Abstract

Starch and gelatin are two of the most abundantly available natural polymers. Their non-toxicity, low cost, and compatibility with aqueous solvents make them ideal for use in ubiquitous, environmentally friendly electronics systems. This work presents the results of conductivity measurements through impedance spectroscopy for gelatin- and starch-based aqueous gel electrolytes. The NaCl-based gels were physically cross-linked. The conductivity values were 84.6 mS/cm at 1.5 mol L−1 and 71.5 mS/cm at 2 mol L−1 for gelatin and starch, respectively. The mechanical properties of gelatin were found preferable to those of starch, although they deteriorated significantly when the salt concentration exceeded 2 mol L−1. The ability of the gels to successfully act as a supercapacitor electrolyte was demonstrated with printed electrodes on plastic substrate. The devices were characterized through cyclic voltammetry measurements. The results imply that these polymer gel electrolytes are very promising for replacing the traditional aqueous liquid electrolytes in supercapacitors in applications where, for example, user and environmental safety is essential.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There is an increasing demand to add intelligence to everyday objects, leading to the concept of the internet of everything (IoE). One key issue for making the IoE economically and environmentally viable is the supply of energy; due to recycling issues, batteries cannot be the solution for all IoE objects. An alternative is harvesting of available energy from the environment and interim storage in supercapacitors. Supercapacitors, also known as electrochemical double layer capacitors, can be made entirely from non-toxic materials, and have much higher cycle life (though lower total energy density) than secondary batteries, and, for these reasons, are promising devices for interim storage of harvested energy. Supercapacitors based on solutions of water and salt have successfully been implemented in energy harvesting and storage systems [1].

The properties of the electrolyte, such as ionic conductivity and stability against evaporation and leakage, are critical to the performance of supercapacitors. Gel electrolytes have reduced risk of leakage, but they can still retain good absorption into the electrode pores unlike solids. The semi-solid nature of gels makes them able to replace the separator in some applications, as gels are capable of withstanding some mechanical stress [2, 3]. On the other hand, many gel formulations contain toxic materials.

Natural polymers are a promising class of materials for gel formation because of their renewability and their non-toxic often biodegradable properties. Starch and gelatin are two of the most abundantly available natural polymers and suitable for mass production due to their very low cost. They are also compatible with non-toxic salt solutions; with a combination of just water, salt, and natural polymers, efficient yet non-toxic components can be manufactured to ensure maximal consumer and environmental safety. Raw materials for aqueous electrolytes are also typically more affordable and place less strict requirements on the manufacturing facilities than organic solvents. The use of natural polymers as solid electrolytes has previously been studied [4,5,6,7,8], but comparative studies of the performance of different polymers have been scarce so far.

In this work, we demonstrate the use of the two most widely available natural polymers, gelatin and starch, and compare their performance as solid electrolytes intended for use in supercapacitors. Electrolytes from both of these polymers were prepared with similar methods in various concentrations. The conductivities were measured and compared to each other as well as to the conductivity of an aqueous reference electrolyte. The potential of the gels to act as a supercapacitor electrolyte is also qualitatively demonstrated by recording the cyclic voltammetry (CV) response of the materials in a printed supercapacitor cell. The presented gels are manufactured from completely non-toxic raw materials to minimize any adverse effects to the environment and end-users.

2 Experimental procedure

2.1 Gel electrolytes

Gelatin from porcine skin (Sigma-Aldrich) and unmodified starch from wheat (Sigma-Aldrich) were used to manufacture the hydrogel electrolytes. Aqueous NaCl solutions with concentrations varying from 0.34 to 1.5 mol L−1 for starch and from 0.34 to 2 mol L−1 for gelatin were prepared in advance, before incorporating the polymer powders.

To prepare the starch--based gel, NaCl was dissolved in deionized water, followed by dispersion of 4 g of the polymer powder into 30 ml of the solution. The mixture was then brought to a boil to thicken it and immediately cooled to ambient temperature without further boiling.

The gelatin-based gel was prepared by incorporating 4 g of the polymer powder into 30 ml of the aqueous NaCl solution and warming to 70–80 °C on a hot plate until complete dissolution of the polymer particles. The solution was not allowed to boil. The solution was removed from the heat and 3 ml of glycerol was added while thoroughly mixing as the solution was allowed to cool to ambient temperature.

Glycerol was used as a plasticizer to improve the mechanical properties of the gelatin-based polymer gel, as solutions without the additive turn very rigid over time. With certain electrolytes, glycerol is also known to promote better ionic conductivity in some gelatin-based gels [9]. However, in this work, the glycerol concentration was decided based on the most favorable effect on mechanical properties, where the gel is still free-standing yet elastic. Correlation of plasticizer concentration and ionic conductivity was not assessed as the focus is in the comparison of electrolyte performance manufactured with different polymers. Starch gel does not structurally require additional plasticizing, and thus, no glycerol was incorporated into the starch.

The gelatin-based electrolyte relies on the physical cross-linking of the polymer to avoid toxic cross-linker remnants. The gel can be repeatedly heated above melting point and reset. For remelting, the gel was placed in a glass vial onto a hot plate set to 65 °C.

The conductivity of a liquid aqueous electrolyte containing only water and NaCl was used as a reference for the solid electrolytes. Pörhönen et al. have demonstrated the use of 1 mol L−1 aqueous sodium chloride in carbon-based supercapacitors [10]. The NaCl solution and all gel solutions were prepared in a clean room. The compositions of all the gels are presented in Table 1.

2.2 Characterization

Impedance spectroscopy was used to determine the ionic conductivity of the gel electrolytes. Measurements were conducted using a sample holder with two stainless steel electrodes of 10.5 cm2 area and 1 mm distance. Dimensions of the sample holder are critical for accurate and reproducible measurement. In this study, the ratio of surface area to electrode distance was 105 as it was observed that smaller ratios between the dimensions yield irreproducible results. The opened half of the sample holder setup is presented in Fig. 1.

The gel was dispensed into the sample holder with an injection needle, starting from the bottom of the vessel to reach uniform coverage of the electrodes and to avoid air pockets. Starch gel was injected as is between the steel electrodes. The gelatin gel was re-melted, injected, and allowed to cool and set before measurement. Conductivity of the liquid reference solution was measured with the same setup.

Complex impedance was measured using a Zahner Zennium potentiostat’s impedance spectroscopy module in upper limit sweep mode, so that the measurement was initiated from 1 Hz, raised to 1 MHz, and decreased back down to 20 mHz [11]. The voltage amplitude was 10 mV. All measurements were conducted in room temperature.

Scanning electron microscope (SEM) images of the gels were taken to observe the microstructures. The images were taken using Tescan VEGA3 LMU environmental SEM with water vapor to protect the samples from excessive drying.

Differential scanning calorimetry (DSC) was performed on the gel samples to assess their thermal properties and to observe possible phase changes in the materials affecting the mechanical properties of the gels. The measurements were done with TA instruments Q1000 DSC using hermetically sealed aluminum pans to eliminate the effect of evaporating water.

The starch and gelatin gels were demonstrated as part of a printed supercapacitor cell prepared from graphite ink current collector (PF-407C, Henkel) and activated carbon (AC) electrodes. The AC ink was prepared with the composition of 30.9% of AC (YP-80F AV powder, Kuraray), 1.7% chitosan (Sigma-Aldrich), 0.7% acetic acid (Sigma-Aldrich), and 66.7% deionized water. The ink layers were blade-coated on a PET substrate (Melinex ST506, DuPont) and assembled as a symmetric supercapacitor device in a procedure described in our earlier work [12]. The supercapacitors were characterized using cyclic voltammetry (CV) with a Zahner Zennium potentiostat. The CV curves were measured between 0 and 0.9 V using 5 and 10 mV/s scan rates at two electrode configuration. At each scan rate, the devices were cycled four times before obtaining the final CV curve.

3 Results

The ionic conductivity of the gels was obtained from the Nyquist plots, where the imaginary part of the complex impedance Z″ is plotted against the real part Z′. The resistance R of the gel sample is indicated by the intersection of the curve with the real axis and the ionic conductivity σ is then obtained using

where l is the thickness of the electrolyte and A the surface area of the electrode covered in electrolyte.

Even coverage of the electrode plates is essential for reliable and reproducible measurement results. Figure 2a, b shows the excellent filling of the device after the samples have been measured and disassembled from the setup. The gelatin gel has suffered minor deformation at the left edge during disassembly, but it can be clearly seen that the coverage is continuous and complete without air pockets within the bulk gel. The starch gel in itself is significantly cloudier than gelatin, but still, it shows that there are no considerable bubbles entrapped within the gel layer or at the electrode interface. In cases where bubbles were left in the layer, they were clearly visible at the disassembly stage and such measurement results were excluded from the data, since they alter the active surface area. In addition, the free-standing nature of the gels is demonstrated in Fig. 2a, b, where relatively thick (1 mm) gel layers are unsupported on top of the steel electrodes. The difference in the mechanical stability of the gels is demonstrated by a peel-off test in Fig. 2c and d, where it is seen that the gelatin film has high enough cohesion to be peeled off the electrode as an intact layer, whereas the starch, which is a suspension in structure and thus lacks cohesion, cannot.

Disassembled samples of gelatin (a) and starch (b) after impedance spectroscopy. The fill of the measurement setup is complete. The difference in the mechanical properties of the gels is demonstrated in the lower images. Gelatin (c) can be peeled off the electrode as a free-standing film, whereas the cohesion of starch (d) is poor

With the large area-to-distance ratio in the sample holder, the standard deviation between similar samples of the same gel was successfully reduced to 0.33–2.7 mS/cm which is 1.5–5.7% of the σ depending on the gel. For the 1 mol L−1 NaCl reference solution, a conductivity of 82.1 mS/cm was obtained with the same sample holder. This conductivity value is 6.5% larger than the literature value of 77.06 mS/cm, which has been interpolated from the data in Ref. [13]. However, the results of the measurements in this paper are well reproducible as indicated and the measurements data obtained from gels with varying NaCl concentrations are comparable across the gels. Due to the measurement system, the gels are subject to the same moderate measurement error of approximately 6.5% as seen above with the reference solution.

Polymer gels prepared from 0.34–0.51 mol L−1 NaCl solutions were measured first for both gelatin and starch. Based on the measured conductivities, higher concentrations were chosen and prepared as the conductivity was targeted to that of the reference solution of aqueous 1 mol L−1 NaCl. The Nyquist plots of the complex impedance for the gelatin samples are presented in Fig. 3.

As expected, the conductivity increases with increasing NaCl content. The maximum NaCl concentration for the gelatin-based gel was close to 2 mol L−1. Above this concentration, the gel deteriorated significantly under mechanical stress and the bulk gel was not able to withstand its own weight when handled. Gels with 2 mol L−1 or less of NaCl were easy to handle and injection of the gel into the sample holder was very reliable.

The impedance plots for starch-based gels are shown in Fig. 4, where it can be seen that the resistance decreases rapidly with increasing NaCl content as expected. The addition of NaCl had no notable effect on the mechanical properties of the starch-based gel. Handling the gel is somewhat challenging at any NaCl concentration, since it is less mechanically robust than the gelatin. Removal of any excess air from the starch gel was less reliable than from gelatin because of the structure, but still complete coverage of the electrode plates can be reached through the injection method.

The conductivity values for all the gels are presented in Table 2. The conductivity of starch gels increases from 25.7 to 62.2 mS/cm as the NaCl concentration increases from 0.34 to 1 mol L−1. For gelatin, the increase is from 19.1 to 43.2 mS/cm, respectively. Predictably, the conductivities from 1 mol L−1 solution are lower than for pure mol L−1 NaCl, because the final concentration of the gel is slightly lower and the solid polymer network reduces ion mobility in the electrolyte.

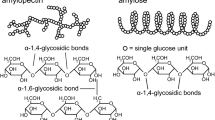

The starch gel shows higher conductivity than gelatin for a given concentration, even though the polymer quantities are the same. Part of the difference results from the slightly reduced final NaCl concentration of the gelatin gel due to the addition of plasticizer. However, some of the difference can be associated with the more ordered, partly helical structure of gelatin which makes the gel much stiffer [14] than corresponding starch gels, which more resemble a suspension in structure. Accordingly, cations and anions are able to better move through the liquid phase of starch than through the more rigid gelatin. The two-phase suspension structure of the starch can be seen in Fig. 5a. On the other hand, the polymer chains of gelatin are fully dissolved and the structure of the gelatin gel appears uniform in the SEM image in Fig. 5b.

This structural difference also makes gelatin more robust in terms of mechanical properties. The gelatin gel is elastic in handling and completely free-standing films can be produced easily. In comparison, the starch gel is prone to undergo plastic deformation without notable elastic property. In terms of their mechanical behavior, gelatin more resembles a flexible solid, whereas starch is more susceptible to flowing under localized perpetual stress, suggesting that gelatin gels would be more promising to act as a separator in a supercapacitor as well as the electrolyte. The mechanical difference between the gels is evident during the sample preparation process required for the impedance measurements.

The structural difference of the gels can also be observed in the DSC results in Fig. 6, where a melting peak for the 2 mol L−1 gelatin gel can be seen, starting at 57 °C, the temperature where the physically cross-linked gel begins to melt as would be expected from a thermoplastic. In case of many IoT energy harvesting and storage systems, the main environment of operation is in room temperature, and based on the DSC results, it appears that the gelatin gel has sufficient thermal stability and the melting point is high enough for the gel to operate reliably in that range. With 1.5 mol L−1 starch, only a melting peak of water is observed at around 0 °C; otherwise, the material appears thermally stable.

As can be seen from Fig. 7, the 1.5 mol L−1 starch gel is very close to the aqueous reference in conductive properties and 2 mol L−1 gelatin comes close to the reference value of 82.1 mS/cm of the aqueous NaCl, before its mechanical properties start to suffer. The previous studies with gelatin gels have found conductivities somewhat lower than the ones found here.

The CV method was used to obtain qualitative data of the performance of the gels as part of a functional supercapacitor. The CV was recorded at 5 and 10 mV/s for both gel types, and the data were normalized to voltage sweep rate and electrode mass. The normalized CV curves at 10 mV/s for both gel types are presented in Fig. 8. The CV measurement was performed on the highest concentrations gels, 1.5 mol L−1 for starch and 2 mol L−1 for gelatin, which showed conductivity values closest to the reference electrolyte.

CV curves for starch and gelatin, recorded with the sweep rate of 10 mV/s in room temperature. On the y-axis, the value for F/g has been derived from the measurement current mA normalized to the sweep rate V/s and then to the mass g of the electrodes in the supercapacitor, resulting in mAs/(Vg) which equals F/g

The CV curves for both materials are highly rectangular, which indicates good capacitive function. Equivalent series resistance, indicated by the curvature of the corners of the curve, is moderate for both [15, 16]. From the charging phase of the curve, it can be estimated that the specific capacitance for both starch- and gelatin-based supercapacitors is in the order of 20 F/g, which is similar to results obtained with the same device using aqueous NaCl as electrolyte.

4 Discussion

The conductivity values presented in literature for gelatin gels are typically for materials cross-linked with glutaraldehyde or formaldehyde. Different salts at varying concentrations as well as the use of acidic and basic solutions have been investigated. In a study of gelatin doped with acetic acid and cross-linked with glutaraldehyde [4], the best conductivities reached at room temperature were in the order of 10−5 S/cm. Similar values have been reached with systems containing Li-ion salts [17, 18], where the cross-linking was aldehyde based, as well. Another study with glutaraldehyde has been conducted by Choudhury et al. [2], where 0–3 N sodium chloride solutions were used to dope gelatin gels. Higher conductivities were seen in gels containing higher concentrations of NaCl and an inverse correlation was also seen with the concentration of the polymer and the conductivity. Conductivity values observed were reported to be in the scale of 10−3–10−1 S/cm, the highest values being reached with 3 N NaCl solution, but because of the low gelatin content, the very best gels were not mechanically rigid enough to form free-standing films.

In literature, starch gels have been manufactured with starch from various different source plants. Potato starch films have been studied by Kumar et al. [19] for use in supercapacitors together with ammonium iodide salt. With 20 weight-% of the salt and added glycerol plasticizer, the best conductivity values reached were in the order of 10−4 S/cm. Similar values have been reached using unmodified [6] and high amylose [7] corn-based starch materials. In both cases, a lithium salt was used as a dopant in large quantities (20 and 30 weight-%, respectively). High amylose starch was plasticized with glycerol and physically cross-linked, reaching a conductivity of 10−4 S/cm in room temperature. A 10−4 S/cm conductivity was reached with the unmodified starch as well, with a glutaraldehyde cross-linking.

In this study, the starch-based electrolyte reached the reference value of the NaCl solution at the highest studied ion concentration, showing the conductivity of 84.6 mS/cm. The ion concentration of the gelatin gel is limited by the gelling behavior, but at the highest studied concentration, conductivity of 71.5 mS/cm was reached. The high conductivity found here compared to literature can partly be explained with the lack of chemical cross-linking in the gel, which leaves the polymer chains more mobile and allows the ions to move more freely. The lack of chemical cross-linking limits the higher end of the temperature range within which the gel is able to act also as a separator. However, the gelatin gel can well be utilized in many room temperature applications as demonstrated by the DSC measurements, and the thermoplastic quality of the gel makes it easier to process also in large scale. The mechanical performance observed during the testing suggests that the mechanical strength and elasticity of the gel would enable it to successfully function in supercapacitors as solid electrolyte.

The qualitative analysis of the electrolytic performance of the gels through the CV method indicates that electrically, the two most conductive gels behave very similarly. The gel supercapacitors manifest good capacitive properties based on the CV curves [10, 16].

5 Conclusions

Non-toxic natural polymer electrolytes based on starch and gelatin were prepared with similar methods and equal polymer concentrations for comparison. The ionic conductivity values for the hydrogels varying from 0.34 to 1.5 mol L−1 for starch and from 0.34 to 2 mol L−1 for gelatin were measured using impedance spectroscopy at room temperature. The measured conductivity of 82.1 mS/cm for aqueous 1 mol L−1 NaCl was used as a reference. The starch-based electrolyte reached the reference value at the highest ion concentration, showing the conductivity of 84.6 mS/cm, but the mechanical rigidity of the gel is inferior to that of gelatin. The ion concentration of the gelatin gel is limited by the gelling behavior, but at the highest concentration, conductivity of 71.5 mS/cm was reached. Because the mechanical properties of the gelatin gel are superior to the starch gel, it is better for use in supercapacitors, although starch yields a higher conductivity. The CV method effectively demonstrates the ability of the electrolyte gels to successfully function as a part of a supercapacitor and indicates that the potential of these gels as a non-toxic alternative for solid electrolytes should be further investigated.

References

S. Lehtimäki, M. Li, J. Salomaa, J. Pörhönen, A. Kalanti, S. Tuukkanen, P. Heljo, K. Halonen, D. Lupo, Int. J. Electr. Power Energy Syst. 58, 42 (2014)

N.A. Choudhury, S. Sampath, A.K. Shukla, Energy Environ. Sci. 2, 55 (2009)

J.Y. Song, Y.Y. Wang, C.C. Wan, J. Power Sources 77, 183 (1999)

D.F. Vieira, C.O. Avellaneda, A. Pawlicka, Electrochim. Acta 53, 1404 (2007)

E. Raphael, C.O. Avellaneda, B. Manzolli, A. Pawlicka, Electrochim. Acta 55, 1455 (2010)

M.F. Shukur, F.M. Ibrahim, N.A. Majid, R. Ithnin, M.F.Z. Kadir, Phys. Scr. 88, 25601 (2013)

R.F.M.S. Marcondes, P.S. D’Agostini, J. Ferreira, E.M. Girotto, A. Pawlicka, D.C. Dragunski, Solid State Ionics 181, 586 (2010)

J.R. Andrade, E. Raphael, A. Pawlicka, Electrochim. Acta 54, 6479 (2009)

A. Al-Kahlout, D. Vieira, C.O. Avellaneda, E.R. Leite, M.A. Aegerter, A. Pawlicka, Ionics (Kiel). 16, 13 (2010)

J. Porhonen, S. Rajala, S. Lehtimaki, S. Tuukkanen, Electron Devices. IEEE Trans. 61, 3303 (2014)

B.E. Conway, Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications (Springer, Berlin, 2013)

J. Keskinen, S. Lehtimäki, A. Dastpak, S. Tuukkanen, T. Flyktman, T. Kraft, A. Railanmaa, D. Lupo, Electron. Mater. Lett. 12, 795 (2016)

W.M. Haynes (ed.), CRC Handbook of Chemistry and Physics (CRC Press, Boca Raton, 2016)

S.B. Ross-Murphy, Polymer (Guildf). 33, 2622 (1992)

A.M. Österholm, D.E. Shen, A.L. Dyer, J.R. Reynolds, A.C.S. Appl, Mater. Interfaces 5, 13432 (2013)

S. Lehtimäki, M. Suominen, P. Damlin, S. Tuukkanen, C. Kvarnström, D. Lupo, A.C.S. Appl, Mater. Interfaces 7, 22137 (2015)

D.F. Vieira, A. Pawlicka, Electrochim. Acta 55, 1489 (2010)

C.O. Avellaneda, D.F. Vieira, A. Al-Kahlout, S. Heusing, E.R. Leite, A. Pawlicka, M.A. Aegerter, Sol. Energy Mater. Sol. Cells 92, 228 (2008)

M. Kumar, T. Tiwari, N. Srivastava, Carbohydr. Polym. 88, 54 (2012)

Acknowledgements

The authors are indebted to the Finnish Funding Agency for Technology and Innovation [Dec. No. 40337/14] and the Academy of Finland [Dec. No. 139881] for the financial support given to this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Railanmaa, A., Lehtimäki, S. & Lupo, D. Comparison of starch and gelatin hydrogels for non-toxic supercapacitor electrolytes. Appl. Phys. A 123, 459 (2017). https://doi.org/10.1007/s00339-017-1068-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1068-1