Abstract

This study aimed to optimize free fatty acid production by enzymatic hydrolysis of cottonseed, olive and palm kernel oils in stirred-tank reactors using a lipase from Geotrichum candidum (GCL-I). The effect of pH, temperature and substrate concentration on the hydrolytic activity of GCL-I using these vegetable oils was investigated. Thermal stability tests and thermodynamic studies were also performed. A complete hydrolysis of cottonseed oil was obtained after 120 min of reaction, while for olive and palm kernel maximum hydrolysis percentage was 96.4% and 60.1%, respectively. GCL-I exhibited the highest activity in the hydrolysis of vegetable oils that are rich in unsaturated-fatty acids (cottonseed and olive oils). Under optimal conditions (46.8% m/m of oil, 6.6 U/g of the reaction mixture at 40 °C), complete cottonseed oil hydrolysis was observed at 60 min of reaction performed in an emulsifier-free system with no buffer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

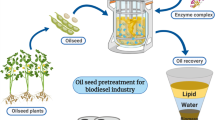

Introduction

Free fatty acids (FFA) and glycerol are important precursors used by oleochemical industries, which can be obtained from the hydrolysis of several oils and fats [1,2,3]. They have been used in a wide range of applications involving a significant number of high-value products, such as coatings, surfactants, adhesives, lubricating oils, fatty alcohols, shampoos and other personal care products [1,2,3]. Oil and fat hydrolysis for obtaining concentrated free fatty acids by Colgate-Emery process is the mainstream technology for industrial free fatty acid production [1, 4]. However, this process requires high temperature (250 °C) and pressure (50 bar) conditions, which may lead to the occurrence of undesirable reactions such as oxidation, dehydration, and interesterification of triacylglycerol [1, 4]. To overcome such problems, alternative process for obtaining free fatty acids have been successfully used, e.g. hydrolysis reactions using acidic heterogeneous catalysts [5], supercritical conditions [6, 7] and enzymatic hydrolysis [4, 8,9,10]. An enzymatic process uses lipases from several sources as potential catalysts, which have many advantages when compared to the aforementioned methods on account of occurring at low temperatures (35–40 °C) and atmospheric pressure, thus enabling the obtainment of high concentration of free fatty acids, since there are no parallel or undesirable reactions. Moreover, fatty acids formed and glycerol can be easily separated and the equipment required for such a purpose is rather simple [4, 8, 9].

Lipases have a peculiar mechanism of catalysis, known as interfacial activation. This mechanism allows that these enzymes act in interfaces between hydrophobic and aqueous environments that involves the movement of a polypeptide chain called lid. In the absence of these interfaces, the lid covers their active sites center making them inaccessible to substrate molecules (closed conformation). On the other hand, in the presence of hydrophobic interfaces, including oil droplets, a conformational change of the lip occurs, thus exposing their active centers to the medium (open conformation) [11].

However, most studies on the enzymatic hydrolysis of vegetable oils to produce FFA use emulsifier agents [12], organic solvents [8, 13, 14], or ultrasonic irradiation [15], to promote increased interaction between the enzyme and oil droplets, thus improving the hydrolysis reaction. The enzymatic hydrolysis of triacylglycrols has been commonly performed in the presence of buffer agents to avoid a decrease in pH solution due to free fatty acids formation, thus resulting in a decrease of catalytic activity of some lipases [8, 16]. From an industrial standpoint, these strategies are limitations that must be overcome to make such process economically feasible.

Lipases from different sources show different substrate specificities [17]. Lipases those have selectivity towards unsaturated long-chain fatty acids can quickly hydrolyze esters bonds formed by oleic and linoleic acids, which are components of different triacylglycerols from vegetable oils (e.g. olive, soybean, canola, sunflower, cottonseed oils) [17,18,19]. Therefore, a short reaction time is required, thus demanding less energy and making the process less expensive.

The concept of combi-lipase biocatalysts proposed by Alves et al. [20], is based on the use of a mixture of different lipases as biocatalysts [21,22,23]. The nature of triacylglycerols is very complex, based on their fatty acids composition, suggesting that the use of a mixture of lipases with different specificities and selectivities can improve hydrolysis reaction rates and, thus, free fatty acids production [20, 23].

Geotrichum candidum (G. candidum) has been described as a microorganism able to produce different lipases in the presence of an inducer in culture medium [24, 25]. These lipases exhibit high specificity towards different fatty acids [24, 25].

In a previous work performed in our research group, a single lipase (GCL-I) was produced by submerged fermentation [26]. Similar results were previously reported by Jacobsen [27]. This lipase presents high selectivity to hydrolyze ester bonds of unsaturated long-chain fatty acids, such as oleic and linoleic acid [26]. In this present study, similar experimental conditions were also used to produce GCL-I for further use as a biocatalyst in vegetable oils hydrolysis aiming the free fatty acids production.

Thereby, the present study aims at FFA production via enzymatic hydrolysis of three different vegetable oils having different fatty acid composition in stirred-tank reactors (batch mode) catalyzed by specific lipase from G. candidum. This lipase was produced via submerged fermentation using cottonseed oil as substrate [26]. A complete characterization was performed by evaluating the influence of pH, temperature and substrate concentration on the hydrolysis of emulsified oils with gum arabic so as to demonstrate the effect of each vegetable oil on its catalytic activity. Kinetic and thermodynamic parameters also determined by this set of experiments. Moreover, thermal inactivation tests of cottonseed oil hydrolysis were performed to determine inactivation constants and thermodynamic parameters by Arrhenius plot. According to the economic aspect, an excellent alternative would be the enzymatic production of FFA performed in the absence of emulsifier, buffer agents and organic solvents, used to improve the catalytic activity of lipase in heterogeneous systems (oil/water interface). In such a case, the reaction system would be composed of oil, water and enzyme only, thus reducing possible process costs. Thus, hydrolyses assays in emulsifier-free systems using a mechanical stirrer (stirred-tank reactors) was conducted to select the vegetable oil for further FFA production optimization. Subsequently, the effect of important variables on the enzymatic hydrolysis of cottonseed oil (vegetable oil selected herein) was evaluated using the CCRD to understand the significance and interaction of variables affecting the hydrolysis reaction. The enzymatic hydrolysis of vegetable oils to produce FFA has been well-documented, however, the use of GCL-I as potential biocatalyst is still scarce in literature [28, 29].

Materials and methods

Materials

Cottonseed oil was purchased from Indústria Campestre (São Bernardo do Campo, SP, Brazil), palm kernel oil from Agropalma (Belém, PA, Brazil) and olive oil (Carbonell) at a local market (Alfenas, MG, Brazil). Gum arabic was obtained from Synth® (São Paulo, SP, Brazil). All other chemical reagents and organic solvents were of analytical grade and acquired from Synth® (São Paulo, SP, Brazil).

Microorganism and lipase production

Geotrichum candidum strain (NRRL Y-552) was used for lipase production via submerged fermentation in shaker flasks as described by a previous study [26]. Under these conditions, a single lipase was produced [26]. The broth was filtered under vacuum after 48 h of fermentation and the resulting supernatant contained lipase from G. candidum (GCL-I) with 22.91 U/mL of activity, which was used in further studies as crude extract without another purification step.

Catalytic properties of produced GCL-I using different vegetable oils as substrates

Optimum pH conditions of free GCL-I (1 mL of crude extract containing 0.1 mg of protein) for the hydrolysis of different vegetable oils (cottonseed, olive and palm kernel oils) were determined at 37 °C in a pH range of 5.0–9.0 at 100 mM of buffer solution (sodium acetate at pH 5.0; sodium phosphate at pH ranging between 6.0 and 8.0; sodium bicarbonate at pH 9.0). The effect of temperature, ranging between 20 and 80 °C, on hydrolysis activities was determined using 1 mL of crude extract containing 0.1 mg of GCL-I in 100 mM sodium phosphate buffer solution at pH 7.0. The reaction blanks were prepared by adding 1 mL of culture medium without lipase in which each assay was performed under the same conditions as those described to determine optimal temperature and pH conditions.

Effect of substrate concentration

The effect of substrate concentration on the hydrolytic activity using three vegetable oils was evaluated. In this set of experiments, the oil concentration varied from 1 to 50% m/m, that corresponds to a range of 31.0–1900.0 mmol/L of theoretical free fatty acids (FFA) concentration, depending of each oil. The emulsions were prepared by mixing a certain amount for each oil with a gum arabic solution at 7% m/v. The reaction mixtures containing 5 mL of emulsion, 4 mL of 100 mM sodium phosphate buffer at pH 7.0 and 1 mL of crude extract (0.1 mg of GCL-I) were incubated at 37 °C for 5 min under continuous agitation in an orbital shaker (200 rpm). The reaction blanks were performed under the same condition for each assay by adding 1 mL of culture medium instead of GCL-I solution.

To determine apparent kinetic parameters (Km and Vmax), Michaelis–Menten model (Eq. 1) was fitted to these experimental data:

where v is the reaction rate, Vmax is the maximum reaction rate achieved by the system, at saturating substrate concentration (U/mL), [S] is the vegetable oil concentration (mmol/L), and Km is the Michaelis–Menten constant (mmol/L).

The following equations were used to calculate apparent parameters kcat, Gibbs free energy of substrate binding (ΔGE–S) and Gibbs free energy of transition state binding (ΔGE–T) [30, 31]:

where [Et] is the lipase concentration (0.00154 μmol/mL), R is the universal gas constant (8.314 × 10−3 kJ/mol K), T is the experimental absolute temperature (310 K), kcat is the Turnover number (1/min), ΔGE–S is the Gibbs free energy of substrate binding (kJ/mmol) and ΔGE–T is the Gibbs free energy of transition state binding (kJ/mmol).

Enzymatic hydrolysis of different vegetable oils in a stirred-tank reactor

Hydrolysis reactions of cottonseed, olive and palm kernel oils were performed in a jacketed glass reactor (200 mL capacity) containing 60 g of reaction medium composed of 15 g of vegetable oil, 30 g of distilled water and 15 g of crude lipase extract (corresponding to 345 U or 1.5 mg of protein). The reaction mixtures were stirred by a mechanical stirrer at constant speed of 1000 rpm and 37 °C, and 3 h of incubation time. Samples (1 g of the reaction mixture) were periodically removed from the reactor and transferred to flasks containing a solution of 10 mL of ethanol and acetone (1:1) titrated with 20 mM NaOH solution using phenolphthalein as indicator. All reactions were performed in triplicate. Percentages of hydrolysis were calculated in accordance with Rooney and Weatherley [32], as shown in Eq. (5).

where V is the volume of NaOH solution required during titration; M is the concentration of NaOH (20 mM); MM is the average molecular mass of fatty acids for each vegetable oil in g/mol; Wt is the sample mass (1 g) and f is the oil fraction at the beginning of the reaction.

Optimization of enzymatic hydrolysis of cottonseed oil for producing concentrated fatty acids

The hydrolysis of cottonseed oil was performed in the absence of emulsifying agents using GCL-I, which was optimized by CCDR. Systems containing 100 g of the reaction mixture (cottonseed oil, crude extract of GCL-I and distiller water) were in accordance with the CCRD matrix. The reactions were performed under continuous agitation (1000 rpm) using a mechanical stirrer coupled to a jacketed glass reactor. A 23 full factorial design was performed with tree assays in the central point and six-star points (seventeen assays). The levels of each independent variable were chosen based on the results obtained from preliminary tests (not shown herein). The parameters and their levels were: cottonseed oil concentration (13.2–46.8% m/m), lipase concentration (2.9–10.3 U/g of the reaction mixture) and reaction temperature (35–45 °C). The percentage of enzymatic hydrolysis obtained after 50 min of the reaction was selected as response variable. The results were analyzed at 95% confidence level using the software Statistica 5.0.

To validate the optimization by the CCRD, a new assay was performed in triplicate at 40 °C using the CCRD’s highest cottonseed oil concentration level (46.8% m/m) and intermediate level for lipase concentration (6.6 U/g of the reaction mixture).

Thermal stability tests for GCL-I

The stability of GCL-I was evaluated by thermal inactivation at different temperatures. Soluble lipase (1 mL of crude lipase extract, which corresponds to 0.1 mg of protein) was incubated in the absence of a substrate at 35, 40, 45 and 50 °C. Samples were collected at determined time intervals, which were immediately cooled in an ice bath for 5 min. Residual activity was determined through cottonseed oil emulsion hydrolysis, as the one described for olive oil through analytical methods. A nonlinear decay model proposed by Sadana and Henley [33] was used to calculate thermal inactivation constant (kd) and half-lives (t½). The activation energy for the thermal denaturation of GCL-I (Ed) was also determined by a plot of ln kd as a function of 1/T, as shown in the linearized Arrhenius equation (Eq. 6).

where A is the Arrhenius frequency of collision factor, Ed is the activation energy for thermal denaturation (kJ/mol), R is the universal gas constant (8.314 × 10−3 kJ/mol K) and T is the absolute temperature (K).

Analytical methods

Determination of hydrolytic activity

Hydrolytic activities of GCL-I crude extract were assayed by the olive oil emulsion hydrolysis which was previously described by Castro et al. [26]. The substrate was prepared by mixing 50 mL of olive oil with 50 mL of a gum arabic solution at 7% m/v. The reaction mixture contained 5 mL of emulsion, 4 mL of 100 mM sodium phosphate buffer at pH 7.0 and 1 mL of supernatant. The reaction systems were incubated at 37 °C for 5 min under continuous agitation in an orbital shaker (200 rpm). The reactions were stopped by adding a 10 mL solution of acetone and ethanol (1:1). The liberated free fatty acids (FFA) were then titrated with a 20 mM sodium hydroxide solution in the presence of phenolphthalein as indicator. The reaction blanks were made by adding 1 mL of culture medium without GCL-I. One international unit (U) of activity was defined as the amount of enzyme required to liberate 1 μmol of FFA per minute under the experimental conditions described above.

Determination of protein concentration

Protein concentration analyses were performed using bovine serum albumin (BSA) as standard according to the methodology described by Bradford [34].

Substrate specificity

The FFA liberated through the enzymatic hydrolysis of vegetables oils were separated and purified as described previously by Castro et al. [26], using a methodology adapted from Borgstrom [35], and Belfrage and Vaughan [36]. Afterwards, FFA were converted into methyl esters (derivatization) [37] and analyzed by gas chromatography (GC).

GC analysis

Fatty acid methyl esters (FAME) were analyzed according to the EN 14103 method [38] using a gas chromatographic system with a FID detector and a Thermo Scientific-TR-BD capillary column with 30 m in length, internal diameter of 0.25 mm and film thickness of 0.25 µm. Operational conditions were: 1.5 mL/min of flow rate; 260 °C injector temperature; 260 °C/min detector temperature; oven temperature at 45 °C for 2 min, 250 °C at 7 °C/min, 250 °C for 7 min; nitrogen as carrier gas; injected volume of 1.0 µL. FAME standards were used from Supelco® (GLC-10;GLC-30;GLC-100).

Results and discussion

Catalytic properties of GCL-I using different vegetable oils as substrates

The effect of pH on the catalytic activity of GCL-I using different vegetable oils as substrates was determined in a pH range from 5.0 to 9.0 (Fig. 1a). An optimum pH value of 8.0 was observed for all vegetables oils, which corresponded to the maximum hydrolytic activity of 17.0 ± 0.6 U/mL for cottonseed oil, 16.3 ± 0.5 U/mL for olive oil and 9.9 ± 0.2 U/mL for palm kernel oil. At alkaline pH (9.0), a strong decrease in its activity was observed.

Although the maximum activity of lipase using different vegetable oils has been observed at pH 8, its hydrolytic activity values were different and maximum activity was found for cottonseed oil, followed by olive and palm kernel oils, as aforementioned. These results are probably due to the substrate specificity of GCL-I, as reported in a previous study [26], which we found that GCL-I had high specificity to hydrolyze ester bonds of triacylglycerols containing unsaturated long-chain fatty acids in cis-9 or cis-9,12 positions, such as oleic and linoleic acids, respectively.

The enzyme recognizes long-chain fatty acids due to its specificity, thus allowing that the hydrolysis of their ester bonds occurs rapidly [17]. Thus, it was expected that this lipase presented a higher hydrolytic activity for vegetable oils that were rich in long-chain and unsaturated fatty acids in their composition, such as cottonseed, soybean, and olive oils. Over 70% of these oils is composed of oleic and linoleic acids, whereas palm kernel oil has is only composed of about 16% of oleic acid and 47% of lauric acid (see Table 1).

The effect of reaction temperature on the hydrolytic activity of GCL-I was determined at temperatures ranging from 20 to 50 °C, as shown in Fig. 1b. Maximum hydrolytic activity was observed at 37 °C for all substrates, corresponding to 14.0 ± 0.1 U/mL for cottonseed, 13.8 ± 0.1 U/mL for olive and 9.9 ± 0.2 U/mL for palm kernel oils. The activity was strongly reduced when the temperature increased above 37 °C due to a possible distortion of its native conformation (thermal inactivation).

Effect of substrate concentration

Figure 2 shows the effect of substrate concentration on the hydrolytic activity of GCL-I for different vegetable oils used in this study. The classical Michaelis–Menten kinetic model was fitted to the experimental data so as to determine apparent kinetic parameters (Table 2) such as maximum reaction rate (Vmax) and affinity constant—Km, i.e. a constant that determines the substrate concentration required to attain half of the maximum activity, using the software OriginPro 8.0 through which high coefficients of determination were obtained for all substrates (R2 above 0.98).

Vmax values were similar for cottonseed oil (14.96 U/mL) and olive (14.75 U/mL) oils, slightly higher than that found for palm kernel oil (11.41 U/mL), as expected (see Table 2). These results are due to the difference in fatty acid composition between oils, since cottonseed and olive oils have a higher concentration of long chain polyunsaturated fatty acids than palm kernel oil (Table 1), and the GCL-I was very efficient at the hydrolysis of oleic and linoleic acid esters bonds (especially the latter) present in triacylglycerols, thus explaining the maximum reaction rate values found for cottonseed and olive oils.

The affinity of certain lipases is dependent on droplet size at oil/water interface and/or composition of the substrate emulsion since they are firstly adsorbed on the oil droplet surface then catalyzing the hydrolysis of ester bonds of triacylglycerol molecules [39, 40]. In other words, the substrate is not soluble and is forming drops, thus is really measured the affinity of the lipase by the oil droplets. This depends on the droplets (that is, some information may be related to the affinity of the lipase by the droplets), but also of other parameters. For example, of the droplets size, that will depend on the stirring and shape of the reactor. Moreover, when all droplet surface is covered by lipase molecules, a “saturation” of activity/substrate is reached. But this value will depend on the lipase concentration used in the assay, the higher the lipase concentrations, the higher the amount of droplets required to adsorb all lipases. To improve the adsorption of GCL-I at oil/water interfaces, emulsions were prepared under intense stirring in the presence of gum arabic, a classical emulsifier agent commonly used in lipolysis reactions [41], to prevent the oil droplets aggregation (coalescence), as reported in previous reports [42, 43].

According to results in Table 2, the apparent Km value for cottonseed oil (437.42 mmol/L) was smaller than those obtained for olive oil (526.62 mmol/L) and palm kernel oil (693.90 mmol/L), hence demonstrating that the produced lipase has higher affinity for cottonseed oil as substrate in comparison with the other vegetable oils. These results can be also due to possible better dispersion of cottonseed and olive oils in the reaction mixtures, thus improving the lipase adsorption on oil droplets at oil/water interfaces. It was already expected since cottonseed oil has 56.9% (m/m) of linoleic acid in its composition and GCL-I has a higher specificity for it [26].

The thermodynamics analysis results from the hydrolysis of different vegetables by GCL-I (see Table 2) showed that the apparent Gibbs free energy values of substrate binding (ΔGE–S) were positive for all vegetable oils (15.67, 16.15 and 16.86 kJ/mol obtained by cottonseed, olive and palm kernel oils, respectively).

This means that the interaction of the substrate with this lipase is not a spontaneous process, thus for the formation of the enzyme–substrate complex (ES) it is necessary to supply energy to the system, through the increase of the temperature [30]. Evidently, a higher affinity of the lipase for the substrate (lower values of Km) implies a lower amount of energy required for the formation of the substrate binding state.

The results obtained for apparent transition state binding (ΔGE–T) were all negative, which means that this reaction was spontaneous in the product release phase. This means that the degree of reaction disorder was increasing, and the enzyme was releasing into the system a part of the energy received in the substrate binding phase (with the increasing of temperature). Thus, the results of ΔGE–T for cottonseed and olive oils were lower (− 7.48 and − 7.47 kJ/mol) than that obtained by palm kernel oil (− 6.32 kJ/mol), indicating that more product is being formed when cottonseed and olive oils were used as substrate, thus corroborating with previously discussed results about the role of substrate specificity on the hydrolysis reactions of these oils.

Enzymatic hydrolysis in a stirred-tank reactor for different vegetable oils

This set of experiment was designed to verify the behavior of hydrolysis reactions using cottonseed, olive and palm kernel oils catalyzed by GLC-I without the addition of emulsifiers, or solvents, or buffer solution. The 60 g systems were composed of 15 g of vegetable oil, 30 g of distilled water and 15 g of crude extract containing GCL-I. In this set of experiments, mechanical stirring was set at 1000 rpm according to previous studies on the enzymatic hydrolysis of vegetable oils catalyzed by crude lipase extract from dormant castor bean seeds [16, 44]. FFA production via enzymatic hydrolysis of vegetable oils performed in the absence of emulsifying agents requires intense stirring to avoid possible coalescence (aggregation) of oil droplets in the reaction mixture, which drastically reduces the interfacial area between the lipase and substrate molecules, thus reducing the catalytic activity of the enzyme.

As shown in Fig. 3, GCL-I was perfectly able to hydrolyze cottonseed oil and 96.4% of olive oil after 120 min of reaction without any optimization step using classical mechanical stirrers in the absence of emulsifying or buffer agents.

The FFA liberated from the hydrolysis of vegetable oils were extracted, purified and derivatized to be analyzed by the gas chromatographic system (GC). The obtained FAME composition was considered as 100% (FAME values less than 1% were not considered) (Fig. 4) and it was compared with the respective original FAME composition of each vegetable oil.

As regards cottonseed oil, there was no significant difference in the composition obtained after GCL-I hydrolysis and its original oil composition, since its hydrolysis has been fully achieved. However, for olive oil (96.4% of hydrolysis) and palm kernel oil (60.1% of hydrolysis), the FAME composition percentages obtained by enzymatic hydrolysis were different from their original composition. This can be explained by the GLC-I substrate specificity, more precisely by its typoselectivity. When the enzyme preferably hydrolyzes a particular type of FFA, they are fully hydrolyzed in a short time (linoleic and oleic acids, for example), thus increasing their percentage in the mixture, while other FFA are more slowly hydrolyzed (such as lauric and mysristic acids, for example). This behavior is caused by differences observed in olive and palm kernel FAME compositions, which may persist when a full enzymatic hydrolysis is not achieved.

With respect to palm kernel oil, for example, whose partial hydrolysis was achieved after 120 min, it was observed a higher percentage of oleic acid than that present in the original oil, which shows that oleic acid, if compared to lauric acid (47.2% m/m), was preferentially hydrolyzed to GCL-I, even in smaller percentages (15.9% m/m), thus demonstrating the typoselectivity of this enzyme, in accordance with our previous studies performed by Castro et al. [26]. If GCL-I has not exhibited such typoselectivity, the FAME composition obtained from the original oil and from the one after the enzymatic hydrolysis would be similar, regardless of whether total or partial hydrolysis of the vegetable oil had been achieved.

Optimization of enzymatic hydrolysis of cottonseed oil

According to the obtained results, cottonseed oil was selected as substrate for FFA production. A CCDR with three independent variables was used; cottonseed oil concentration in the mixture (% m/m), lipase concentration GCL-I (U/g of the reaction mixture) and reaction temperature (°C). CCRD matrix and the results obtained are summarized in Table 3. After 50 min of reaction, a complete cottonseed oil hydrolysis was achieved in two assays (3 and 9) of the CCRD. The lowest value of enzymatic hydrolysis (41.4%) was in assay 11 of CCRD, which corresponded to the lowest level used for lipase concentration (2.9 U/g of the reaction mixture).

These results were used to estimate the regression coefficients and their interactions on the enzymatic hydrolysis synthesis, as shown in Table 4. The statistical analysis was carried out using coded variables at 95% confidence level, and significant parameters were: linear (x1) and quadratic (x 21 ) coefficients for cottonseed oil concentration, linear (x2) and quadratic (x 22 ) coefficients for lipase concentration, linear (x3) coefficient for temperature and interaction (x2·x3) between lipase concentration and temperature.

The coefficients that were not statistically significant were removed from the model and sent to residual. Table 4 was then recalculated again and new values were obtained only for statistically significant coefficients that were used for the construction of the second-order polynomial regression model (Eq. 7):

The analysis of variance (ANOVA) (Table 5) showed that the pure error was very low (0.88), thus indicating good reproducibility of the obtained experimental data. The F test also showed high significance by the regression model once the calculated F value (108.96) was higher than the table F value (3.22) for an enzymatic hydrolysis percentage at 95% confidence level. The coefficient of determination (R2) was 0.99, which indicates that only 0.01 of the overall variation was not explained by the model. Thus, the model given by the Eq. (7) can be used to generate the response surface for the analysis of variable effects on enzymatic hydrolysis of cottonseed oil.

Figure 5a shows the response surface generated through an interaction between the variables that were statistically significant. Higher enzymatic hydrolysis percentage by increasing lipase concentration from 2.9 to 10.3 (U/g of the reaction mixture) may be observed. As it can be observed, a complete cottonseed oil hydrolysis was obtained when maximum levels of lipase concentration were used (+ 1 and + 1.68). These results suggest excellent adsorption capacity of GCL-I on droplet size at oil/water interface, thus indicating that only lipase molecules acting are those adsorbed on oil droplets. In other words, the intense mechanical stirring (1000 rpm) used in this set of experiments led to the formation of an oil droplet interface able to interact efficiently with lipase molecules, thus improving the reaction rate. This shows that the hydrolysis reaction was intrinsically and kinetically controlled.

In Table 3, the assays that achieved complete hydrolysis were obtained at cottonseed oil concentrations ranging from 13.9 to 20.0% m/m (assays 9 and 3, respectively) and GLC-I concentration varying from 6.6 to 8.8 U/g of the reaction mixture, respectively, and at reaction temperatures between 38 and 40 °C. For the assays performed using maximum levels of lipase concentration (assays 4, 7, 8 and 12), hydrolysis percentage of 90.2, 90.4, 79.3 and 90.0% were obtained, respectively. It is important to note that the only value below 90% of hydrolysis (assay 8; 79.3%) between the assays was also the one in which the reaction temperature (43 °C) was above the optimum range established by the factorial design (35–40 °C), thus demonstrating that the response surface plot clearly shows the relations between these variables.

Lower hydrolysis percentage by raising the reaction temperature may be due to a possible inactivation of GCL-I at high temperatures. It is well known that the conformational stability of an enzyme is essential for its activity [45]. Therefore, the enzyme thermal stability is an important parameter that must be taken into account if its application in industrial processes is desired [46]. Thereby, thermal stability assays involving GCL-I at different temperatures were performed in further experiments.

To validate the optimization by CCRD, a new assay was performed in triplicate using the highest cottonseed oil concentration level of CCRD (46.8% m/m), and an intermediate level of lipase concentration (6.6 U/g of system) at 40 °C.

Under optimal experimental conditions, full hydrolysis of cottonseed oil was achieved within 60 min of reaction (Fig. 5b). These results indicate that a short-reaction time was required to attain maximum FFA concentration when compared to studies reported in Table 6 using other free lipases as catalysts in oil hydrolysis. It should be noted that the condition adopted in this work in which almost half the system was composed by cottonseed oil produced a hydrolysis reaction without the addition of emulsifiers, solvents, buffer solution, or the utilization of ultrasonic bath. Therefore, the high GCL-I substrate specificity was the main factor for the success of the enzymatic hydrolysis reaction so as to enable FFA production in a shorter time, which allowed energy savings through an ecofriendly process (without the addition of organic solvents or emulsifier agents).

Thermal stability tests for GCL-I

In this set of experiments, thermal stability tests at temperatures ranging from 35 to 50 °C were performed into determine the inactivation profile and estimation of kinetic and thermodynamic parameters under optimal experimental conditions in which GCL-I display high catalytic activity, as previously described in the “Optimization of enzymatic hydrolysis of cottonseed oil” section.

The half-life of an enzyme (t½) is the time required for the enzymatic activity to decrease to 50% of its initial activity at a given temperature. A longer half-life is an indication that the enzyme is thermally stable at this temperature, this broadening the possibility of its industrial application [47]. The thermal inactivation constant (kd) was calculated according to the nonlinear decay model proposed by Sadana and Henley (Fig. 6a). The coefficient of determination was higher than 95% for all fitted temperatures curves. kd is an important factor for analyzing the irreversible effects of enzyme thermal denaturation. At lower values of kd, or higher values of half-life (t½), greater enzyme thermal stability is expected [46].

These results indicate that values of t½ (700, 160, 60 and 40 min) decreased considerably as temperature increased (35, 40, 45 and 50 °C respectively), whereas kd values increased progressively (see Fig. 6a), thus showing that there was greater irreversible denaturation of GCL-I as temperature increased. At 35 °C, kd value was the lowest among the other temperatures evaluated, and t½ value of 700 min was considered as high for this lipase when compared to other free lipases [48].

The activation energy for the thermal denaturation of GCL-I (Ed) was calculated by the linear fit of the Arrhenius Eq. (6), Fig. 6b. Ed is the energy required for the soluble (native state) enzyme to be denatured (irreversible conformational modification), thus higher values of this parameter are a strong indication of a higher thermostability of the enzyme [45]. Thus, the high and positive Ed value found (94.25 kJ/mol) for GCL-I is an indicative of the enzyme high stability.

Although a lower thermal stability value has been observed for GCL-I at 40 °C (160 min) than at 35 °C (700 min), the enzyme will be active for as long as necessary to achieve a total cottonseed oil hydrolysis (60 min), which demonstrates that the utilization of free GLC-I is adequate for cottonseed oil hydrolysis, thus being a good alternative to produce concentrated FFA.

Conclusion

The present study provides an ecofriendly and low-cost process to produce FFA production via enzymatic hydrolysis of vegetable oils catalyzed by a non-commercial crude lipase extract from G. candidum (GCL-I). According to the obtained results, GCL-I selectively catalyzed the hydrolysis of ester bounds of unsaturated fatty acids (high hydrolysis percentage for cottonseed and olive oils), whereas ester bounds of saturated fatty acids (partial hydrolysis of palm kernel oil) remained preferentially unhydrolyzed. Among the different vegetable oils selected for the study, the highest FFA concentration was achieved by cottonseed oil, thus it was selected further studies. The CCDR was used to evaluate the influence of some important factors on the hydrolysis reaction and a complete hydrolysis percentage of cottonseed oil was observed in a short reaction time (60 min of reaction). These results clearly indicate the promising use of GCL-I as potential biocatalyst for FFA production using vegetable oils containing a high concentration of unsaturated fatty acids in their composition. Moreover, this lipase does not require the use of chemicals, such as emulsifiers and buffer agents, to exhibit high catalytic activity, thus reducing the generation of wastes during the FFA purification steps.

References

Murty VR, Bhat J, Muniswaran PKA (2002) Hydrolysis of oils using immobilized lipase enzyme: a review. Biotechnol Bioprocess Eng 7:57–66

Farile JM, Garcia JI, Herrerías CI, Pires E (2017) Synthetic transformations for the valorization of fatty acid derivatives. Synthesis 49:1444–1460

Santos KC, Cassimiro DMJ, Avelar MHM, Hirata DB, Castro HF, Fernández-Lafuente R, Mendes AA (2013) Characterization of the catalytic properties of lipases from plant seeds for the production of concentrated fatty acids from different vegetable oils. Ind Crops and Prod 49:462–470

Chen W, Sun S, Liang S, Peng L, Wang Y, Shen M (2014) Lipase-catalysed hydrolysis of linseed oil: optimization using response surface methodology. J Oleo Sci 63:619–628

Satyarthi JK, Srinivas D, Ratnasamy P (2011) Hydrolysis of vegetable oils and fats acids over solid acid catalysts. Appl Catal A Gener 391:427–435

Holliday RL, King JW, List GR (1997) Hydrolysis of vegetable oils in sub- and supercritical water. Ind Eng Chem Res 36:932–935

Pinto JSS, Lanças FM (2006) Hydrolysis of corn oil using subcritical water. J Braz Chem Soc 17:85–89

Fu X, Zhu X, Gao K, Duan J (1995) Oil and fat hydrolysis with lipase from Aspergillus sp. J Am Oil Chem Soc 72:527–531

Goswami D, Basu JK, De S (2013) Lipase applications in oil hydrolysis with a case study on castor oil: a review. Crit Rev Biotechnol 33:81–96

Almeida AF, Terrasan CRF, Terrone CC, Tauk-Tornisieloc SM, Carmona EC (2018) Biochemical properties of free and immobilized Candida viswanathii lipase on octyl-agarose support: hydrolysis of triacylglycerol and soy lecithin. Process Biochem 65:71–80

Verger R (1997) Interfacial activation of lipases: facts and artifacts. Trends Biotechnol 15:32–38

Aziz M, Husson F, Kermasha S (2015) Optimization of the hydrolysis of safflower oil for the production of linoleic acid, used as flavor precursor. Int J Food Sci 2015:1–10

Yigitoglu M, Temoçin Z (2010) Immobilization of Candida rugosa lipase on glutaraldehyde-activated polyester fiber and its application for hydrolysis of some vegetable oils. J Mol Catal B Enzym 66:130–135

Serri NA, Kamarudin AH, Rahaman SNA (2008) Preliminary studies for production of fatty acids from hydrolysis of cooking palm oil using C. rugosa lipase. J Phys Sci 19:79–88

Liu Y, Jin Q, Shan L, Liu Y, Shen W, Wang X (2008) The effect of ultrasound on lipase-catalyzed hydrolysis of soy oil in solvent-free system. Ultrason Sonochem 15:402–407

Avelar MHM, Cassimiro DMJ, Santos KC, Domingues RCC, Castro HF, Mendes AA (2013) Hydrolysis of vegetable oils catalyzed by lipase extract powder from dormant castor bean seeds. Ind Crops Prod 44:452–458

Stránský K, Zarevúcka M, Kejík Z, Wimmer Z, Macková M, Demnerová K (2007) Substrate specificity, regioselectivity and hydrolytic activity of lipases activated from Geotrichum sp. Biochem Eng J 34:209–216

Gunstone FD (2002) Vegetable oils in food technology: composition, properties and uses. Blackwell, London

Baillargeon MW, Bistline RG Jr, Sonnet PE (1989) Evaluation of strains of Geotrichum candidum for lipase production and fatty acid specificity. Appl Microbiol Biotechnol 30:92–96

Alves JS, Vieira NS, Cunha AC, Silva AM, Ayub MAZ, Fernandez-Lafuente R, Rodrigues RC (2014) Combi-lipase for heterogeneous substrates: a new approach for hydrolysis of soybean oil using mixtures of biocatalysts. RSC Adv 4:63–68

Poppe JK, Matte CR, Fernandez-Lafuente R, Rodrigues RC, Ayub MAZ (2018) Transesterification of waste frying oil and soybean oil by combi-lipases under ultrasound-assisted reactions. Appl Biochem Biotechnol 186:576–589

Poppe JK, Matte CR, de Freitas VO, Fernandez-Lafuente R, Rodrigues RC, Ayub MAZ (2018) Enzymatic synthesis of ethyl esters from waste oil using mixtures of lipases in a plug-flow packed-bed continuous reactor. Biotechn Progress 34:952–959

Poppe JK, Matte CR, Do Carmo Ruaro Peralba M, Fernandez-Lafuente R, Rodrigues RC, Ayub MAZ (2015) Optimization of ethyl ester production from olive and palm oils using mixtures of immobilized lipases. Appl Catal A Gen 490:50–56

Sidebottom CM, Charton E, Dunn PPJ, Mycock G, Davies C, Sutton JL, Macrae AR, Slabas AR (1991) Geotrichum candidum produces several lipases with markedly different substrate specificities. Eur J Biochem 202:485–491

Brabcová J, Deminanová Z, Vondrásek J, Jágr M, Zarevúcka M, Palomo JM (2013) Highly selective purification of three lipases from Geotrichum candidum 4013 and their characterization and biotechnological applications. J Mol Catal B Enzym 98:62–72

Castro PF, Moreira NC, Esperança MN, Oliveira LM, Badino AC, Tavano OL, Mendes AA, Basso RC, Fernández-Lafuente R, Hirata DB (2016) High lipase production from Geotrichum candidum in reduced time using cottonseed oil: optimization, easy purification and specificity characterization. J Chem Eng Res Updates 2016:60–69

Jacobsen T, Olse J, Allermann K (1998) Production, partial purification, and immunochemical characterization of multiple forms of lipase from Geotrichum candidum. Enzyme MicrobTechnol 11:90–95

Diks RMM, Lee ML (1999) Production of a very low saturate oil based on the specificity of Geotrichum candidum lipase. JAOCS 76:455–462

Foglia TA, Jones KC, Sonnet PE (2000) Selectivity of lipases: isolation of fatty acids from castor, coriander, and meadowfoam oils. Eur J Lipid Sci Technol 102:612–617

Saleem M, Rashid MH, Jabbar A, Perveen R, Khalid AM, Rajoka MI (2005) Kinetic and thermodynamic properties of an immobilized endoglucanase from Arachniotus citrinus. Process Biochem 40:849–855

Siddiqui KS, Aala A, Saqib N, Rashid MH (2000) Carboxyl group modification significantly altered the kinetic properties of purified carboxymethylcellulase from Aspergillus niger. Enzyme Microb Technol 27:467–474

Rooney D, Weatherley LR (2001) The effect of reaction conditions upon lipase catalysed hydrolysis of high oleate sunflower oil in a stirred liquid-liquid reactor. Process Biochem 36:947–953

Sadana A, Henley JP (1987) Single-step unimolecular non-first-order enzyme deactivation kinetics. Biotechnol Bioeng 30:717–723

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein dye binding. Anal Biochem 72:248–254

Borgstrom B (1952) Investigation on lipid separation methods: separation of cholesterol esters, glycerides and free fatty acids. Acta Physiol Scand 25:111–119

Belfrage P, Vaughan M (1969) Simple liquid–liquid partition system for isolation of labeled oleic acid from mixtures with glycerides. J Lipid Res 10:341–344

Hartman L, Lago RCA (1973) Rapid preparation of fatty acid methyl esters from lipids. Lab Pract 22:475–476

EN 14103 (2011) Fat and oil derivatives—fatty acid methyl esters (FAME)—determination of ester and linolenic acid methyl ester contents

Benzonana G, Desnuelle P (1958) Action de la lipase pancréatique sur les esters en émulsions. Biochim Biophys Acta 30:513–521

Borel P, Armand M, Ythier P, Dutot G, Melin C, Senft M, Lafont H, Lairon D (1994) Hydrolysis of emulsions with different triglycerides and droplet sizes by gastric lipase in vitro. Effect on pancreatic lipase activity. J Nutr Biochem 5:124–133

Tiss A, Carriéri F, Douchet I, Patkar S, Svendsen AE, Verger R (2002) Interfacial binding and activity of lipases at the lipid–water interface: effects of gum arabic and surface pressure. Colloid Surf B Bioint 26:135–145

McClements DJ (2005) Food emulsions: principles, practice, and techniques. CRC Press, Boca Raton

Mun S, Decker EA, McClements DJ (2007) Influence of emulsifier type on in vitro digestibility of lipid droplets by pancreatic lipase. Food Res Int 40:770–781

Bressani APP, Garcia KCA, Hirata DB, Mendes AA (2015) Production of alkyl esters from macaw palm oil by a sequential hydrolysis/esterification process using heterogeneous biocatalysts: optimization by response surface methodology. Bioprocess Biosyst Eng 38:287–297

Saqib AAN, Hassan M, Khan NF, Baig S (2010) Thermostability of crude endoglucanase from Aspergillus fumigatus grown under solid state fermentation (SSF) and submerged fermentation (SmF). Process Biochem 45:641–646

Souza PM, Aliakbarian B, Ferreira Filho EX, Magalhães PO, Pessoa Junior A, Converti A, Perego P (2015) Kinetic and thermodynamic studies of a novel acid protease from Aspergillus foetidus. Int J Biol Macromol 81:17–21

Marangoni AG (2003) Enzyme Kinetics: a modern approach. Wiley, New Jersey

Miranda JS, Silva NCA, Bassi JJ, Corradini MCC, Lage FAP, Hirata DB, Mendes AA (2014) Immobilization of Thermomyces lanuginosus lipase on mesoporous poly-hydroxybutyrate particles and application in alkyl esters synthesis: isotherm, thermodynamic and mass transfer studies. Chem Eng J 251:392–403

Cavalcanti-Oliveira EA, Silva PR, Ramos AP, Aranda DAG, Freire DMG (2010) study of soybean oil hydrolysis catalyzed by Thermomyces lanuginosus lipase and its application to biodiesel production via hydroesterification. Enzyme Res 2011:1–8

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)-Finance Code 001. The authors are grateful to Fundação de Amparo à Pesquisa do Estado de Minas Gerais-FAPEMIG (TEC-APQ-02755-16) for its financial support. MSc. Matheus M. Ferreira thanks CAPES for his student fellowship. Gustavo F. Oliveira thanks Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for his IC fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferreira, M.M., de Oliveira, G.F., Basso, R.C. et al. Optimization of free fatty acid production by enzymatic hydrolysis of vegetable oils using a non-commercial lipase from Geotrichum candidum. Bioprocess Biosyst Eng 42, 1647–1659 (2019). https://doi.org/10.1007/s00449-019-02161-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02161-2