Abstract

Highly crystalline Cr-doped SrTiO3 nanoparticles were effectively synthesized with strontium acetate, titanium isopropoxide, and chromium nitrate as precursors via citric acid-assisted hydrothermal process followed by calcinations. The synthesized Cr-SrTiO3 NPs possess monodispersity with average particle size diameter 50 ± 5 nm, leading to agglomeration of NPs which might create grain boundaries and oxygen vacancies in the crystal. Doping of Cr into SrTiO3 lattice tailored the electronic structure which extended its absorption into the visible region. The photocatalytic activity was successfully explored to demonstrate the facile degradation of rhodamine-B (RhB) dye under visible light illumination. The result shows the excellent degradation (~77%) of RhB dye in short time span of 120 min and degradation followed the first-order reaction kinetics with rate constant k = 0.0103 min−1 .

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industrial development is pervasively connected with disposal of large number of various toxic pollutants that are not only harmful to the aquatic environment but also hazardous to human health as these pollutants are non-biodegradable [1, 2]. Industrial discharges including non-biodegradable dyes with azomoiety (N-N) which after anaerobic oxidations leads to potential carcinogenic products [3, 4]. To overcome these environmental problems, it is necessary to check out hazardous effluents before pouring them into water bodies. The conventional methods are remarkably ineffective for facile degradation which causes secondary pollution. Among reported techniques [5, 6], the semiconductor photocatalysis is widely accepted for effective degradation of toxic organic compounds into carbon dioxide and water or less harmful materials [7, 8].

Strontium titanate (SrTiO3) has been considered one of the promising photocatalytic candidates because of its excellent thermal stability and resistance to photo-corrosion [9, 10]. Domen et al. successfully reported its photocatalytic decomposition of water [11]. Because of its wide band gap (3.2 eV), it could respond only to UV region which upon doping tailored its electronic environment and extends its absorption into visible region which contributes ~48% solar spectrum [12]. The common and conventional methods for synthesis of SrTiO3 require high temperature which causes non-stoichiometry and uncontrolled growth of materials [12, 13]. In order to maintain stoichiometry, shape and homogeneity solution phase hydrothermal process is one of the alternative methods. Herewith, we report a facile synthesis of Cr-doped SrTiO3 nanoparticles by simple hydrothermal method and execute their photocatalytic activity by monitoring degradation of rhodamine B (RhB) under visible light illumination.

Experimental

Cr-doped SrTiO3 and bare SrTiO3 have been synthesized following similar procedure; first, an appropriate amount (6.7 mL) of titanium isopropoxide (TIPO) was dissolved in isopropanol (20 mL) under continuous stirring. Afterward, 10 mL citric acid (3.84 g) solution was added slowly into TIPO solution; here, it acts as chelating agent to bind with metal because as TIPO comes into contact with moisture, it would be reduced and precipitated. For effective doping of 1% atom by weight, 0.0238 g chromium nitrate was dissolved in water (10 mL), which was gradually added into freshly prepared strontium acetate (4.61 g) in 10 mL and the resulting solution was gradually added into the TIPO solution. After 30 min of vigorous stirring, the obtained solution was transferred into a Teflon-lined stainless steel autoclave and heated up to 80 ± 5 °C for 6 h. After completion of reaction, pale yellow crystalline powder was obtained, that was repeatedly washed with deionized water followed by ethanol and acetone and dried in oven at 50 °C. Then, it was calcined for 2 h at 600 °C followed by grinding into fine powder before characterization and photocatalytic application.

The photocatalytic activity of as-synthesized Cr-doped SrTiO3 nanoparticles has been performed upon the discoloration reaction of RhB dye in Pyrex flask reactor under xenon arc lamp (Toshiba, SHLS-1002) attached with UV cut-off filter. For the effective degradation, 0.15 g of Cr-SrTiO3 nanoparticles was added in 10 ppm RhB dye solution under continuous stirring. Prior to illumination, suspension was continuously stirred for 30 min to develop adsorption-desorption equilibrium between nanoparticles and dye. Afterward, the stable dye suspension was exposed to light illumination which is followed by measurement of the absorption behavior of decomposed dye repeatedly after time interval of 10 min using UV-vis spectrophotometer (2550-Shimadzu, Japan). The discoloration reaction obeyed the pseudo-first-order kinetics and rate constant was determined by the following relation: ln(C o/C) = kt, where k can be calculated from plot between ln(C o/C) vs. time interval and C o and C denote concentration of RhB dye at time t = 0 and t = t, respectively.

Results and discussion

The FESEM images of as-synthesized bare and Cr-doped SrTiO3 are depicted in Fig. 1a, b. The obtained results confirmed that there were no significant differences in size and morphology of bare and Cr-doped SrTiO3 NPs. Both as-synthesized bare and Cr-doped SrTiO3 NPs were spherical in shape showing homogeneous growth pattern. Interestingly, Cr-doped SrTiO3 NPs with average particle diameter 50 ± 5 nm which upon annealing at high temperature got agglomerated result in the development of grain boundary and oxygen vacancy in crystal lattice. Straumal et al. reported that the grain boundary and oxygen vacancies are responsible for enhanced photocatalytic activity [14, 15, 16]. The elemental composition of Cr-doped SrTiO3 NPs was estimated by energy-dispersive X-ray (EDX) spectroscopy (Fig. 1b inset), which shows an excellent agreement with desired percentage of atoms.

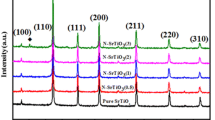

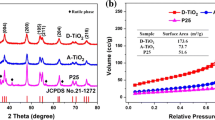

The crystallinity and crystal phase of as-synthesized Cr-doped SrTiO3 NPs are depicted in Fig. 1c. The prominent reflections appeared at 22.58°, 32.47°, 40.15°, 46.69°, 52.43°, 57.77°, 68.07°, and 77.38° corresponding to (100), (110), (111), (200), (210), (211), (220), and (310) hkl planes, respectively, and the result matched with JCPDS card number 350743. It was interesting to observe that there was no change in XRD pattern of Cr-doped SrTiO3 NPs since the ionic radii of six coordinated Cr3+ ions (0.61 Å) are similar to Ti4+ ion (0.61 Å) but smaller than Sr2+ ion (1.26 Å), which attributes that Cr3+ ion can be easily incorporated into the crystal lattice and there would be no change into the diffractogram [16]. The average particle size of Cr-SrTiO3 NPs was also enumerated by the Debye-Scherrer equation: D = Κλ/βcosθ, where D is mean particle size, Κ is a constant (0.94), λ corresponds to operating wavelength of diffractometer (Cu-Κα = 1.54 Å), θ is the Bragg angle, and β represents the full width at half maxima (FWHM) of a diffracted peak. By taking the FWHM at (110), the average particle size is found to be ~30 nm, which is inconsistent with FESEM result. Figure 1d shows the UV-vis diffused reflectance spectrum of Cr-SrTiO3 NPs at ambient temperature. The effective doping of Cr3+ ions into the SrTiO3 lattice tailored its electronic band structure and creates a donor level just above the valence band while conduction band remains unaltered, which effectively extends the steep of absorption of Cr-SrTiO3 NPs into the visible region. As shown in Fig. 1d, the strong absorption in 400–500 nm can be attributed to the charge transfer from Cr3+ to Ti4+, whereas the broad absorption around 580–750 nm could be due to d-d transition of 4A2 to 4T2 in Cr3+ in octahedral environment [17]. The band gap energy of Cr-SrTiO3 NPs can be calculated by using the equation E (eV) = 1240/λ (nm), where λ denotes absorption edge and E is the band gap energy of as-synthesized nanoparticles. However, the absorption edge of as-synthesized nanoparticles at ~480 nm corresponds to the band gap energy of about 2.58 eV.

X-ray photoelectron spectroscopy (XPS) was executed to analyze surface composition and valence states of elements present in as-synthesized Cr-SrTiO3 NPs. Figure 2a represents Sr spectrum; the binding energy peaks at 132.15 and 130.04 eV could be assigned to Sr 3d3/2 and Sr 3d5/2, respectively. Ti 2p spectrum as shown in Fig. 2b reveals two well-resolved binding energy peaks at ~457.5 and 463.2 eV corresponding to Ti 2p3/2 and Ti 2p1/2, respectively. The deconvoluted O1s spectra depicted in Fig. 2c reveal four fitted peaks at ~530.3, 531.2, 532.1, and 532.8 eV. The peak with binding energy ~530.4 eV could be ascribed for characteristic metal oxide peak [18]. The high-resolution Cr 2p spectrum depicted in Fig. 2d shows two peaks at 576.5 and 585.5 eV and could be assigned to Cr3+ 2p3/2 and Cr3+ 2p1/2, respectively, which infers that doping of Cr element into the SrTiO3 mainly presents in trivalent oxidation state [19]. The shifting of Ti 2p peaks from their position (464.3 and 458.6 eV) in the spectrum implies that doping of Cr into SrTiO3 successfully replaced the Ti4+ from their lattice site.

The photocatalytic activity of Cr-SrTiO3 NPs was executed by monitoring the degradation reaction of RhB dye under visible light illuminations. Figure 3a shows UV-vis spectra of decomposed RhB dye with respect to time and exhibited the maximum absorption wavelength at ~554 nm. The efficiency of dye degradation reaction mediated over Cr-SrTiO3 NP surface could be calculated by the following relation:

a UV-vis absorbance spectra of RhB dye as function of time over Cr-doped SrTiO3 nanoparticles under visible light illumination. b Extent of discoloration of RhB dye in every successive time interval. c The plot of A/A o of RhB dye degradation as a function of time. d Kinetics of RhB dye degradation for first-order linear plot lnC o/C = f(t)

where C o represents initial concentration and C denotes final concentration. As shown in Fig. 2b, ~77% RhB dye was degraded within 120 min under visible light illumination in the presence of Cr-SrTiO3 NPs while there was no appreciable degradation occurred in the absence of Cr-SrTiO3 NPs, which suggests that the degradation reaction is facilitated by the Cr-SrTiO3 NPs. Moreover, Fig. 3c illustrates the plot of A/A o vs. time for RhB degradation. It reveals that RhB dye is continuously degraded with the increase of time over Cr-SrTiO3 under light illumination, indicating the rapid degradation of RhB dye. The kinetics of RhB degradation as depicted in Fig. 3d is followed by pseudo-first-order kinetics. A plot between ln(C o/C) vs. time represents a straight line with slope that is equal to the apparent first-order rate constant k app (0.0103 min−1). This result is consistent with previously reported works for RhB degradation by other catalysts [20].

The mechanism of degradation reaction facilities by semiconductor could be explained on the basis of literature [21]. Illumination of photon with appropriate wavelength results in molecular excitation which leads to generation of electron-hole (e −/h +) pairs, i.e., promotion of electron to conduction band (CB) and generation of hole in valence band (VB). Firstly, photogenerated e − in CB moves towards the surface of Cr-SrTiO3 NPs and is scavenged by ubiquitous O2 to generate superoxide anion O2− which gets protonated to produce HOO• radicals. However, the unstable radicals further react with e − yielding H2O2. Holes h + in VB moves towards backside of Cr-SrTiO3 surface and reacts with H2O/OH− as well as with dye molecules to produce active species such as OH• and dye+. The following steps could be possible in RhB dye degradation reaction [22].

Therefore, formation of the active oxygen species {O2 •−, HOO•, or −OH} are responsible for facile degradation of RhB dye into less harmful minerals. Photogenerated e −/h + pairs recombine together if fail to reach on the NP surface which results in the sharp reduction in the photodegradation efficiency [23]. However, doping of Cr ion impurity into SrTiO3 lattice facilitates the mobility of photogenerated e −/h + pairs, i.e., discourage the recombination process, which results in the enhancement in photocatalytic degradation reaction.

Conclusion

The highly crystalline Cr- SrTiO3 NPs were successfully synthesized by facile low-temperature hydrothermal method followed by calcinations for 2 h at 600 °C in air furnace. As-synthesized Cr-SrTiO3 NPs exhibited homogeneous growth pattern with average particle diameter 50 ± 5 nm which upon annealing at high temperature got agglomerated, resulting in the development of grain boundary and oxygen vacancy in the lattice. The morphological property unfolds that Cr3+ ions successfully replacing Ti4+ ions from SrTiO3 lattice results in the lowering of band gap (2.58 eV) and, thus, it becomes visible light active. Doping of Cr ion also facilitates the mobility of photogenerated e −/h + pairs which leads to many-fold enhancement in photocatalytic degradation. Interestingly, more than three fourths of RhB dye degraded within 60 min under visible light illumination in the presence of Cr-SrTiO3 NPs while there was no appreciable degradation occurs in the absence of Cr-SrTiO3 NPs. The degradation reaction followed first-order kinetics with rate constant calculated k = 0.0103 min−1 .

References

Hoffman MR, Martin ST, Choi W, Bahnemann DW (1995) Chem Rev 95:69–96

Chen SHS, Wu TY, Juan JC, Teh CY (2011) J Chem Technol Biotechnol 86:1130–1158

McCann J, Ames BN (1976) Proc Natl Acad Sci U S A 73:950–954

Ameen S, Akhtar MS, Kim YS, Shin HS (2011) Appl Catal B Environ 103:136–142

Legrini O, Oliveros E, Braun AM (1993) Chem Rev 93:671–698

Herrmann JM (1999) Catal Today 53:115–129

Rahman QI, Ahmad M, Misra SK, Lohani M (2012) JNanosciNanotechnol 12:7181–7186

Umar A, Akhtar MS, Al-Hajry A, Al-Assiri MS, Almehbad NY (2012) Mater Res Bull 47:2407–2414

Burnside S, Moser JE, Brooks K, Gratzel M (1999) J Phys Chem B 43:9328–9332

Wang D, Ye J, Kako T, Kimura T (2006) J Phys Chem B 110:15824–15830

Domen K, Kudo A, Onishi T, Kosugi N, Kuroda H (1986) J.Phys.Chem. 90:292–295

Miyauchi M, Takashio M, Tobimatsu H (2004) Langmuir 20:232–236

Wang J, Yin S, Komatsu M, Sato T (2005) JEuropCeramSoc 25:3207–3212

Straumal BB, Protasova SG, Mazilkin AA, Myatiev AA, Straumal PB, Schutz G (2010) J Appl Phys 108:073923–073926

Mo SD, Ching WY, Chisholm MF, Duscher G (1999) Phys Rev B 60:2416–2424

Serpone N, Lawless D, Disdier J, Herrmann JM (1994) Langmuir 10:643–652

Liu JW, Chen G, Li ZH, Zhang ZG (2006) JSolid State Chem 179:3704–3708

Tanner RE, Liang Y, Altman EI (2002) SurfSci 506:251–271

Hii T, Kato T, Kudo AJ (2004) PhotochemPhotobiolA 163:181–185

Rahman QI, Ahmad M, Misra SK, Lohani M (2013) Mater Lett 91:170–174

Gaya UI, Abdullah AM (2008) J Photochem Photobiol C: Photochem Rev 9:1–12

Choi W, Termin A, Hoffman MR (1994) J Phys Chem B 98:13669–13679

Serpone N, Lawless D, Khairutdinov R (1995) JPhysChem 99:16646–16654

Acknowledgments

We are expressing our sincere thanks to Prof. K.M. Rafi, Director of JETGI, Barabanki, India, for his kind support and encouragement towards our research work. Authors would like to acknowledge the support of UGC start-up grant, New Delhi, India, for this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Rahman, Q.I., Ahmad, M. & Mehta, S.K. Hydrothermal synthesis of Cr-doped SrTiO3 nanoparticles for rhodamine-B dye degradation under visible light illumination. Colloid Polym Sci 295, 933–937 (2017). https://doi.org/10.1007/s00396-017-4085-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4085-x