Abstract

This study investigates the effects of viscosity, friction, and sonication on the morphology and the production of lovastatin, (+)-geodin, and sulochrin by Aspergillus terreus ATCC 20542. Sodium alginate and gelatine were used to protect the fungal pellet from mechanical force by increasing the media viscosity. Sodium alginate stimulated the production of lovastatin by up to 329.0% and sulochrin by 128.7%, with inhibitory effect on (+)-geodin production at all concentrations used. However, the use of gelatine to increase viscosity significantly suppressed lovastatin, (+)-geodin, and sulochrin’s production (maximum reduction at day 9 of 42.7, 60.8, and 68.3%, respectively), which indicated that the types of chemical play a major role in metabolite production. Higher viscosity increased both pellet biomass and size in all conditions. Friction significantly increased (+)-geodin’s titre by 1527.5%, lovastatin by 511.1%, and sulochrin by 784.4% while reducing pellet biomass and size. Conversely, sonication produced disperse filamentous morphology with significantly lower metabolites. Sodium alginate-induced lovastatin and sulochrin production suggest that these metabolites are not affected by viscosity; rather, their production is affected by the specific action of certain chemicals. In contrast, low viscosity adversely affected (+)-geodin’s production, while pellet disintegration can cause a significant production of (+)-geodin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aspergillus terreus ATCC 20542 is a prolific fungus strain known for its ability to produce lovastatin, a potent cholesterol-lowering drug. Lovastatin is synthesised via type I polyketide synthase (PKS), a common multi-domain enzyme used to produce secondary metabolites in microorganisms. PKS is also responsible for the production of two co-metabolites of lovastatin, namely, (+)-geodin and sulochrin. To date, the function of these secondary metabolites in the natural environment remains unclear. However, it is widely accepted that most secondary metabolites are expressed for competitive purposes and are important for the survival of the microorganism, such as defense against predators [1].

Previous studies demonstrated that the manipulation of different rheological properties or viscosity can influence the fungal morphology, trigger the organism’s defense system, and consequently induce the synthesis of secondary metabolites [2, 3]. Higher viscosity is thought to have a “protective” effect against mechanical stress in fungi [4]. Various effects of viscosity have been reported in different microorganisms so far [4,5,6,7]. For example, in Aspergillus niger, the application of higher viscosity resulted in a significantly higher metabolite production [4]. Similarly, Streptomyces species showed a favourable morphology and growth under higher viscosity condition [8]. By contrast, high viscosity has been reported to negatively influence the growth, cultivation, and post-processing of desired products in some fungi species [9]. The use of specific compounds, such as polysaccharides, to increase viscosity is preferable due to their additional ability to stimulate the microorganism’s metabolite production [10,11,12,13].

The use of mechanical stress usually leads to morphological alteration in fungi, especially the size. To date, conflicting findings have been reported on the optimal pellet size of A. terreus in relation with metabolite production. Some studies suggest that small pellets are associated with improved metabolite production [18, 19], while others suggest that bigger pellets are better for metabolite production [20, 21]. The introduction of mechanical stress by sonication has previously been performed in A. terreus [14]. Although it improved metabolite production in bacteria, yeast, and plant cell [15], this method has been reported to reduce the production of lovastatin in A. terreus [14]. This was thought to be associated with the production of disperse morphology of the A. terreus resulting from the sonication. Although the disperse morphology favors metabolite production in certain type of fungal cultivation [16], the production of metabolites in A. terreus is more prominent in the pellet form [17].

This study aimed at inducing morphological change in A. terreus using viscosity and friction. Consequently, the effects of these treatments on the production of lovastatin, sulochrin, and (+)-geodin by A. terreus were characterised.

Materials and methods

Culture conditions, fungal biomass determination, and the quantification of metabolites

The fungal strain used in this study is A. terreus ATCC 20542. The culture conditions, fungal biomass determination, and the quantification of metabolites and substrates have been described previously [22] with slight modifications. Briefly, the freeze-dried fungus (Cryosite Distribution Pty. Ltd., Sydney, Australia) was rehydrated with 1 mL of sterile deionised water for 2 h followed by culture on potato dextrose agar at 30 °C for 7 days. The spores were harvested with 0.001% (v/v) tween 80 in sterile deionised water and kept at 4 °C until further use. For long-term storage, 15% glycerol was added and the spored were kept at −80 °C. The spore numbers were determined using a haemocytometer. The spore suspension was adjusted to 107 spores/mL prior to inoculation in 125 mL Erlenmeyer flasks with a total volume of 50 mL culture media.

The basal media used in this study consisted of—0.4 g/L KH2PO4, 0.4 g/L MgSO4·7H2O, 0.4 g/L CaCl2, and 0.001 g/L ZnSO4·7H2O. The nitrogen source used was yeast extract at 4 g/L and the carbon source used was glycerol at 30 g/L in a 125 mL shake flask. The initial pH of the culture media was adjusted to 7. To stimulate the fungal growth, pre-culture was performed 24 h prior to the real cultivation, where 8 g/L of yeast extract was used instead of 4 g/L. The fungal pellets were then transferred into a sterile shake flask containing the basal media in the presence of appropriate treatments (viscosity and friction) at 30 ± 1 °C in a shaking incubator (185 ± 5 rpm).

For the bioreactor (BR) study, a BR with 2–5 L working volume (Real Time Engineering Pty. Ltd., Australia) without baffles was agitated by a two-level mixing impeller (radial flow) using Boehm Frame 23 motor with a speed of 180 rpm. The BR medium pH was not controlled and was measured by an AppliSens Z001038510 pH probe. The volume of dissolved oxygen in the medium was controlled at 0.8 Lair L−1 min−1 and the concentration was measured using an AppliSens Z010059020 oxygen probe. The temperature was controlled at 30 ± 1 °C for the duration of cultivation.

Fungal biomass was measured at the end of cultivation by drying the fungal pellet until it reached a constant weight. The quantification of lovastatin, (+)-geodin, and sulochrin was performed using High Pressure Liquid Chromatography (HPLC) using C-18 column, at a sample chamber temperature of 4 °C, a flow rate of 1.0 mL/min, an injection volume of 10 µL, and a wavelength of 238 nm, with a reference wavelength of 360 nm.

Application of mechanical stress

The experimental design for all experiments is summarised in Table 1.

Sodium alginate is a type of polysaccharide that can form viscous gum upon contact with water containing calcium ions. This particular gelling agent was chosen as it has been shown to possess special properties that can provoke the production of metabolites [12, 13]. A positive control containing gelatine was used to mimic the viscosity effect of sodium alginate, but without an influence on the metabolite production. Basal media without any additional treatment represented the negative control.

The sonication was performed continuously throughout the experiment at 40 kHz using a sonicator (UP400S, Hielscher Ultrasonics, Germany). Friction was introduced by placing a small piece of linen cloth (5 × 5 cm) at the bottom of the shake flask.

Statistical analysis

All experiments were conducted in a minimum of triplicates, except for the BR study (duplicates). The data obtained for metabolite production involving lovastatin, (+)-geodin and sulochrin were analysed using one-way ANOVA with Tukey post hoc test. The results were considered significant when p < 0.05. All statistical analyses was performed using GraphPad Prism, version 6.01 (GraphPad Software, Inc., USA). For the plotting of the graph, 95% confidence interval was used for the error bars. The symbols on graphs show experimental values, while dashed lines connecting symbols are used as a visual guide only.

Results

(+)-geodin was strongly induced in the bioreactor compared to the shake flask

Figure 1 shows the glycerol consumption and biomass production by A. terreus for 7 days in the shake flask (SF) and the BR. The SF culture showed a higher production of biomass compared to the BR culture, which plateaued at day 3. In contrast, the growth in BR only plateaued at day 4. The glycerol consumption was higher and faster in the BR (rate = 13.84 glycerol/day) compared to SF (rate = 2.34 glycerol/day) (Fig. 1). Figure 2 shows that higher glycerol consumption was correlated with higher production of metabolites in the BR at day 7 (lovastatin = 46.18 mg/L, (+)-geodin = 56.96 mg/L, sulochrin = 35.55 mg/L), compared to SF experiment which was significantly lower (15.61, 14.23, and 8.36 mg/L, respectively).

Glycerol consumption and biomass production in shake flask (SF) and bioreactor (BR). The fermentation was carried out under basal salt media (0.4 g/L KH2PO4, 0.4 g/L MgSO4·7H2O, 0.4 g/L CaCl2, and 0.001 g/L ZnSO4·7H2O) 4 g/L of yeast extract, 20 g/L of glycerol, and the treatment of interest. The temperature was setup at 30 °C, initial pH at 6.5, and speed at 180 rpm in a shaking incubator. Seed culture was performed 24 h prior to the actual experiment

Metabolite production of A. terreus in BR and SF under normal condition. The metabolites were analysed using High Pressure Liquid Chromatography (HPLC) using C-18 column, sample chamber temperature at 4 °C, a flow rate of 1.0 mL/min, an injection volume of 10 µL, and a wavelength of 238 nm, with a reference wavelength of 360 nm

There are several key observations, especially in relation with the production pattern of (+)-geodin and sulochrin. First, although the production of (+)-geodin and sulochrin was low in SF experiments, both compounds were detected at a greater concentration in the BR. In comparison with SF, (+)-geodin and sulochrin productions in the BR were increased by 300.3% (56.96 mg/L) and 325.2% (35.55 mg/L), respectively. Second, (+)-geodin production in the BR was the highest compared to the other metabolites, while its production in SF was the lowest.

Sodium alginate improved lovastatin production early in cultivation and induced a unique production pattern of (+)-geodin and sulochrin

Next, the effects of increasing media viscosity on the production of metabolites were examined. It should be noted that all experiments from here onwards were conducted in the SF only. The viscosity of the media was increased by adding sodium alginate or gelatine to the culture. The biomass production in sodium alginate- and gelatine-treated media was higher than that of the negative control (Table 2). The treatment with 200 mg/L sodium alginate and 300 mg/L gelatine produced the largest increase in biomass (g) (24.4 and 24.2%, respectively) and diameter (26.7 and 33.3%, respectively) of the pellet. This was followed by treatments with 100 mg/L sodium alginate and 150 mg/L gelatine, with a biomass increase of 24.1 and 21.1%, respectively.

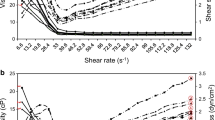

The pattern of lovastatin production is depicted in Fig. 3. Lovastatin production was significantly higher in all sodium alginate treatments compared to the gelatine treatment and negative control. The treatment with 200 mg/L sodium alginate produced the highest lovastatin yield (329.0% higher compared to the negative control, day 9). This was followed by treatment with 100 mg/L sodium alginate, with an increased of 203.2% at day 9. A significant increase in lovastatin production was observed as early as day 3 (729.3% increase at 200 mg/L sodium alginate, day 3). In contrast to sodium alginate treatment, only slight improvement in lovastatin production was observed with 75 mg/L gelatine treatment (42.8%, day 3). In fact, high gelatine concentration (300 mg/L) produced lower lovastatin titre (6.23 mg/L) compared to the negative control (10.86 mg/L) at the final day of cultivation (day 9).

Lovastatin, (+)-geodin, and sulochrin production under different viscosities, induced by different chemicals. The graphs show a lovastatin production, b (+)-geodin production, and c sulochrin production. Two chemicals (sodium alginate and gelatine) were added during the cultivation at specific concentrations to increase the viscosity of the culture media

Under normal circumstances, increased (+)-geodin production was followed by a comparable rise in sulochrin production (Fig. 3, refer to control experiment). However, each of the treatments produced a different pattern of metabolites production. The production of (+)-geodin was lower with sodium alginate and gelatine treatments compared to negative control. On the other hand, sulochrin production was increased with sodium alginate treatment compared to negative control, but not with gelatine treatment.

Fungal pellet integrity is related to increased (+)-geodin production

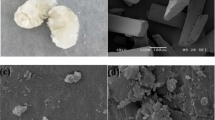

This experiment was devised to examine the role of mechanical stress on pellet integrity and the production of metabolites. It has been demonstrated that (+)-geodin production was strongly induced in the BR, especially after the pellet started to disintegrate at day 4. The media also turned dark brown in the BR, which might indicate high production of metabolites [23]. When friction was applied, the biomass was slightly reduced (8.1 g/L) compared to the negative control (9.0 g/L). The size of the pellet was also reduced (0.5 mm compared to 1.5 mm in control, in average diameter). On the other hand, sonication resulted in dispersed hyphae morphology; therefore, no such measurement was taken.

Glycerol consumption was active in both conditions (friction and sonication), with friction showing the fastest glycerol consumption (Fig. 4). Metabolites were also detected up to the final days of cultivation (Fig. 5). Lovastatin production was consistently the highest when friction was used, while the use of sonication consistently produced the lowest lovastatin. During the peak production of lovastatin at day 9, friction was able to produce up to 511.1%. In contrast, sonication significantly reduced lovastatin production, by 39.8% at day 9.

The most interesting observation was the production of (+)-geodin and sulochrin when friction was introduced. (+)-Geodin production was increased by 1527.5%, while sulochrin production was increased by 784.4% as compared to the control at day 6. Of note, although the increase was only 16.9% at day 6, (+)-geodin was continuously produced until day 9, as opposed to the control which showed reduced (+)-geodin production after day 6.

Discussion

As shown in Figs. 1 and 2, our findings suggest that the BR provides better conditions than SF for the A. terreus secondary metabolites’ production, which correlated with a higher glycerol consumption. In comparison with SF, the BR is a more efficient fermentation system owing to its sophisticated control system of temperature, oxygen content, and aeration. Better oxygen supplementation in BR may be one of the factors that contribute to enhanced metabolites’ production [24, 25].

At the end of the cultivation in SF, the production of sulochrin was observed to be higher than (+)-geodin, in contrast to the observations in BR. In BR, significant increase in (+)-geodin production was attained which corresponded with the disintegration of pellet at day 4. Pellet disintegration in BR was likely due to shear stress from continuous contact with Rushton-type impeller and oxygen bubbling. This observation suggests that (+)-geodin may be excreted as a response reaction to structural injury.

Next, a viscosity experiment was setup in SF to confirm our findings on the effect of mechanical stress on the production of (+)-geodin. Our initial observation indicates that the increase in viscosity enhanced the biomass production and the size of the pellet (Table 2). These changes may result from the viscosity-protective effect, which allowed better distribution of nutrients and protected the fungal pellets from the sheer force due to mixing [4,5,6,7], although the effect on metabolite production is still unclear [17].

In terms of metabolite production, only sodium alginate treatments significantly enhanced lovastatin production (Fig. 3) compared to the controls (gelatine and negative control). This observation indicates that viscosity alone is insufficient to stimulate lovastatin production, as it requires additional substance (such as sodium alginate) that can provoke the metabolite production of the fungus. Studies have demonstrated that alginates can trigger the activity of glucose oxidase—a cell marker for defense mechanism and metabolite production, by almost 50% [12]. Furthermore, treatment with alginate and its derivatives induced the major penicillin biosynthetic pathway (pcbAB, pcbC, and pentDE) in penicillin-producing fungi [13]. Apart from penicillin, sodium alginate can also stimulate the production of pigments such as chrysogenin [26].

Notably, lovastatin production was significantly higher as early as day 3 following sodium alginate treatment, indicating an immediate stimulatory effect of sodium alginate on lovastatin production. A similar trend was also observed in sulochrin production, although the increase was observed much later, at day 6. The rapid increase in lovastatin may be attributed to the ability of certain types of polysaccharides, such as sodium alginate, to induce enzyme activity within a short period of time. For instance, in Penicillium variabile P16, an increase in enzyme activity was detected as early as 24 h after the addition of sodium alginate and sodium alginate-type chemical compounds [12]. The low lovastatin and sulochrin production observed with gelatine treatment suggests that high viscosity media, without the additional properties of sodium alginate, may be less favourable for the production of these metabolites possibly due to decreased mass transfer, heat transfer, and oxygen transfer [27]. In addition, the effect of gelatine treatment on pellet size may contribute to low lovastatin production as it induced the formation of bigger pellet which had been reported to be unfavourable for lovastatin production [20, 21].

Our observations in viscosity experiment also suggest that neither viscosity nor stimulatory effect of sodium alginate and gelatine can stimulate (+)-geodin production. As discussed earlier, a significant increase in (+)-geodin production was associated with pellet disintegration in the BR. Consistent with this observation, (+)-geodin production was low at higher viscosity (alginate and gelatine) due to the presence of low shear pressure or mechanical stress. To confirm this finding, the fungal pellet was subjected to the mechanical stress of friction and sonication, to break and reduce its size.

The pellets did not exhibit favourable morphological features when friction or sonication was introduced in the cultivation system. Nevertheless, the effect of friction on the breakage of the pellet was not as detrimental as the effects of sonication. Friction caused the formation of smaller fungal pellet (size ~0.5 mm), whereas sonication produced dispersed morphology, which is characterised by freely dispersed hyphae in the culture medium [28]. The dispersed morphology of A. terreus is known to be unfavourable for the production of lovastatin [17]. In contrast, smaller pellet has been shown to be more efficient for lovastatin production, due to the higher active area for lovastatin biosynthesis within the fungal pellet [18, 19]. Smaller pellet size also led to higher uptake of glycerol (Fig. 4), which is most likely contributed by a higher surface to volume ratio that allowed greater intake of glycerol.

The application of friction caused a significant increase in (+)-geodin and sulochrin yield, particularly (+)-geodin, which was increased by 15-fold (Fig. 5). The significant increase in metabolites may occur due to the release of intracellular metabolites as the pellet burst. Although the breakage of pellet was observed as early as day 2, high (+)-geodin was consistently produced until the end of cultivation at day 9. This indicates that other factors might play a role in the (+)-geodin production, such as the continuous mechanical stress or injury to the fungal pellet. Overall, the pattern of lovastatin, (+)-geodin and sulochrin production under friction treatment closely resembled the pattern of production of metabolites in the BR. In contrast, the production of (+)-geodin and sulochrin was very low in sonication experiment, most likely due to dispersed morphology.

These findings suggest that lovastatin and sulochrin productions were strongly induced in the presence of sodium alginate, a chemical component that is known to stimulate the metabolite production of the microorganism, rather than the effect of viscosity itself. In contrast, (+)-geodin production was more responsive to the reduction of the fungal pellet size, and possibly, mechanical stress. Such observation implies that lovastatin and sulochrin are responsive to both stimulatory chemicals and morphological changes, while (+)-geodin may be more sensitive to the change in the morphology of A. terreus [2, 3, 9, 29]. The patterns of metabolites production also suggest that lovastatin and sulochrin are more closely related to each other than initially thought.

References

Bennett RN, Wallsgrove RM (1994) Secondary metabolites in plant defence mechanisms. New Phytol 1994(127):617–633

Krull R, Wucherpfennig T, Esfandabadi ME, Walisko R et al (2013) Characterization and control of fungal morphology for improved production performance in biotechnology. J Biotechnol 2013(163):112–123

Antecka A, Bizukojc M, Ledakowicz S (2016) Modern morphological engineering techniques for improving productivity of filamentous fungi in submerged cultures. World J Microbiol Biotechnol 2016(32):193

Rugsaseel S, Morikawa S, Kirimura K, Usami S (1995) Stimulation of citric acid production in Aspergillus niger by addition of viscous substances in shake culture. Appl Microbiol Biotechnol 1995(42):839–843

Chisti Y (2009) Shear sensitivity. In: Encyclopedia of industrial biotechnology, bioprocess, bioseparation, and cell technology, vol 7. Wiley, New York, pp 4360–4398

Metz B, Kossen NWF (1977) The growth of molds in the form of pellets—a literature review. Biotechnol Bioeng 1977(19):781–799

van Suijdam JC, Metz B (1981) Influence of engineering variables upon the morphology of filamentous molds. Biotechnol Bioeng 1981(23):111–148

O’Cleirigh C, Casey JT, Walsh PK, O’Shea DG (2005) Morphological engineering of Streptomyces hygroscopicus var. geldanus: regulation of pellet morphology through manipulation of broth viscosity. Appl Microbiol Biotechnol 2005(68):305–310

Oncu S, Tari C, Unluturk S (2007) Effect of various process parameters on morphology, rheology, and polygalacturonase production by Aspergillus sojae in a batch bioreactor. Biotechnol Prog 23:836–845

Karwasara VS, Jain R, Tomar P, Dixit VK (2010) Elicitation as yield enhancement strategy for glycyrrhizin production by cell cultures of Abrus precatorius Linn. Vitr Cell Dev Biol Plant 2010(46):354–362

Siegrist J, Mühlenbeck S, Buchenauer H (1998) Cultured parsley cells, a model system for the rapid testing of abiotic and natural substances as inducers of systemic acquired resistance. Physiol Mol Plant Pathol 1998(53):223–238

Petruccioli M, Federici F, Bucke C, Keshavarz T (1999) Enhancement of glucose oxidase production by Penicillium variabile P16. Enzyme Microb Technol 1999(24):397–401

Radman R, Saez T, Bucke C, Keshavarz T (2003) Elicitation of plants and microbial cell systems. Biotechnol Appl Biochem 2003(37):91–102

Sainz Herrán N, Casas López JL, Sánchez Pérez JA, Chisti Y (2008) Effects of ultrasound on culture of Aspergillus terreus. J Chem Technol Biotechnol 2008(83):593–600

Chisti Y (2003) Sonobioreactors: using ultrasound for enhanced microbial productivity. Trends Biotechnol 2003(21):89–93

Wucherpfennig T, Lakowitz A, Driouch H, Krull R, Wittmann C (2012) Customization of Aspergillus niger morphology through addition of talc micro particles 2012. J Vis Exp 2012(61):4023

Bizukojc M, Ledakowicz S (2009) Physiological, morphological and kinetic aspects of lovastatin biosynthesis by Aspergillus terreus. Biotechnol J 2009(4):647–664

Gupta K, Mishra PK, Srivastava P (2007) A correlative evaluation of morphology and rheology of Aspergillus terreus during lovastatin fermentation. Biotechnol Bioprocess Eng 2007(12):140–146

Bizukojc M, Ledakowicz S (2010) The morphological and physiological evolution of Aspergillus terreus mycelium in the submerged culture and its relation to the formation of secondary metabolites. World J Microbiol Biotechnol 2010(26):41–54

Casas López JL, Sánchez Pérez JA, Fernández Sevilla JM, Rodríguez Porcel EM, Chisti Y (2005) Pellet morphology, culture rheology and lovastatin production in cultures of Aspergillus terreus. J Biotechnol 2005(116):61–77

Rodríguez Porcel EM, Casas López JL, Sánchez Pérez JA, Fernández Sevilla JM et al (2006) Aspergillus terreus broth rheology, oxygen transfer, and lovastatin production in a gas-agitated slurry reactor. Ind Eng Chem Res 2006(45):4837–4843

Abd Rahim MH, Hasan H, Montoya A, Abbas A (2015) Lovastatin and (+)-geodin production by Aspergillus terreus from crude glycerol. Eng Life Sci 2015(15):220–228

Lai L-ST, Hung C-S, Lo C-C (2007) Effects of lactose and glucose on production of itaconic acid and lovastatin by Aspergillus terreus ATCC 20542. J Biosci Bioeng 2007(104):9–13

Sutherland A, Auclair K, Vederas JC (2001) Recent advances in the biosynthetic studies of lovastatin. Curr Opin Drug Discov Dev 2001(4):229–236

Pecyna M, Bizukojc M (2011) Lovastatin biosynthesis by Aspergillus terreus with the simultaneous use of lactose and glycerol in a discontinuous fed-batch culture. J Biotechnol 2011(151):77–86

Asilonu E, Bucke C, Keshavarz T (2000) Enhancement of chrysogenin production in cultures of Penicillium chrysogenum by uronic acid oligosaccharides. Biotechnol Lett 2000(22):931–936

El-Enshasy H (2007) Chapter 9. Filamentous fungal cultures—process characteristics, products, and applications. In: Yang S-T (ed) Bioprocessing for value-added products from renewable resources. Elsevier, Amsterdam, pp 225–261

Polona Ž, Aleksander P (2001) The morphology of filamentous fungi in submerged cultivations as a bioprocess parameter. Food Technol Biotechnol 2001(39):727

Abd Rahim MH, Harith HH, Montoya A, Abbas A (2017) Growth and lovastatin production by Aspergillus terreus under different carbohydrates as carbon sources. Biocatal Agric Biotechnol 10:379–385

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interests. This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Rahim, M.H.A., Hasan, H., Harith, H.H. et al. The effect of viscosity, friction, and sonication on the morphology and metabolite production from Aspergillus terreus ATCC 20542. Bioprocess Biosyst Eng 40, 1753–1761 (2017). https://doi.org/10.1007/s00449-017-1830-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1830-y