Abstract

Electrolytic manganese residue (EMR) is a type of industrial solid waste with a high silicon content. The silicon in EMR can be used as an essential nutrient for plant growth, but most of the silicon is found in silicate minerals with very low water solubility, that is, it is inactive silicon and cannot be absorbed and used by plants directly. Thus, developing a highly effective and environmentally friendly process for the activation of silicon in EMR is important both for reusing solid waste and environmental sustainability. The aim of this study was to investigate the desilication of EMR using cultures of Paenibacillus mucilaginosus (PM) and Bacillus circulans (BC). The results showed that the two types of silicate bacteria and a mixed strain of them were all able to extract silicon from EMR with a high efficiency, but the desilication performance of the mixed PM and BC was the best. Fourier transform infrared spectroscopy indicated that silicate bacteria can induce a suitable micro-environment near the EMR particles and release Si into the solution through their metabolism. X-ray diffraction analysis confirmed that layered crystal minerals, such as muscovite and diopside, were more likely to be destroyed by the bacterial action than quartz, which has a frame structure. Scanning electron microscopy–energy dispersive spectrometry proved that the silicate structures were destroyed and that Si in the residue was decreased, indicating the dissolution of silicon under the action of these microorganisms. This study suggests that bioleaching may be a promising method for the activation of silicon in EMR.

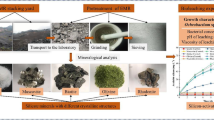

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrolytic manganese residue (EMR) is a type of solid waste generated along with the production of electrolytic manganese from the electrolytic manganese industry [1]. With the increase in demand for electrolytic manganese and the decrease in quality of manganese ore, the amount of EMR increases continuously by 10 million tons per year and has exceeded 50 million tons in 2016 in China [2]. Currently, most manganese residue is stored in open air, which not only occupies vast land, but also seriously pollutes the surrounding environment [3, 4]. Therefore, the rational use of resources to reduce the disposal of EMR has important practical significance.

Silicon is recognized as the fourth nutrient element following nitrogen, phosphorus, and potassium by the international soil community. However, 99% of the silicon in the soil is found in very low water-solubility silicate minerals, and it is inactive and cannot be directly absorbed by plants [5]. The only form of silicon that can be directly used by plants is monosilicic acid (H4SiO4), which is called available silicon (active silicon). Although silicon is the main component of soil, accounting for approximately 70%, available silicon only accounts for 0.03% in cultivated soil. At present, more than 50% of the arable land in China lacks available silicon, which is of importance to the soil [6, 7]. It is impossible to maintain the balance of available silicon in the soil because of the natural weathering of soil silicon and the return of crops to the field [8, 9]. EMR is an important source of silicon; thus, using it as a raw material to activate silicon can not only solve the problem of a serious shortage of available silicon in the soil, but also be an effective way to reduce the treatment of manganese residue [10, 11].

Biological leaching (bioleaching) is a widely noticed and environmentally friendly tailings disposal technology recently [12, 13]. Compared with traditional physical and chemical processes, bioleaching has the advantages of process simplicity, low costs, and environmentally friendly effects [14, 15]. In recent years, it has been found that silicate bacteria, such as Paenibacillus mucilaginosus (PM) and Bacillus circulans (BC), have a strong ability to dissolve phosphorus and potassium, fix nitrogen, and leach available silicon [16,17,18]. Many studies proved that the effects of microbial species on the leaching of elements contained in EMR are significant [19, 20]. If a suitable bacterial strain is used, bioleaching could potentially be a good recycling and disposal alternative for the utilization of EMR.

In this study, the EMR from a typical manganese ore deposit in Guangxi, China was used as raw materials, and pure P. mucilaginosus (PM), pure B. circulans (BC), and the mixed cultures of them were used separately to activate the silicate in EMR. The objective of the study was to gain insights into the desilication of EMR in the presence of different types of silicate bacteria.

Materials and methods

EMR

The raw EMR samples contain a large number of breakable lumps and granules without a peculiar smell, and have an appearance similar to soil. The EMR samples were dried in an oven at 105 °C for 24 h, and then screened. The elemental composition and the mineral distribution of the EMR are shown in Table 1 and Fig. 1, respectively. As shown in Table 1, the main elements are O, Si, Mn, Ca, S, and Fe, and the content of Si accounting for the largest proportion is 15.06%.

As shown in Fig. 1, the minerals contained in the EMR mainly include calcite, silicalite, plagioclase, quartz, and a small amount of muscovite, diopside, and olivine. The quartz occupies a large proportion, showing an irregular and scattered distribution, and the particle size is between 0.01 and 0.15 mm. The content of silicalite is also relatively high, and most of them consist of sub-round pellets, containing diopside and muscovite. The size of the pellets is 0.05–0.2 mm.

Bacteria culture

Bacterial species

The silicate bacteria used in this study, PM and BC, were purchased from Cangzhou Wangfa Biological Technology Research Institute Company Limited, China. According to the existing reports, these two types of silicate bacteria exert an excellent decomposition effect on silicate minerals [21,22,23].

The PM bacteria are Gram negative and their colony characteristics on a flat medium (30 °C, 3 days) are rod and elastic, with both ends obtuse. The colonies have a smooth surface with colorless transparent uplifts and sticky colonies.

The BC bacteria on a flat medium are round, as glass balls. The surface of the bacteria is smooth and protuberant. The center has a turbid point after a period of culture, while its edge is transparent. The colonies are thick and elastic, with colorless transparent uplifts, and can be drawn into filaments. They are Gram positive.

Medium

The culture medium for fermentation and the culture of silicate bacteria was shown as follows: sucrose 5.0 g, Na2HPO4 2.0 g, MgSO4·7H2O 0.5 g, FeCl3 0.005 g, CaCO3 0.1 g, soil mineral 1.0 g, distilled water 1000 mL, and pH 7.0 [24]. Soil mineral: 200 g of soil samples was added to 20% HCl (soil: 20% HCl = 1:10), and boiled for 30 min with distilled water until no Cl− was found.

Bioleaching experiments

A bioleaching system was used to investigate the transformation of silicon in the EMR. The chemical form changes in the EMR and the leaching toxicity of metals in the EMR were analyzed. Flask-leaching experiments were conducted to obtain optimal parameters for higher transformation rates of silicon, such as leaching time, temperature, pH, pulp density [EMR (g)/media (mL)%; (w/v)%], stirring rate, and particle diameter of the EMR.

First, 90 mL silicate bacteria culture medium was loaded into 250 mL conical flasks after sterilization. The EMR with an average particle diameter of 0.150 mm was then added to the conical flasks with the inoculation of different types of silicate bacteria (pure PM, pure BC, and 5 mL + 5 mL mixed cultures of them) in the logarithmic growth phase to ensure an initial bacterial concentration of approximately 1 × 107 cells mL−1. Under the conditions of a temperature of 30 °C, solution pH 7.0, 5% pulp density, and stirring rate of 210 r min−1, the effects of the leaching time on the content of the available silicon were investigated. Thus, the optimal leaching time was employed, but the temperature, pH value, pulp density, stirring rate, and particle diameter were altered in turn to explore the desilication effect of the EMR. All the experiments were repeated three times. The SiO2 concentration, pH, and bacterial concentration in the leaching solutions were measured daily. The EMR was placed into 90 mL silicate bacteria culture medium after sterilization (121 °C, 20 min) as the control groups.

Treatment of leaching residues after bioleaching

The bioleaching experiments were conducted under the optimal conditions for 8 days and 16 days. Then, the remaining residues were rinsed twice with deionized water (pH 2, which was adjusted using the sulphuric acid solution) at the ratio of water/residue (v/w) as 10:1 (mL g−1). The residues were then dried in an oven at 105 °C after filtration.

Analytical methods

The silicon–molybdenum blue spectrophotometry (Shanghai Guangpu Company, China, 721E spectrophotometry) was used to determine the concentrations of silicon in the leachates during the bioleaching process. The pH measurements were carried out using a pH meter (PHS-3C, Shanghai Ray Magnetic Instrument Factory, China). The populations of bacteria in the bacterial culture medium and the leaching solution were determined by the plate count method using an XS-212 biological microscope (Nanjing Jiangnan Yongxin Optical Instrument, China). The micromorphology and the mineral composition of the EMR before and after bioleaching were observed with a scanning electron microscope (SEM) (SU8010, Hitachi High-Technologies Corporation, China), an X-ray diffraction (XRD) (D8 ADVANCE, BRUKER Corporation, Germany), and a poloidal reflectance microscope (Nikon LV100POL). The Fourier Transform Infrared spectra (FTIR) (Nicolet Nexus 470, Perkin-Elmer, America) of the bioleaching liquid in the range of 4000–500 cm−1 were recorded for qualitatively investigating the differences in the functional groups of the leachate in different leaching systems (control groups and experimental groups).

Results and discussion

Growth of bacteria

The bacterial growth curves of PM, BC, and mixed PM and BC are shown in Fig. 2. They show similar growth trends. The lag, logarithmic growth and stable periods of PM and BC were 0–12 h, 12–78 h, and 78–108 h, respectively, and the decay phases start at 108 h. The growth curve of mixed PM and BC is consistent with that of PM or BC.

Figure 3 shows the pH changes versus time during the growth of bacteria. The pH values correlate strongly with the bacterial growth in the culture media. In the logarithmic growth and stable periods, the pH values decrease rapidly, from the initial 7.0 to the lowest pH of 4.3, 4.8, and 4.1 for the PM, BC, and PM + BC cultures, respectively. After approximately 102 h, the pH in the media begins to recover slowly, and the final pH values are stable at 4.8, 5.1, and 5.0 for the PM, BC, and PM + BC cultures, respectively, which implies that the bacteria in the logarithmic growth and stable phases can produce acids. However, due to the consumption of nutrients, the produced acids (the production of acid due to the metabolism of bacteria during the growth of microorganisms) lead to a poor nutritional environment later [25], and then, the silicon bacteria have to use metabolism-products such as organic acids produced by themselves, which results in a slight increase in pH during the later growth stage.

Bioleaching of EMR

Effect of the leaching time on the content of available silicon

Figure 4 shows the effect of the leaching time on the content of available silicon. As seen, the content of available silicon in the control group is relatively stable, indicating that the silicate cannot be leached without the bacteria. The content of available silicon in the experimental groups obviously increases with the increase in leaching time, and the data trends are consistent for the three types of bacterial cultures. The best leaching performance for the available silicon is achieved by the mixed PM and BC culture with the available silicon of 163.3 mg L−1 compared to 139.4 and 133.1 mg L−1 for PM and BC, respectively. Overall, the leached amounts of available silicon remain relatively stable after 16 days. Hence, 16 days was chosen as the optimal reaction time for biological leaching.

Effect of the temperature on the content of available silicon

The effect of temperature on the content of available silicon and the bacterial population is shown in Fig. 5. The influence of temperature on desilication is significant. The available silicon caused by these three types of cultures has a strong correlation with the bacterial growth. The results show that the optimal temperature for the bioleaching of silicon is 30–35 °C, and the bacterial population in the leaching solution could be maintained at > 3 × 106 cells mL−1. However, when the temperature is below 20 °C or above 40 °C, the silicate bacteria cannot grow well and this results in the unsatisfactory results of desilication for EMR.

Effect of the initial pH on the content of available silicon

The effect of the initial pH values of the bioleaching solutions with different types of bacterial cultures on the content of available silicon is shown in Fig. 6. As shown, the control group has lower pH values, but a higher content of available silicon in the leaching solutions. In the three experimental groups, the content of available silicon decreases after a sharp initial increase. Afterwards, it becomes stable and remains at approximately 80–90 mg L−1. The best desilication result is obtained at pH 7.0. Therefore, the optimal pH for available silicon leaching is determined.

Effect of the pulp density on the content of available silicon

The effect of pulp density on the content of available silicon is shown in Fig. 7. It is observed that the content of available silicon is approximately negatively related with the pulp density. When the pulp density is 5%, the maximum content of available silicon can be obtained, and the specific concentration is 138.8, 134.3, and 164.3 mg L−1 with the PM, BC, and mixed cultures, respectively. The effects of the pulp density on the content of available silicon mainly lie in the following two aspects in the leaching system. First, the pulp density affects the concentration of O2 and CO2 in the bioleaching solution. It was reported that a pulp density under 5% would not have influences on the transfer speeds of O2 and CO2 in an agitation leaching system, but the oxygen consumption rate of microorganisms would be higher than the gas–liquid mass transfer rate when the pulp density is high, resulting in an oxygen deficit of the leaching system [26]. When the pulp concentration reaches 25%, the dissolved oxygen in the system decreases significantly, which would seriously affect the growth of microorganisms and result in the decrease in available silicon [27]. Second, the pulp density would affect the activity of bacteria. A higher pulp density would lead to less biomass per unit mass of pulp. Moreover, the friction between solid particles and the fluid shear stress would increase with an increase in pulp density, which would cause mechanical damage to microbial cells, prevent microbial reproduction and metabolism, alter the structure of extracellular proteins, and even destroy the cellular and ecological structure [28]. This result explains the trends of available silicon with the pulp density in our experiments and the optimal pulp density in the study was chosen to be 5%.

Effect of the stirring rate on the content of available silicon

Figure 8 shows the effect of the stirring rate on the content of available silicon. The content of available silicon in the control group indicates that the stirring rate does not have significant effects on the silicon leaching. However, the measured contents of available silicon in the three experimental groups reach very high levels, i.e., 129.9, 136.3, and 164.3 mg L−1 with PM, BC, and the mixed PM and BC at 210 rpm, and they reversely decrease as the stirring rate is increased from 210 to 240 rpm, mainly because the EMR in the bioleaching system can be fully exposed to bacteria with the increase in the stirring rate, but an excessive stirring rate would cause mechanical damage to bacteria and result in a decrease in the content of available silicon [29].

Effect of the particle diameter on the content of available silicon

The effect of particle diameter on the content of available silicon is shown in Fig. 9. The leaching efficiency should be associated with the specific surface area of solids in the bacterial leaching process. Theoretically, the smaller the particle diameter of ore, the larger the specific surface area, the more favorable for microorganism to contact with the ore, which is beneficial to improve the leaching rate and reaction speed. Therefore, the greater leaching efficiency can be obtained [30, 31], which is consistent with the results of experiments with particle diameters above 0.150 mm. However, in our study, the leaching rate of the available silicon increases, as the particle diameter rises in the range of 0.075–0.150 mm, which is attributed to the nature of the EMR itself. The smaller particles would have larger surface areas to adsorb the specific materials containing silicon, and it is easier to prevent dissociated compounds from entering the solution. Thus, the available silicon on the surface of the EMR cannot be released easily. The contents of available silicon for the three experimental groups all reach their maximum as 144.4 and 132.1 mg L−1 with pure PM and BC, respectively, with a particle diameter of 0.150 mm. The mixed bacteria yield the best content of available silicon, up to approximately 157.3 mg L−1. Thus, the particle diameter of 0.150 mm was selected as the optimal diameter for the EMR.

Characteristics of the samples during the bioleaching process

FTIR analysis of leachate

The FTIR spectra of the leachate in the control and experimental groups (16 days leaching with mixed PM and BC) are shown in Fig. 10. It is observed that the functional groups in the leaching solution have obvious changes after the bacterial action, although the rough shapes of the spectra are consistent. An obvious peak appears at 1079.94 cm−1 for the experimental sample, which is ascribed to the Si–O–Si antisymmetric stretching vibration, which may be due to the polysaccharides produced by bacterial metabolism or other organics, such as the amide group C–N, combining with quartz [32]. The bending vibration peak of Si–O–M (M represents metals) at approximately 617.11 cm−1 in the experimental samples is stronger than that of the control group, indicating that the silicate materials have combined with metals to form complexes in the process of bioleaching.

In addition, the FTIR spectra of leachates in the experimental group and the control group exhibit the presence of carbohydrates, where an O–H stretching vibration absorption peak (strong and wide) is centered at 3378.67 cm−1 in the experimental group. This result illustrates that both groups of leachates have abundant O–H bonds. Moreover, there are stretching vibration absorption peaks of C=O (1673.91 cm−1) and –CH3 (1434.78 cm−1). As for C=O, it was found in both groups, which may be the organic matter produced by bacterial metabolism in the original EMR, and it still exists in the system even after the sterilization treatment. For –CH3, the intensity is different between the two samples. It is obvious that the peak of –CH3 in the experimental group is more acute, indicating that more –CH3 groups are generated in the system under the experimental conditions.

XRD analysis of bioleaching residues

Figure 11 shows the XRD spectra of the raw EMR sample, the control and the experimental samples after bioleaching with mixed PM and BC for 8 days and for 16 days. The results indicate that the characteristic peaks of quartz in the raw EMR samples are clear and strong. The peaks of muscovite, rhodonite, and diopside are also detected, but the diffraction absorption peak intensity is much weaker than that of quartz. After bioleaching, the characteristic peaks of muscovite, quartz and diopside become weak, and even disappear, while some new characteristic peaks of the secondary minerals can be found. This result is due to the mineral weathering by silicate bacteria, which causes the decrease in crystal silicate composition [33]. In addition, muscovite, with a layered crystal structure, is more likely to be destroyed by the bacterial action than quartz with a frame structure, to release the contained silicon [34, 35]. It is suggested that in the presence of a variety of silicate minerals, the microorganisms have a certain selectivity for the dissolution of minerals with different crystal structures [36,37,38]. By comparing (c) and (d) in Fig. 12, it can be seen that the decreasing trend of some mineral peaks becomes more obvious and some even disappear with the increase in reaction time. Taking silicate minerals as an example, the peak of quartz decreased significantly after bioleaching for 16 days, and the peak of muscovite also changed. This result indicates that the silicate bacteria have further improved the leaching of silicate minerals within the reaction time of 8–16 days, which is consistent with the partial results of the optimum experiment. Regarding the XRD spectra in this study, the change in the characteristic diffraction peaks of silicate minerals can only be preliminarily qualitatively analyzed, which only reflects the mineral weathering by the silicate bacteria, and the specific leaching mechanism of silicon requires further research.

SEM–EDS analysis of bioleaching residues

The SEM pictures of different samples are shown in Fig. 12. As shown from Fig. 12a, b, the clear lamellar frameworks of silicate minerals in the raw EMR are observed, and the crystal structure is intact. For the samples in the control groups (Fig. 12c, d), it can be seen that the surface morphology of the particles was changed slightly. The lamellar structure becomes weak, but it is still angular and significantly uneven in shape, and the whole surface of particles remains in a relatively integrated crystal form. However, after the bioleaching with mixed PM and BC for 16 h, the experimental group shows obvious changes in mineral surface: the initial lamellar structure of minerals disappeared and was converted into a relatively smooth irregular block structure (Fig. 12e, f). Moreover, the larger particles in the bump were broken into smaller and more angular particles. The original mineral crystal structure is destroyed, especially for the uneven parts, such as corners and gaps. By comparing Fig. 12a and e, it can be observed clearly that the lamellar frameworks of silicate minerals in the raw EMR samples have almost dissolved. Then, the tiny particles and the amorphous materials have significantly increased after bioleaching, and the particles were bonded together to form the flocculent structures by comparing Fig. 12b with f, which can be speculated that this is caused by the crosslinking action of the extracellular macromolecular materials produced by the bacteria.

Figure 12g–i presents the EDS multipoint scanning point analysis and the surface element quality score statistics for the samples in Fig. 12a, c, e, respectively, after cleaning and drying. As seen, Fig. 12g indicates that the main composition of the raw EMR samples is C, O, Si, S, and Ca. As for the control groups (Fig. 12h), C, O, Si ,and Fe account for a considerable proportion, while the main elements are C, O, and Fe for the sample in the experimental group (Fig. 12i). As shown in Fig. 12g–i, the relative content of Si in the different EMR samples is somewhat different. Especially, in the experimental group (bioleaching for 16 days), the relative content of Si is reduced from the initial 28.82 to 1.67% under the effect of bacterial growth and metabolism. The results affirm that the silicate bacteria can release Si from the EMR into the solution through metabolism, which can convert the inactive silicon in the EMR to the available silicon in the leaching solution.

Conclusions

This study demonstrates that bioleaching is a highly efficient feasible method to activate silicon in EMR using PM and BC. It is shown that the maximum concentration of the available silicon in the solution is up to approximately 160 mg L−1, 140 mg L−1, and 130 mg L−1 using mixed strains of PM and BC, PM and BC, respectively, under the optimal conditions. FTIR indicates that the silicate bacteria can cause a suitable micro-environment near the EMR particles and release Si into the solution through metabolism. XRD reveals that the transformation of silicate minerals occurs during bioleaching. Especially, the layered crystal minerals, such as muscovite and diopside, are more likely to be destroyed by the bacterial action than quartz with a frame structure. SEM–EDS demonstrates the morphological changes on the surfaces and the alterations of the mineral composition. Particularly, the content of silicon in the EMR has decreased obviously after bioleaching, which is the theoretical foundation of using bioleaching technology to realize the activation of silicon and resource of EMR. Further studies need to be conducted to investigate the potential applications of bioleaching in the treatment of other solid wastes.

References

Liang YR, Li MZ (2015) Improvement of effective silicon content in magnesium reduction slag leached by hydrochloric acid. Nonferrous Metals 7:55–59

Wang NF, Fang ZJ, Peng S, Cheng DX, Du B, Zhou CB (2016) Recovery of soluble manganese from electrolyte manganese residue using a combination of ammonia and CO2. Hydrometallurgy 164:288–294

Jiang ML, Du YG (2014) Technology for producing silicon-manganese fertilizer from EMR residue. Chin Mang Ind 32:16–19

Xu LH, Hu YH, Tian J, Wu HQ, Yang YH, Zeng XB, Wang Z, Wang JM (2016) Selective flotation separation of spodumene from feldspar using new mixed anionic/cationic collectors. Miner Eng 74:86–90

Muhammad I, Muhammad SR, Muhammad AM, Muhammad A, Sher MS, Balal Y, Dawood AS (2016) Silicon occurrence, uptake, transport and mechanisms of heavy metals, minerals and salinity enhanced tolerance in plants with future prospects: a review. J Environ Manage 183:521–529

Sun DS, Chen Y (2012) Effects of mineral environments on desilicon from bauxite by silicate bactreia. Chem Ind Eng Prog 21:2341–2348

Wu T, Chen J (2007) Advance in studies on the function of microbes to the weathering of silicate minerals. Bull Miner Petrol Geochem 26:263–268

Cheng Y, Li ZC (2011) Bacteria applied in biohydrometallurgy. Chem Eng Equ 88:148–156

Tian J, Xu LH, Deng W, Jiang H, Gao ZY, Hu YH (2017) Adsorption mechanism of new mixed anionic/cationic collectors in a spodumene-feldspar flotation system. Chem Eng Sci 164:99–107

Butnariu M, Negrea P, Lupa L, Ciopec M, Negrea A, Pentea M, Sarac I, Samfira I (2015) Remediation of rare earth element pollutants by sorption process using organic natural sorbents. Int J Environ Res Public Health 12:11278–11287

Caunii A, Negrea A, Pentea M, Samfira I, Motoc M, Butnariu M (2015) Mobility of heavy metals from soil in the two species of the aromatic plants. Rev Chim 66:382–386

Anshu P, Subrata H (2018) Extraction of metals from high grade waste printed circuit board by conventional and hybrid bioleaching using Acidithiobacillus ferrooxidans. Hydrometallurgy 177:132–139

Keishi O, Kazuhiko S, Jun-ichiro I, Hajime M, Naoko O (2018) Silver-catalyzed bioleaching of enargite concentrate using moderately thermophilic microorganisms. Hydrometallurgy 177:197–204

Ehrlich H, Demadis KD (2010) Modern views on desilicification: biosilica and abiotic silica dissolution in natural and artificial environments. Chem Rev 110:4656–4689

Liu K, Diao MX (2012) Bioleaching of chalcopyrite concentrate using mixed thermophilic culture and succession of microbial community during leaching process. Chin J Nonferrous Metals 20:346–353

Lv Y, Li J, Ye HP, Du DY, Li JX, Sun P, Ma MY, Wen JX (2019) Bioleaching behaviors of silicon and metals in electrolytic manganese residue using silicate bacteria. J Clean Prod 228:901–909

Zhan SF, Liu JJ, Chen Y, Sun DS (2013) Single and coorperative bauxite bioleaching by silicate bacteria. IERI Procedia 5:172–177

Zhang YT, Dan ZG, He XY, Tia Y, Wang J, Qi SY, Duan N, Xin BP (2017) Mn bio-dissolution from low-grade MnO2 ore and simultaneous Fe precipitation in presence of waste electrolytic manganese anolyte as nitrogen source and iron scavenger. J Clean Prod 158:182–191

Li MS (2006) Ecological restoration of mineland with particular reference to the metalliferous mine wasteland in China: a review of research and practice. Sci Total Environ 357:38–53

Xin BP, Chen B, Duan N, Zhou CB (2011) Extraction of manganese from electrolytic manganese residue by bioleaching. Bioresour Technol 102:1683–1687

Hu J, Yu JP, Lian B (2011) Capability and mechanism of potassium releasing from potassium-bearing minerals by Aspergillus niger. Bull Miner Petrol Geochem 30:277–284

Huang HL, Huang MQ, Liu WF (2011) Current status of microorganisms in biohydrometallurgy. Hydrometallurgy 30:184–189

Lian B, Wang B, Pan M (2008) Microbial release of potassium from K-bearing minerals by themophilic fungus Aspergillus fumigatus. Geochim Cosmochim Acta 72:87–98

Hu XF, Li SX, Wu JG (2010) Transfer of Bacillus mucilaginosus and Bacillus edaphicus to the genus Paenibacillus as Paenibacillus mucilaginosus comb. nov. and Paenibacillus edaphicus comb.Nov. Int J Syst Evol Micr 60:8–14

Ma LY, Wang XJ, Tao JM, Feng X, Zou K, Xiao YH, Liang YL, Yin HQ, Liu XD (2017) Bioleaching of the mixed oxide-sulfide copper ore by artificial indigenous and exogenous microbial community. Hydrometallurgy 189:41–48

Liu YG, Zhou M, Zeng GM (2007) Effect of solids concentration on removal of heavy metals from mine tailings via bioleaching. J Hazard Mater 141:202–208

Tipre DR, Dave SR (2004) Bioleaching process for Cu–Pb–Zn bulk concentrates at high pulp density. Hydrometallurgy 75:37–43

Mousavi SM, Yaghmaei S, Vossoughi M (2007) Bacterial leaching of low-grade ZnS concentrate using indigenous mesophilic and thermophilic strains. Hydrometallurgy 85:59–65

Siti KC, Robi SS, Wahyudin PM, Mohammad ZM (2017) Indirect bioleaching of low-grade nickel limonite and saprolite ores using fungal metabolic organic acids generated by Aspergillus niger. Hydrometallurgy 18974:29–37

Akyalcina S, Akyalcina L, Bjørgenb M (2019) Optimization of desilication parameters of low-silica ZSM-12 by Taguchi method. Micropor Mesopor Mat 273:256–264

Yin SH, Wang LM, Eugie K, Chen X, Yan RF, An K, Zhang L, Wu AX (2018) Copper bioleaching in China: review and prospect. Minerals 8:32–34

Lian B, Smith DL, Fu PQ (2000) Application and mechanism of silicate bacteria in agriculture and industry. Eur PMC 18:43–53

Lin QM, Rao ZH, Sun YX (2002) Identification and practical application of silicate-dissolving bacteria. Agric Sci China 1:81–85

Liu WX, Xu XS, Wu XH, Yang QY, Luo YM, Christie P (2006) Decomposition of silicate minerals by Bacillus mucilaginosus in liquid culture. Environ Geochem Health 28:133–140

White AF, Brantley SL (2003) The effect of time on the weathering of silicate minerals: why do weathering rates differ in the laboratory and field? Chem Geol 202:479–506

Dopson M, Lovgren L, Bostrom D (2009) Silicate mineral dissolution in the presence of acidophilic microorganisms: implications for heap bioleaching. Hydrometallurgy 96:325–329

Saiz JC (1999) Biogeochemistry of weathering processes in monuments. Geomicrobiol J 16:27–37

Smith BJ, Warke PA, Moses CA (2000) Limestone weathering in contemporary arid environments: a case study from southern Tunisia. Earth Surf Proc Land 25:1343–1354

Acknowledgements

This project is financially supported by the National Natural Science Foundation of China (no. 51804354), and the Scientific Special of Central Higher Education Institutions (nos. CZD19006, CZD18010). The authors are grateful to Prof. Jeff Kuo for his assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, Y., Li, J., Ye, H. et al. Bioleaching of silicon in electrolytic manganese residue using single and mixed silicate bacteria. Bioprocess Biosyst Eng 42, 1819–1828 (2019). https://doi.org/10.1007/s00449-019-02178-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02178-7