Abstract

In recent years, multilayer metal arrays have received much attention in the fabrication of surface-enhanced Raman scattering (SERS) substrates. In this study, we prepared three-layer spherical nanoarrays by depositing double layers of Ag on hexagonal close-packed polystyrene (PS) sphere arrays and oxidizing the bottom layer of Ag to form oxide layer at ambient conditions, obtaining Ag/Ag2O/Ag three-layer spherical nanoarrays. By optimizing the thickness of silver layers and medium oxide layer, the SERS activity can be enhanced effectively. Using R6G molecule as the analyst, the SERS enhancement factor of the substrate can be up to 3.93 × 107, indicating that the substrate has high SERS sensitivity. It was found by the experiment that the SERS performance of the three-layer Ag nanosphere array was about 5.2 times stronger than that of the single-layer Ag nanosphere array with the same thickness, and it had good reproducibility and uniformity. It shows that ultra-thin oxide layer in the three-layer structure played a key role in SERS enhancement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Surface-enhanced Raman scattering (SERS), as a spectral analysis technology, has shown a strong ability in the detection of trace amounts of chemical and biological molecules at extremely low concentration or even single molecule level, and has been widely applied in biomedicine [1, 2], clinical diagnosis [3, 4], environmental sensing application [5,6,7,8] and food safety [9]. As we all know, the main principle of SERS is localized surface plasmon resonance (LSPR) caused by the collective oscillation of electrons, which leads to the enhancement of electromagnetic field of surface nanostructures [10]. Noble metal nanostructures are often used as SERS substrates because of their important surface plasmas, which are determined by the metal type, shape, size and surrounding dielectric. Noble metals such as Ag, Au and Cu were widely accepted as ideal nanostructured materials [11,12,13], among which silver nanostructure became the first choice of SERS substrate due to its superior plasma effect and cheapness compared with other metals [14]. The sensitivity of the substrate can be effectively improved by adjusting the shape of the Ag nanostructure [15,16,17] and the nanogap [18]. In addition, the multilayer structure of nanostructures is conducive to plasma enhancement [19]. Nowadays, most of the multilayer SERS substrates are double-layer (metal/medium or metal/metal) or three-layer (metal/medium/metal). For example, Syu et al. [20] reported a double-layer structure for Ag and Au deposition on a plane, which showed better signal-to-noise ratio and repeatability than the single-layer structure. Zhang et al. [21] reported an Au/ZnO/Au sandwich SERS substrate with higher sensitivity.

However, these substrates suffer from poor homogeneity and low reproducibility. To address this problem, template-assisted manufacturing [22, 23], especially in combination with self-assembly processes [24], provides a way to produce large-area periodic metal arrays in a more economical and convenient manner. Commonly used templates include porous anodic alumina (AAO) templates [25], microporous glass templates [26], densely packed polystyrene (PS) beads [27] and silica beads [28]. Compared with the multilayer structure on the plane, the multilayer material coated on the surface of the nanosphere has extra degrees of freedom in the plasma band, which can enhance the Raman scattering more effectively [29].

Makes it easy, so in order to get a low cost, good reproducibility, good uniformity and high sensitivity of the base, we take advantage of a novel multilayer recently enhanced geometric structure, namely alternating layers of metal and dielectric, it can effectively enhance the surface Raman signal, and Ag can be used to form natural oxidation, the characteristics of the oxide layer as dielectric layer [30], the three-layer structure of Ag/Ag2O/Ag is coated on the surface of polystyrene (PS) sphere, which can form a dense hexagonal structure with dense rows through self-assembly [31], with good uniformity. And such a structure is simple to make, only need depositing two layers of Ag film.

In this study, the oxide layer of Ag was introduced as an ultra-thin dielectric layer to form composite materials with Ag plasma material, and atomic layer deposition was no longer required. A layer of Ag was firstly evaporated on PS bead template to form Ag film over polystyrene nanospheres (AFOPN). Then, the oxide layer is formed by natural oxidation, and then, a layer of Ag is evaporated to form a composite three-layer nanosphere array of Ag and oxide layer. Compared with other three-layer structures, it has the advantages of easy production and low cost. Furthermore, Rhodamine 6G (R6G) molecule was used as the analyst to evaluate the performance of the SERS of the substrates. It was revealed that the detection limit of our substrates could reach 10−9 M and the Raman signals were similar at different spots on the substrate which shown high sensitivity and high uniformity. Our results may provide a low-cost and high-controllable SERS substrate for dye molecule detection applications.

2 Materials and methods

2.1 Chemicals and materials

All chemicals used in the current study were of analytical reagent grade. Ethanol and acetone were used directly without further purification. Rhodamine 6G (R6G) was purchased from Shanghai Runjie Chemical Reagent Co., Ltd. Sodium dodecyl sulfate (SDS) was purchased from TCI Shanghai Co., Ltd. All aqueous solutions were prepared in Milli-Q ultra-pure water (resistivity ≥ 18.2 MΩ cm−1). Ag materials were purchased from Shanghai TIM New Materials Technology Co., Ltd. Polystyrene (PS) colloidal particles (2.5 wt% aqueous solution) were purchased from Beijing Bailingwei Technology Co., Ltd. Si wafers were obtained from Zhejiang Lijing Technology Co., Ltd.

2.2 Methods

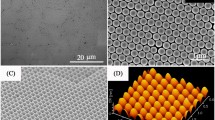

2.2.1 Assemble of monolayer hexagonal close-packed (hcp) PS arrays

The detailed procedure to fabricate the two-dimensional (2D) monolayer hexagonal close-packed (hcp) PS templates on silicon wafers is similar to that previously published [32]. Firstly, the silicon wafers were cut into small silicon wafers of 0.5 cm × 0.5 cm, and then, the beakers, glassware, indium tin oxide (ITO) and silicon wafers were cleaned by ultrasonic for 10 min with acetone, alcohol and deionized water, and then dried by nitrogen. At the same time, polystyrene microsphere suspension and anhydrous ethanol were mixed in a ratio of four to one and placed in an ultrasound processor for half an hour. Then, the hydrophilic treated ITO was placed in a beaker filled with water at a 45 degree Angle. Next, the prepared mixture of 120 μl polystyrene microsphere suspension and anhydrous ethanol is dripped along the conductive glass into the beaker by slow drip irrigation, when the drip is done, take out ITO. Then, it was found that a layer of colorful film would be formed on the surface of water. Adding a drop of SDS solution on the liquid surface without forming a film would make the PS sphere array more compact. At last, the film on the surface would be carefully removed with silicon wafers and dried naturally at ambient conditions.

2.2.2 Three-layer spherical nanostructure

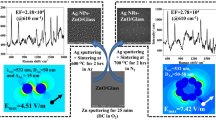

Deposition of Ag films on these nanosphere-coated silicon wafers was performed by mounting them on a rotating sample holder 15 cm above the tungsten boat in the vacuum evaporator (JSD-300; Anhui Jiashuo Vacuum Technology Co., Ltd). To ensure that an even coating of Ag was formed on the nanostructured substrate, the sample holder was slowly rotated during evaporation. The chamber was maintained at a pressure of ~ 8 × 10–4 Pa and an evaporation rate of 0.3 Å/s (monitored by a quartz crystal microbalance) was employed during the entire deposition to obtain a high-quality film. The deposition of the second layer of Ag film takes place after the natural oxidation of AFOPN at 25 °C for a period of time. The result is a three-layer spherical nanostructure of Ag/Ag2O/Ag. The preparation process is shown in Fig. 1.

2.3 Measurements and characterizations

Field-emission scanning electron microscope (Gemini SEM 300) was used to characterize morphology. Raman spectra detection used laser wavelength of 785 nm, 10 mW power and integration time of 10 s. Before Raman test, 20 μl of R6G solution with different concentrations were titrated on surface of SERS-active substrates, and Raman test was undertaken after drying naturally.

3 Results and discussion

The diameter of the polystyrene bead used in this experiment is 600 nm, because the 600 nm polystyrene beads were not only easy to form the hexagonal dense single-layer structure, but also Ag covered on their surface had good roughness, making them the optimal SERS substrates [33]. It is important to note that in this article, two layers of Ag film in the structure using the same thickness, sample oxidation in indoor, when the environment temperature is 25 °C, and the samples stored in transparent plastic petri dish, replace the lid with a layer of plastic wrap and poke holes in the sides with tweezers to make sure oxygen is permeable and the surface is protected from dust and airborne water.

In the experiments, we found that the thickness of the upper silver had an impact on the SERS intensity of the substrate. Through depositing different thicknesses of Ag, we can determine the optimal thickness of Ag by comparing their SERS intensity. In this study, three-layer spherical nanoarrays substrates and single-layer spherical nanoarrays substrates were prepared, with a total Ag thickness of 60, 120 and 240 nm. The Ag island and continuous Ag film on its surface can be studied, respectively, as shown in Fig. 2a–c. In the case of a three-layer spherical nanoarrays substrate, all substrates were prepared to be two layers of equal thickness. For example, for a total Ag thickness of 120 nm, the substrate of the three-layer spherical nanoarrays substrate is prepared by depositing two layers. In order to compare the SERS signal of three-layer spherical nanoarrays substrate and single-layer spherical nanoarrays substrate, the single-layer spherical nanoarrays substrate is also prepared by depositing two layers of Ag of the same thickness. Different from the three-layer spherical nanoarrays substrate, the single-layer substrate is kept in the vacuum box after the bottom layer of Ag is deposited (because of the vacuum, silver does not oxidize to produce an oxide layer), and then, the upper layer of Ag is deposited after the temperature is cooled to room temperature. In this way, we can compare the SERS signal of three-layer spherical nanoarrays substrate and single-layer spherical nanoarrays substrate. After the substrate was made, 20 µl R6G aqueous solution point samples with a concentration of 1 × 10–6 M were taken to each substrate and diffused to a circular area with a diameter of 2.5 cm. In this way, high reproducibility was achieved in the transportation of analyte, and then, the water on its surface was evaporated. SERS spectra were obtained using the measurement system described above. Figure 2d–f shows the results of this study, with each line representing the average of eight measurements (normalized to the maximum of the measured maximum signal measurements). As can be seen from Fig. 2, SERS signal intensity obtained on the three-layer spherical nanoarrays substrate increased from 60 to 120 nm with the thickness of Ag film. When the thickness exceeded 120 nm, SERS intensity began to decrease. For the three-layer spherical nanoarrays substrate, compared with the respective single-layer spherical nanoarrays substrate, the SERS intensity of all substrates increased significantly, even though the total thickness of Ag film remained unchanged. It can be seen from Fig. 2a–c that 60 and 120 nm thickness Ag is Ag films, while 240 nm thickness Ag shows Ag island distribution. In Fig. 2d–f, the maximum value of the signal in the total Ag thickness of 120 nm indicates that the substrate with continuous Ag film provides more effective signal enhancement than the substrate with discontinuous Ag island. It was determined that SERS enhancement was the strongest when the total Ag film thickness was 120 nm. After that, the analysis in this paper was carried out on single-layer spherical nanoarrays substrates and three-layer spherical nanoarrays substrates with the total Ag thickness of 120 nm.

Due to the rapid oxidation of Ag under environmental conditions and the lack of surface roughness difference between the single-layer and three-layer spherical nanoarrays substrates, it is clear that the formation of Ag oxide between the two layers must play a key role in the signal enhancement mechanism. Therefore, the signal enhancement capability of oxidation on the substrate of three-layer spherical nanoarrays substrates was systematically studied. In this study, a series of 120 nm-deposition thickness three-layer spherical nanoarrays substrates were prepared. After depositing Ag on silicon substrates assembled with PS beads, they were exposed to the same environment for oxidation for different periods of time, ranging from 0 to 60 h, before a second layer of Ag was applied to the substrate. 20 µl aqueous solution of 1 × 10–6 M R6G was placed on the substrate and SERS measurements were obtained (after the water evaporated). The results of these measurements are shown in Fig. 3, where each data point represents the average signal intensity of the highest signal peak (621 cm−1) in the SERS spectrum of 1 × 10–6 M R6G aqueous solution at five different positions on the substrate measured at each time point. In Fig. 3, it can be seen that SERS signal intensity increased significantly when the bottom layer of Ag was exposed to environmental conditions from 0 to 24 h. Compared with the exposure of 0 h, the signal was enhanced by about 5.2 times. When the Ag substrate is exposed to air for 0 h (not shown), the substrate corresponds to the single-layer spherical nanoarrays substrate because the vacuum on the chamber is never destroyed until deposition of the second 60 nm Ag. In the experiment, 0 h is not removed from the chamber of the vacuum coating machine, and there is no exhaust, which means that the chamber is kept vacuum, the sample did not contact with oxygen. After exposing the Ag substrate to air for more than 24 h, the signal strength decreased significantly. Finally, we could determine the optimal Ag film thickness and oxidation time of this three-layer spherical nanoarrays substrate, and then use R6G, a probe molecule often used to characterize Raman signal intensity, to show the SERS effect of this substrate.

From these studies, it can be seen that the role of the Ag oxide layer is important in determining the enhancement of the dual layer substrates. One potential explanation for this three-layer enhancement is that the Ag oxide layer that forms between the two Ag layers acts as an insulator between them, allowing two individual electromagnetic (EM) fields to be produced, one in each layer, following excitation. These two EM fields can then interact to reinforce each other, providing a long-range EM enhancement to any sample placed on the upper layer. For initial exposure time between substrate and air, oxidation is occurring on the Ag substrate surface between 0 and 24 h. Initially, between 0 and 24 h, the two Ag layers were still able to make direct Ag–Ag contact between them, thus reducing the ability to form two independent electromagnetic fields associated with each layer. As the underlying exposure time increases, the separation of the two Ag layers increases, increasing the intensity of the two separate EM fields. After 24 h of exposure, the underlying surface is sufficiently oxidized to reduce direct Ag–Ag contact between the two layers, thus allowing the generation of two completely independent electromagnetic fields close enough to reinforce each other. When the underlying exposure time was more than 24 h, the silver oxide layer became thick enough to reduce the electromagnetic interaction between the two fields, thus reducing the overall strength of SERS signal. Further evidence showed that this increased separation distance was the reason for the reduction of SERS signal, which was provided by the decay rate of SERS signal and the underlying exposure time after the optimal 24 h exposure. In addition, the thickness of the upper silver layer also affects the influence of the oxidation layer on the upper layer. As shown in Fig. 2f, when the upper Ag layer is 120 nm (total thickness is 240 nm), the three-layer spherical nanoarrays substrate does not enhance compared with the single-layer spherical nanoarrays substrate.

Spatial repeatability and uniformity of Raman signal are important factors for stable and reliable SERS substrate. Therefore, the current study randomly selected 50 points from optimal substrate and used R6G with concentration of 10–6 M as probe for SERS stability detection. Collected Raman spectra are shown in Fig. 4a. All the main vibrational modes of R6G molecule were apparently detected. Relative standard deviation (RSD) was used to analyze repeatability of samples. Smaller RSD indicated higher repeatability. Raman intensity at 621 cm−1 of R6G characteristic peak (Fig. 4b) was selected and computed RSD value was approximately ~ 4.67%, indicating excellent SERS stability of prepared three-layer spherical nanoarrays substrates.

Furthermore, the current study analyzed concentration-dependent SERS spectra for R6G molecules with concentration range of 10–9–10–5 M based on 120 nm-deposition thickness three-layer spherical nanoarrays substrate. Findings are shown in Fig. 5a. Results showed that when R6G concentration was as low as 10–9 M, main vibrational mode of 621 cm−1 could still be detected. Notably, SERS intensity increased monotonously with increase in concentration; peak shape and peak position were consistent, and number of characteristic peaks were basically the same, indicating that surface of three-layer spherical nanoarrays substrate can stably adsorb R6G molecules, and no new chemical bonds were generated. Furthermore, linear analysis of concentration dependence was undertaken in the current study. Pearson correlation coefficient was 0.96807 (Fig. 5b), indicating that three-layer spherical nanoarrays have good prospects for application in quantitative analysis.

Figure 6 shows representative Raman and SERS signals from the best SERS-active substrate. To obtain the Raman signals, a higher concentration of 10–1 M R6G was used due to the order of magnitude weaker intensity of the Raman relative to SERS peaks. Based on the measured results, the analytical enhancement factor (EF) at each main peak was calculated from Eq. (1):

where ISERS and IRaman are the signal intensities of vibration at 621 cm−1 in SERS spectra and Raman spectra, respectively, which could be obtained by experiment. In addition, CSERS and CRaman are the concentrations of the R6G solutions absorbed on the SERS and normal Raman substrate, respectively. ISERS is 12967, IRaman is 33. As a result, the EF was calculated to be c. a. 3.93 × 107.

4 Conclusions

In this work, we successfully prepared the three-layer spherical nanoarrays of Ag/Ag2O/Ag. The structure has good controllability, excellent uniformity and high SERS sensitivity, which is realized by vacuum thermal depositing of double Ag layers on the hexagonal close-packed PS sphere array. In the middle of double Ag layer is the oxide layer formed by natural oxidation of the bottom Ag. Different from the preparation of three-layer structure in the past, our preparation method is simple and inexpensive. Importantly, the oxide layer in the middle has greatly contributed to the improvement of SERS performance. Compared with the monolayer nanosphere array with the same thickness, the SERS intensity increased by about 5.2 times. The 120 nm-deposition thickness three-layer spherical nanoarrays under air oxidation for 24 h generates a SERS enhancement factor as high as 3.93 × 107 with a good reproducibility (RSD < 10%), which can detect R6G with a low concentration down to 10–9 M experimentally. Furthermore, we also revealed that the SERS intensity is linearly proportional to the concentration of R6G, indicating that the as-prepared SERS substrate is highly suitable for use as a quantitative chemical sensor. Therefore, it is very meaningful for the application of fast trace detection.

Data availability

All data, models, and code generated or used during the study appear in the submitted article.

References

S. Schlucker, SERS microscopy: nanoparticle probes and biomedical applications. ChemPhysChem 10, 1344–1354 (2009)

D. Chen, K.P. Taylor, Q. Hall, J.M. Kaplan, The neuropeptides Flp-2 and Pdf-1 act in concert to arouse caenorhabditis elegans locomotion. Genetics 204, 1151–1159 (2016)

V. Moisoiu, S.D. Iancu, A. Stefancu, T. Moisoiu, B. Pardini, M.P. Dragomir, N. Crisan, L. Avram, D. Crisan, I. Andras, D. Fodor, L.F. Leopold, C. Socaciu, Z. Balint, C. Tomuleasa, F. Elec, N. Leopold, SERS liquid biopsy: an emerging tool for medical diagnosis. Colloids Surf. B Biointerfaces 208, 112064 (2021)

S.X. Leong, Y.X. Leong, E.X. Tan, H.Y.F. Sim, C.S.L. Koh, Y.H. Lee, C. Chong, L.S. Ng, J.R.T. Chen, D.W.C. Pang, L.B.T. Nguyen, S.K. Boong, X. Han, Y.C. Kao, Y.H. Chua, G.C. Phan-Quang, I.Y. Phang, H.K. Lee, M.Y. Abdad, N.S. Tan, X.Y. Ling, Noninvasive and point-of-care surface-enhanced Raman scattering (SERS)-based breathalyzer for mass screening of Coronavirus disease 2019 (Covid-19) under 5 min. ACS Nano 16, 2629–2639 (2022)

S. Chang, S.L. Eichmann, T.-Y.S. Huang, W. Yun, W. Wang, Controlled design and fabrication of SERS–SEF multifunctional nanoparticles for nanoprobe applications: morphology-dependent SERS phenomena. J. Phys. Chem. C 121, 8070–8076 (2017)

Y.M. Chen, S. Pekdemir, I. Bilican, B. Koc-Bilican, B. Cakmak, A. Ali, L.S. Zang, M.S. Onses, M. Kaya, Production of natural chitin film from Pupal shell of moth: fabrication of plasmonic surfaces for SERS-based sensing applications. Carbohydr. Polym. 262, 117909 (2021)

C. Li, S. Xu, J. Yu, Z. Li, W. Li, J. Wang, A. Liu, B. Man, S. Yang, C. Zhang, Local hot charge density regulation: vibration-free pyroelectric nanogenerator for effectively enhancing catalysis and in-situ surface enhanced Raman scattering monitoring. Nano Energy 81, 105585 (2021)

W. Kim, W. Hwang, N.H. Kim, J. Kim, K. Baek, K. Kim, Permselective two-dimensional polymer film-based chemical sensors. Bull. Chem. Soc. Jpn. 94, 869–871 (2021)

L. Jiang, M.M. Hassan, S. Ali, H.H. Li, R. Sheng, Q.S. Chen, Evolving trends in SERS-based techniques for food quality and safety: a review. Trends Food Sci. Technol. 112, 225–240 (2021)

S.Y. Ding, J. Yi, J.F. Li, B. Ren, D.Y. Wu, R. Panneerselvam, Z.Q. Tian, Nanostructure-based plasmon-enhanced Raman spectroscopy for surface analysis of materials. Nat. Rev. Mater. 1, 16021 (2016).

Y.F. Huang, M. Zhang, L.B. Zhao, J.M. Feng, D.Y. Wu, B. Ren, Z.Q. Tian, Activation of oxygen on gold and silver nanoparticles assisted by surface plasmon resonances. Angew. Chem. Int. Ed. Engl. 53, 2353–2357 (2014)

R. Ban, Y. Yu, M. Zhang, J. Yin, B. Xu, D.Y. Wu, M. Wu, Z. Zhang, H. Tai, J. Li, J. Kang, Synergetic SERS enhancement in a metal-like/metal double-shell structure for sensitive and stable application. ACS Appl. Mater. Interfaces 9, 13564–13570 (2017)

A. Jimbo, Y. Nishikado, K. Imura, Optical field and chemical environment near the surface modified gold nanoparticle assembly revealed by two-photon induced photoluminescence and surface enhanced Raman scattering. Bull. Chem. Soc. Jpn. 94, 2272–2278 (2021)

S. Schlucker, Surface-enhanced Raman spectroscopy: concepts and chemical applications. Angew. Chem. Int. Ed. Engl. 53, 4756–4795 (2014)

Y. Liu, S.H. Wu, X.Y. Du, J.J. Sun, Plasmonic Ag nanocube enhanced SERS biosensor for sensitive detection of oral cancer DNA based on nicking endonuclease signal amplification and heated electrode. Sensor Actuat B-Chem 338, 129854 (2021)

Y.L. Zeng, F.Y. Wang, D.X. Du, S. Liu, C.B. Wang, Z.P. Xu, H.Y. Wang, ZnO nanotower arrays decorated with cubic and tetrahedral shaped Ag-Nps as hybrid SERS-active substrates. Appl. Surf. Sci. 544, 148924 (2021)

L. Mikac, M. Ivanda, M. Gotic, V. Janicki, H. Zorc, T. Janci, S. Vidacek, Surface-enhanced Raman spectroscopy substrate based on Ag-coated self-assembled polystyrene spheres. J. Mol. Struct. 1146, 530–535 (2017)

Y. Liu, L. Zhang, X. Liu, Y. Zhang, Y. Yan, Y. Zhao, In situ SERS monitoring of plasmon-driven catalytic reaction on gap-controlled Ag nanoparticle arrays under 785 nm irradiation. Spectrochim. Acta A Mol. Biomol. Spectrosc. 270, 120803 (2022)

L. Sabri, M. Shahabadi, M. Ghaffari-Miab, K. Forooraghi, Multilayer dielectric substrate for improved Raman spectroscopy. Opt. Commun. 451, 255–259 (2019)

W.L. Syu, Y.H. Lin, A. Paliwal, K.S. Wang, T.Y. Liu, Highly sensitive and reproducible SERS substrates of bilayer Au and Ag nano-Island arrays by thermal evaporation deposition. Surf. Coat. Technol. 350, 823–830 (2018)

Z. Haibao, L. Guang, Z. Xian, X. Tian, Preparation and optical properties of Au nanoparticle “Sandwich” structure (Aunps/Znns/Aunps) substrate based on Zno nanosheets template. Mater. Chem. Phys. 268, 124715 (2021)

Z. Yi, G. Niu, J. Luo, X. Kang, W. Yao, W. Zhang, Y. Yi, Y. Yi, X. Ye, T. Duan, Y. Tang, Ordered array of Ag semishells on different diameter monolayer polystyrene colloidal crystals: an ultrasensitive and reproducible SERS substrate. Sci. Rep. 6, 32314 (2016)

T.R. Jensen, M.D. Malinsky, C.L. Haynes, R.P. Van Duyne, Nanosphere lithography: tunable localized surface plasmon resonance spectra of silver nanoparticles. J. Phys. Chem. B 104, 10549–10556 (2000)

J. Yu, Q. Yan, D. Shen, Co-self-assembly of binary colloidal crystals at the air–water interface. ACS Appl. Mater. Interfaces 2, 1922–1926 (2010)

V. Sadasivan, C.P. Richter, L. Menon, P.F. Williams, Electrochemical self-assembly of porous alumina templates. AIChE J. 51, 649–655 (2005)

N. Su, S. Guo, F. Li, B. Li, Electrodeposition of Bi–Te thin films on silicon wafer and micro-column arrays on microporous glass template. Nanomaterials (Basel) 10, 431 (2020)

W. Zhang, T. Xue, L. Zhang, F. Lu, M. Liu, C. Meng, D. Mao, T. Mei, Surface-enhanced Raman spectroscopy based on a silver-film semi-coated nanosphere array. Sensors (Basel) 19, 3966 (2019)

X. Hou, Q. Wang, G.M. Mao, H. Liu, R.D. Yu, X.M. Ren, Periodic silver nanocluster arrays over large-area silica nanosphere template as highly sensitive SERS substrate. Appl. Surf. Sci. 437, 92–97 (2018)

G.K. Pandey, N.K. Pathak, R. Uma, R.P. Sharma, Study of surface-enhanced Raman scattering of plasmonic coupled biomolecule: role of multi-layered nanosphere. Plasmonics 13, 221–229 (2017)

H. Li, B.M. Cullum, Dual layer and multilayer enhancements from silver film over nanostructured surface-enhanced Raman substrates. Applied spectroscopy 59, 410–417 (2005)

V. Lotito, T. Zambelli, Self-assembly of single-sized and binary colloidal particles at air/water interface by surface confinement and water discharge. Langmuir 32, 9582–9590 (2016)

S.M. Weekes, F.Y. Ogrin, W.A. Murray, P.S. Keatley, Macroscopic arrays of magnetic nanostructures from self-assembled nanosphere templates. Langmuir 23, 1057–1060 (2007)

L.I. Bin, G. Niu, Y.I. Yong, X.W. Zhou, X.D. Liu, Y.E. Xin, C.Y.J.S. Wang, Fabrication and surface-enhanced Raman scattering research on polystyrene nanospheres arrays. Guang Pu Xue Yu Guang Pu Fen Xi 36, 2812-2817 (2016)

Acknowledgements

This work is supported by the National Key Scientific Instrument and Equipment Development Projects of China (2011YQ030134); Talent introduction program of Nantong University (135420602125); University general project of Jiangsu Province (21KJB140015); and special thanks to Nantong University Analysis & Testing Center of for their support of the SEM characterization results in this work.

Author information

Authors and Affiliations

Contributions

JS contributed to conceptualization, methodology, formal analysis, validation, investigation, resources, data curation, and writing—original draft. JW contributed to software, validation, formal analysis, and writing—review and editing. YJ contributed to software and project administration. JF contributed to investigation and formal analysis.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, J., Wu, J., Jin, Y. et al. Hierarchical nanoarchitectonics with three-layer (Ag/Ag2O/Ag) spherical nanoarrays with highly sensitive SERS performance. Appl. Phys. A 129, 197 (2023). https://doi.org/10.1007/s00339-022-06368-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-06368-1