Abstract

For the investigation of the influence of (PVP: Zn-TeO2) interphase layer on the electrophysical parameters, Al/p-Si structures with/without (PVP: Zn-TeO2) interlayer grown by spin-coating technique and then these factors were studied by I–V and Z–f measurements. First, the Field Emission Scanning Electron Microscopy (FE-SEM), X-ray Diffraction (XRD), Energy Dispersive X-ray Spectroscopy (EDS), and UV–Vis analyses techniques were performed to investigate the morphology, purity determination, and the optical properties of the nanostructures, respectively. Second, I–V measurements and Z–f were performed at ± 3 and 1.5 V (at 100 Hz–1 MHz), respectively. The values of ideality factor (n), barrier height (BH:ΦB), and series resistance (Rs) of them were obtained using various methods such as thermionic emission, Cheung’s and Norde functions and compared. The energy dependence of surface states (Nss) were extracted from the forward bias I–V measurements by assuming the voltage dependence of BH and n. The frequency-dependence profiles of dielectric constant (ε′)/loss (ε″), and ac electrical conductivity (σac) were extracted from the Z–f measurements. Experimental results show that (PVP: Zn-TeO2) interlayer leads to an increase in the ε′, ε″, BH, Rsh, and decrease in Nss. Therefore, Al/(PVP: Zn-TeO2)/p-Si structures can be used as an electronic part in nanoscale instead of MS structures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last decade, the increasing need for smaller energy and information storage devices, the increases in transfer rates, and more shrinking the electrical components, including the Schottky diodes (SDS), solar batteries/cells (SCs), capacitors, and transistors as new nanoparticles. With decreasing the dimensions of electrical components, along with reducing the consumed power, the production speed is improved. In the last decades, many advancements have been made in the area of reducing the size of these parts and increasing the storage capacity of them, which have led to doubling the processing speed in 18 months. It promises a huge change in the microelectronic industry in the near next [1, 2]. Schottky type diodes which are made of metal–semiconductor (MS) junction and considered as important components of the electronics and optics devices have found a superior place in the industry such as the SCs, photodiodes or photodetectors (PDs), transistors, microwave mixers, rectifiers, varactor diodes, Zener diodes, and integrated circuits compared to the traditional p–n junction/diodes. Such a wide range of applications have resulted in the unique characteristics of these diodes, e.g., low voltage drops, low direct pre-voltage and high-speed switching, low space occupation in the integrated circuits, easy construction, and compatibility.

To modify and control the SBDs height of the conventional MS diodes, in the last two decades, extensive studies have been done on the metal–insulator/polymer-semiconductor (MIS/MPS) SDs, specifically in the electronic and optoelectronic industry. The use of a high-dielectric insulator/polymer between metal and semiconductor can increase the capacity and decreasing the leakage current, stabilizes the performance and enhances the efficiency and rectification [3]. On the other hand, the decrease in the size of these electronic parts leads to a drop in the thickness of the polymer/oxide interlayer on the metal/semiconductor junction. Such a size reduction leads to the emergence of factors, such as an increment in interlayer tunneling, a decrease in doping depth, and the change in carrier mobility, which consequently results in a reduction in efficiency of the part. Therefore, the interlayer (or inherent) contamination method by the metal-oxide nanoparticles is suggested as one of the tricks to prevent this problem recently, which has been widely studied by the researchers [4,5,6,7,8,9,10,11].

Singh Group made two Au/Al-ZnO/p-Si and Au/ZnO/p-Si SDs and studied the effects of Al contamination in the ZnO interlayer on the electric characteristics of the diode, by the I–V measurement. The obtained results indicated that Al contamination indicated that it reduces barrier height (BH) and the turn-on voltage, which is suitable for switching functions [12]. Ozkartal et al. [13] studied the effects of the methyl violet organic layer on the dielectric and electric features of the Sn/p-Si/Al SD by measuring the C–V and I–V using Norde, Cheung, and TE theory. Their results showed that the presence of an organic interlayer increases the n, BH, series, and shunt resistance in comparison with the MS structure. Kumar et al. [14] investigated the dielectric features of the Ni/SiO2/p-Si/Al SD in different temperatures from 95 to 300 K, the voltage of 1–3 V, and frequency of 10 kHz to 1 MHz by measuring the C–V–f and G–V–f. Their shows that indicated that the dielectric constant value in the interlayer diode is increased with a rise in the temperature and is reduced with a climb in frequency. Rajagopal et al. [15] investigated the dielectric characteristics of the MIS type SDs with the Au/Bi0.5Na0.5TiO3-BaTiO3(BT)/n-GaN structure by measuring the C–V and I–V between 120 and 420 K. They reported that the BH increases and Nss decrease with increasing temperature. TeO2 has a multipurpose material with a high energy gap. These types of materials are widely used in the active devices, e.g., deflectors, modulators, optical storages, optical waveguides and filters, gas sensors, and adjustable filters thanks to its special electro-optical and acoustic-optical characteristics, e.g., good optical quality, high refractive index, and elastic behavior. Moreover, TeO2 is considered as a potential substance for amplifiers and switching performance of optical devices because of the large non-linear polarizability and having an extensive cross section for stimulated Raman scattering (SRS) [16,17,18]. Among the polymers, the polyvinylpyrrolidone (PVP) has some advantages, including easy and cheap production, good conductivity, non-toxic attributes, and relatively high environmental stability [19, 20].

The utilization of high-performance doped polymer nanostructures as an interface layer in Schottky structures is a challenge which important for controlling device efficiency. In this study, we aimed that the use of a thin (Zn-TeO2) doped PVP polymer/organic at Al/p-Si interface as an interlayer to determine the effects on it both on the basic electrical and dielectric parameters. For this aim, both the Al/p-Si (MS) and Al/(PVP: Zn-TeO2)/p-Si (MPS) structures were performed same p-Si wafer in the same conditions and then both the I–V and Z–f measurements of them were done in voltages from − 3 to + 3 V and frequencies (100 Hz–1 MHz) at 1.5 V, respectively. The results were indicated that the presence of the (PVP: Zn-TeO2)- interlayer led to the improve the performance of MPS when compared MS structures in respect of increase in the ε′, ε″, BH, Rsh, and decrease in Rs, n and Nss.

2 Experimental procedure

Cadmium acetate dihydrate (Cd (CH3COO)2) and zinc acetate dehydrate precursors were purchased from the Rankem Co. and used for the preparation of the zinc telluride nanostructures by the ultrasonic method. 20 ml of 0.2 M precursors of zinc and cadmium were selected and mixed. For adjusting the pH, 2 M NaOH was used, and subsequently, the final composition was exposed to the ultrasonic wave with 100 W power for 15 min. After the rinsing, filtration, and drying at room temperature, the obtained nanopowder was put inside an oven with a temperature of 40 °C for 45 h. For the preparation of the PVP: Zn-TeO2 interlayer, 10 mg of the Zn-TeO2 nanostructure was distributed in 5cc of PVP (5%) and a layer with a thickness of 100 nm was coated by spin-coating method on the p-type silicon wafer.

Before the prepared (PVP: Zn-TeO2) solution on the p-Si Wafer, B-doped (p-Si) single Si wafer with the orientation of (100), the thickness of ~ 300 μm and resistivity of 1–10 Ω cm was rinsed by the acetone, methanol, H2O2, NH4OH, and HF compounds and then high purity Al (99.999%) with 120 nm thickness was thermally grown on the whole back-side wafer at 10−6 Torr. Consequently, they were annealed in the nitrogen ambient at 450 °C to get a good ohmic contact for two-quarter p-Si wafers. After that, the prepared solution of (PVP: Zn-TeO2) was grown on one of the quarter p-Si wafers by spin coating technique. Eventually, Al circular dots with 7.85 × 10−3 cm2 and 120 nm thickness were also evaporated both on the (p-Si/Al) and ((PVP: Zn-TeO2)/p-Si/Al) quarter wafers in the same high-vacuum system. Thus, both the fabrication of the Al/p-Si/Al (MS) and Al/(PVP: Zn-TeO2)/p-Si/Al (MPS) structures were completed. Both the schematic diagram of the MPS and analyses devices, as shown in Fig. 1. The schematic represented that the Au/n-GaAs contacts and analysis devices are shown in Fig. 1.

To investigate the structural, morphological, and optical properties of the prepared nanostructures, the X-ray device (Philips, X λ = 1.5406 Å), field emission SEM (Tescan-Mira III, Czech Republic), and the Mary-ultraviolet spectroscopy (UV-1800, Shimadzu, Japan) were used. The I–V analysis was done by a Keithley 2400 I–V source meter, Z–f analysis was done by a KEYSIGHT (E4980Al 20 Hz–1 MHz).

3 Results and discussion

3.1 Structural and optical analysis

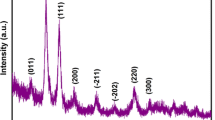

Figure 2 depicts XRD pattern of TeO2 nanostructures doped with Zn. As indicated in Fig. 2a, the emerged peak in the position of 2θ = 30, belonging to the (102) plane, in the tetragonal structure based on the standard card of ICDD#00-008-0484 [21, 22]. According to the X-ray diffraction pattern, it seems that the impurity of Zn has led to the emergence of an almost amorphous peak, which has a significant broadness due to the tension created in the material structure as a result of the contamination of Zn atoms [23].

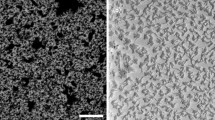

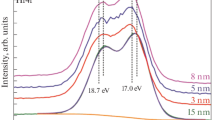

Compound percentages Zn-TeO2 nanostructures are depicted in Fig. 2b. In the EDS spectrum of the sample, it can be observed that the nanostructures contain only Te and Zn elements, and there are no other impurities. However, O cannot be detected in this material owing to its low weight. Figure 2c, d presents the morphology of the prepared nanostructures in two different magnifications. According to these images, the spherical nanostructures have a size of < 100 nm, and the nanoclusters with a size of < 0.5 µm are formed due to their agglomeration. The optical properties and energy gap of the prepared nanostructures were calculated by the ultraviolet-absorption spectrum. The energy gap results are shown in Fig. 3a, b. As it is clear in Fig. 3, the absorption spectrum has two linear parts, which its cross section is placed in the 310 nm wavelength, equivalent to an energy gap of 4 eV, based on E = 1240/λ equation. The sample’s energy gap is calculated 4.1 eV by the x-intercept of the linear part of the graph (αhν)2 per photon energy (hν), according to the below equation [24]:

where α is the absorption coefficient, n is the optical transition, and its value for the direct transition is 0.5.

3.2 Electrical characteristics

The important parameters of the SDs, e.g., effective saturation reverse, n, and BH, can be derived from I–V data. Hence, the I–V measurement in the ± 3 V voltage range at room temperature with a dark environment was done for both MS and MPS diodes (Fig. 4). Figure 4a, b presents the I–V graph and semilogarithmic forward and reverse bias of the diodes, respectively. As is observable in Fig. 4a, the I–V graph of both heterojunction structures has a diode behavior and the value of the direct bias current is exponentially increased with voltage increase. Also, it is apparent that MPS-type SDs show a good rectification behavior, and a suitable linear area in the bias voltage range for both direct and reverse range, compared to the MS-type diodes. The turn-on voltage value for both MS and MPS SDs is 0.7 and 0.4 V, respectively. In higher bias voltages, the ln I–V graphs of both SDs have a significant deviation from the linear state because of the impacts of the series resistance. Figure 4b shows that the MPS diode has a lower reverse bias current, and consequently, the leakage, which is one of the effective parameters in the efficiency, is reduced owing to the availability of the interfacial layer. The dependence of the SDs on the voltage–current with the condition of (V > 3kT/q) can be exhibited in Eq. (2) per thermionic emission (TE) [12]:

The ideality factor value and the saturation current values can be measured by the slope and y-intercept of the linear part of the ln I–V graph in the low direct voltages. After determining the saturation current value, the diodes barrier’s values can be calculated by Eqs. 3a and 3b:

where ΦΒ0, A, A*, and are zero-bias BH, contact area, and Richardson constant, respectively. The other parameters have been introduced in our previous works [25, 26]. The ideal factor, reverse current, and barrier height values calculated by the Eqs. (3a, 3b) and (4a, 4b) are 6.78, 2.75 × 10−5 A, and 0.53 eV for MS diode, and 3.48, 6.14 × 10−6 A, and 0.57 eV for MPS diode.

From the obtained results, it can be observed that the use of an interlayer on the metal–semiconductor junction has led to an improvement in all three parameters, namely a reduction in the ideality factor, a drop in the reverse saturation current, and an increment in barrier’s height. Thus, the rectification of the MPS diode is about 20 times more than the MS diode. Also, the ideality factor values of both diodes are above one owing to the various factors, such as the presence of an inherent and polymer interlayer, the density of Nss in the metal–semiconductor junction, and non-heterogeneity of the barrier’s height (BH), which led to deviation from the TE ideal theory [27, 28]. Among the other crucial parameters in SDs, series resistance (Rs) and shunt resistance (Rsh) can be noted. These parameters may be affected by the interlayer and create a major error in the physical data extraction from these diodes. The high value of Rs derives to a drop in the direct current, and consequently, a drop in diode’s efficiency, while the high value of Rsh results in Fig. 5. The decline in leakage current, and accordingly an increment in the rectification of diode. In the current study, the Rs values are compared and calculated using Ohm’s law, Norde functions, Chung, and modified Borde by Bohlin [28,29,30]. The voltage dependence of the series and shunt resistance is calculated, and their graphs are presented in Fig. 5.

AS depicted in Fig. 5, the Ri value approaches toward a constant value in the high bias voltages (V = 3 V), which is in harmony with the real value of Rs of the SD. By contrast, the Ri value again approaches toward a constant value in the sufficiently low reverse bias voltages (V = − 3 V), which is consistent with the real value of Rs of the SD. Based on the Ohm’s law, the Rs and Rsh values are 663 Ω and 6.08 kΩ for the MS diode, and 303 Ω and 52.6 kΩ for the MPS diode. The results indicate that the Rs is reduced and the Rsh is increased, and thus, the efficiency and rectification of the diode are significantly increased because of the presence of the interlayer. In the following, BH, n, and Rs have been derived by the use of the Norde method. With condition of V > 3kT/q, Eq. (2) can be written as below (Eqs. 4a, 4b):

In which β = q/kT. The values of series resistance and ideality factor can be measured in the direct bias area using the linear part of the graph dV/d ln (I) per I. The Rs value can be estimated from the slope of the linear area, and the n value can be obtained from the x-intercept. The change function can be implemented for determining the barrier height, which is defined as Eqs. (5a) and (5b) [7]:

The barrier height value is estimated from the linear part of the direct bias area of graph H(I) per (I). The Rs is measured from the slope, and ΦB is obtained from the x-intercept of the linear part of the mentioned graph. However, for calculation of the barrier height, the n value is needed, which is achieved from Eqs. (4a, 4b). The empirical graph dV/d (ln I) and H(I) per I for MS and MPS diodes are shown in Fig. 6. The estimated parameters by this method are presented in Table 1 and a comparison was implemented with those attained by the TE method.

Moreover, Rs and BH values of the diodes are determined by the Norde method and compared to each other. The Norde [31], Sato, and Yasumara [32] function is defined as the following equation:

where γ is the initial integer above n.

The F(V)-V curves of both diodes are shown in Fig. 7. In an SD with Rs, based on the Norde method, the F(V) graph per V has a minimum pint in the concave area. According to the specifications of such a point, Rs, and \(\varPhi_{\text{B}}\) can be calculated using Eqs. (7a) and (7b):

In Eq. 6, where Imin and Vmin are current and voltage values of the minimum point, respectively. The minimum point specifications and the calculated parameters for the diodes are presented in Table 2. Comparing the obtained results in Tables 1 and 2, it is apparent that the ideality factor, series resistance, and leakage current values for MPS diode are lower than those for MS diode. Therefore, the diode’s efficiency and rectification are improved by an interlayer. This outcome is true for all the parameters obtained from all three methods. The differences in the extracted parameters, which are derived from the high series resistance, voltage drop in the middle area, and the density of surface states [33], are used for the voltage area.

Another effective factor in the diode’s efficiency is the density of surface states (Nss). These surface or trap states, which are created with manufacturing a diode in the forbidden gap, can change carriers transport mechanism by storing or releasing the electrical charges in bias, and affect the main parameters of the part. Accordingly, to investigate the density of surface states, derived from the interlayer on the metal–semiconductor junction, the graph of the energy dependence of these traps has been calculated using I–V, n–V, and ΦB–V data of these diodes and is shown in Fig. 8.

The energy levels of the surface states (Ess) to the valence band edge (Ev) in a p-type semiconductor is expressed by Eq. (8) [34]:

where Φe is the effective BH, and V is the voltage drop in the diode. Both n and BH values are a function of the direct bias voltage. Also, the n value depends on the width of the empty layer (WD), which is proportionate to the reverse root of the contaminated atoms density and the thickness of the created inherent insulator film on a metal–semiconductor junction. It is described by the Card and Rhoderick’s proposed equations (Eqs. 9a, 9b) [29]:

where δ and WD are the thickness of the interlayer, and the width of the empty area, respectively. εs and εi are the dielectric constants of the semiconductor and the interlayer. The permittivity rate of silicon is 11.8 ε0 and the dielectric constant of SiO2 and PVP: Zn-TeO2 inherent layers are 3.5 and 70, respectively, calculated by the measured C–f data and using equation k = ε/ε0. Also, the ε0 is the vacuum’s permittivity (ε0 = 8.86 × 10−14 F/cm). The surface states’ energy rates for the MS and MPS diodes have been calculated between 0.37 and 0.48 eV-Ev and 0.37 and 0.53 eV-Ev, respectively. The Nss approximately grow exponentially from the middle energy gap towards the Ev height band edge. The value of Nss at 0.37 eV-Ev equal to 5.8 × 1013 eV−1 cm−2 for MPS, and 1.1 × 1014 eV−1 cm−2 for MS-type structure, respectively. The obtained results indicate that the use of (PVP: Zn-TeO2) organic interlayer leads to a decrease in Nss value due to the passivation effect of it and hence can be used as successfully as an intrinsic layer in the MS-type SDs in respect of easy grown techniques such as spin coating, sol–gel, and electrospinning, low-cost and weight per molecule, and flexibility.

3.3 Dielectric properties

The dielectric factors, e.g., σac, tan δ, ɛ′, and ɛ″, were estimated by C (capacitance) and G (conductance) measurement for both diodes between 100 Hz and 1 MHz at 1.5 V voltage at the room temperature. The complex permittivity function (ε) is expressed by Eq. (10) [14, 35]:

where ɛ′, ɛ″, C0, Y*, and ω, are real and imaginary parts of the complex permitivity, capacitance of the empty capacitor, admittance, and angular frequency of applied field, respectively. The value of C0 is calculated through C0 = εoA/d equation. In this equation, the vacuum permittivity constant is εo = 8.5 × 10−14 F/cm, the contact area is A (= 7.85 × 10−3 cm2), and d is the interlayer thickness, which is 6 mm for the SiO2 intrinsic layer and 100 nm for the PVP: Zn-TeO2 layer. Figures 9a and 10a show the changes in C and G; also, Figs. 9b and 10b indicate the alternations of ɛ′ and ɛ″ in frequencies from 100 Hz–1 MHz. It is observed in Figs. 9b and 10b that the ɛ′ and ɛ″ are highly dependent on the frequency in the low-frequency range, and their values are decreased with a growth in the frequency. However, it is independent of the frequency in high-frequency ranges.

This behavior, namely frequency dependence of ɛ′ and ɛ″ values, is due to the interface states’ response to the frequency. These interface states are possible in the low frequencies, leading to higher dielectric constants in the lower frequencies. By contrast, the interface state is almost stopped at higher frequencies, and therefore, these parameters are independent of the frequency. This interface state in the lower frequencies can be explained by the Koop equation, which is developed based on the Maxwell–Wagner bipolar model. According to this model, most of the charge carriers participating in the current guidance mechanism are agglomerated on the dielectric environment surface by the creation of high polarization, resulting in a high-dielectric constant in the low frequencies.

At high frequencies, the Nss cannot follow the alternating filed owing to the high longevity of the charge carriers (1/τ > ω), and consequently, the polarization value of the interlayer reaches a fixed number [14, 35]. Also, it is observed in Figs. 9 and 10 that the dielectric constant of the (PVP: Zn-TeO2) in the frequency of 100 Hz is 70, and for the SiO2 intrinsic layer, it is 3.5. In other words, the dielectric constant of the polymer layer is ~ 20 times higher than the intrinsic layer, which indicates that this polymer layer can be a good option for the capacitors. The waste energy in the dielectric layer is evaluated by the waste tangent, based on Eq. (11) [36]:

Figure 11a shows the frequency dependence of the waste tangent tan (δ). Similar to the frequency dependence graphs of ɛ′ and ɛ″, the tan (δ) is also highly dependent on the frequency, reducing with frequency increase, and getting steady in higher frequencies. This behavior of the waste tangent depends on the different parameters, including Nss, Rs, and the interlayer’s thickness. In the low-frequency zone, the tan δ value for the MPS2 diode (which comprises of a polymer nanocomposite with barium titanate nanostructures) is higher than the other diodes, because this polymer layer has the lowest series resistance and polarization, leading to an increment in the eddy current, and consequently, in the energy waste of structure. The resistance and polarization values become fixed with frequency rising, and as a result, the waste tangent value also becomes approximately steady [36].

The ac electrical conductivity can be calculated by Eq. (12), and its frequency dependence graph is also provided in Fig. 10b [36]:

As shown in Fig. 11b, the value of σac for all diodes is fixed in the low-frequency zones and is independent of the frequency. However, this value is increased in high frequencies with rising frequency due to a decrease in Rs, which agrees with the results obtained in various studies [25, 26]. Also, according to this figure, the ac electrical conductivity of the MS is lower than MPS owing to the used polymer interlayer. The reason behind this phenomenon is the low value of Rs in the MPS compared to the MS diode, resulting in a 200-times boost in the ac electrical conductivity.

4 Conclusions

In this study, both the Al/p-Si (MS) and Al/(PVP: Zn-TeO2)/p-Si (MPS) heterojunction structures have been fabricated on the same p-Si substrate to see the effect of (PVP: Zn-TeO2) organic interlayer on the electrical and dielectric characteristics using I–V and C/G–V–f analysis. Before the investigation of electric and dialectic properties, the morphology, purity determination, and the optical properties of the performed Zn-TeO2 nanostructures have been investigated using the SEM, XRD, EDS, and UV–Vis analyses methods. The energy bandgap of the Zn-TeO2 nanostructures was found as 4.1 eV from the intercept of the linear part of the graph (αhν)2 vs. (hν) curve. To get more information about the electrophysical parameters, I–V measurements and Z–f were done in wide range bias voltage (± 3 V) and frequency (100 Hz–1 MHz) at 1.5 V, respectively. The obtained experimental values of n, ΦB, and Rs from the forward bias I–V data were found both as a function of voltage and calculation method. While the values of rectifying-rate (RR = If/Ir at ± 3 V), ΦB, and Rsh of the MPS were found higher than the MS structure, leakage current and Rs decreases. The derived Nss parameter from the forward-bias I–V data for MPS is also considerably lower than the MS-type structure and they increase almost the mid-gap of Eg towards to edge of the conduction band. Also, obtained experimental values of ε′, ε″ and tan δ (= ε″/ε′) from the C/G–V data at 1.5 V was found strong function frequency especially at low and intermediate frequencies and decrease with increasing frequency, whereas σac increases. All these experimental results are indicated the use of (PVP: Zn-TeO2) organic interlayer between Al and p-Si leads to an increase in the ε′, ε″, BH, Rsh, and decrease in the leakage current, Nss due to the passivation effect of it. Therefore, Al/(PVP: Zn-TeO2)/p-Si structures can be used as an electronic part in nanoscale instead of MS structures. The observed high value of capacitance or dielectric constant for MPS heterojunction structure is also evidence that it can be more storage charges and energy when compared to MS structure with and without and the low-dielectric insulator layer.

References

S.K. Kulkarni, Nanotechnology: principles and practices (Springer, New York, 2014)

S. Manzoor, M. Filipič, A. Onno, M. Topič, Z.C. Holman, Visualizing light trapping within textured silicon solar cells. J. Appl. Phys. 127, 063104 (2020)

V. Baranwal, S. Kumar, A. Pandey, D. Kanjilal, Effect of ion irradiation on current–voltage characteristics of Au/n-GaN Schottky diodes. J. Alloys Compd. 480, 962–965 (2009)

M. Yıldırım, Current conduction and steady-state photoconductivity in photodiodes with bismuth titanate interlayer. Thin Solid Films 615, 300–304 (2016)

A. Buyukbas-Ulusan, İ. Taşçıoğlu, A. Tataroğlu, F. Yakuphanoğlu, S. Altındal, A comparative study on the electrical and dielectric properties of Al/Cd-doped ZnO/p-Si structures. J. Mater. Sci.: Mater. Electron. 30, 12122–12129 (2019)

A. Turut, M. Coșkun, F. Coșkun, O. Polat, Z. Durmuș, M. Çağlar, H. Efeoğlu, The current-voltage characteristics of the ferroelectric p-YMnO3 thin film/bulk p-Si heterojunction over a broad measurement temperature range. J. Alloy. Compd. 782, 566–575 (2019)

C. Sharma, A.K. Visvkarma, R. Laishram, A. Kumar, D.S. Rawal, S. Vinayak, R. Singh, Effect of γ-ray irradiation on Schottky and ohmic contacts on AlGaN/GaN hetero-structures. Microelectron. Reliab. 105, 113565 (2020)

Y. Azizian-Kalandaragh, Dielectric properties of CdS-PVA nanocomposites prepared by ultrasound-assisted method. Optoelectron Adv. Mater. Rapid Commun. 4, 1655–1658 (2010)

S. Demirezen, Ş. Altındal, S. Özçelik, E. Özbay, On the profile of frequency and voltage dependent interface states and series resistance in (Ni/Au)/Al0. 22Ga0. 78N/AlN/GaN heterostructures by using current–voltage (I–V) and admittance spectroscopy methods. Microelectron. Reliab. 51, 2153–2162 (2011)

S. Demirezen, The role of interface traps, series resistance and (Ni-doped PVA) interlayer effects on electrical characteristics in Al/p-Si (MS) structures. J. Mater. Sci.: Mater. Electron. 30, 19854–19861 (2019)

S.A. Yerişkin, The investigation of effects of (Fe2O4-PVP) organic-layer, surface states, and series resistance on the electrical characteristics and the sources of them. J. Mater. Sci.: Mater. Electron. 30, 17032–17039 (2019)

M. Singh, M. Rajoriya, M. Sahni, P. Gupta, Effect of aluminum doping on potential barrier of gold-ZnO-Si Schottky barrier diode. Mater. Today: Proc. (2020). https://doi.org/10.1016/j.matpr.2020.01.268

A. Ozkartal, R.H. Ameen, C. Temirci, A. Turut, Electrical properties of Sn/Methyl Violet/p-Si/Al Schottky diodes. Mater. Today: Proc. 18, 1811–1818 (2019)

N. Kumar, S. Chand, Effects of temperature, bias and frequency on the dielectric properties and electrical conductivity of Ni/SiO2/p-Si/Al MIS Schottky diodes. J. Alloy. Compd. 817, 153294 (2020)

V.R. Reddy, V. Manjunath, V. Janardhanam, C.-H. Leem, C.-J. Choi, Double Gaussian distribution of barrier heights, interface states, and current transport mechanisms in Au/Bi0.5Na0.5TiO3-BaTiO3/n-GaN MIS structure. J. Electron. Mater. 44, 549–557 (2015)

G. Dai, F. Tassone, A.L. Bassi, V. Russo, C.E. Bottani, F. D’Amore, TeO2-based glasses containing Nb2O5, TiO2, and WO3 for discrete Raman fiber amplification. IEEE Photonics Technol. Lett. 16, 1011–1013 (2004)

Z. Liu, T. Yamazaki, Y. Shen, T. Kikuta, N. Nakatani, T. Kawabata, Room temperature gas sensing of p-type TeO2 nanowires. Appl. Phys. Lett. 90, 173119 (2007)

S.S. Kim, J.Y. Park, S.-W. Choi, H.G. Na, J.C. Yang, D.S. Kwak, H.J. Nam, C.K. Hwangbo, H.W. Kim, Drastic change in shape of tetragonal TeO2 nanowires and their application to transparent chemical gas sensors. Appl. Surf. Sci. 258, 501–506 (2011)

F. Haaf, A. Sanner, F. Straub, Polymers of N-vinylpyrrolidone: synthesis, characterization and uses. Polym. J. 17, 143–152 (1985)

V. Bühler, Polyvinylpyrrolidone excipients for pharmaceuticals: povidone, crospovidone and copovidone (Springer Science & Business Media, New York, 2005)

T. Siciliano, A. Genga, G. Micocci, M. Siciliano, M. Tepore, A. Tepore, Porous tellurium oxide microtubes for room-temperature NO2 gas sensors. Sens. Actuators B: Chem. 201, 138–143 (2014)

F. Arab, M. Mousavi-Kamazani, M. Salavati-Niasari, Synthesis, characterization, and optical properties of Te, Te/TeO2 and TeO2 nanostructures via a one-pot hydrothermal method. RSC Adv. 6, 71472–71480 (2016)

N. Tagiara, D. Palles, E. Simandiras, V. Psycharis, A. Kyritsis, E. Kamitsos, Synthesis, thermal and structural properties of pure TeO2 glass and zinc-tellurite glasses. J. Non-Cryst. Solids 457, 116–125 (2017)

L. Pei, H. Liu, N. Lin, H. Yu, Bismuth titanate nanorods and their visible light photocatalytic properties. J. Alloys Compd. 622, 254–261 (2015)

S. Altindal, J. Farazin, G. Pirgholi-Givi, E. Maril, Y. Azizian-Kalandaragh, The effects of (Bi2Te3–Bi2O3-TeO2-PVP) interfacial film on the dielectric and electrical features of Al/p-Si (MS) Schottky barrier diodes (SBDs). Phys. B 582, 411958 (2020)

Y. Badali, Y. Azizian-Kalandaragh, E.A. Akhlaghi, Ş. Altındal, Ultrasound-assisted method for preparation of Ag2S nanostructures: fabrication of Au/Ag2S-PVA/n-Si Schottky barrier diode and exploring their electrical properties. J. Electron. Mater. 49, 444–453 (2020)

Ç.G. Türk, S.O. Tan, Ş. Altındal, B. İnem, Frequency and voltage dependence of barrier height, surface states, and series resistance in Al/Al2O3/p-Si structures in wide range frequency and voltage. Phys. B: Condensed Matter. 582, 411979 (2020)

F. Aslan, H. Esen, F. Yakuphanoglu, Al/P-Si/Coumarin: TiO2/Al organic-inorganic hybrid photodiodes: investigation of electrical and structural properties. Silicon 12, 2149–2164 (2019)

H. Card, E. Rhoderick, Studies of tunnel MOS diodes I. Interface effects in silicon Schottky diodes. J. Phys. D: Appl. Phys. 4, 1589 (1971)

N. Yıldırım, A. Turut, M. Biber, M. Saglam, B. Guzeldir, The electrical current characteristics of thermally annealed Co/anodic oxide layer/n-GaAs sandwich structures. Int. J. Mod. Phys. B 33, 1950232 (2019)

H. Norde, A modified forward I–V plot for Schottky diodes with high series resistance. J. Appl. Phys. 50, 5052–5053 (1979)

K. Sato, Y. Yasumura, Study of forward I–V plot for Schottky diodes with high series resistance. J. Appl. Phys. 58, 3655–3657 (1985)

Ö. Güllü, A. Türüt, Electrical analysis of organic dye-based MIS Schottky contacts. Microelectron. Eng. 87, 2482–2487 (2010)

S. Tan, İ. Taşcıoğlu, S.A. Yerişkin, H. Tecimer, F. Yakuphanoğlu, Illumination dependent electrical data identification of the cdzno interlayered metal-semiconductor structures. Silicon (2020). https://doi.org/10.1007/s12633-020-00382-9

N. Baraz, İ. Yücedağ, Y. Azizian-Kalandaragh, G. Ersöz, I. Orak, Ş. Altındal, B. Akbari, H. Akbari, Electric and dielectric properties of Au/ZnS-PVA/n-Si (MPS) structures in the frequency range of 10–200 kHz. J. Electron. Mater. 46, 4276–4286 (2017)

I. Afandiyeva, I. Dökme, Ş. Altındal, M. Bülbül, A. Tataroğlu, Frequency and voltage effects on the dielectric properties and electrical conductivity of Al–TiW–Pd2Si/n-Si structures. Microelectron. Eng. 85, 247–252 (2008)

Acknowledgements

This study was supported by Gazi University Scientific Research Center with (GU-BAP.05/2019-26) project number.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azizian-Kalandaragh, Y., Farazin, J., Altindal, Ş. et al. Electrical and dielectric properties of Al/(PVP: Zn-TeO2)/p-Si heterojunction structures using current–voltage (I–V) and impedance-frequency (Z–f) measurements. Appl. Phys. A 126, 635 (2020). https://doi.org/10.1007/s00339-020-03804-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03804-y