Abstract

Surfactants play major role in the delignification of lignocellulosic biomass. Surfactant-assisted hydrothermal pretreatment was evaluated for chili post-harvest residue. Maximum reducing sugar yield of 0.445 g per g of dry biomass (g/g) was obtained when surfactant PEG 6000 was used. Compositional analysis revealed an efficient removal of lignin and hemicelluloses from the pretreated biomass. Fermentation inhibitors such as furfural, 5-hydroxymethylfurfural and organic acids were absent in the hydrolyzate. After pretreatment, the biomass can be directly hydrolyzed without any neutralization, washing and drying, and the hydrolyzate is devoid of major fermentation inhibitors. Fermentation with Saccharomyces cerevisiae yielded 1.84% of ethanol with a fermentation efficiency of 63.88%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The increase in price of petroleum, depletion of fossil fuels and increasing concerns of environmental impact related to greenhouse gas emissions lead to the search for new alternative sources of energy [1]. Lignocellulosic biomass is a carbohydrate complex composed of cellulose, hemicelluloses, and lignin. One of the prime factors affecting efficiency of biofuel production is the chemical composition of lignocellulosic materials. The recalcitrance of lignocellulose is one of the main barriers for the economical production of bioethanol. To make the lignocellulosic biomass to overcome recalcitrance, pretreatment of the lignocellulosic biomass is carried out to remove the barriers as well as to make cellulose more accessible for enzymatic hydrolysis [2]. Pretreatment of lignocellulosic biomass is one of the most expensive steps in the conversion of biomass to fermentable sugars. Several R and D activities are going on to develop a cost-effective strategy [3, 4]. Another major challenge is the formation of degradation products which will affect further downstream operations. An effective pretreatment can lower the downstream unit operation cost [5].

Several reports are available on the positive impact of surfactants in enzymatic saccharification. It prevents the unproductive adsorption of enzymes onto lignin [6] as well as removes degradation products of hemicelluloses and lignin Kurakake et al. [7]. It also protects enzymes from thermal denaturation [8]. Surfactants help in delignification. Not many studies were carried out for exploiting the potential of surfactant on delignification. Escalante et al. [9] reported that the hydrophilic and hydrophobic properties of surfactants decrease surface tension between the two liquid faces and improves the removal of hydrophobic compounds. Kurakake et al. [7] reported that surfactant extracts the hydrophobic degradation products from lignin and hemicelluloses which in turn helps in lignin removal during pretreatment. Surface activation properties of surfactant help in better lignin removal during pretreatment. Few reports were available on surfactant or surfactant-assisted pretreatment [10,11,12,13,14,15,16,17]. Though several surfactant or surfactant-assisted pretreatment strategies were available, to the best of our knowledge no studies were carried out on surfactant-assisted hydrothermal pretreatment of chili post-harvest residue.

The residue which is left out after harvesting of chili comprising of leaves and stalks constitutes the chili post-harvest residue (CPHR). This is one of the biomass which is underexploited. Normally it is burnt in the field and it will cause environmental issues. Utilization of this waste agro-residue for bioethanol seems promising based on ecological and environmental benefits.

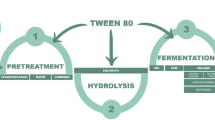

The objective of the present study was to evaluate surfactant-assisted hydrothermal pretreatment of chili post-harvest residue for the production of bioethanol and to optimize various process parameters affecting pretreatment as well as utilization of hydrolyzate for the production of bioethanol.

Materials and methods

Screening of various surfactants for surfactant-assisted hydrothermal pretreatment of chili post-harvest residue (SAHTP CPHR)

The biomass used in this study was received from Virudhanagar, Tamil Nadu, India. Samples were dried and milled in a knife mill. NREL protocol was adopted for compositional analysis of the biomass [18].

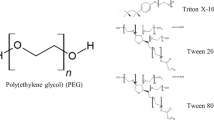

Different surfactants (Tween 80, Triton X 100, Tween 40 and (polyethylene glycol) PEG 6000) at an initial concentration of 1% w/w were used for selecting the best surfactant. Other parameters such as biomass loading were set at 20% w/w and SAHTP was carried out in an autoclave at 121 °C, 15 lb pressure for 60 min. After pretreatment, one set of samples was used as such for hydrolysis without washing and drying, and the other set was used for hydrolysis after washing and drying.

Optimization of various process parameters affecting surfactant-assisted hydrothermal pretreatment of chili post-harvest residue and validation of optimized conditions of pretreatment

Optimization of various process parameters affecting SAHTP CPHR was carried out by adopting a Box–Behnken design. The experiment consists of a total of 15 runs. The details are presented in Table 1. The parameters selected were biomass (solid) loading, incubation time and surfactant concentration. Three parameters were selected at three levels—lower, middle and higher levels. To validate the model, three confirmation experiments were carried out within the range defined previously and correlation analysis were performed based on the experimental and the predicted responses.

Enzymatic saccharification

Pretreated biomass was used for enzymatic saccharification. The conditions of hydrolysis were biomass loading of 20% w/w, incubation time of 48 h at 50 °C, surfactant (Tween 80) concentration of 0.1% w/w, enzyme loading (Zytek India Ltd, Mumbai, India) of 30 FPU per g of pretreated biomass and 200 µl of antibiotic (Penicillin–Streptomycin cocktail, Hi-media, India). Total reaction volume was made up to 30 ml with 0.1 M citrate buffer (pH 4.8). 3,5-Dinitrosalicylic method was used for reducing sugar analysis [19].

Scanning electron microscopy

Morphological differences were analyzed by taking scanning electron microscopy images (JEOL JSM-5600). Samples were sputter-coated with gold–palladium using a JEOL JFC-1200 fine coater. Micrographs were taken at a magnification of 250X with an accelerating voltage set at 10–15 kV.

Inhibitor analysis of the hydrolyzate and fermentation

The hydrolyzate samples were used for inhibitor analysis. The samples were centrifuged and filtered through PES membrane filters (Pall, USA). Inhibitors such as organic acids, furfural and 5-hydroxymethylfurfural were analyzed by HPLC. The conditions were: 0.01N H2SO4 was used as solvent and the flow rate was maintained at 0.6 ml/min. Organic acid column (ROA Phenomenex) was used for inhibitor analysis. Retention time was 50 min and oven temperature was maintained at 55 °C, PDA detector was used.

Fermentation was carried out with non-detoxified hydrolyzate in 250-ml stoppered conical flasks. The sample was inoculated with seed culture (2% v/v) of 18 h old Saccharomyces cerevisiae and incubated at 30 °C for 72 h. Ethanol analysis was carried out by gas chromatography (Chemito, India) [20].

Results and discussion

Compositional analysis of native and pretreated chili post-harvest residue

The native biomass contains 39.95% of cellulose, 17.85% of hemicellulose and 25.32% of lignin. The SAHTP CPHR contains 57.23% of cellulose, 13.15% of hemicellulose and 11.79% of lignin. Hydrothermal-pretreated biomass contains 42.03% of cellulose, 16.95% of hemicellulose and 23.11% of lignin. More effective removal of hemicelluloses and lignin were observed in the SAHTP CPHR. There was 30% of weight loss after pretreatment. The weight loss was due to hemicelluloses and lignin removal and also during the filtration stage. It is very difficult to recover the very fine particles produced after pretreatment; hence this weight loss is in an acceptable range. Percentage weight loss varies based on the strategy adopted for pretreatment. Weight loss may affect the economic feasibility of the process, but it could be reduced by adopting efficient filtration process. An effective pretreatment would remove more hemicelluloses and lignin from the biomass after pretreatment. The increase of cellulose content and a decrease of hemicelluloses and lignin content in the pretreated biomass indicate that pretreatment is effective.

Screening profile of various surfactants for surfactant-assisted hydrothermal pretreatment of chili post-harvest residue

Four different surfactants at a concentration of 1% w/w—Tween 80, Tween 40, Triton X100 and PEG 6000—were used to select the best surfactant. The results are presented in Table 2. The conditions of pretreatment were 20% w/w of biomass (solid) loading and pretreatment was carried out in a laboratory autoclave at 121 °C for 60 min. All the surfactants gave almost same reducing sugar yield in both samples where hydrolysis was carried out with or without washing and drying of the pretreated sample. Control samples where the pretreatment was carried out without any surfactant gave a reducing sugar yield of 0.112 g of reducing sugar per g of pretreated biomass after enzymatic saccharification (g/g). One of the main advantages of using surfactant in hydrolysis is that it is adsorbed on to cellulose surface, lowers the surface tension and improves the wettability of the substrate, and improves the saccharification rate [21].

Inhibitor profile of enzymatic hydrolyzate of SAHTP CPHR without washing and drying is presented in Table 3. In all the samples, major fermentation inhibitors such as furfural and 5-hydroxymethylfurfural were absent. In PEG 6000 pretreated samples, organic acids such as formic acid, citric acid, succinic acid and propionic acid were absent. Acetic acid was present at low concentration (0.085 mM/l). In Tween 80 pretreated samples, all types of organic acids were present at lower levels. For Triton X 100 pretreated samples, organic acids such as citric acid, succinic acid and propionic acid were absent while formic acid and acetic acid were present at low levels. In Tween 40 pretreated samples, acetic acid, citric acid and succinic acid were found while no formic acid and propionic acid were measured.

Inhibitor profile of enzymatic hydrolyzate of SAHTP CPHR with washing and drying is presented in Table 4. In all samples, major fermentation inhibitors such as furfurals and 5-hydroxymethylfurfurals and organic acids such as citric and succinic acid were absent. Triton X100 and PEG 6000 pretreated samples were devoid of all inhibitors. Tween 80 pretreated samples contain propionic acid and formic acid at lower concentration while the Tween 40 pretreated samples contain inhibitors such as formic acid and acetic acid at lower concentration.

The reducing sugar yield was same for all samples pretreated with different surfactants with and without washing and drying. Since the PEG 6000 pretreated sample is devoid of major fermentation inhibitors in the hydrolyzate of surfactant-assisted hydrothermal pretreated CPHR without washing and drying, PEG 6000 was selected for further studies. Elimination of neutralization, washing and drying make the process economically viable and there will not be any effluent generation which is one of the major drawbacks with conventional pretreatment strategies.

Nasirpour et al. [12] reported the potential of PEG for effective delignification. An increase in enzymatic saccharification rate was observed when pretreatment was carried out with ionic liquid at higher temperature. The increase in reducing sugar yield is due to increase of crystallinity index and delignification. The increase in crystallinity index is due to removal of amorphous components such as hemicelluloses and lignin which in turn increase the proportion of cellulose and, therefore, resulted in an increase of crystallinity index.

One of the main advantages of SAHTP when compared to conventional pretreatment using acid or alkali is that there is no need for washing, neutralization or drying of biomass after pretreatment. The pretreated biomass can be directly used as such for enzymatic saccharification. Since the hydrolyzate is devoid of major fermentation inhibitors such as furfurals, 5-hydroxymethylfurfurals and organic acids, it can be used for fermentation without any detoxification. Similar observations were earlier made by Sindhu et al. [22] for crude glycerol-assisted surfactant pretreatment of chili post-harvest residue where the major fermentation inhibitors such as furfural and 5-hydroxymethylfurfural and organic acids such as citric acid, propionic acid and succinic acid were absent.

Effect of different process parameters on surfactant-assisted hydrothermal pretreatment of chili post-harvest residue

The results are presented in Table 1. Maximum reducing sugar yield (0.445 g of reducing sugar per g of dry biomass, g/g) was observed with run number 14, where the conditions of pretreatment were biomass loading of 20% w/w, incubation time of 30 min and surfactant concentration of 3% w/w. Run number 5 gave a reducing sugar yield of 0.422 g/g where the conditions of pretreatment were biomass loading of 30% w/w, incubation time of 45 min and surfactant concentration of 1% w/w. Since the biomass loading was high and the reagent concentration was low, this condition was selected for further studies. Pretreatment carrying out with high biomass loading and low reagent concentration makes the process more economically viable.

Interactions between various process parameters affecting SAHTP CPHR were presented in Fig. 1A-C.

a–c Contour plots showing interactions of various process parameters affecting surfactant-assisted hydrothermal pretreatment of chili post-harvest residue. a Interactions between biomass loading and incubation time. b Interactions between biomass loading and surfactant concentration. c Interactions between incubation time and surfactant concentration

An interaction between incubation time and biomass loading is presented in Fig. 1a. At low levels of biomass loading, the reducing sugar yield is low, reducing sugar yield increases with the increase of biomass loading and maximum reducing sugar yield (0.4 g/g) was observed with high levels of biomass loading (24–30% w/w). At low levels of incubation time, the reducing sugar yield is high (0.4 g/g). Reducing sugar yield decreases with the increase of incubation time. Maximum reducing sugar yield was observed with low levels of incubation time (30–40 min). Contrary observations were reported for PEG pretreatment of corn stover where there is no significant change in reducing sugar yield with an increase of incubation time from 1 to 4 h. Surfactants have both hydrophilic and hydrophobic properties [16]. They help in the removal of hydrophobic substances by decreasing surface tension between the two liquid phases. Surfactants serve as good additives of pretreatment by increasing lignin removal by extracting the hydrophobic products of lignin degradation [12]. Lignin present in the biomass reduces swelling of cellulose and accessibility of enzymes.

An interaction between surfactant concentration and biomass loading is presented in Fig. 1b. At low levels of biomass loading, the reducing sugar yield is low. Reducing sugar yield increases with an increase of biomass loading. Maximum reducing sugar yield (0.375 g/g) was observed with high levels of biomass loading (26–30% w/w). Low to the middle level of surfactant concentration (1–4% w/w) gave the same reducing sugar yield. At high levels of surfactant concentration (4–5% w/w), there was a decrease in reducing sugar yield (0.3 g/g).

Interactions between surfactant concentration and incubation time is presented in Fig. 1c. At low levels of incubation time, the reducing sugar yield is high. Reducing sugar yield decreases with an increase of incubation time (40–60 min). Maximum reducing sugar yield (0.4 g/g) was observed with low levels of incubation time (30–40 min). An identical observation was earlier reported on PEG pretreatment of high lignin containing corn stover, the increase of incubation time was found to be insignificant [23]. At low levels of surfactant concentration (1–3.5% w/w) the reducing sugar yield is high. Reducing sugar yield decreases with increase of surfactant concentration (3.5–5% w/w). Maximum reducing sugar yield (0.4 g/g) was observed with low levels of surfactant concentration (1–3.5% w/w). The increase in surfactant concentration above 0.6 g/g of glucan does not have a significant role in reducing sugar yield and was reported for pretreatment of corn stover with polyethylene glycol [16].

The second-order polynomial equation obtained from the experimental data can be used to predict the reducing sugar yield at any biomass loading, surfactant concentration and incubation time within the experimental design.

The polynomial equation is given below:

where X1, X2 and X3 were biomass loading, incubation time and surfactant concentration, respectively.

The regression coefficient for reducing sugar yield was found to be best with biomass loading. The p value verifies the significance of each of the coefficients thereby identifies the pattern of interactions between the selected variables. In this model biomass loading is the only significant factor. Other factors such as incubation time and surfactant concentration were found to be insignificant since the p values were 0.06. p value less than 0.05 is found to be significant. The R2 value explains the variability in the reducing sugar yield. R2 value (coefficient of determination) was calculated as 97.21, indicating that this model can explain 97.21% variability in response.

Validations of model results are presented in Table 5. Predicted results and the experimental values were used to calculate the correlation analyses. Correlation coefficient was found to be 0.917, indicating that the model developed is accurate.

Scanning electron micrographic profile of native and pretreated biomass

Scanning electron micrographs of native and pretreated samples are presented in Fig. 2a, b. Native samples showed a rough, compact and highly ordered structure, while the pretreated samples showed a highly distorted structure. After pretreatment the biomass was swollen and stacked bundles were opened. Multiple morphological changes were observed. Cracked and flaked off surface were observed indicating the separation of compact structure. Similar observation was reported earlier for pretreated hemp herd biomass [23].

Fermentation

Fermentation of the non-detoxified hydrolyzate by S. cerevisiae produced 1.84% of ethanol with a fermentation efficiency of 63.88%. Optimization of various process parameters affecting fermentation may improve the efficiency. Till date, only one report is available for comparing the fermentation efficiency of CPHR. Fermentation of the non-detoxified hydrolyzate of crude glycerol-assisted surfactant pretreated CPHR yielded 8.6 g of bioethanol with a fermentation efficiency of 36.68% [22]. Fermentation efficiency of the hydrolyzate obtained from SAHTP CPHR was found to be better. Fermentation of the non-detoxified hydrolyzate of SAHTP CPHR yielded 14.52 g of ethanol with a fermentation efficiency of 63.88%. The results presented in this study are without any optimization of various process parameters affecting fermentation. Fine tuning can improve the fermentation efficiency.

Conclusions

The results indicate that chili post-harvest residue could be used as a potential substrate for bioethanol production. One of the main advantages of SAHTP is that the pretreated biomass can be used for enzymatic saccharification without any neutralization, washing or drying. The optimum conditions for pretreatment were biomass loading of 30% w/w, surfactant concentration of 1% w/w and incubation time for 30 min. This is economically viable since pretreatment was carried out at high biomass loading and with low concentration of surfactant. Since the hydrolysate is devoid of major fermentation inhibitors, detoxification is not required. Elimination of unit operations such as neutralization, washing, drying as well as detoxification will reduce the overall process economics. To the best of our knowledge, this is the first report on SAHTP of CPHR for the production of bioethanol.

References

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energ Conv Manag 52:858–875

Zhu JY, Wang GS, Pan XJ, Gleisner R (2008) The status and key barriers in lignocellulosic ethanol production: a technological perspective. In: International conference on biomass energy technologies, Guangzhou, China, December 3–5

Chandel AK, Es C, Rudravaram R, Narasu ML, Rao LV, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol Rev 2:14–32

Zheng Y, Pan Z, Zhang R (2009) Overview of biomass pretreatment for cellulosic ethanol production. Int J Agric Biol Eng 2:51–68

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod Biorefin 2:26–40

Eriksson T, Borjesson J, Tjerneld F (2002) Mechanism of surfactant effect in enzymatic hydrolysis of lignocellulose. Enzyme Microb Technol 31:353–364

Kurakake M, Ooshima H, Kato J, Harano Y (1994) Pretreatment of bagasse by nonionic surfactant for the enzymatic-hydrolysis. BioresourTechnol 49:247–251

Eckard AD, Muthukumarappan K, Gibbons W (2013) A review of the role of amphiphiles in biomass to ethanol conversion. Appl Sci 3:396–419

Escalante M, Rodriguez-Malaver AJ, Araujo E, Gonzalez AM, Rojas OJ, Penaloza N, Bullon J, Lara MA, Dmitrieva N, Perez-Perez E (2005) Effect of surfactants on Fenton’s reagent-mediated degradation of Kraft black liquor. J Environ Biol 26:709–718

Sindhu R, Kuttiraja M, Binod P, Preeti VE, Sandhya SV, Vani S, Sukumaran RK, Pandey A (2012) Surfactant-assisted acid pretreatment of sugarcane tops for bioethanol production. Appl Biochem Biotechnol 167:1513–1526

Sindhu R, Kuttiraja M, Preeti VE, Vani S, Sukumaran RK, Binod P (2013) A novel surfactant-assisted ultrasound pretreatment of sugarcane tops for improved enzymatic release of sugars. Bioresour Technol 135:67–72

Nasirpour N, Mousavi SM, Shojaosadati SA (2014) A novel surfactant-assisted ionic liquid pretreatment of sugarcane bagasse for enhanced enzymatic hydrolysis. Bioresour Technol 169:33–37

Qi B, Chen X, Wana Y (2010) Pretreatment of wheat straw by nonionic surfactant-assisted dilute acid for enhancing enzymatic hydrolysis and ethanol production. Bioresour Technol 101:4875–4883

Kapu NUS, Manning M, Hurley TB, Voigt J, Cosgrove DJ, Romaine CP (2012) Surfactant-assisted pretreatment and enzymatic hydrolysis of spent mushroom compost for the production of sugars. Bioresour Technol 114:399–405

Cao S, Aita GM (2013) Enzymatic hydrolysis and ethanol yields of combined surfactant and dilute ammonia treated sugarcane bagasse. Bioresour Technol 131:357–364

Eckard AE, Muthukumarappan K, Gibbons W (2012) Pretreatment of extruded corn stover with polyethylene glycol to enhance enzymatic hydrolysis: optimization, kinetics and mechanism of action. Bioenerg Res 5:424–438

Qing Q, Yang B, Wyman CE (2010) Impact of surfactants on pretreatment of corn stover. Bioresour Technol 101:5941–5951

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) NREL Technical Report, NREL/TP-510-42618

Miller GM (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Sindhu R, Binod P, Janu KU, Sukumaran RK, Pandey A (2012) Organosolvent pretreatment and enzymatic hydrolysis of rice straw for the production of bioethanol. World J Microbiol Biotechnol 28:473–483

Helle SS, Duff SJB, Cooper DG (1993) Effect of surfactants on cellulose hydrolysis. Biotech Bioeng 42:611–617

Sindhu R, Gnansounou E, Pandey A, Binod P (2015) A novel crude glycerol assisted surfactant pretreatment strategy of chili post-harvest residue for bioethanol production. Biofuels. https://doi.org/10.1080/17597269.2015.1110780

Abraham RE, Barrow CJ, Puri M (2013) Relationship to reducing sugar production and scanning electron microscope structure to pretreated hemp hurd biomass (Cannabis sativa). Biomass Bioenerg 58:180–187

Acknowledgements

Financial support from MNRE, Government of India, New Delhi and TIFAC, New Delhi, is acknowledged. Raveendran Sindhu acknowledges financial support from DBT, New Delhi, for DBT Bio-CARe programme. Financial support from EPFL, Lausanne, Switzerland, and Marie Curie Actions-International Research Staff Exchange Scheme—Contact Number 318931 is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sindhu, R., Binod, P., Mathew, A.K. et al. An effective surfactant-assisted hydrothermal pretreatment strategy for bioethanol production from chili post-harvest residue by separate hydrolysis and fermentation. Bioprocess Biosyst Eng 41, 565–571 (2018). https://doi.org/10.1007/s00449-018-1891-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-1891-6