Abstract

Antioxidants are substances that defend cells against damage, kidnapping and destroying free radicals. They have been largely used in the food industry due the possibility to control the oxidation process, aimed to increase shelf life. Thus, esterification reaction to obtain ascorbyl linoleate catalyzed by Novozym 435 lipase assisted by ultrasound bath was investigated. In this work, molecular sieve (4 Å) was added to the reaction medium to remove the water formed during the esterification reaction to improve the process performance. According to the results, ascorbyl linoleate production up to 90 % was reached after 1 h of reaction time carried out using ultrasound bath, 1:9 molar ratio of substrates l-ascorbic acid to linoleic acid, 20 mL of tert-butanol as organic solvent, 5 wt% of Novozym 435 lipase, 10 wt% of molecular sieve at 70 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

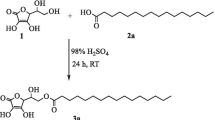

Oxidation is one of the main reasons to discard food, especially oils and fats. To increase foods shelf life, antioxidants have been widely used in the food industry [1]. Thus, the development of new nontoxic compounds with higher antioxidant capacity has been studied. Antioxidants are substances formed by vitamins, especially C vitamin. However, the use of l-ascorbic acid (C vitamin) to stabilize fats and oils is complex due to the hydrophilic characteristic, and this problem can be solved using fatty acid esters from C vitamin as ascorbyl linoleate [2, 3].

An effective methodology to change l-ascorbic acid can be performed by esterification. According to Rajendran et al. [4], esterification reactions occur slowly and require the use of catalyst to increase the reaction rate. The use of lipases allows the development of technological processes like these. Reactions catalyzed by lipase in organic medium have shown promise for l-ascorbic acid esters synthesis due to mild reaction conditions, high catalyst efficiency and high regioselectivity of the biocatalyst which leads to pure products. In addition, l-ascorbic acid esters synthesized by enzymatic process may be considered as natural additives [5–8].

An important requirement for reactions catalyzed by lipase is the system homogeneity. Mechanical stirring is the most common and used method due to the low cost and high efficiency. However, in research of alternatives to increase the positive effect of homogenizing reaction medium, different methods have been reported [9]. A method in ascension is the use of ultrasonic bath, where chemical and physical changes may occur due to cavitation as alternate wave in height to the base, and the influence of the ultrasonic waves on the activity and stability of enzymes has been shown to be specific for each enzyme-dependent parameter [10].

Deshmane [11] and Zheng [12] studied the positive effect of ultrasound on the kinetics parameters of the catalyzed esterification reactions by enzymes; the application of ultrasound to this type of reaction has been under explored. Martins et al. [13] used two different reaction systems, ultrasound and mechanical stirring, for the esterification of acetic acid and butanol added as a catalyst of the immobilized lipase Novozym 435®. The authors obtained as a result the increase of the reaction yield by 7.5 times with ultrasound, thus proving the efficiency of its use.

In face of state of art, this work reports the study of enzymatic synthesis of ascorbyl linoleate from l-ascorbic acid and linoleic acid by esterification reaction using immobilized lipase as catalyst, organic solvent and molecular sieve in ultrasound-assisted system.

Experimental

Materials

Two different lipases as biocatalysts were used: Novozym 435 from Candida antarctica and Lipozyme TL IM from Thermomyces lanuginosus, both by Novozymes Brazil/Araucaria-PR, chosen from experimental results obtained by our research group. Molecular sieve 4 Å (mesh 8–12), tert-butanol (≥90 %), l-ascorbic acid (99 %, Vetec) and linoleic acid (99 %, Vetec) was used as substrates from Sigma Aldrich.

Kinetic study of ascorbyl linoleate synthesis by enzymatic esterification

The assays were performed using ultrasound bath (UNIQUE), with 37 kHz of frequency and 132 W of power, as can be observed in Fig. 1. As reaction conditions we used: 20 mL of organic solvent (tert-butanol), molar ratio of substrates l-ascorbic acid to ascorbyl linoleate 1:9, 5 wt% enzyme (Novozym 435 and Lipozyme TL IM) at 70 and 50 °C were evaluated. The experimental conditions (ratio of substrate and enzyme) were defined based on previous experiments in ascorbyl oleate by Balen et al. [14] and ascorbyl palmitate for Lerin et al. [16] the amount of solvent is not varied due to the previous search results presented that showed the tert-butanol as a solvent which is a less reactive alcohol to other solvents tested, thus being more soluble in the reaction. Subsequently, the samples were placed in a vacuum oven (Quimis) at 40 °C for 8 h for organic solvent evaporation. The reactions were performed in triplicate (n = 3) and values are expressed as mean ± SD (n = 3). The samples were taken out in pre-determined interval 0–12 h.

The product quantification was performed by high performance liquid chromatography (HPLC, Perkin Elmer 200) equipped with UV–Vis detector, software Total Chrom V6.20.0.1 with LC control instrument. The following instruments and conditions were used: Reverse phase column (C18, 300 × 4 mm, 5 μm) (Phenomenex), flow rate 1.0 mL/min, mobile phase methanol: H2O/CH3COOH (95:5:0.1, v/v/v). The mobile phase was used as sample of dissolution solvent, with injection volume of 1.0 µL and UV detection at 254 nm. The samples were analyzed in duplicate (n = 2) using 0.0015 g of sample, supplementing with 1.5 mL of HPLC methanol grade. l-Ascorbic acid content was obtained from the peak area, and conversions were calculated based on consumption of l-ascorbic acid. Molar ratio of substrates l-ascorbic acid to ascorbyl linoleate (1:9) and enzyme content (5 wt%) were used based on previous studies reported in the literature [14–16].

Kinetic study of enzymatic esterification using molecular sieve

To maximize the enzymatic synthesis of ascorbyl linoleate, molecular sieve (4 Å) was used to remove the water formed in the reaction medium at concentrations of 2.5, 10, and 20 wt% (dried for 24 h at 100 °C). The reactions were performed in triplicate (n = 3) and values are expressed as mean ± SD (n = 3). The samples were taken out in pre-determined interval 0–12 h.

Water content

Molecular sieves added to the reaction medium were analyzed to determine the water content. The analysis was performed in a moisture determiner Karl Fischer, based on the SO2 oxidation from I 2, in the presence of water. Equation 1 was used for water content quantification. The correction factor (F) was determined with pure water, and then the water content on the molecular sieve was determined. Where V is the volume of Karl Fischer solution used in the titration (mL) and P is the sample weight (g). The samples were titrated with Karl Fischer solution containing iodine and sulfur dioxide.

Results and discussion

Effect of enzyme on ascorbyl linoleate synthesis

From Table 1 is possible to observe the catalytic efficiency for both studied enzymes in the ascorbyl linoleate synthesis. For the range studied in this work, a considered variation in terms of ascorbyl linoleate synthesis was observed. When Novozym 435 was used 77 % of ascorbyl linoleate after 1 h of reaction time was related, on the other hand, when Lipozyme TL IM was used, ascorbyl linoleate was not identified after 12 h of reaction time. This fact can be associated with the denaturation of support of Lipozyme TL IM under the effect of ultrasound bath, observed visually in the reaction medium during the experiment. It is worth to mention that our main objective and the contribution were to evaluate the behavior of substrates on the ester production and not to verify the ultrasound variables.

Richetti [17] reported the esterification of 2-ethylhexyl palmitate carried out in a shaker in a free solvent system using Novozym 435 and Lipozyme RM IM as catalyst. The author reported high 2-ethylhexyl palmitate yield for both enzymes, after 6 h of reaction, with 89 % of 2-ethylhexyl palmitate yield when Lipozyme RM IM was used and 95 % of 2-ethylhexyl palmitate yield when Novozym 435 was used as catalyst. Wang et al. [18] studied the efficiency of three different commercial enzymes (Novozym 435, Lipozyme RM IM and Lipozyme TL IM) as catalyst on the ethyl caffeate synthesis by esterification reaction. The studies were carried out using shaker at 120 rpm and 75 °C. The results showed higher results for ethyl caffeate synthesis when Novozym 435 was used (93 %), on the other hand, for Lipozyme TL IM and Lipozyme RM IM the obtained ethyl caffeate was 23 and 20 %, respectively, after 6 h of reaction.

Even in the literature, Lipozyme TL IM was reported as a good catalyst for different ester synthesis, in this work, under the evaluated conditions, Lipozyme TL IM not showed results good enough to be compared with Novozym 435. For this reason, the next stages of this research work were carried out using Novozym 435.

Effect of temperature on the ascorbyl linoleate synthesis

Based on the obtained results, the subsequent stage of this study was the kinetic production study of ascorbyl linoleate using Novozym 435 as catalyst at different temperatures (50 and 70 °C). In this stage, molar ratio of substrates ascorbic acid to linoleic acid (1:9), 5 wt% of Novozym 435 (in relation to substrate), 20 mL of tert-butanol, and 100 % of ultrasound bath frequency was kept constant. From the results was possible to obtain the conversion as function of time for the studied temperatures as shown in Table 2.

From the results shown in Table 2 is possible to observe ascorbyl linoleate yield as function of reaction time at 50 and 70 °C. In this study, was observed that when temperature was increased to 70 °C ascorbyl linoleate yield decrease. It was also observed that after 1 h of reaction time maximum ascorbyl linoleate yield (77 %) was reached at 50 °C, on the other hand, under the same reaction conditions and at 70 °C, a lower ascorbyl linoleate yield (45 %) was reported, evidencing a reduction in ascorbyl linoleate yield with temperature increase. Song and Wei [19] reported a similar effect for the synthesis of ascorbyl oleate catalyzed by lipase Candida sp. using tert-amyl as solvent in the presence of molecular sieves (4 Å). The author reported that the product concentration increased when the temperature was increased from 35 °C (15 g/L of ascorbyl oleate) to 55 °C (20 g/L of ascorbyl oleate) and then decreased at 75 °C (12 g/L of ascorbyl oleate).

Lerin et al. [16] investigated the influence of temperature in the synthesis of ascorbyl palmitate reaction using tert-butanol as solvent in ultrasound bath (37 kHz and 132 W) using Novozym 435. The authors reported that increasing temperature from 50 to 80 °C increase the ascorbyl palmitate conversion, with maximum yield of ascorbyl palmitate (35 %) at 80 °C after 3 h of reaction time. Bansode and Rathod [20] showed the same temperature effect for the isoamyl butyrate esterification in ultrasound bath catalyzed by Novozym 435 lipase in a free solvent system. The conversion increased when temperature was increased from 40 to 60 °C. The esterification reaction reached maximum conversion (88 %) in 2 h of reaction at 60 °C, whereas the authors used molecular sieves.

The temperature has a significant effect on the equilibrium of the reaction and the activity and stability of the immobilized lipase. Increasing temperature is possible to increase reaction rate and improves the solubility of the reaction medium. However, the use of high temperatures can lead to enzyme activity loss, i.e., once that enzyme has a maximum temperature of operation and in the case of this study 70 °C to Novozym 435 [14]. As shown in Table 2, the best results in terms of ascorbyl linoleate yield was related at 50 °C even satisfactory results at 70 °C were reported. However, due to the higher ascorbyl linoleate yield and reaction stability the next stages of this work were conducted at 50 °C.

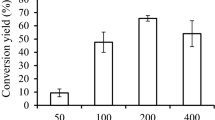

Effect of molecular sieve content on ascorbyl linoleate production

To maximize the enzymatic synthesis of ascorbyl linoleate the presence of molecular sieve (4 Å) was studied. The influence of molecular sieve to removing water from the reaction medium was evaluated at concentrations 2.5, 10, and 20 wt% (dried for 24 h at 100 °C). In this investigation, temperature at 50 °C, molar ratio l-ascorbic acid to linoleic acid (1:9), enzyme concentration (5 wt%), 20 mL solvent, and 100 % ultrasonic frequency was kept constant. Table 3 shows ascorbyl linoleate yield as function of reaction time at different molecular sieve concentrations.

From the results (Table 3), it was noted that for molecular sieve content of 2.5 and 10 wt%, the conversion increased with reaction time, however, 20 wt% molecular sieve not showed high results of ascorbyl linoleate yield when compared with 2.5 and 10 wt% of molecular sieve. The reported effect can be associated with the total absence of water in the reaction medium when 20 wt% of molecular sieve was used, reducing the catalytic activity of enzyme which needs a minimum water content to keep the stability as catalyst.

After 12 h of reaction time 79, 92, and 65 % of ascorbyl linoleate yield was obtained for 2.5, 10, and 20 wt% of molecular sieve, respectively. To evaluate the influence of molecular sieve as catalyst, a reaction without enzyme and 2.5 wt% of molecular sieve was carried out. As shown in Table 3 high ascorbyl linoleate yield (21 %) was reported without enzyme presence after 12 h of reaction time suggesting from the results of this work that a combination of effects between enzyme and molecular sieve led to a higher ascorbyl linoleate yield.

Similar results were reported by Paludo et al. [8] that reported esterification reaction between butyric acid and ethanol catalyzed by Lipozyme TL IM lipase in the presence of molecular sieves (4 Å). Molecular sieves effect on esterification reaction yield was evaluated in a range of concentration from 0 to 120 mg of molecular sieves per mmol of butyric acid using ultrasound bath at 30 °C for 6 h. The authors reported that after 6 h of reaction time, esterification final yield was 60 % for reaction without molecular sieves and esterification final yield of 90 % when the experiment was carried out combining molecular sieve and Lipozyme TL IM.

Fallavena et al. [21] analyzed the effect of molecular sieves (3 Å) in a range from 0 to 120 mg/mmol in butyric acid esters synthesis using Lipozyme RM IM as biocatalyst conducted in ultrasound bath at 45 °C for 2.5 h. The observed yields were gradually improved with the addition of molecular sieve up to 90 mg/mmol, where conversion increased from 86 to 96 %, and reduced when 120 mg/mmol of molecular sieve was used to 80 %.

Determination of water content on molecular sieve

To explore the molecular sieve efficiency to retain water in the esterification reaction medium, different molecular sieve contents were analyzed in terms of moisture determination according to Karl Fischer technique, as previously described and the results are shown in Table 4.

By analyzing the results, it can be seen that the highest water removal from esterification reaction medium was obtained when 20 wt% of molecular sieve was used. As seen in Table 4, 2.5 % molecular sieve content leads to 6.58 % of water removal from esterification reaction medium, increasing to 9.56 % of water removal from esterification reaction medium increasing the molecular sieve to 20 wt% which leads to lower conversions of ascorbyl linoleate yield when compared to the molecular sieve content of 2.5 and 10 wt%. The results obtained from this work showed that the studied enzyme Novozym 435 needs a minimum of water content to improve the esterification of l-ascorbic acid and linoleic acid in the evaluated range of conditions in this work.

Some works done by our group have shown promising results for the use of ultrasound in enzymatic reactions, among these we can highlight the work of Lerin et al. [16] and the Balen et al. [14], which showed that the enzymatic reactions carried out without the aid of ultrasound-assisted system presented lower initial rates, showing that ultrasound reduces mass transfer limitations, improving the mixture and thus increasing the interfacial area for action of the enzyme.

Conclusions

In general, the method used for ascorbyl linoleate synthesis showed great potential to be used in the production of esters. Under evaluated conditions, Novozym 435 showed the better catalytic efficiency at 70 °C when compared with Lipozyme TL IM, and the esterification reactions performance was improved with the addition of 10 wt% molecular sieve, lead to better results in terms of ascorbyl linoleate yield (90 %) after 1 h of reaction time. The satisfactory results obtained in this work has demonstrated the efficacy of the used methodology, as well as importance of enzyme as catalyst in the esterification reaction, the use of ultrasonic energy, and the importance of water content control by molecular sieves, to achieve higher ascorbyl linoleate yield.

References

Torres de Pinedo A, Peñalver P, Pérez-Victoria I, Rondon D, Morales JC (2007) Food Chem 105:657–665

Liu XY, Guo FL, Wu LM, Liu YC, Liu ZL (1996) Chem Phys Lipids 83:39–43

Ayres-Barros MR (2002) Boletin de Biotecnologia 72:2–13

Rajendran A, Palanisamy A, Thangavelu V (2009) Braz Arch Biol Technol 52:201–219

Kuwabara K, Watanabe Y, Adachi S, Nakanishi K, Matsuno R (2003) Biochem Eng J 16:17–22

Hsieh H, Chen J, Giridhar R, Wu W (2005) Preparative Biochem Biotechnol 35:113–118

Hasan F, Shah AA, Hameed A (2006) Enzyme Microb Technol 38:235–251

Paludo N, Alves JS, Altman NC, Ayub MAZ, Fernandez-Lafuente R, Rodrigues RC (2015) Ultrason Sonochem 22:89–94

Martins AB (2012) Trabalho de Conclusão do Curso de Engenharia de Alimentos. Universidade Federal do Rio Grande do Sul, Brasil

Martinez MAU, Davolos MR, Jafelicci MJ (2000) Quim Nova 23:251–256

Deshmane VG, Gogate PR, Pandit AB (2009) Ultrason Sonochem 16:345–350

Zheng MM, Wang L, Huang FH, Guo PM, Wei F, Deng QC, Zheng C, Wan CY (2013) J Mol Catal B Enzym 95:82–88

Martins AB, Schein MF, Friedrich JLR, Fernandez-Lafuente R, Ayub MAS, Rodrigues RC (2013) Ultrason Sonochem 20:1155–1160

Balen M, Silveira C, Kratz JM, Simões MO, Valério A, Ninow JL, Nandi LG, Di Luccio M, Oliveira D (2015) Biocat Agric Biotechnol 4:514–520

Humeau C, Girardin M, Coulon D, Miclo A (1995) Biotechnol Lett 17:1091–1094

Lerin LA, Feiten MC, Richetti A, Toniazzo G, Treichel H, Mazutti MA, Oliveira JV, Oestreicher EG, Oliveira D (2011) Ultrason Sonochem 18:988–996

Richetti A (2009) Dissertação de Mestrado. Universidade Federal do Rio de Janeiro, Brasil

Wang J, Wang S, Li Z, Gu S, Wu X, Wu F (2015) J Mol Catal B Enzym 111:21–28

Song Q-X, Wei D-Z (2002) J Mol Catal B Enzym 18:261–266

Bansode SR, Rathod VK (2014) Process Biochem 49:1297–1303

Fallavena LP, Antunes FHF, Alves JS, Paludo N, Ayub MAZ, Fernandez-Lafuente R, Rodrigues RC (2014) RSC Adv 4:8675–8681

Acknowledgments

The authors thank CAPES and CNPq for the financial support of this work and scholarships.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balen, M., Gomes, G.R., Kratz, J.M. et al. Enzymatic synthesis of ascorbyl ester derived from linoleic acid. Bioprocess Biosyst Eng 40, 265–270 (2017). https://doi.org/10.1007/s00449-016-1694-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1694-6