Abstract

A series of spherical gold nanoparticles (AuNPs) stabilized by amphiphilic hyperbranched polymers, which have a hydrophilic hyperbranched polyethylenimine core and a hydrophobic shell formed by many long acidamide chains such as saturated palmitamide, octadecanamide, and unsaturated oleamide chains, were prepared by chemical reduction. The effect of the kinds and the ratio of the aliphatic chain in amphiphilic polymers, the amount of the amphiphilic polymers, and the storage time on their size, solubility, and stability in chloroform, toluene, petroleum ether, and n-butyl acetate was investigated by TEM, UV-vis. The results revealed that a high-concentration polymer with a double bond can greatly improve the organic solubility and stability of the AuNPs in the toluene, petroleum ether, and n-butyl acetate. All the AuNPs in different solvents could be used as highly efficient catalysts for the biphasic catalytic reduction of 4-nitrophenol. The effect of the concentration of AuNPs and the capping polymers, the volume of organic phase, and temperature on the turnover number (TON) values of AuNPs is also studied. Their TON values could be enhanced by the AuNPs capped with more polymers or selecting a good solvent. The maximum TON values of the AuNPs in different solvents are about 5040 which has never been reported in the heterogeneous catalytic reduction of 4-nitrophenol.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

4-Nitrophenol is one of the most intractable organic pollutants in industrial and agricultural wastewater, which leads to its notorious reputation. It is recorded in “the U.S. Environmental Protection Agency List of Priority Pollutants” due to its carcinogenic, mutagenic, and cyto- and embryotoxic potential in humans [1]. Thus, the interest in the catalysis of the reduction of 4-nitrophenol is also motivated because the product 4-aminophenol, as an important raw material, has been widely used in many fields. For example, it is an important intermediate in the manufacture of many analgesic and antipyretic drugs [2–4]. In recent years, due to the excellent catalytic properties of gold nanoparticles (AuNPs), as highly efficient, fast, and eco-friendly catalysts, AuNPs have been widely applied to the reduction of 4-nitrophenol [5, 6].

Correspondingly, much work has been concentrated on the synthesis of highly dispersed, size-controllable, long-term, and recyclable AuNPs [7, 8]. The high surface-to-volume ratio of AuNPs leads to a shift of the electron affinity and cohesive energy of the atoms, which accounts for their high catalytic activity [9]. However, one challenge in applying traditional AuNPs as catalysts is that small AuNPs generally tend to aggregate, due to their high surface energies, which results in the significant reduction or even loss of catalytic activity due to the reduction of active surface atoms. To overcome the kinetically unstable nature of AuNPs, various stabilizing agents have been explored to decorate their surface, such as citrate [10, 11], thiol-containing compounds [12–16], ionic surfactants [17–21], and polymers [22]. In particular, dendrimers [23, 24] and their less-defined hyperbranched [25–33] analogs are often used as stabilizers in water or organic solvents to enhance the stability and catalytic activity of AuNPs due to their specific spheroid-like shape and multifunctionality, and cost-effective synthesis for large-scale productions. For the reduction of 4-nitrophenol by NaBH4, the heterogeneous catalysis is considered to separate the catalyst and minimize contamination of metal residues in the products. In particular, organic/aqueous biphasic solutions have attracted much attention due to their convenient catalyst separation and reuse [34]. So the stabilizers for organic-soluble AuNPs are needed because 4-nitrophenol and the product 4-aminophenol are water-soluble. However, the stabilizers for the organic-soluble AuNPs were usually complicated and costly, which limited their further application in industry. For example, Liu et al. and Kojima et al. have designed and prepared a hyperbranched polymeric stabilizer terminated with a hydrophobic dendritic shell or quaternary ammonium by a multistep organic synthesis [35, 36]. Thus, there is a need to develop efficient and simple stabilizers for organic-soluble AuNPs. Tang et al. reported a simple synthesis of amphiphilic hyperbranched polyethylenimine (HPEI) modified with palmitic acid. These amphiphilic polymers exhibited a higher performance in stabilizing big-sized AuNPs in organic solvent than their linear analog [37]. In a subsequent study [38], the AuNPs capped with this amphiphilic HPEI were successfully used as efficient catalysts for the heterogeneous catalytic reduction of 4-nitrophenol by NaBH4. Comparing with the linear counterpart, the amphiphilic HPEI rendered the AuNPs to have a bigger turnover number (TON). However, the above-mentioned hyperbranched polymer used as the stabilizer of the AuNPs can only be dissolved in high-toxicity chloroform or dichloromethane whereas the solubility in the low-toxicity organic solvent is poor, which limited the range of their application. From both an economic and environmental point of view, solvents are a key factor. The use of low-toxicity solvents instead of chloroform or dichloromethane is becoming crucial for the chemical industry. Therefore, there is a need to synthesize a hyperbranched polymer with the tunable solubility in each organic solvent of interest for a specific application.

In this paper, we reported our research into the preparation of AuNPs stabilized by amphiphilic hyperbranched polymers, with a hydrophilic hyperbranched polyethylenimine (HPEI) core and a hydrophobic shell formed by many long acidamide chains such as saturated palmitamide(C16), octadecanamide (C18), and unsaturated oleamide (OC) chains in different solvents, such as toluent, n-butyl acetate, and petroleum ether, and their application in the reduction of 4-nitrophenol to 4-aminophenol by NaBH4 in an organic/aqueous biphasic solution. The amphiphilic polymer with a double bond can greatly improve the organic solubility of AuNPs in different solvents. The influence of solvents, the concentration of the polymer, and storing time on the size of AuNPs is studied systematically. At the same time, the catalytic performance of AuNPs stabilized by HPEI modified with unsaturated fatty acid in different solvents is evaluated by comparing with the ones stabilized by HPEI modified with saturated fatty acid.

Experimental

Materials

Hyperbranched polyethylenimines (HPEI; Aldrich, M n = 10 × 103 g/mol, M w/M n = 2.5) were dried under vacuum prior to use. HAuCl4 (A.R.) was purchased from Tianjin Yinda chemical company and used directly. 1,1′-Carbonyldiimidazole (Acros, 97 %) and oleic acid (Alfa Aesar, 90 %) were used directly. Deionized water was double-distilled before use. NaBH4 (A.R.), 4-nitrophenol (A.R.), and poly(N-vinylpyrrolidone) (PVP-K30) were purchased from Tianjin University Kewei Chemical Company and used directly. The syntheses of amphiphilic palmitic acid and octadecanoic acid-modified hyperbranched polymers have been published elsewhere [39, 40], which are shown in Scheme 1.

Preparation of the HPEI modified by oleic acid

As is shown in Scheme 1, the amphiphilic HPEI was synthesized according to the procedures in the literature [39, 40]. CDI, 4.86 g (30.0 mmol), was slowly added to the solution of oleic acid (8.47 g, 30.0 mmol) in 20 mL chloroform. The solution was stirred at room temperature for 1 h. Then, 1.0 g (0.1 mmol) of HPEI in 10 mL chloroform was added. The mixture was stirred at room temperature for 6 h and was refluxed for 24 h at 70 °C. After cooling down to room temperature, the mixture was washed three times with saturated sodium chloride solution and dried by anhydrous magnesium sulfate. Then the organic phase was dialyzed against chloroform for 2 days to remove the redundant 1,1′-carbonyldiimidazole and oleic acid. After removing the volatile, the products were kept at 40 °C in a vacuum oven overnight. 1H NMR and FT-IR spectra of the obtained polymers are shown in Fig. S1(a) and S1(b). 1H NMR (CDCl3): δ = 5.36 (s, –CO(CH2)7CH=CH(CH2)7CH3); 3.43 (s, –CH2CH2NHCO–); 3.00–2.12 (br, –CH2CH2NHCH2–); 2.02(s, –CO(CH2)6CH2CH=CHCH2(CH2)6CH3); 1.65 (br, –COCH2–); 1.28 (br, –COCH2(CH2)5CH2CH=CHCH2(CH2)6CH3); and 0.88 (t, –CH3). IR: ν = 1718 cm−1 (carbonyl group).

Preparation of AuNPs in different solvents using NaBH4 as reducing reagent

A methanol solution of HAuCl4 (2.5 × 10−2 M, 0.10 mL) was added into 9.5 mL of the organic solution of the polymer (the ratio of nitrogens of polymers to Au atoms was in the range of 0.1–10). This mixture was stirred for half an hour. Subsequently, a fresh methanol solution of NaBH4 (6.2 × 10−2 M, 0.40 mL) was added into this mixture under vigorous stirring. Immediately, the solution turned orange or red. After 10 min, the volatiles were evaporated off under reduced pressure at room temperature. The residue was dissolved in 10 mL of different solvents. These polymers in different solvents are used as templates and stabilizers to prepare AuNPs as depicted in Scheme 2.

Catalytic reduction of 4-nitrophenol using the AuNPs as catalysts in different solvents

To 20 mL of 4-nitrophenol aqueous solution (3.0 × 10−3 M), 1 mL of the prepared polymer-stabilized AuNPs solution was added. Subsequently, 3 mL of organic solution was added to dilute the organic phase to 4 mL. The mixture was thermostated at a fixed temperature. After solid NaBH4 (0.23 g, 6.0 mmol) was added to the mixture, the mixture was stirred vigorously with a mechanical stirrer. The reaction was stopped when the yellow color of the mixture disappeared.

Recovery and reuse of AuNPs in different solvents

When the catalytic reduction of 4-nitrophenol was over, the mixture was kept to be still till the obvious phase separation. The polymer-stabilized AuNPs existing in the organic phase were recovered by removing the aqueous phase containing the final products. If the volume of the organic phase became less than 4 mL, fresh organic solvents would be added to compensate it to be 4 mL again. The recovered catalyst solution was reused for the next batch of catalytic reaction through mixing with a new portion of aqueous solution of 4-nitrophenol and NaBH4.

Characterization

1H NMR spectra were recorded on a Varian INOVA 500 MHz spectrometer. The chemical shifts are given in parts per million (ppm). Tetramethyl silane (TMS) was used as the internal standard. UV-vis spectra were obtained from Purkinje General (China) T6 UV-vis Spectrophotometer. Transmission electron microscopy (TEM) observation was made on a Philips TECNAI G2 F20 operated at 200 kV. A small drop of micellar solution was deposited onto a preheated carbon-coated copper grid and dried at atmospheric pressure. Samples were also prepared by staining with phosphotungstic acid. FT-IR spectra were recorded on a BIO-BAD EAALIBUR FTA-3000 Fourier transform infrared spectrometer. Transmittance measurements were taken on the samples in KBr pellets.

Results and discussion

Preparation and characterization of AuNPs in different solvents

A series of amphiphilic hyperbranched polymers, which have a hydrophilic hyperbranched polyethylenimine (HPEI) core and a hydrophobic shell formed by many long acidamide chains such as palmitamide, octadecanamide, and oleamide, were prepared according to the procedure reported previously [38]. The resultant polymers are designated as HPEI-X y . X means the length of the chain (C16 and C18 mean the palmitamide and octadecanamide chains without a double bond, respectively; OC90 represents oleamide with a double bond and the purity of the oleic acid is 90 %); y means the ratio of the palmitamide (octadecanamide) or oleamide groups relative to the total amino groups of HPEI. The preparation condition of AuNPs dissolved in different solvents and the size of the resulting AuNPs are listed in Table 1. According to our previous results [38], HPEI-C160.73 and HPEI-C180.73 were only dissolved in chloroform or dichloromethane (composites 1 and 2 in Table 1). As shown in Table 1, HPEI-OC500.73 and HPEI-OC900.73 are not only dissolved in chloroform or dichloromethane but also dissolved in petroleum ether, toluene, and n-butyl acetate. Thus, we used these polymers as templates and stabilizers to prepare AuNPs with tunable solubility in different solvents.

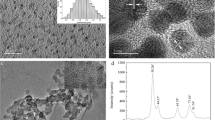

TEM images of the AuNPs stabilized by the HPEI-X y were used to identify their surface morphology and size distributions. As shown in Fig. 1, it is clear that AuNPs stabilized by HPEI-X y in different solvents displayed approximately spherical morphology. According to the TEM images with a 20-nm scale bar (more than 100 particles exist there) and the histograms of the AuNP size distribution (Fig. S2 in Supporting information), the mean diameters of the formed AuNPs were calculated, and the results are listed in Table 1. The UV-vis spectra of the solutions of HPEI-C160.73, HPEI-C180.73, HPEI-OC500.73, and HPEI-OC900.73 in chloroform or dichloromethane and of HPEI-OC900.73 in four different solvents are shown in Fig. S3 and S4, respectively. The surface plasmon resonance (SPR) peak at around 510 nm [38] is very weak or invisible, and all solutions exhibit a brown color. In chloroform or dichloromethane, the average sizes of AuNPs stabilized by HPEI-C160.73, HPEI-C180.73, HPEI-OC500.73, and HPEI-OC900.73 are all similar (composites 1–5 in Table 1). It is not obvious that the size of the formed AuNPs is affected by the kinds and the ratio of the aliphatic chain in amphiphilic polymers. For HPEI-OC900.73, the diameters of AuNPs in chloroform or dichloromethane (composites 4–5 in Table 1, Fig.1d) are a little bigger than the ones in toluene, n-butyl acetate, and petroleum (composites 6–8 in Table 1, Fig. 1e–g) when the ratio of [N]/[Au] is about 10. This implied that the degree of dispersion of the AuNPs is better in latter solvents.

The amount of polymers in different solvents has an effect on the size of the AuNPs. The AuNPs, stabilized by HPEI-C180.73 and HPEI-OC900.73, respectively, were prepared and characterized by a UV-vis spectrometer (Fig. 2). As above-mentioned, HPEI-C180.73 without a double bond can only dissolve in chloroform or dichloromethane. As shown in Fig. 2(1a), the low amount of polymer ([N]/[Au] = 1) leads to the big size of AuNPs and the intense peak of AuNPs located at around 510 nm in SPR. As the ratio of [N]/[Au] is increased, the decreased diameters of AuNPs lead to the weak or invisible peak in SPR (Fig. 2(1b and 1c)). The AuNPs stabilized by HPEI-OC900.73 with a double bond exhibited good organic solubility not only in chloroform but also in toluene, n-butyl acetate, and petroleum. However, the solubility is different at the different ratio of [N]/[Au] in these four solvents. When the ratio of [N]/[Au] is 1, the AuNPs stabilized by HPEI-OC900.73 in chloroform and dichloromethane exhibit good solubility while the ones in the other three solvents exhibited aggregation or precipitation. In n-butyl acetate, there are still precipitations even though the ratio of [N]/[Au] is increased to 5. In petroleum ether, instability of the AuNPs leads to the weak absorbance of the upper solution in the UV-vis spectrum ([N]/[Au] = 1). This accounts that the fewer the amphiphilic hyperbranched polymers are, the less stable the AuNPs are. Figure 2(2) shows the typical UV-vis spectra of the petroleum ether solution of AuNPs stabilized by HPEI-OC900.73 at different ratios of [N]/[Au]. As shown in Fig. 2(2), the intensity of the absorption peak in all the UV-vis spectra is very weak, which can be explained by the fact that the size of AuNPs is very small in the TEM images (Fig. 1g–i). Thus, we can draw a conclusion that a high-concentration polymer with a double bond can improve the organic solubility in different solvents (composites 8–10 in Table 1), consistent with the ones reported in the literature [38].

The time-dependent stability of AuNPs stabilized by HPEI-OC900.73 in n-butyl acetate was also investigated. After 30 days of storage at room temperature, the AuNPs did not exhibit any trace of aggregation or precipitation macroscopically. Moreover, the colors of all the solutions also had no obvious difference after 30 days (see Fig. 3 inset). For instance, the AuNPs stabilized by HPEI-OC900.73 with [N]/[Au] = 10 exhibited a brown color in n-butyl acetate. After 30 days, the color was still brown and did not turn red or purple due to the obvious ripening of the AuNPs during the shelf storage. The n-butyl acetate solutions of the AuNPs stored for a certain time were also measured by the UV-vis spectrometer (Fig. 3). It was found that the spectra of all the long-term-stored solutions were similar to those freshly prepared. These above phenomena indicate that toluene, n-butyl acetate, and petroleum are good media for the amphiphilic hyperbranched polymers to stabilize the AuNPs.

Catalytic activity of the AuNPs in different solvents

As is well-known, 4-aminophenol is an important intermediate and is widely used in the synthesis of drugs, dyes, antioxygen, and photographic developer [41, 42]. Thus, the reduction of 4-nitrophenol to 4-aminophenol by NaBH4 in an organic/aqueous biphasic solution was chosen as a model reaction to evaluate the catalytic properties of the as-prepared AuNPs in different organic media. Vigorous stirring must be kept to enhance the collision chance of the AuNP catalysts with the reactants located in the different phases because the AuNPs stabilized by the amphiphilic hyperbranched polymers are organo-soluble, whereas the reactants 4-nitrophenol and NaBH4 are water-soluble. Comparing with the reaction time for a certain conversion, reaction rate, rate coefficient, and so on, the turn number (TON) can quantitatively express the lifetime of the catalysts in the reaction. TON means the number of moles of substrate that a mole of catalyst can convert before becoming inactivated. Hu et al. [38] found that the TON values (more than 1000) of the AuNPs, stabilized by amphiphilic palmitic acid-modified hyperbranched polyethylenimine, are far greater than the ones (less than 100) reported in some literatures [43–45]. Thus, we also adopted the TON to clarify the catalytic activity of the AuNPs stabilized by the as-prepared polymers in different organic media. TON is embodied here as Eq. (1):

\( \frac{n\left(4\hbox{-} \mathrm{nitrophenol}\right)\kern0.5em }{n\left(\mathrm{A}\mathrm{u}\right)} \) means the feed molar ratio of 4-nitrophenol to Au. The reaction conversion at time t can be calculated according to Eq. (2). Since the AuNP catalyst and the reactant 4-nitrophenolate are in chloroform and water phases, respectively, the absorbance of 4-nitrophenolate at 400 nm will not be interfered by the SPR absorbance of AuNPs, and the ratio of absorbance A t of 4-nitrophenolate at time t to its value A 0 at t = 0 (A t /A0) could be directly interpreted as the ratio of the respective concentrations C t /C 0. OCT means the overall catalytic times of the AuNPs. Here, all the gold atoms are countered, not merely the surface atoms with catalytic activity; thus, the calculated TON values will be significantly less than the real one. However, this kind of calculated TON values will be meaningful for the practical application since catalysts are usually so expensive that every atom should be considered.

The effect of different capping polymers on the catalytic activity and TONs of these organo-soluble AuNPs was studied. For comparing with HPEI-C160.73 and HPEI-C180.73 without a double bond, the catalytic activity of AuNPs stabilized by HPEI-OC500.73 and HPEI-OC900.73 with a double bond in chloroform was studied at a constant ratio of [N]/[Au]. Due to the similar size of the AuNPs stabilized by these four polymers, the catalytic activity is similar too. As shown in Fig. 4, the overall times and TON values of the AuNPs stabilized by HPEI-OC500.73 and HPEI-OC900.73 are similar with those stabilized by HPEI-C160.73 and HPEI-C180.73. Comparing with the traditional water-soluble PVP (PVP-K30)-stabilized AuNPs with [N]/[Au] = 10, the TON value of the AuNPs capped with HPEI-OC500.73 and HPEI-OC900.73 is around 3600 which is much higher than the former (1920).

The effect of different solvents on the catalytic activity was also studied at 32 °C. As above-mentioned, HPEI-C160.73 and HPEI-C180.73 without a double bond only dissolved in chloroform or dichloromethane while HPEI-OC500.73 and HPEI-OC900.73 with a double bond not only dissolved in chloroform or dichloromethane but also dissolved in petroleum ether, toluene, and n-butyl acetate. The solubility of these hyperbranched polymers is greatly improved. However, the stability of the polymer in different solvents leads to the different catalytic activity in reduction reaction of 4-nitrophenol by NaBH4. The TON values of AuNPs stabilized by HPEI-OC900.73 in these four kinds of solvent are shown in Fig. 5 when the molar feed ratio of 4-nitrophenol/Au in all the organo-soluble AuNP-catalyzed reactions was kept to be 240. As shown in Fig. 5, it can be known that the AuNPs stabilized in chloroform, petroleum ether, and n-butyl acetate have similar catalytic reactivity while the AuNPs stabilized in toluene have a lower catalytic reactivity than the others, Which means the AuNPs have similar stability in chloroform, petroleum ether, and n-butyl acetate, better than in toluene.

The time-dependent stability of AuNPs has an effect on their catalytic activity. The effect of storing time on the TON of the AuNPs, stabilized by HPEI-OC900.73 in petroleum, for the reduction reaction of 4-nitrophenol by NaBH4 at 32 °C is shown in Fig. 6. The catalytic activity of the newly prepared AuNPs increased slightly and reached a maximum at about the seventh day. After that, the TON values will not change greatly during even a month. Thus, the AuNPs stabilized by HPEI-OC900.73 showed not only good catalytic activity but also excellent time-dependent stability in the reduction of 4-nitrophenol to 4-aminophenol. So, the AuNPs used in the following factors affecting the TON for the reduction reaction of 4-nitrophenol by NaBH4 are stored for 7 to 30 days.

Taking the AuNPs stabilized by HPEI-OC900.73 in petroleum as examples, we studied the effect of the concentration of AuNPs and the capping polymers, the volume of the organic phase, and the temperature on the TON values for the reduction reaction of 4-nitrophenol by NaBH4 at 32 °C. The overall catalytic times and TONs of the AuNPs with the different gold concentration are shown in Fig. 7. The AuNPs with a higher gold concentration have more reused times but smaller TON values. This may be attributed to the higher concentration of Au which enhances the chance of direct contact of the AuNPs, which makes the AuNPs prone to aggregation and the loss of their activity gradually at constant volume of the organic solvent. The effect of the capping polymer concentration on the TON values was also studied when the volume of the organic phase and the concentrations of gold atoms were kept constant, whereas the ratio of [N]/[Au] varied. As shown in Fig. 8, the AuNPs stabilized by more polymers can be reused more times and have larger TON values. From these results, it can be deduced that the increase of the polymer concentration makes the size of AuNPs small and uniform, enhancing their catalytic activity and leading to strong interactions between the polymers and AuNPs, inhibiting the aggregation of AuNPs, and slowing the loss in their catalytic activities. However, when the amount of polymers is too large, it will take more time to finish the reduction reaction each time, and we only count the catalytic runs with full conversion time less than 120 min, which accounts for the lower TON value at [N]/[Au] = 50 than that of [N]/[Au] = 30.

The reduction reaction of 4-nitrophenol by NaBH4 catalyzed by the composites of AuNPs with different concentrations of gold atoms at 32 °C. The effect of the concentration of Au on the TON (black squares) and overall catalytic times (red circles). (20 mL of aqueous phase: [4-nitrophenol] = 3.0 × 10−3 M, [NaBH4] = 0.30 M; 4.0 mL of petroleum ether phase: HPEI10K-OC900.73 as stabilizer, [N]/[Au] = 10)

The effect of the ratio of nitrogens of HPEI10K-OC900.73 polymer to Au atoms on the overall catalytic times (red circles) and TON (black squares) in the reduction reaction of 4-nitrophenol by NaBH4 at 32 °C (20.0 mL of aqueous phase: [4-nitrophenol] = 3.0 × 10−3 M, [NaBH4] = 0.30 M; 4.0 mL of petroleum ether phase: [Au] = 6.25 × 10−5 M)

For the AuNPs stabilized by HPEI-OC900.73 in petroleum ether, the effect of the volume of the organic phase on the catalytic activity of the AuNPs was also investigated at the constant ratio of [N]/[Au] and the amount of gold atoms. As shown in Fig. 9, the TON values decrease along with the increase of the volume of the organic phase at the constant total amount of AuNPs. The greater the volume of the organic phase is, the lower the concentration of the amphiphilic polymers, which leads to the increase in the chance of direct contact of the AuNPs. This makes the overall catalytic times and TON of AuNPs in the reduction of 4-nitrophenol decrease greatly due to their aggregation.

The effect of temperature on the overall catalytic times and TON of AuNPs in the reduction reaction of 4-nitrophenol by NaBH4 is shown in Fig. 10. As seen from Fig. 10, it is obvious that the overall catalytic times and the TON values increase as the temperature is elevated. This is because the higher temperature decreases the activation energy of the reaction and increases the activity of the AuNPs.

The effect of temperature on the overall catalytic times (red circles) and TON (black squares) on the reduction reaction of 4-nitrophenol by NaBH4 (20.0 mL of aqueous phase: [4-nitrophenol] = 3.0 × 10−3 M, [NaBH4] = 0.30 M; 4.0 mL of petroleum ether phase: HPEI10K-OC900.73 as stabilizer, [N]/[Au] = 10, [Au] = 6.25 × 10−5 M)

At the same time, the catalytic stability of the AuNPs was studied. The reduction reaction of 4-nitrophenol is carried out in a heterogeneous way. After the reaction is over, the AuNPs are in the organic phase while the 4-aminophenol and NaBH4 are in the water phase. So, the Au catalyst can be recycled by phase separating. In the first several runs, the catalytic activity of the AuNP catalysts was similar, but it decreased clearly at a certain run (Fig. S5 in Supporting Information). With the further decrease of the catalytic activity, it took much time for the reaction to be over. TEM was used to detect the recovered catalyst becoming less active after reusing certain times, and it was found that the AuNPs had grown up to 15 nm (Fig. S6 in Supporting Information).

Conclusions

In summary, the amphiphilic hyperbranched polyethylenimine, modified with saturated and unsaturated fatty acids, respectively, was used successfully as templates and stabilizers of AuNPs with a spherical shape in different organic solvents. Different aliphatic chains on the hyperbranched polyethylenimine polymers have almost no effect on the size of the formed AuNPs whether they contain double bonds or not. But the oleic acid with a double bond improved the solubility of the amphiphilic hyperbranched polyethylenimine in toluene, petroleum ether, and n-butyl acetate. For HPEI-OC900.73, the solubility and stability of the AuNPs are different at the different ratio of [N]/[Au] in these three solvents. Increasing the feed ratio of polymers to Au atoms can get the smaller AuNPs with relatively lower polydispersity. All the organo-soluble AuNPs are stable enough for more than 30 days.

All the AuNPs in different solvents could be used as highly efficient catalysts for the biphasic catalytic reduction of 4-nitrophenol. The organo-soluble AuNPs could be conveniently recovered and reused many times. Their TON values could be enhanced by the AuNPs capped with more polymers or selecting a good solvent. The structure of the capping polymers had no obvious effect on the lifetime of the AuNP catalysts in the catalytic reduction of 4-nitrophenol. All the hyperbranched polymers rendered the AuNPs to have a bigger TON than their linear PVP that is a well-known AuNP stabilizer. For the AuNPs stabilized by HPEI-OC900.73 in petroleum ether, the TON values are affected by the concentration of AuNPs and the capping polymers, the volume of the organic phase, and temperature. The maximum TON of the organo-soluble AuNPs is about 5040, and so high a TON value exhibited by AuNPs or other metal nanoparticles has never been reported in the heterogeneous catalytic reduction of 4-nitrophenol. Owing to their excellent catalytic activity, easy separation, and low-toxicity organic solvents, the AuNPs are proposed as a potential system for the reduction of 4-nitrophenol in a large-scale process.

References

Manivannan S, Krishnakumari B, Ramaraj R (2012) Chem Eng J 204–206:16–22

Rode CV, Vaidya MJ, Jaganathan R, Chaudhair RV (2001) Chem Eng Sci 56:1299–1304

Komatsu T, Hirose T (2004) Appl Catal A Gen 276:95–102

Rode CV, Vaidya MJ, Chaudhari RV (1999) Org Process Res Dev 3:465–470

Hayakawa K, Yoshimura T, Esumi K (2003) Langmuir 19:5517–5521

Kuroda K, Ishida T, Haruta M (2009) J Mol Catal A Chem 298:7–11

Davis SC, Klabunde KJ (1982) Chem Rev 82:153–208

Vajda S, Pellin MJ, Greeley JP, Marshall CL, Curtiss LA, Ballentine GA, Elam JW, Catillon-Mucherie S, Redfern PC, Mehmood F, Zapol P (2009) Nat Mater 8:213–216

Wen X, Li G, Chen QZ, Zhang HL, Ba XW, Bai GY (2014) Ind Eng Chem Res 53:11646–11652

Turkevich J, Stevenson PC, Hillier J (1951) Discuss Faraday Soc 11:55–75

Frens G (1973) Nat Phys Sci 241:20–22

Brust M, Fink J, Bethell D, Schiffrin DJ, Kiely C (1995) Chem Commun 16:1655–1656

Templeton AC, Wuelfing WP, Murray RW (2000) Acc Chem Res 33:27–36

Aslan K, Pérez-Luna VH (2002) Langmuir 18:6059–6065

Lin SY, Tsai YT, Chen CC, Lin CM, Chen CH (2004) J Phys Chem B 108:2134–2139

Mayya KS, Patil V, Sastry M (1997) Langmuir 13:3944–3947

Thomas KG, Zajicek J, Kamat PV (2002) Langmuir 18:3722–3727

Cheng W, Dong SJ, Wang E (2003) Langmuir 19:9434–9439

Choo H, Isaacs SR, Small A, Parmley S, Shon YS (2007) J Colloid Interface Sci 316:66–71

Isaacs SR, Cutler EC, Park JS, Lee TR, Shon YS (2005) Langmuir 21:5689–5692

Zhua H, Tao C, Zheng S, Wu S, Li J (2005) Colloid Surf A 256:17–20

Shan J, Tenhu H (2007) Chem Commun 4580–4598

Knecht MR, Garcia-Martinez JC, Crooks RM (2005) Langmuir 21:11981–11986

Love CS, Ashworth I, Brennan C, Chechik V, Smith DK (2006) J Colloid Interface Sci 302:178–186

Keilitz J, Radowski MR, Marty JD, Haag R, Gauffre F, Mingotaud C (2008) Chem Mater 20:2423–2425

Moisan S, Martinez V, Weisbecker P, Cansell FO, Mecking S, Aymonier C (2007) J Am Chem Soc 129:10602–10606

Garamus VM, Maksimova T, Richtering W, Aymonier C, Thomann R, Antoniertti L, Mecking S (2004) Macromolecules 37:7893–7900

Shen Y, Kuang M, Shen Z, Nieberle J, Duan H, Frey H (2008) Angew Chem Int Ed Engl 47:2227–2230

Krämer M, Pérignon N, Haag R, Marty JD, Thomann R, de Viguerie NL, Mingotaud CM (2005) Macromolecules 38:8308–8315

Signori AM, Santos KDO, Eising R, Albuquerque BL, Giacomelli FC, Domingos JB (2010) Langmuir 26:17772–17779

Zhou L, Gao C, Xu WJ (2010) Langmuir 26:11217–11225

Zhou L, Gao C, Hu XZ, Xu WJ (2011) Chem Mater 23:1461–1470

Hu XZ, Zhou L, Gao C (2011) Colloid Polym Sci 289:1299–1320

Jesús E, Flores JC (2008) Ind Eng Chem Res 47:7968–7981

Liu Y, Fan Y, Yuan Y, Chen Y, Cheng F, Jiang S (2012) J Mater Chem 22:21173–21182

Kojima K, Chikama K, Ishikawa M, Tanaka A, Nishikata T, Tsutsumi H, Igawa K, Nagashima H (2012) Chem Commun 48:10666–10668

Tang Q, Cheng F, Lou XL, Liu HJ, Chen Y (2009) J Colloid Interface Sci 337:485–491

Hu N, Yin YY, Tang Q, Chen Y (2011) J Polym Sci Part A Polym Chem 49:3826–3834

Liu H, Chen Y, Zhu D, Shen Z, Stiriba SE (2007) React Funct Polym 67:383–395

Chen Y, Shen Z, Pastor-Pérez L, Frey H, Stiriba SE (2005) Macromolecules 38:227–229

Zhang Z, Shao C, Sun Y, Ma J, Zhang M, Zhang P, Guo Z, Liang P, Wang C, Liu Y (2012) J Mater Chem 22:1387–1395

Raffaele M, Pietro A, Cristina L (2013) Curr Org Chem 17:2516–2537

Sahiner N, Ozay H, Ozay O, Aktas N (2010) Appl Catal A Gen 385:201–207

Maksod IHAE, Hegazy EZ, Kenawy SH, Salehc TS (2010) Adv Synth Catal 352:1169–1178

Liu XY, Cheng F, Liu HJ, Liu Y, Chen Y (2010) J Mater Chem 20:360–368

Acknowledgments

This work was supported by the National Training Programs of Innovation and Entrepreneurship for Undergraduates (201410061050) and the outstanding young teachers in higher schools in Tianjin.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 1937 kb)

Rights and permissions

About this article

Cite this article

Pan, H., Liu, D., Hu, N. et al. Hyperbranched polymer-protected gold nanoparticles well-dispersed in different organic solvents: preparation and their catalytic applications to 4-nitrophenol reduction. Colloid Polym Sci 293, 2017–2026 (2015). https://doi.org/10.1007/s00396-015-3591-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3591-y