Abstract

Ba2Co2Fe12O22 (Co2Y, 0 wt%, 2 wt%)-added Ni0.8Zn0.2Fe2O4 polycrystalline ferrites are prepared by solid-state reaction method, and the magnetic properties of ferrites are investigated. Magnetic measurements show that the magnetic loss is obviously decreased with Co2Y addition. Loss separation reveals that both hysteresis loss and eddy current loss reduce significantly after Co2Y addition. The mechanism of magnetic loss decreasing due to Co2Y additive is discussed, and the decrease of magnetic hysteresis loss and eddy current loss caused by Co2+ cation doping was regarded as the main reason for the observed power loss decrease in ferrites and insulating grain boundary composed by barium compound which plays a role in decreasing eddy current loss. The Q value of Co2Y-added Ni0.8Zn0.2Fe2O4 ferrite was much higher than that of Ni0.8Zn0.2Fe2O4 sample which can be used as inductors for high-frequency applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ni–Zn ferrites are important soft magnetic materials with numerous applications in electronics and communication technologies. High electrical resistivity, high cutoff frequency, broadband and low magnetic losses make Ni–Zn ferrite an obvious choice as a magnetic core material for high-frequency applications. In comparison, M-type ferrites with hexagonal structure are suitable as higher-frequency soft magnet ferrites [1,2,3,4,5,6], but they have a relatively large hysteresis loss, so Ni–Zn ferrites are suitable for application in the 1–200 MHz band. Different applications need different characteristics of ferrites, which can be achieved by doping of suitable cations in materials [5,6,7,8,9,10,11,12,13,14,15,16]. For example, manganese dioxide doped in nickel–zinc ferrites can decrease the magnetic loss in materials [17,18,19]. The nickel–zinc ferrites applied as inductance cores in radio frequency band-pass filters need high-temperature stability of permeability and low magnetic loss, and the temperature stability of common nickel zinc ferrites cannot meet this requirement. It was reported that Co2Y added to nickel–zinc ferrites can obviously improve the temperature stability of permeability [20,21,22,23,24] and improve DC-bias superposition characteristics [25]. However, only a few works have been done on the effect of Co2Y addition on magnetic power loss in Ni–Zn ferrites [25, 26], so the influence of Co2Y additive on magnetic loss in Ni–Zn ferrites is investigated in this paper.

2 Experiment

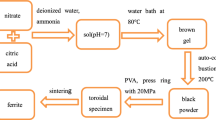

The ferrite samples are prepared by solid-state reaction method. Reagent-grade Ni2O3, ZnO, and Fe2O3 are used in the required proportion in the chemical formula Ni0.8Zn0.2Fe2O4, the mixtures are milled thoroughly in agate mortar to ensure the raw materials are mixed evenly and then calcined at 1050 °C for 3 h in air. The resulting mixtures are reground to reduce them into micron-sized particles. The obtained powder is divided into two parts, and 2% weight ratio Co2Y powder is added in one part. Every part is mixed thoroughly and then pressed in a toroidal shape in 200 MPa pressure using 5% PVA solution as the binder. The toroidal green samples are sintered for 3 h at 1220 °C in air followed by natural cooling to room temperature. The crystal structure of obtained ferrite samples is investigated by X-ray diffractometer (XRD, Mac Science MPX18AHF, Cu Kα radiation), and the power losses of ferrite are measured by BH analyzer (Iwatsu SY-8258) and the measurement error is controlled at 1%.

3 Results and discussion

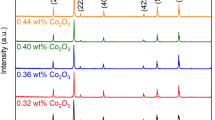

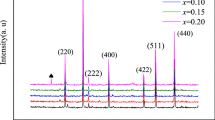

As shown in Fig. 1a, b, the XRD patterns of Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 ferrite powders match well with the standard XRD data for spinel phase; no other phases can be found in the patterns. Initial permeability measurement shows that Co2Y addition caused decrease in permeability (from 28 to 20). Power loss data at different magnetic flux densities and frequencies are measured for ferrite samples. The magnetic flux density (Bm) dependence of power loss of Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 ferrites at 200 kHz is shown in Fig. 2. It is found that the power loss of Co2Y-added Ni0.8Zn0.2Fe2O4 ferrite is about half of Ni0.8Zn0.2Fe2O4 sample, which indicated that moderate addition of Co2Y in Ni–Zn ferrites could dramatically decrease the power loss of sample [26].

The measured magnetic loss dependence on the frequency of two samples at Bm = 6 mT is shown in Fig. 3 and it is found that the measured power loss increases with increase of frequency. Compared with Co2Y-added Ni0.8Zn0.2Fe2O4, the power loss of Ni0.8Zn0.2Fe2O4 sample is about twice of the former, which also shows that the power loss of Ni0.8Zn0.2Fe2O4 obviously decreased with Co2Y additive.

The measured power loss includes hysteresis loss, eddy current loss and residual loss. It is regarded that the power loss can be separated using the empirical Legg formula at low frequency and low magnetic flux density range [27]. To investigate the Co2Y additive influence on hysteresis loss, the relative loss factor (tanδ/µ′) versus magnetic flux density at 500 kHz is measured for Co2Y-added Ni0.8Zn0.2Fe2O4 and Ni0.8Zn0.2Fe2O4 samples. The measured data are shown in Fig. 4. Theoretically, tanδ/µ' vs Bm obeys a simple linearity, as predicted by the Legg formula:

where f is frequency, a, e and c are hysteresis loss coefficient, eddy current loss coefficient and residual loss coefficient, respectively. The Legg formula tells that the slope represents hysteresis loss coefficient. Compared to the experimental results in Fig. 4, it can be found that the linear slope of Ni0.8Zn0.2Fe2O4 ferrites is bigger than that of Co2Y-added Ni0.8Zn0.2Fe2O4 sample. The hysteresis loss coefficient obtained from the linear fitting of measured data in Fig. 4 is 3.4 × 10–5/mT and 2.3 × 10–5/mT for Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 samples, respectively, which indicates that the hysteresis loss of Co2Y-added Ni0.8Zn0.2Fe2O4 is about two-thirds of Ni0.8Zn0.2Fe2O4 under the same test condition.

The hysteresis loss performance of ferrite can be observed by measuring its hysteresis loop. The amount of energy lost in the material in one cycle of the applied field is proportionate to the area inside the hysteresis loop. Figure 5 gives the room temperature magnetic hysteresis loop for Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 samples measured at 10 mT and 1 MHz. It can be found in Fig. 5 that the Co2Y addition obviously reduced the area of hysteresis loop, in spite of the decrease in permeability. The hysteresis loops in Fig. 5 also indicate that hysteresis loss decreases with Co2Y addition in Ni–Zn ferrites.

The influence of Co2Y addition in Ni0.8Zn0.2Fe2O4 ferrite on the eddy current loss can also be investigated using the Legg formula. The measured \({{\tan \delta } \mathord{\left/ {\vphantom {{\tan \delta } {\mu^{^{\prime}} }}} \right. \kern-\nulldelimiterspace} {\mu^{^{\prime}} }}\) as a function of frequency for Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 samples at Bm = 6 mT is shown in Fig. 6. It was noted that the measured \({{\tan \delta } \mathord{\left/ {\vphantom {{\tan \delta } {\mu^{^{\prime}} }}} \right. \kern-\nulldelimiterspace} {\mu^{^{\prime}} }}\) linearly increased with increasing f, which was consistent with Formula (1). The eddy current loss coefficient obtained from the linear fitting of measured data in Fig. 6 is 6.9 × 10−11 s and 2.3 × 10−11 s for Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 samples, respectively, which indicates that the eddy current loss of Co2Y-added Ni0.8Zn0.2Fe2O4 is about one-third of Ni0.8Zn0.2Fe2O4 under the same measurement conditions. Experimental data indicate that Co2Y added in Ni0.8Zn0.2Fe2O4 ferrite can obviously reduce the eddy current loss. Considering that the eddy current loss would play a dominant role at high frequency, Co2Y-added Ni–Zn ferrites are more suitable for high-frequency applications [25].

The above experimental results show that the addition of Co2Y reduced the power loss of ferrite to about half of the Ni0.8Zn0.2Fe2O4 sample at the same frequency and magnetic flux density. Considering that the permeability of Co2Y-added Ni0.8Zn0.2Fe2O4 is less than that of Ni0.8Zn0.2Fe2O4, the field energy stored in the Co2Y-added Ni–Zn is more than that in Ni–Zn ferrite with the same magnetic flux density. The reduction of power loss due to the addition of Co2Y is underestimated, in case of the same magnetic flux density. The Q factor of two samples is measured to compare the ratio of stored field energy to power loss in one cycle, and the variation of Q factor with magnetic flux density and frequency is shown in Figs. 7 and 8. It could be found that the Q value of Co2Y-added Ni0.8Zn0.2Fe2O4 ferrite is about three times higher than that of Ni0.8Zn0.2Fe2O4 sample in Figs. 7 and 8, which shows that the difference in Q value between the two samples is more obvious than that of power loss.

The reason for power loss reduction caused by Co2Y addition in Ni–Zn ferrites can be analyzed as follows. Co2Y cannot form a single phase, which reveals that Y-type ferrite is unstable at a high temperature [28]. It is considered that Co2Y added to Ni–Zn ferrites decomposes at a high temperature, and Co2+ ion enters the spinel lattice. The addition of Co2+ in spinel improves the performance, as validated by the reduction of power loss, however at the expense of μi [29]. It is regarded that Co2+ doping is the main reason for hysteresis loss reduction in Ni–Zn ferrites. Ba2+ ion cannot enter lattice due to its big radius, so it concentrates on the grain boundary to form a high-resistance layer, which leads to a reduction in eddy current loss. On the other hand, the presence of Co2+ stabilizes Fe3+, as its third ionization energy is higher than that of Fe2+, which also reduces eddy current loss [29].

4 Conclusions

In summary, Ni0.8Zn0.2Fe2O4- and Co2Y-added Ni0.8Zn0.2Fe2O4 ferrite samples are prepared by solid-state reaction method and their magnetic properties are investigated. Magnetic measurements show that the magnetic loss obviously decreased after Co2Y addition. Magnetic loss separation indicates that the hysteresis loss coefficient and eddy current loss coefficient both decreased due to the addition of Co2Y to Ni–Zn ferrites. The Q value of Co2Y-added Ni0.8Zn0.2Fe2O4 ferrite is about three times higher than that of Ni0.8Zn0.2Fe2O4 sample. The reduction of hysteresis loss caused by Co2+ cation doping in Ni–Zn ferrite and decrease in eddy current loss are considered to be the formation of high-resistance insulating grain boundary containing the barium compound. The obvious reduction of eddy current loss reveals that Co2Y-added Ni–Zn ferrites are more suitable for high-frequency applications.

References

V. Turchenko, A. Trukhanov, S. Trukhanov, M. Balasoiu, N. Lupu, Correlation of crystalline and magnetic structures of barium ferrites with dual ferroic properties. J. Magn. Magn. Mater. 477, 9–16 (2019)

A.V. Trukhanov, M.A. Darwish, L.V. Panina, A.T. Morchenko, V.G. Kostishyn, V.A. Turchenko, D.A. Vinnik, E.L. Trukhanova, K.A. Astapovich, A.L. Kozlovskiy, M. Zdorovets, S.V. Trukhanov, Features of crystal and magnetic structure of the BaFe12-xGaxO19 (x ≤ 2) in the wide temperature range. J. Alloys Compd. 791, 522–529 (2019)

S.V. Trukhanov, A.V. Trukhanov, V.G. Kostishyn, L.V. Panina, A.V. Trukhanov, V.A. Turchenko, D.I. Tishkevich, E.L. Trukhanova, V.V. Oleynik, O.S. Yakovenko, L.Y. Matzui, D.A. Vinnik, Magnetic, dielectric and microwave properties of the BaFe12-xGaxO19 (x ≤ 12) solid solutions at room temperature. J. Magn. Magn. Mater. 442, 300–310 (2017)

A.V. Trukhanov, S.V. Trukhanov, V.G. Kostishyn, L.V. Panina, V.V. Korovushkin, V.A. Turchenko, D.A. Vinnik, E.S. Yakovenko, V.V. Zagorodnii, V.L. Launetz, V.V. Oliynyk, T.I. Zubar, D.I. Tishkevich, E.L. Trukhanova, Correlation of the atomic structure, magnetic properties and microwave characteristics in substituted hexagonal ferrites. J. Magn. Magn. Mater. 462, 127–135 (2018)

I.O. Troyanchuk, S.V. Trukhanov, H. Szymczak, K. Baerner, Effect of oxygen content on the magnetic and transport properties of Pr0.5Ba0.5MnO3-γ. J. Phys. Condens. Matter. 12, L155–L158 (2000)

S.V. Trukhanov, I.O. Troyanchuk, I.M. Fita, H. Szymczak, K. Bärner, Comparative study of the magnetic and electrical properties of Pr1-xBaxMnO3-δ manganites depending on the preparation conditions. J. Magn. Magn. Mater. 237, 276–282 (2001)

K.Q. Wang, Y. Sun, Y.B. Li, X.D. He, Effects of SiO2 addition on microstructure and magnetic properties of Ni–Zn ferrites prepared by SHS. J. Alloy. Compd. 494, 236–238 (2010)

A. Lucas, R. Lebourgeois, F. Mazaleyrat, E. Laboure, Temperature dependence of core loss in cobalt substituted Ni–Zn–Cu ferrites. J. Magn. Magn. Mater. 323, 735–739 (2011)

G. Herrera, M.M. Perez-Moreno, Microstructure dependence of the magnetic properties of sintered Ni–Zn ferrites by solid-state reaction doped with V2O3. J. Mater. Sci. 47, 1758–1766 (2012)

E.E. Ateia, M.A. Ahmed, L.M. Salah, A.A. El-Gamal, Effect of rare earth oxides and La3+ ion concentration on some properties of Ni–Zn ferrites. Phys. B 445, 60–67 (2014)

A.V. Trukhanov, V.G. Kostishyn, L.V. Panina, V.V. Korovushkin, V.A. Turchenko, P. Thakur, A. Thakur, Y. Yang, D.A. Vinnik, E.S. Yakovenko, LYu. Matzui, E.L. Trukhanova, S.V. Trukhanov, Control of electromagnetic properties in substituted M-type hexagonal ferrites. J. Alloys Compd. 754, 247–256 (2018)

A.V. Trukhanov, L.V. Panina, S.V. Trukhanov, V.G. Kostishyn, V.A. Turchenko, D.A. Vinnik, T.I. Zubar, E.S. Yakovenko, L.Y. Macuy, E.L. Trukhanova, Critical influence of different diamagnetic ions on electromagnetic properties of BaFe12O19. Ceram. Int. 44, 13520–13529 (2018)

S.V. Trukhanov, A.V. Trukhanov, M.M. Salem, E.L. Trukhanova, L.V. Panina, V.G. Kostishyn, M.A. Darwish, A.V. Trukhanov, T.I. Zubar, D.I. Tishkevich, V. Sivakov, D.A. Vinnik, S.A. Gudkova, C. Singh, Preparation and investigation of structure, magnetic and dielectric properties of (BaFe11.9Al0.1O1.9)1–x - (BaTiO3)x bicomponent ceramics. Ceram. Int. 44, 21295–21302 (2018)

M.M. Salem, L.V. Panina, E.L. Trukhanova, M.A. Darwish, A.T. Morchenko, T.I. Zubar, S.V. Trukhanov, A.V. Trukhanov, Structural, electric and magnetic properties of (BaFe11.9Al0.1O1.9)1–x - (BaTiO3)x composites. Compos. B Eng. 174, 107054–107058 (2019)

S.V. Trukhanov, Magnetic and magnetotransport properties of La1-xBaxMnO3-x/2 perovskite manganites. J. Mater. Chem. 13, 347–352 (2003)

V.D. Doroshev, V.A. Borodin, V.I. Kamenev, A.S. Mazur, T.N. Tarasenko, A.I. Tovstolytkin, S.V. Trukhanov, Self-doped lanthanum manganites as a phase-separated system: Transformation of magnetic, resonance, and transport properties with doping and hydrostatic compression. J. Appl. Phys. 104, 093909–93919 (2008)

Y. Matsuo, M. Inagaki, T. Tomozawa, F. Nakao, High performance Ni–Zn ferrite. IEEE Trans. Magn. 37, 2359–2361 (2001)

A.K. Singh, T.C. Goel, R.G. Mendiratta, Magnetic properties of Mn-substituted Ni–Zn ferrites. J. Appl. Phys. 92, 3872–3876 (2002)

E. Rezlescu, L. Sachelarie, P.D. Popa, N. Rezlescu, Effect of substitution of divalent ions on the electrical and magnetic properties of Ni–Zn–Me ferrites. IEEE Trans. Magn. 36, 3962–3967 (2000)

Y. Bai, J. Zhou, Z.L. Gui, L.T. Li, An investigation of the magnetic properties of Co2Y hexaferrite. Mater. Lett. 57, 807–811 (2002)

D. Liu, X. Chen, Y. Ying, L. Zhang, W. Li, L. Jiang, MnZn power ferrite with high Bs and low core loss. Ceram. Int. 42, 9152–9156 (2016)

J. Topfer, A. Angermann, Complex additive systems for Mn–Zn ferrites with low power loss. J. Appl. Phys. 117, 17A504 (2015)

G. Kogias, V.T. Zaspalis, Temperature stable Mn–Zn ferrites for applications in the frequency region of 500 kHz. Ceram. Int. 42, 7639–7646 (2016)

Y. Wang, H. Zhou, H. Qi, L. Ren, Z. Xu, Z. Yue, Sintering, microstructure and magnetic properties of low temperature co-fired Ni–Cu–Zn ferrites with Nb2O5 and MoO3 additions. Ceram. Int. 41, 12253–12257 (2015)

H. Hsiang, C.S. Hsi, R.L. Lin, C.Y. Chiang, Addition of a minor amount of Co2Y effects on the microstructure, magnetic properties and DC-bias superposition characteristics of low-fire Ni–Cu–Zn ferrites. Mater. Chem. Phys. 151, 295–300 (2015)

J.L. Ni, S.J. Feng, X.S. Liu, Influence of manganese dioxide and Ba2Co2Fe12O22-additives on the magnetic power loss of Ni08Zn02Fe2O4 ferrites. Materialwiss. Werkstofftech. 49, 986–990 (2018)

S.J. Feng, J. Li, S.G. Huang, X.S. Liu, Z.Y. Zhong, Magnetic hysteresis loss crossover in Ni0.4Zn0.6Fe1.95Ti0.05O4 ferrite. J Alloy Compd. 660, 398–401 (2016)

R.C. Pullar, Hexagonal ferrites: A review of the synthesis, properties and applications of hexaferrite ceramics. Prog. Mater. Sci. 57, 1191–1334 (2012)

S. Tokatlidis, G. Kogias, V.T. Zaspalis, Low loss Mn–Zn ferrites for applications in the frequency region of 1–3 MHz. J. Magn. Magn. Mater. 465, 727–735 (2018)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51872004), the Key Program of the Education Department of Anhui Province (KJ2019ZD03) and the Key Program of the College Excellent Talent Support Program (Grant No. gxyq2018129).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ni, J., Feng, S. & Liu, X. Effect of Co2Y additive on power loss of Ni0.8Zn0.2Fe2O4 ferrites. Appl. Phys. A 126, 10 (2020). https://doi.org/10.1007/s00339-019-3197-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-3197-1