Abstract

In this study, five different glasses encoded ND1, ND2, ND3, ND4 and ND5 based on (59.5–x) P2O5–30Na2O–10Al2O3–0.5CoO–xNd2O3 (x = 1, 2, 3, 4 and 5 mol%) glass system were fabricated. Using two γ- ray energies emitted from point sources, 356 keV (133Ba) and 662 keV (137Cs), γ-ray attenuation coefficients were measured as a function of the Nd2O3 concentration. The theoretical values of the mass attenuation coefficient were calculated using the XCOM program at 0.015–15-MeV photon energies. As it is underlined in the results section, the mass attenuation coefficient increases as the Nd2O3 concentration increases. X-ray diffraction (XRD) was characterized for fabricated glasses. Moreover, different shielding parameters such as half-value layer (HVL), mean free path (MFP), effective atomic numbers (Zeff), basic gamma-ray attenuation properties such as exposure buildup factors (EBF) and energy absorption buildup factors (EABF) at different penetration depths were calculated. With increasing Nd2O3 additive in glass samples, half-value layer (HVL), average free path (MFP), exposure and energy absorption buildup factor (EBF and EABF) values decrease. On the other hand, Zeff values increase with increasing Nd2O3 additive in glass samples at the photon energy 0.015–15 MeV. The results highlighted that ND5 sample with highest value of Nd2O3 (5 mol%) showed excellent nuclear radiation shielding properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ionizing radiation is an important term to be considered along with its benefits and potential risks. Despite its benefits in medical diagnosis and treatment practices, the risk status on living biological structures should always be considered and minimized. Gamma radiation shielding is a very important application because γ-rays have risky effect on human health. The ALARA principle suggests the use of the most suitable shielding material to reduce the amount of ionized radiation exposed. Technological developments have brought with the use of new methods for radiation shielding studies. Moreover, the development and use of radiation shielding materials that are environmentally friendly, low cost and have high material durability is one of the most popular research topics in the literature in recent years. Glass materials which are new and promising material types in terms of structural development, transparency, high durability and environmental friendliness features used for radiation shielding have gained a very useful place in nuclear reactors, fusion reactors and modern accelerator technology. As it is clearly seen from the previous studies, lead (Pb) materials which have various disadvantages to protect against gamma rays have been replaced by various types of materials such as concrete and glass to protect them from gamma rays [1,2,3]. Glass materials [4,5,6,7,8] are a very reliable material used in radiation shielding instead of concrete [9,10,11]. Various phosphate glass systems (PG) with characteristics such as low dispersion power, low refractive index, high gain density, low melting point and high thermal stability are being developed day by day by combining glass-forming oxides (SiO2 and TeO2) and modifying oxides (Al2O3, CaO, K2O, PbO, Na2O, BaO, MgO, CaF2, Fe2O3, ZnO, TiO2, etc.). By adapting the chemical mixtures of phosphate-based glass structures, it can be quite suitable material types which can be manufactured for different functional applications.

The addition of Al2O3 to phosphate-based glass samples has the effect of increasing cross-links between PO4 units that form Al–O–P bonds. These Al–O–P bonds are more covalent than P–O–P bonds. On the other hand, P–O–P bonds have a straight impact on some characteristic features [chemical resistance, glass transition temperature (Tg), density and thermal expansion coefficient (α)] of glass samples. In addition, as alkali metal oxide (e.g., Na2O) is added to the glass materials, it causes the P–O–P bonds to break, the three-dimensional networks turn into linear phosphate chains and the formation of NBOs consisting of P–O–Na (K) bonds that are weaker than P–O–Al bonds. CoO, added to glass materials, has a positive effect due to its easy processing, stability at high temperatures and adjustable release kinetics [12,13,14,15,16,17,18,19,20,21,22,23,24]. In this paper, five different glasses based on (59.5–x) P2O5–30Na2O–10Al2O3–0.5CoO–xNd2O3 system were examined in terms of structural and gamma ray shielding properties. To examine the shielding properties of the materials, the most basic parameter used is the mass attenuation coefficient (µm). The attenuation principle of photons is interpreted in three different processes. The first of these interaction processes are photoelectric absorption, which is effective in low energies; the second is Compton scattering, which is effective in medium energies; and lastly pair production that is active in high energies. The total value of the mass attenuation coefficient is equal to the sum of these three processes and is related by the primary energy of the photon, average atomic number (Z) and chemical system of the substance [25, 26]. In this study, five different glasses encoded ND1, ND2, ND3, ND4 and ND5 based on (59.5–x) P2O5–30Na2O–10Al2O3–0.5CoO–xNd2O3, where x = 1, 2, 3, 4 and 5 (mol%) glass system, were fabricated. In addition, X-ray powder diffraction (XRD) was utilized for structural analyses. Next, an experimental gamma-ray transmission setup was established for calculation of mass attenuation coefficients of fabricated glasses. We used 0.356- and 0.662-MeV gamma photons energies emitted from point isotropic gamma sources, namely 133Ba and 137C. It is worth to mention that this study aimed to observe the total impact of P2O5 replacement by Nd2O3. Therefore, the hypothesis of recent investigation can be highlighted by Nd2O3 reinforce effect and multiple impact on structural and gamma-ray attenuation properties of fabricated glasses. To provide the infrastructure of this hypothesis, Al205, Na2O and CoO ratios were kept constant and the effect of Nd2O3 ratio, which increased with partial decrease of P2O5 ratio (Table 1), was investigated. On the other hand, the theoretical mass attenuation coefficient values were examined using the XCOM program at 356-keV and 662-keV photon energy values. X-ray diffraction (XRD) was characterized for fabricated glasses. The investigated properties of novel glasses can be listed as follows:

-

X-ray powder diffraction (XRD) of fabricated glasses.

-

Half-value layer (HVL), mean free path (MFP).

-

Effective atomic numbers (Zeff).

-

Exposure buildup factors (EBF) and energy absorption buildup factors (EABF) at different penetration depths have been calculated at different Nd2O3 mol% levels and the energies (0.015–15 MeV).

-

A comprehensive mass attenuation coefficient investigation.

The data achieved from this study can be useful for further research on the use of glass materials, a new generation material, in efficient and environmentally friendly shielding applications. The hypothesis of this research is to evaluate the multiple effects of increasing Nd2O3 additive amount on structural and ionizing radiation attenuation features of fabricated glass samples. Therefore, outcomes from recent investigation will be discussed in terms of increased Nd2O3 additive amount in manufactured glass samples. The obtained results from this experimental investigation can be useful for new approaches on novel, efficient and eco-friendly glass shields and their utilization for different types of ionizing radiation facilities such as medical radiation facilities, industrial radiation areas and research laboratories.

2 Materials and methods

Glass samples with chemical formula (59.5–x) P2O5–30Na2O–10Al2O3–0.5CoO–xNd2O3, where x = 1, 2, 3, 4, mol%). were prepared by the conventional melt quenching method and are given in Table 1. The materials that initiate the reaction are reagent grade (NH4)2HPO4, Na2CO3, Al2O3, CoO and Nd2O3. Powdered oxides were melted at 1050–1150 °C in a porcelain vessel in an air-conditioned electric oven for 35–45 min. To ensure homogeneity, melt shaking was performed during the preparation phase. Samples prepared by pouring the melt into preheated molds at 350 °C were left to anneal for a few hours at 450 °C. The oven was then left to cool to room temperature. The prepared samples were then ground and polished for XRD. XRD is often used to verify the glassy structure of the samples. When no peak is observed in the patterns obtained as a result of verification, the amorphous structure of the samples examined is verified. Gamma-ray shielding parameters of glass samples were measured using 0.356-MeV and 0.662-MeV gamma photons, which were emitted from point sources of 133Ba and 137Cs. The mass attenuation coefficients (µm) of the samples were evaluated using the NaI (T1) scintillation detector with the setup scheme depicted in Fig. 1. Some of the features of this detector are: Gammas of 0.662 MeV, emitted from 137Cs point source, have a 7.5% resolution and the thickness of the Al window is 0.5 mm. The measurement time for each sample was approximately 4 h and the measurement were repeated three times. Finally, densities of glasses have been determined with well-known Archimedes method. We remark that the measurement was repeated three times on each sample.

3 Theory

If the absorbent material is a chemical mixture or compound, the mass attenuation coefficient (µm) is estimated by the mixture rule and is expressed as given in the equation below [27, 28]:

Here, wi is partial mass component of the ith element in the investigated glass sample. In our work, the \({}_{\mathrm{m}}\) results of glass samples were obtained using the theoretical XCOM program. By the help of \({}_{\mathrm{m}}\) values, other shielding terms such as transmission factors (e.g., HVL, MFP) were then calculated by employing the equations as follows:

Zeff values of fabricated glass samples were determined by the help of Eq. 4 [29,30,31]:

In the formula, fi, μ, Zi and Ai indicate the fraction of each element, linear attenuation coefficient, atomic number and atomic weight, respectively. The equivalent atomic number (Zeq) values for the prepared glass samples were estimated using the equation given below [32,33,34].

The terms of EBF and EABF give successful information about the number of photons, intensity, energy flux, and dose. Recently, EBF and EABF of ND1, ND2, ND3, ND4 and ND5 based on (59.5–x) P2O5–30Na2O–10Al2O3–0.5CoO–xNd2O3, where x = 1, 2, 3, 4 and 5 (mol%), were determined for gamma energies up to 15 MeV and for penetration depth up to 40 MFP using G-P fitting method. To estimate the buildup factors of fabricated glass samples, the equivalent atomic numbers (Zeq) are first determined. The Zeq can be determined based on the following interpolation equation [35,36,37]:

where

Here, R is the ratio between Compton-attenuation and total attenuation ((µ/ρ)Comp/(µ/ρ)total). The next step is to obtain G-P fitting parameters using Zeq values utilizing the Eq. 8. Finally, the buildup factors of fabricated glasses were studied. These equations contain x as the distance between the source and the detector. At 1 mfp, the EBF is coded by b. K(E, X) factor has a meaning of dose multiplication [38, 39].

4 Results and discussion

4.1 XRD analysis

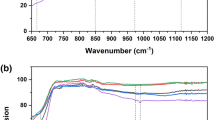

To initiate XRD measurement and verify the glassy structure of the samples, three of the powder samples were selected and shown in Fig. 2. As can be clearly seen from Fig. 2, a bump structure was observed at 15°–35° in all three examples; while, diffraction peaks confirming the non-crystalline glass structure of the prepared samples were not observed.

4.2 Radiation shielding parameters

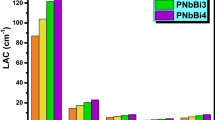

High-density glass samples have larger atomic numbers and can be considered an effective material for the gamma-ray shielding. This is related to the chemical composition of the glasses as well as the commitment to photon energy. The experimental and theoretically (XCOM) calculated mass attenuation coefficients (µm) of glass samples prepared at 0.356- and 0.662-MeV gamma photons emitted from spot sources 133Ba and 137C can be seen from Table 2. According to Table 2, the µm values in the 0.356 MeV and 0.662 MeV energy increase with increasing Nd2O3 contribution (i.e., when switching from ND1 glass sample to ND5 glass sample) [40]. The µm values are highest for the ND5 sample, while the lowest for the ND1 sample (see Table 2). This is because the ND5 sample contains the highest amount of Nd2O3 additives than other samples. The experimental results and XCOM results are slightly different underlining the performance of the model in terms of both robustness and high correlation with experimental outcomes. As can be seen also from Fig. 3, the experimental and theoretical data of µm values are highly compatible and supportive. As seen in Fig. 3, a peak is observed at 0.4154 MeV, 0.5506 MeV, 0.6858 MeV, 0.821 MeV and 0.9562 MeV due to the K absorption edge of the Nd element for glass samples of ND1, ND2, ND3, ND4 and ND5, respectively. As it is known, photons interact with the material in three ways and the sharp decrease in µm values in Fig. 3 is caused by the photoelectric event from these interaction processes [41,42,43]. Because the microscopic cross-section value is directly proportional to Z4−5 and inversely proportional to E−3.5. While the change in µm values is quite low in medium energies where Compton scattering is effective, the µm values take almost constant value due to the dominant pair production in high energies [44, 45]. The effect of the Nd2O3 additive on the half-value layer (HVL) and the mean free path (MFP) measurement results in glass samples is shown in Figs. 4 and 5. As can be seen from the Figs. 4 and 5, these values decrease with increasing Nd2O3 contribution. On the other hand, when photon energy is high, HVL and MFP values are also high. The HVL, one of the well-known shielding parameters, is a shield or absorber that reduces the radiation level to half the original intensity. On the other hand, the MFP shows the average distance between two consecutive gamma photon interactions [45, 46]. These two concepts are quick and very practical in approximate shielding calculations. Therefore, HVL and MFP should be small to achieve a strong radiation shielding in glass samples means low HVL and MFP values indicate the best radiation shielding. That is, as the density values of the glass samples increase, the MFP and HVL values decrease [47]. Thus, the high density ND5 glass sample has the minimum value for these two measurements, i.e. ND5 glass sample is the best shielding material among the glass samples. In composite materials, the effective atomic number and density values affect the absorption and scattering of photon interactions. Composite materials are very successful at reducing gamma rays when they have a higher effective mass number, since they will have more electrons per atom. The effective atomic number (Zeff) values of the five glass samples were calculated using Eq. 4 in the energy region of 0.015–15 MeV and are shown in Fig. 6. As can be seen from the figure, Zeff value decreases for all glass samples with the increase of photon energy. In addition, instant changes in Zeff values are seen due to the K absorption edge. Also, the Zeff values increases as the Nd2O3 increases from 1 to 5 mol%. The two other important gamma shielding parameters are exposure buildup factor (EBF) and energy absorption buildup factor (EABF). While EBF expresses the energy absorption properties of air, EABF describes the energy absorbed or accumulated in the attenuator. The calculated values of equivalent atom number (Zeq), EBF and EABF are shown in Tables 3, 4, 5, 6 and 7, respectively, for glass samples ND1, ND2, ND3, ND4 and ND5. Figures 7 and 8 show EBF and EABF changes for five different glass samples in the energy region of 0.015–15-MeV photon energy and at different penetration depths (1 mfp, 5 mfp, 10 mfp, 20 mfp and 40 mfp). As can be seen from Figs. 7 and 8, the minimum EBF and EABF values of the glass samples were observed at low energies. The reason for this is perhaps the photoelectric effect process [7, 48, 49]. EBF–EABF values increase with increasing energy in the middle energy region and reach a maximum of approximately at 0.6-MeV energy and then decrease with increasing energy value. This response can be associated with multiple scattering caused by Compton effect. In addition, EBF and EABF values increase with increasing penetration depth values for glass samples. On the other hand, in Figs. 9 and 10, the EBF and EABF values of all glass samples at a certain penetration depth value of 15 mfp are examined depending on the energy. While the EBF and EABF values of ND1 glass sample with the lowest Nd2O3 additive (1%) are highest, the EBF and EABF values of ND5 glass sample with the highest Nd2O3 additive (5%) are minimum.

5 Conclusion

The glass system of (59.5–x) P2O5–30Na2O10Al2O3–0.5CoO–xNd2O3, where x = 1, 2, 3, 4 and 5 (mol%), has been successfully fabricated with the help of the melt quenching technique to indicate gamma shielding properties. Al205, Na2O and CoO ratios were kept constant and the effect of Nd2O3 ratio, which increased with partial decrease of P2O5 ratio, on the shielding properties of glass samples was investigated. The theoretical values of the mass attenuation coefficient were calculated using the XCOM program at 356-keV and 662-keV photon energy values with XCOM program. X-ray diffraction (XRD) was characterized for fabricated glasses. The µm values of the samples were measured using the NaI (T1) scintillation detector. Zeff, HVL, MFP, EBF and EABF gamma shielding parameters were calculated to examine the gamma radiation shielding features of ND1, ND2, ND3, ND4 and ND5 glass samples. The results highlighted that both the µm and Zeff values increased as the Nd2O3 concentration increased. On the other hand, HVL, MFP, EBF and EABF values decreased as the Nd2O3 concentration increased. ND5 glass has the lowest HVL, MFP, EBF and EABF values. Finally, the mass attenuation coefficient comparison has been done between experimental results and XCOM program. Theoretical and experimental data of µm values are highly compatible and supportive indicating the distinctive protection ability to attenuate photon radiation of ND5 glass sample. Thus, glass samples prepared have been shown to reduce the harmful effects of radiation. The data achieved from this study can be useful for further research on the use of glass materials, a new generation material, in efficient and environmentally friendly shielding applications. The different comprehensive measurements can be performed between traditional lead shields and studied glasses considering the significant parameters such as production cost, environmental effects, toxicity, durability. Hereby, it should be noted that continuous efforts on further improvements are necessary.

References

H.E. Hassan, H.M. Badran, A. Aydarous, T. Sharshar, Studying the effect of nano lead compounds additives on the concrete shielding properties for γ-rays. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact Mater. Atoms 360, 81–89 (2015). https://doi.org/10.1016/j.nimb.2015.07.126

A.S. Wagh, S.Y. Sayenko, A.N. Dovbnya, V.A. Shkuropatenko, R.V. Tarasov, A.V. Rybka, A.A. Zakharchenko, Durability and shielding performance of borated ceramicrete coatings in beta and gamma radiation fields. J. Nucl. Mater. 462, 165–172 (2015). https://doi.org/10.1016/j.jnucmat.2015.03.049

D.K. Gaikwad, M.I. Sayyed, S.S. Obaid, S.A.M. Issa, P.P. Pawar, Gamma ray shielding properties of TeO2–ZnF2–As2O3–Sm2O3 glasses. J. Alloys Compd. 765, 451–458 (2018). https://doi.org/10.1016/j.jallcom.2018.06.240

O. Agar, Z.Y. Khattari, M.I. Sayyed, H.O. Tekin, S. Al-Omari, M. Maghrabi, M.H.M. Zaid, I.V. Kityk, Evaluation of the shielding parameters of alkaline earth based phosphate glasses using MCNPX code. Results Phys. 12, 101–106 (2019). https://doi.org/10.1016/j.rinp.2018.11.054

O. Agar, H.O. Tekin, M.I. Sayyed, M.E. Korkmaz, O. Culfa, C. Ertugay, Experimental investigation of photon attenuation behaviors for concretes including natural perlite mineral. Results Phys. 12, 237–243 (2019). https://doi.org/10.1016/j.rinp.2018.11.053

H.O. Tekin, E.E. Altunsoy, E. Kavaz, M.I. Sayyed, O. Agar, M. Kamislioglu, Photon and neutron shielding performance of boron phosphate glasses for diagnostic radiology facilities. Results Phys. 12, 1457–1464 (2019). https://doi.org/10.1016/j.rinp.2019.01.060

M.G. Dong, O. Agar, H.O. Tekin, O. Kilicoglu, K.M. Kaky, M.I. Sayyed, A Comparative study on gamma photon shielding features of various germanate glass systems. Compos. Part B Eng. 165, 636–647 (2019). https://doi.org/10.1016/j.compositesb.2019.02.022

A. Sharma, M.I. Sayyed, O. Agar, H.O. Tekin, Simulation of shielding parameters for TeO2–WO3–GeO2 glasses using FLUKA code. Results Phys. 13, 102199 (2019). https://doi.org/10.1016/j.rinp.2019.102199

S. Tuscharoen, J. Kaewkhao, P. Limkitjaroenporn, P. Limsuwan, W. Chewpraditkul, Improvement of BaO:B2O3: fly ash glasses: radiation shielding, physical and optical properties. Ann. Nucl. Energy 49, 109–113 (2012). https://doi.org/10.1016/j.anucene.2012.05.017

S.R. Manohara, S.M. Hanagodimath, L. Gerward, Photon interaction and energy absorption in glass: a transparent gamma ray shield. J. Nucl. Mater. 393, 465–472 (2009). https://doi.org/10.1016/j.jnucmat.2009.07.001

C. Bootjomchai, J. Laopaiboon, C. Yenchai, R. Laopaiboon, Gamma-ray shielding and structural properties of barium-bismuth-borosilicate glasses. Radiat. Phys. Chem. 81, 785–790 (2012). https://doi.org/10.1016/j.radphyschem.2012.01.049

S.P. Edirisinghe, C.A. Hogarth, Optical properties of some copper phosphate glasses containing calcium and barium. J. Mater. Sci. Lett. 8, 789–792 (1989). https://doi.org/10.1007/bf01730139

M.A. Karakassides, A. Saranti, I. Koutselas, Preparation and structural study of binary phosphate glasses with high calcium and/or magnesium content. J. Non-Cryst. Solids 347, 69–79 (2004). https://doi.org/10.1016/j.jnoncrysol.2004.08.111

A. Mogus-Milankovic, A. Gajovic, A. Santic, D.E. Day, Structure of sodium phosphate glasses containing Al2O3 and/or Fe2O3. Part I. J. Non-Cryst. Solids 289, 204–213 (2001). https://doi.org/10.1016/S0022-3093(01)00701-3

J. Yifen, J. Dehua, C. Xiangsheng, B. Beiya, H. Xihuai, Raman spectrum studies of the glasses in the system Na2O–Al2O3–P2O5. J. Non-Cryst. Solids 80, 147–151 (1986). https://doi.org/10.1016/0022-3093(86)90388-1

S.M. Abo-Naf, N.A. Ghoneim, H.A. Ei-Batal, Preparation and characterization of solegel derived glasses in the ternary Na2O–Al2O3–P2O5 system. J. Mater. Sci. Mater. Electron. 15, 273–282 (2004). https://doi.org/10.1023/B:JMSE.0000024226.51362.de

Y. Yue, Y. Wang, Y. Cao, S. Chen, Q. Zhou, W. Chen, L. Hu, Effect of Al2O3 on structure and properties of Al2O3–K2O–P2O5 glasses. Opt. Mater. Express 8, 245–258 (2018). https://doi.org/10.1364/OME.8.000245

Y.B. Saddeek, M.A. Kaid, M.R. Ebeid, FTIR and physical features of Al2O3–La2O3–P2O5–PbO glasses. J. Non-Cryst. Solids 387, 30–35 (2014). https://doi.org/10.1016/j.jnoncrysol.2013.12.029

A. Faivre, F. Despetis, L. Duffours, P. Colombel, Effect of CaO and Al2O3 addition on the properties of K2O–Na2O–P2O5 glass system. Int. J. Appl. Glass Sci. 10, 162–171 (2019). https://doi.org/10.1111/ijag.13066

D. Manzani, J.B. Souza Junior, A.S. Reyna, M.L. Silva Neto, J.E.Q. Bautista, S.J.L. Ribeiro, C.B. de Araújo, Phosphotellurite glass and glass-ceramics with high TeO2 contents: thermal, structural and optical properties. Dalton Trans. 48, 6261–6272 (2019). https://doi.org/10.1039/C9DT00691E

A.K. Yadav, P. Singh, A review of the structures of oxide glasses by Raman spectroscopy. RSC Adv. 5, 67583–67609 (2015). https://doi.org/10.1039/C5RA13043C

A. Langar, N. Sdiri, H. Elhouichet, M. Ferid, Structure and electrical characterization of ZnO–Ag phosphate glasses. Results Phys. 7, 1022–1029 (2017). https://doi.org/10.1016/j.rinp.2017.02.028

Q. Yin, S. Kang, X. Wang, S. Li, D. He, L. Hu, Effect of PbO on the spectral and thermo-optical properties of Nd3 p-doped phosphate laser glass. Opt. Mater. 66, 23–28 (2017). https://doi.org/10.1016/j.optmat.2017.01.036

M.K. Narayanan, H.D. Shashikala, Thermal and optical properties of BaO–CaF2–P2O5 glasses. J. Non-Cryst. Solids 422, 6–11 (2015). https://doi.org/10.1016/j.jnoncrysol.2015.04.038

H.O. Tekin, L.R.P. Kassab, S.A.M. Issa, C.D.S. Bordon, E.E. Altunsoy Guclu, G.R. da Silva Mattos, O. Kilicoglu, Synthesis and nuclear radiation shielding characterization of newly developed germanium oxide and bismuth oxide glasses. Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.08.204

M.I. Sayyed, S.A.M. Issa, H.O. Tekin, Y.B. Saddeek, Comparative study of gamma-ray shielding and elastic properties of BaO–Bi2O3–B2O3 and ZnO–Bi2O3–B2O3 glass systems. Mater. Chem. Phys. (2018). https://doi.org/10.1016/j.matchemphys.2018.06.034

N. Chanthima, J. Kaewkhao, Investigation on radiation shielding parameters of bismuth borosilicate glass from 1 keV to 100 GeV. Ann. Nucl. Energy 55, 23–28 (2013). https://doi.org/10.1016/j.anucene.2012.12.011

M.I. Sayyed, S.A.M. Issa, S.H. Auda, Assessment of radio-protective properties of some anti-inflammatory drugs. Prog. Nucl. Energy 100, 297–308 (2017). https://doi.org/10.1016/j.pnucene.2017.07.003

S.A.M. Issa, M.I. Sayyed, M.H.M. Zaid, K.A. Matori, Photon parameters for gamma-rays sensing properties of some oxide of lanthanides. Results Phys. 9, 206–210 (2018). https://doi.org/10.1016/j.rinp.2018.02.039

A.A.A. Darwish, S.A.M. Issa, M.M. El-Nahass, Effect of gamma irradiation on structural, electrical and optical properties of nanostructure thin films of nickel phthalocyanine. Synth. Met. 215, 200–206 (2016). https://doi.org/10.1016/j.synthmet.2016.03.002

S.A.M. Issa, A.A.A. Darwish, M.M. El-Nahass, The evolution of gamma-rays sensing properties of pure and doped phthalocyanine. Prog. Nucl. Energy. 100, 276–282 (2017). https://doi.org/10.1016/j.pnucene.2017.06.016

P. Sathiyaraj, E.J.J. Samuel, C.C.S. Valeriano, M. Kurudirek, Effective atomic number and buildup factor calculations for metal nano particle doped polymer gel. Vacuum 143, 138–149 (2017). https://doi.org/10.1016/j.vacuum.2017.06.005

S.A.M. Issa, H.O. Tekin, T.T. Erguzel, G. Susoy, The effective contribution of PbO on nuclear shielding properties of xPbO–(100–x)P2O5 glass system: a broad range investigation. Appl. Phys. A 125, 640 (2019). https://doi.org/10.1007/s00339-019-2941-x

S.A.M. Issa, H.O. Tekin, The multiple characterization of gamma, neutron and proton shielding performances of xPbO–(99–x)B2O3–Sm2O3 glass system. Ceram. Int. 45, 23561–23571 (2019). https://doi.org/10.1016/j.ceramint.2019.08.065

M. Kurudirek, S. Topcuoglu, Investigation of human teeth with respect to the photon interaction, energy absorption and buildup factor. Nucl. Instru. Methods Phys Res. Sect. B Beam Interact Mater. Atoms 269, 1071–1081 (2011). https://doi.org/10.1016/j.nimb.2011.03.004

V.P. Singh, N.M. Badiger, Energy absorption buildup factors, exposure buildup factors and Kerma for optically stimulated luminescence materials and their tissue equivalence for radiation dosimetry. Radiat. Phys. Chem. 104, 61–67 (2014). https://doi.org/10.1016/j.radphyschem.2013.11.025

Y. Karabul, L. Amon Susam, O. İçelli, Ö. Eyecioğlu, Computation of EABF and EBF for basalt rock samples. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 797, 29–36 (2015). https://doi.org/10.1016/j.nima.2015.06.024

I.S. Mahmoud, S.A.M. Issa, Y.B. Saddeek, H.O. Tekin, O. Kilicoglu, T. Alharbi, M.I. Sayyed, T.T. Erguzel, R. Elsaman, Gamma, neutron shielding and mechanical parameters for lead vanadate glasses. Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.04.105

S.A.M. Issa, A.M.A. Mostafa, T.A. Hanafy, M. Dong, X. Xue, Comparison study of photon attenuation characteristics of poly vinyl alcohol (PVA) doped with Pb(NO3)2 by MCNP5 code, XCOM and experimental results. Prog. Nucl. Energy 111, 15–23 (2019). https://doi.org/10.1016/j.pnucene.2018.10.018

M.J. Berger, J.H. Hubbell, S.M. Seltzer, J. Chang, J.S. Coursey, R. Sukumar, D.S. Zucker, K. Olsen, XCOM: photon cross section database (version 1.5). National Institute of Standards and Technology, Gaithersburg, MD (2010). http://physics.nist.gov/xcom. Accessed 8 June 2020

R. Divina, K. Marimuthu, M.I. Sayyed, H.O. Tekin, O. Agar, Physical, structural, and radiation shielding properties of B2O3–MgO–K2O–Sm2O3 glass network modified with TeO2. Radiat. Phys. Chem. 160, 75–82 (2019). https://doi.org/10.1016/j.radphyschem.2019.03.029

E. Kavaz, H.O. Tekin, O. Agar, E.E. Altunsoy, O. Kilicoglu, M. Kamislioglu, M.M. Abuzaid, M.I. Sayyed, The Mass stopping power/projected range and nuclear shielding behaviors of barium bismuth borate glasses and influence of cerium oxide. Ceram. Int. 45, 15348–15357 (2019). https://doi.org/10.1016/j.ceramint.2019.05.028

H.O. Tekin, E. Kavaz, E.E. Altunsoy, M. Kamislioglu, O. Kilicoglu, O. Agar, M.I. Sayyed, N. Tarhan, Characterization of a broad range gamma-ray and neutron shielding properties of MgO–Al2O3–SiO2–B2O3 and Na2O–Al2O3–SiO2 glass systems. J. Non-Cryst. Solids 518, 92–102 (2019). https://doi.org/10.1016/j.jnoncrysol.2019.05.012

H.O. Tekin, E. Kavaz, A. Papachristodoulou, M. Kamislioglu, O. Agar, E.E. Altunsoy Guclu, O. Kilicoglu, M.I. Sayyed, Characterization of SiO2–PbO–CdO–Ga2O3 glasses for comprehensive nuclear shielding performance: alpha, proton, gamma, neutron. Radiat. Ceram. Int. 45, 19206–19222 (2019). https://doi.org/10.1016/j.ceramint.2019.06.168

S.A.M. Issa, G. Susoy, A.M. Ali, H.O. Tekin, Y.B. Saddeek, A. Al-Hajry, H. Algarni, P.S. Anjana, O. Agar, The effective role of La2O3 contribution on zinc borate glasses: radiation shielding and mechanical properties. Appl. Phys. A 125, 867 (2019). https://doi.org/10.1007/s00339-019-3169-5

M.R. Kacal, H. Polat, M. Oltulu, F. Akman, O. Agar, H.O. Tekin, Gamma shielding and compressive strength analyses of polyester composites reinforced with zinc: an experiment, theoretical, and simulation based study. Appl. Phys. A 126, 205 (2020). https://doi.org/10.1007/s00339-020-3382-2

M.S. Al-Buriahi, H.O. Tekin, E. Kavaz, B.T. Tonguc, Y.S. Rammah, New transparent rare earth glasses for radiation protection applications. Appl. Phys. A 125, 866 (2019). https://doi.org/10.1007/s00339-019-3077-8

S.A.M. Issa, Y.B. Saddeek, M.I. Sayyed, H.O. Tekin, O. Kilicoglu, Radiation shielding features using MCNPX code and mechanical properties of the PbO–Na2O–B2O3–CaO–Al2O3–SiO2 glass systems. Compos. Part B Eng. 167, 231–240 (2019). https://doi.org/10.1016/j.compositesb.2018.12.029

A.S. Abouhaswa, Y.S. Rammah, M.I. Sayyed, H.O. Tekin, Synthesis, structure, optical and gamma radiation shielding properties of B2O3–PbO2–Bi2O3 glasses. Compos. B 172, 218–225 (2019). https://doi.org/10.1016/j.compositesb.2019.05.040

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elsaman, R., Issa, S.A.M., Tekin, H.O. et al. (59.5–x) P2O5–30Na2O–10Al2O3–0.5CoO–xNd2O3 glassy system: an experimental investigation on structural and gamma-ray shielding properties. Appl. Phys. A 126, 502 (2020). https://doi.org/10.1007/s00339-020-03697-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03697-x