Abstract

Ag nanoparticles were obtained in Ag/AZO and AZO/Ag/AZO films by magnetron sputtering method at room temperature with different deposition time. The morphology of Ag nanoparticles is strongly affected by the particle size, shape and distribution as well as annealing temperatures, which determine the optical response of films. The high quality of AZO film with better crystallinity can enhance the optical transmittance and a good coverage by AZO as top layer on Ag nanoparticles can also enhance the surface plasmon resonance (SPR) absorption of Ag in long wavelengths. The mechanisms involved in shifts and broadening of SPR peaks have been explained detailedly. The effect of annealing process on SPR of Ag and photoelectric properties of AZO/Ag/AZO films can be also discussed. It is shown that the SPR peak of 664 nm only appears in AZO/Ag (5 s)/AZO film and no SPR peaks are found in annealed AZO/Ag/AZO films. The AZO/Ag (20 s)/AZO film annealed at 300 °C shows a great figure of merit (\(F_{\text{TC}}\)) of 4.8 × 10−2 Ω−1 because of high visible optical average transmittance of 85% and low sheet resistance (\(R_{\text{S}}\)) of 4.1 Ω/sq. The overall results reveal that annealing process can improve the electrical property of film and may not be able to promote the SPR of Ag nanoparticles, especially when AZO top layer is added. The introduction of Ag nanoparticles in AZO/Ag/AZO films should be very effective for improving the SPR or photoelectric properties of films depending on deposition conditions and annealing process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The surface plasmon resonance (SPR) of metallic nanoparticles and the related applications regarded as a promising way to further improve the conversion efficiency of solar cells have attracted considerable interest [1,2,3]. The amorphous silicon (a-Si:H) solar cells absorb less than half of the incident solar light with very weak absorption in longer wavelengths of solar spectrum. It is suggested that the better light management should be needed, including higher possibility for light trapping in the absorbed layer and reduction of refection [4, 5]. Light trapping shows strong interaction of incident light with the conduction electrons in metallic nanoparticles with a diameter smaller than the wavelength of light, where it leads to a collective oscillation of conduction electrons at a frequency known as the localized surface plasmon resonance (LSPR) [6, 7]. At plasmon resonance, light is preferentially scattered by metallic nanoparticles into the actively absorbed layer and improves free carrier generation. The resonance of most metallic nanoparticles is in the visible or near infrared region of the solar spectrum, which depends on the inter-particles distance, shape and size of metallic nanoparticles as well as the dielectric properties of the surrounding medium [8,9,10]. In particular, Ag is an appropriate plasmonic metal, which exhibits strong LSPR and large scattering cross-section but yet a low absorption cross-section in the visible and near infrared region of the solar spectrum with desired size or shape of particles. This is beneficial to be applied in solar cells with increased effective optical path so that to enhance absorption in the absorbed layer.

The size, shape and distribution of Ag nanoparticles can be controlled to tune the plasmonic scattering peak, thus several fabrication methods of Ag nanoparticles were studied, such as chemical synthesis [11], vacuum vapor evaporation with post-annealing [12], and nanosphere lithography [13] and so on. It is most important that these techniques should be compatible with technology used in photovoltaic industry. Magnetron sputtering method provides a feasible alternative to fabricate Ag nanostructures with low cost and no toxic reagents, which could produce high quality films at a high deposition rate [14]. Recently, Al-doped zinc oxide (AZO) has received a lot of attention not only for its excellent photoelectric properties, but also for a medium with appropriate dielectric constant to produce the desired LSPR [15]. There are already many reports about Ag films deposited on AZO films to enhance the electrical properties and Ag nanoparticles embedded in AZO layers with proper size and shape to control SPR peaks [16,17,18]. However, few studies focus on the comparison of electrical properties and LSPR of Ag base AZO films jointly. Moreover, Ag nanoparticles are usually fabricated by dewetting of Ag films upon annealing or at substrate temperature more than room temperature (RT) [4, 12].

In this paper, we prepare Ag/AZO and AZO/Ag/AZO films by magnetron sputtering method at RT. Ag particles can be obtained directly by controlling deposition conditions. The formation mechanism of Ag particles and correlation of their size, shape and distribution with SPR properties have been investigated. Moreover, the annealing process not only has an important influence on SPR of Ag nanoparticles, but also can improve optical and electrical properties of films. It is shown that annealing can not certainly promote SPR of Ag, but it greatly enhances photoelectric properties of AZO/Ag/AZO films. The figure of merit (\(F_{\text{TC}}\)) of 4.8 × 10−2 Ω−1 has been obtained in our work, which is much higher than that of tin-doped indium oxide (ITO) film.

2 Experimental details

Ag/AZO and AZO/Ag/AZO films were deposited on substrates by magnetron sputtering method at RT using a commercially available metallic Ag target (99.99% purity; Ф 6 cm) and AZO target (2 wt% Al2O3; Ф 6 cm). The sputtering was performed in high-purity (99.99%) argon atmosphere with the distance of target to substrate is 87 mm. The deposition chamber was evacuated to a base pressure of about 6.4 × 10−4 Pa. AZO films were deposited at different sputtering power (90 and 105 W) with working pressure of 1.3 Pa using argon gas flow rate of 20 sccm for 20 min. The thickness of AZO films is about 80 and 110 nm at 90 and 105 W, respectively. Ag nanoparticles films with different particle sizes controlled by the different deposition time [5, 10 and 20 s, labeled Ag (5 s), Ag (10 s) and Ag (20 s), respectively] were fabricated at a sputtering power of 15 W with a working pressure of 0.5 Pa using argon gas flow rate of 10 sccm. Then, to study the effect of thermal annealing on the LSPR of Ag nanoparticles and optimize the photoelectric properties of these films, the thermal annealing process of Ag/AZO and AZO/Ag/AZO films were performed in rapid annealing furnace (RTP-300) under high-purity (99.99%) nitrogen atmosphere for 30 min at 200 and 300 °C, respectively. The preparation conditions were listed in Table 1 in detail.

The SPR of Ag nanoparticles can be characterized by a minimum in the transmittance curve [14]. The evolution of the SPR properties of the Ag nanoparticles was measured with a UV–Visible spectrophotometer (LENG GUANG 756MC) at wavelengths ranged from 300 to 1100 nm. Surface morphology of Ag nanoparticles was studied by field-emission scanning electron microscopy (FE-SEM, JSM-6700F). The size and distribution of Ag nanoparticles obtained from FE-SEM were evaluated using image analysis software (Nano Measure 1.2). Crystalline structures of the multilayer films were characterized by θ/2θ X-ray diffraction (XRD, D/MAX2500) with Cu Kα radiation (λ = 0.154 nm). The sheet resistance of films was obtained by Hall-effect measurements that were carried out at RT in a standard van der Pauw configuration with four Au contacts.

3 Results and discussion

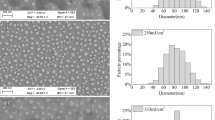

The morphology of Ag nanoparticles on AZO film is strongly influenced by the deposition time, as shown in Fig. 1. It is seen that the Ag particles deposited by magnetron sputtering method at RT distribute randomly on AZO substrate without forming the continuous layer. The size of Ag nanoparticles increases with increase of the deposition time. The high-density small Ag nanoparticles grow with deposition time of 5 and 10 s. For Ag (20 s), the spherical Ag nanoparticles are formed and dispersed on the substrate, whereas the density decreases sharply. From the corresponding size distribution histograms of Ag nanoparticles, the average particle sizes of Ag are 55 nm, 75 and 150 nm, respectively. The bigger Ag particles are subjected to the aggregation involved in the film growth mechanism controlled by the deposition time.

The optical properties of Ag nanoparticles are highly dependent on the particle size, shape and also the surrounding dielectric environment [18]. It is known that the AZO substrate has important effect on the growth of Ag in Ag/AZO film because the deposited AZO film most likely acts as nucleation centers for Ag particles. Therefore, we study the optical response of Ag nanoparticles on AZO films deposited at the different sputtering power. Figure 2 shows transmittance spectra of Ag/AZO and AZO/Ag/AZO films with the different sputtering power of AZO films. As seen from the transmittance spectra of AZO films, the highest average transmittance (400–800 nm) of AZO film is calculated as 92% obtained at the sputtering power of 105 W. The quality of AZO film was determined by the preparation process and the better crystallinity of AZO film has higher optical transmittance, which can be also seen from XRD spectra of AZO films in Fig. 3. The spectral curves of Ag/AZO and AZO/Ag/AZO films for the different AZO substrates change with the deposition time. The SPR peak positions are listed in Table 1.

It is most important that AZO film with better crystalline quality has well-distributed grains as nucleation centers, which can promote the growth Ag to form larger particles. The larger Ag particles can lead to SPR absorption in long wavelengths. As for Ag/AZO films, the SPR peak at 594 nm shifts to 618 nm with Ag deposition time from 5 to 10 s for AZO at 90 W while the SPR peak shifts from 616 to 625 nm for AZO at 105 W. The red shift in SPR peak is due to the increase in Ag particle size. However, the intensities of SPR peaks in these films are relatively low, as well as the peaks gradually broaden with increasing deposition time.

Long exposure of Ag nanoparticles to atmosphere leads to the modification of Ag nanoparticles and the damping process appear as the particle size increases, which could broaden the dipole resonance and excite higher multipole resonance [12]. Moreover, the loss of spherical shape of Ag nanoparticles also results in a decrease in electromagnetic field and random scattering of light. On the other hand, from XRD spectrum of as-deposited Ag (10 s)/AZO in Fig. 3, weak Ag (111) peak can be only detected at the 2θ = 38.08°. The average crystalline size obtained by Scherrer formula [20] is about 10.4 nm. The comparison of this value with the average Ag particle size of 75 nm from the SEM image in Fig. 1b suggests that Ag nanoparticles are polycrystalline and actually formed by more than one grain domain. This has a considerable influence on the plasmon response of Ag nanoparticles because the collectively oscillating electrons in Ag nanoparticles would lose their energy interacting with grain boundaries or defects in the metal, which results in an increase in the parasitic light absorption and a decrease in the scattering intensity at the plasmon resonance [4]. Consequently, all these factors as mentioned above should be responsible for the broadening and weak intensities of peaks.

When the Ag deposition time is 20 s, no SPR peaks appear in these films. The large crystalline size more than 150 nm and poor surface coverage contribute to the absence of SPR peaks because the incident light could transmit through the film allowed by the dispersed large Ag particles.

In addition, AZO layer was deposited on top of Ag/AZO film to investigate the effect of AZO top layer on plasmon resonance and optical properties of AZO/Ag/AZO films. The thickness of AZO top layer is the same as that of bottom layer (80 nm for 90 W and 110 nm for 105 W). From Fig. 2, the SPR peaks are only found in AZO/Ag (5 s)/AZO films and shift to long wavelengths attributed from the AZO top layers. The SPR peaks are 636 and 664 nm for AZO films deposited at 90 W and 105 W in these films, respectively. AZO dielectric encapsulation performed in the same chamber with deposition of Ag nanoparticles can avoid exposure of Ag to atmosphere, which exhibit relatively strong SPR peak compared with Ag/AZO films. However, similar changes are not observed in AZO/Ag (10 s)/AZO films. This might explain that the large size Ag crystalline cannot be completely covered by AZO top layer forming a thick AZO layer in the nanoparticle-free surface areas [14], which would further change the SPR property of Ag nanoparticles. In addition, the visible optical transmittance of AZO/Ag (20 s)/AZO films increases compared with Ag/AZO films because introduction of AZO layer can reduce the visible light scattering and improve the transmittance of film.

The AZO substrate with better crystalline quality can contribute to nucleation growth of Ag particles and improve the optical response, such as the SPR peak of 664 nm in AZO/Ag (5 s)/AZO film, especially when AZO film was deposited at 105 W, as mentioned above. Moreover, the thermal annealing can promote grain growth and recrystallization. From Fig. 3, Ag/AZO films after annealing exhibit preferred orientation along ZnO (002) plane and Ag (111) peak gradually becomes distinct with increase of annealing temperature. Therefore, we choose AZO film deposited at 105 W to perform the annealing experiments of Ag/AZO and AZO/Ag/AZO films in the following.

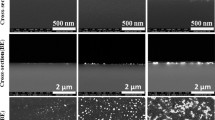

Figure 4 shows SEM images of Ag nanoparticles on AZO films with the different annealing temperatures and the related transmittance spectra of these films are seen in Fig. 5. The SPR peak positions are also listed in Table 1. Normally, Ag particles become bigger and the particle density decreases after annealing, which is attributed to the coalescence process favored in the film growth process at higher temperatures [21]. In our case, the results based on SEM images are quite different. As for Ag (5 s), the smaller particles intensely grow and the particle density increases after annealing. However, no SPR peaks are found in these films. It is considered that Ag nanoparticles thermally favored diffuse to make contact with bottom AZO particles forming Ag–AZO particle aggregates, which in turn change the SPR of Ag nanoparticles.

With respect to Ag (10 s), bigger Ag particles with size more than 100 nm appear for annealing at 200 °C but not uniformly distributed. The XRD spectrum of this film in Fig. 3 shows Ag (111), Ag (200), Ag (220) and Ag (111) peaks, respectively. The average crystalline size along Ag (111) plane is calculated to 13.6 nm. This indicates that Ag particles are polycrystalline containing many small particles and this is also found in other annealed Ag/AZO films. Further increasing annealing temperature to 300 °C, Ag nanoparticles are preferential orientation of (111) plane and the qualitatively more spherical Ag nanoparticles are observed. At these annealing temperatures, the blue shifts occur compared with films before annealing, which should be due to decreased particle density from the coalescence of big particles [19].

When Ag deposition time is increased to 20 s, annealing process has important effect on the surface morphology of Ag nanoparticles. It is possible to assume that Ag atoms make a step further to diffuse from the surface of large particles to that of small ones at annealing temperatures. This thermally active surface diffusion make redistribution of particle size where the large-sized Ag particles decreases and the number of small particles increases. This would more often happen in thick Ag film. As a result, Ag nanoparticles with size of about 100 nm are obtained after annealing, which lead to SPR peaks in Ag/AZO films.

However, there are no SPR peaks found in annealed AZO/Ag/AZO films as shown in Fig. 5. It is likely due to the poor surface coverage of bigger Ag nanoparticles by AZO top layer as explained above. Moreover, Ag nanoparticles and AZO layers are continuously deposited in the same chamber and annealed afterward. The AZO top layer could inhibit the surface diffusion and particle formation. Especially for AZO/Ag (20 s)/AZO films, the average transmittance (400–800 nm) of as-deposited sample is increased from 79.8 to 87.7% for annealing at 200 °C and 85% for annealing 300 °C, respectively, (see Table 2). The average transmittance can be determined by Huang et al. [22]. The uniform distribution and close arrangement of Ag nanoparticles reducing the light scattering contribute to the high visible optical transmittance, which lead to higher reflection in near infrared region (see the inset in Fig. 5b). The oblique view of AZO/Ag (20 s)/AZO film annealed at 300 °C is seen in Fig. 4f. The interface of Ag layer can be distinguished from the entire AZO/Ag/AZO film. Grains of AZO film with columnar structure are visible in this range of thickness. Therefore, the annealing process and covered AZO layer determine the SPR properties and the corresponding optical response of films.

We notice that the size distribution and SPR properties of Ag nanoparticles are affected by deposition time and annealing process, as shown in Fig. 6. As-deposited Ag on AZO substrates actually does not form a continuous Ag layer, instead small Ag particles are formed, which can be determined by Ag sputtering time. Annealing can enable the surface diffusion of Ag, migration and formation of more favored large Ag particles, leading to produce uniform plasmonic surfaces. In addition, the following points need to be further considered upon annealing: (1) Ag nanoparticles thermally favored diffuse along polycrystalline AZO substrates and coalesce with each other forming bigger Ag particles; (2) increasing annealing temperature leads to the formation of large Ag nanoparticles with reduced surface coverage accompanied with increase of inter-particle spacing; (3) annealing can reconstruct the shape and size of Ag nanoparticles. These thermally activated kinetic processes can minimize the total free energy of system by rearranging the Ag nanoparticles distribution. From Fig. 6, it can be seen that as only for Ag (10 s), as-deposited and annealed Ag/AZO films exhibit SPR effect. Annealing process blue-shifts the resonance with increase of inter-particle spacing. As for Ag (20 s), annealing reconstructs Ag particles and greatly changes surface morphology and distribution of Ag nanoparticles. And then SPR peaks red-shift compared to Ag (10 s) due to increase of particle density. Therefore, annealing is more conducive to the SPR in long wavelengths for thick Ag film. However, no SPR peaks are found in Ag (5 s) after annealing, which is attributed to incomplete surface morphology of Ag nanoparticles with formation of Ag–AZO particle aggregates from thermally favored diffusion of Ag nanoparticles on AZO discussed above.

Annealing can promote grain growth, reduce carrier scattering at grain boundaries and increase carrier mobility, thereby improving the conductivity of film [23]. The measured sheet resistance (\(R_{\text{S}}\)) of samples are listed in Table 1. The electrical properties of doped oxide films were found to be strongly dependent on the crystallinity and thickness of films [24]. AZO film with high crystallinity has low resistivity. According to thickness of both AZO films (80 nm for 90 W and 110 nm for 105 W) and \(R_{\text{S}}\) definition [25], \(R_{\text{S}}\) value of AZO film deposited at 105 W is lower than that at 90 W, which exhibits better crystalline quality, as seen from Fig. 3. Since the resistivity of Ag is much lower than that of AZO, the total resistivity of the film is mainly determined by Ag layer with different deposition time. In our work, the discontinuous Ag layer that composed of Ag nanoparticles could be still conductive due to quantum mechanical tunneling and near-field plasmonic coupling effect among Ag nanoparticles [26, 27]. The \(R_{\text{S}}\) values of Ag/AZO films with the different deposition time are much larger than 100 Ω/sq, however, the deposited AZO top layer can help to form an electric conduction net and high quality AZO layer can also enhance the electrical conductivity. It can be seen that when AZO layer was deposited at 105 W, \(R_{\text{S}}\) values of AZO/Ag/AZO films sharply decrease from 37 to 11.2 Ω/sq with increase of Ag deposition time and further reduce to 4.1 Ω/sq with Ag (20 s) after annealing at 300 °C. Compared with optical transmittance spectra and electrical parameters of AZO/Ag/AZO films, one can see that the film shows SPR peak of 664 nm with \(R_{\text{S}}\) of 37 Ω/sq, while no SPR peak is found for Ag (20 s) exhibiting high visible optical average transmittance of 85% with \(R_{\text{S}}\) value of 4.1 Ω/sq after annealing. This indicates that the SPR and electrical properties of these films can not be optimized simultaneously. AZO/Ag/AZO films with shorter Ag deposition time tend to appear SPR properties while exhibiting good photoelectric properties for longer Ag deposition time, which further improves after annealing.

It is known that the optical and electrical properties of AZO/Ag/AZO films usually cannot be optimized simultaneously to achieve maximum transmittance and conductivity. The parameter of \(F_{\text{TC}}\) should be used to evaluate the overall photoelectric properties of films as defined by Haacke [28]: \(F_{\text{TC}} = T^{10} /R_{\text{S}}\), where T is the average transmittance and \(R_{\text{S}}\) is the sheet resistance. As seen from \(F_{\text{TC}}\) in Table 2, even though AZO/Ag (20 s)/AZO films do not exhibit SPR property, \(F_{\text{TC}}\) of the film annealed at 300 °C reaches to 4.8 × 10−2 Ω−1 much higher than that of the as-deposited one (0.93 × 10−2 Ω−1). Based on the results discussed above, photoelectric properties of AZO/Ag/AZO films can be controlled by surface morphology of Ag nanoparticles, coverage of AZO layer and annealing process, which exhibit SPR property or better \(F_{\text{TC}}\). Moreover, the SPR peaks in visible or near infrared region of solar spectrum are expected to have strong light-trapping effects to improve the efficiency of thin film solar cells. Thus, these films could fully satisfy the requirement for transparent conductive applications and work in good prospects in optoelectronic devices.

4 Conclusions

In summary, Ag nanoparticles were deposited by magnetron sputtering method at RT with a good control of particle size, shape and distribution. The surface morphology and photoelectric properties of as-deposited and annealed Ag/AZO and AZO/Ag/AZO films were investigated adequately. The deposition time, annealing temperature and the quality of AZO film have important influence on the surface morphology of Ag nanoparticles, optical response and electrical property of these films. The loss of spherical shape and polycrystalline structure of Ag nanoparticles can results in a decrease in random scattering of light and scattering intensity at the plasmon resonance, which are under consideration for the broadening of SPR peaks. The SPR peaks disappear in annealed AZO/Ag/AZO films, which might be mainly attributed from the poor surface coverage by AZO top layer and inhibition of AZO in the subsequent annealing. The SPR peak of 664 nm appear in AZO/Ag (5 s)/AZO film with \(R_{\text{S }}\) of 37 Ω/sq. The high visible optical average transmittance of 85% with \(R_{\text{S }}\) value of 4.1 Ω/sq is found in AZO/Ag (20 s)/AZO film annealed at 300 °C as well as \(F_{\text{TC}}\) of 4.8 ×10−2 Ω−1.

References

H.A. Atwater, A. Polman, Plasmonics for improved photovoltaic devices. Nat. Mater. 9, 205–213 (2010)

W.J. Ho, Y.Y. Lee, S.Y. Su, External quantum efficiency response of thin silicon solar cell based on plasmonic scattering of indium and silver nanoparticles. Nanoscale Res. Lett. 9, 483 (2014)

S. Pillai, C.E. Disney, Y. Yang, M.A. Green, The effect of ageing on the scattering properties of silver nanoparticles for a plasmonic solar cell. J. Appl. Phys. 118, 153102 (2015)

D. Gaspar, A.C. Pimentel, M.J. Mendes, T. Mateus, B.P. Falcao, J.P. Leitao, J. Soares, A. Araujo, A. Vicente, S.A. Filonovich, H. Aguas, R. Martins, I. Ferreira, Ag and Sn nanoparticles to enhance the near-infrared absorbance of a-Si: H thin films. Plasmonics 9, 1015–1023 (2014)

U.W. Paetzold, M. Meier, E. Moulin, V. Smirnov, B.E. Pieters, U. Rau, R. Carius, Plasmonic back contacts with non-ordered Ag nanostructures for light trapping in thin-film silicon solar cells. Mater. Sci. Eng. B 178, 630–634 (2013)

N.A. Mirin, N.J. Halas, Light-bending nanoparticles. Nano Lett. 9, 1255–1259 (2009)

S. Eustis, M.A. El-Sayed, Why gold nanoparticles are more precious than pretty gold: noble metal surface plasmon resonance and its enhancement of the radiative and nonradiative properties. Chem. Soc. Rev. 35, 209–217 (2006)

Y. Lin, X.Q. Liu, T. Wang, C. Chen, H. Wu, L. Liao, C. Liu, Shape-dependent localized surface plasmon enhanced UV-emission from ZnO grown by atomic layer deposition. Nanotechnology 24, 125705 (2013)

G. Xu, M. Tazawa, P. Jin, S. Nakao, K. Yoshimura, Wavelength tuning of surface plasmon resonance using dielectric layers on silver island films. Appl. Phys. Lett. 82, 3811 (2003)

A.R. Tao, D.P. Ceperley, P. Sinsermsuksakul, A.R. Neureuther, P.D. Yang, Self-organized silver nanoparticles for three-dimensional plasmonic crystals. Nano Lett. 8, 4033 (2008)

B.J. Wiley, Y. Chen, J.M. McLellan, Y.J. Xiong, Z.Y. Li, D. Ginger, Y. Xia, Synthesis and optical properties of silver nanobars and nanorice. Nano Lett. 7, 1032–1036 (2007)

M.M. Rahman, N. Hattori, Y. Nakagawa, X. Lin, S. Yagai, M. Sakai, K. Kudo, K. Yamamoto, Preparation and characterization of silver nanoparticles on localized surface plasmon-enhanced optical absorption. Jpn. J. Appl. Phys. 53, 11RE01 (2014)

Z.Y. Ma, X.D. Ni, W.P. Zhang, X.F. Jiang, H.F. Yang, J. Yu, W. Wang, L. Xu, J. Xu, K.J. Chen, D. Feng, Hexagonal Ag nanoarrays induced enhancement of blue light emission from amorphous oxidized silicon nitride via localized surface plasmon coupling. Opt. Express 22, 28180–28189 (2014)

H. Nasser, Z.M. Saleh, E. Özkol, M. Günoven, A. Bek, R. Turan, Fabrication of Ag nanoparticles embedded in Al: ZnO as potential light-trapping plasmonic interface for thin film solar cells. Plasmonics 8, 1485–1492 (2013)

Y. Kim, W. Lee, D.R. Jung, J. Kim, S. Nam, H. Kim, B. Park, Optical and electronic properties of post-annealed ZnO: Al thin films. Appl. Phys. Lett. 96, 171902 (2010)

C.Y. Huang, C.X. Xu, J.F. Lu, Z.H. Li, Z.S. Tian, 3D Ag/ZnO hybrids for sensitive surface-enhanced Raman scattering detection. Appl. Surf. Sci. 365, 291–295 (2013)

J.D. Winans, C. Hungerford, K. Shome, L.J. Rothberg, P.M. Fauchet, Plasmonic effects in ultrathin amorphous silicon solar cells: performance improvements with Ag nanoparticles on the front, the back, and both. Opt. Express 23, A92–A105 (2015)

Z.M. Saleh, H. Nasser, E. Özkol, M. Günöven, B. Altuntas, A. Bek, R. Turan, Enhanced optical absorption and spectral photocurrent in a-Si: H by single-and double-layer silver plasmonic interfaces. Plasmonics 9, 357–365 (2014)

P. Mao, J. Chen, R.Q. Xu, G.Z. Xie, Y.J. Liu, G.H. Gao, S. Wu, Self-assembled silver nanoparticles: correlation between structural and surface plasmon resonance properties. Appl. Phys. A 117, 1067–1073 (2014)

P. Scherrer, GöttingerNachrichten. Gesell 2, 98–100 (1918)

N.F. Ren, L.J. Huang, M. Zhou, B.J. Li, Introduction of Ag nanoparticles and AZO layer to prepare AZO/Ag/FTO trilayer films with high overall photoelectric properties. Ceram. Int. 40, 8693–8699 (2014)

L.J. Huang, N.F. Ren, B.J. Li, M. Zhou, A comparative study of different M (M=Al, Ag, Cu)/FTO bilayer composite films irradiated with nanosecond pulsed lase. J. Alloys Comp. 617, 915–920 (2014)

R. Swapna, M.C. Santhosh, Kumar, The role of substrate temperature on the properties of nanocrystalline Mo doped ZnO thin films by spray pyrolysis. Ceram. Int. 38, 3875–3883 (2012)

D. Kim, M. Park, H. Lee, G. Lee, Thickness dependence of electrical properties of ito film deposited on a plastic substrate by RF magnetron sputtering. Appl. Surf. Sci. 253, 409–411 (2006)

C. Granqvist, Transparent conductive electrodes for electrochromic devices: a review. Appl. Phys. A 57, 19–24 (1993)

D.S. Ghosh, in Ultrathin Metal Transparent Electrodes for the Optoelectronics Industry. ICFO-The Institute of Photonic Sciences, (Barcelona, Spain, 2013), p. 21

C.Y. Liu, K.C. Liang, W. Chen, C. Tu, C.P. Liu, Y. Tzeng, Plasmonic coupling of silver nanoparticles covered by hydrogen-terminated graphene for surface-enhanced Raman spectroscopy. Opt. Express 19, 17092–17098 (2011)

G. Haacke, New figure of merit for transparent conductors. J. Appl. Phys. 47, 4086–4089 (1976)

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 61404080).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, J., Hui, C., Liu, C. et al. Effect of Ag nanostructures and annealing process on the localized surface plasmon resonance properties of Ag-based AZO films. Appl. Phys. A 123, 521 (2017). https://doi.org/10.1007/s00339-017-1132-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1132-x