Abstract

In this paper, we prepared monodisperse porous silica nanospheres (SiO2 NSs) to adsorb organic dyes. The obtained porous SiO2 NSs have uniform size of ~ 350 nm in diameter. Zeta potential result reveals the obtained porous SiO2 NSs are negative charged. The adsorption property of porous SiO2 NSs was analyzed by various influenced factors, such as adsorbent doses, adsorption time, removal efficiency, and adsorption capacity and recycle adsorption capability. In a very short adsorption time of 5 min, the obtained porous SiO2 NSs have efficient removal efficiency of 99.71% (for Alcian blue) and 99.06% (for methylene blue) and high adsorption capacity of 250 mg/g (for Alcian blue) and 160 mg/g (for methylene blue), higher than previously reported adsorbents. Recycle adsorption experiments (using calcination method) show that porous SiO2 NSs could be recycled at least six times while the removal efficiency had no significant decrease (< 2%).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the rapid development of economy, the toxic pollutants in industrial, agricultural, and domestic discharged water have seriously threatened the natural water resources [1, 2]. Among those pollutants, dyes, due to high color density and severe harms to aquatic organisms and environment, have attracted widespread attention [3,4,5,6,7,8]. Thus, it is essential to remove dyes from discharged water [9]. Current treatment methods of dyes in wastewater include coagulation, flocculation, photo degradation, solvent extraction, and electrochemical method [10,11,12,13,14]. However, those methods still have the limits of low efficiency, high costs, and complex operating steps [15]. Besides the above methods, adsorption strategy has been widely used to remove dyes due to low cost, easy operation, and high efficiency [16,17,18]. So far, various types of adsorbents, including polymer, zeolite, modified clay, activated carbon, and carbon nanotubes, have been developed [19, 20]. However, these materials for removing of dyes still face several challenges in terms of high adsorption efficiency, easy separation, and high recyclability [21]. Therefore, it is extremely necessary to develop an adsorbent with advantages of non-toxicity, low cost, easy separation, high efficiency, and recyclability.

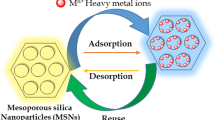

In recent years, the advancements of nanomaterial have been widely highlighted in the treatment of dye wastewater [22,23,24,25,26,27]. Porous silica nanospheres (SiO2 NSs) have been widely used as adsorbent due to their distinguishing features, such as good biocompatibility and high surface area [28, 29]. In this paper, we obtained porous SiO2 NSs by NaOH treatment for SiO2 NSs, a sample and cost-effective method [22,23,24,25, 30]. And the obtained porous SiO2 NSs were used as an efficient and recyclable adsorbent for cationic organic dyes. Some cationic organic dyes such as Alcian blue and methylene blue both have very stable molecular structures which make them difficult for degradation. Porous SiO2 NSs can efficiently remove of these dyes from water owing to the strong electrostatic interactions between negative charged porous SiO2 NSs and positive charged organic cationic dye molecules. However, in order to use porous SiO2 NSs as an ideal absorbent, the obtained porous SiO2 NSs should be dispersed homogeneously in water and easily be separated from water after dye adsorption through simple precipitation method. This requires the prepared SiO2 NSs should have moderate size. Porous SiO2 NSs with small size (< 200 nm) are not easy to precipitate even adsorbed with dyes. We found that porous SiO2 NSs with size of ~ 350 nm can well disperse in water without dyes and have been precipitated in a short time (less than 10 min) after adsorbed with dyes (showed in Fig. 1a–d). Moreover, when calcined dye adsorbed porous SiO2 NSs at 550 °C for 6 h, the calcined SiO2 NSs can well redispersed in water (Fig. 1e, f). During the calcination, the adsorbed dye molecules will convert to carbon dioxide at high temperature, while porous SiO2 NSs can maintain stable after calcination because of their good thermal stability. These results suggest that the prepared porous SiO2 NSs possess the potential advantages as an efficient and recyclable adsorbent for cationic organic dyes.

Experimental

Experimental reagents

Ammonia solution (25%) and ethanol were purchased from Tianli Chemical Reagent Co., Ltd, China. Tetraethyl orthosilicate (TEOS, A. R.) was purchased from Tianjin Guangfu Fine Chemical Research Institute, China. Sodium hydroxide (G. R.) was purchased from Beijing Chemical Reagent Factory, China. Deionized water (MilliQ, 18.3 MΩ·cm) was used in all experiments. Alcian blue (AB), methylene blue (MB), Congo red (CR), and Coomassie Brilliant Blue (CB) were purchased from Sigma Chemical Co. (St. Louis, MO, USA).

Characterization

The morphology of the silica products was investigated by scanning electron microscopy (SEM; Hitachi, S4800, Tokyo, Japan) and transmission electron microscopy (TEM; JEM-1200EX, Tokyo, Japan). The composition of the products was identified by using Fourier-transform infrared spectrometer (FT-IR; Optical Instrument Co., Ltd. Tianjin, China) in the range of 4000 to 400 cm−1 using KBr disk method. X-ray diffraction (XRD; SHIMADZU, Kyoto, Japan) was used to further confirm the crystallographic structure of the samples. It was exposed to Cu-Kα radiation under 30 kV and 30 mA. The scan speed was 4°/min and the range (2θ) was from 5° to 70°. Dynamic light scattering (DLS) was used to characterize the size distribution of the obtained silica nanospheres. The thermogravimetric data (TG) of the samples were assessed with a NETZSCH STA 449CDSC/DTA-TG analyzer scanning from 23 to 600 °C under an air atmosphere. The samples were weighted and introduced into aluminum pans. The pans were heated at a constant rate of 10 °C/min in nitrogen atmosphere with an empty aluminum pan as the reference probe. The sample mass was in the range of 5~7 mg. All samples were run in duplicate. Furthermore, the adsorption experiments of AB, MB, CR, and CB from aqueous solution on SiO2 NSs and porous SiO2 NSs were studied by UV-vis absorbance spectrophotometer (PerkinElmer Lambda 605S UV/Vis spectrometer). Deionized water was used as blank sample. N2 adsorption-desorption measurements were performed on a MicroActive for ASAP-2460 instrument (sample mass, 0.1269 g; equilibration interval, 10 s; sample density, 1.000 g/cm3), using Brunauer–Emmett–Teller (BET) calculations for surface area and Barrett–Joyner–Halenda (BJH) calculations for pore size distribution. To investigate the surface charge of the products, zeta (ζ) potentials were performed on the samples by using a Malvern Nano ZS ZEN3600 instrument. Measurements were averaged over 12 runs in deionized water at pH = 7.0.

Preparation of porous SiO2 NSs

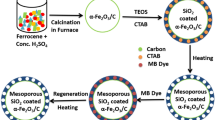

The preparation of porous SiO2 NSs adopted the modified reported methods [31]. The detailed preparation process was illustrated in Scheme 1. Brifely, 18 mL of ammonia solution, 24.8 mL of ethanol, and 9.8 mL of H2O were mixed together in an Erlenmeyer flask. The mixture was stirred (1000 rpm) for 10 min. Then, 1.8 mL of TEOS was rapidly added into the flask. After 1 min, the stirring speed was adjusted to 500 rpm. After that, the experiment was further reacted for 2 h. The products were collected by centrifugation and rinsed by deionized water for several times. After that, 0.3 g lyophilized silica nanospheres were dispersed in 10 mL H2O with the aid of ultrasonication. To get porous SiO2 NSs, according to the reported method [32], 0.063 g of NaOH was added into silica nanosphere dispersion. After being treated for 24 h, the products were collected by centrifugation at 10,000 rpm for 2 min and washed with deionized water and absolute ethanol successively for at least five times. After that, they were lyophilized for 24 h for further dye adsorption.

Adsorption of dyes by the obtained porous SiO2 NSs

We chose two cationic dyes (AB, MB) and two anionic dyes (CR, CB) as model dyes; chemical structures of these four dyes are shown in Fig. 2. The maximum absorption wavelength of AB, MB, CR, and CB solutions locates in 601, 664, 498, and 595 nm, respectively. And the molecular weights of AB, MB, CR, and CB solutions are 1298.88, 373.90, 696.66, and 825.97, respectively. The model dyes’ solution of AB (2 mmol/L), MB (6 mmol/L), CR (0.07 mmol/L), and CB (0.05 mmol/L) was prepared. The adsorption capacity (q e) was calculated according to the reported equation [32]:

where C 0 and C e are the initial and the equilibrium concentrations of dyes in the test solution (mg/L), V is the volume of the testing solution (L), and W is the weight of the adsorbent (g). Furthermore, the adsorption property of porous SiO2 NSs was analyzed by different influenced factors including adsorbent dosages and adsorption time. Concrete experiments are as follows.

Effect of different adsorbent dosages on the adsorption of dyes

The different dosages of SiO2 NSs and porous SiO2 NSs were ranged from 0 mg to 100 mg, respectively. The dosage interval was 10 mg. Adsorbents were dispersed in 4 mL of dye solutions. After adsorbed for 5 min, the mixture was centrifuged. Absorbance of the supernatant was measured by UV-vis spectrophotometer.

Effect of different adsorption time on the adsorption of dyes

The different adsorption time ranged from 0 to 10 min was carried out. Forty milligram SiO2 NSs and 40 mg porous SiO2 NSs were weighed accurately and dispersed in 4 mL of dyes, respectively. The time interval was 1 min. After centrifugation, the absorbance of each supernatant was recorded.

Recycling experiment

To study the recyclability of the adsorbents, the precipitations were dried and calcined by a muffle furnace for 6 h at 550 °C to desorb dyes. After calcination, the products were reused to adsorb dyes. Such “adsorption-calcination-adsorption” process was repeated for several times. The removal efficiency (D) of each time was calculated according to the following equation [33].

where A 0 and A are the absorbance of the dye solutions before and after the adsorption.

Results and discussion

The morphologies of the obtained SiO2 products are shown in Fig. 3. SEM (Fig. 3a) and TEM (Fig. 3b) images both clearly reveal that SiO2 particles before NaOH treatment are spheres with smooth surfaces in uniform size. Figure 3c (SEM) shows these NaOH-treated SiO2 particles are monodisperse spheres with various pores distributed on the surface. Figure 3d (TEM) further reveals the porous structure of NaOH-treated SiO2 particles. Comparing the morphological results between SiO2 and porous SiO2 showed in Fig. 3, it seemed that the size of the products has increased a little after being treated with NaOH solution. This was further demonstrated by size distribution results (DLS, in Fig. 4); SiO2 NSs have average diameter of 350 nm (Fig. 4a), while porous SiO2 NSs have average size of 370 nm (Fig. 4b). This may be caused by NaOH treament of SiO2 NSs. NaOH might change the structure of SiO2 NSs during the produce of pores both on the surface and inside part of the nanospheres by dissolving part of the silica nanospheres. Thus, water molecules will run into the pores of porous SiO2 NSs. Subsequently, during the freeze-drying process, water molecules will freeze and expand. Therefore, such “NaOH treament-freeze-drying process” makes the size of porous SiO2 NSs a little larger than the initial SiO2 NSs [34]. In order to study the porosity and pore size distribution of the SiO2 NSs before treatment with NaOH and porous SiO2 NSs, the Brunauer–Emmett–Teller (BET) measurements were carried out. BET surface area of SiO2 NSs before treatment with NaOH is 37 m2/g, with an average pore size of 2.17 nm (Fig. S1). While the larger surface area of 259 m2/g is achieved for porous SiO2 NSs with an average pore size of 4.31 nm (Fig. 5) after being treated by NaOH, these data suggest that the porous SiO2 NSs can supply lots of adsorption sites for organic dye molecules.

Figure 6 (XRD pattern) presents an obvious broad diffraction peak of porous SiO2 NSs at 2θ = 23°, which confirms the amorphous structure of porous SiO2 NSs. Figure 7 presents the FT-IR spectra of silica samples and dyes (AB and MB) adsorbed silica nanospheres. Figure 7a presents the spectrum of naked porous SiO2 NSs. The absorption peaks located at 465 and 804 cm−1 are ascribed to the bending and symmetric stretching vibration of Si-O-Si linkages, while the strong peak near 1089 cm−1 is assigned to the anti-symmetric stretching vibration of Si-O-Si linkages [35]. And the weak peak located at 945 cm−1 is ascribed to the bending vibration of Si-OH bond. The broad absorption peak located at 3443 cm−1 and the peak at 1635 cm−1 might ascribe to hydrogen bond of water molecules, which may be attributed to the surface adsorbed water during preparation procedures or from air humidity [36]. Figure 7 further indicates that the characteristic absorption peaks of AB (located at 1394 cm−1; Figure 7b) and MB (located at 1389, 1337 cm−1; Fig. 7d) have appeared in the spectrum of silica samples after adsorption of AB (Fig. 7c) and MB (Fig. 7e), respectively. As the dye adsorbed silica sample has been thoroughly washed before FT-IR measurement, thus, the results in Fig. 7c, e indicate that the adsorbed dyes molecules might have been tightly anchored to those porous silica nanospheres. This may probably due to the electrostatic interaction between cationic dye molecule and anion porous silica nanospheres.

To further validate the electrostatic interaction between dye molecules and porous silica nanospheres, we compared the zeta potential distribution of porous SiO2 NSs and porous SiO2 NSs adsorbed with four individual dyes (Fig. 8). It was found that porous SiO2 NSs present negative charged surface (− 46.6 mV; Fig. 8a). After adsorbing cationic dyes of AB and MB, the surface charges were increased up to about − 25 mV (Fig. 8b, c). These changes may be because the adsorbed positively charged dye molecules had neutralized the surface negative charge on those porous silica nanospheres. As the zeta potential increased, it can be inferred that the stable dispersion of the porous silica nanospheres will be decreased after adsorbing dyes, which would result precipitation. While, after adsorbing anionic dyes of CR and CB, the surface charge of those porous SiO2 NSs increased a little (− 37.1 mV for CR adsorbed samples, Fig. 8d; − 38.4 mV for CB adsorbed samples, Fig. 8e). These changes may suggest that the repulsion between negative charged porous SiO2 NSs and anionic dyes has restricted the adsorption of dyes by silica nanospheres. Therefore, the small amount of adsorbed dyes could not affect the surface charge of those porous SiO2 NSs obviously. Thermogravimetric analysis (TGA; Fig. 9) further proved that those porous SiO2 NSs have only adsorbed small amount of anionic dyes. The small weight loss (1.41%) on porous SiO2 NSs in TGA curve (Fig. 9a) may due to the adsorbed water molecules. Figure 9b, c indicates that porous SiO2 NSs have adsorbed amounts of 96.25 wt% for AB and 95.13 wt% for MB, respectively. The similar adsorption capacities of porous SiO2 NSs to AB and MB probably due to the molecular size of MB is smaller than that of AB, which results in the more molecules bonded to the surface of porous SiO2 NSs. While for CR and CB (Fig. 9d, e), the adsorbed amounts are only 5.18 and 2.07 wt%. Such difference probably because the molecule size of CB is larger than that of CR, which may obstruct the adsorption.

As porous SiO2 NSs are insufficient for adsorbing CB and CR, we focus on the detailed adsorption properties of porous SiO2 NSs on AB and MB in the following investigation. In order to determine the optimal volume and initial concentrations of dyes solution before adsorption experiment, we have investigated the effect of the different AB and MB solution volume and initial concentration on the adsorption capacity of porous SiO2 NSs according to the Eq. (1). As shown in Fig. S2, the maximum adsorption capacities were calculated at optimal dyes solutions volume of 4 mL. Then, we used 40 mg of AB and 50 mg of MB to adsorb 4 mL of AB and MB solutions with different initial concentrations; the results are shown in Fig. S3. And the maximum adsorption capacities were calculated at initial dyes solutions concentration of 2 and 6 mmol/L, respectively. Then, we analyzed the adsorption performance of porous SiO2 NSs mainly from two aspects including different adsorbent dosages and adsorption time. The effect of different adsorbent dosages on the adsorption of AB and MB is displayed in Fig. 10. Figure 10a, b shows the increasing adsorbent dosages of porous SiO2 NSs will decrease the absorbance at 601 nm (maximum absorption peak of AB) and 664 nm (maximum absorption peak of MB) gradually. The needed dosage of porous SiO2 NSs to almost completely adsorb AB (99.71 wt%) and MB (99.06 wt%) is only 40 and 50 mg, respectively. The insets in Fig. 10a, b show the images of AB (2 mmol/L, left image) and MB solutions (6 mmol/L, left image) and the supernatants after adsorption by porous SiO2 NSs (right image). It is obvious that the blue color of AB and MB solutions has faded in the supernatant. Both the disappearance of absorption peak and the color fade indicate that the porous SiO2 NSs have strong adsorption capability for cationic dyes AB and MB solutions. Figure 10c, d shows the statistical results of the adsorption rates under various dosages of porous SiO2 NSs. To further investigate maximum adsorption capacity of these porous SiO2 NSs, we use calibration curve method based on UV-vis spectroscopy as our work reported previously [37]. First, AB (2 mmol/L) and MB (6 mmol/L) solutions were diluted and placed into a curette and analyzed by UV-vis spectroscopy at 601 and 664 nm, respectively. Then, the calibration curves were determined by taking absorbance versus dyes concentration between 0 and 4 × 10−3 mmol/L for AB and 0 and 1.4 × 10−3 mmol/L for MB as parameters. For the intervals, the calibration curves fit Lambert and Beer’s law:

where A is the absorbance and C is the concentration (mmol/L). Equations (3) and (4) are the calibration curves for AB and MB, respectively. The calculated results reveal that the porous SiO2 NSs have maximum adsorption capacities of 250 and 160 mg/g for AB and MB, respectively.

The effect of different porous SiO2 NSs doses on the adsorption of AB and MB by a, b absorbance spectra of porous SiO2 NSs-AB and porous SiO2 NSs-MB under various porous SiO2 NSs doses, respectively. c, d The statistical results of removal efficiency for AB and MB vs different adsorbent doses of porous SiO2 NSs. The insert pictures are the color change of AB and MB solution before and after adsorption, respectively (n = 3, *P < 0.05)

Figure 11 further provides the effect of adsorption time on the adsorption behavior of porous SiO2 NSs in AB and MB solutions under optimal adsorbent dosage, respectively. For porous SiO2 NSs, when reaction time reached 5 min, AB and MB molecules could be removed completely (Fig. 11a, b). These results display the adsorption behavior of AB and MB by porous SiO2 NSs is adequately fast. Figure 11c, d shows the statistical results of the adsorption rates under various adsorption times. Such fast adsorption of AB and MB from water solution may due to the large surface area of porous SiO2 NSs. Except for these two aspects of different adsorbent dosages and adsorption time, we also discussed the effect of different pH values on the adsorption behavior of porous SiO2 NSs in AB and MB solutions under optimal adsorbent dosages and adsorption time. The results were shown in Fig. S4. With the increasing pH values, the adsorption capacity increased until reaching the maximum value at pH = 7 for porous SiO2 NSs. This may be explained the increase of negatively charged sites on the surface of porous SiO2 NSs resulted in more adsorption of the cationic dyes.

The effect of different adsorption time on the adsorption of AB and MB by a, b absorbance spectra of porous SiO2 NSs-AB and porous SiO2 NSs-MB under various adsorption time, respectively. c, d The statistical results of removal efficiency for AB and MB vs different adsorption time. The insert pictures are the color change of AB and MB solution before and after adsorption, respectively. (n = 3, *P < 0.05)

The recyclability of porous SiO2 NSs was also investigated. Recycling experiment was performed for six cycles (adsorption-desorption), and the results are shown in Fig. 12. In the first run, a very high removal efficiency of AB and MB is up to 99.71 and 99.06%, respectively. At the sixth cycle, the removal efficiency is still 97.75 ± 0.08% (for AB) and 97.96 ± 0.05% (for MB), which has no significant decrease (less than 2%; Fig. 12a). Figure 12b further directly shows the adsorption and desorption results of dyes by porous SiO2 NSs in the recycling experiments. It is apparent that the porous SiO2 NSs have good recycling adsorption capability for AB and MB.

We have carried out the contrast experiment of dyes adsorption by SiO2 NSs before the treatment of NaOH and porous SiO2 NSs (Fig. S5). The contrast results clearly indicated the adsorption capacity and efficiency of porous SiO2 NSs are much larger than those of SiO2 NSs before the treatment of NaOH. The improvement of adsorption capacity and efficiency of porous SiO2 NSs are attributed to the increasing surface area and pore size. Thus, the remove of dyes by porous SiO2 NSs from aqueous solution is more rapid and efficient process (Fig. S5a, b) than those of using SiO2 NSs before the treatment of NaOH.

A comparison of the adsorption efficiency, adsorption capacity, and adsorbent recyclability for MB in this paper and the reported results are summarized in Table 1. It is obvious that the adsorption efficiency and adsorption capacity of MB by the presented porous SiO2 NSs are larger (99.06%, 160 mg/g) and the adsorbent recyclability (6 cycles) is remarkably more than those materials reported previously [33,33,34,35,37]. For instance, Varghese reported that adsorption efficiency and adsorption capacity of γ-MnOOH nanorods as adsorbent for the removal of MB are 89% and 24 mg/g, respectively. The adsorbent recyclability for equilibrium is 3 cycles [38]; Fan reported that adsorption efficiency and adsorption capacity of sludge-derived biochar as adsorbent for the removal of MB is 95% and 16.25 mg/g, respectively. The adsorbent recyclability for equilibrium is three cycles [39]. Therefore, these porous SiO2 NSs can be used as rapid and efficient adsorbent to remove cationic dyes from aqueous solution.

Conclusions

In this work, we prepared monodisperse porous silica nanospheres with the average size of ~ 350 nm. The obtained porous silica nanospheres can rapidly and efficiently remove 99–100% dye molecules of AB and MB as soon as 5 min. The adsorption capacity of those porous silica nanospheres is as high as 100–200 mg/g for the cationic dyes. Besides, we also found that these porous SiO2 NSs have a high recycling capability. Our results demonstrate that the obtained porous SiO2 NSs can be used as ideal, rapid, efficient, and recyclable adsorbent to remove cationic dyes from water.

References

Echeveste P, Malagón CG, Dachs J, Berrojalbiz N, Agustí S (2016) Toxicity of natural mixtures of organic pollutants in temperate and polar marine phytoplankton. Sci Total Environ 571:34–41

Nuengmatcha P, Chanthai S, Mahachai R, Oh WC (2016) Sonocatalytic performance of ZnO/graphene/TiO2 nanocomposite for degradation of dye pollutants (methylene blue, texbrite BAC-L, texbrite BBU-L and texbrite NFW-L) under ultrasonic irradiation. Dyes Pigments 13:487–497

Srivastava S, Sinha R, Roy D (2004) Toxicological effects of malachite green. Aquat Toxicol 66:319–329

Koley P, Sakurai M, Takei T, Aono M (2016) Facile fabrication of silk protein sericin-mediated hberarchical hydroxyapatite-based bio-hybrid architectures: excellent adsorption of toxic heavy metals and hazardous dye from wastewater. RSC Adv 89:86607–86616

Atchudan R, Edison TNJI, Perumal S, Karthikeyan D, Lee YR (2017) Effective photocatalytic degradation of anthropogenic dyes using graphene oxide grafting titanium dioxide nanoparticles under UV-light irradiation. J Photochem Photobiol A Chem 333:92–104

Wang J, Bai R (2016) Formic acid enhanced effective degradation of methyl orange dye in aqueous solutions under UV-vis irradiation. Water Res 101:103–113

Kumar DP, Reddy NL, Karthikeyan M, Chinnaiah N, Bramhaiah V, Kumari VD, Shankar MV (2016) Synergistic effect of nanocavities in anatase TiO2 nanobelts for photocatalytic degradation of methyl orange dye in aqueous solution. J Colloid Interface Sci 477:201–208

Shen Y, Wang W, Xiao K (2016) Synthesis of three-dimensional carbon felt supported TiO2 monoliths for photocatalytic degradation of methyl orange. J Environ Chem Eng 4:1259–1266

Chaudhuri H, Dash S, Ghorai S, Pal S, Sarkar A (2016) SBA-16: application for the removal of neutral, cationic, and anionic dyes from aqueous medium. J Environ Chem Eng 4:157–166

Kasperchik VP, Yaskevich AL, Bil’dyukevich AV (2012) Wastewater treatment for removal of dyes by coagulation and membrane processes. Pet Chem 52:545–556

Hameed YT, Idris A, Hussain SA, Abdullah N (2016) A tannin-based agent for coagulation and flocculation of municipal wastewater: chemical composition, performance assessment compared to Polyaluminum chloride, and application in a pilot plant. J Environ Manag 184:494–503

Feng Y, Feng NN, Wei YZ, Zhang GY (2014) An in situ gelatin-assisted hydrothermal synthesis of ZnO–reduced graphene oxide composites with enhanced photocatalytic performance under ultraviolet and visible light. RSC Adv 4:7933–7943

Masklik E, Vaňura P (2005) Solvent extraction of lead using a nitrobenzene solution of strontium dicarbollylcobaltate in the presence of polyethylene glycol PEG 400. J Radioanal Nucl Chem 267:233–235

Yu RF, Lin CH, Chen HW, Cheng WP, Kao MC (2013) Possible control approaches of the Electro-Fenton process for textile wastewater treatment using on-line monitoring of DO and ORP. Chem Eng J 218:341–349

Bhatt AS, Sakaria PL, Vasudevan M, Pawar RR, Sudheesh N, Bajaj HC, Mody HM (2012) Adsorption of an anionic dye from aqueous medium by organoclays: equilibrium modeling, kinetic and thermodynamic exploration. RSC Adv 2:8663–8671

Cui W, Ji J, Cai YF, Li H, Ran R (2015) Robust, anti-fatigue, and self-healing graphene oxide/hydrophobically associated composite hydrogels and their use as recyclable adsorbents for dye wastewater treatment. J Mater Chem A 3:17445–17458

Imamoglu M, Tekir O (2008) Removal of copper (II) and lead (II) ions from aqueous solutions by adsorption on activated carbon from a new precursor hazelnut husks. Desalination 228:108–113

Zhuang X, Wan Y, Feng CM, Shen Y, Zhao DY (2009) Highly efficient adsorption of bulky dye molecules in wastewater on ordered mesoporous carbons. Chem Mater 21:706–716

Yaqub S, Pei LS, Mellon N, Shariff AM (2016) Performance evaluation of covalent organic polymer adsorbent prepared via microwave technique for CO2 and CH4 adsorption. Procedia Eng 148:249–253

Ihsanullah, Asmaly HA, Saleh TA, Laoui T, Gupta VK, Atieh MA (2015) Enhanced adsorption of phenols from liquids by aluminum oxide/carbon nanotubes: comprehensive study from synthesis to surface properties. J Mol Liq 206:176–182

Wang SM, Li ZH, Lu C (2015) Polyethyleneimine as a novel desorbent for anionic organic dyes on layered double hydroxide surface. J Colloid Interface Sci 458:315–322

Das SK, Khan MM, Parandhaman T, Laffir F, Guha AK, Sekaran G, Mandal AB (2013) Nano-silica fabricated with silver nanoparticles: antifouling adsorbent for efficient dye removal, effective water disinfection and biofouling control. Nano 12:5549

Parandhaman T, Das A, Ramalingam B, Samanta D, Sastry TP, Mandal AB, Das SK (2015) Antimicrobial behavior of biosynthesized silica-silver nanocomposite for water disinfection: a mechanistic perspective. J Hazard Mater 290:117–126

Parandhaman T, Pentela N, Ramalingam B, Samanta D, Das SK (2016) Metal nanoparticle loaded magnetic-chitosan microsphere: water dispersible and easily separable hybrid metal nano-biomaterial for catalytic applications. ACS Sustain Chem Eng 5:489–501

Ramalingam B, Khan MMR, Mondal B, Mandal AB, Das SK (2015) Facile synthesis of silver nanoparticles decorated magnetic-chitosan microsphere for efficient removal of dyes and microbial contaminants. ACS Sustain Chem Eng 3:2291–2302

Tang L, Wang JJ, Wang L, Jia CT, Lv GX, Liu N, Wu MH (2016) Facile synthesis of silver bromide-based nanomaterials and their efficient and rapid selective adsorption mechanisms toward anionic dyes. ACS Sustain Chem Eng 4:4617–4625

Jia WX, Lu DT, Shuang SM, Yang J, Dong C (2017) Facile synthesis of chitosan modified Fe3O4 magnetic nanoparticles for azo dye amido black 10B adsorption. J Nanopart Res 49:149–162

Yu Q, Wang P, Hu S, Hui JF, Zhuang J, Wang X (2011) Hydrothermal synthesis of hollow silica spheres under acidic conditions. Langmuir 27:7185–7191

Zhang TR, Zhang Q, Ge JP, Goebl J, Sun MW, Yan YS, Liu YS, Chang CL, Guo JH, Yin YD (2009) A self-templated route to hollow silica microspheres. J Phys Chem C 113:3168–3175

Xia HJ, Wan GP, Zhao JL, Liu JW, Bai Q (2016) Preparation and characterization of monodisperse large-porous silica microspheres as the matrix for protein separation. J Chromatogr A 471:138–144

Yoo WC, Stein A (2011) Solvent effects on morphologies of mesoporous silica spheres prepared by pseudomorphic transformations. Chem Mater 23:1761–1767

Ma JC, Wang XQ, Fu QX, Si Y, Yu JY, Ding B (2015) Highly Carbonylated cellulose Nanofibrous membranes utilizing maleic anhydride grafting for efficient lysozyme adsorption. ACS Appl Mater Interfaces 7:15658–15666

Seo D, Yun TS (2017) NOx removal rate of photocatalytic cementitious materials with TiO2 in wet condition. Build Environ 112:233–240

Hu XW, Du YM, Tang YF, Wang Q, Feng T, Yang JH, Kennedy JF (2007) Solubility and property of chitin in NaOH/urea aqueous solution. Carbohydr Polym 70:451–458

Xu BG, Chen L, Li YG, Luo P, Ma QK (2017) Study on the preparation of silica particles from chlorosilane residues. J Non-Cryst Solids 463:72–79

Hu WB, Li MM, Chen W, Zhang N, Li B, Wang M, Zhao ZM (2016) Preparation of hydrophobic silica aerogel with kaolin dried at ambient pressure. Colloids Surf A Physicochem Eng Asp 501:83–91

Chen ZH, Wang CH, Chen JZ, Li XD (2013) Biocompatible, functional spheres based on oxidative coupling assembly of green tea polyphenols. J Am Chem Soc 135:4179–4182

Varghese SP, Babub AT, Babuc B, Antonyb R (2017) γ-MnOOH nanorods: efficient adsorbent for removal of methylene blue from aqueous solutions. J Water Process Eng 19:1–7

Fan SS, Wang Y, Wang Z, Tang J, Tang J, Li XD (2017) Removal of methylene blue from aqueous solution by sewage sludge-derived biochar: adsorption kinetics, equilibrium, thermodynamics and mechanism. J Environ Chem Eng 5:601–611

Rabbani M, Seghatoleslami ZS, Rahimi R (2017) Selective adsorption of organic dye methylene blue by Cs4H2PMo11FeO40·6H2O in presence of methyl orange and Rhodamine-B. J Mol Struct 1146:113–118

Wang PF, Cao MH, Wang C, Ao YH, Hou J, Qian J (2014) Kinetics and thermodynamics of adsorption of methylene blue by a magnetic graphene-carbon nanotube composite. Appl Surf Sci 290:116–124

Nekouei F, Nekouei S (2017) Comparative evaluation of BiOCl–NPls–AC composite performance for methylene blue dye removal from solution in the presence/absence of UV irradiation: kinetic and isotherm studies. J Alloys Compd 701:950–966

Funding

This study was funded by the Natural Science Foundation of Liaoning Province (No. 20170540386) and National Natural Science Foundation of China (Nos. 81771987, 81471854, and 81671907).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 891 kb)

Rights and permissions

About this article

Cite this article

Lv, X., Zhao, M., Chen, Z. et al. Prepare porous silica nanospheres for water sustainability: high efficient and recyclable adsorbent for cationic organic dyes. Colloid Polym Sci 296, 59–70 (2018). https://doi.org/10.1007/s00396-017-4224-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4224-4