Abstract

Microemulsions are thermodynamically stable mixtures of water and oil. For many applications, such as in cosmetics, it is important that the components are biocompatible. For the formulation of a new biocompatible microemulsion based on Tween 20 (Tw20) surfactant, the glycerol ether 2-ethylhexylglycerin (EHG) is employed as an alternative to commonly used short- to medium chain alcohols as cosurfactant. Tw20 itself is not capable of any significant solubilization but the addition of EHG allows to enhance the solubilization capacity for the polar oil isopropyl palmitate (IPP) largely. At a Tw20 to EHG molar ratio of 1:12, i.e., very large excess of cosurfactant, the solubilization capacity is increased by nearly three orders of magnitude compared to a pure Tw20 solution. The resulting oil-in-water (O/W) microemulsion is studied using static and dynamic light scattering (SLS/DLS) and small-angle neutron scattering (SANS). The SANS spectra are analyzed with a core–shell ellipsoid model, which indicates formation of oblate droplets at higher EHG content. Dynamic light scattering experiments confirm the presence of microemulsion droplets with hydrodynamic radii increasing from 3.8 to 19.8 nm upon addition of cosurfactant. In summary, this study shows that EHG is a cosurfactant that enhances the solubilization properties of a biocompatible surfactant largely and thereby renders it very useful for formulations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microemulsions (ME) are thermodynamically stable mixtures of oil and water facilitated by the presence of a surfactant. Their ability to solubilize both hydrophilic and hydrophobic compounds and their long shelf-life (basically infinite from the colloidal thermodynamic point of view) have been exploited in a number of applications including drug delivery, cosmetics, and enhanced oil-recovery [1,2,3]. Microemulsion formation has been studied quite intensely for typical ionic [4, 5] and non-ionic [6, 7] surfactants, mostly employing alkanes as oil. Recently, phase behavior and structures of microemulsions have been reviewed comprehensively with the perspective of how the structures can be related to their applications [8]. In general, their formation requires a low spontaneous curvature of the amphiphilic monolayer and a very low interfacial tension for the oil–water interface [8]. For non-ionic ethylene oxide (EO) surfactants, the spontaneous curvature can be tuned by choice of the length of alkyl chain and by the number of EO groups. It can also be systematically varied by changing the temperature [7, 8]. For ionic surfactants tuning the curvature is normally done by the addition of salt or a cosurfactant [5, 9]. Tuning the spontaneous curvature therefore is a central aspect in microemulsion formation [8] and is based on the packing parameter concept [10]. Accordingly, either the head group area can be adjusted (for non-ionic EO surfactant reducing it by raising the temperature, or for ionic head groups by screening head group repulsion by salt addition) or the hydrophobic volume (adding cosurfactant). For instance, high solubilization capacities have been achieved for nonionic surfactants like tetradecyl dimethylamine oxide (TDMAO) upon addition of 1-hexanol [11] or for anionic surfactants such as sodium dodecyl sulphate (SDS) with medium-chain alcohols as cosurfactants and/or at rather high salinities [12].

Many fundamental studies have been working with alkanes as oil, which allow for easy tuning of the oil properties via the chain length of the alkane. In the form of mineral oil, alkanes are often employed in applications of cosmetics, biomedicine, etc. However, for certain applications, it is important to have a polar and more biocompatible oil component. Advances in the formulation of biocompatible microemulsions have been summarized by Gupta and Moulik a longer while ago [13]. Common choices for biocompatible surfactants include non-ionic polysorbates [14,15,16] (Tween) and polyethylene glycol ethers [17, 18] (Brij) which generally require large amounts of surfactant for achieving solubilization of a given amount of oil. Typically, the solubilization capacity can be increased largely by adding cosurfactants, which lower the interfacial tension and reduce the preferred curvature of the surfactant film [8, 9, 19]. Most microemulsion formulations rely on short- to medium-chain alcohols as cosurfactants [20], but also esters may function in a similar way [21]. Common biocompatible oils include esters with at least one long alkyl chain, such as ethyl oleate [22,23,24], isopropyl myristate [17, 25, 26], or renewable feedstock oils [27] to name a few.

A particular biocompatible nonionic surfactant is Tween 20 or polysorbate 20, which is ethoxylated sorbitan monolaurate with 20 EO units on average. It is a rather hydrophobic surfactant in nature and by itself typically not very good for solubilizing oils in form of swollen micelles/microemulsion droplets. However, it can be a good partner with other surfactants like lecithin in forming microemulsions, e.g., with peppermint oil [28]. Of course, cosurfactants like alkanols can also enhance the propensity for microemulsion formation with Tween 20 [29].

In the present study, we suggest a new biocompatible microemulsion formulation based on Tween 20 (Tw20), isopropyl palmitate (IPP), and 2-ethyhexylglycerin (EHG). The cosurfactant EHG is a non-toxic compound frequently used in cosmetics [30]. In this work, EHG is presented as an alternative for medium-chain alcohols as cosurfactant to enhance solubilization. There has been a small number of studies on microemulsions employing EHG as cosurfactant, which showed that it can lead efficiently to the formation of microemulsion with anionic surfactants like dodecyl ethoxy sulfate [31,32,33] or nonionic surfactants like alkyl polyglucosides [31,32,33]. IPP is frequently used in cosmetic and pharmaceutical formulations and is a more polar oil compared to alkanes. In our work, we systematically varied the EHG content and determined the phase behavior, with a focus on the formation of microemulsions with solubilized IPP. In the ternary systems at higher EHG concentration, not only globular micellar aggregates are observed but also liquid crystalline (LC) phases. The structures in the microemulsion region, formed upon addition of IPP, were characterized comprehensively by means of static and dynamic light scattering (SLS/DLS) and small-angle neutron scattering (SANS), as in particular small-angle scattering has been shown to be a very powerful method for characterizing microemulsions [34]. This characterization led to a consistent picture regarding the ability of EHG to enable Tw20 to become a surfactant system able to effectively form microemulsions. The central aim of this investigation then was to relate the molecular composition of the amphiphilic system to its ability to form microemulsions and here we were particularly interested in the situation where the amphiphilic monolayer is largely dominated by the presence of the EHG.

Materials and methods

Materials

The chemicals used in this work are all approved for usage in cosmetics and/or food products. Polyoxyethylene (20) sorbitanmonolaurate, also known as Tween 20, is a non-ionic surfactant which is a common food additive to stabilize oils, for example in dairy products [35]. Tween 20 (53% C12, the rest mostly C14 and C18) was obtained from Sigma-Aldrich. 2-Ethyhexylglycerin, a chemical approved for cosmetic formulations, is used for its amphiphilic and antimicrobial properties [30]. 2-Ethylhexylglycerin (> 99%) was obtained from Clariant as a gift. Isopropyl palmitate (technical grade, 90%) was purchased from Sigma-Aldrich. All chemicals were used without further purification. The samples were prepared in Milli-Q water or D2O (> 99.9% D, Eurisotop).

Sample preparation

The Tw20 concentration was kept fixed at 50 mM for all samples presented in this work. For the preparation of a given sample, the appropriate amounts of Tw20, EHG, IPP, and water were added to cylindrical 4 mL glass vials. The exact weight of each component was noted down to work with the exact concentrations (error below 0.5%). The samples were vortexed for 30 s and then rolled overnight before use. Samples designated for use in SANS experiments were prepared with D2O instead of Milli-Q water, where the concentrations were retained by taking into account the density of D2O. The D2O was filtered with a 0.2 μm cellulose acetate filter prior to use. Any physical effects of switching H2O for D2O are neglected. Samples at the IPP solubilization boundary were prepared by adding an excess amount of IPP to the appropriate ternary Tw20/EHG solution in a cylindrical glass vial with a septum cap. The samples were then turned upside down and centrifugated for 5 min at 4500 rpm to ensure complete phase separation. The fully saturated O/W microemulsion phase was then extracted using a syringe while keeping the vial upside down. For a better comparability among samples, the parameters are discussed as functions of the molar ratio of EHG to Tw20 X = c(EHG)/c(Tw20).

Methods

Phase behavior

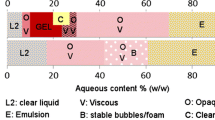

The phase diagram was created by preparing various ternary Tw20/EHG/water samples, which were then split into 10 parts, 2.5 mL each. Increasing amounts of IPP were then added to each part. This increases the overall volume and thus both the Tw20 and EHG concentrations decrease compared to their original values. To remedy this, we first calculate the new final concentrations of all three components and then normalize by the Tw20 concentration thus yielding the ratios X = c(EHG)/c(Tw20) and Y = c(IPP)/c(Tw20) as the x- and y-axes, respectively. The resulting phase diagram is discussed further below (see Fig. 1).

Section of the phase diagram of the quaternary system Tw20/EHG/IPP/water at 25 °C. The L1 microemulsion phase (in blue) is found up to an EHG to Tw20 ratio of X = 12, where the solubilization capacity is maximized. In the lower right corner of the phase diagram, i.e., at high EHG and low IPP concentrations, various different bi- and triphasic regions are found

Light scattering

Static (SLS) and dynamic (DLS) light scattering measurements were performed simultaneously with a Litesizer 500 instrument from Anton Paar (Graz, Austria), equipped with a 40 mW semiconductor laser diode with a wavelength λ = 658 nm. The scattering angle was kept fixed at θ = 90°. All samples were measured using a low volume 3 × 3 mm quartz cuvette at a constant temperature of 25 °C. All given values represent averages of ten individual measurements with a measurement time of 10 s each.

The static light scattering intensities were normalized to Itoluene,θ=90°. Given the laser wavelength λ, the scattering angle θ and the refractive index of the solvent n, the magnitude of the scattering vector q = \(\frac{4\pi n}{\lambda }\mathrm{sin}\left(\frac{\theta }{2}\right)\) is 0.022 nm−1. For small particles, i.e., where qR ≪ 1, the scattering intensity is only weakly dependent on the scattering angle. Since this generally holds for microemulsion droplets, we shall make here the approximation that I(θ = 90°) ≈ I0, where I0 is the forward scattering intensity. I0 is directly proportional to the effective molecular weight Mw,eff of the scattering particles

where f is a contrast factor that depends on the employed radiation, in this case either light or neutrons

Here, NAv is Avogadro’s constant, cg the total mass concentration of scatterers, n the refractive index of the solvent, \((d\mathrm{n}/d{\mathrm{c}}_{\mathrm{g}})\) the refractive index increment, \(\overline{\rho }\) the average density of the scatterer, ϕ the volume fraction, and ΔSLD the difference of scattering length density between scatterer and solvent. Details about the calculation of \((d\mathrm{n}/d{\mathrm{c}}_{\mathrm{g}})\) and \(\Delta SLD\) can be found in the supplementary information.

For DLS, the normalized intensity-autocorrelation function g(2)(τ) was fitted using a monoexponential decay \({g}^{\left(2\right)}\left(\tau \right)-1=\beta \mathrm{exp}\left(-2\Gamma \tau \right)\) to determine the decay rate Γ (the amplitude β is a correction factor). For diffusing particles, Γ is related to the translational diffusion coefficient D via

The diffusion coefficient D is given by the Stokes–Einstein relation

where kB is the Boltzmann constant, T is the temperature, ffr the friction coefficient (here for a spherical particle), η is the viscosity and Rh is the hydrodynamic radius of the diffusing particle. For some samples, a bimodal simple exponential fit was used according to

where x1, x2 and Γ1, Γ2 are the fractions and decay rates of two differently sized species, respectively.

Small-angle neutron scattering

Small-angle neutron scattering (SANS) experiments were carried out on the D11 instrument of the Institut Laue-Langevin (ILL, Grenoble, France), using a sample changer with 6 sample positions and 1 mm path length cylindrical quartz cuvette cells. The samples were kept at a temperature of 25 °C during the experiments. Two configurations with sample-to-detector distances of 2.5 and 20.5 m, collimation lengths of 5.5 and 20 m, and a wavelength of 4.6 Å were used to cover a total q-range of 0.003 to 0.488 Å−1. Some additional SANS measurements were performed on the ZOOM instrument at ISIS Pulsed Neutron and Muon Source in Didcot, UK. These samples were measured at 25 °C in cylindrical quartz cuvette cells with 1 mm path length with a pinhole collimation of 4 m and a sample-to-detector distance of 8 m to cover a q-range of 0.004 to 0.489 Å−1. Neutrons of wavelengths λ of 1.75–16.5 Å were used simultaneously by time-of-flight. Data reduction for D11 data was done using GRASP software [36]. For the ZOOM data, MANTID software [37] was used. The raw intensity data were corrected for the background scattering and weighted by the transmission of the sample [38]. In addition, a Cadmium sample was used to subtract the electronic background noise. For normalization and absolute scaling, a 1 mm reference sample containing distilled water was used as an isotropic scatterer. The 2D data were finally radially averaged to give the 1D scattering intensity.

Results and discussion

Phase diagram

The quaternary system Tw20/EHG/IPP/water shows a complex phase behavior that depends on the ratio of its four components as well as temperature. In this work, we focus on the formation of microemulsion and in particular, look at a specific section of the phase diagram where the Tw20 concentration is kept fixed at 50 mM and the EHG and IPP concentrations are varied. The temperature was fixed at 25 °C. The resulting phase diagram is shown in Fig. 1 using the molar concentration ratios X = c(EHG)/c(Tw20) and Y = c(IPP)/c(Tw20) as the x- and y-axes, respectively. For the ternary system Tw20/EHG/water (along the x-axis in Fig. 1), we can identify three single phase regions. For low EHG ratios X < 2 an optically isotropic L1 phase is formed. After a two-phase region, the samples become birefringent for X > 2.5, indicating the presence of a lamellar Lα phase before another two-phase region starts at X = 6.4. For X > 6.8 another low-viscous isotropic phase is formed, which due to its location in the phase diagram is presumed to be a sponge phase (L3). Upon addition of IPP, the different phases are all transformed into a single phase state of micelles swollen with oil or microemulsion droplets (L1) [8]. The L1 phase extends up to X = 12, i.e., very large cosurfactant excess, while for still higher EHG content no longer a monophasic L1 phase can be formed. At such high EHG:Tw20 ratios, the phase diagram shows many different biphasic and even triphasic regions as a function of both EHG and IPP content. Since we are mainly interested in the solubilization capacity, these regions were not studied further. At the same time, the solubilization capacity for IPP increases continuously to reach a maximum ratio of Y ≈ 10. The samples show no signs of phase separation, even after centrifugation, indicating the presence of microemulsion droplets. For X = 12 and Y = 10, the volume fraction of the dispersed phase is 0.37. The dispersed phase itself is made up of 51% surfactant + cosurfactant and 49% oil. The microemulsions could thus also be referred to as swollen micelles. Note also, that the amphiphilic film is largely dominated by the EHG, making up more than 92% in number and more than 69% in volume. At such high volume fractions of the dispersed phase, significant interparticle interactions are expected, or even a percolated structure.

A pure 50 mM Tw20 solution solubilizes close to no IPP. An exact determination of the solubilization capacity is thus challenging. Quantitative NMR measurements are not possible, because the large number of different Tw20 protons prevents singling out a defined IPP peak. The only remaining option is to add IPP to a large volume of a 50 mM Tw20 solution and to visually check whether all IPP is solubilized or not. Using this procedure, we could deduce that the solubilization capacity for IPP of a pure 50 mM Tw20 solution is less than 0.57 mM. This means that adding EHG increases the solubilization capacity more than 900 times compared to the pure Tw20 solution. From the solubilization enhancement, it is possible to estimate the reduction in chemical potential ΔμIPP of the IPP which is incurred upon the EHG addition via \(\Delta {\mu }_{\mathrm{IPP}}=RT\mathrm{ln}\left({x}_{2,\mathrm{IPP}}/{x}_{1,\mathrm{IPP}}\right)\), where x2,IPP and x1,IPP are the mole fractions of IPP in the microemulsion droplets with and without added EHG. From this calculation, we obtain ΔμIPP > 9.1 kJ/mol, which describes the reduction of the chemical potential of IPP in the Tw20 micelles by the addition of 600 mM EHG (X = 12). This reduction quantifies the large driving force for the observed formation of the microemulsion phase. It is also interesting to note that the phase behavior shown in Fig. 1 resembles quite a bit the effect of 1-hexanol on the solubilization of decane in aqueous solutions of TDMAO [11]. The volume fractions of solubilized oil are similar but the molar ratio of 1-hexanol to TDMAO is much smaller (by a factor 10) than here. In addition, the maximum solubility is reached for cosurfactant concentrations in the center of the ternary lamellar phase, while here the L1 phase extends to much higher cosurfactant concentrations.

Light scattering

Light scattering experiments were performed on samples at the solubilization boundary up to c(EHG) = 600 mM or X = 12. From the static scattering intensity, the effective molecular weight Mw,eff was calculated using Eqs. (1) and (2). Mw,eff can be converted into an apparent radius Rapp for a spherical particle with homogeneous density \({\overline{\rho }}_{\mathrm{agg}}\) (for details, see supplementary information). It is also instructive to divide the microemulsion droplets into a core and a shell, where the core is made up of IPP and the hydrocarbon tails of Tw20 and EHG and the shell is made up of the head groups of Tw20 and EHG (assuming all molecules to be contained in the aggregates). The core volume Vc is given by \({V}_{c}={V}_{\mathrm{IPP}}+{V}_{\mathrm{Tw}20,\mathrm{tail}}+{V}_{\mathrm{EHG},\mathrm{tail}}\), where the volume of each component can be calculated using the known molar concentrations \(c\), molar masses M and densities ρ of all components:

Here, i can refer to either IPP or the hydrocarbon tails of Tw20 and EHG. The core radius is then readily calculated by assuming a spherical core with homogeneous density \({\overline{\rho }}_{\mathrm{core}}\) (volume-weighted average of the densities of the core components). As for DLS, the measured intensity auto-correlation functions g(2)(τ) were fitted using a bimodal simple exponential model (Eq. (6)). The three radii Rapp, Rc and Rh are shown as a function of the EHG:Tw20 ratio X in Fig. 2.

The hydrodynamic radius Rh coincides well with Rapp just being slightly larger which can be explained by the hydration of the head groups and the resulting extension into the aqueous surroundings. This finding corroborates the presence of O/W microemulsion droplets with radii increasing from 3.8 nm for the pure Tw20 case to up to 19.1 nm at X ≈ 10. The increase in size is explained by a decreased spontaneous curvature of the surfactant film upon the addition of cosurfactant [39]. This leads to larger droplets and a higher solubilization capacity. The presence of a bimodal correlation function indicates that there is a second, much slower dynamic process taking place next to the diffusion of the microemulsion droplets. From Mw,eff, we can also calculate the number of Tw20 and EHG molecules per droplet NTw20 and NEHG, using the known molar concentrations of all components. If we assume that the interface between water and the droplet core is made up of the head groups of Tw20 and EHG, we find that

where Adroplet is the droplet interfacial area, and ao,Tw20 and ao,EHG are the head group areas of Tw20 and EHG, respectively. ao,Tw20 is readily calculated from the pure Tw20 micelles, where NEHG = 0, which yields a value of 0.58 nm2, which compares well to the value of 0.595 nm2 deduced from surface tension measurements at 20 °C [40]. Plotting Adroplet/NTw20 (Fig. 3) shows a substantial increase of the value with increasing EHG content, which proves that the EHG resides at the amphiphilic interface and increases it correspondingly. This increase is very marked for lower X values but then levels of around X = 5, which indicates that additional EHG molecules are only little surface active. Assuming that \({N}_{\mathrm{EHG}}={N}_{\mathrm{Tw}20} c(\mathrm{EHG})/c(\mathrm{Tw}20)\), i.e., all EHG molecules are at the interface, we can derive

which means that ao,EHG is available from the slope of a linear fit of the left hand side of Eq. (9) versus c(EHG) (cTw20 is constant at 50 mM). Using this procedure, we find ao,EHG = (0.26 ± 0.03) nm2. This value can be compared to that of 0.1 nm2 previously reported for 1-hexanol at the amphiphilic interface with TDMAO [11]. Apparently, the EHG requires a substantially larger area than 1-hexanol at the amphiphilic interface, which is to be expected given the much bulkier head group with two hydroxyl groups instead of just one. Consequently, the addition of EHG initially leads to an increase of the head group area, which then levels off continuously and remains rather constant for X values above 5. With rising EHG content, an increasing amount of EHG becomes incorporated more into the core of the aggregates instead of its palisade layer. All relevant parameters from the light scattering experiments are shown in Table 1.

Small-angle neutron scattering

To get further insight into the structure of the microemulsions, small-angle neutron scattering (SANS) experiments were performed on a number of samples at various EHG:Tw20 ratios X. The resulting scattering spectra are shown in Fig. 4. The three spectra with the highest EHG concentrations were measured on the ZOOM instrument (ISIS, Didcot, England). Since the samples showed signs of multiple scattering, only neutrons with wavelengths λ < 7 Å were considered, explaining the smaller q-range. The scattering curves for the oil-swollen droplets up to X = 2 show the typical scattering patterns of globular aggregates, just increasing in intensity with increasing EHG content and shifting the intensity decrease in the range of 0.05–0.1 Å−1 a bit to lower q, both indicating the growth of these droplets. For higher EHG content, the scattering patterns stay generically similar but the intensity increase becomes much more marked. In addition, a correlation peak appears with increasing EHG content. Going from X = 0 to X = 5, the volume fraction of dispersed material (neglecting the hydration water of the surfactant head group) increases from 0.055 to 0.182. Such high volume fractions induce an enhanced ordering of the microemulsion droplets, explaining the correlation peak.

For a quantitative analysis, the spectra were fitted with a core–shell ellipsoid model. The core consists of IPP, EHG and the hydrocarbon Tw20 surfactant tail, while the shell consists of the Tw20 surfactant head group and water. We tested three different ways of distributing EHG: (a) completely into the core, (b) completely into the shell, and (c) the hydrocarbon tail into the core and the rest into the shell. For the discussion below, option (a) was chosen since it yielded the best fit results. The choice between (a) and (c) influences mainly the volumes and SLDs of the core and shell. A detailed description of the model can be found in the supporting material. The model has four free parameters. The first one is the number of Tw20 molecules per aggregate NTw20, which fixes the molecular weight of the aggregate since the exact molar concentrations of Tw20, EHG and IPP are known (assuming that all molecules are incorporated into the aggregates in the corresponding proportions). The second parameter is the aspect ratio of the rotational ellipsoid ε = Rax/Req, where Req and Rax are the equatorial and the axial radii, respectively. For oblate ellipsoidal particles, ε < 1 while for prolate ellipsoidal particles ε > 1. Here, it should be noted that the ellipticity could also be interpreted as an effective polydispersity of the droplet radii, as both have a similar effect on the experimentally observed scattering curves (in our model, we neglected the possibility of a polydispersity of the particle size/volume and this parameter is exclusively contained in ε). The third main parameter α is the amount of water in the shell. The Tw20 head group is very large and contains ethylene oxide (EO) groups, which bind a lot of water. Thus, it can be assumed that the shell volume will consist of a large degree of water. In the model, the water content is characterized by the parameter \(\alpha\) through \({V}_{shell}={N}_{Tw20}{v}_{m,head}\left(1+\alpha \right)\), where Vshell is the total volume of the shell and vm,head is the molecular volume of the Tw20 head group (the core volume is made up of the volumes of IPP, EHG and the hydrocarbon tails of Tw20). The last fit parameter λshs is part of the sticky hard-sphere structure factor and controls the attractive interaction of the spheres, where λshs = 0 means the purely repulsive hard sphere case and λshs \(>0\) describes an attractive interaction [41]. The fitted curves are included in Fig. 4 and compared to the experimental scattering data. The core–shell model fits were performed up to q = 0.15 Å−1. At higher values of q, the model prediction (broken lines) deviates significantly from the data points. The core–shell model assumes a step-wise contrast profile, and thereby a sharp interface between shell and solvent which yields a q−4 power law decay in high-q according to Porod’s law [42]. In reality, the shell contrast, arising from the Tw20 head groups, will decrease continuously, as the oligomeric (EO)n chains will protrude into the solvent in a more or less coiled fashion. This explains the power law decay with an exponent close to 2, which corresponds to a Gaussian polymer chain [43]. However, we did not analyze the high q-behavior in any further detail as it should not be relevant to the phase behavior of the microemulsion studied here.

The results for the fit parameters elucidate the structural changes taking place when increasing the EHG concentration. The Tw20 aggregation number NTw20 (Fig. 5A) shows a steady increase from 42 up to 971 for X = 5, indicating the formation of generally larger droplets with higher EHG content. This increase is particularly marked for ratios X > 2. At the same time, the aspect ratio ε decreases to lower values (Fig. 5B), meaning the particles become more ellipsoidal and/or more polydisperse (where for higher EHG content, a softening of the amphiphilic monolayer would be expected, which would result in a higher degree of polydispersity [9]). At the same time, the amount of water incorporated into the shell increases dramatically by about a factor 10, from an α value of ~ 2.6 to ~ 19 (Fig. 5C). This corresponds to 130 or 940 water molecules per Tw20 head group, respectively (see Fig. S1 in the supplementary information). Dividing by 20 yields 6.5 or 47, which is the number of water molecules per EO unit in the surfactant head group. A possible explanation for the large amount of water is that upon EHG addition, the Tw20 molecules are pushed further apart. This is quantified by the values for the area per Tw20 molecule (Table 2), which show an increase by more than a factor of two for the presence of 250 mM EHG (X = 5). This increase of the space between the (EO)n groups leads to a much larger volume in the shell, which has to be filled with water. The particles also show increasing degrees of attraction as shown by λshs (Fig. 5D). The attractiveness is likely mediated by the presence of the EHG with its multiple OH-groups in the amphiphilic layer. In that context, it is interesting to note that Cazabat and co-workers have previously reported an ellipsoidal shape and attractiveness for O/W microemulsion droplets made up of sodium dodecyl sulfate (SDS), butanol and toluene in brine [44]. In addition, there have been reports of a short-range attractive interaction between microemulsions droplets that have been attributed to the overlapping of surfactant hydrocarbon tails [45] or to the perturbation of the dilute surfactant solution which coexists with the surfactant incorporated into the droplets [46]. Since the attractive potential is short-ranged, the influence becomes stronger with an increase in droplet size. Here, it might also be noted that SANS is not really able to distinguish between ellipsoidal deformation and polydispersity.

In Fig. 5E, the radii of the core and shell are shown, where Rsphere represents the radius of a volume-equivalent sphere to the respective ellipsoid and tshell is the shell thickness. Both the equatorial and the axial radii increase steadily and reach maximum values of 32 nm and 8.1 nm, respectively, at X = 5. From the Tw20 aggregation number NTw20 and the core radius Rc,sphere of the pure Tw20 micelles, we can again calculate the amount of interfacial area per Tw20 molecule Adropet/NTw20. The value at X = 0 corresponds to the Tw20 head group area a0,Tw20 and is found to be a0,Tw20 = 0.70 nm2, which is slightly larger than the value determined from light scattering. With increasing EHG content, Adropet/NTw20 increases to a value of up to 1.42 nm2. Using the same procedure as outlined for light scattering (see Fig. 3), we retrieve a value of a0,EHG = (0.18 ± 0.03) nm2, a similar, but somewhat smaller value as deduced from the light scattering results before. The difference here may arise from the fact that in SANS, we assume an ellipsoidal shape and in SLS a spherical one, where both differ in their surface-to-volume ratio.

Conclusion

In this work, we have demonstrated a new biocompatible microemulsion formulation based on Tw20, EHG as surfactant and cosurfactant which can solubilize a large amount of the polar oil IPP. Keeping the Tw20 concentration constant at 50 mM, we found that the oil solubilization capacity increases immensely upon addition of EHG. The monophasic droplet microemulsion extends up to an EHG concentration of 600 mM, which corresponds to a cosurfactant to surfactant ratio of X = 12. At the same time, the IPP solubilization capacity also steadily increases up to an increase by a factor of 900 compared to the value seen for the pure surfactant solution. Apart from the enormous increase of solubilization, it is also very interesting to note that for this system, the amphiphilic film of the microemulsion is dominated by the cosurfactant EHG. This is also confirmed by the large increase of the interfacial area upon EHG addition.

From light scattering experiments, we concluded that O/W droplets with hydrodynamic radii ranging from 3.8 to 19.1 nm are formed. For the Tw20 head group area, we found a value of 0.58 nm2, which is in good agreement with previously reported values of 0.595 nm2 [40] or 0.5 nm2 [47]. The obtained SANS spectra were fitted with an ellipsoidal core–shell model to find that the droplets assume an oblate ellipsoidal shape. Furthermore, large amounts of water are incorporated into the shell. The aggregation numbers reported in SANS are generally a bit smaller than the ones from light scattering. The most probable reason for this is that the samples used for SANS were prepared at IPP concentrations slightly below the solubilization boundary. This could also explain to some extent the ellipticity of the droplets. The biocompatibility of the surfactant and cosurfactant combined with a high solubilization capacity for polar oils makes this system very promising for applications in cosmetics or drug delivery, as very large amounts of such oils can become dispersed in a thermodynamically stable way.

References

Lawrence MJ, Rees GD (2000) Microemulsion-based media as novel drug delivery systems. Adv Drug Deliv Rev 45:89–121. https://doi.org/10.1016/S0169-409X(00)00103-4

Paul BK, Moulik SP (1997) Microemulsions: an overview. J Dispers Sci Technol 18:301–367. https://doi.org/10.1080/01932699708943740

Klier J, Tucker CJ, Kalantar TH, Green DP (2000) Properties and applications of microemulsions. Adv Mater 12:1751–1757. https://doi.org/10.1002/1521-4095(200012)12:23%3c1751::AID-ADMA1751%3e3.0.CO;2-I

Bellocq AM, Biais J, Bothorel P et al (1984) Microemulsions. Adv Colloid Interface Sci 20:167–272. https://doi.org/10.1016/0001-8686(84)80005-6

Miller CA, Ghosh O, Benton WJ (1986) Behavior of dilute lamellar liquid-crystalline phases. Colloids Surf 19:197–223. https://doi.org/10.1016/0166-6622(86)80336-5

Shinoda K (1967) The correlation between the dissolution state of nonionic surfactant and the type of dispersion stabilized with the surfactant. J Colloid Interface Sci 24:4–9. https://doi.org/10.1016/0021-9797(67)90270-6

Kahlweit M, Strey R (1985) Phase behavior of ternary systems of the type H2O–oil–nonionic amphiphile (microemulsions). Angew Chem Int Ed 24:654–668. https://doi.org/10.1002/anie.198506541

Gradzielski M, Duvail M, de Molina PM et al (2021) Using microemulsions: formulation based on knowledge of their mesostructure. Chem Rev 121:5671–5740. https://doi.org/10.1021/acs.chemrev.0c00812

Gradzielski M (1998) Effect of the cosurfactant structure on the bending elasticity in nonionic oil-in-water microemulsions. Langmuir 14:6037–6044. https://doi.org/10.1021/la980074c

Israelachvili JN, Mitchell DJ, Ninham BW (1976) Theory of self-assembly of hydrocarbon amphiphiles into micelles and bilayers. J Chem Soc Faraday Trans 2(72):1525–1568. https://doi.org/10.1039/F29767201525

Gradzielski M, Hoffmann H, Langevin D (1995) Solubilization of decane into the ternary system TDMAO/1-hexanol/water. J Phys Chem 99:12612–12623. https://doi.org/10.1021/j100033a039

Kunieda H, Aoki R (1996) Effect of added salt on the maximum solubilization in an ionic-surfactant microemulsion. Langmuir 12:5796–5799. https://doi.org/10.1021/la960472k

Gupta S, Moulik SP (2008) Biocompatible microemulsions and their prospective uses in drug delivery. J Pharm Sci 97:22–45. https://doi.org/10.1002/jps.21177

el Maghraby GM (2008) Transdermal delivery of hydrocortisone from eucalyptus oil microemulsion: effects of cosurfactants. Int J Pharm 355:285–292. https://doi.org/10.1016/j.ijpharm.2007.12.022

Yaghmur A, Aserin A, Garti N (2002) Phase behavior of microemulsions based on food-grade nonionic surfactants: effect of polyols and short-chain alcohols. Colloids Surf A Physicochem Eng Asp 209:71–81. https://doi.org/10.1016/S0927-7757(02)00168-1

Constantinides PP, Scalart J-P (1997) Formulation and physical characterization of water-in-oil microemulsions containing long- versus medium-chain glycerides. Int J Pharm 158:57–68. https://doi.org/10.1016/S0378-5173(97)00248-2

Acharya A, Sanyal SK, Moulik SP (2001) Physicochemical investigations on microemulsification of eucalyptol and water in presence of polyoxyethylene (4) lauryl ether (Brij-30) and ethanol. Int J Pharm 229:213–226. https://doi.org/10.1016/S0378-5173(01)00863-8

Gupta S, Sanyal SK, Datta S, Moulik SP (2006) Preparation of prospective plant oil derived micro-emulsion vehicles for drug delivery. Indian J Biochem Biophys 43:254–7. http://nopr.niscpr.res.in/handle/123456789/3289. Accessed 26 Apr 2020

Zana R (1995) Aqueous surfactant-alcohol systems: a review. Adv Colloid Interface Sci 57:1–64. https://doi.org/10.1016/0001-8686(95)00235-I

Kaur G, Mehta SK (2017) Developments of polysorbate (Tween) based microemulsions: preclinical drug delivery, toxicity and antimicrobial applications. Int J Pharm 529:134–160. https://doi.org/10.1016/j.ijpharm.2017.06.059

Gradzielski M, Horbaschek K, Deme B (2019) Effect of biocompatible esters and alcohols as cosurfactants on structure and solubilization behavior of the zwitterionic surfactant tetradecyldimethylamine oxide. Ind Eng Chem Res 58:2596–2605. https://doi.org/10.1021/acs.iecr.8b05232

Park KM, Kim CK (1999) Preparation and evaluation of flurbiprofen-loaded microemulsion for parenteral delivery. Int J Pharm 181:173–179. https://doi.org/10.1016/S0378-5173(99)00029-0

Hwang SR, Lim SJ, Park JS, Kim CK (2004) Phospholipid-based microemulsion formulation of all-trans-retinoic acid for parenteral administration. Int J Pharm 276:175–183. https://doi.org/10.1016/J.IJPHARM.2004.02.025

Kaur G, Chiappisi L, Prévost S et al (2012) Probing the microstructure of nonionic microemulsions with ethyl oleate by viscosity, ROESY, DLS, SANS, and cyclic voltammetry. Langmuir 28:10640–10652. https://doi.org/10.1021/la300540d

Moreno M, Frutos P, Ballesteros MP et al (2000) Release of nortriptyline hydrochloride from oil-water microemulsions. Chem Pharm Bull 48:1623–1627. https://doi.org/10.1248/cpb.48.1623

Chiappisi L, Noirez L, Gradzielski M (2016) A journey through the phase diagram of a pharmaceutically relevant microemulsion system. J Colloid Interface Sci 473:52–59. https://doi.org/10.1016/j.jcis.2016.03.064

Klossek ML, Touraud D, Kunz W (2012) Microemulsions with renewable feedstock oils. Green Chem 14:2017–2023. https://doi.org/10.1039/C2GC35035A

Chen H, Guan Y, Zhong Q (2015) Microemulsions based on a sunflower lecithin–Tween 20 blend have high capacity for dissolving peppermint oil and stabilizing coenzyme Q10. J Agric Food Chem 63:983–989. https://doi.org/10.1021/jf504146t

Mehta SK, Bala K (2000) Tween-based microemulsions: a percolation view. Fluid Phase Equilib 172:197–209. https://doi.org/10.1016/S0378-3812(00)00378-2

Aerts O, Verhulst L, Goossens A (2016) Ethylhexylglycerin: a low-risk, but highly relevant, sensitizer in “hypo-allergenic” cosmetics. Contact Derm 74:281–288. https://doi.org/10.1111/COD.12546

Khan A, Lindstrom B, Shinoda K, Lindman B (1986) Change of the microemulsion structure with the hydrophile-lipophile balance of the surfactant and the volume fractions of water and oil. J Phys Chem 90:5799–5801. https://doi.org/10.1021/j100280a065

Fukuda K, Olsson U, Ueno M (2001) Microemulsion formed by alkyl polyglucoside and an alkyl glycerol ether with weakly charged films. Colloids Surf B Biointerfaces 20:129–135. https://doi.org/10.1016/S0927-7765(00)00183-1

Shinoda K, Kunieda H, Arai T, Saijo H (1984) Principles of attaining very large solubilization (microemulsion): inclusive understanding of the solubilization of oil and water in aqueous and hydrocarbon media. J Phys Chem 88:5126–5129. https://doi.org/10.1021/j150665a065

Prévost S, Gradzielski M, Zemb T (2017) Self-assembly, phase behaviour and structural behaviour as observed by scattering for classical and non-classical microemulsions. Adv Colloid Interface Sci 247:374–396. https://doi.org/10.1016/j.cis.2017.07.022

Hu X, Zhang X, Chen D et al (2019) How much can we trust polysorbates as food protein stabilizers - the case of bovine casein. Food Hydrocoll 96:81–92. https://doi.org/10.1016/j.foodhyd.2019.05.013

Dewhurst C (2003) GRASP: graphical reduction and analysis SANS program for Matlab

Arnold O, Bilheux JC, Borreguero JM et al (2014) Mantid—data analysis and visualization package for neutron scattering and μ SR experiments. Nucl Instrum Methods Phys Res A 764:156–166. https://doi.org/10.1016/j.nima.2014.07.029

Chen S-H, Lin T-L (1987) 16. Colloidal solutions. In: Price DL, Sköld K (eds) Methods in Experimental Physics. Academic Press, pp 489–543

Strey R, Jonstroemer M (1992) Role of medium-chain alcohols in interfacial films of nonionic microemulsions. J Phys Chem 96:4537–4542. https://doi.org/10.1021/j100190a075

Szymczyk K, Zdziennicka A, Jańczuk B (2018) Adsorption and aggregation properties of some polysorbates at different temperatures. J Solution Chem 47:1824–1840. https://doi.org/10.1007/s10953-018-0823-z

Baxter RJ (1968) Percus-Yevick equation for hard spheres with surface adhesion. J Chem Phys 49:2770–2774. https://doi.org/10.1063/1.1670482

Porod G (1951) Die Röntgenkleinwinkelstreuung von dichtgepackten kolloiden Systemen. Kolloid-Zeitschrift 124:83–114. https://doi.org/10.1007/BF01512792

Debye P (1947) Molecular-weight determination by light scattering. J Phys Colloid Chem 51:18–32. https://doi.org/10.1021/j150451a002

Cazabat AM, Langevin D, Meunier J, Pouchelon A (1982) Critical behavior in microemulsions. Adv Colloid Interface Sci 16:175–199. https://doi.org/10.1016/0001-8686(82)85016-1

Huang JS, Safran SA, Kim MW et al (1984) Attractive interactions in micelles and microemulsions. Phys Rev Lett 53:592–595. https://doi.org/10.1103/PhysRevLett.53.592

Pincus PA, Safran SA (1987) Solvent induced attractions in micelles and microemulsions. J Chem Phys 86:1644–1645. https://doi.org/10.1063/1.452209

Łuczak J, Latowska A, Hupka J (2015) Micelle formation of Tween 20 nonionic surfactant in imidazolium ionic liquids. Colloids Surf A Physicochem Eng Asp 471:26–37. https://doi.org/10.1016/j.colsurfa.2015.02.008

Gradzielski M, Schmidt RF, Simon M et al (2020) Testing different microemulsion model predictions for the structure scaling in the bicontinuous regime. Institut Laue-Langevin (ILL). https://doi.org/10.5291/ILL-DATA.9-10-1704

Gradzielski M, Doutch J, Omasta T, Schmidt R (2022) Self-assembly of selected sugar surfactants in choline chloride-urea natural deep eutectic solvent and their mixtures with terpenoids. STFC ISIS Facility. https://doi.org/10.5286/ISIS.E.RB2210341

Funding

Open Access funding enabled and organized by Projekt DEAL. We thank the Fonds der chemischen Industrie (FCI) and the Technische Universität Berlin for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest. However, one of the authors (M. Gradzielski) is guest editor of this special issue “100 Years Colloid Society / Colloid Science—as Modern as Ever”.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Schmidt, R.F., Prause, A., Prévost, S. et al. Phase behavior and structure of a biocompatible microemulsion based on Tween 20, 2-ethylhexylglycerine and isopropyl palmitate in water. Colloid Polym Sci 301, 753–762 (2023). https://doi.org/10.1007/s00396-023-05119-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05119-9