Abstract

Monitoring of internal exposure to short-lived alpha-emitting radionuclides such as actinium-225 (225Ac), which are becoming increasingly important in nuclear medicine, plays an important role in the radiation protection of occupationally exposed persons. After having tested gamma spectrometry, liquid scintillation counting and alpha spectrometry for monitoring of internal exposure, the focus of the present study was on solid phase extraction of 225Ac from urine in combination with alpha spectrometry. The development of the method was based on recent findings from the literature on this topic. The method was used in a pilot phase to monitor internal exposure of four workers who were directly or indirectly involved in the manufacture and/or use of 225Ac. The monitoring protocol allowed a relatively short 24-hour urine sample analysis with excellent recovery of the internal standard, but it did not allow for a detection limit of less than 1 mBq nor a sufficient yield of 225Ac. Based on these results it is concluded that an in vitro excretion analysis alone is not appropriate for monitoring internal exposure to 225Ac. Instead, different radiation monitoring techniques have to be combined to ensure the radiation protection of employees.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In 2021, Sung et al. (2021) reported statistics on cancer, which is one of the top reasons for premature mortality (age 0–69) in most parts of the world, especially Europe and North America, thus making it a great challenge for human health. The treatment of cancer in earlier years mostly depended on cytotoxic chemotherapies, whereas in the last decades new techniques were developed (Zugazagoitia et al. 2016). One of those techniques is targeted alpha therapy (TAT), which is based on linking a cancer-cell specific molecule to a chelated alpha-emitting radioactive nuclide (Kim and Brechbiel 2012; Morgenstern et al. 2018). The resulting active compound docks on specific areas of the cancer cell, with the alpha-particles emitted by the compound destroying essential parts of the cancer cell with minimal collateral damage. In some cases, this approach resulted in very promising treatments (Kim and Brechbiel 2012; Morgenstern et al. 2018). Right now, there are eight alpha-emitting radionuclides in focus of such radiopharmaceuticals (Eychenne et al. 2021), of which one is actinium-225 (225Ac). 225Ac has a physical half-life of about 10 days and, due to five short-lived daughter nuclides of which three emit alpha particles, a high dose coefficient of 1.8·10− 6 Sv/Bq (for inhalation, solubility class M corresponding to medium solubility, activity median aerodynamic diameter (AMAD) 5 μm) (ICRP 2022).

In accordance with the German Radiation Protection Act, German companies working with 225Ac must, under certain conditions, monitor employees who handle 225Ac (occupationally exposed persons) (ISO 20553 2006; Radiation Protection Act 2022). Monitoring for internal exposure can take place in various ways, e.g. by whole-body measurement using gamma spectrometry (in vivo) or by excretion analysis (in vitro) (ISO 20553 2006). Given the biokinetic data of 225Ac as provided by the International Commission on Radiological Protection (ICRP) (for inhalation, type M as the default for actinium (ICRP 2022), a monitoring interval of ≤ 7 days for in vitro analyses and of ≤ 30 days for in vivo analyses would have to be used for employees to satisfy Eqs. 3 and 4 of ISO 20553 (2006). For in vitro analyses, this would require measurements every week (i.e., 52 per year) and one would then have to detect 1/52 of the yearly dose limit of 1 mSv per measurement. This can be achieved with in vitro analyses, given the fact that the detection limit of e.g. alpha spectrometry is lower than that of gamma spectrometry (Jia and Jia 2012). However, to date there is no method available for the monitoring of internal exposure of 225Ac using e.g. urine samples. However, recently it has been shown that 225Ac can be quantitively extracted from urine using a Y-imprinted resin for solid-phase extraction (Cusnir et al. 2022). This method served as the basis for the present study where this method was modified and applied in the context of internal monitoring. For this purpose, a collaboration with Isotope Technologies Munich (ITM) was established, because this company works on 225Ac radiopharmaceuticals, amongst other things. Due to the high activities to be handled (MBq to GBq) by ITM in combination with the high dose coefficient of 225Ac, a potential effective dose of more than 1 mSv per calendar to ITM employees cannot be ruled out. This would require regular monitoring of internal exposure of the employees (ISO 20553 2006). As mentioned above, employees would have to be measured or, in case of in vitro monitoring, would have to collect one 24-hour urine sample per week (a total of 52 samples per year, leading to 1/52 mSv per sample to be detected). This would mean an activity to be determined in the order of 1 mBq per sample (calculated using OIR Data Viewer v. 5.27.9.21 (ICRP 2022). Therefore, any method would have to fulfil the following requirements:

-

1.

A short analysis time, as samples must be processed weekly,

-

2.

the detection limit must be lower than the activity to be detected of 1 mBq,

-

3.

the chemical yield of 225Ac or, in case of alpha spectrometry, of the internal standard should be > 50% (Vogl 1992),

-

4.

the chemical yield of the internal standard and 225Ac should be in a similar range, and.

-

5.

for routine application of the method, only commercially available materials and standard radiochemistry laboratory equipment is preferred.

In order to develop such a method for the radiation protection of individuals with potential occupational intake of 225Ac, different methods were explored. The focus was on testing a promising method for the practical monitoring of internal exposures with four probands, in order to explore the applicability and practicability of an in vitro excretion analysis method in the near future.

Materials and methods

Chemicals and radioactive substances

If not stated otherwise, all chemicals were from Chemsolute® (Th. Geyer GmbH & Co. KG, Germany) or Supelco® (Merck KGaA, Germany) in the grade p.a. Radioactive substances were purchased from Eckert & Ziegler Nuclitec GmbH (Germany) or Physikalisch-Technische Bundesanstalt (PTB, Germany); their activities were traceable to national standards. 225Ac was provided as 225Ac-chloride solution in 0.04 M HCl by ITM. Deionized water (dH2O) was created using an in-house deionization system. Synthetic urine was purchased from Synthetic Urine e.K. (Germany).

Calculation of radionuclide activity, yield, effective dose and detection limit

The 225Ac yield (ηAc−225) from in vitro measurements (i.e. radiochemical measurements in course of the excretion analysis) was calculated using Eq. (1):

Where ϕ is the calibration factor in Bq/s, Rb is the counting rate of the sample in 1/s, R0 is the counting rate of a blank sample in 1/s, ε is the emission probability of 225Ac, and aAc−225 is the added activity of 225Ac in Bq.

The yield of the tracer used (243Am, also referred to as “internal standard”) was calculated analogous to Eq. (1).

The effective dose was calculated according to ISO 20553 (2006). The detection limit was calculated according to DIN EN ISO 11929 (2021).

All uncertainties are presented with a coverage factor of k = 1.

Gamma spectrometry

Samples consisted of 200 mL synthetic urine spiked with 225Ac solution. The samples were filled in 250 mL polyethylene flasks with a fill height of 8 cm. All samples were measured with a p-type pure Germanium (ultra-low-level configuration) detector, Model GEM-FX 7030-S relative efficiency 32.3% (ORTEC, USA). The 225Ac activity concentration was determined via the gamma line of its daughter nuclide 221Fr at the gamma energy of 218.2 keV, whereby radioactive equilibrium between 225Ac and its short-lived daughter nuclides was assumed.

Liquid scintillation counting measurements

For LSC measurements, LSC vials were filled to 8 mL with dH2O, spiked with a 225Ac solution, and 12 mL of a scintillation cocktail Ultima Gold™ AB (PerkinElmer Inc., USA) were added. The samples were measured using Hidex 300SL (Hidex Oy, Finland) for 12,000 s using an alpha/beta discrimination method from Hidex Oy, Finland, with an alpha energy region from 2.7 to 1,800 keV and a beta energy region from 0.1 to 1,800 keV. For the background, samples without the addition of 225Ac were measured simultaneously. The analysis was performed using MikroWin 300SL v.5.53 software (Hidex Oy, Finland).

24-hour urine samples

For the pilot-phase 24-hour urine samples were collected by the probands. The collection was done using 2.7 L PET flasks, and should involve the morning urine from the starting day and the day after. Then the samples were tightly closed, wrapped in cellulose and plastic bag and shipped to the laboratory within 36 h.

Excretion analysis

The excretion analysis was based on recent work from Cusnir et al. (2022). The finally developed method is presented below.

Sample preparation

Urine samples were divided into 500 mL aliquots. These aliquots were acidified with 5 mL HNO3 (14.4 M).

Coprecipitation (step 1)

To the 500 mL aliquots of urine samples a 243Am tracer solution including 50–250 mBq sample activity was added. If required for pre-trials and QA samples (quality assuring (QA) samples during the pilot-phase, provided by ITM) 225Ac was also added in varying activity ranges. The samples were then stirred and heated near boiling point until the urine cleared up. The hot plate was then switched off and 5 mL Ca(NO3)2 solution (20 mg/mL) was added, following the addition of 2 mL H3PO4 (6 M). To induce the coprecipitation an NaOH solution (32% w/v) was added until pH 8–9. The samples were stirred for 30 min at 70 °C and afterwards the precipitate was allowed to settle down for 2–3 h.

Digestion of organic matter (step 2)

The precipitate was decantated from the urine and transferred to a centrifuge tube with dH2O. The mix was centrifuged for 5 min at 4000 rpm (rotations per minute) and room temperature. The supernatant was discarded, the precipitate solved in 5 mL HNO3 (14.4 M) and 1 mL H2O2 (30% v/v) and transferred to a microwave tube. Organic matter was digested using a microwave system for 20 min at 40 bar and 180 °C. The resulting solution was transferred to a beaker and filled up to 20 mL with dH2O.

Solid-phase extraction (step 3)

For solid-phase extraction a vacuum box system (Triskem International, France) with diglycolamide (DGA) branched resin prepacked cartridges (2 mL bed volume, 50–100 μm particle size, Triskem International, France) were used. The cartridges were conditioned using 5 mL HNO3 (4 M) twice. Flow rate was adjusted to 1–2 mL/min. The 20 mL sample solution was loaded onto the cartridges and the flow through was discarded. For the washing step 5 mL HNO3 (4 M) were used twice and flow throughs were discarded. For elution 15 mL HCl (0.25 M) was used and the eluate was collected in a beaker.

Electrodeposition (step 4)

The electrodeposition protocol was based on previous work (Bajo and Eikenberg 1999). For electrodeposition, stainless steel discs were placed in electrolysis cells. To the 15 mL sample solution 0.6 mL NaHSO4 (1 M) and 0.4 mL H2SO4 (18.2 M) were added. The solution was slowly heated on a sand bath (increasing temperature) till dry. Afterwards the sample was calcinated for 30–60 min. The beaker was removed from the sand bath and the residue was dissolved in 0.3 mL H2SO4 (18.2 M). The beaker was again placed on a sand bath, heated until fumes formed and removed again from the sand bath. When cool, the residue was dissolved in 5 mL dH2O and transferred to an electrolysis cell. The beaker was rinsed twice with 5 mL dH2O and the solution was also added to the electrolysis cell. The pH was adjusted to 2.4 with H2SO4 (1.5 M) and NH3 solution (13.4 M). Electrolysis was performed at 1.2 A for 75 min. One minute before the end 1 mL NH3 solution (13.4 M) was added to the electrolysis cell. After electrolysis the stainless-steel disc was washed with dH2O and dried on air.

Alpha spectrometry (step 5)

For alpha spectrometry an Alpha Analyst™ type 7210 alpha spectrometer (Mirion Technologies (Canberra) GmbH, Germany) with PIPS® detectors (Mirion Technologies (Canberra) GmbH, Germany) were used. The efficiency calibration was traceable to a national standard. The samples were measured for 20,000 s under low pressure. For background, untreated stainless-steel disks were measured for 300,000 s under low pressure. For analysis Genie™ 2000 v3.3 software (Mirion Technologies (Canberra) GmbH, Germany) was used.

Results

In order to develop a practical analytic method for the excretion analysis of 225Ac from 24-hour urine samples, different preliminary tests were conducted. First, the three methods alpha spectrometry (AS), liquid scintillation counting (LSC) and gamma spectrometry (GS) were compared. Afterwards, the most promising method in terms of yield, detection limit and processing time was applied for a pilot-phase with real 24-h urine samples. For method selection (i.e. AS vs. LSC vs. GS) a pure 225Ac-chloride (AcCl3) solution was kindly provided by ITM, typically 100 µL HCl (0.04 M) with 100 kBq of activity, which was further diluted for the tests.

Gamma spectrometry and LSC

Gamma spectrometry

Gamma spectrometry was tested by preparing samples consisting of 200 mL synthetic urine with different 225Ac activities in the range of 9 to 20 Bq. This method allowed a direct measurement of samples without any previous sample preparation. Six samples (GS1-GS6) were measured on a pure Germanium detector in polyethylene flasks with a fill height of 8 cm. The samples consisted of 200 mL synthetic urine with 225Ac. Added 225Ac activity values with resulting recovery rates, measurement times and detection limits (for a daily urine excretion of 1.4 L) were: 10.5 Bq, 80.0% ± 5.7%, 315,000 s, 1.4 Bq for GS1; 17.5 Bq, 103.5% ± 8.1%, 80,000 s, 4.2 Bq for GS2; 17.7 Bq, 77.8% ± 7.3%, 160,000 s, 6.2 Bq for GS3; 8.8 Bq, 81.2% ± 7.8%, 160,000 s, 6.4 Bq for GS4; 9.4 Bq, 95.3% ± 7.5%, 320,000 s, 4.9 Bq for GS5; and 18.7 Bq, 95.6% ± 8.0%, 320,000 s, 6.3 Bq for GS6. Uncertainties were determined regarding DIN 1319-1 (1995). For all samples the activity was measured once. The samples were measured for 80,000 s to 320,000 s. The results showed that for all six samples measured (GS1 – GS6), the recovery rate was higher than 78%. With a mean value of the six samples of 89 ± 10% the GS proved to be very efficient regarding 225Ac recovery. Yet, even with a measurement time of 320,000 s (i.e. ~4 d), the lowest detection limit (for a daily urine excretion of 1.4 L) obtained was 1.4 Bq, which is significantly higher than the required detection limit of less than 1 mBq.

LSC measurements

Unlike the GS samples, the LSC samples did not contain synthetic urine. A specific 225Ac activity was added to LSC vials containing 8 mL dH2O and 12 mL scintillation cocktail (Ultima Gold™ AB). Six samples were prepared (LSC1-LSC6) with 225Ac activity in the range of 0.6 to 600 Bq, which were measured for 12,000 s using the alpha/beta discrimination method from Hidex Oy.

For the set 225Ac activity values, measured 225Ac activity values, yields and detection limits the following results were obtained: 592 Bq, 148 Bq ± 30 Bq, 25%, 4.5 Bq for LSC1; 297.3 Bq, 76.8 Bq ± 15.4 Bq, 26%, 3.2 Bq for LSC2; 146.3 Bq, 39.8 Bq ± 8.0 Bq, 27%, 2.3 Bq for LSC3; 20.7 Bq, 7.9 Bq ± 2.0 Bq, 38%, 1.6 Bq for LSC4; 5.9 Bq, 2.0 Bq ± 0.5 Bq, 34%, 490 mBq for LSC5; and 0.6 Bq, 0.006 Bq ± 0.003 Bq, 1%, 510 mBq for LSC6. The measured value of LSC6 6 mBq was lower than the detection limit of 510 mBq and the yield only 1%. Values given are mean values of two technical replicas for each sample. The uncertainties were determined using the software MikroWin 300SL v.5.53 and the standard deviation of the mean value. The results showed for all samples, except LSC6, reasonable 225Ac yields with 25–38%, which is still lower than expected, possibly due to problems with alpha-beta discrimination. In addition, the detection limit was for example about 490 mBq for sample LSC5, which is lower compared to those obtained for the GS samples. However, it was still higher than the required detection limit of 1 mBq. Moreover, for monitoring of internal exposure, the necessary 225Ac activity value to be measured would be in an activity range of 1–50 mBq. The only sample somewhat close to that value was LSC6 (set 225Ac value 600 mBq), which showed difficulties in the evaluation. Also, further measurements (data not shown) of set 225Ac values lower than 2 Bq showed similar results. Therefore, LSC seemed not sufficient and the study was continued with the AS.

Solid-phase-extraction in combination with alpha spectrometry

Recent work on the solid-phase extraction of 225Ac from urine showed one of the first examples for a qualitative and quantitative radiochemical analysis of low 225Ac activities (Cusnir et al. 2022). However, these authors used a self-made Y-imprinted resin for solid-phase extraction chromatography, which can make the procedure somewhat challenging for in vitro monitoring by internal exposure laboratories, since the equipment and technical perquisites required may not be available to them. Nonetheless, the present work is based on the protocol and results of Cusnir et al. (2022) with the aim of using only commercially available reagents and materials, making the method easier to be used for a widespread future application of in vitro monitoring of internal exposure to 225Ac.

In the present study, the steps described in the Materials and Method section were combined in three different ways, i.e., the complete analysis (steps 1–5), the separation (step 3 to step 5) and the electrodeposition (step 4 to step 5). For the first preliminary tests an AcCl3 solution was used. Additionally, 243Am was used as a tracer for radiochemical yield determination (Cusnir et al. 2022). Due to a limited supply of AcCl3 in the phase of the preliminary tests, the first experiments for each mentioned group (i.e. complete analysis, separation and electrodeposition) could only be conducted once. For the adapted method the corresponding 225Ac yields and 225Ac/243Am yield ratios were: Electrodeposition: 45.3%, 0.8; Separation: 3.4%, 0.1; Complete: 0.01%, 0.1.

For comparison of 225Ac yields and 225Ac/243Am yield ratios, literature values were calculated as mean values from the corresponding Tables: 1 (Electrodeposition), 2 (Separation) and 3 (Complete) (Cusnir et al. 2022), with the uncertainty presented being the standard deviation of the values. The corresponding 225Ac yields and 225Ac/243Am yield ratios were: Electrodeposition: 100.6% ± 1.6%, 1.1; Separation: 68.4% ± 15.5%, 0.9; Complete: 54.9% ± 19.4%, 0.9.

First, the electrodeposition (i.e. steps 4–5) was examined starting with a 0.25 M HCl solution, as this represented the actual elution solution form the previous step 3. 270 mBq 225Ac and 210 mBq 243Am were added, and the sample was treated according to the literature (Cusnir et al. 2022) by adjusting the pH to 1.9. Electrolysis was carried out at 1.2 A for 75 min. A stainless-steel disc was then measured for 20,000 s in the alpha spectrometer. The results showed a yield of 45% for 225Ac, which was about 55% lower than the reported values from Cusnir et al. (2022). However, the ratio between the yield of 225Ac and the tracer 243Am was (with 0.8) in a similar range (literature value 1.1 (Cusnir et al. 2022), which is an important perquisite for the method.

Next, the separation (i.e. steps 3–5) was examined, using DGA branched resin for the solid-phase extraction. This material is, in contrast to the Y-imprinted resin from Cusnir et al. (2022), commercially available and typically used for the separation of actinides (Maxwell 2007; Vajda et al. 2020). The test started with a 3.5 M HNO3 solution, as this represented the actual solution after the microwave digestion (step 2), and 170 mBq 225Ac and 210 Bq 243Am were added. The washing and elution steps on the DGA branched columns were performed similar to the reported procedures for Am purification using the DGA normal resin (Maxwell 2007; Luisier et al. 2009; Vajda et al. 2020). 5 mL 4 M HNO3 were used twice for washing, and 15 mL 0.25 M HCl for elution of Am and Ac. The following steps were identical as previously described. The results showed a yield of only ~ 3% for 225Ac, which was significantly lower than the reported value from Cusnir et al. (2022). Also, the 225Ac/243Am yield ratio of 0.15 obtained was lower than the reported value of 0.9 (Cusnir et al. 2022). A reason for this could be the use of the DGA-branched resin.

Last, the complete analysis (i.e. steps 1 to 5) was examined, starting with 0.5 L of synthetic urine, which was spiked with 210 mBq 225Ac and 210 mBq 243Am. The coprecipitation was performed at pH 9 with CaPO4, which is commonly used for 241Am excretion analysis in the occupational monitoring laboratory of department MB 5 of the Federal Office of Radiation Protection, Germany. Afterwards, the precipitate was treated with 5 mL 14.5 M HNO3 and 1 mL 30% (v/v) H2O2 and placed in a microwave digestion system for 20 min. The resulting solution was filled up to 20 mL with dH2O, resulting in an approximately 3–4 M HNO3 solution. From that point on the treatment was the same as described before. The results showed, as expected from the previous experiment, a low 225Ac yield of < 1%. In comparison to the results reported in the literature (Cusnir et al. 2022), neither the yield nor the 225Ac/243Am ratio were similar. It is noteworthy that the yield for the tracer 243Am was only 1% in this test and therefore not well suited for a comparison or for drawing firm conclusions. Even though only one test for each step could be performed, the overall poor yields and - in case of the separation and complete analysis - also poor 225Ac/243Am ratio had to be addressed before a pilot phase could be initiated.

Due to the currently high demand of 225Ac and a resulting shortage of AcCl3 solution on the market, it was decided to continue the optimization of the method without the addition of 225Ac.

In order to further optimise the method, the electrodeposition (steps 4–5) was further examined. For this, the pH value was changed from 1.9 to 2.4, which is typically used by the authors for 241Am excretion analysis. First attempts did not significantly increase the 243Am yield. Therefore, the protocol of electrolysis sample preparation was modified by adding 0.6 mL 1 M NaHSO4 to the initial solution containing 15 mL 0.25 M HCl. Following the addition of 0.4 mL H2SO4 18.2 M as the buffer system, the sample was evaporated to dryness, and the residue was calcinated for 30 to 60 min. Then, the residue was solved in 5 mL dH2O, transferred to the electrolysis cell and the beaker was rinsed with 5 mL dH2O, which was also transferred to the cell. Finally, the pH was adjusted to 2.4. The results (Table 1) showed an increase in 243Am yield of ~ 25% compared to the first test (electrodeposition: corresponding value for 243Am was 58.0%). Also, the yield was closer to the literature value of ~ 95%, indicating that the modified sample preparation protocol in combination with pH change from 1.9 to 2.4 prior to electrolysis had an important influence. From this point on, this electrodeposition protocol was used.

Next, the separation (steps 3–5) was performed according to the first test, with the modified electrodeposition. The results (Table 1) now showed a much higher 243Am yield with about 77% compared to the first test (separation: corresponding value for 243Am was 23.0%). Furthermore, the yield was in the same range compared to the literature value of ~ 73% (Cusnir et al. 2022). This showed that the chromatography using the DGA-branched resin worked, with the eluate treatment afterwards and electrolysis being the crucial part.

Finally, modified separation and electrodeposition steps were applied the complete extraction analysis was examined (steps 1–5). Compared to the first test, the only change made prior to the separation and following steps was adding 2 mL 6 M H3PO4 instead of 2 mL 14.8 M H3PO4 for CaPO4 precipitation. The 6 M H3PO4 solution was sufficient for a quantitative precipitation. This was checked by using 0.5 L of synthetic urine, adding 3 Bq 241Am, performing the precipitation with 6 M H3PO4, decanting the precipitate from the supernatant and measuring 0.2 L of the supernatant on a gamma detector (similar to the first gamma spectrometry tests) for any activity of 241Am. The results showed no 241Am signal, suggesting that the precipitation was rather complete (considering the detection limit of the measurement: with a detection limit of 0.05 Bq, the yield was estimated to be > 96% yield). Using the adjusted precipitation with the in the same protocol, the final result for the complete analysis (Table 1) showed with about 34% a much higher and more reliable 243Am yield compared to the first test with only 1% (which was the corresponding value for 243Am, for the complete procedure). Still, the 243Am yield reported in the literature (Cusnir et al. 2022) with ~ 60% was higher than the present value. Nonetheless, a tracer yield higher than 30% was considered enough for initiating a pilot phase and testing the developed 225Ac excretion analysis method by monitoring actual internal exposure, with the assumption that the Ac3+ and Am3+ ions behave similar during the radiochemical procedure.

Pilot phase of actinium-225 monitoring of internal exposure

The pilot phase was performed in cooperation with ITM with four of its employees (E1-E4), directly or indirectly involved in 225Ac production and usage. The aim was that each employee should collect a 24-hour urine sample every two weeks for six months during handling 225Ac, resulting in 12 samples per person and 48 samples in total. The samples should then be analysed with the developed method as described above. However, only 4–6 samples per individual could be collected, delivered and measured, due to operational reasons.

The samples were collected on any day between Friday and Monday by the employees, sent to the laboratory Tuesday afternoon and delivered with a parcel service provider on Wednesday morning. Upon arrival, the samples were registered, acidified for stability and then analysed with the above described method. The total processing time was two days, so that Thursday evening/Friday morning the alpha spectrometry results were obtained.

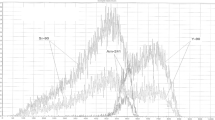

The 243Am yield mean value, the mean value of the 225Ac detection limit and the amount of samples s were: E1: 32.0% ± 2.7%, 7.9 ± 0.7 mBq (s = 4); E2: 34.5% ± 23.8%, 30.9 ± 38.5 mBq (s = 5); E3: 27.6% ± 18.7%, 23.2 ± 22.4 mBq (s = 5) and E4: 35.6% ± 21.5%, 21.5 ± 27.7 mBq (s = 6) (see also Fig. 1).

For neither of the four employees 225Ac signals were measured in the alpha spectrometry, with the 243Am yield being at least 27% (Fig. 1). The average 243Am yield was 32%, consistent with the previous findings (Table 1). The developed procedure could be integrated into the routine of laboratory work, and with the reagents and materials used, it did not pose a substantial challenge. Unfortunately, the obtained detection limits for 225Ac were higher than the desired value of 1 mBq for all samples. Furthermore, it must be considered that only four employees collected samples every two weeks, with occasional interruptions. In practice, monitoring for internal exposure due to 225Ac would require collection, shipment and processing of one sample per employee every week. Thus, laboratory capacities must be carefully evaluated in advance.

As quality control during the pilot phase, three synthetic urine samples were spiked by ITM with a known activity of 225Ac. The shipment of these samples was identical to the 24-hour urine samples of the employees. Upon arrival, the samples were diluted with synthetic urine leading to eight 0.5 L QA samples (QA1-QA8) with an activity range of 1 to 10 Bq. Note that these activities were up to 10,000 times higher than those expected in real conditions (about 1 mBq).

The resulting 225Ac yields, 243Am yields, 225Ac/243Am yield ratios and 225Ac detection limit of the samples were: QA1: 0.5%, 52.3%, 0.01, 4.9 mBq; QA2: 0.6%, 49.8%, 0.01, 5.2 mBq; QA3: 0.6%, 62.4%, 0.01, 19.9 mBq; QA4: 0.9%, 39.0%, 0.02, 28.6 mBq; QA5 0.3%, 13.3%, 0.03, 19.7 mBq; QA6: 0.4%, 72.4%, 0.01, 3.4 mBq; QA7: 3.9%, 87.6%, 0.05, 7.1 mBq and QA8: 2.6%, 84.0%, 0.03, 5.6 mBq (see also Fig. 2).

The results (Fig. 2) showed, firstly, that it was possible to achieve 243Am yields of up to 84% with an average of 58%. This value was higher than in the preliminary tests and the measurement of the E1-E4 24-hour urine samples. The main reasons for this could be a better handling of the method over time, or that the human urine may be somewhat different from the synthetic urine. Second, the yield for 225Ac was between 0.3 and 3.9% with an average of 1.2%. The reasons for these poor 225Ac yields are yet to be determined. A possible explanation could be that the separation columns used are not as efficient as the Y-imprinted resin (Cusnir et al. 2022). These poor 225Ac yields also led to the third finding, that the 225Ac/243Am ratio was with an average of 0.02 50-times lower than the value of about 1 reported by Cusnir et al. (2022).

Discussion

The aim of the present study was to develop a method that can be widely used for an excretion analysis of occupational internal exposure to 225Ac. Important factors for 225Ac excretion analyses are: a relatively short analysis, a detection limit lower than 1 mBq (based on the annual dose limit of 1 mSv for occupationally exposed persons (ISO 20553 2006), an 225Ac yield or tracer yield in case of AS greater than 50% (Vogl 1992), and an 225Ac/243Am yield ratio close to 1. The results obtained (Table 2) show that neither GS nor LSC are applicable for this purpose. While showing the best 225Ac yield (81%) and allowing for direct urine sample measurements, GS finally gave - even with measurements times up to 4 days - a detection limit that was higher than the required 1 mBq. Yet, this method can be used for special monitoring after incidents at workplace or for measurements of members of the public in emergency exposure situations. In special cases an effective dose of 1 mSv needs to be assessed from a single incident (quote translated: “in contrast to 1 mSv in the course of a year as in routine monitoring” ((RiPhyKo 2007). In emergency exposure situations only, incorporated activities leading to effective doses of 100 mSv need to be detected (AKI 2023). In both scenarios, the sampling would be conducted close to the intake, leading to relatively high excretion rates (e.g. after three days the excretion rate would be 3.5 times that that after seven days) and, thus, to higher detectable activities.

With a short measurement time and a reasonable yield at lower 225Ac concentrations than what could be measured with GS, the LSC measurements appeared applicable for the purpose of monitoring of internal exposure. However, at 225Ac activities lower than 5.9 Bq the 225Ac yield dropped drastically. Furthermore, analyses included dH2O and not urine samples. This could mean that the method finally would require an additional sample treatment prior to the activity measurements, resulting in a possible 225Ac loss during the process and in an increased time required for analysis. In addition, for LSC the detection limit was still higher than the required 1 mBq. In conclusion, also the LSC measurement is not helpful for routine occupational monitoring. However, similar to GS, LSC could be used for higher 225Ac activities to be detected. The third method examined here was the combination of solid-phase extraction in combination with AS. With an analysis duration of in general three days and a detection limit of 11 ± 8 mBq for the analysed QA samples, the method matched some of the requirements. However, even with a tracer yield of up to 87.6% the maximum 225Ac yield obtained was only 3.9% (see Fig. 2, sample QA7) in synthetic urine. The reasons for this disbalance in the 225Ac/243Am ratio, which Cusnir et al. (2022) had reported to be nearly 1 when they used their own method, could not addressed in the present study. Even with a better reliability of the method developed and described here with constantly high chemical yields, the reachable detection limits would not suffice to detect an annual effective dose of 1 mSv. However, a novel method has recently been developed that includes combined evaluation of several emissions of 225Ac and alpha spectra that are recorded throughout a year can significantly reduce the detectable dose to values even below 1 mSv (Meisenberg 2024).

From an analytical point of view, the presented AS method is not optimal for monitoring of internal exposure of 225Ac, mainly due to the poor 225Ac/243Am yield ratio and the impossibility to reach the desired detection limit of 1 mBq. Furthermore, the results of the pilot phase presented here showed some disadvantages of the applied in vitro excretion analysis. The number of samples to be expected for a company working with 225Ac can be estimated based on the assumption that one has to take one 24-hour urine sample per week or 52 samples per year per employee who is in contact with 225Ac. This translates into a considerable workload and financial burden for the company. For those employees who finally have to collect a sample every week, this might pose a non-negligible challenge. During the pilot phase described here, although the employees were asked to collect the samples only every second week, the number of samples collected was only 50% of the “target” value.

Conclusion

The study described here represents a first attempt to develop a method for the in vitro incorporation monitoring of 225Ac. Although the analytical methods of gamma spectrometry and liquid scintillation counting showed very good 225Ac yields, the required detection limit of 1 mBq could not be reached by several orders of magnitude. Nevertheless, both methods are suitable for analysing samples in emergency exposure situations that would presumably include a significantly higher 225Ac activity than the samples to be analysed in routine incorporation monitoring, partly because they allow for direct measurements.

The alpha spectrometry method developed based on the work of Cusnir et al. (2022) showed promising results. Detection limits close to 1 mBq were achieved, together with very good tracer yields. However, the 225Ac yields of around 2% were far too low. It is clear that intensive research is still required to bring the yields of 225Ac to the same level as those of the tracer 243Am.

It is concluded that methods other than those investigated in the present study, or the combination of different methods should be explored for the monitoring of internal exposure to 225Ac. This could involve air monitoring with an occasion-based in vivo whole-body measurement and in vitro excretion analysis of the employees as an additional feature. However, the exact details and procedures still need to be defined, especially in the area of room air monitoring, and decided by the competent authorities.

Data availability

No datasets were generated or analysed during the current study.

Change history

09 August 2024

ORCID of author Oliver Meisenberg updated

References

AKI (2023) Monitoring in Radiological Emergencies – A Catalog of Requirements for Incorporation Monitoring of Individuals. (German: „Anforderungskatalog zu Inkorporationsüberwachungen von Personen bei radiologischen Notfällen) FS-2023-185-AKI (ISSN 1013–4506), Germany

Bajo S, Eikenberg J (1999) Electrodeposition of actinides for alpha-spectrometry. J Radioanal Nucl Chem 242:745–751. https://doi.org/10.1007/BF02347389

Cusnir R, Froidevaux P, Carbonez P, Straub M (2022) Solid-phase extraction of 225Ac using ion-imprinted resin and 243Am as a radioactive tracer for internal dosimetry and incorporation measurements. Anal Chim Acta 1191:339421. https://doi.org/10.1016/j.aca.2021.339421

DIN EN ISO/IEC 11929 (2021) Determination of the characteristic limits (decision threshold, detection limit and limits of the coverage interval) for measurements of ionizing radiation - Fundamentals and application - Part 1: Elementary applications (ISO 11929-1:2019); German version EN ISO 11929-1:2021

DIN 1319-1 (1995) Deutsches Institut für Normung 1319-1:1995-01. Fundamentals of metrology - Part 1: Basic terminology

Eychenne R, Chérel M, Haddad F, Guérard F, Gestin JF (2021) Overview of the most promising radionuclides for targeted alpha therapy: the Hopeful eight. Pharmaceutics 13:906. https://doi.org/10.3390/pharmaceutics13060906

ICRP (2022) Occupational intakes of radionuclides: electronic annex of ICRP publications 130. 134(137):141

ISO 20553 (2006) Radiation protection - Monitoring of workers occupationally exposed to a risk of internal contamination with radioactive material (ISO 20553:2006); German version EN ISO 20553:2017

Jia G, Jia J (2012) Determination of radium isotopes in environmental samples by gamma spectrometry, liquid scintillation counting and alpha spectrometry: a review of analytical methodology. J Environ Radioact 106:98–119. https://doi.org/10.1016/j.jenvrad.2011.12.003

Kim YS, Brechbiel MW (2012) An overview of targeted alpha therapy. Tumor Biol 33:573–590. https://doi.org/10.1007/s13277-011-0286-y

Luisier F, Alvarado JAC, Steinmann P, Krachler M, Froidevaux P (2009) A new method for the determination of plutonium and americium using high pressure microwave digestion and alpha-spectrometry or ICP-SMS. J Radioanal Nucl Chem 281:425–432. https://doi.org/10.1007/s10967-009-0004-z

Maxwell IIISL (2007) Rapid method for determination of plutonium, americium and curium in large soil samples. J Radioanal Nucl Chem 275:395–402. https://doi.org/10.1007/s10967-007-7032-3

Meisenberg O (2024) Reduction of detection limits in monitoring of internal exposures by a combined evaluation of emissions and measurements. Radiation and Environmental Biophysics (submitted

Morgenstern A, Apostolidis C, Kratochwil C, Sathekge M, Krolicki L, Bruchertseifer F (2018) An overview of targeted alpha therapy with 225Actinium and 213Bismuth. Curr Radiopharm 11:200–208. https://doi.org/10.2174/1874471011666180502104524

Radiation Protection Act (2022) Act on the Protection Against the Harmful Effect of Ionising Radiation. Germany

RiPhyKo Teil 2 (2007) Guideline for physical radiation protection monitoring for the determination of equivalent and effective doses, Part 2: Determination of equivalent and effective doses for internal radiation exposure. Germany

Sung H, Ferlay J, Siegel RL, Laversanne M, Soerjomataram I, Jemal A, Bray F (2021) Global Cancer statistics 2020: GLOBOCAN estimates of incidence and Mortality Worldwide for 36 cancers in 185 countries. Ca Cancer J Clin 71:209–249. https://doi.org/10.3322/caac.21660

Vajda N, Zagyvai M, Groska J, Bokori E, Monár Z, Braun M (2020) Determination of uranium, plutonium and americium in soil and sediment by a sequential separation procedure using a single DGA column. J Radioanal Nucl Chem 326:695–710. https://doi.org/10.1007/s10967-020-07337-9

Vogl K (1992) Alpha spectrometry measurement instructions for the monitoring of radioactive substances in the environment and external radiation. „Alphaspektrometrie Messanleitungen für die „Überwachung Radioaktiver Stoffe in Der Umwelt und externer Strahlung). (ISSN 1865 – 875), Germany, German

Zugazagoitia J, Guedes C, Ponce S, Ferrer I, Molina-Pinelo S, Paz-Ares L (2016) Current challenges in Cancer Treatment. Clin Ther 38:1551–1566. https://doi.org/10.1016/j.clinthera.2016.03.026

Acknowledgements

The authors are grateful to the ITM employees who agreed to collect samples during the pilot phase.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Conceptualization: S.H., O.M.; Investigation: K.T., T.V., U-K.S.; Formal analysis: S.H., K.T., T.V., U-K.S.; Supervision: S.H., C.S.; Project administration: M.M., C.K.; Writing - original draft: S.H.; Writing - review & editing: S.H., O.M., C.S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hartmann, S., Taubner, K., Vogt, T. et al. Actinium-225 as an example for monitoring of internal exposure of occupational intakes of radionuclides in face of new nuclear-medical applications for short-lived alpha emitting particles. Radiat Environ Biophys 63, 385–394 (2024). https://doi.org/10.1007/s00411-024-01081-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00411-024-01081-4