Abstract

Poultry feather keratin is the most important by-product from the poultry industry due to its abundance. Different methods have been still applied to process this by-product such as enzymatic hydrolysis which is expensive and inapplicable at the industrial level. This paper presents a study of acid hydrolysis of poultry feathers using different types of acids, sulphuric acid concentration, different temperatures and solid to liquid ratio to obtain a liquid product rich in peptides. The feathers analysis revealed a crude protein content of 88.83%. A maximum peptides production of 676 mg/g was reached using sulphuric acid, 1 molar acid concentration and 50 g/l solid to liquid ratio at a temperature of 90 °C after 300 min. A reaction scheme for protein aggregation and decomposition to polypeptides and amino acids was proposed and a kinetic model for peptides production was developed. The proposed kinetic model proved to be well adapted to the experimental data with R 2 = 0.99.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Diverse poultry products have been increasing continuously generating large amounts of organic by-products. Poultry feathers are the main by-product of poultry processing industry. Feathers represent about 10% of the total poultry weight [1]. A billon tonnes of poultry feathers are generated annually worldwide and the Tunisian contribution is about 20 thousand tonnes.

85–90% of a feather weight consists of keratin [2, 3]. Keratin protein is an insoluble highly stable structure that is cross-linked by disulfide, hydrophobic and hydrogen bonds. Cross-linking of protein chains by cysteine bridges confers a high mechanical stability and resistance to degradation by proteolytic enzymes such as pepsin, trypsin and papain [4–6]. The feathers natural degradation takes more than 2 years [7] and their accumulation in nature may become an environmental problem.

Traditionaly, feathers are used as animal feed after being treated with high temperature and pressure. Recently, the isolated hydrolysated proteins contained in animal by-products recovered from slaughterhouses have been reused because of their functional and bioactive properties [8]. Many processes have been developed such as the enzymatic, chemical and chemical–enzymatic treatments to produce hydrolysated proteins feathers. Enzymatic hydrolysis has been reported by several microorganisms such as actinomycetes [9] and some species of Bacillus such as Bacillus licheniformis [10] and Bacillus pumilus [5, 11] and fungi [12, 13]. The production of hydrolysate proteins feathers after alkalin pretreatment followed by enzymatic hydrolysis has been the focus of [14]. Chemical hydrolysis has been treated by high temperature with diluted acids as hydrochloric acid or alkali as calcium hydroxide [15].

Enzymatic treatment requires a carefully controlled environment and expensive equipement, whereas acid hydrolysis is cheap and easy to control. Besides, it is applicable to industrial processes but at the detriment of some amino acids [16, 17]. The concentration of proteins that can be processed by chemical hydrolysis is over 50 mg/ml [18], while utmost 10 mg/ml concentration of proteins can be processed by enzymatic methods [19].

The objective of this work was the study of acid hydrolysis of poultry feathers in different conditions of acid concentration, temperature and solid to liquid ratio for peptides production. A kinetics model was developed relying on various kinetic parameters that were estimated from the expiremental data. Therefore, through the above process, we tried to value the wastes produced by poultry industry by providing a useful product, and simultaneously reducing the wastes effect on the environment. This could be of great importance to a great number of researchers and industrialists.

Materials and methods

Feathers

Fresh poultry feathers (10 kg) were collected from a local slaughterhouse and transferred to the laboratory in clean plastic bags. They were washed several times with tap water and finally with distilled water. The washed feathers were treated in boiling water for 20 min before being dried at 90 °C for 5 h and stored at room temperature.

Analytical methods

Dry matter was obtained by oven drying at 105 °C for constant mass [20]. The sample ash content was determined by combustion at 550 °C. Fat content was determined by the samples extraction with hexane at 70 °C for 6 h with Soxhlet extraction method. The total nitrogen content was estimated using the Kjeldahl method. Crude protein was determined by multiplying the total nitrogen content by the factor of 6.25 [15]. The water activity was determined using aw-meter ‘Rotronic Hygropalm’ (HP23-AW-A).

Feathers acid hydrolysis

The feathers hydrolysis was carried out in a jacketed glass reactor with a temperature control and mechanical agitation. The desired amount of acid solution of a given concentration was placed in the reactor and heated to the required temperature with a continuous agitation at 500 rpm. When the desired temperature was achieved and maintained, the required amount of feathers was introduced.

The operation conditions were varied to survey the effect of the different settings on the hydrolysis reaction and can be stated as follows: sulphuric acid concentrations (0–6 M), the hydrolysis temperature (70–90 °C), solid to liquid ratio (50–90 g/l) and the three types of acid (sulphuric, nitric and phosphoric).

Samples were taken from the reactor at different times to follow the evolution of the hydrolysis. The samples total volume must be less than 10% of the initial volume of the solution to maintain a constant volume reaction of the experiment. The hydrolysis reaction was stopped by samples neutralisation with sodium hydroxide up to pH of 7. The neutralised samples were centrifuged to separate the supernatant from the residual solid. The peptides content of supernatants was measured.

Soluble peptides analysis

The soluble peptides produced in the hydrolysis reaction were measured by Biuret’s method [21]. This spectroscopy method was based on the appearance of the purple colour which is absorbed at 540 nm when peptide bonds and cupric ions react. Bovin Serum Albumin (1–5 mg/ml) was used as a standard.

Feathers acid hydrolysis kinetic model

The feathers hydrolysis kinetics depends on such different factors as operating conditions, temperature, agitation, time of hydrolysis, as well as the protein characteristics such as structure, composition, and size [22]. This has resulted in various difficulties in the hydrolysis kinetic modelling. Several models were proposed using irreversible first-order kinetics for the hydrolysis reaction [22, 23].

The reaction scheme responsible for the peptides production is proposed in Fig. 1, where k 1 is the rate constant for the protein aggregation, k 2 is the rate constant of the decomposition of the aggregated proteins to polypeptides. k 3 and k 4 are the rate constants of amino acids production from aggregated proteins and polypetides, respectively.

The first step of the reaction is the formation of the aggregated proteins from protein feathers, then their decomposition into soluble polypeptides and then the production of amino acids [24]. These steps were described in the following equation:

where C p is the protein concentration, C agg is the aggregated proteins concentration and C poly is the soluble polypeptides concentration.

In the initial conditions at t = 0: C p = C p0 and C agg = C poly = 0

where C p0 is the readily hydrolysable protein fraction, leading to the next solutions of the differential equations of the protein, aggregated protein and peptides concentrations as a function of reaction time.

Assuming these hypotheses and the pathways shown in Fig. 1, a kinetic model for peptides production from acid hydrolysis of feathers was proposed:

Results and discussion

Physico-chemical characterization of feathers

As shown in Table 1, the dried feathers at 90 °C present a high dry matter (98.51%) and a low a w (0.19) may protect the product against microbiological spoilage during its storage. Protein was the main component with 88.83%, whereas fat and ash contents represent the lowest components with 3.92 and 0.75%, respectively.

Effects of acid concentration

Figure 2 shows a plot of peptides production versus time at six different sulphuric acid concentrations of 0, 0.5, 1, 2, 4 and 6 M in the hydrolysis reaction carried out at 90 °C and a solid to liquid ratio of 50 g/l. The figure clearly shows the effect of acid concentrations on both the peptides production and kinetic hydrolysis. Except for the hydrolysis reaction without acid, an increase in the peptides production with time was revealed in all the experiments.

The data also show that the highest peptides production reaches 676 mg/g at 300 min with 1 M acid hydrolysis. However, the fastest increase in peptides production with time is observed at 6 M acid hydolysis, and the peptides production reaches 500 mg/g after only 30 min of hydrolysis. After this maximum value, the peptides production starts to decrease rapidly and achieves lower values than observed at the lower acid concentration. This may indicate that the rate of peptides decomposition to amino acids is higher than the rate of peptides production.

Lower peptides production is observed at 4 M acid concentration. In this concentration, only 430 mg/g of peptides production is achieved after 120 min. Beyond this maximun, the rate of peptides production loss is much slower than that observed beyond the maximum one reached with the higher acid of 6 M.

The hydrolysis reaction proceeds much slower with the lower acid concentrations of 4, 2, 1 and 0.5 M than that observed at 6 M. At 0.5 M acid concentration, the hydrolysis reaction rates increase slowly but no maximum peptides production is observed within that time. The maximum peptides production obtained with 1 M acid can be anticipated and achieved using 0.5 M concentration for any reaction time extent.

It is important to note that 1 M acid provides the best results in our study. In contrast, 6 M sulphuric acid proved to yield the highest peptides production for the hydrolysis reaction of blood reported in [16].

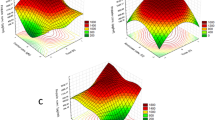

Effect of temperature

Figure 3 depicts the effect of temperature on the peptides production in a hydrolysis reaction carried out at 1 M concentration of sulphuric acid and solid to liquid ratio of 50 g/l. The data show that the hydrolysis reaction runs more slowly at the lower temperatures of 70 and 80 °C than that achieved at a temperature of 90 °C. Moreover, at 90 °C, a maximum peptide yield of 676 mg/g is obtained, which is higher than that achieved at the two lower temperatures within the experimental run time. In fact, most of the previous studies were achieved using such a moderate temperature (90 °C). Higher temperatures would need more sophisticated machinery and naturally higher expenses [15].

Effect of solid to liquid ratio

Figure 4 shows the peptides production versus time for the feather hydrolysis reaction conducted at 1 M concentration of sulphuric acid at 90 °C. The data show that the increase of the solid to liquid ratio leads to the decrease in the obtained peptides production with time as a consequence of starting with higher protein concentration, which acts as a limiting reactant, resulting in a low percentage of protein degradation.

Moreover, the maximum peptides production achieved at around 300 min decreases from 676 mg/g at solid to liquid ratio of 50 g/l to 400 mg/g at a ratio of 90 g/l. This finding about the limiting effect was similar to that reported by sulphuric acid hydrolysis of date-palm trees [25] and enzymatic hydrolysis of feathers [11, 26]. In addition, the yield of peptides obtained in this study (34 g/l) is higher than that obtained by the enzymatic hydrolysis (10 g/l).

Acid types effect

Figure 5 shows the effect of different types of acids on the peptides production in the hydrolysis reaction carried out at 90 °C, 1 N acid concentration and 50 g/l solid to liquid ratio. The data show that the highest peptides production was obtained with sulphuric acid hydrolysis and a maximum peptides production of 540 mg/g was achieved after 210 min of hydrolysis. However, only 410 and 290 mg/g of peptides production were reached using nitric and phosphoric acids, respectively, after 360 min. These results are in agreement with the blood hydrolysis [16], proving that the best peptides production was obtained with sulphuric acid. Sulphuric acid is more currently used in lignocellulosic hydrolysis than other acids [23].

Kinetic model for peptides production

The kinetic parameters of peptides production from hydrolysis experiments in different conditions were estimated by fitting the experimental data in the model Eq. (6) using curve expert. Table 2 summarises the best fitting values of C p0, k 1–k 4 and the corresponding regression coefficient ‘R 2’ for the kinetic data obtained in different conditions of the hydrolysis reaction.

As shown in Table 2, all k values are probable depending on the hydrolysis reaction temperature, acid concentration and solid to liquid ratio. Moreover, the high values of the estimated correlation coefficients for each regression (R 2 = 0.99) reflect the strong correlation between kinetic data generated in the various test conditions with Eq. (6) and is also proved by the excellent fitting model in Figs. 2, 3, 4 and 5.

The data present an increase in k values with the reaction temperature. As far as all kinetic data are concerned, an Arrhenius equation is used to model the temperature dependence of the reaction rate constant and is written as follows:

The results of the Arrhenius Eq. (7) can be clarified in the Arrhenius plot [Eq. (8)] by plotting the kinetic constant logarithm versus the temperature:

where k i,0 is the pre-exponential factor (min−1), E is the activation energy (kJ/mol), R is the universal gas constant [8.314 kJ/(mol K)] and T is the reaction temperature (K).

Figure 6 shows the plot of the natural log of k 1, k 2, k 3 and k 4 versus 1/T according to Eq. (8) based on the kinetic parameters of the hydrolysis reaction at 1 molar acid concentration and a ratio of 50 g/l. The yield plot of the kinetic constant logarithm described by straight lines showing a resonable confidence. These kinetic parameters satisfying the Arrhenius equation present high regression coefficients R 2 (0.90–0.97) as indicated in Table 3.

As can be seen in Table 3, the model predicts the values of the pre-exponential factor k 2,0 of 7.09 × 106 min−1 and an activation energy E 2,0 of 64.49 KJ/mol for the polypeptides production from the aggregated proteins. Comparing the activation energy E 2,0 with the activation energy E agg,po(71.90 KJ/mol) reported by Sunphorka et al. [24], one can easily notice that both values are close. For the amino acids production from polypeptides, the model predicts values of the pre-exponential factor k 4,0 of 92.06 min−1 and an activation energy E 4,0 of 30.52 KJ/mol, for the amino acids production from aggregated protein, the model predicts values of the pre-exponential factor k 3,0 of 2.59 × 1011 min−1 and an activation energy E 3,0 of 95.97 KJ/mol. The activation energy E 4,0 is lower than the activation energy E po,aa (54.6 KJ/mol) reported in [24], whereas the activation energy E 3,0 is higher than activation energy E agg,aa (59.3 KJ/mol) reported in [24]. The values of k 4,0 and k 3,0 indicated that the rate constants of amino acids production depend on the temperature and decomposition pathway. That the amino acids were produced from polypeptides at a greater amount than from the aggregated proteins is probably be because of the greater water solubility and less complicated structure of the polypeptides compared to the aggregated proteins.

Conclusions

This study focused on the production of peptides from poultry feathers using chemical hydrolysis. Sulphuric acid is more efficient than nitric and phosphoric acid for obtaining large amount of peptides producing almost complete hydrolysis of feathers. The temperature, the acid concentration and the solid to liquid ratio have an important influence on the maximum amounts of peptides that can be hydrolysed in each experiment. The maximum peptides production obtained was 676 mg/g at 90 °C, 1 M acid concentration and solid to liquid ratio of 50 g/l. The experimental hydrolysis data could be well correlated with high accuracy of the kinetic model of the reaction. The model allows the elucidation of the differences between the kinetic parameters in different conditions.

References

Grazziotin A, Pimentel FA, de Jong EV, Brandelli A (2006) Nutritional improvement of feather protein by treatment with microbial keratinase. Anim Feed Sci Technol 126(1–2):135–144

Papadopoulos MC (1985) Processed chicken feathers as feedstuff for poultry and swine. A review. Agric Wastes 14(4):275–290

Taskin M, Esim N, Ortucu S (2012) Efficient production of l-lactic acid from chicken feather protein hydrolysate and sugar beet molasses by the newly isolated Rhizopus oryzae TS-61. Food Bioprod Process 90(4):773–779

Yamamura S, Morita Y, Hasan Q, Yokoyama K, Tamiya E (2002) Keratin degradation: a cooperative action of two enzymes from Stenotrophomonas sp. Biochem Biophys Res Commun 294(5):1138–1143

Agrahari S, Wadhwa N (2010) Degradation of chicken feather a poultry waste product by keratinolytic bacteria isolated from dumping site at Ghazipur poultry processing plant. Int J Poult Sci 9(5):482–489

Paul T, Halder SK, Das A, Bera S, Maity C, Mandal A, Das PS, P. K. D. Mohapatra, Pati BR, Mondal KC (2013) Exploitation of chicken feather waste as a plant growth promoting agent using keratinase producing novel isolate Paenibacillus woosongensis TKB2. Biocatal Agric Biotechnol 2(1):50–57

Dudyński M, Kwiatkowski K, Bajer K (2012) From feathers to syngas—technologies and devices. Waste Manag 32(4):685–691

Lasekan A, Abu Bakar F, Hashim D (2013) Potential of chicken by-products as sources of useful biological resources. Waste Manag 33(3):552–565

Syed DG, Lee JC, Li W-J, Kim C-J, Agasar D (2009) Production, characterization and application of keratinase from Streptomyces gulbargensis. Bioresour Technol 100(5):1868–1871

Lee CG, Ferket PR, Shih JCH (1991) Improvement of feather digestibility by bacterial keratinase as a feed additive. FASEB J 5:A596–A596

Fakhfakh N, Ktari N, Haddar A, Mnif IH, Dahmen I, Nasri M (2011) Total solubilisation of the chicken feathers by fermentation with a keratinolytic bacterium, Bacillus pumilus A1, and the production of protein hydrolysate with high antioxidative activity. Process Biochem 46(9):1731–1737

Kushwaha RKS (1983) The in vitro degradation of peacock feathers by some fungi/Der in-vitro-Abbau von Pfauenfedern durch einige Pilze. Mycoses 26(6):324–326

Anbu P, Gopinath SC, Hilda A, Mathivanan N, Annadurai G (2006) Secretion of keratinolytic enzymes and keratinolysis by Scopulariopsis brevicaulis and Trichophyton mentagrophytes: regression analysis. Can J Microbiol 52(11):1060–1069

Dalev PG (1994) Utilisation of waste feathers from poultry slaughter for production of a protein concentrate. Bioresour Technol 48(3):265–267

Coward-Kelly G, Chang VS, Agbogbo FK, Holtzapple MT (2006) Lime treatment of keratinous materials for the generation of highly digestible animal feed: 1. chicken feathers. Bioresour Technol 97(11):1337–1343

Alvarez C, Rendueles M, Diaz M (2012) The yield of peptides and amino acids following acid hydrolysis of haemoglobin from porcine blood. Anim Prod Sci 52(5):313–320

Gao M-T, Hirata M, Toorisaka E, Hano T (2006) Acid-hydrolysis of fish wastes for lactic acid fermentation. Bioresour Technol 97(18):2414–2420

Flork M (1989) Industrial process for the preparation of amino acids by hydrolysis of proteins in acid medium., 4874893, 17 Oct 1989

Su RX, Qi W, He Z-M (2006) Time-dependent nature in peptic hydrolysis of native bovine hemoglobin. Eur Food Res Technol 225(5–6):637–647

Horwitz W (2000) AOAC (Association of official analytical chemists) official methods of analysis. University of Michigan, Association of Official Anaiytical Chemists

Gornall AG, Bardawill CJ, David MM et al (1949) Determination of serum proteins by means of the biuret reaction. J Biol Chem 177(2):751–766

Kumar S, Dheeran P, Singh SP, Mishra IM, Adhikari DK (2015) Kinetic studies of two-stage sulphuric acid hydrolysis of sugarcane bagasse. Renew Energy 83:850–858

Romero I, Ruiz E, Castro E, Moya M (2010) Acid hydrolysis of olive tree biomass. Chem Eng Res Des 88(5–6):633–640

Sunphorka S, Chavasiri W, Oshima Y, Ngamprasertsith S (2012) Kinetic studies on rice bran protein hydrolysis in subcritical water. J Supercrit Fluids 65:54–60

Bamufleh HS, Alhamed YA, Daous MA (2013) Furfural from midribs of date-palm trees by sulfuric acid hydrolysis. Ind Crops Prod 42:421–428

Kumar DM, Priya P, Balasundari SN, Devi G, A. I. N. Rebecca, Kalaichelvan PT (2012) Production and optimization of feather protein hydrolysate from Bacillus sp. MPTK6 and its antioxidant potential. Middle-East J Sci Res 11(7):900–907

Acknowledgements

This research was supported financially by the Tunisian Ministry of Higher Education, Scientific Research. We would like to thank Mr. Abdelmajid Dammak for his proofreading and correction of the English of the paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Ben Hamad Bouhamed, S., Kechaou, N. Kinetic study of sulphuric acid hydrolysis of protein feathers. Bioprocess Biosyst Eng 40, 715–721 (2017). https://doi.org/10.1007/s00449-017-1737-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1737-7