zhang L, Zhang Z, Tang Y, Ma C (2018) Efficient pretreatment of sugarcane bagasse via dilute mixed alkali salts (K2CO3/K2SO3) soaking for enhancing its enzymatic saccharification. Process Biochem 68:121–130

Nosratpour MJ, Karimi K, Sadeghi M (2018) Improvement of ethanol and biogas production from sugarcane bagasse using sodium alkaline pretreatments. J Environ Manag 226:329–339

You Y, Li P, Lei F, Xing Y, Jiang J (2017) Enhancement of ethanol production from green liquor–ethanol-pretreated sugarcane bagasse by glucose–xylose cofermentation at high solid loadings with mixed Saccharomyces cerevisiae strains. Biotechnol Biofuels 10:92

Acknowledgements

Mrs. Alokika acknowledges the financial assistance as senior Research fellowship (No. 09/382(0179)/2016-EMR-1) from Council of Scientific and Industrial Research, New Delhi during the tenure of this research work. We are thankful to Dr. Rajvinder Singh, Department of Genetics (Forensic Science), M. D. U., Rohtak for providing FTIR facility. We are also thankful to Dr. Anil Ohlan, Department of Physics, M. D. U., Rohtak for extending XRD facility for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alokika, Singh, B. Enhanced production of bacterial xylanase and its utility in saccharification of sugarcane bagasse. Bioprocess Biosyst Eng 43, 1081–1091 (2020). https://doi.org/10.1007/s00449-020-02306-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02306-8