Abstract

Objectives

The Gekkou-drill® is an industrial drill that is highly efficient due to reduced cutting resistance resulting from its characteristic drill point shape. In this experiment, we compared the degree of thermal damage to bone tissue caused by conventional medical drills and these same drills with Gekkou modifications.

Methods

Holes were created in the tibias of living pigs using two different 3.2-mm diameter drills and their modified versions. Regarding the drilling parameters, the thrust force was 10 N and the drilling speeds were 800 revolutions per minute (rpm) and 1500 rpm. We compared the original and modified drills in terms of the bone temperature around the drill bit and the total time necessary to create each hole, the latter calculated using imaging data captured during drilling. In histopathological examination, the percentages of empty lacunae in osteocytes of the cortical bone beneath the periosteum were evaluated at 400 × magnification with an optical microscope.

Results

Compared to the original drills, the modified drills required significantly less time to create each hole and caused a significantly lower temperature rise during bone drilling. With the modified drills, the percentages of empty lacunae around the drilling holes were about 1/2–1/3 of those with the original drills, and were significantly lower for both drilling speeds.

Conclusions

Gekkou-modified medical drills shortened drilling times despite low thrust force, and histopathological assessment demonstrated a significant reduction in osteocyte damage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In bone drilling during orthopedic surgery, is known that bone around the drill hole is affected by temperature elevations [1], and if these exceed a certain level, thermal necrosis of the bone may occur [2, 3]. There are two factors, drilling parameters and drill specifications that influence the thermal exposure during bone drilling. Shortening drilling duration is considered to be the only means of reducing thermal exposure, and therefore, modifications of the above factors have aimed to efficiently decrease drilling time. In previous studies this has been achieved by increasing the drilling speed, feed rate, and thrust force, and has contributed to lower tissue toxicity [4,5,6,7,8,9,10]. Drill specifications have also been improved to reduce heat generation. There are many reports in which drill specifications such as drill diameter [7], cutting face [11], flutes and helix angle [12], drill point [11], and drill wear [13, 14] have been modified to improve drilling efficiency or reduce thermal exposure. Some authors have reported that the use of a coolant is beneficial [15,16,17]. However, with any drill specification improvement, it is difficult to decrease the amount of time that bone tissue is exposed to high temperatures without increasing the drilling speed or the thrust force, and no commercially available medical drills can achieve these goals.

On the other hand, some industrial drills have recently been marketed with drill specifications that dramatically improve work efficiency, and their usefulness has been drawing attention [6, 18, 19]. One of these drills, sold under the brand name Gekkou-drill®, can remarkably reduce cutting resistance and improve the efficiency of discharging shavings. The excellent performance of this drill is reportedly due to the unique shape of the drill point. We predicted that minimally invasive bone drilling would be possible by adapting this industrial drill point shape to currently available medical drills. In a previous pilot study, we evaluated the performance of commercially available medical drills whose points that had undergone the Gekkou modifications. We found that both the cutting resistance and temperature elevation during bone drilling were significantly lower for drills with the Gekkou modifications than for conventional medical drills. However, the difference between the thermal damage caused by these two drill specifications has not been assessed in terms of histopathological findings under in vivo conditions. The present in vivo study aimed to evaluate the histopathology of living bone, comparing the effects of thermal exposure resulting from four drill specifications. The study used living pigs and preserved the periosteum, and therefore, cooling mechanisms such as blood flow from the periosteum (particularly the cortical layer) and bone marrow were active, enabling evaluation of bone temperature in a state that more closely resembles normal physiology.

Methods

Experimental setup

The experiment was performed using 16 tibias in 8 living pigs (female, 4 months old, and specific pathogen-free; body weight was 47.5–52.3 kg, and cortical thickness at the drilling area was 2.5–3.5 mm). General anesthesia was administered in the operating room, which was maintained at a constant temperature and humidity (around 25 °C and 60%, respectively). The periosteum was preserved. Peeling and incision of soft tissue was minimized to preserve blood flow. After a pig’s leg was placed on a board, an assistant held the ankle joint and then rotated the lower leg externally to keep the anterior medial aspect of the tibia parallel with the floor. The first drilling point was located 20 mm distal from the end of the proximal tibiofibular joint and at the center of the bone width. The second drilling point was 30 mm distal from the center of the first hole.

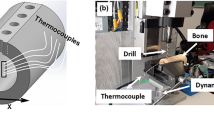

We investigated four different 3.2-mm drill bits: an original bit designed by Johnson & Johnson Inc., New Brunswick, NJ, USA (A); a Gekkou-modified A bit (AG); an original bit designed by Zimmer Biomet Inc., Warsaw, IN, USA (B); and a Gekkou-modified B bit (BG) (Fig. 1). Modification of the drill bits (adjustment of the point angle and creation of a rake at the cutting edge) was performed by BIC TOOL Co., Ltd, Hiezu, Tottori, Japan (Fig. 1b, d).

Bones were drilled with a CORE universal driver (Stryker Inc., USA), which was connected to the drill bits with a Jacobs drill system. The drilling speed was maintained at 800 revolutions per minute (rpm) or 1500 rpm. We fixed a rod perpendicular to the board and connected the drill holder to the rod. The holder could move smoothly along the rod and guide the drill bit vertically to the board. The drill holder was equipped with a digital force gauge (RZ-20 Aikoh Engineering Co., Ltd., Japan) that displayed the force at the tip of the drill bit every half second (Fig. 2). After the lower leg of the pig was fixed to the board and the force gauge was calibrated, drilling was performed without irrigation. The thrust force was adjusted to 10 N. We changed the drill bit every time we created a hole to prevent errors due to wear. In each pig, two holes were created under the same conditions (drilling speed, thrust force) using the original drill bit in one lower limb, and another two holes were created in the other lower limb using the Gekkou-modified drill bit.

The bone temperature was captured with a visual infrared thermometer (FLIR T650sc, measurement accuracy ± 1 °C or ± 1%, FLIR Inc., USA). The total time necessary to create each hole, the time that the temperature was over 47 °C, and the maximum temperature during drilling were all recorded. The reason for setting 47 °C as the temperature at which thermal damage occurs was based on previous findings that the risk of osteonecrosis is significantly increased if bone tissue is exposed to thermal damage above 47 °C for more than 60 s [3].

After two holes were drilled in a pig’s left and right pig tibias, the animal was euthanized by blood loss. Then the soft tissue around the tibia was removed and the bone at a distance of 15 mm from the hole was cut into 30-mm blocks. The samples were fixed with 10% formalin, then embedded in paraffin after decalcification. Cortical bone specimens at thicknesses of 4 μm were sliced perpendicular to the surface of the drill entry side and stained by hematoxylin–eosin (HE). An optical microscope (Eclipse E800, Nikon Instruments Inc., Japan) was used to examine the cortical bone beneath the periosteum at 400 × magnification. The number of empty lacunae and the total number of cells were counted in four locations that were in contact with the drill hole site, located clockwise around the drill hole at 0, 90, 180, and 270°. The percentage of empty lacunae were then calculated (Fig. 3).

Statistical analysis

Four holes were created with each drill bit, for a total of 32 drill holes. For each rpm value, the student's t test was used to compare parameters between the original and customized drill bits. The difference in drilling speed with each bit was also examined. The correlation coefficients between the percentage of empty lacunae and drilling time, time at which the bone temperature was over 47 °C, and maximum temperature were calculated. Values of p < 0.05 were considered significant.

Results

We captured bone temperature data during drilling with the Johnson & Johnson original drill bit (A), Johnson & Johnson Gekkou-modified drill bit (AG), Zimmer original drill bit (B), and Zimmer Gekkou-modified drill bit (BG). Then we calculated the total time spent creating the hole, the time at which the bone temperature was over 47 °C, and the maximum temperature during drilling (Table 1). The mean times spent creating the holes at 800 rpm were 42.3 s with A, 8.0 s with AG, 218.5 s with B, and 16.3 s with BG; the corresponding values at 1500 rpm were 31.8 s with A, 4.3 s with AG, 273.3 s with B, 11.8 s with BG. Both original drill bits required more time than the customized ones significantly, except for B vs BG at 800 rpm. Regardless of drilling speed, the time at which the bone temperature was over 47 °C tended to be shorter with the improved drill bits, but a significant difference was recognized only at 800 rpm. The mean maximum temperatures during drilling at 800 rpm were 58.1 °C with A, 44.4 °C with AG, 68.1 °C with B, 48.5 °C with BG; the corresponding values at 1500 rpm were 67.4 °C with A, 49.2 °C with AG, 115.6 °C with B, and 53.0 °C with BG, with a significant difference between B and BG. While there was no significant difference between A and AG, the temperature for AG was numerically lower. For each individual drill bit, there was no significant difference between the 800 and 1500 rpm speeds in terms of drilling time, the time at which the bone temperature was over 47 °C, or the maximum temperature reached.

Figure 4 shows a photomicrograph of bone drilled with a B drill bit at 1500 rpm, which resulted in a maximum temperature of 160.2 °C and a 157-s duration at which the bone temperature was over 47 °C. The majority of lacunae are empty, even in areas not immediately adjacent to the drill hole. On the other hand, the photomicrograph in Fig. 5 of bone drilled with an AG drill bit at 1500 rpm, which resulted in a maximum temperature of 40.8 °C and no elevation of bone temperature over 47 °C, shows that almost all osteocytes survived, even in the region surrounding the drill hole. In each field of view, we counted the total number of lacunae that were empty and those containing live osteocytes. Counting was performed twice each by two orthopedic surgeons who were blinded regarding the drill bit used. The intraclass correlation coefficients (ICCs) for each examiner were 0.98 and 0.97, respectively, and the ICC between examiners was 0.98. The mean percentages of empty lacunae that were empty after drilling with each drill bit at 800 rpm were 28.0% with A, 14.6% with AG, 36.9% with B, and 18.6% with BG. The corresponding values after drilling at 1500 rpm were 30.1% with A, 15.6% with AG, 66.9% with B, and 22.0% with BG (Table 2). There were significant differences between the original and modified drill bits regardless of manufacturer and drill speed. For each individual drill bit, the drilling speed had no significant effect on the percentage of empty lacunae.

Photomicrograph of bone drilled with a Zimmer original (B) drill bit at 1500 rpm (maximum temperature, 160.2 °C; total drilling time, 169 s) evaluated under a light microscope at 400 × magnification (hematoxylin–eosin staining). Even areas far from the drill site exhibit empty lacunae (black arrowheads)

Photomicrograph of bone drilled with a Johnson and Johnson Gekkou-modified drill bit (AG) at 1500 rpm (maximum temperature, 40.8 °C; total drilling time, 8 s) evaluated under a light microscope at 400 × magnification (hematoxylin–eosin staining). Almost all lacunae contain live osteocytes, even in the area just beside the drill hole site (white arrowhead). The black arrowhead shows an empty lacuna, and the black arrow indicates a Haversian canal

Discussion

In this study, we could significantly shorten drilling time and reduce temperature elevation by improving the chisel edge of the drill bit to optimize its cutting function. These modifications led to significant reductions in the percentages of empty lacunae in osteocytes compared with conventional drills. Excessive heat results in the presence of empty lacunae in bone tissue [5, 20,21,22]. Most studies have reported that the disappearance of osteocytes caused by heating or physical stimulation, but not apoptosis, is activating osteoclast and disadvantageous for mineral metabolism regulation, remodeling of the perilacunar matrix, and mechanosensor functions [23,24,25,26]. In view of the roles of osteocytes in bone remodeling, as shown in these previous studies, a reduced number of necrotic osteocytes is expected to suppress early bone resorption after invasive treatments involving bone. For example, in osteosynthesis, bone resorption is suppressed around the drill holes created by modified drills, which reduces the risk of screw loosening and at the same time leads to enhanced fixation. In other words, these modified drills are considered to significantly reduce the osteocyte damage caused by bone drilling, at least in the early stages after treatment.

To the best of our knowledge, no studies thus far have shown that it is possible to shorten the time required for drilling procedures while still maintaining a high feed rate, low thrust force, and low drilling speed [4,5,6, 27,28,29]. This is probably due to the fact that a suitable drill has not yet been developed. Kim et al. evaluated thrust force and drill speeds from 200 to 1180 rpm, and found that the lower the rotational speed and the higher the thrust force, the greater the suppression of heat generation [30]. In addition, Lee et al. created bone holes in pig ribs using drill bits with a 2.0-mm or 3.0-mm diameter without exceeding 47 °C, by drilling at 50 rpm and raising the thrust force [31]. However, a high thrust force risks overdrilling, increases the heat production per unit time, and can cause micro-cracks [5]. Therefore, we considered that the least invasive drilling method would use a low thrust force and low rotational speed. Our pilot study even evaluated a rotational speed of 300 rpm, but since this resulted in an overly long drilling time with a conventional drill, this speed was avoided in the present study due to concerns about animal welfare. The rotational speed of 800 rpm and thrust force of 10 N used in this in vivo experiment were low enough to be suitable for general bone drilling, and the histopathological findings with Gekkou-modified drills showed significantly reduced bone tissue damage compared to the non-modified drills. Although this drill specification may be insufficient for true minimally invasive drilling, our findings show that it is useful for reducing bone tissue damage during bone drilling.

The features of Gekkou-modified drills result from the special processing of the drill point, and in this study, our refinement of the chisel edge at the drill point was critical in achieving our results. Modification of the drills used in this experiment, including reduction of the chisel edge and crescent moon cutting, were carried out by BICTOOL Co., Ltd., which has no funding relationship with this study. It was previously stated that an unmodified chisel edge has no drilling function and is responsible for more than 50% of drill resistance [32]. Many reports demonstrated that reducing the sizes of chisel edges leads to a lower thrust force and shorter drilling duration, which results in a lower temperature rise during bone drilling [11, 33, 34]. Additionally, because unmodified chisel edges have no chip evacuation function, the chips remain in the drill hole, making efficient drilling impossible [32]. The modified drills used in this experiment were rounded into a crescent shape from the original sharp edge that causes strong resistance during bone drilling, and this crescent shape improved chip evacuation. We surmise that this change succeeded in reducing cutting resistance and suppressing temperature elevations during bone drilling.

There are several limitations to this study. The first is the small number of specimens. Only four tibial holes could be created per pig, so as to avoid the difference in cortical thickness and influence of an adjacent drill hole. However, despite the small sample size, the results showed a statistically significant difference. Additionally, this was a simple and reproducible experiment, so the number of specimens can be increased in the future. The second limitation is that bone mineral density and strength vary among individuals, and these factors were not considered in this study. Karaka et al. assumed that there was a positive correlation between bone mineral density and the total amount of heat produced in bone drilling under any given condition, and in particular, that the difference between genders is large [5]. Although all pigs in our experiments were female, there was a difference of up to 1 mm in the thickness of the bone cortex (results not shown), and this point was not taken into consideration in our analysis. However, we compared the use of the original and Gekkou-modified drills with the same rotational speeds within each individual, so the error related to variations in bone thickness should be minimal. The third limitation is that we only examined tissues immediately after drilling. In many cases the lacunae around the drilling holes were empty at this time. As mentioned above, osteoclasts should subsequently be activated and lead to bone resorption, but we could not evaluate these in vivo processes over time. Future tasks include observing in vivo histological changes over time and increasing the number of specimens.

In conclusion, histopathological findings showed that Gekkou-modified drills significantly reduced the percentage of empty lacunae in in vivo pig bone drilling experiments. The cause was reduction of bone temperature elevation and shortening of drilling time. These specifications of these modified drills are expected to be useful as minimally invasive medical drills in the future to reduce thermal damage caused by drilling in bone tissue.

References

Eriksson RA, Albrektsson T, Magnusson B (1984) Assessment of bone viability after heat trauma. A histological, histochemical and vital microscopic study in the rabbit. Scandinavian J Plastic Reconstr Surg 18 (3):261–268.

Krause WR (1987) Orthogonal bone cutting: saw design and operating characteristics. J Biomech Eng 109(3):263–271

Eriksson RA, Albrektsson T (1984) The effect of heat on bone regeneration: an experimental study in the rabbit using the bone growth chamber. J Oral Maxillofac Surg 42(11):705–711

Toews AR, Bailey JV, Townsend HG, Barber SM (1999) Effect of feed rate and drill speed on temperatures in equine cortical bone. Am J Vet Res 60(8):942–944

Karaca F, Aksakal B, Kom M (2011) Influence of orthopaedic drilling parameters on temperature and histopathology of bovine tibia: an in vitro study. Med Eng Phys 33(10):1221–1227. https://doi.org/10.1016/j.medengphy.2011.05.013

Chen YC, Hsiao CK, Ciou JS, Tsai YJ, Tu YK (2016) Effects of implant drilling parameters for pilot and twist drills on temperature rise in bone analog and alveolar bones. Med Eng Phys 38(11):1314–1321. https://doi.org/10.1016/j.medengphy.2016.08.009

Augustin G, Davila S, Mihoci K, Udiljak T, Vedrina DS, Antabak A (2008) Thermal osteonecrosis and bone drilling parameters revisited. Arch Orthop Trauma Surg 128(1):71–77. https://doi.org/10.1007/s00402-007-0427-3

Brisman DL (1996) The effect of speed, pressure, and time on bone temperature during the drilling of implant sites. Int J Oral Maxillofac Implants 11(1):35–37

Hillery MT, Shuaib I (1999) Temperature effects in the drilling of human and bovine bone. J Mater Process Technol 92–93:302–308. https://doi.org/10.1016/S0924-0136(99)00155-7

Sharawy M, Misch CE, Weller N, Tehemar S (2002) Heat generation during implant drilling: The significance of motor speed. J Oral Maxillofac Surg 60(10):1160–1169. https://doi.org/10.1053/joms.2002.34992

Natali C, Ingle P, Dowell J (1996) Orthopaedic bone drills-can they be improved? Temperature changes near the drilling face. J Bone Joint Surg Br 78(3):357–362

Cordioli G, Majzoub Z (1997) Heat generation during implant site preparation: an in vitro study. Int J Oral Maxillofac Implants 12(2):186–193

Jochum RM, Reichart PA (2000) Influence of multiple use of Timedur-titanium cannon drills: thermal response and scanning electron microscopic findings. Clin Oral Implant Res 11(2):139–143

Allan W, Williams ED, Kerawala CJ (2005) Effects of repeated drill use on temperature of bone during preparation for osteosynthesis self-tapping screws. Br J Oral Maxillofac Surg 43(4):314–319. https://doi.org/10.1016/j.bjoms.2004.11.007

Matthews LS, Hirsch C (1972) Temperatures measured in human cortical bone when drilling. J Bone Joint Surg Am 54(2):297–308

Sener BC, Dergin G, Gursoy B, Kelesoglu E, Slih I (2009) Effects of irrigation temperature on heat control in vitro at different drilling depths. Clin Oral Implant Res 20(3):294–298. https://doi.org/10.1111/j.1600-0501.2008.01643.x

Augustin G, Davila S, Udilljak T, Staroveski T, Brezak D, Babic S (2012) Temperature changes during cortical bone drilling with a newly designed step drill and an internally cooled drill. Int Orthop 36(7):1449–1456. https://doi.org/10.1007/s00264-012-1491-z

Gupta V, Pandey P, Mridha A, Gupta R (2017) Effect of various parameters on the temperature distribution in conventional and diamond coated hollow tool bone drilling: a comparative study. Procedia Eng 184:90–98. https://doi.org/10.1016/j.proeng.2017.04.074

Hein C, Inceoglu S, Juma D, Zuckerman L (2017) Heat generation during bone drilling: a comparison between industrial and orthopaedic drill bits. J Orthop Trauma 31(2):e55–e59. https://doi.org/10.1097/bot.0000000000000723

Tawy GF, Rowe PJ, Riches PE (2016) Thermal damage done to bone by burring and sawing with and without irrigation in knee arthroplasty. J Arthroplast 31(5):1102–1108. https://doi.org/10.1016/j.arth.2015.11.002

James TP, Chang G, Micucci S, Sagar A, Smith EL, Cassidy C (2014) Effect of applied force and blade speed on histopathology of bone during resection by sagittal saw. Med Eng Phys 36(3):364–370. https://doi.org/10.1016/j.medengphy.2013.12.002

Franssen BB, van Diest PJ, Schuurman AH, Kon M (2008) Drilling K-wires, what about the osteocytes? An experimental study in rabbits. Arch Orthop Trauma Surg 128(1):83–87. https://doi.org/10.1007/s00402-007-0382-z

Verborgt O, Gibson GJ, Schaffler MB (2000) Loss of osteocyte integrity in association with microdamage and bone remodeling after fatigue in vivo. J Bone Miner Res 15(1):60–67. https://doi.org/10.1359/jbmr.2000.15.1.60

Gu G, Mulari M, Peng Z, Hentunen TA, Vaananen HK (2005) Death of osteocytes turns off the inhibition of osteoclasts and triggers local bone resorption. Biochem Biophys Res Commun 335(4):1095–1101. https://doi.org/10.1016/j.bbrc.2005.06.211

Bonewald LF (2011) The amazing osteocyte. J Bone Miner Res 26(2):229–238. https://doi.org/10.1002/jbmr.320

Jilka RL, Noble B, Weinstein RS (2013) Osteocyte apoptosis. Bone 54(2):264–271. https://doi.org/10.1016/j.bone.2012.11.038

Krause WR, Bradbury DW, Kelly JE, Lunceford EM (1982) Temperature elevations in orthopaedic cutting operations. J Biomech 15(4):267–275

Wang W, Shi Y, Yang N, Yuan X (2014) Experimental analysis of drilling process in cortical bone. Med Eng Phys 36(2):261–266. https://doi.org/10.1016/j.medengphy.2013.08.006

Pandey RK, Panda SS (2015) Optimization of multiple quality characteristics in bone drilling using grey relational analysis. J Orthop 12(1):39–45. https://doi.org/10.1016/j.jor.2014.06.003

Kim SJ, Yoo J, Kim YS, Shin SW (2010) Temperature change in pig rib bone during implant site preparation by low-speed drilling. J Appl Oral Sci 18(5):522–527

Lee J, Ozdoganlar OB, Rabin Y (2012) An experimental investigation on thermal exposure during bone drilling. Med Eng Phys 34(10):1510–1520. https://doi.org/10.1016/j.medengphy.2012.03.002

Stephenson DA (1996) Metal cutting theory and practice. Taylor & Francis, Boca Raton

Saha S, Pal S, Albright JA (1982) Surgical drilling: design and performance of an improved drill. J Biomech Eng 104(3):245–252

Bertollo NWW (2011) Drilling of bone: practicality, limitations and complications associated with surgical drill bits. Biomech Appl https://doi.org/10.5772/20931

Acknowledgements

We appreciate Mr. Satoshi Teshima, who modified the drill tip; Mr. Akihiko Sugiyama, who gave us advice on histological evaluation; and Mrs. Sayaka Murata and Mrs. Nobuko Nozawa, who created and adjusted experimental instruments.

Funding

The authors report grants from the Japan Agency for Medical Research and Development (AMED) Grant Number 16hk0102013h0003.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kanaya, H., Enokida, M., Uehara, K. et al. Thermal damage of osteocytes during pig bone drilling: an in vivo comparative study of currently available and modified drills. Arch Orthop Trauma Surg 139, 1599–1605 (2019). https://doi.org/10.1007/s00402-019-03239-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00402-019-03239-y