Abstract

Foliar application could improve grain iron (Fe) concentration (GFeC) by following 4Rs, i.e., the right Fe compound with right concentration sprayed at the right growth stage with right number of sprays. We studied the Fe mobilisation towards grain and its use efficiency using chelated-Fe and nano-Fe compounds in rice. Various Fe formulations [Fe-citrate, Fe-EDTA, FePO4, nano-Fe oxide, and humic acid with FeCl3 (HA + Fe)] were evaluated for their effect on growth, yield, and Fe mobilisation in rice. Single spray was done at tillering (set 1), anthesis (set 2), and grain-filling (set 3) stages, or sprayed twice at anthesis and grain-filling (set 4) and thrice at all stages (set 5). In all sets, shoot Fe at harvest (SFeH) correlated significantly with grain yield whereas SFeH and GFeC were negatively correlated, indicating that higher Fe in foliage promotes growth but would not necessarily increase grain Fe. A significant correlation between GFe uptake (GFeU) with Fe mobilisation efficiency index revealed that Fe mobilisation from shoot rather than root was the primary contributor to GFeU. Among Fe compounds, HA + Fe application enhanced grain yield and GFeU (> 70%) relative to control in all sets whereas nano-Fe (4 mM) resulted in highest GFeC in sets 4 and 5. Improved yield and Fe mobilisation from shoot towards grain was obtained with a single spray of HA + Fe either at anthesis or grain-filling stage. Thus, foliar Fe regimen has potential to enhance grain mineral quality and alleviate Fe deficiency that have implications for human health.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Iron (Fe) is essential for human health and its inadequate intake is the main cause of global Fe deficiency in humans (Wei et al. 2012; Camaschella 2019; Bindraban et al. 2020). The presence of antinutrient factor such as phytic acid that complexes with Fe, limits Fe absorption in the human body (Prom-u-thai et al. 2020). Rice (Oryza sativa L.) is an ideal target for Fe biofortification because Fe-deficiency anaemia is a predominant problem in the developing nations where rice is consumed as a staple food (Masuda et al. 2013). Moreover, the Fe concentration in rice grain is very low (8–30 ppm) (Prom-u-thai et al. 2020) which is due to restricted uptake by roots or translocation to grains or both. Fe deficiency in the soil is mainly due to high soil pH and a lack of moisture resulting in available Fe to change from ferrous (Fe2+, soluble or preferred form of Fe by plants) to ferric (Fe3+, insoluble Fe) form, thereby restricting its absorption by roots (Sharma et al. 2019a; Shukla et al. 2021).

Three key approaches such as conventional breeding, agronomic, and genetic engineering have been proposed and applied to improve Fe status of crops. However, the yield factor, genotype-environment interactions, and the lack of genetic diversity in modern cultivars are the key bottlenecks in breeding programmes, whereas consumer preferences and environmental safety are the main concerns with genetically modified crops (Wei et al. 2012). In contrast, the agronomic approach which involves applying nutrients to soil or directly to the foliage, is a straightforward solution for improving Fe concentration in the rice grain (Niyigaba et al. 2019). Agronomic biofortification is a quick, safe, and economical approach to increase the nutrient concentration, especially Fe and Zn, in our diet. Unlike genetic engineering/breeding approaches, agronomic biofortification can be easily done by farmers on existing high-yielding genotypes without compromising yield, and hence the product is readily acceptable by the consumers (Chaudhary et al. 2022). It has been hypothesised that rice adopts a combined strategy to absorb Fe from the soil that combines all of the features of Strategy II plants with some of the characteristics of Strategy I plants (Ricachenevsky and Sperotto 2014). Most of the cultivated rice is well adapted to lowland conditions and the capacity to absorb Fe2+ would have developed in rice as an adaptation to flooded paddies. However, due to high fresh water consumption (> 70% irrigated freshwater), aerobic or upland rice cultivation is an alternative to flooded anaerobic paddy, the former practice being at higher risks of Fe deficiency (Lampayan et al. 2013). Moreover, reduced soil moisture causes oxidation of available Fe which in turn, decreases its solubility and bioavailability to plants roots, thereby reducing grain Fe concentration and yield (Kumar et al. 2017). Due to the rapid conversion of soil applied Fe into insoluble Fe(III) form, foliar application of Fe fertilisers may be a preferable strategy for upland rice to overcome this Fe deficiency.

Foliar application of Fe is considered as a short-term tool for rice biofortification, and its efficacy is influenced by environmental factors (humidity, light, temperature, and wind), plant's physiological traits (age, expansion, and surface area of leaves, waxiness, and source/sink status), and physicochemical properties of spray solutions (concentration, electric charge, solubility, and pH) (Fernández and Ebert 2005; Pandey et al. 2013; Malhotra et al. 2020; Hong et al. 2021). A good foliar fertilisation takes into account not only the effective diffusion of Fe into the foliage, but also its mobilisation towards the edible parts. Various chelated and organic forms of Fe compounds such as Fe-citrate, ferrous sulphate, Fe-DTPA (diethylene triamine penta-acetic acid), and Fe-EDTA (ethylene diamine tetra acetic acid), have been used as foliar application (Fernández et al. 2009) but their response to Fe symptomatic plants were contradictory. According to Fernández and Eichert (2009), Fe-chelated forms were more readily translocated within the plant than the inorganic salts, while a few other studies showed enhanced penetration and leaf-greening with inorganic Fe salts over Fe-chelates (El-Jendoubi et al. 2014; Rios et al. 2016; Sharma et al. 2019a). In the recent past, foliar spray of humic acid has shown encouraging results on plant growth by improving nutrient uptake, hormone activity, enhanced antioxidant scavenging capacity and photosynthesis (Pizzeghello et al. 2013; Sharma et al. 2019a) besides being environmentally safe (Delfine et al. 2005). Likewise, foliar application of nano-Fe-fertilisers, considered as a novel technology, have improved plant growth and yield of many crop species (Bakhtiari et al. 2015; Wang et al. 2016). The Fe nano-oxide is much smaller than conventional Fe-oxide, so it enters the plant cells by binding with carrier proteins through ion channels or aquaporins (Bastani et al. 2018).

In addition to selection of Fe compound, plant growth stage is one of the key factors which determines the uptake effectiveness and mobilisation of Fe towards grain. According to Fageria et al. (2009), the transitioning phase from vegetative to the reproductive is the most critical phase for foliar application. The number of foliar sprays may also have an impact on the amount of Fe accumulated in the grains. Single or multiple foliar sprays of Fe at various developmental stages improved growth and yield in several crops (Erdal et al. 2004; Armin et al. 2014; Jalali et al. 2017). Once the Fe is absorbed by the foliage, its intra-cellular translocation depends to a great extent on phloem transport by forming complex with nicotianamine (NA); however, Fe re-distribution via phloem was found to be extremely poor (Thomine and Vert 2013). The concentration of the endogenous chelate, NA, is likely the limiting factor for loading of Fe into the phloem (Takahashi et al. 2003). In several crops, foliar application increased the Fe concentration in leaf, stem, and grain (Erdal et al. 2004; Moosavi and Ronaghi 2011; Armin et al. 2014; Sharma et al. 2019a, b), but very little information is available on its accumulation in the roots. Based on previous reports, we hypothesised that the foliar Fe application would result in an increased Fe concentration in grains only if the right Fe compound is sprayed at specific growth stage(s) of plants with optimised concentration. We expected that foliar application would also influence the root Fe uptake and minimise the requirement of soil Fe application. By applying Fe directly onto the foliage, the Fe source-to-sink translocation distance from root to grain would reduce relative to the foliage to grain distance.

Materials and Methods

Plant Material and Growth Conditions

A pot experiment was conducted under the natural environment conditions in the pot culture at ICAR-Indian Agriculture Research Institute, New Delhi, India located between latitude 28°38′23″N, longitude: 77°09′27″E; 228.61 m above mean sea level. The weather conditions during crop growth period such as temperature and rainfall, is presented in the Suppl. Fig. 1. The aerobic rice variety MAS 946–1, developed by the University of Agricultural Sciences in Bangalore, India, was selected for this study. Soil (0–30 cm) was collected from the experimental field of the institute. Before filling the pots with 15 kg of soil, air-dried soil was passed through a 5 mm sieve and a sub-sample was analysed for nutrients (N, P, K, Fe, and Zn) and physicochemical properties (Suppl. Table 1). The recommended dose of NPK (120:60:40 kg ha−1) was applied to each pot at the rate of 900 mg pot−1 of N (50% as basal dose, 25% at tillering and 25% at anthesis), 450 mg P2O5 pot−1 and 300 mg K2O pot−1. The seedlings were raised in nursery in mid-June followed by transplanting of 21-day-old plants in pots containing puddled soil. Initially, five seedlings were transplanted in the plastic pot (30 cm diameter, 28 cm height) and later two healthy plants were retained. Plants were irrigated as and when required with tap water.

Source of Fe Compounds Used as Foliar Treatments

Fe-citrate (Sigma 3522-50-7), Fe-EDTA (Sigma 149022-26-4), Fe-phosphate (Sigma 13463-10-0), humic acid (Sigma 1415-93-6), ferric chloride (Sigma 7705-08-0), nano-ferric oxide (Sigma 1309-37-1), and triton X100 (Sigma 9036-19-5).

Foliar Treatments and Sampling at Different Growth Stages

To determine the optimal concentration of different Fe compounds, a preliminary experiment was conducted in the glasshouse of National Phytotron Facility, ICAR-Indian Agriculture Research Institute New Delhi. The detailed methodology and results of the preliminary experiment are mentioned in the Supplementary text. Briefly, two concentrations (2 and 4 mM) of different Fe compounds, i.e., Fe-Citrate, Fe-EDTA, Fe-phosphate, and two different doses of humic acid (25 mg L−1 and 50 mg L−1) with 2 mM of FeCl3 were used as foliar fertiliser. Spray with deionized water was used as a control. All Fe formulations were applied at the maximum tillering and anthesis stages in rice. Based on their effects on yield attributes such as grain yield plant−1, test weight, number of productive tillers plant−1 and % filled grains and Fe concentration of shoot and grain, Fe formulations and their suitable concentrations were selected for the main experiment (Suppl. Fig. 2 and 3).

The Fe formulations and their optimum concentrations selected for main experiment included Fe-citrate 2 and 4 mM (Fe-Cit-2 and Fe-Cit-4), Fe-EDTA 2 mM (Fe-EDTA-2), Fe-phosphate 4 mM (FeP-4), humic acid 25 mgL−1 with ferric chloride 2 mM (HA + Fe), nano-powder of ferric oxide 2 and 4 mM (nano-Fe-2 and nano-Fe-4). The nano-Fe was included after the preliminary study; therefore, we considered both concentrations. The spray solutions were prepared for each Fe compound using distilled water and added 100 µl L−1 of Triton X100 as surfactant. The final pH of spray solutions was adjusted to 6.0 using 1N KOH/HCl. Before spray, the plants were divided into five sets with equal number of pots (40 pots per set). Each set differed in terms of the number of sprays applied at different growth stages (Fig. 1). The set 1, set 2 and set 3 plants received single spray at tillering, anthesis, and grain filling stages, respectively. The set 4 plants were sprayed twice at anthesis and grain-filling stages while set 5 plants were sprayed thrice (at all stages). Before spraying, the base of each plant was covered with polythene to avoid dripping of excess solution from the foliage into the soil. The plants were sprayed with Fe solution in the forenoon and samples of different parts like shoot (leaf + stem), root, and grain were collected on the 6th day after spray. In set 1 and set 5, sampling was done at all three growth stages, while in set 2 and set 4, samples were collected at anthesis and grain filling stages. In set 3, samples were collected only at grain filling stage.

Pictorial representation of foliar spraying schedule at different growth stages in rice. The plants of set 1, set 2 and set 3 received single spray at tillering, anthesis and grain filling stages, respectively while set 4 plants were sprayed twice and set 5 plants were sprayed at all three growth stages

Observations

Aboveground samples were harvested by cutting the plants at collar region. Roots were extracted from pots by washing the soil with a jet of water followed by proper cleaning to remove adhered soil particles. Root and shoot samples were dried in a hot air oven at 65 °C to a constant weight to obtain dry weight (g plant−1). At maturity, total grain yield per plant and test-weight (1000-seed weight) were recorded. For Fe quantification in root and shoot, tissues were thoroughly rinsed with double-distilled water to remove any surface adhered Fe. The paddy was dehusked and Fe concentration in grains (unpolished rice) was estimated. All samples were digested using a di-acid mixture (Nitric acid: Perchloric acid; 9:4) following standard protocol. Fe (%) estimation was carried out using inductively coupled plasma—optical emission spectrometer (5110 ICP-OES, Agilent). The instrument was calibrated using ICP-OES wavelength calibration solution (Agilent 6610030100), and the Fe analysis was performed in axial viewing mode. The certified reference material (Agilent 5190–8472, 1000 ppm in 5% HNO3 as matrix) was used and the recovery was found to be 97.4 to 103.8%. The Fe uptake was calculated by multiplying the Fe concentration with dry weight of the respective plant part and expressed as mg plant−1. Other traits such as Fe use efficiency (FeUE), Fe harvest index (FeHI), and Fe mobilisation efficiency index (FeMEI) were computed using the formulae (Shivay et al. 2010; Zulfiqar et al. 2021).

Statistical Analysis

The experiment was laid out in a completely randomised design with two factors, foliar treatments and growth stages, and five replicates for each treatment. The procedure for basic statistical analysis and ANOVA were carried out in a MS-DOS-based statistical software package AGRES ver. 3.01 (Pascal Intl Software Solution 1994). To quantify the association between traits, Pearson’s correlation coefficient and linear regression were calculated using MS-Excel 2016. Graphs were made using GraphPad Prism version 6.0 (GraphPad Software, La Jolla, CA).

Results

Influence of Foliar Fe Application on Biomass Production

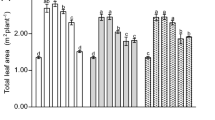

The above-ground biomass (AGB) production at different growth stages, viz., tillering (AGBT), anthesis (AGBA), grain filling (AGBGf), and harvest (AGBH) was significantly (P < 0.05) influenced by foliar application of different Fe compounds in all sets (Fig. 2a, Suppl. Table 2, 3). In set 1, more than 25% increase in AGBT was recorded with all Fe compounds except Fe-EDTA-2, FeP-4, and nano-Fe-4, as compared to control (Suppl. Table 3). Further, nano-Fe-2 resulted in maximum production of AGBA (52%), more than 46% by Fe-Cit at 2 and 4 mM at AGBGf while at harvest (AGBH), 63% increase in biomass was recorded with Fe-Cit-4 application, as compared to control. In set 2 plants, single foliar application at anthesis stage showed more than 40% increase in AGBA by nano-Fe-2, HA + Fe, and FeP-4. However, FeP-4 resulted in more than double biomass production followed by Fe-Cit-2 and HA + Fe which was consistent in AGBGf and AGBH in set 2. In set 3 with single foliar application at grain filling stage, HA + Fe caused maximum biomass at AGBGf (83%) and AGBH (78%), compared to control. In set 4, foliar application of Fe-Cit-2 and HA + Fe resulted in consistently higher biomass at AGBA, AGBGf, and AGBH. In set 5 with 3 foliar sprays, significant increase in biomass production was observed, but it was not consistent throughout the stages with any specific Fe compound. However, nano-Fe-2 resulted in more than 50% increase in biomass production at all stages. Among the various Fe compounds used, the final AGBH was consistently higher by more than 70% due to foliar application of HA + Fe, as compared to control in all sets, except set 1. Among various sets, a maximum of two foliar applications at anthesis and grain filling (set 4) in rice resulted in maximum AGBH, whereas foliar spray at tillering stage (set 1) showed least increase in total biomass (Fig. 2a).

Influence of foliar application of Fe compounds on a aboveground shoot biomass at harvest, b root biomass at harvest, and cgrain yield. Rice plants were grown in pots under natural environmental conditions. Data correspond to mean ± SEm (n = 5). The plants of set 1, set 2, and set 3 received single spray at tillering, anthesis and grain filling stages, respectively while set 4 plants were sprayed twice (anthesis and grain filling stages) and set 5 were sprayed at all three stages of growth. Data analysis was carried using one way ANOVA separately for each set and least significant difference calculated. Mean with same letter are not significantly difference at P < 0.05. Values on bars represents mean of different treatments under each set and LSD (P < 0.05) value presented on right-top of each graph for comparison between different sets

The root biomass produced at different growth stages, viz., tillering (RBT), anthesis (RBA), grain filling (RBGf), and harvest (RBH) was significantly (P < 0.05) influenced by foliar application of different Fe compounds in all sets (Fig. 2b, Suppl. Table 2, 4). In set 1, no significant difference was found in root biomass due to foliar treatments except for HA + Fe and nano-Fe-2, which increased RBT and RBA by more than 25 and 15%, respectively in comparison to control. In addition, nano-Fe-4 resulted in maximum accumulation of RBGf (44%) and RBH (27%) as compared to control. In set 2 plants, more than 29% increase in RBA was recorded by nano-Fe-2 and Fe-EDTA-2. but a significant reduction (> 15%) was recorded in RBGf and RBH by all Fe treatments except nano-Fe-2 and nano-Fe-4. In the set 3, both RBGf and RBH decreased, as compared to control in all Fe treatments except Fe-Cit-4 and HA + Fe. Similarly, in set 4, RBGf and RBH decreased significantly in all Fe treatments except HA + Fe, which enhanced RBGf and RBH by more than 40% as compared to control. In set 5, most of the Fe treatments increased RBT and RBA with a few exceptions (Fe-Cit-4 and nano-Fe-4), while RBGf and RBH declined significantly in all Fe treatments, indicating that root biomass decreased with the increase in the number of Fe foliar sprays (Fig. 2b; Suppl. table 4).

Influence of Foliar Fe Application on Grain Yield

The grain yield in rice was significantly (P < 0.05) influenced by Fe formulations and number of foliar sprays, whereas the test weight was significantly influenced by Fe formulations while number of foliar sprays showed no significant effect (Suppl. Table 2). Among Fe formulations, more than 50% increase in grain yield was recorded with HA + Fe and FeP-4, as compared to control in the set 1 (Fig. 2c). In set 2, Fe-Cit at both concentrations of 2 and 4 mM resulted in more than 90% grain increase, whereas FeP-4 and HA + Fe also resulted in more than 70% higher grain yield, in comparison to control. In set 3, grain yield increase was more than double with FeP-4 and HA + Fe application, while in set 4 and set 5, only HA + Fe resulted in highest (80%) yield, as compared to other Fe formulations. The interaction between Fe treatments and stage of foliar application was highly significant (P < 0.05) which showed maximum increase in grain yield in set 2 (spray at anthesis stage) and set 3 (spray at grain filling stage).

Influence of Foliar Fe Application on Above- and Below- Ground Fe Accumulation

The total aboveground Fe uptake (AGFeU) (including shoot and grain) at different growth stages viz., tillering (AGFeUT), anthesis (AGFeUA), grain filling (AGFeUGf), and harvest (AGFeUH) were significantly (P < 0.001) influenced by Fe formulation and number of foliar sprays (Table 1, Suppl. Table 4). In set 1 plants with single spray at tillering, maximum increase in AGFeUT was recorded by nano-Fe-2 (67%), while FeP-4 and Fe-Cit-4 also resulted in more than 50% increase, as compared to the control (Table 1). The Fe AGFeUA was significantly higher with nano-Fe-2 (71%), while at AGFeUGf, more than 45% increase was recorded with Fe-Cit-2 and nano-Fe-2, as compared to the control. However, at harvest (AGFeUH), Fe-Cit-4 resulted in maximum Fe uptake but at the same time, Fe-Cit-2, HA + Fe, and nano-Fe-2 also resulted in more than 50% increase in Fe accumulation in shoot, as compared to the control.

In set 2 with single foliar spray at anthesis stage, nano-Fe-2 resulted in more than double increase in Fe accumulation in the biomass (AGFeUA) followed by FeP-4 (71%), as compared to the control (Table 1). However, at both grain filling (AGFeUGf) and harvest (AGFeUH) stages, FeP-4 resulted in more than 140% higher Fe accumulation in the aboveground biomass in comparison to control. In addition to FeP-4, Fe-Cit-2 (98%) at AGFeGf and AGFeH (124%) also resulted in maximum Fe uptake. In set 3, with single foliar application at grain filling stage, increase in Fe uptake was noted with HA + Fe and nano-Fe-2 at both AGFeGf and AGFeH, as compared to other Fe compounds.

In set 4 with foliar application at anthesis and grain filling, maximum Fe uptake was noted with nano-Fe-2 at AGFeA (Table 1). However, more than double Fe uptake was recorded at AGFeGf and AGFeH with all Fe compounds except with nano-Fe-2 and Fe-EDTA-2 at AGFeGf. In set 5, with three foliar applications, the aboveground biomass accumulated maximum Fe with nano-Fe-2 at AGFeT and AGFeA in comparison to the control. But at AGFeGf and AGFeH, all Fe compounds exhibited more than double the amount of Fe uptake. This implies that a greater number of Fe sprays, particularly at grain filling stage, resulted in higher Fe retention in the shoot biomass which is not partitioned towards the grain.

The shoot Fe uptake at harvest (SFeUH) (excluding grain Fe uptake) varied significantly (P < 0.001) as a function of Fe formulations and the different treatment sets (Suppl. Table 2). Among the foliar treatments, both concentrations of Fe-Cit showed maximum SFeUH in set 1 plants, as compared to the control (Table 1). In set 2 plants, SFeUH was more than double with Fe-Cit-2 and FeP-4, while in set 3, HA + Fe application resulted in highest level of Fe. However, in set 4 and 5, with foliar Fe application more than once, SFeUH increased up to 1.7-folds, except with HA + Fe in set 5 which was 89% higher, in comparison to the control. The minimum increase in SFeUH was recorded in set 1 while set 5 with three foliar sprays at different growth stages resulted in maximum increase in SFeUH.

The root Fe uptake (RFeU) was significantly (P < 0.05) influenced by the number of foliar applications and various Fe formulation, while root Fe concentration (RFeC) was significant only at anthesis (RFeCA) and harvest (RFeCH) stages (Suppl. Tables 2, 4). In set 1, Fe accumulation in roots increased with the application of nano-Fe-2, HA + Fe, and Fe-EDTA-2, as compared to control, which was consistent at tillering (RFeUT), anthesis (RFeUA), grain filling (RFeUGf), and harvest (RFeUH) stages (Suppl. Table 4). In set 2, only nano-Fe-2 showed increased root Fe uptake whereas HA + Fe and nano-Fe-4 exhibited significant reduction in RFeUA, RFeUGf, and RFeUH stages. However, in set 3 with single spray at grain filling, significant reduction was noted in RFeH with all Fe compounds except Fe-Cit-4. In set 4 and set 5, with two and three foliar sprays respectively, Fe accumulation in root was reduced with HA + Fe and nano-Fe-4 throughout the growth stages as compared to control. Lower Fe accumulation in roots at grain filling or harvest stage signifies relatively higher transportation of Fe to shoot or towards grain. In set 2, set 3, and set 4, there a was significant reduction in Fe accumulation in the roots even when Fe was applied on the foliage. It was also evident from the root Fe concentration which was significantly reduced at harvest stage in these sets with almost all Fe compounds (Suppl. Table 4).

Influence of Foliar Fe Application on Grain Fe Accumulation

The primary focus of this study was to enhance the total Fe content in the grain by foliar application with various Fe compounds as a function of different growth stages. The Fe compounds and number of sprays significantly (P < 0.001) influenced total grain Fe content as well as Fe concentration (Suppl. Table 2). In set 1, maximum Fe accumulation in grain (GFeU) was recorded with HA + Fe (93%), while Fe-Cit-4 and FeP-4 also enhanced GFe by more than 75%, as compared to the control (Table 1). In set 2, GFeU was enhanced by HA + Fe, Fe-Cit-4, Fe-Cit-2, and FeP-4 by 146, 140, 113 and 104%, respectively, as compared to the control. However, in set 3, with single spray at grain filling, HA + Fe resulted in 88% increase in GFeU, whereas other FeP-4 and Fe-Cit-2 also resulted in > 75% higher GFeU, as compared to the control. In set 4 with two foliar applications, HA + Fe enhanced 1.5-fold increase in GFeU while nano-Fe also led to double the GFeU. In set 5 with three foliar sprays, all Fe compounds resulted in more than double accumulation of Fe in the grains per plant, except for Fe-Cit-4.

The Fe concentration in shoot tissue at harvest (SFeCH) increased in set 2, set 4, and set 5. In grain, Fe concentration (GFeC) increased by > 35% in set 2 and 3 with HA + Fe whereas in set 4 and 5, nano-Fe-4 resulted in higher grain Fe concentration. Among various Fe compounds, HA + Fe was found to enhance the total GFeU consistently throughout the sets. Among the sets, foliar spray at all three growth stages (set 5) viz., tillering, anthesis, and grain filling, showed maximum GFeU while least was recorded in set 1. There was no significant difference in GFeU in set 2, 3, and 4 plants.

Influence of Foliar Fe Application on Fe Indices and Their Relationship with Grain Fe Uptake

The Fe harvest index (FeHI) and Fe use efficiency (FeUE) were significantly (P < 0.001) influenced by Fe compounds and number of foliar sprays in different sets (Suppl. Table 2). Among the Fe compounds, foliar application of HA + Fe showed a consistently higher FeHI than control in all sets (Table 1). Application of HA + Fe resulted in 54% increase in FeHI in set 3, followed by 28% increase in set 2, whereas the least response was noted in set 4 with two sprays. With the exception of Fe-EDTA, the Fe formulations resulted in significant reduction in FeHI, as compared to the control; the effect was prominent in set 4 and 5. The FeUE described as the amount of grain produced per unit of Fe uptake, decreased significantly with almost all Fe compounds, except FeP and HA + Fe in set 3 which showed significant increase, as compared to the control (Table 1). The percent reduction in FeUE was higher in set 4 and set 5, indicating that a greater number of Fe sprays does not increase grain yield, but rather only increases the Fe content in shoot. This was also evident from the linear regression obtained between grain yield and FeUE which exhibited a significant relationship in set 1 (R2 = 0.18; P < 0.05), set 2 (R2 = 0.17; P < 0.05), and set 3 (R2 = 0.48; P < 0.05) while it was non-significant in set 4 and set 5 (Fig. 3a–e).

Linear regression between Fe use efficiency (FeUE) and grain yield of rice plants with foliar application of different Fe compounds. The plants in a set 1, b set 2, and c set 3 received single spray at tillering, anthesis and grain filling stages, respectively while d set 4 plants were sprayed twice (anthesis and grain filling) and e set 5 were sprayed at all three stages of growth

The Fe mobilisation efficiency index (FeMEI), which represents the Fe mobilized from shoot to the grain during their developmental stage, was significantly (P < 0.001) influenced by Fe formulations and number of sprays (Suppl. Table 2). Among Fe formulation, the foliar application of HA + Fe showed significant increase in FeMEI, which was consistent in all sets, with highest FeMEI in set 2 (38%) and set 3 (52%) (Table 1). Besides HA + Fe, foliar Fe-EDTA-2 application also showed significantly enhanced FeMEI in set 1, set 2, and set 3. In set 5, all Fe formulations significantly increase in GFe content (> 90%) but FeMEI was significantly decrease in all treatments except Fe-Cit-4 and HA + Fe, as compared to the control (Fig. 4, Table 1). Moreover, the linear regression of FeMEI with GFe content showed a significant positive relationship in all sets (set 1, P < 0.001; set 2, P < 0.05; set 3 and 4, P < 0.01) except set 5 (P = 0.406) (Fig. 4a–e).

Influence of foliar application of Fe compounds on grain Fe content (percent increase compared to control) and Fe mobilization efficiency index (FeMEI). The plants of a set 1, b set 2, and c set 3 received single spray at tillering, anthesis and grain filling stages, respectively while d set 4 plants were sprayed twice (anthesis and grain filling stages) and e set 5 were sprayed at all three stages of growth. Data analysis was carried using one way ANOVA separately for each set and least significant difference calculated. Mean with same letter are not significantly difference at P < 0.05 (the lower-case letter represents grain Fe content and upper case letter represents FeMEI)

The relationship between SFeUH and grain yield studied by linear regression showed a significant association in all sets (set 1 R2 = 0.20; P < 0.01, set 2 R2 = 0.29; P < 0.001, set 3 R2 = 0.18; P < 0.01, set 4 R2 = 0.23; P < 0.01, and set 5 R2 = 0.14; P < 0.05) suggesting that an adequate amount of Fe in shoot enhanced overall plant growth leading to increased grain yield in rice (Fig. 5a–e). Further, a significant positive correlation between SFeUH and GFeC was observed in set 1 (R2 = 0.16; P < 0.05), set 4 (R2 = 0.20; P < 0.01), and set 5 (R2 = 0.30; P < 0.01), whereas in other two sets, positive but non-significant association was observed (Fig. 5a–e). The Pearson’s correlation analysis revealed that grain yield and GFeU had no significant association with RFeU at any growth stage in all five sets (Suppl. Table 5).

Linear regression between Fe mobilization efficiency index (FeMEI) versus grain Fe uptake. Rice plants were grown under natural environmental condition with foliar application of different Fe compounds. The plants of a set 1, b set 2, and c set 3 received single spray at tillering, anthesis and grain filling stages, respectively while d set 4 plants were sprayed twice (anthesis and grain filling stages) and e set 5 were sprayed at all three stages of growth

Discussion

The foliar application of various Fe fertilisers at different growth stages of rice plants had a considerable impact on the above ground biomass accumulation, grain yield, and grain Fe concentration. The effect of HA + Fe on plant growth was significant, resulting in enhanced above ground biomass and grain yield in all sets in comparison to other Fe compounds (Fig. 2a, c, Suppl. Table 3). Previous reports found that foliar application of Fe alone or with other nutrients significantly increased leaf area and shoot biomass in wheat (Triticum aestivum) (Abu-Dahi et al. 2009; Farhan and Al- Dulaemi 2011; Bameri et al. 2012) and peach (Prunus persica) (Fernández et al. 2008). Being a co-factor of several enzyme complex, Fe is an essential element for photosynthesis and its deficiency reduces photosynthetic rate as well as alter the chloroplast structure (Eberhard et al. 2008). In our earlier study, we found that HA + Fe improved overall plant growth and enhanced yield and seed Fe concentration in soybean (Sharma et al. 2019a). Similarly, the foliar application of HA has shown encouraging effects on plant growth and yield in crops such as tomato (Solanum lycopersicum) (Adani et al. 1998), gerbera (Nikbakht et al. 2008), wheat (Katkat et al. 2009), and ryegrass (Lolium Perenne) Maibodi et al. 2015). This response might be due to the fact that foliar HA increases membrane permeability and solubility of several nutrients by forming a complex or chelating form with the nutrient (Lobartini et al. 1997; Katkat et al. 2009). Faster Fe translocation via xylem, more evenly Fe distribution in plants, and enhanced Fe partitioning into the juvenile leaves during subsequent growth stages might have contributed towards higher biomass accumulation in response to foliar application of Fe with HA.

The Fe compounds, plant growth stage and number of sprays significantly influenced grain yield and Fe uptake in aboveground biomass in rice (Table 1). Results showed that grain yield and FeUE were positively correlated in sets 1, 2, and 3 with single spray at different growth stages, but the correlation was not significant in sets 4 and 5 indicating that additional Fe supply (two or more foliar spray) might improve GFeC but not grain yield (Fig. 3a–e). Similarly, the plants in set 2 (sprayed at anthesis stage) and 3 (sprayed at grain filling stage) showed maximum increase in grain yield, whereas set 5 plants exhibited maximum increase in GFeC and GFeU. Previous reports have also suggested that the number and timing of foliar sprays impact plant growth and yield in different crops. Multiple foliar sprays (more than two) of Fe fertilisers at various developmental stages improved overall growth and yield in Strawberry (Frageria vesca) (Erdal et al. 2004) and maize (Jalali et al. 2017), whereas two foliar sprays in wheat (Armin et al. 2014) and soybean (Sharma et al. 2023) was sufficient for improving growth and grain yield. A few studies reported that single foliar application of Fe compound also increased growth and yield of rice (Zhang et al. 2009), wheat and soybean (Sharma et al. 2019a), and tobacco (Bastani et al. 2018).

We found a significant positive correlation between SFeUH and grain yield in all sets while the relationship between SFeUH and GFeU was dependent on the growth stage at which foliar application was done as well as the number of sprays being significant in sets 1, 4, and 5 (Fig. 5). In all sets, grain yield and GFeU showed no significant association with RFeU at any growth stage, suggesting that GFe content in upland rice was predominantly driven by Fe mobilisation from shoot rather than roots (Suppl. Table 4). However, this needs further validation with other rice varieties as there may be genotypic variation. The Fe concentration in grains revealed a wide range of outcomes for each Fe compound, depending on the number and stage of foliar spray. The highest grain Fe concentration was recorded when two or more sprays of nano-Fe-4 were administered to the same plants (sets 4 and 5) (Suppl. Table 3). However, results also showed that a greater concentration of Fe in the foliage would not necessarily result in higher grain Fe concentration because foliar applied Fe were mostly retained in the foliage in majority of the treatments. Bastani et al. (2018) compared the absorption and distribution of foliar nano-Fe and bulk Fe complex in tobacco plants. They found that most of the bulk Fe complex were retained in the foliage, while nano Fe showed better mobility in the xylem and phloem. According to Ghafari and Razmjoo (2013), nano-Fe sprayed wheat plants exhibited highest grain Fe concentration, as compared to other Fe fertilisers such as Fe sulphate and Fe chelates. Similarly, higher Fe content in the seeds of cowpea (Vigna unguiculata) (Afshar et al. 2012), soybean (Sheykhbaglou et al. 2010), and peanuts (Arachis hypogea) (Liu et al. 2005) was observed following application of nano Fe spray, which is in agreement with our findings.

The single spray of Fe with HA at anthesis (set 2) or grain filling (set 3) improved grain Fe content as compared to other treatments. Furthermore, except in set 1, the application of HA with Fe demonstrated not only maximum grain Fe accumulation but also highest Fe mobilisation efficiency index (FeMEI) in all sets (Fig. 6a–e). In addition to increasing membrane permeability, which stimulates ion absorption (Katkat et al. 2009; Daneshvar et al. 2015), foliar application of HA had a substantial influence on root nutrient uptake (Adani et al. 1998; Sharif et al. 2002). The positive effect of HA foliar spray on soil absorption of many macro- and micronutrients have been reported earlier (Fernández-Escobar et al. 1996; Bidegain et al. 2000; Katkat et al. 2009). We have also reported enhanced activities of antioxidant scavenging enzymes and reduced lipid peroxidation in HA + Fe treated soybean plants leading to positive effect on growth, nutrient uptake and mobilisation (Sharma et al. 2019a; 2023). Application of various Fe compounds at different developmental stages resulted in a significant reduction in root Fe (RFe) content, more so when Fe was applied more than two times (Suppl. Table 4). Though little information is available on the effect of foliar Fe application on root Fe content but according to Singh and Bhatt (2013), foliar application of Zn enhanced absorption of NPK by roots with no significant effect on root Zn content. The positive influence of foliar spray of HA with or without other nutrients have been reported in other studies (Bidegain et al. 2000; Nikbakht et al. 2008; Katkat et al. 2009; Daneshvar et al. 2015). According to earlier studies, the foliar spray of HA also improved nitrogen absorption in tomato, maize, and rye grass (Adani et al. 1998; Sharif et al. 2002; Daneshvar et al. 2015). Our finding is accordance with these studies confirming that HA along with Fe is an ideal foliar fertilizer for improving plant growth and Fe status in grains.

Influence of foliar application of Fe compounds on grain Fe content (percent increase compared to control) and Fe mobilization efficiency index (FeMEI). The plants of set 1, set 2, and set 3 received single spray at tillering, anthesis and grain filling stages, respectively while set 4 plants were sprayed twice (anthesis and grain filling stages) and set 5 were sprayed at all three stages of growth. Data analysis was carried using one way ANOVA separately for each set and least significant difference calculated. Mean with same letter are not significantly difference at P < 0.05 (the lower case letter represents grain Fe content and upper case letter represents FeMEI)

Conclusions

The present study demonstrated that foliar application of Fe improved plant growth, Fe use efficiency, Fe remobilisation, and grain Fe biofortification in rice plants; nevertheless, variations were apparent among different Fe compounds, application stage, and number of sprays. We found that the overall Fe status of aboveground part was enhanced due to Fe spray. However, higher shoot Fe concentration does not guarantee an increase in grain Fe concentration, as the latter is dependent on many other factors such as the number of sprays, type of Fe compound, and the growth stage of plant at the time of foliar application. In rice, foliar application of various Fe formulations showed a considerable effect on root Fe absorption; with more number of Fe sprays on foliage, the root Fe uptake was reduced. Further, root Fe content had no meaningful relationship with grain Fe indicating that GFe content was predominantly driven by Fe mobilisation from the shoot rather than root. The foliar application of nano-Fe at anthesis and grain-filling stages could improve grain nutritional quality by increasing Fe concentration, whereas foliar application of HA + Fe at anthesis or grain-filling stage improved grain quality, plant growth, and yield by increasing FeMEI and uptake of other nutrients. Thus, our findings indicate that foliar agronomic biofortification is an important strategy for sustainable and productive agriculture; however, impact of foliar nutrition depends on efficient absorption of nutrient by foliage, its partitioning, and metabolization.

References

Abu-Dahi YM, Shati RK, Al-Taher FM (2009) Effect of foliar feeding of iron, zinc and potassium on grain yield, and protein percentage of bread wheat. Iraqi J Agri Sci 40(4):27–37

Adani F, Genevini P, Zaccheo P, Zocchi G (1998) The effect of commercial humic acid on tomato plant growth and mineral nutrition. J Plant Nutr 21(3):561–575. https://doi.org/10.1080/01904169809365424

Afshar RM, Hadi H, Pirzad A (2012) Effect of Nano-iron foliar application on qualitative and quantitative characteristics of cowpea, under end season drought stress. Intl Res J Appl Basic Sci 3(8):1709–1717

Agres. 1994. Statistical Software Version 3.01. Pascal International Software Solutions, USA.

Armin M, Akbari S, Mashhadi S (2014) Effect of time and concentration of nano-Fe foliar application on yield and yield components of wheat. Int J Biosci 4(9):69–75. https://doi.org/10.12692/ijb/4.9.69-75

Bakhtiari M, Moaveni P, Sani B (2015) The effect of iron nanoparticles spraying time and concentration on wheat. Biol Forum 7(1):679

Bameri M, Abdollahi R, Mohammadi-Nejad G, Yousefi K, Tabatabaie S (2012) Effect of different microelement treatments on wheat (Triticum aestivum) growth and yield. Ires J Appl Basic Sci 3:219–223

Bastani S, Hajiboland R, Khatamian M, Saket-Oskoui M (2018) Nano iron (Fe) complex is an effective source of Fe for tobacco plants grown under low Fe supply. J Soil Sci Plant Nutr 18(2):524–541. https://doi.org/10.4067/S0718-95162018005001602

Bidegain RA, Kaemmerer M, Guiresse M, Hafidi M, Rey F, Morard P, Revel JC (2000) Effects of humic substances from composted or chemically decomposed poplar sawdust on mineral nutrition of ryegrass. J Agri Sci 134(3):259–267. https://doi.org/10.1017/S0021859699007492

Bindraban PS, Dimkpa CO, Pandey R (2020) Exploring phosphorus fertilizers and fertilization strategies for improved human and environmental health. Biol Fertil Soils 56(3):299–317. https://doi.org/10.1007/s00374-019-01430-2

Camaschella C (2019) Iron deficiency. Blood Am Soc Hematol 133(1):30–39. https://doi.org/10.1182/blood-2018-05-815944

Chaudhary M, Mandal A, Muduli S, Deepasree A (2022) Agronomic biofortification of food crops: a sustainable way to boost nutritional security. Revisiting Plant Biostimulants. IntechOpen, London

Daneshvar HM, N, Kafi M, Nikbakht A, Rejali F, (2015) Effect of foliar applications of humic acid on growth, visual quality, nutrients content and root parameters of perennial ryegrass (Lolium perenne L.). J Plant Nutr 38(2):224–236. https://doi.org/10.1080/01904167.2014.939759

Delfine S, Tognetti R, DesiderioE AA (2005) Effect of foliar application of N and humic acids on growth and yield of durum wheat. Agron Sustain Dev 25(2):183–191. https://doi.org/10.1051/agro:2005017

Eberhard S, Finazzi G, Wollman FA (2008) The dynamics of photosynthesis. Annu Rev Genet 42:463–515. https://doi.org/10.1146/annurev.genet.42.110807.091452

El-Jendoubi H, Vázquez S, Calatayud Á, Vavpetič P, Vogel-Mikuš K, Pelicon P, Morales F (2014) The effects of foliar fertilization with iron sulfate in chlorotic leaves are limited to the treated area A study with peach trees (Prunus persica L. Batsch) grown in the field and sugar beet (Beta vulgaris L.) grown in hydroponics. Front Plant Sci 5:2. https://doi.org/10.3389/fpls.2014.00002

Erdal I, Kizilgoz KK, I, (2004) Effect of foliar iron applications at different growth stages on iron and some nutrient concentrations in strawberry cultivars. Turk J Agri for 28(6):421–427

Fageria NK, Filho MB, Moreira A, Guimarães CM (2009a) Foliar fertilization of crop plants. J Plant Nut 32(6):1044–1064. https://doi.org/10.1080/01904160902872826

FAO (Food and Agriculture Organization) (2017a) Database of agricultural production. FAO Statistical Databases. http://faostat.fao.org/site/339/default

Farhan HN, Al-Dulaemi TMB (2011) The effect of foliar application of some microelements on growth and productivity of wheat (Triticum aestivum L.). Jordan J Agri Sci 7(1):105–118

Fernández V, Ebert G (2005) Foliar iron fertilization: a critical review. J Plant Nut 28(12):2113–2124. https://doi.org/10.1080/01904160500320954

Fernández V, Eichert T (2009b) Uptake of hydrophilic solutes through plant leaves: current state of knowledge and perspectives of foliar fertilization. Cri Rev Plant Sci 28:36–68. https://doi.org/10.1080/07352680902743069

Fernández-Escobar R, Benlloch M, Barranco D, Duenas A, Gañán JG (1996) Response of olive trees to foliar application of humic substances extracted from leonardite. Sci Hortic 66:191–200. https://doi.org/10.1016/S0304-4238(96)00914-4

Fernández V, Del Río V, Pumariño L, Igartua E, Abadía J, Abadía A (2008) Foliar fertilization of peach (Prunus persica L. Batsch) with different iron formulations: effects on re-greening, iron concentration and mineral composition in treated and untreated leaf surfaces. Sci Hortic 117(3):241–248. https://doi.org/10.1016/j.scienta.2008.05.002

Fernández V, Orera I, Abadía J, Abadía A (2009) Foliar iron-fertilisation of fruit trees: present knowledge and future perspectives – a review. J Hortic Sci Biotechnol 84(1):1–6. https://doi.org/10.1080/14620316.2009.11512470

Ghafari H, Razmjoo J (2013) Effect of foliar application of nano-iron oxidase, iron chelate and iron sulphate rates on yield and quality of wheat. Intl J Agron Plant Prod 4(11):2997–3003

Hong J, Wang C, Wagner DC, Gardea-Torresdey JL, He F, Rico CM (2021) Foliar application of nanoparticles: mechanisms of absorption, transfer, and multiple impacts. Environ Sci Nano 8(5):1196–1210. https://doi.org/10.1039/D0EN01129K

Jalali M, Ghanati F, Modarres-Sanavi AM, Khoshgoftarmanesh AH (2017b) Physiological effects of repeated foliar application of magnetite nanoparticles on maize plants. J Agron Crop Sci 203:593–602. https://doi.org/10.1111/jac.12208

Katkat AV, Çelik H, Turan MA, Asik BB (2009) Effects of soil and foliar applications of humic substances on dry weight and mineral nutrients uptake of wheat under calcareous soil conditions. Aust J Basic Appl Sci 3(2):1266–1273

Kumar VD, Kumar YV, Raj R (2017) Water productivity nutrients uptake and quality of aerobic rice as influences by variety and iron nutrition. Paddy Water Environ 15:821–830. https://doi.org/10.1007/s10333-017-0595-x

Lampayan RM, Sibayan EB, Cabangon RJ, Samoy-Pascual KS, Quicho Ma Quilloy AM, Palis FG (2013) AWD [alternate wetting and drying] in Asia: resource conservation, climate change mitigation, and social conflict reduction. Philippine J Crop Sci (philippines) 38:109

Liu XM, Zhang FD, Zhang SQ, He XS, Fang R, Feng Z, Wang Y (2005) Effects of nano-ferric oxide on the growth and nutrients absorption of peanut. Plant Nutr Ferti Sci 11:14–18

Lobartini JC, Orioli GA, Tan KH (1997) Characteristics of soil humic acid fractions separated by ultrafiltration. Commu Soil Sci Plant Anal 28:787–796. https://doi.org/10.1080/00103629709369830

Maibodi DM, Kafi NM, Nikbakht A, Rejali F (2015) Effect of foliar applications of humic acid on growth, visual quality, nutrients content and root parameters of perennial ryegrass (Lolium perenne L.). J Plant Nutr 38:224–236. https://doi.org/10.1080/01904167.2014.939759

Malhotra H, Pandey R, Sharma S, Bindraban PS (2020) Foliar fertilization: possible routes of iron transport from leaf surface to cell organelles. Arch Agron Soil Sci 66:279–300. https://doi.org/10.1080/03650340.2019.1616288

Masuda H, Aung MS, Nishizawa NK (2013) Iron biofortification of rice using different transgenic approaches. Rice 6(1):1–12. https://doi.org/10.1186/1939-8433-6-40

Moosavi AA, Ronaghi A (2011) Influence of foliar and soil applications of iron and manganese on soybean dry matter yield and iron–manganese relationship in a calcareous soil. Aust J Crop Sci 5:1550–1556

Nikbakht A, Kafi M, Babalar M, Xia YP, Luo A, Etemadi NA (2008) Effect of humic acid on plant growth, nutrient uptake, and postharvest life of gerbera. J Plant Nut 31:2155–2167. https://doi.org/10.1080/01904160802462819

Niyigaba E, Twizerimana A, Mugenzi I, Ngnadong WA, Ye YP, Wu BM, Hai JB (2019) Winter wheat grain quality, zinc and iron concentration affected by a combined foliar spray of zinc and iron fertilizers. Agron 9(5):250. https://doi.org/10.3390/agronomy9050250

Pandey R, Krishnapriya V, Bindraban PS (2013) Biochemical nutrient pathways in plants applied as foliar spray: phosphorus and iron. VFRC Rep 1:6–60

Pizzeghello D, Francioso O, Ertani A, Muscolo A, Nardi S (2013) Isopentenyladenosine and cytokinin-like activity of different humic substances. J Geochem Explor 129:70–75. https://doi.org/10.1016/j.gexplo.2012.10.007

Prom-U-Thai C, Rashid A, Ram H, Zou C, Guilherme LRG, Corguinha APB, Cakmak I (2020) Simultaneous biofortification of rice with zinc, iodine, iron and selenium through foliar treatment of a micronutrient cocktail in five countries. Front Plant Sci 11:589835. https://doi.org/10.3389/fpls.2020.589835

Ricachenevsky FK, Sperotto RA (2014) There and back again, or always there? The evolution of rice combined strategy for Fe uptake. Front Plant Sci 5:1–5. https://doi.org/10.3389/fpls.2014.00189

Rios JJ, Carrasco-Gil S, Abadía A, Abadía J (2016) Using Perls staining to trace the iron uptake pathway in leaves of a Prunus rootstock treated with iron foliar fertilizers. Front Plant Sci 7:893. https://doi.org/10.3389/fpls.2016.00893

Sharif M, Khattak RA, Sarrir MS (2002) Effect of different levels of lignitic coal derived HA on growth of maize plants. Commun Soil Sci Plants Anal 33:3567–3580. https://doi.org/10.1081/CSS-120015906

Sharma S, Chandra S, Kumar A, Bindraban P, Saxena AK, Pande V, Pandey R (2019a) Foliar application of iron fortified bacteriosiderophore improves growth and grain Fe concentration in wheat and soybean. Indian J Microbiol 59(3):344–350. https://doi.org/10.1007/s12088-019-00810-4

Sharma S, Malhotra H, Borah P, Meena MK, Bindraban P, Chandra S, Pandey R (2019b) Foliar application of organic and inorganic iron formulation induces differential detoxification response to improve growth and biofortification in soybean. Plant Physiol Rep 24(1):119–128. https://doi.org/10.1007/s40502-018-0412-6

Sharma S, Anand N, Bindraban PS, Pandey R (2023) Foliar application of humic acid with Fe supplement improved rice, soybean, and lettuce iron fortification. Agriculture 13:132. https://doi.org/10.3390/agriculture13010132

Sheykhbaglou R, Sedghi M, Tajbakhsh shishevan M, Sharifi SR, (2010) Effects of nano-iron oxide particles on agronomic traits of soybean. Notulae Scientia Biologicae 2:112–113

Shivay YS, Prasad R, Rahal A (2010) Genotypic variation for productivity, zinc utilization efficiencies, and kernel quality in aromatic rice under low available zinc conditions. J Plant Nutr 33(12):1835–1848. https://doi.org/10.1080/01904167.2010.503832

Shukla AK, Behera SK, Prakash C, Tripathi A, Patra AK, Dwivedi BS, Singh AK (2021) Deficiency of phyto-available sulphur, zinc, boron, iron, copper and manganese in soils of India. Sci Rep 11(1):1–13. https://doi.org/10.1038/s41598-021-99040-2

Singh AK, Bhatt BP (2013) Effect of foliar application of zinc on growth and seed yield of late-sown lentil (Lens culinaris). Indian J Agri Sci 83(6):622–626

Takahashi M, Terada Y, Nakai I, Nakanishi H, Yoshimura E, Mori S, Nishizawa NK (2003) Role of nicotianamine in the intracellular delivery of metals and plant reproductive development. Plant Cell 15:1263–1280. https://doi.org/10.1105/tpc.010256

Thomine S, Vert G (2013) Iron transport in plants: better be safe than sorry. Curr Opin Plant Bio 16(3):322–327. https://doi.org/10.1016/j.pbi.2013.01.003

Wang J, Fang Z, Cheng W, Tsang PE, Zhao D (2016) Ageing decreases the phytotoxicity of zero-valent iron nanoparticles in soil cultivated with Oryza sativa. Ecotoxicology 25(6):1202–1210. https://doi.org/10.1007/s10646-016-1674-2

Wei Y, Shohag MJI, Yang X, Yibin Z (2012) Effects of foliar iron application on iron concentration in polished rice grain and its bioavailability. J Agri Food Chem 60(45):11433–11439. https://doi.org/10.1021/jf3036462

Zhang J, Wang MY, Wu LH (2009) Can foliar iron containing solutions be a potential strategy to enrich iron concentration of rice grains (Oryza sativa L.)? Acta Agri Scand B. https://doi.org/10.1080/09064710802203545

Zhang YJ, Cheng YD, Wang C, Xu JN, Li JP, Ye Q, Yang JC (2019) The effect of dry cultivation on yield, water, and iron use efficiency of rice. Agron J 111(4):1879–1891. https://doi.org/10.2134/agronj2018.09.0551

Zulfiqar U, Hussain S, Ishfaq M, Ali N, Yasin MU, Ali MA (2021) Foliar manganese supply enhances crop productivity, net benefits, and grain manganese accumulation in direct-seeded and puddled transplanted rice. J Plant Growth Regul 40(4):1539–1556. https://doi.org/10.1007/s00344-020-10209-x

Funding

This work was funded by the Virtual Fertilizer Research Centre of the International Fertilizer Development Center, USA [Grant No. 02838/14].

Author information

Authors and Affiliations

Contributions

Conceptualization: RP, SS; Methodology: SS, RP, PSB; Formal analysis and investigation: SS, RP; writing—original draft preparation: SS, RP; Writing—review and editing: SS, RP, COD, AK, PSB; Funding acquisition, Resources, and Supervision: RP, PSB.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Handling Editor: Heather Nonhebel.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, S., Pandey, R., Dimkpa, C.O. et al. Growth Stage-Dependent Foliar Application of Iron Improves its Mobilisation Towards Grain and Enhances Fe Use Efficiency in Rice. J Plant Growth Regul 42, 5628–5641 (2023). https://doi.org/10.1007/s00344-023-10944-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00344-023-10944-x