Abstract

Ca-doped barium titanate BaTiO3 nanopowders were synthesized by the sol–gel process using barium acetate [Ba(CH3COO)2], calcium acetate [Ca(CH3COO)2] and titanium butoxide [Ti(OC4H9)4] as precursors. This method was adopted because it allows obtaining powders of high purity, chemical homogeneity and fine particle size, and crystallization is possible at very low temperatures (800 °C) compared to that used by the conventional solid-state reaction method. In this study, the characterization of nanopowders and ceramics using X-ray diffraction (XRD), scanning electron microscopy (SEM), photoluminescence (PL), dielectric measurements, FTIR and Raman spectroscopy is carried out. The results revealed that the calcium ion incorporation had significant effect on structural and dielectric properties of barium titanate BaTiO3 (BT). XRD patterns suggested that nanopowders calcined at the temperature of 800 °C during 2 h could be crystallized into perovskite structure, with an average crystallite size in the range of 19.89–25.04 nm. Furthermore, it was observed that the Ca concentration variation affected the emission process with little displacement in the peak position. These results proved the optical band gap reduction by the presence of inter-band electron levels. Finally, the dielectric properties of the prepared samples were measured, revealing that the dielectric permittivity decreased with frequency increase, and the grain size and Curie temperature of the Ba1−xCaxTiO3 (BCT) ceramics sintered at 1200 °C were greatly affected by Ca substitution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Barium titanate BaTiO3 (BT) is currently one of the most studied ferroelectric compounds [1,2,3,4]. Not only does it allow the comprehension of ferroelectric phenomena in a general way, but also it is interesting from the viewpoint of the applications. In fact, it offers a good chemical and mechanical stability, as well as good dielectric properties, thus making it very useful in making transducers and multilayer capacitors in a variety of shapes and sizes.

Barium titanate belongs to the family of perovskites ABO3, in which A and B are generally metals. It is ferroelectric at room temperature and it is paraelectric beyond the Curie temperature TC close to 130 °C.

The doping of ferroelectric powders BaTiO3 is of great importance in the fabrication of electrical and electronic devices [1,2,3,4,5] due to intrinsic capacity of the perovskite structure to host ions of different size and the large number of different dopants can be incorporated in the titanate barium (BT) lattice.

The substitution of Ba2+ by Ca2+ in BaTiO3 leads to the formation of Ba1−xCaxTiO3 (BCT) in the tetragonal phase for x < 0.23, which shows the solubility limit following the increase in size differences between these two ions (Ba2+ and Ca2+). Above this value, a mixture of tetragonal and orthorhombic phases appears up to x = 0.9, and, beyond the value, the orthorhombic phase exists.

In the Barium Calcium Titanate system (BCT), the piezoelectric coefficient has been improved from 180 up to 310 pC N−1 for 0.02 < x < 0.34 [6].

This is interesting that other elements, such as Sr2+ (BST solution), can replace Ba2+ in BaTiO3 to form solid solutions without solubility limits [7]. However, the properties of BCT are better than those obtained in the BST system.

Moreover, calcium incorporation improves the physical properties, especially the stability of the piezoelectric ones, which makes BCT a very useful compound in the creation of electro-optical materials for holographic and photo-refractive applications [8].

In addition, another parameter can significantly influence the physical properties of materials, which is the crystallite size in ceramics. This parameter is directly dependent on the annealing temperature and turns out to be one of the key parameters considerably influencing the dielectric response of the material, such as Curie temperature TC, physical and structural properties of many compound oxides [9, 10].

On the other hand, several studies [11,12,13,14] have shown that the synthesis of ceramics by the traditional solid-state method at temperatures about 1500 °C makes it impossible to obtain crystallites with sizes less than 1 µm.

Furthermore, when the next step is to disperse the nanoparticles in polymer matrices, a fine particle size is required and the sol–gel process is preferable.

In fact, this soft chemistry technique offers us the possibility to obtain powders and ceramics of high purity, good chemical homogeneity and fine particle size at very low temperatures in reference to the classical solid–solid reaction method. On the other hand, the major problem in the nanocrystalline oxide synthesis is the stoichiometry control at the nanoscale level and this is overcome by the sol gel process [11].

To obtain ferroelectric materials with nanoparticle size, we choose the Ba1−xCaxTiO3 system with x inferior to 0.2. These nanoparticle compounds were prepared by sol–gel method at low temperature. The structural, spectroscopic and optical properties of Ca-doped BaTiO3 powders were investigated using different techniques such as X-ray diffraction (XRD), FTIR, Raman spectroscopy and photoluminescence analysis. The crystallite size was calculated using Scherrer formula. In addition, the dielectric properties were investigated.

2 Experimental procedure

2.1 Materials and samples preparation

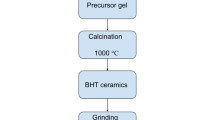

Ba1−xCaxTiO3 nanopowders with different Ca concentrations (x = 0–0.2) were synthesized by sol–gel process using barium acetate [Ba(CH3COO)2] (99%, Fluka), calcium acetate [Ca(CH3COO)2] (99–100%, Aldrich), tetrabutyl titanium [Ti(C4H9O)4] (97%, Aldrich), absolute ethanol (C2H6O) (99.8%, Aldrich) and acetic acid (C2H4O2) (99–100%, Aldrich) as starting chemicals. The pursued synthesis procedure is presented in Fig. 1 and described as follows:

-

First, a stoichiometric quantity of Ti(C4H9O)4 was dissolved in a mixture of concentrated ethanol and acetic acid with constant stirring using magnetic stirrer for 40 min at room temperature. Subsequently, Ba(CH3COO)2 and a stoichiometric quantity of Ca(CH3COO)2 was dissolved in a mixture of acetic acid and deionized water before being heated up to 80 °C.

-

Afterwards, the acquired preparation was drizzled slowly into the Ti(C4H9O)4 solution and stirred vigorously for approximately 1 h to form a homogeneous solution. 3 h later, a clear gel was formed. The xerogels acquired after this step were dried at 120 °C for 8 h. The xerogels were then calcined at 800 °C for 2 h. This process aimed not only to decompose any organic components formed during the sol–gel process, but also to reach crystalline nanopowder formation (Fig. 1).

-

At last, to prepare ceramics, the powders were compressed into discs of 8 mm in diameter and 1 mm in thickness, followed by sintering at 1200 °C for 4 h.

2.2 Characterization

The thermal decomposition of xerogels was studied by means of a TGA 4000 Thermogravimetric Analyzer over the temperature range of 30–800 °C (10 °C/min) and differential scanning calorimeter DSC 4000 (PerkinElmer) over the temperature range of 30–400 °C (10 °C/min) in a dynamic oxygen atmosphere.

The crystal structures of Ba1−xCaxTiO3 powders were determined by X-ray diffraction (XRD) using a D8 Advance instrument (Bruker) with the main specifications of CuKα1 radiation (λ = 1.54178 Å). Lattice parameters were defined by Rietveld refinement using Fullprof program. IR spectra were recorded with an FT-IR spectrometer VERTEX 80 (Bruker) in the 400–4000 cm−1 range on as-pressed disks using KBr as the binding material. The Raman spectroscopy data were obtained at room temperature by a system Horiba Jobin Yvon Spectrometer Micro Raman with source laser excitation and detector of 1024 pixels with CCD High sensitivity, mounted in an Olympus microscope BX41TF with spatial resolution < 1 µm.

The photoluminescence (PL) spectra were recorded at room temperature. In PL measurements, the samples were excited at 380 nm. Dielectric constant εr for the investigated samples was measured by precise impedance analyzer 4294A (Agilent Technologies) controlled by a computer at 1 kHz over the temperature range from − 150 to 250 °C for the ceramics and in the frequency range from 1 kHz to 1 MHz over the temperature range from room temperature to 250 °C for the nanopowders.

3 Results and discussion

3.1 Thermal behaviour of Ba0.9Ca0.1TiO3

In Fig. 2a, the thermogravimetric analysis (TGA) curve is shown, as recorded for the thermal decomposition process of the Ba0.9Ca0.1TiO3 xerogel. The curve shows the xerogel mass loss of 37% (from 100 to 63%). In general, the decomposition process of Ba0.9Ca0.1TiO3 xerogel proceeds in three steps: (1) a mass loss occurring between 40 and 250 °C and indicative of an existing solvent residue into the Xerogel (organic solvent and water); (2) a second mass loss is obvious between 250 and 400 °C, corresponding to the titanium butoxide decomposition to TiO2, barium acetate to BaCO3 and calcium acetate to CaCO3 [15, 16]; and (3) a last mass loss occurring between 600 and 750 °C, attributed to the formation of Ba0.9Ca0.1TiO3, which is created by the reaction between nanocrystalline carbonates (BaCO3 and CaCO3) and amorphous TiO2, as well as the release of CO2 [17].

Figure 2b shows the differential scanning calorimetry (DSC) curve recorded for the thermal decomposition process of Ba0.9Ca0.1TiO3 xerogel, which confirms the results obtained by TGA. The peak at about 80 °C proves the evaporation of adsorbed moisture and volatile organic components of the xerogel, such as acetic acid and ethanol. In addition, there is another peak at 330 °C accredited to the decomposition of barium acetate, calcium acetate and tetrabutyl titanium to BaCO3, CaCO3 and TiO2, respectively.

3.2 Phase and microstructure of the Ba1−xCaxTiO3 nanopowders

The X-ray diffraction (XRD) patterns of the Ba1−xCaxTiO3 nanopowders calcined at 800 °C for 2 h are shown in Fig. 3. All the samples were well crystallized into a perovskite phase with a tetragonal structure (Fig. 3, JPCDS 83-1878) [18]. Besides, the orthorhombic phase of barium carbonate (BaCO3, JCPDS 1-506) was detected with characteristic diffraction peaks at 24.08° and 34.28° (2θ) [18]. According to many previous works [19, 20], this small amount of BaCO3 did not affect the formation of the perovskite phase of BCT. This shows the importance of this method, which drastically reduces the calcination time and temperature compared to the conventional solid-state reaction [11, 21,22,23].

A deep examination of the XRD patterns reveals that the diffraction peaks tend to shift to the higher degrees with the Ca content increase. This shows a good diffusion of Ca2+ in the BaTiO3 host network [24, 25]. This is shown by the variation of the peak (200/220) at 2θ = 45.5° (Fig. 3a, inset). It could be suggested that the substitution of Ba2+ ions (ionic radius 1.61 Å) by Ca2+ ions (ionic radius 1.34 Å) promotes the lattice contraction and indicates the increase of the material pressure as well as the peaks broadening following the creation of stacking defects [24, 25]. The cell parameters were obtained by Rietveld refinement of XRD patterns using Fullprof program (Fig. 3b; Table 1). According to Jabarov et al. [26], under normal conditions, BaTiO3 is in ferroelectric state up to the phase-transition temperature TC, and the crystal structure is characterized by the tetragonal symmetry in space group P4mm with the unit cell parameters a = b = 3.992 ± 0.001 Å, c = 4.035 ± 0.001 Å (the tetragonal-distortion value c/a = 1.011). In our BT compound, the unit cell parameters are a = b = 4.007 ± 0.007 Å, c = 4.022 ± 0.003 Å, and thus the tetragonal-distortion value is c/a = 1.004. The difference could be attributed to the difference of the synthesis conditions.

Moreover, when the Ca2+ calcium ions replace those of Ba2+ in the Ba1−xCaxTiO3 network, the unit cell volume, as well as the lattice parameters (a, c), decreases (Table 1; Fig. 4a, b), which is due to the smaller ionic size of Ca2+ compared to that of Ba2+. The partial substitution of Ba2+ by Ca2+ ions the BaTiO3 lattice certainly causes local distortions in the tetragonal network which leads to the increasing of Coulomb interaction owing to the contraction of the Ti-O distance [27]. The literature shows that large ions are energetically favorable for doping with compensation for the vacancy charge, while smaller ions can self-compensate during replacement, such as Ba/Ca [28].

Using the Scherrer equation (Eq. 1), we can see that the average crystallite size of the BCT powders decreases with Ca content increase (Fig. 4c), such as for x = 0, 0.02, 0.05, 0.10, we have 25.04, 23.97, 22.44, 19.89 nm, respectively (Table 2).

The Scherrer equation is defined as:

where L, λ, K and β are defined as follows: L is the crystallite size; λ is the wavelength of the X-ray radiation (λ = 1.54178 Å) for CuKα1; K is usually taken as 0.89; β is the line width at half-maximum height after correction of the equipment broadening.

As can be seen in Fig. 5a, the Scanning Electron Microscopy (SEM) photograph of the Ba0.98Ca0.02TiO3 (x = 0.02) nanopowders calcined at 800 °C shows many nanoparticles that appear mostly in a round shape, having a large specific surface with the tendency to agglomerate [29]. The average particle size in the powders is ~ 81 nm, which is a little larger than that estimated by XRD analysis.

Figure 5b shows the SEM micrographs of the BCT ceramics sintered at 1200 °C for 4 h. It can be seen that the average grain size of BaTiO3 ceramics decreases with the increase in Ca2+ content. The average grain size of BaTiO3 is about 655 nm, whereas it is about 605 nm and 255 nm for BaTiO3 with 3% and 5% of Ca2+, respectively (Table 3). This indicates that the incorporation of Ca2+ inhibits the grain growth in BaTiO3 ceramics which confirms the decreasing of the c/a ratio deduced by X-ray analysis. This result could be contributed to the substitution of larger Ba2+ ions by smaller Ca2+ ions, structural defects or agglomerate formation.

3.3 Raman spectroscopy

The Raman spectra of Ba1−xCaxTiO3 nanopowders calcined at 800 °C for 2 h are shown in Fig. 6. All the samples exhibit bands at around 183, 252, 305, 519 and 712 cm−1, which defines a perovskite structure [30,31,32].

In fact, the crystallography shows that BaTiO3 presents the following Raman-active modes: 4E (TO + LO) + 3 A1 (TO + LO) + B1 (TO + LO) defining the tetragonal phase (space group P4mm). Indeed, Busca et al. [33] assigned peaks at 183, 252 and 519 cm−1 to three TO modes of A1 symmetry i.e. to A1 (TO1), A1 (TO2) and A1 (TO3) modes, respectively.

Some authors (i.e. Smith et al.; Rabuffetti and Brutchey; Sun et al.) [34,35,36] have confirmed the fact that the combination of modes E (TO + LO) influences the formation of the mode at 305 cm−1, which could be indicative of a displacement of Ti atoms from octahedral TiO6. This suggests the intrinsic structural distortion in tetragonal BaTiO3 [34].

For BaTiO3 (i.e. x = 0), the bands are observed at 518 and 712 cm−1, whereas for x = 0.1, they are observed at 519 and 715 cm−1. Such displacement towards higher wavenumbers is due to Ba substitution by Ca in BaTiO3, which leads to the formation of CaBa defects. These two vibration modes are associated with those of the Ba–O bonds [30].

On the other hand, a shift was observed towards lower wavenumbers by increasing Ca content. While the bands are observed at 252 and 305 cm−1 for x = 0, they are observed at 250 and 300 cm−1 for x = 0.1. These two vibration modes are attributed to the vibrations of the Ti–O bonds [30, 34].

Moreover, in the Raman spectra, it is obvious that with Ca doping, the intensity proceeds first with an increase, then, followed by a decrease for all modes. In addition, the calcium incorporation into BaTiO3 provokes the enlargement of some Raman bands corresponding to A1 (TO) mode accompanied by an intensity decrease of B1 + E (LO + TO) modes, which is the consequence of the disordered nature of the phase. When Ba is substituted by Ca, the electrical neutrality is normal.

Among others, the characteristic band intensity of the tetragonal phase at around 712 cm−1 is greatly decreased when x increases, indicating the lattice distortion and the tendency to transit from tetragonal to cubic phase. The results were confirmed by the XRD data.

3.4 FT-IR spectra analysis

Figure 7 shows the infra-red spectra of Ba1−xCaxTiO3 (x = 0.01; 0.02; 0.03) calcined at 800 °C for 2 h, as recorded in the wavelength range from 400 to 4000 cm−1.

The spectrum of pure BT nanopowder calcined at 800 °C shows almost total absence of absorption bands for organic compounds, such as the two absorption bands located at 1537 and 1392 cm−1. These bonds are due to the symmetrical and asymmetric vibrations of the acetate groups present in the precursors used in synthesis.

A broad band is observed at 673 cm−1 that is a characteristic of crystalline BaTiO3, indicating the oxygen-metal vibration of TiO6 octahedra. It is attributed to the symmetric and asymmetric stretching of the Ti–O octahedron within [TiO6], featuring its distortion [37].

The IR spectra of the Ba1−xCaxTiO3 nanopowders calcined at 800 °C (x = 0.01; 0.02; 0.03) are similar to the spectrum of pure BT calcined at 800 °C. Indeed, the absence of bands of water and organic elements such as acetates clearly show that Ba1−xCaxTiO3 are well crystallized. In 1050–1200 cm−1 band region, the absorption peaks are attributed to CO32− anions [38,39,40].

3.5 Photoluminescence (PL)

The photoluminescence spectra of the Ba1−xCaxTiO3 samples are shown in Figure 8. Photoluminescence in titanates may be due to radiative recombination between excited electrons and holes trapped in the states in the forbidden band of the perovskite, which is generated by oxygen deficiency and local distortions that behave as intrinsic defects due to the stretching of the Ti–O bond [18, 41]. In all cases, photoluminescence, therefore, depends on the structural and electronic properties including the presence of impurities and defects. The variation in Ca concentration has an effect on the emission process with a displacement in the peak position towards higher wavelengths (532.6 nm at x = 0 to 534.8 nm at x = 0.1), i.e. as Ca content increases, this red-shift means the hole trapped states move upward to CB, which decreases the forbidden band gap (Eg) as observed in the PL spectra (Fig. 8).

The oxygen vacancies in titanates can occur in three different states of charge [42].

-

Complex state [TiO5.Vox]that has two paired electrons and is relatively neutral to the lattice.

-

The only ionized complex state [TiO5.Vo.] with an unpaired electron.

-

The doubly positively charged complex state [TiO5.Vo..] that did not trap any electron.

Before donor excitation, a hole in the acceptor and an electron in the donor are created, according to equations using the Kröger–Vink notations [43]:

where [TiO6]′ is donor, [TiO5·Vo·] is donor–acceptor and [TiO5·Vo··] is acceptor.

Thus, it is likely that the addition of Ca contributes to the formation of deformed groups or to the broken symmetry of the resulting complex group (containing gaps).

3.6 Dielectric properties

As the dielectric response for powders treated at 800 °C is very low (the dielectric permittivity did not exceed 280) (Fig. 9), it is of no interest for the present study. That is why it was necessary to pass to a higher sintering temperature optimized at 1200 °C, which leads to an increase of the specific surface causing the boost of the polarizability and thus obtaining a considerable dielectric response.

Nevertheless, it can be mentioned that the value of dielectric constants of the nanopowders calcined at 800 °C vary slightly over the temperature range on either side of room temperature, therefore, making this type of material a potential candidate for the manufacture of capacitors at nanoscale (Fig. 9).

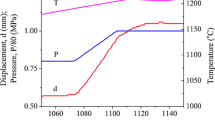

As shown in Fig. 10, the Curie temperatures TC were detected at 403.46 ± 0.05 K (130.46 °C) for BaTiO3, 413.28 ± 0.05 K (140.28 °C) for Ba0.96Ca0.04TiO3, 416.91 ± 0.05 K (143.91 °C) for Ba0.95Ca0.05TiO3 and 414.53 ± 0.05 K (141.53 °C) for Ba0.90Ca0.1TiO3 (Fig. 10; Table 4). Moreover, the value of Curie Weiss constant CW varied with the increase of Ca2+ concentration. On the other hand, we can see that orthorhombic—tetragonal transition temperatures shifted to the lower ones (Fig. 10; Table 4).

The dielectric constant εr and the Curie Weiss temperature of a ferroelectric can be described by Curie Weiss’s law (Eq. 5):

where Cw is the Curie Weiss constant, T0 is the Curie Weiss temperature.

The curves representing 1/εr as function of \(\frac{{T~ - ~{T_0}}}{{{C_{\text{w}}}}}\) are shown in Fig. 10 (insets).

Figure 11 reveals the effect of calcium on Curie transition TC which increased significantly between 0 and 5% of Ca2+, then decreased slightly. On the other hand, Ba0.96Ca0.04TiO3 presents the higher maximum permittivity value. For all Ca2+ concentration, it is clear that T0 always remains lower than TC; the nature of the transition is of the first order.

Initially, the dielectric constant εr increases gradually until reaching its maximum at Curie temperature TC, and then an abrupt fall was observed at temperature above TC, indicating a phase transition (Fig. 10). This leads to a phase transition occurring at (Tc), at which Ba1−xCaxTiO3 transformed from the ferroelectric phase (polarized state) into the paraelectric phase (unpolarized state) [44]. In this process, the polarization affects the permanent dipole moment. Furthermore, the negatively charged O2− and positively charged Ti4+ ions are displaced from their symmetrical positions, which are known as upward displacement [44].

In general, the distortion of the material along c axis can lead to a crystallization of tetragonal phase [45,46,47]. The dielectric behavior of barium calcium titanate produced in the tetragonal phase is in good agreement with our XRD data.

Alternatively, the dielectric constant εr has significantly decreased by conducting the heating of Ba1−xCaxTiO3 above its Curie temperature. This can be explained by the fact that the formed tetragonal phase (noncentrosymmetric) at lower temperature has been transformed into cubic phase (Centrosymmetric) at temperature higher than TC [45]. Thus, the formed crystalline phase of Ba1−xCaxTiO3 is considered as paraelectric, which has no permanent dipole moment that explains its dielectric behavior [44].

4 Conclusion

The structural, spectroscopic and dielectric properties of Ba1−xCaxTiO3 (BCT where x = 0–0.2) nanopowders prepared at low temperature of 800 °C by the recent sol–gel route have been investigated. The structural characterization of the BCT compounds by XRD reveals a complete crystallization in the pure perovskite structure with nanocrystalline sizes. This result was confirmed by the Raman spectroscopic analysis that exhibits bands at around 183, 252, 305, 519 and 712 cm−1, which define a perovskite structure. The samples show single tetragonal phase in space group P4mm. Lattice parameters (a, c), unit cell volume and crystallite sizes were affected by Ca substitution in BaTiO3 lattice due to the difference of atomic radii of calcium and barium.

The microstructure of BaTiO3 calcined at 800 °C for 2 h shows that the distribution of the grains is rather uniform with an average diameter of 81 nm. The SEM data agreed with the results obtained by Scherrer equation using XRD patterns.

It was observed that the variation in Ca concentration promoted a red-shift in the PL peaks. These results prove the reduction of the optical band gap value by appearance of the inter-band electron levels. The specific surface would be determined by BET analysis. Nevertheless, in general and according to Dubois et al. [48], it is often assumed that there is an inverse proportionality between surface area and particle size, thus, as BCT was at nanoscale, its higher surface area leads to a high photoluminescence emission shown by this material, thus making it a good candidate for optical applications.

The dielectric properties of Ba1−xCaxTiO3 systems sintered at 1200 °C for 4 h in the ferroelectric phase showed strong temperature dependence. Therefore, the calcium substitution greatly affects Curie temperature TC which increased significantly between 0 and 5% of Ca2+, and then it decreased slightly up to 10%. Moreover, the value of Curie Weiss constant CW varies according to Ca2+ concentration. On the other hand, the concentration x = 0.1 shows the most diffuse transition character.

References

H.Y. Tian, Y. Wang, J. Miao, H.L.W. Chan, C.L. Choy, J. Alloys Compd. 431, 197–202 (2007)

F. Boujelben, F. Bahri, C. Bouday, A. Maalej, H. Khemakhem, A. Simon, M. Maglione, J. Alloys Compd. 481, 559–562 (2009)

Q. Xu, X.F. Zhang, Y.H. Huang, W. Chen, H.X. Liu, M. Chen, B.H. Kim, J. Alloys Compd. 488, 448–453 (2009)

J.Y. Chen, Y.W. Tseng, C.L. Huang, J. Alloys Compd. 494, 205–209 (2010)

X. Cheng, M. Shen, Solid State Commun. 141, 587–590 (2007)

D. Fu, M. Itoh, S. Koshihara, Appl. Phys. Lett. 93, 012904 (2008)

X. Cheng, M. Shen, Mater. Res. Bull. 42, 1662–1668 (2007)

F.V. Motta, A.P.A. Marques, J.W.M. Espinosa, P.S. Pizani, E. Longo, J.A. Varela, Curr. Appl. Phys. 10, 16–20 (2010)

S.V. Trukhanov, A.V. Trukhanov, S.G. Stepin, H. Szymczak, C.E. Botez, Phys. Solid State 50, 886–893 (2008)

V.D. Araujo, F.V. Motta, A.P.A. Marques, C.A. Paskocimas, M.R.D. Bomio, E. Longo, J.A. Varela, J. Mater. Sci. 49, 2875–2878 (2014)

S.V. Trukhanov, V.V. Fedotova, A.V. Trukhanov, S.G. Stepin, H. Szymczak, Crys. Rep. 53, 1177–1180 (2008)

V.V. Atuchin, T.A. Gavrilova, J.-C. Grivel, V.G. Kesler, Surf. Sci. 602, 3095–3099 (2008)

V.V. Atuchin, T.A. Gavrilova, J.-C. Grivel, V.G. Kesler, I.B. Troitskaia, J. Solid State Chem. 195, 125–131 (2012)

H.P. Ji, L. Wang, M.S. Molokeev, N. Hirosaki, R.J. Xie, Z.H. Huang, Z.G. Xia, O.M.T. Kate, L.H. Liu, V.V. Atuchin, J. Mater. Chem. C 4, 6855–6863 (2016)

B. Cui, P. Yu, X. Wang, J. Alloys Compd. 459, 589–593 (2008)

F.V. Motta, A.P.A. Marques, C.A. Paskocimas, M.R.D. Bomio, A.S.F. Santos, E.R. Leite, J.A. Varela, E. Longo, in Polymerization, 3nd edn. (INTECH, Rijeka, 2012), pp. 261–278

Y.Y. Yao, J.N. Cheng, P. Zhao, J. Chin. Ceram. Soc. 32, 751–754 (2004)

A.E. Souza, S.R. Teixeira, C.M. -Santos, W.H. Schreiner, P.N.L. Filho, E. Longo, J. Mater. Chem. C 2, 7056 (2014)

R.S. Silva, M.I.B. Bernardi, A.C. Hernandes, J. Sol–Gel Sci. Technol. 42, 173–179 (2007)

R.S. Silva, A.C. Hernandes, J.-C. M’Peko, Mater. Res. 15, 522–529 (2012)

C.S. Lim, A.S. Aleksandrovsky, M.S. Molokeev, A.S. Oreshonkov, V.V. Atuchin, J. Solid State Chem. 228, 160–166 (2015)

C.S. Lim, A.S. Aleksandrovsky, M.S. Molokeev, A.S. Oreshonkov, D.A. Ikonnikov, V.V. Atuchin, Dalton Trans. 45, 15541–15551 (2016)

C.S. Lim, V.V. Atuchin, A.S. Aleksandrovsky, M.S. Molokeev, Mater. Lett. 181, 38–41 (2016)

R.S. Silvaa, L.M. Jesus, T.C. Oliveira, D.V. Sampaio, J.C.A. Santos, A.C. Hernandes, J. Eur. Ceram. Soc. 36, 4023–4030 (2016)

M.R. Panigrahi, S. Panigrahi, Phys. B 405, 1787–1791 (2010)

S.H. Jabarov, A.I. Mammadov, A.V. Trukhanov, J. Surf. Invest. 11, 223–225 (2017)

X. Jin, D. Sun, Y. Zhang, J. Qian, J. Electrocer. 22, 285–290 (2009)

J.A. Dawson, X. Li, C.L. Freeman, J.H. Harding, D.C. Sinclair, J. Mater. Chem. C 1, 1574–1582 (2013)

X.Y. Wang, B. Lee, M. Hu, E.A. Payzant, D.A. Blom, J. Eur. Ceram. Soc. 26, 2319–2326 (2006)

A. Pinczuk, W. Tayler, E. Burstein, Solid state Commun. 5, 429 (1967)

M. Didomenico, S.H. Wemple, S.P.S. Porto, Phys. Rev. 174, 522–530 (1968)

Y. Shiratori, C. Pithan, J. Dornseiffer, R. Waser, J. Raman Spectrosc. 38, 1288–1299 (2007)

G. Busca, V. Buscaglia, M. Leoni, P. Nanni, Chem. Mater. 6, 955–961 (1994)

Q. Sun, Q. Gu, K. Zhu, R. Jin, J. Liu, J. Wang, J. Qiu, Sci. Rep. 7, 42274 (2017)

M.B. Smith, K. Page, T. Siegrist, P.L. Redmond, E.C. Walter, R. Seshadri, L.E. Brus, M.L. Steigerwald, J. Am. Chem. Soc. 130, 6955–6963 (2008)

F.A. Rabuffetti, R.L. Brutchey, J. Am. Chem. Soc. 134, 9475–9487 (2012)

L. Wang, H. Kang, D. Xue, C. Liu, J. Crys. Growth 311, 605–607 (2009)

Y.D. Hou, L. Hou, J.F. Yang, M.K. Zhu, H. Wang, H. Yan, Acta Chim. Sinica 10, 950–954 (2007)

Y.V. Kolen’ko, K.A. Kovnir, I.S. Neira, T. Taniguchi, T. Ishigaki, T. Watanabe, N. Sakamoto, M. Yoshimura, J. Phys. Chem. C 111, 7306–7318 (2007)

X.S. Wang, L.L. Zhang, H. Liu, J.W. Zhai, X. Yao, Mater. Chem. Phys. 112, 675–678 (2008)

W.F. Zhang, Z. Yin, M.S. Zhang, Z.L. Du, W.C. Chen, J. Phys. Cond. Mater. 11, 5655–5660 (1999)

K. Asokan, J.C. Jan, J.W. Chiou, W.F. Pong, P.K. Tseng, I.N. Lin, J. Synchrot. Radiat. 8, 839–841 (2001)

F.A. Kröger, H.J. Vink, Solid State Phys. 3, 307–435 (1956)

R.M. Mahani, I.K. Battisha, M. Aly, A.B. Abou-Hamad, J. Alloys Compd. 508, 354–358 (2010)

M. Nayak, T.Y. Tseng, J. Thin Solid Films 408, 194–199 (2002)

X. Wei, G. Xu, Z. Ren, Y. Wang, G. Shen, G. Han, Mater. Lett. 62, 3666–3669 (2008)

I.K. Battisha, A.B. Abou Hamad, R.M. Mahani, Phys. B 404, 2274–2279 (2009)

I.E. Dubois, S. Holgersson, S. Allard, M.E. Malmstrom, W.-R. Interaction, B. Torres-Alvarado (eds.), Taylor & Francis Group, London, 717–720 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khedhri, M.H., Abdelmoula, N., Khemakhem, H. et al. Structural, spectroscopic and dielectric properties of Ca-doped BaTiO3. Appl. Phys. A 125, 193 (2019). https://doi.org/10.1007/s00339-019-2487-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-2487-y