Abstract

Cheese whey fermentation to ethanol using immobilized Kluyveromyces marxianus cells was investigated in batch and continuous operation. In batch fermentation, the yeast cells were immobilized in carboxymethyl cellulose (CMC) polymer and also synthesized graft copolymer of CMC with N-vinyl-2-pyrrolidone, denoted as CMC-g-PVP, and the efficiency of the two developed cell entrapped beads for lactose fermentation to ethanol was examined. The yeast cells immobilized in CMC-g-PVP performed slightly better than CMC with ethanol production yields of 0.52 and 0.49 g ethanol/g lactose, respectively. The effect of supplementation of cheese whey with lactose (42, 70, 100 and 150 g/l) on fermentative performance of K. marxianus immobilized in CMC beads was considered and the results were used for kinetic studies. The first order reaction model was suitable to describe the kinetics of substrate utilization and modified Gompertz model was quite successful to predict the ethanol production. For continuous ethanol fermentation, a packed-bed immobilized cell reactor (ICR) was operated at several hydraulic retention times; HRTs of 11, 15 and 30 h. At the HRT of 30 h, the ethanol production yield using CMC beads was 0.49 g/g which implies that 91.07 % of the theoretical yield was achieved.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Whey is a byproduct of dairy industries which is generated during cheese making process. About 80–90 % of the milk entering the process is converted to cheese whey after coagulation and separation of the curd [1]. The world production of cheese whey is estimated around 160 million tons per annum [2–4], with annual growth of 1–2 % [3]. Although a large portion of the generated cheese whey is treated and converted into food products, including whey powder used for human food and animal feed, almost half of the generated wastewater is directly entered to the environment, which in addition to significant loss of resources, creates serious environmental pollutions [5]. Recent researches have shown that the concentration of untreated whey in aquatic ecosystems is almost five times higher than the allowable limit [6].

Due to the high organic content of whey, it is considered as a highly polluted wastewater too strong for direct discharge into the aquatic systems. Cheese whey is characterized as a wastewater with biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of 30–50 and 60–80 g/l, with a biodegradability index (BOD5/COD ratio) of about 0.4–0.8 [7–12]. Cheese whey contains about 50 % of milk solids [13]. The whey components are mainly relevant to milk carbohydrates and proteins, including lactose and casein, with minor contribution of fats, suspended solids and mineral salts [14]. Therefore, whey is a valuable source of food constituents from which, lactose, protein and minerals can be recovered. Lactose in the whey can be fermented to numerous valuable compounds including ethanol, organic acids, single cell protein (SCP), bio-hydrogen, biogas, amino acids, enzymes, vitamins, biopolymers and biodegradable plastics [3, 15]. Considering the above discussion, it would be most desirable to produce value-added products from cheese whey and simultaneously provide an effluent stream, clean and safe enough to be discharged into the environment or reused.

Cheese whey has been utilized as a low cost and nutritionally rich raw material for ethanol fermentation. Although many yeasts can assimilate lactose aerobically, very few ones including Kluyveromyces marxianus, K. lactis and Candida pseudotropicalis are able to ferment lactose [3]. Among the yeasts that can ferment lactose to ethanol, K. marxianus is the most efficient one [16]. The ethanol produced from cheese whey can be either used in beverage, food, pharmaceutical and cosmetic industries or blended as a renewable fuel with gasoline to reduce petrol consumption and environmental pollutions [17]. Production of 2nd generation bioethanol from agro-industrial wastes [18, 19] and dairy industry waste streams using yeast genera could be a sustainable response to ever increasing controversy over the 1st generation bioethanol.

One of the major hurdles encountered during batch fermentation of ethanol is product inhibition; wherein, ethanol concentrations in the range of 6–15 % (w/v) can impose inhibitory effect depending on the ethanol tolerance of the microorganism [20]. Such phenomenon can retard the cell growth and slow down the fermentation rate and eventually conclude to cell death. Among the viable routes to address this issue is the immobilization of microbial cells in a solid matrix. Cell immobilization can effectively eliminate the inhibition caused by high concentrations of product and substrate; it can assure good substrate utilization, enhanced productivity and improved yield of ethanol production [21]. Becerra et al. [22] immobilized K. marxianus cells in calcium alginate polymer to produce ethanol from cheese whey and found that approximately 99.55 % of whey lactose was hydrolyzed. In another investigation by Gunasekaran and Kamini [23], ethanol production from lactose using K. fragilis cells immobilized in calcium alginate was compared to that of free cells. The attained ethanol production yields were 61.9 and 51.7 % of the theoretical yield for immobilized and free cells, respectively. Ozmihci and Kargi [24], operated a continuous packed bed bioreactor for ethanol production from cheese whey powder solution using K. marxianus cells immobilized on olive pits. They obtained a high ethanol production yield of 0.54 g ethanol/g lactose at hydraulic retention time (HRT) of 50 h. It would be worth to note that the maximum theoretical yield of ethanol from lactose is 0.538 g ethanol/g lactose [25, 26].

In this study, deproteinized sweet cheese whey was fermented using K. marxianus for ethanol production. For this purpose, cells were immobilized in carboxymethyl cellulose (CMC) polymer and used to ferment cheese whey to ethanol in batch system. As a comparison, the cells were also immobilized in the synthesized carboxymethyl cellulose-g-poly (N-vinyl-2-pyrrolidone) (CMC-g-PVP) graft copolymer and the efficiency of the immobilized cells for fermentation was investigated. Kinetics of substrate utilization and product formation were studied and the corresponding kinetic parameters were determined. A packed-bed immobilized cell reactor (ICR) was also operated for continuous ethanol production and the effect of HRT on ethanol production was considered.

Materials and methods

Microorganism

Kluyveromyces marxianus PTCC 5194 was obtained from Iranian Research Organization for Science and Technology (IROST). The growth medium contained (g/l): lactose, 1; yeast extract, 5; peptone, 2; KH2PO4, 1 and MgSO4, 1. For start-up, the yeast strain was inoculated into a 250 ml Erlenmeyer flask containing 100 ml of sterilized growth medium and incubated in an incubator shaker at 30 °C and 150 rpm for 2 days.

Graft copolymerization

In this study, both carboxymethyl cellulose (CMC) and cross-linked graft copolymer of CMC with N-vinyl-2-pyrrolidone (N-VP), denoted as CMC-g-PVP, were used as matrix for cell immobilization. The method for synthesis of CMC-g-PVP was adopted from the work of Gökgöz and Yiğitoğlu [34]. For this purpose, 0.5 g of sodium carboxymethyl cellulose (NaCMC, Daejung, Korea) was dissolved in 50 ml distilled water, under continuous flow of nitrogen for 30 min. 6.92 ml N-vinyl-2-pyrrolidone (N-VP, Merck, Germany) was dissolved in 25 ml distilled water and mixed with the CMC solution. 0.052 g azobisisobutyronitrile (AIBN, Sigma) was dissolved in 2 ml acetone and mixed with reaction solution as the initiator of the grafting reaction. The total volume of the reaction mixture was brought up to 100 ml by addition of distilled water. Grafting reaction was performed at 70° C for 4.5 h under continuous flow of nitrogen. To stop the reaction, a saturated solution of hydroquinone (Scharlau, Spain) was added to the solution. The product was obtained by precipitation in an excess of acetone and then separation by filtration. For purification, the product was extracted using ethanol to remove the unreacted homopolymer (PVP) for 24 h. The purified graft copolymer, CMC-g-PVP, was then separated by filtration and dried at 40 °C in vacuo to a constant weight.

Immobilization technique

For immobilization, K. marxianus cells were grown on pre-described medium at 30 °C for 16 h. The synthesized CMC-g-PVP copolymer (3 % w/v) and CMC (2 % w/v) were separately added to the flasks containing yeast culture; wherein, the cells were in exponential growth phase. The slurry of yeast culture was dripped into a bath of aluminum chloride solution (4 wt%). Once the slurry was added to the AlCl3 solution, beads of CMC and CMC-g-PVP with entrapped yeast cells were formed. The so-obtained beads were allowed to harden overnight at 4 °C. The cells were assumed to be well entrapped in the polymer matrix as there was no evidence of leakage of the cells from the beads to the surrounding medium. The beads were finally washed using sterile saline solution (0.9 %) to remove unbound cells and excess aluminum ions.

Batch fermentation experiment

The fresh sweet cheese whey was obtained from a local dairy industry (Kaleh, Amol, Iran). The whey, as-received from the factory, was characterized to determine its COD and contents of lactose, proteins, fats, minerals and total suspended solids; the results are presented in Table 1. The cheese whey was then deproteinized to prevent the precipitation of protein during heat sterilization process. Deproteinization was performed by addition of dilute HCl to the cheese whey to pH 4 and then boiling the acidified solution for 20 min; the precipitates were separated by filtration and pH of the filtrate was adjusted to 7 using NaOH solution (2 M). The solution was boiled for 20 min and then filtered to remove the precipitates; the filtrate was stored in freezer. The protein content of cheese whey after deproteinization was 0.4 g/l.

The partially deproteinized cheese whey was used as fermentation medium. Fermentation experiments were carried out in 500 ml Erlenmeyer flasks; CMC and CMC-g-PVP beads were separately poured into two flasks to a volume of about 125 ml and sterilized cheese whey was added to make a total volume of 250 ml. In experiments where the effect of lactose concentration on ethanol production was aimed to study, defined amounts of lactose (Scharlau, Germany) were added to the media to have initial lactose concentrations of 70, 100 and 150 g/l. The flasks were incubated in an incubator shaker at 30 °C and pH 5. Samples were withdrawn every 12 h and analyzed to determine the lactose consumption and ethanol production.

Continuous fermentation experiments

The continuous cheese whey fermentation experiments were carried out in a packed-bed immobilized cell reactor (ICR). The ICR was a plug flow tubular column operated in up-flow mode; it was constructed from Plexiglas with inner diameter of 6 cm, thickness of 5 mm and height of 80 cm. The sterilized cheese whey was fed to the bottom of the ICR from the feed reservoir using a variable speed peristaltic pump (ASF THOMAS D-82178, Germany). To prevent the contamination of feed line and feed reservoir, a flow breaker was installed between the bioreactor and feed pump. The effluent stream from the bioreactor was collected in a product reservoir.

To start the lactose fermentation experiments, the prepared CMC beads entrapping K. marxianus cells were loaded in the bioreactor. There was a perforated plate at the bottom of the column to prevent the clogging of inlet pipe. About 60 % of the total volume of the bioreactor was packed with the prepared beads; the extra space was considered for bead growth and bed expansion. To determine the void volume of the bed, after loading the beads in the bioreactor the working volume was filled with sterilized distilled water; the volume of distilled water was considered as the void volume. For continuous operation, fresh cheese whey with lactose concentration of 50 g/l at different flow rates was fed to the ICR; this was to have various HRTs of 11, 15 and 30 h. During the course of fermentation, samples were taken from the effluent stream and analyzed for lactose and ethanol concentrations.

Analytical methods

In characterization of cheese why, lactose concentration was measured using DNS method [27], fat content was determined by Rose-Gottlieb gravimetric method [28]. Bradford assay was used to quantify the amount of protein [29]. The COD of the whey was measured according to standard method [30]; the total solid (TS) [31], total suspended solid (TSS) [32] and ash [33] content were also determined according to the corresponding standard methods. The concentration of the free K. marxianus cells in the growth medium was determined by OD reading at 620 nm, using a pre-developed calibration curve.

Samples collected from the fermentation broth were centrifuged at 3500 rpm for 15 min and the supernatants were analyzed. The ethanol concentration was determined using a Gas Chromatograph (Agilent, 7890A, USA), equipped with a flame ionization detector (FID) and Porapak Q packed column (Supelco, USA). The initial oven temperature was set at 120 °C for 1 min and then increased at a rate of 40 °C/min to 185 °C and kept at this temperature for 9 min. The temperature of injector and detector was set at 120 and 250 °C, respectively. Nitrogen at a flow rate of 30 ml/min was used as carrier gas. 2-propanol (Merck, Germany) was used as internal standard.

To analyze the surface morphology of the cell entrapped beads, samples were taken from fresh and also used beads after 72 h fermentation. The beads were freeze-dried for 48 h and then the samples were analyzed using Scanning Electron Microscope (SEM, Philips XL30, Netherlands). To confirm the successful synthesis of cross-linked graft copolymer CMC-g-PVP, its surface functional groups were determined and compared to that of CMC using a WQF-510A Fourier transform infrared (FTIR) spectrometer with KBr pellets.

Results and discussion

Batch fermentation

Performance of CMC and CMC-g-PVP immobilized cells

In this work, both CMC and CMC-g-PVP graft copolymer were used as matrix for cell immobilization. The successful synthesis of cross-linked graft copolymer was confirmed by FTIR analysis. The FTIR spectra of NaCMC and synthesized CMC-g-PVP graft copolymer are presented in Fig. 1. The broad band between 3100 and 3600 cm−1 is attributed to O–H stretching vibrations. The presence of a sharp intense peak at 2132 cm−1 in the spectrm of CMC-g-PVP is a certain evidance of grafting reaction; this peak is associated with C–N stetching of PVP. The strong band at 1624 cm−1 in the spectrum of NaCMC is assigned to the carbonyl group that shifted to 1710 cm−1 in the spectrum of CMC-g-PVP due to carbonyl stretching vibration of N-VP [34, 35].

The yeast cells were immobilized in CMC and CMC-g-PVP polymer matrix and their performance in batch fermentation of whey lactose (42 g/l) to ethanol was investigated; the results are reflected in Fig. 2. As results show, in both experiments, lactose was rapidly consumed within 24 h after which, the lactose concentration in the media was almost negligible. The prompt consumption of lactose was coincide with increase of ethanol concentration in the media until 24 h using both beads; thereafter, the ethanol concentration slightly increased. Maximum ethanol production using CMC-g-PVP and CMC beads was 21.53 and 19.79 g/l with productivities of 0.79 and 0.73 g/l.h, respectively. The obtained ethanol yield using yeast cells immobilized in CMC-g-PVP and CMC was 0.52 and 0.49 g ethanol/g lactose, respectively. To show the effectiveness of cell immobilization in enhancement of ethanol production, similar experiment was carried out using free K. marxianus cells and the results were compared to those of immobilized cells (Fig. 2). At this condition, the ethanol concentration was 14.58 g/l; this means that ethanol production enhanced by about 37 % through cell immobilization. With free cells, productivity of 0.60 g/l h and ethanol production yield of 0.35 g/g were achieved.

Comparison of the results obtained using two different polymers used for cell immobilization reveals that ethanol production using CMC-g-PVP was only slightly better than CMC. Considering that the synthesis of cross-linked graft copolymer CMC-g-PVP was not quite straightforward and required costly chemicals, it was not selected as the preferred matrix for cell immobilization and subsequent batch and continuous fermentation experiments were carried out using CMC beads.

The surface morphology of the developed CMC beads wherein yeast cells were entrapped was investigated by SEM analysis. Figure 3a, b show the inner surface of the fresh bead and the used one after 72 h fermentation, respectively. As observed in the micrograph of the fresh bead, some yeast cells are entrapped in the porous polymer matrix; however, high growth of the cells during the fermentation and increase in their number is quite clear in the used bead (Fig. 4b). The morphology of the outer surface of CMC beads are shown in Fig. 3c, d, for fresh and used beads, respectively. The yeast cells can be apparently seen on the outer surface of fresh beads. By contrast, after 72 h of fermentation the cells completely covered the CMC surface.

Effect of lactose concentration

It was attempted to increase the amount of ethanol produced via alcoholic fermentation by supplementation of cheese whey with lactose to have higher concentrations of sugar in the fermentation medium. The effect of initial lactose concentration (42, 70, 100 and 150 g/l) on fermentative performance of K. marxianus immobilized in CMC beads is illustrated in Fig. 4. When cheese whey was supplemented with lactose (70 g/l), ethanol production enhanced as compared to the raw cheese whey with lactose concentration of 42 g/l. Nevertheless, increase of the lactose concentration to beyond 70 g/l significantly reduced the ethanol production due to possible substrate limitations. The high osmotic pressure created at high lactose concentrations could impose inhibitory effect. The ethanol concentration obtained using 100 and 150 g/l lactose was only 14.68 and 11.26 g/l, respectively. This corresponds to the lower amount of lactose being metabolized as could be inferred from the low sugar conversions of 45.92 and 29.23 % obtained for 100 and 150 g/l lactose, respectively. In batch fermentation, maximum ethanol concentration of 23.6 g/l was achieved at lactose concentration of 70 g/l, where 93.36 % of the sugar was metabolized.

The results corresponding to ethanol yield (Y EtOH/S), productivity (Q P) and yield percent for the implemented initial lactose concentration are summarized in Table 2. Yield percent was calculated as the ratio of “actual yield” over “theoretical yield”; it presents how close the obtained actual yield is to the theoretical yield.

Kinetic studies

Kinetics of substrate utilization

To describe the utilization of lactose using CMC immobilized K. marxianus cells during batch fermentation of cheese whey to ethanol, a first-order rate model was used:

The expression for time-dependent concentration of substrate is obtained by integration from first-order substrate consumption rate model:

where S 0 and S are initial and instantaneous substrate (lactose) concentrations (g/l), t represents the fermentation time (h) and k is the first-order rate constant (h−1). Figure 5 illustrates the consumption of lactose using immobilized yeast cells during the course of fermentation. As observed, high regression coefficients (R 2 > 0.98) were obtained at all lactose concentrations implying the suitability of the first order reaction model to describe the kinetics of substrate utilization. The rate constant k, obtained from the curve fitting, was 0.0697, 0.0341, 0.008341, 0.004482 h−1 for lactose concentrations of 42, 70, 100 and 150 g/l, respectively. The lower the lactose concentration, the higher the rate of lactose utilization.

Application of Eq. (2) to the experimental data obtained for lactose consumption in cheese whey fermentation for initial lactose concentrations of 42 g/l (unfilled square), 70 g/l (unfilled diamond), 100 g/l (+) and 150 g/l (unfilled circle)

Kinetics of production formation

In this study, kinetics of ethanol formation as the cheese whey fermentation product was studied using a modified Gompertz equation defined as [36, 37]:

where P is the amount of product (ethanol) formed (g/l), P max is the maximum ethanol production potential (g/l), R max denotes the maximum ethanol production rate (g/l h), λ is the lag time to exponential product formation (h), t represents the fermentation time (h) and e = 2.71828.

The application of modified Gompetrz model to experimental data is depicted in Fig. 6 and the corresponding kinetic parameters of the model determined from the curve fitting are tabulated in Table 3. The regression coefficients obtained for all lactose concentrations were above 0.98 signifying that this model was able to adequately describe the formation of ethanol during batch fermentation of cheese whey using immobilized K. marxianus cells.

Figure 7 compares the maximum ethanol production predicted by the modified Gompertz model (P max) to that of experimental ones for different lactose concentrations. As observed in the figure, there is a good agreement between the experimental and model results and both curves follow same trend. The results of our experiments showed that the highest ethanol production was attainable at lactose concentration of 70 g/l; this result was also confirmed by the model prediction. At lactose concentrations higher than 70 g/l, the ethanol production was retarded due to substrate inhibition and the modified Gompertz model was successful to predict this behavior.

Product yield

In batch fermentation where the formation of product is growth associated, the correlation between product formation and substrate utilization can be expressed as [38]:

where P is the instantaneous product concentration (g/l), S 0 and S are initial and instantaneous substrate concentrations (g/l) and Y P denotes the product yield. The suitability of Eq. (5) for yield calculations was examined by developing the plots of ethanol production versus lactose consumption; the results are depicted in Fig. 8. The fermentation data at various lactose concentrations fitted very well to the linear equation (Eq. (5)) with high regression coefficients. The product yield determined from the slopes of the linear plots and the regression coefficients are presented in Table 4.

Continuous fermentation in ICR

The developed ICR was operated at several HRTs of 11, 15 and 30 h and the effect of retention time, which is the inverse of dilution rate, on whey lactose utilization, ethanol yield and productivity was considered. Figure 9 shows the results of this investigation at constant lactose concentration of 50 g/l. Increase of the HRT enhanced lactose consumption by the yeast cell where sugar utilization for HRTs of 11, 15 and 30 h was 53.3, 59.9 and 72.6 %, respectively. Parallel to the increased lactose consumption, ethanol production improved with increasing HRTs. As the HRT was raised from 11 to 30 h, ethanol concentration enhanced from 10.21 to 17.67 g/l.

Such results could be expected as the substrate requires sufficient time to diffuse into the interior of the beads and the produced ethanol should diffuse back into the fermentation broth. The results obtained for ethanol production yield, productivity and yield percent at different HRTs are summarized in Table 5. Increase of HRT enhanced the ethanol production; however, the productivity decreased due to the prolonged retention time. In this study, the highest lactose utilization and ethanol production was obtained at HRT of 30 h, wherein 91.07 % of the theoretical yield was attained.

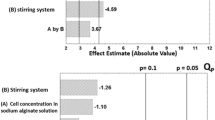

A comparison of the results of this study to those available in the literature on lactose fermentation using immobilized Kluyveromyces yeasts are summarized in Table 6. The results show that compared to sodium alginate as a common polymer used for cell immobilization, CMC immobilized cells had reasonable performance for lactose fermentation. This implies that CMC matrix was permeable to substrate and product, where lactose could penetrate into the beads to be metabolized by the cells for ethanol synthesis and the produced ethanol then diffused back into the bulk of fermentation broth.

Conclusions

Ethanol production from cheese whey was investigated using K. marxianus immobilized in CMC polymer and synthesized CMC-g-PVP graft copolymer. Although the yeast cell entrapped in CMC-g-PVP performed slightly better than CMC; however, due to its complicated synthesis process and cost considerations, CMC was used as the preferred matrix for cell immobilization. In kinetic studies, the first order reaction model and modified Gompertz were successfully adopted to describe the substrate utilization and product formation behavior, respectively. In continuous fermentation in a packed bed ICR using cells entrapped in CMC, ethanol production yield was 0.49 g/g at HRT of 30 h which corresponds to a yield percent of 91.07 %. The results achieved in this study show that CMC with excellent properties such as biocompatibility, high water absorption capacity and biodegradability can be used as a very potential matrix for cell immobilization.

References

Carvalho F, Prazeres AR, Rivas J (2013) Cheese whey wastewater: characterization and treatment. Sci Total Environ 445:385–396

Güven G, Perendeci A, Tanyolaç A (2008) Electrochemical treatment of deproteinated whey wastewater and optimization of treatment conditions with response surface methodology. J Hazard Mater 157:69–78

Guimarães PM, Teixeira JA, Domingues L (2010) Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey. Biotechnol Adv 28:375–384

Smithers GW (2008) Whey and whey proteins—from ‘gutter-to-gold’. Int Dairy J 18:695–704

Siso MG (1996) The biotechnological utilization of cheese whey: a review. B Bioresour Technol 57:1–11

Panesar PS, Kennedy JF, Gandhi DN, Bunko K (2007) Bioutilisation of whey for lactic acid production. Food Chem 105:1–14

Zafar S, Owais M (2006) Ethanol production from crude whey by Kluyveromyces marxianus. Biochem Eng J 27:295–298

Demirel B, Yenigun O, Onay TT (2005) Anaerobic treatment of dairy wastewaters: a review. Process Biochem 40:2583–2595

Farizoglu B, Keskinler B, Yildiz E, Nuhoglu A (2004) Cheese whey treatment performance of an aerobic jet loop membrane bioreactor. Process Biochem 39:2283–2291

Gannoun H, Khelifi E, Bouallagui H, Touhami Y, Hamdi M (2008) Ecological clarification of cheese whey prior to anaerobic digestion in upflow anaerobic filter. Bioresour Technol 99:6105–6111

Orhon D, Görgün E, Germirli F, Artan N (1993) Biological treatability of dairy wastewaters. Water Res 27:625–633

Papachristou E, Lafazanis CT (1997) Application of membrane technology in the pretreatment of cheese dairies wastes and co-treatment in a municipal conventional biological unit. Water Sci Technol 36:361–367

Gabardo S, Pereira GF, Klein MP, Rech R, Hertz PF, Ayub MAZ (2015) Dynamics of yeast immobilized-cell fluidized-bed bioreactors systems in ethanol fermentation from lactose-hydrolyzed whey and whey permeate. Bioprocess Biosyst Eng 39:1–10

Rivas J, Prazeres AR, Carvalho F (2011) Aerobic biodegradation of precoagulated cheese whey wastewater. J Agric Food Chem 59:2511–2517

Koushki M, Jafari M, Azizi M (2012) Comparison of ethanol production from cheese whey permeate by two yeast strains. J Food Sci Technol 49:614–619

Hacking A, Taylor I, Hanas C (1984) Selection of yeast able to produce ethanol from glucose at 40 °C. Appl Microb Biotechnol 19:361–363

Balat M, Balat H (2009) Recent trends in global production and utilization of bio-ethanol fuel. Appl Energy 86:2273–2282

Fan C, Qi K, Xia X-X, Zhong J-J (2013) Efficient ethanol production from corncob residues by repeated fermentation of an adapted yeast. Bioresour Technol 136:309–315

Qi K, Xia X-X, Zhong J-J (2015) Enhanced anti-oxidative activity and lignocellulosic ethanol production by biotin addition to medium in Pichia guilliermondii fermentation. Bioresour Technol 189:36–43

Dale MC, Wankat PC, Okos MR (1987) Immobilized cell reactor-separator with simultaneous product separation and methods for design and use thereof. US Patents No.: US4665027A

Najafpour G, Younesi H, Ismail KSK (2004) Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae. Bioresour Technol 92:251–260

Becerra M, Baroli B, Fadda A, Mendez JB, Siso MG (2001) Lactose bioconversion by calcium-alginate immobilization of Kluyveromyces lactis cells. Enzyme Microb Technol 29:506–512

Gunasekaran P, Kamini N (1991) High ethanol productivity from lactose by immobilized cells of Kluyveromyces fragilis and Zymomonas mobilis. World J Microbiol Biotechnol 7:551–556

Ozmihci S, Kargi F (2008) Ethanol production from cheese whey powder solution in a packed column bioreactor at different hydraulic residence times. Biochem Eng J 42:180–185

Sansonetti S, Curcio S, Calabrò V, Iorio G (2009) Bio-ethanol production by fermentation of ricotta cheese whey as an effective alternative non-vegetable source. Biomass Bioenergy 33:1687–1692

Mawson A (1994) Bioconversions for whey utilization and waste abatement. Bioresour Technol 47:195–203

X-j QI, Gou J-x HAN, X-j Yan B (2004) Study on measuring reducing sugar by DNS reagent [J]. J Cellul Sci Technol 3:17–20

Fenelon M, Guinee T (1999) The effect of milk fat on Cheddar cheese yield and its prediction, using modifications of the Van Slyke cheese yield formula. J Dairy Sci 82:2287–2299

Kruger NJ (1994) The Bradford method for protein quantitation. Springer

APHA (1999) Standard methods for the examination of water and wastewater, 22nd edn. Method 5220 D. COD

APHA (1999) Standard methods for the examination of water and wastewater, 22nd edn. Method 2540 B. Total solids

APHA (1999) Standard methods for the examination of water and wastewater, 22nd edn. Method 2540 D. TSS

ASTM (2015) Standard test method for ash in biomass, Method E 1755. Ash

Yiğitoğlu M, Işıklan N, Özmen R (2007) Graft copolymerization of N-vinyl-2-pyrrolidone onto sodium carboxymethylcellulose with azobisisobutyronitrile as the initiator. J Appl Polym Sci 104:936–943

Gökgöz M, Yiğitoğlu M (2011) Immobilization of Saccharomyces cerevisiae on to modified carboxymethylcellulose for production of ethanol. Bioprocess Biosyst Eng 34:849–857

Mu Y, Wang G, Yu H-Q (2006) Kinetic modeling of batch hydrogen production process by mixed anaerobic cultures. Bioresour Technol 97:1302–1307

Mohammadi M, Mohamed AR, Najafpour GD, Younesi H, Uzir MH (2014) Kinetic studies on fermentative production of biofuel from synthesis gas using Clostridium ljungdahlii. Sci World J 2014:1–8

Yang S, Tang I, Okos M (1988) Kinetics and mathematical modeling of homoacetic fermentation of lactate by Clostridium formicoaceticum. Biotechnol Bioeng 32:797–802

Gabardo S, Rech R, Ayub MAZ (2012) Performance of different immobilized-cell systems to efficiently produce ethanol from whey: fluidized batch, packed-bed and fluidized continuous bioreactors. J Chem Technol Biotechnol 87:1194–1201

Christensen AD, Kádár Z, Oleskowicz-Popiel P, Thomsen MH (2011) Production of bioethanol from organic whey using Kluyveromyces marxianus. J Ind Microbiol Biotechnol 38:283–289

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roohina, F., Mohammadi, M. & Najafpour, G.D. Immobilized Kluyveromyces marxianus cells in carboxymethyl cellulose for production of ethanol from cheese whey: experimental and kinetic studies. Bioprocess Biosyst Eng 39, 1341–1349 (2016). https://doi.org/10.1007/s00449-016-1610-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1610-0