Abstract

α,ω-Dicarboxylic acids (DC) are versatile chemical intermediates with different chain length. For biosynthesis of DC, to obtain the highly pure product via crystallization, it is required to remove pigments and proteins in fermentation broth. However, a trade-off between decolorization/deproteinization ratio and DC recovery during the purification process was found, which impeded DC production by fermentation. When ultrafiltration (UF) was applied to treat α,ω-dodecanedioic acid (DC12) broth, 93.4% of DC12 recovery, 80.5% of decolorization ratio and 61.7% of deproteinization ratio were achieved by a PES 3 membrane. However, the membrane technology could not effectively retain the pigments or proteins with low molecular weight when a high DC12 permeation was required. Meanwhile, the selected activated charcoal or macroporous resins were not good adsorbents for the present system. Furthermore, an integrated process for decolorization and deproteinization was developed. After filtration with PES3 membrane, an activated charcoal was used to remove the small proteins and pigments in the UF permeate. As a result, 91.4% of DC12 recovery, 94.7% of decolorization ratio and 84.8% of deproteinization ratio were obtained by such two-stage strategy. These results would serve as a valuable guide for process design and practical operation in subsequent industrial application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

α,ω-Dicarboxylic acids (DC) are generally represented as HOOC–(R)n–COOH [1], and they are also considered as a promising alternative energy substrate for metabolism [2, 3]. At present, the DC production from microbial fermentation has attracted more and more attention due to its moderate conditions, simple procedures, low cost and high yield [1, 4, 5]. Currently, the process for purifying the DCs from fermentation broth is typically classified into two types: organic solvent extraction and physical separation. The process using organic solvents is significantly restricted by the problems such as high investment, residual alkane and solvent in the product, safety issue and so on. The physical separation is green and mild, however, the purity of its product using the current techniques cannot attain to a high level required by polymerization [6]. Thus, a further purification process is involved to obtain the high purity DC from crude product, such as molecular distillation [7], recrystallization [6] and staged oxidation [8]. Usually, pigments and proteins are the main impurities in the crude product [6, 8], which are required to be removed to obtain a high product purity. However, during the process, some technical problems, such as low ratios of decolorization and deproteinization, and high DC loss, are impeding this technological upgrading in DC industry.

Usually, activated carbon could effectively adsorb pigments owing to its high surface area. However, adsorption capacity of the activated carbon was non-specific, which would simultaneously adsorb pigments and product. As a result, the product recovery ratio was relatively low. For example, only 85% protease could be recovered with a decolorization ratio of 90% using activated charcoal as a decoloring agent during decolorizing the enzyme from a crude extract in solid state fermentation of wheat bran by Rhizopus oryzae [9]. Therefore, another alternative method for the decolorization using macroporous resin was developed for enhancing the product recovery ratio. For example, Zhen et al. [10] used macroporous resin for ε-poly-L-lysine decolorization. And the recovery ratio of ε-poly-L-lysine was up to 97.3% with a decolorization ratio of 83.9%. For the purification of alkaline protease produced by Bacillus clausii [11], a protease yield of 99.7% with a decolorization ratio of 79% was obtained by diaion HPA75. Therefore, a higher recovery ratio of product could be obtained using proper resins as a decoloring agent, while the decolorization ratio was relatively low during the process. The reason may be that the relatively macromolecular substances (i.e., proteins) in the broth could hamper the adsorption of pigments by the resin. If the macromolecular substances could be first removed, then the decolorization ratio by adsorption may be enhanced. In fact, membrane could act as a selectively permeable barrier to separate target substance, which has been successfully used to separate macromolecular substances (i.e., proteins) from a targeted solution [12, 13]. Interestingly, it was also reported that a color removal kept more than 95% with a high sucrose recovery of up to 98% during refining sugar cane juice using membrane technology [14]. Therefore, a higher DC recovery ratio with a higher decolorization ratio may be achieved by membrane technology.

In the study reported here, a process for the simultaneous decolorization and deproteinization of the DC fermentation broth with membrane technology was evaluated. And the decolorization and deproteinization ratios by membrane filtration were also compared with those by activated carbon or resin. Finally, an optimal method for simultaneous decolorization and deproteinization of the DC fermentation broth would be established. And α,ω-dodecanedioic acid (DC12) broth from Candida viswanathii ipe-1 was used as a representative of the DCs in this study.

Materials and methods

Microorganism, media, and cultivation conditions

Candida viswanathii ipe-1 (CGMCC No. 8824), cultivation conditions, and the medium for DC12 production were the same as described by Cao et al. [15]. The seed culture medium contained 50 mL/L n-dodecane, 8.0 g/L KH2PO4, 5.0 g/L yeast extract (Beijing Aoboxing Bio-tech Co. LTD, China), 1.5 g/L dry powder of corn steep liquor, 30 g/L sucrose and 3.0 g/L urea in deionized water. For the production of DC12 in the 7.5 L bioreactor (BioFio®110), the following fermentation medium was used: 8.0 g/L KH2PO4, 4.0 g/L yeast extract (Beijing Aoboxing Bio-tech Co. LTD, China), 1.5 g/L dry powder of corn steep liquor, 60.0 g/L sucrose, 4.0 g/L sodium acetate, 3.0 g/L KNO3, 1.0 g/L NaCl, 0.5 g/L Tween 60 and 2.0 g/L urea in deionized water. After sterilization, 200 mL sterile n-dodecane was added to per liter fermentation medium at the initial phase, and another 200 mL n-dodecane per liter fermentation medium was added in the broth at 42 h.

Membranes

Six spiral-wound UF membrane module (Model 1812, 0.3 m2) were supplied by Amfor Inc. (Beijing, China) and their physical properties are listed in Table 1. The UF device consists of a feed tank (5 L) with an insulating jacket, a feed pump, a spiral-wound membrane module, and a water bath tank equipped with a circulating pump. The cross-flow velocity was measured by a rotor flow meter and adjusted by the frequency converter of pump. The trans-membrane pressure (TMP) was adjusted using a ball valve and the frequency converter of pump. Operation temperature was controlled at 30 ± 1 °C except for cleaning procedure. A cross-flow velocity was controlled at 5 L/min. A TMP was 10 bar for PES1, PES3 and PES5, and 5 bar for PES8, PES20 and PES50. First, new membrane modules were rinsed by deionized water for 1 h at a chose TMP (10 bar for PES1, PES3 and PES5, and 5 bar for PES8, PES20 and PES50), and the permeate was returned to the feed bank. After each test, UF membrane was first rinsed using deionized water with the same temperature as operating temperature. Then, NaOH solution (pH 10–12) was used to further clean the membrane to regenerate its permeability (within 5%). To illuminate the mechanism of the fouling during the membrane filtration, the fermentation broth was first centrifuged at 10,000×g for 15 min, and the obtained cell- and dodecane-free broth was named as CFB. The crude DC12 sample was first separated from CFB by adjusting pH to 2.0 with HCl, and then the crude DC12 was re-dissolved in NaOH solution with the final pH 8.0 and the same volume of CFB, which was called as DC12 solution from the CFB (DCFB). After the crude DC12 was removed from CFB, the obtained supernatant was adjusted pH to 8.0, which was called as supernatant of DC12-free CFB (SCFB). The fermentation medium was named as FM for short. The solutions were filtrated respectively by the selected membrane under the optimized conditions and the permeate fluxes were collected for analysis. All the experiments were performed at least twice, to ensure that the observed trends were correct and reproducible.

Adsorbents

Macroporous resins including D3520, D4020, AB-8, AB-8, NAK-II and XAD761 and their physical properties are listed in Table 2. The D3520, D4020, AB-8, AB-8 and NAK-II were purchased from Chemical plant of Nankai University (Tianjing, China). The XAD761 was purchased from Aladdin Industrial Corporation (Shanghai, China). These resins were pretreated with 1 M HCl and 1 M NaOH solutions sequentially to remove the monomers and porogenic agents trapped inside the pores during the synthesis process, and then dried at 60 °C under vacuum. Prior to adsorption experiments, pre-weighed amounts of resins were soaked in 95% ethanol and washed thoroughly with deionized water. Another adsorbent, activated charcoal was purchased from Xilong Chemical Co., Ltd (ACX) or Tianjin Guangfu science and technology Development Co Ltd (ACT). The activated charcoal was pretreated with 5% HCl and 5% NaOH solutions sequentially, and then dried at 80 °C in a drying oven.

Analytical methods

DC12 concentrations were measured as described by Liu et al. [16]. The data presented in the figures are the average values with error bars. The concentrations of protein were measured with a Pierce™ BCA protein assay kit (Thermo scientific, USA). The UV–Vis spectra of the solutions before and after treatment with UF or adsorbent were determined by a UV-9000S spectrophotometer (Shanghai Metash Instruments Co., Ltd, China). In addition, the solutions before and after treatment with UF or adsorbent were photographed by a digitalcamera (IXUS 210, Canon, Japan).

The pure water permeability (Lp) of membrane is expressed as follows:

where J is the permeate flux of deionized water (L/m2 h), TMP is trans-membrane pressure (bar).

Irreversible fouling (IF) is defined as the pure water permeability decrease after filtration experiment divided by initial water permeability, as illustrated in the following:

where Lpi and Lpf are the initial and final pure water permeability, respectively.

The volume reduction ratio (VRR) is defined as:

where Vr is the retentate volume, Vf is the feed volume.

Average flux represents the work efficiency which can express the filtration ability of membrane.

where A is the effective area of membrane, t is the filtration time, Vr is the retentate volume, Vf is the feed volume.

The recovery ratio of DC12 was calculated by the following equation:

where M0 and Me are the concentrations of DC12 (g/L) in the solutions before and after treatment, respectively.

The decolorization ratio was determined according to the following method: the absorbance of the sample solution was measured at 400 nm by the spectrophotometer. The following equation was used to quantify the decolorization ratio of the adsorbent or UF treatment:

where A0 and Ae are the absorbance of the samples at 400 nm before and after treatment, respectively.

Both the Freundlich and the Langmuir models were used to fit the decolorization data [9]. For adsorption of solute from dilute solutions the Freundlich equation expressed as follows:

where υ(A0–Ae) is the apparent adsorption per unit mass of adsorbent and κ and n are constants. The value of n is an indicator of the adsorption characteristics, n = 2–10 representing good, 1–2, moderately difficult, and n < 1, poor adsorption. A plot of ln Ae versus Ln[υ(A0–Ae)] would be a straight line.

The equation for the adsorption isotherm is expressed as follows:

where α is the amount of solute adsorbed by unit weight of adsorbent, [υ=(A0–Ae) (from Eq. 7)], Ae is the equilibrium concentration of solute in the free solution, and γ and β are constants depending on the properties of the adsorbent and the substance being adsorbed. A plot of 1/Ae versus 1/α would be a straight line.

Results and discussion

Characteristic of CFBs from the broth of C. viswanathii ipe-1

DC12 is a major metabolic product obtained from the fermentation with n-dodecane by C. viswanathii ipe-1 [15]. Meanwhile, the obtained fermentation broth is a complex multi-phase system which contains unreacted n-dodecane, unutilized culture medium, cells of the strain ipe-1 and inclusions thereof, secretion substances of the strain, proteins and pigments. A large amount of impurities had a serious effect on the purity and appearance of the DC12. In the system, cells and n-dodecane could be successfully removed with membrane technology, while the remaining proteins and pigments are still problematic. In addition, the peak patterns of absorbance were similar among the supernatants from 0 to 114 h and there was a big peak at 400 nm in the visible light range, while the absolute absorbance decreased with culture time increasing, as shown in Fig. 1a. Therefore, it could be concluded that the pigments mainly came from the culture medium, and 400 nm wavelength was better for decolorization measurement. However, the concentration of proteins was near zero at the initial fermentation, and it increased with culture time increasing (Fig. 1b). Thus, the protein in the supernatants was mainly produced during the fermentation. In fact, it was reported that a large amount of proteins, such as carbonyl reductase [17] and acid lipase [18], could be produced by C. viswanathii. Therefore, in the next sections, we would focus on how to remove the pigments and proteins from the CFBs.

Characteristics of CFBs from the broth of C. viswanathii ipe-1. The courses refer to variation of absorbance of the CFB (a), and the protein concentration in CFB (b). A mixed sample of three independent experiments was used for the measurement in (a), while data are given as mean ± SD (n = 3) in (b)

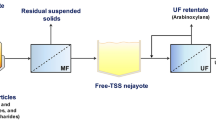

Decolorization and deproteinization by UF

Membrane selection

Membrane acts as a selectively permeable barrier to separate target substance, which has successfully used for decolorization in refining sugar cane juice [14]. In addition, since the pigments mainly came from the culture medium, in this section, fermentation medium (FM) was used for membrane selection. As shown in Fig. 2a, the flux decreased with increasing VRR because pigments and some macromolecular substances were retained and gradually accumulated in the retentate (resulting in membrane fouling and higher solvent viscosity in retentate). At VRR 4 (Fig. 2b), the decolorization ratios for the membranes of PES1, PES3, PES5, PES8, PES20 and PES50 were 82, 78, 65.3, 64.2, 63.9 and 3%, respectively, indicating that PES50 could not be used for decolorization due to the too large molecular weight cut-off (MWCO) of PES50. Although the decolorization trend roughly followed the MWCO of the membranes (higher MWCO, lower decolorization), the decolorization difference was not obvious as expected for PES1 and PES3 as well as PES5, PES8 and PES20, implying that fouling layer played an important role in pigment retention. Meanwhile, the average fluxes for the membranes were 3.09, 3.29, 6.62, 2.42, 6.81 and 63.6 L m−2h−1 for PES1, PES3, PES5, PES8, PES20 and PES50, respectively.

Filtration behavior of different UF membranes with the fermentation medium (FM). a Variation of permeate fluxes with VRR, b decolorization ratio and average flux. A trans-membrane pressure (TMP) was 10 bar for PES1, PES3 and PES5, and 5 bar for PES8, PES20 and PES50. Data are given as mean ± SD, n = 3

In view of the decolorization ratio and average flux, the PES3, PES5 and PES20 membranes were further evaluated for decolorization and deproteinization using cell- and dodecane-free broth (CFB). The average fluxes of the membranes for CFB were 1.86, 1.09 and 1.38 L m−2h−1 respectively for PES3, PES5 and PES20 (Fig. 3b). Compared with the filtration behavior for FM (Fig. 2b), the average fluxes for CFB decreased by 43.5, 83.5 and 79.8% for PES3, PES5 and PES20, respectively (Fig. 3), mainly due to the newly generated proteins. Moreover, the membrane PES3 had the highest average flux 1.86 L m−2h−1 with a decolorization ratio of 80.5%, a deproteinization ratio of 61.7%, a DC12 recovery ratio of 93.4% and a lower irreversible fouling (IF) of 71.7%. Therefore, the membrane PES3 was better for simultaneous decolorization and deproteinization of the DC12 broth. However, the decolorization and deproteinization ratios were still relatively low. Thus, the UF permeate needs further treatment to enhance the total decolorization and deproteinization of the DC12 broth.

Effect of UF MWCO on decolorization and deproteinization of CFB. a Variation of fluxes with VRR, b decolorization ratio, deproteinization ratio and DC12 recovery, c Lp, IF and average flux. A trans-membrane pressure (TMP) was 10 bar for PES3 and PES5, and 5 bar for PES20. Data are given as mean ± SD, n = 3

Mechanism discussion

Different sizes of particles in the feed solution would deposit on the membrane surface and block the membrane pores [19,20,21], resulting in a flux decline. To clarify fouling mechanisms during the CFB treatment by PES3, in this section, the four solutions, FM, CFB, DC12 solution from CFB (DCFB) and supernatant of DC12-free CFB (SCFB), were, respectively, treated with PES3 (Fig. 4). For DCFB, some proteins and pigments were still detected, and the ratio of decolorization and deproteinization with PES3 was only 45.3 and 1.24%, respectively, which was much lower than those for CFB, indicating that the DC12 could combine some small pigments and proteins from CFB during the acidification. Yan et al. [6] also verified that proteins and pigments in the fermentation broth could together precipitate with DC during the acidification. In addition, at VRR 4.0, the average flux of DCFB, FM and CFB was 4.14, 3.29, 1.86 Lm−2h−1, respectively. While for SCFB, the membrane fouling was most serious, and the average flux was only 0.37 Lm−2h−1 at VRR 1.3, which was much lower than that for other three solutions. These results implied that DC12 played a positive effect on permeate flux, and pigments and proteins were mainly responsible for the irreversible fouling. In detail, the adsorption of DC12 molecules with negative charge on the membrane might increase the antifouling performance of the membrane, and thus the extraction of DC12 from CFB resulted in a rapid flux decline for the UF of SCFB. It was worth mentioning that the SCFB was only concentrated to VRR 1.3 by PES 3, leading to a relatively lower irreversible fouling (Fig. 4b). The UF of the DCFB also produced an IF of 55.7%, which was caused by the small pigments and proteins brought by DC12 precipitation.

Variation of fluxes with VRR (a), average flux and Lp (b), and the ratio of decolorization, deproteinization and DC12 recovery (c) for UF of CFB, DCFB, SCFB and FM with PES 3 membrane. The meaning of CFB, DCFB, SCFB and FM was described in the “Membranes”. Data are given as mean ± SD, n = 3

Decolorization and deproteinization by adsorbents

Effect of adsorbent type

To investigate the decolorization and deproteinization of CFB by adsorption, different adsorbents including resins and activated charcoals were evaluated. As shown in Table 3, activated charcoal ACX and resin D4020 had a higher decolorization capacity to the CFB, and the resin XAD761 displayed a little higher deproteinization ability, while the other four resins could not adsorb the proteins. Moreover, the DC12 recovery ratios of the tested resin XAD761 and activated charcoals were all more than 95%, while the other four resins had stronger adsorption capacity to DC12, which was possibly caused by their smaller average pore diameter compared with the resin XAD761 (Table 2). The adsorption of product by resins was also reported in decolorization of ε-poly-L-lysine [10] and crude levan extract [22]. The low ratio of decolorization and deproteinization may be caused by the low dosage of adsorbents. Therefore, the effect of adsorbent dosage was investigated in the next section with ACX, XAD761 and D4020.

Effect of adsorbent dosage

With the increase of ACX dosage (Fig. 5a), the decolorization ratio increased up to 80.5% at 60 mg/mL ACX with a DC12 recovery ratio of 92.6% and a deproteinization ratio of 5.7%. Further increasing the ACX dosage above 60 mg/mL, the decolorization ratio decreased with the increasing ACX dosage. However, the DC12 recovery ratio was gradually decreased with the increasing ACX dosage, and DC12 recovery ratio decreased by 15.9% at 140 mg/mL ACX compared with that at 20 mg/mL ACX. Meanwhile, the deproteinization ratio started to increase when ACX dosage was above 60 mg/mL. Kumar and Parrack [23] also confirmed that the alkaline protease losses increased with enhancing concentration of charcoal. Therefore, it indicated that the decreasing decolorization ratio was caused by the increasing adsorption of DC12 and protein with ACX when ACX dosage was above 60 mg/mL, because activated carbon is a non-specific adsorbent that not only binds the color components but also the protein components and DC12. With increasing XAD761 dosage (Fig. 5b), the ratios of decolorization and deproteinization increased with the decreasing DC12 recovery ratio, and the decolorization ratio could just reach 62.3% at 120 mg/mL XAD761 with a DC12 recovery 91.5%. With the increasing D4020 dosage (Fig. 5c), the ratio of decolorization increased with the decreasing DC12 recovery ratio and almost constant deproteinization ratio, and the decolorization ratio could just reach 62.1% at 120 mg/mL D4020 with a DC12 recovery ratio of 60.3%. The above results showed a similar conclusion that the DC12 recovery ratio decreased with the increasing adsorbent dosage and the selected adsorbents had no significant effect on deproteinization. For decolorization, the activated charcoal ACX showed more effective than the reisns D4020 and XAD761. Therefore, the ACX was the best choice for decolorization of the DC12 broth among the selected adsorbents. However, there was a tradeoff between the decolorization ratio and DC12 recovery ratio with the activated charcoal ACX, and there may be other factors on the results which needed to be studied.

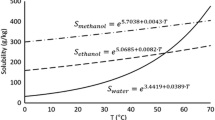

Effect of temperature

Temperature is also a very important factor affecting the adsorption properties of activated charcoals [24]. The thermal motion of the solute molecules increases with the increase of temperature, which benefits the molecules to reach and adsorb on the surface and inner of the ACX, thereby increasing the adsorption capacity of the ACX. As shown in Table 4, the decolorization ratio mildly increased with the increasing temperature, while the DC12 recovery ratio decreased more significantly. Meanwhile, the deproteinization ratio was not obviously affected by temperature. Therefore, it would be better to keep the same temperature during the fermentation (30 °C) for the decolorization of the DC12 broth to obtain the higher DC12 recovery ratio.

Modeling of decolorization process

From the data in Fig. 5a, Eqs. (7) and (8), υ, Ae and υ(A0–Ae) were fitted. The linear plot of LnAeψ versus Ln[υ(A0–Ae)] obtained in Fig. 6a verified the conformity of the decolorization characteristics with the Freundlich Eq. (7). Values from Fig. 5a were taken up to 60 mg/mL of charcoal only (as further increase in charcoal amount did not result in any further decolorization). The values of the Freundlich constants nψ and k were 0.35 and 0.88, respectively. In addition, the linear plot of (1) Aeψ versus (1) υ(A0–Ae) obtained in Fig. 6b, showed that decolorization also followed the Langmuir model (Eq. 8). The nψ value indicated that the activated charcoal ACX was not a good adsorbent for the present system. These results were different from those reported by Aikat et al. [9] for decolorization and purification of crude protease from Rhizopus oryzae by activated charcoal, since the aiming molecular weight of DC12 was lower than that of protease.

Decolorization and deproteinization by integrated UF and activated charcoal

From “Decolorization and deproteinization by UF” and “Decolorization and deproteinization by adsorbents”, it was found that the pigments and proteins with small molecular were still remaining in the UF permeate, and the activated charcoal ACX could efficiently remove the pigments. Therefore, an integrated UF and activated charcoal treatment was investigated in this section. As shown in Table 5, the recovery of DC12 was up to 91.4% with a decolorization ratio of 94.7% and a deproteinization ratio of 84.8% using the PES3 filtration followed by 5 mg/mL ACX treatment. To further validate the high decolorization and deproteinization efficiencies by such two-stage treatment, PES20 filtration followed by 40 mg/mL ACX treatment was also applied for CFB, and a DC12 recovery of 90.8%, a decolorization ratio of 93.8% and a deproteinization ratio of 90.2% were achieved. This result indicated that the integrated two-stage strategy outperformed the only ACX treatment or UF in decolorization and deproteinization of CFB.

Furthermore, the CFBs before and after treatment with the two-stage strategy were characterized by UV–Vis spectroscopy and digital photography. As shown in Fig. 7a, the absorbance in the region of 400–700 nm disappeared after the treatment, indicating that most of the pigments were removed. In addition, the photograph of DC12 broth before and after treatment (Fig. 7b) also demonstrated the excellent decolorization efficiency of the two-stage strategy.

Conclusion

This work demonstrated the feasibility of decolorization and deproteinization of DC12 fermentation broth with an integrated UF and activated charcoal treatment. In the first stage, the PES3 ultrafiltration membrane was suitable to remove the large molecular weight of proteins and pigments from DC12 broth. In the second stage, the activated charcoal ACX could effectively remove the lower molecular weight of proteins and pigments. As a result, a DC12 recovery ratio of 91.4% with a decolorization ratio 94.7% and a deproteinization ratio of 84.8% could be achieved. Therefore, a two-stage strategy for decolorization and deproteinization of DC12 broth would not only provide a good reference for process development and optimization for DC12 production but also could be applied for other fermentation systems.

Abbreviations

- DC:

-

α,ω-Dicarboxylic acids

- UF:

-

Ultrafiltration

- DC12 :

-

α,ω-Dodecanedioic acid

- TMP:

-

Trans-membrane pressure

- CFB:

-

Cell- and dodecane-free broth

- DCFB:

-

DC12 solution from the CFB

- SCFB:

-

Supernatant of DC12 free CFB

- FM:

-

Fermentation medium

- IF:

-

Irreversible fouling

- L pi :

-

Initial pure water permeability

- L pf :

-

Final pure water permeability

- VRR:

-

Volume reduction ratio

- MWCO:

-

Molecular weight cut-off

References

Huf S, Krügener S, Hirth T, Rupp S, Zibek S (2011) Biotechnological synthesis of long-chain dicarboxylic acids as building blocks for polymers. Eur J Lipid Sci Technol 113:548–561

Mingrone G, Castagneto-Gissey L, Macé K (2013) Use of dicarboxylic acids in type 2 diabetes. B Brit J Clin Pharmaco 75:671–676

Salinari S, Bertuzzi A, Gandolfi A, Greco AV, Scarfone A, Manco M, Mingrone G (2006) Dodecanedioic acid overcomes metabolic inflexibility in type 2 diabetic subjects. Am J Physiol Endocrinol Metab 291:E1051-E1058

Lee H, Sugiharto YEC, Lee S, Park G, Han C, Jang H, Jeon W, Park H, Ahn J, Kang K, Lee H (2017) Characterization of the newly isolated ω-oxidizing yeast Candida sorbophila DS02 and its potential applications in long-chain dicarboxylic acid production. Appl Microbiol Biotechnol 101:6333–6342

Iwama R, Kobayashi S, Ishimaru C, Ohta A, Horiuchi H, Fukuda R (2016) Functional roles and substrate specificities of twelve cytochromes P450 belonging to CYP52 family in n-alkane assimilating yeast Yarrowia lipolytica. Fungal Genet Biol 91:43–54

Yan L, Yang Y, Fu S, Chen Y, Wang Z, Cao W (2013) Process for preparing long-chain dicarboxylic acids and the production thereof. US Pat. 2013011647A1

Yu J, Yuan X, Zeng A (2015) A novel purification process for dodecanedioic acid by molecular distillation. Chin J Chem Eng 23:499–504

Sumner CE, Gibson PE, Lin R, Fugate EJ, Arnold EW (2006) Process for the purification of a crude carboxylic acid slurry. US Pat. 7132566

Aikat K, Maiti TK, Bhattacharyya BC (2001) Decolorization and purification of crude protease from Rhizopus oryzae by activated charcoal and its electrophoretic analysis. Biotechnol Lett 23:295–301

Zhen B, Chen X, Han D, Mao Z (2015) An alternative method for the decoloration of ɛ-poly-L-lysine eluate by macroporous resin in the separation and purification of ɛ-poly-L-lysine from fermentation broth. Food Bioprod Process 95:332–338

Koo KB, Joo H-S, Choi JW (2011) Decolorization method of crude alkaline protease preparation produced from an alkalophilic Bacillus clausii. Biotechnol Bioprocess E 16:89–96

Zhang W, Ding L, Grimi N, Jaffrin MY, Tang B (2017) Application of UF-RDM (ultrafiltration rotating disk membrane) module for separation and concentration of leaf protein from alfalfa juice: optimization of operation conditions. Sep Purif Technol 17:5365–375

Chen Z, Luo J, Wang Y, Cao W, Qi B, Wan Y (2017) A novel membrane-based integrated process for fractionation and reclamation of dairy wastewater. Chem Eng J 313:1061–1070

Luo J, Hang X, Zhai W, Qi B, Song W, Chen X, Wan Y (2016) Refining sugarcane juice by an integrated membrane process: filtration behavior of polymeric membrane at high temperature. J Membr Sci 509:105–115

Cao W, Li H, Luo J, Yin J, Wan Y (2017) High-level productivity of α,ω-dodecanedioic acid with a newly isolated Candida viswanathii strain. J Ind Microbiol Biotechnol 44:1191–1202

Liu S, Li C, Fang X, Cao ZA (2004) Optimal pH control strategy for high-level production of long-chain α,ω-dicarboxylic acid by Candida tropicalis. Enzyme Microb Tech 34:73–77

Soni P, Prasad GS, Banerjee UC (2006) Optimization of physicochemical parameters for the enhancement of carbonyl reductase production by Candida viswanathii. Bioprocess Biosyst Eng 29:149–156

de Almeida AF, Tauk-Tornisielo SM, Carmona EC (2013) Acid lipase from Candida viswanathii: production, biochemical properties, and potential application. Biomed Res Int 2013: 435818

Steinhauer T, Hanély S, Bogendörfer K, Kulozik U (2015) Temperature dependent membrane fouling during filtration of whey and whey proteins. J Membr Sci 492:364–370

Zhang X, Guo J, Wang L, Hu J, Zhu J (2013) In situ ozonation to control ceramic membrane fouling in drinking water treatment. Desalination 328:1–7

Lin T, Lu Z, Chen W (2014) Interaction mechanisms and predictions on membrane fouling in an ultrafiltration system, using the XDLVO approach. J Membr Sci 461:49–58

Liu J, Luo J, Sun Y, Ye H, Lu Z, Zeng X (2010) A simple method for the simultaneous decoloration and deproteinization of crude levan extract from Paenibacillus polymyxa EJS-3 by macroporous resin. Bioresour Technol 101:6077–6083

Kumar CGP (2003) Activated charcoal: a versatile decolorization agent for the recovery and purification of alkaline protease. World J Microb Biot 19:243–246

Sessa DJ, Palmquist DE (2008) Effect of heat on the adsorption capacity of an activated carbon for decolorizing/deodorizing yellow zein. Bioresour Technol 99:6360–6364

Acknowledgements

The authors thank the National High Technology Research and Development Program of China (No. 2015AA021002 and No. 2014AA021005), and the National Science Foundation of China (No. 21406240) for the financial supports.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Cao, W., Wang, Y., Luo, J. et al. Simultaneous decolorization and deproteinization of α,ω-dodecanedioic acid fermentation broth by integrated ultrafiltration and adsorption treatments. Bioprocess Biosyst Eng 41, 1271–1281 (2018). https://doi.org/10.1007/s00449-018-1955-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-1955-7