Abstract

Structure, optical and electronic properties of solid solution thin films of Zn(O,S) developed by spray pyrolysis are investigated, and the effect of annealing is investigated for a possible improvement in its electrical properties. A variation in the initial sulphur (S) precursor concentration with fixed Zn-precursor concentration during the spray deposition produces a solid solution of ZnO and ZnS. Both the lower (<20%) and higher (>80%) concentrations of the S-precursor cause isovalent substitution in the system, retaining hexagonal ZnO and cubic ZnS structures, respectively, whereas other concentrations lead to the formation of films in a phase-separated solid solution of ZnO and ZnS. A strain-induced shift in optical band gap in the range of 3.3–3.6 eV is unique in the system with a strong bowing effect. A post-annealing at 370 °C in air is found to improve electron mobility in the film, whereas the annealing in argon ambient improves its electrical conductivity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

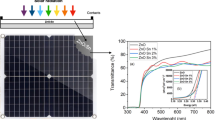

Thin-film solar cells from earth-abundant and non-toxic elements are one of the promising alternative photovoltaic options having the potential of low-cost and eco-friendly technologies. Some of these important photovoltaic absorbers are Cu2ZnSnS4, Cu2SnS3 and SnS [1,2,3,4]. These absorber materials which are being inherently p-type semiconductors need a different n-type buffer layer for creating junction. The buffer material CdS is commonly used for CIGS and CZTS solar cells [5, 6]. Earth-abundant and non-toxic zinc oxysulfide, Zn(O,S), which is a solid solution of ZnO and ZnS is considered as a promising alternative buffer material [7,8,9,10]. One major concern in the heterojunction solar cells, which directly affects their efficiency, is the discontinuity of their conduction and valence bands, also known as conduction band offset (CBO) and valence band offset (VBO), respectively [11]. One of the causes of low performance of CZTS solar cell is unfavourable alignment of conduction band at the interface of absorber and buffer layers. Wider band gap material with favourable band alignment with absorber material gives better response in short-wavelength region [12]. Zinc compound-based buffer layers such as Zn(O,S), Zn1−x Sn x O y and Zn1−x Cd x S are found to be promising buffer materials, alternative to CdS [13,14,15]. The CBO and the doping concentration of buffer layer are the two important parameters to improve the device efficiency [16]. In Zn(O,S), the band gap and hence the CBO can be modified by varying the ratio of oxygen to sulphur fractions [17]. Therefore, an optimum conduction band alignment with the partner absorber layer is possible [18]. A systematic investigation of alloying on their optical and electronic properties will therefore be highly useful for the development of high-efficiency chalcogenide solar cells with Cd-free buffer layers.

In the present study, a series of Zn(O,S) thin films with a variation in the initial precursor concentration of sulphur are synthesized via spray pyrolysis technique. A strain-induced band gap modulation in the solid solution as well as a significant change in the microstructure was observed. The structural and optical properties of the films were correlated with such band gap modulation. The variation in their electrical properties is also studied in different annealing conditions.

2 Experimental

The thin films of Zn(O,S) were deposited by chemical spray pyrolysis of 0.1 M zinc chloride (ZnCl2) (Acros, 98.5% purity) and thiourea (CH4N2S) (Merck, 99% purity) dissolved in the mixture of isopropyl alcohol and de-ionized water in a volumetric ratio of 7:3. A fixed concentration of 0.1 M for ZnCl2 was used, whereas thiourea was used as source of sulphur dopant in ZnO system with a variation in its concentration from 0.01 to 0.1 M (corresponding to 10–100 wt% of the precursor of Zn). The pneumatic spray pyrolysis was conducted on the heated glass substrate placed inside an enclosure containing ambient air as described elsewhere [19]. A pyrolytic decomposition of ZnCl2 and CH4N2S followed by oxidation reaction forms the Zn(O,S) film. Spray parameters such as solution flow rate, nozzle to substrate separation and deposition temperature were optimized before the final deposition. The precursor solution was sprayed from a height of 20 cm on the substrate with a spray rate of 3 ml/min from an atomizing spray nozzle at an air pressure of 20 psi. The spray duration was optimized to keep the Zn(O,S) layer thicknesses at ca. 200 ± 20 nm for all samples (as shown in Fig. S3, electronic supplementary information). During the process optimization, the substrate temperature was found to be an important parameter which influences the film properties. A good quality of the film was obtained without a phase separation of Zn(O,S) into ZnO and ZnS, an optimal substrate temperature between 300 and 320 °C. Usually, at a temperature above 400 °C, a phase separation occurs [20]. The samples were further annealed at 370 °C for an hour under different atmospheric conditions such as vacuum, ambient air and argon to investigate their effect on the electrical properties.

The crystal structure and orientation of the Zn(O, S) thin films were investigated by a XRD pattern recorded by an X-ray diffractometer (PANalytical, model X’Pert PRO) with CuKα radiation (λ) using a Ni filter in thin-film measurement mode. Morphological characterization and compositions of the films were performed by a field emission scanning electron microscope (FESEM) (Zeiss, model Supra 55). The optical band gap, transmittance and the optical parameters were determined by using UV–Vis spectrophotometer (Shimadzu, model UV-2600) in the range of 350–1400 nm. The electrical properties were measured by a Hall measurement system (Ecopia, model HMS-5000). Annealing of the samples was performed in a quartz tube furnace (MTI, EQ–OTF-1200X). The atomic force microscopy (AFM) was performed in the contact mode using a Nanosurf Easyscan 2 system.

3 Results and discussion

3.1 Structure and microstructure variation in Zn(O,S) by variation in S-content

The X-ray diffraction (XRD) measurements were performed to investigate the alloy formation with its crystal structure, phase quantification in terms of percentage crystallinity and lattice strains. The XRD patterns of the as-prepared thin films with the variation in sulphur content (S-content) are shown in Fig. 1. The planes (100), (002), (101) and (110) are observed in the case of S-content equal or below 20 wt% which confirm the wurtzite structure of ZnO having hexagonal unit cells. However, there is a peak shift towards lower 2θ as the S-content increases (JCPDS, 36-1451). This peak shift to a lower Bragg angle is due to the replacement of smaller ionic radii oxygen atoms by larger ionic radii sulphur, causing a lattice strain. By an increase in the S-content, the diffraction peaks closely match with lattice planes (111), (220) and (311) which belong to zinc blend structure of β-ZnS and crystallize in the cubic unit cell (JCPDS, 05-0566). The diffraction lines are found to be sharp for low sulphur content phases which assures no substantial loss of crystallinity and the internal stress is uniform. However, a substitution of oxygen by sulphur results in an increase in bond length and hence its lattice constants. The lattice constant in the case of low S-content varies in the range of 3.25 (pure ZnO) < a < 3.255 and 5.212 (pure ZnO) < c < 5.231 Å (Table 1). Lattice constants in the case of pure ZnO are in agreement with that reported in the case of stress-free ZnO films by Sharma et al. [21] and Wang et al. [22]. As shown in Table 1, for high S-content, the cubic unit cell c-lattice constant does not suffer any substantial change (5.423 < c < 5.428 Å). It is important to note that the crystallite size was determined by the Debye–Scherer formula:

where t is crystallite size, β is the full width at half maximum, θ is the Bragg angle of the characteristic diffraction peak, reduced by half in the case of Zn(O,S) with precursor S concentration less than 20 wt% and remained almost uniform in the case of Zn(O,S) with higher S-content. In order to correlate the crystallite size with the internal stress in the solid solution, the Williamson–Hall (W–H) analysis is presented in Fig. 2. According to W–H analysis, the strain (ε) and crystallite size (t) are correlated by the following equation [23]:

where β, c and λ are the full width at half maximum (FWHM), lattice constant and X-ray wavelength, respectively. A linear fit of βcosθ vs. sinθ normalized by λ and subsequently its slope (Eq. 2) provides the nature of microstrain in the film. A positive slope of the W–H plot is a signature of tensile strain, whereas a negative value indicates its compressive nature. It is evident from Fig. 2a that the films with lower S-content exhibit strain which is tensile in nature, leading the system to reduce its crystallite size through a tendency to phase separation at higher S-content in the wurtzite ZnO system, whereas for higher S-content, Zn(O,S) transforms into cubic ZnS system. In this case, the strain is compressive in nature as shown in Fig. 2b, causing the crystallites to grow in smaller size. This variation in the structure, led by the sulphur fraction in Zn(O,S) induces change in the optical properties of the solid solution as described in subsequent section.

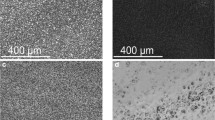

As shown in Fig. 3a, the microstructure of pure ZnO films has a compact morphology with randomly oriented grains with heterogeneous nucleation. With increasing S-content, up to 20 wt%, the grains are more distinct, formed with sharp grain boundaries and better field emission properties (Fig. 3b, c). With further increase in the S-content (Fig. 3d), the microstructure revealed a mix of nearly round and flake-like morphology as a consequence of evolving phase separation. According to Hume–Rothery rule [24], the solid solution ZnO1−x S x should behave as S-doped ZnO for x < 0.15 and O-doped ZnS for x > 0.85, which means an isovalent doping is possible in these range of sulphur fractions. For any other fractions of sulphur, the system enters into the state of phase-separated ZnO and ZnS. In the present case, with the S-content above 60 wt% as shown in Fig. 3e, the new morphology of Zn(O,S) appears. As shown in Fig. 3f, pure ZnS is highly homogeneous and nano-crystalline.

Atomic force microscopy offers significant insight into the local morphological properties of the nano-structured surface affecting the properties of the film. AFM was conducted to check the film morphology and surface roughness at the nanometre scale. Surface morphology of the film is shown using 2D and 3D images in Fig. 4a, b for the ZnO and Zn(O,S)20% films, respectively. The histograms in Fig. 4c, d show the crystalline size distribution of the ZnO and Zn(O,S)20% films, respectively. The crystallite size determined from the XRD analysis using the Debye–Scherer formula differs from that obtained in the AFM data. The obtained grain sizes are larger than the crystallite sizes because grains in the thin film can be the composition of many crystallites [25]. Crystallite size distribution is uniform for all the films. Figure 4c,d shows that the Zn(O,S) films have a narrow range of grain size distribution. For ZnO, a sharp distribution with a centre line at 400 nm is observed, and as the sulphur concentration was increased [i.e. for Zn(O,S)20%], a change in the distribution is observed with the convolution of three peaks. Figure 4a, b clearly shows that the grain size decreases with increasing S-content probably due to the development of strain in the film as shown in Table 1. For ZnO, the AFM-estimated grain size was 309 nm and that for Zn(O,S) with S-content of 20 wt% is 207 nm.

3.2 Optical properties and its correlation with structure and morphologies

The absorption coefficient (α) can be determined from the following expression by considering a direct allowed optical transition,

where A is a constant, \(h\gamma\) is the photon energy and \(E_{\text{g}}\) is the band gap. The band gap energy for each of the above solid solutions is thus determined by plotting \((\alpha h\gamma )^{2}\) vs. \(h\gamma\) and extrapolating the linear region to the energy axis, according to Tauc [26, 27]. Figure S1 (please refer to electronic supplementary material) shows the variations in E g for the Zn(O,S) samples for various S-concentrations. The estimated band gaps for different sulphur content in ZnO are listed in Table 1. The band gap for ZnO film is obtained as 3.3 eV, and with increasing S-content in Zn(O,S), it was decreased to 2.8 eV for a lower S-content of 5–20 wt% followed by an increase up to 3.6 eV for ZnS. This band gap bowing behaviour is parabolic in nature and agrees well with previous reports in Zn(O,S) [20, 28]. According to Persson et al. [28], a band gap bowing in ZnO1−x S x is observed with minimum band gap, E g ~ 2.83 eV for x = 0.5. In our present investigation, the energy-dispersive X-ray spectroscopy of the samples reveals that the Zn(O,S) sample with 20 wt% S shows an atomic wt% ratio of [S]/[Zn] = 0.41 (see supplementary information, Table 1), which agrees well with the prediction by Persson et al. Similar experimental observation was also made by two different groups [7, 17], who investigated the performance of thin-film solar cells made with CIGS as absorber layer with the Zn(O,S) made from atomic layer deposition technique. It was found that the open circuit voltage can be optimized to the highest value in this solar cell, by changing the S-content between 0 and 20 wt%, which is due to the fact that the conduction band offset is minimum and positive in this range. The shift in optical band gap with doping is usually attributed to two competing electronic effects: the Burstein–Moss (BM) effect [29] and the band gap renormalization (BGR) effect [30]. The former is due to the partial filling of conduction band states near its bottom, whereas the latter is originated from many-body interaction. In order to make the BM effect is pronounced, the carrier concentration is required to be more than a critical value of 3 × 1019 cm−3 [31]. Our Hall measurement showed that the carrier concentration in Zn(O,S) lies in the range of 1013–1016 cm−3. Therefore, the possibility of BM shift can be ruled out. Another source of band gap shift in doped ZnO system has been attributed to the internal stress due to structural deformation of the unit cell from the mismatch of ionic radii of dopant and host atoms [20,21,22]. As estimated and summarized in Table 1, the microstrains increase in the allowed doping range of S in ZnO and decrease for that of O in ZnS, respectively. This change is directly correlated with above change in the optical band gap, and it must play a deterministic role when the Zn(O,S) is applied as a buffer layer in heterojunction solar cells.

3.3 Electrical properties and the effect of annealing

An improvement in the electrical properties of Zn(O,S) is required as their intrinsic forms are highly resistive due to low electron mobility. A post-annealing scheme can help significantly improve their electrical properties as compared to the as-deposited Zn(O,S) films. Annealing under different atmospheric conditions such as vacuum, air and the presence of argon is found to create significant effect on the bulk electron concentration, resistivity and mobility. The system Zn(O,S) (with 20 wt% S-content and a lowest band gap of 2.8 eV) is expected to produce minimum band offset with absorber such as CZTS, which was tested for the effect of annealing. During the heat treatment, oxygen can play instrumental role on the stoichiometry and free electron concentration of Zn(O,S). Oxygen vacancies are known to contribute to the electrical conductivity in oxide films [32] by changing the free carrier concentration. The oxygen vacancies could be controlled efficiently through annealing condition in the ZnO lattice [33]. In the present study, three different types of annealing conditions, namely the air annealing, vacuum annealing and argon annealing, were adopted to investigate their effect on the electrical properties of Zn(O,S) with S-content of 20 wt%. The EDX measurement confirmed an at% ratio of [S]/[Zn] = 0.41 (electronic supplementary material, Table S2) in the as-deposited film. The at% ratio was found to be minimum (0.12) when the film was annealed in argon atmosphere, and it was maximum (0.47) after annealing in the presence of oxygen. Annealing in oxygen is indeed useful in reducing oxygen vacancies which in turn contributes to a higher carrier concentration in the film. Above effect has also been seen to improve electrical conductivity in ZnO by desorption of chemisorbed oxygen ions from the surface, donating an electron to the atom. This causes an increase in the conductivity by reducing the grain boundary potential [34]. As evident from the SEM image in Fig. S2(c), a substantial reduction in grain boundaries occurs by the air annealing, and hence, an increase in the mobility can be expected. Such an effect agrees well with that observed earlier in ZnO [35]. In order to confirm this effect, Hall effect measurement was carried out. As listed in Table 2, the room-temperature Hall effect measurement shows that the free electron concentration, electron mobility and the resistivity (and conductivity) of the film were largely affected by the annealing atmospheres. Annealing in the air atmosphere is found to reduce the carrier concentration from 1014 (as prepared) to 1011 cm−3 due to diffusion of oxygen in film and a subsequent reduction in the oxygen vacancies, which act as donor defects in the Zn(O,S). This observation agrees well with the previously reported Zn(O,S) thin films prepared by atomic layer deposition [36]. Annealing in the vacuum and argon atmosphere is found to improve the film conductivity by an order of four. The improvement in bulk conductivity may be attributed to a reduction in the grain boundary scattering resulting from the larger grain size in the annealed film as shown in Fig. S2 (please refer to electronic supplementary material). The electron mobility is found to increase from 8.44 cm2/V.s in the as-prepared film to 17.2 and 21.3 cm2/V.s in argon and air annealed film. The latter mobility value is better by one order of magnitude as reported in oxygen annealed Zn(O,S) with S/Zn = 0.37 [36]. Although the carrier concentration was reduced and the mobility was large in the air annealed film, its conductivity was low probably due to the high film porosity. The conductivity in the argon-annealed film improves, although the carrier concentration remains almost the same order as that of the as-prepared film. This is due to the improvement in electron mobility during the argon annealing scheme in which the electron scattering from the disorders should be reduced by the random removal of sulphur from the interstitial sites. Although the electrical properties were strongly influenced by the above annealing processes, the optical band gap in the film remains unchanged, which is helpful in the application of Zn(O,S) as buffer layer for chalcogenide solar cells as well as further cation site doping to apply this system as transparent conductive layer. The CZTS and CIGS photovoltaic absorber materials are reported to have grown in spray pyrolysis process for solar cell applications. The CZTS materials have been grown at a substrate temperature of 280–360 °C, and the best crystallinity was reported at 340 °C [37, 38]. On the other hand, spray pyrolysed Cu2(In,Ga)S4 has been reported at the process temperature of 300–350 °C [39]. The spray deposition process is therefore highly compatible for a subsequent formation of buffer layer Zn(O,S) that is grown at 370 °C, without any detrimental effect on the crystallinity of CZTS or CIGS layer. A development in the above aspect is underway.

4 Conclusions

A strain-induced band gap bowing in the solid solution Zn(O,S) system is observed when it is prepared by spray pyrolysis of aqueous solution of zinc salt with various concentrations of thiourea. Both for the lower (<20 wt%) and higher (>80 wt%) concentrations of thiourea, an isovalent doping in the system is possible. By optimizing post-annealing conditions in Zn(O,S) with 20 wt% of sulphur, its electrical properties can be improved. The oxygen annealing is found to reduce the carrier concentration by three orders, whereas the Ar-annealing improves the conductivity. The solid solutions with the band gap modulation and annealing-induced improvement in their electrical properties are useful for the development of Zn(O,S) as efficient buffer layer in chalcogenide solar cells.

References

T.K. Todorov, J. Tang, S. Bag, O. Gunawan, T. Gokmen, Y. Zhu, D.B. Mitzi, Adv. Energy Mater. 3, 34 (2013)

A. Kanai, K. Toyonaga, K. Chino, H. Katagiri, H. Araki, Jpn. J. Appl. Phys. 54, 08KC06 (2015)

S. Bag, O. Gunawan, T. Gokmen, Y. Zhu, T.K. Todorov, D.B. Mitzi, Energy Environ. Sci. 5, 7060 (2012)

P. Sinsermsuksakul, L. Sun, S.W. Lee, H.H. Park, S.B. Kim, C. Yang, R.G. Gordon, Adv. Energy Mater. 4, 1400496 (2014)

A. Santoni, F. Biccari, C. Malerba, M. Valentini, R. Chierchia, A. Mittiga, J. Phys. D Appl. Phys. 46, 175101 (2013)

C. Yan, F. Liu, N. Song, B.K. Ng, J.A. Stride, A. Tadich, X. Hao, Appl. Phys. Lett. 104, 173901 (2014)

A. Okamoto, T. Minemoto, H. Takakura, Jpn. J. Appl. Phys. 50, 04DP10 (2011)

L. Sun, R. Haight, P. Sinsermsuksakul, S.B. Kim, H.H. Park, R.G. Gordon, Appl. Phys. Lett. 103, 181904 (2013)

J. Sun, V. Nalla, M. Nguyen, Y. Ren, S.Y. Chiam, Y. Wang, K.F. Tai, H. Sun, N. Zheludev, S.K. Batabyal et al., Sol. Energy 115, 396 (2015)

V. Fjällström, P. Szaniawski, B. Vermang, P.M. Salome, F. Rostvall, U. Zimmermann, M. Edoff, IEEE J. Photovolt. 5, 664 (2015)

A. Klein, J. Phys. Condens. Matter 27, 134201 (2015)

K. Sun, C. Yan, F. Liu, J. Huang, F. Zhou, J.A. Stride, M. Green, X. Hao, Adv. Energy Mater. 6, 1600046 (2016). doi:10.1002/aenm.201600046

C. Platzer-Björkman, C. Frisk, J. Larsen, T. Ericson, S.-Y. Li, J. Scragg, J. Keller, F. Larsson, T. Törndahl, Appl. Phys. Lett. 107, 243904 (2015)

R. Bhattacharya, K. Ramanathan, L. Gedvilas, B. Keyes, J. Phys. Chem. Solids 66, 1862 (2005)

T. Nakada, M. Mizutani, Jpn. J. Appl. Phys. 41, L165 (2002)

N.M. Mangan, R.E. Brandt, V. Steinmann, R. Jaramillo, C. Yang, J.R. Poindexter, R. Chakraborty, H.H. Park, X. Zhao, R.G. Gordon et al., J. Appl. Phys. 118, 115102 (2015)

C. Platzer-Björkman, T. Törndahl, D. Abou-Ras, J. Malmström, J. Kessler, L. Stolt, J. Appl. Phys. 100, 4506 (2006)

T. Ericson, J.J. Scragg, A. Hultqvist, J.T. Wätjen, P. Szaniawski, T. Törndahl, C. Platzer-Björkman, IEEE J. Photovolt. 4, 465 (2014)

M. Patel, I. Mukhopadhyay, A. Ray, J. Phys. D Appl. Phys. 45, 445103 (2012)

R.R. Thankalekshmi, A. Rastogi, J. Appl. Phys. 112, 063708 (2012)

B.K. Sharma, N. Khare, J. Phys. D Appl. Phys. 43, 465402 (2010)

Y. Wang, W. Tang, J. Liu, L. Zhang, Appl. Phys. Lett. 106, 162101 (2015)

V. Mote, Y. Purushotham, B. Dole, J. Theor. Appl. Phys. 6, 1 (2012)

H. Von Wenckstern, H. Schmidt, M. Brandt, A. Lajn, R. Pickenhain, M. Lorenz, M. Grundmann, D. Hofmann, A. Polity, B. Meyer et al., Prog. Solid State Chem. 37, 153 (2009)

N.C. Pandya, U. Joshi, J. Mater. Sci. Mater. Electron. 26, 2445 (2015)

S. Tan, B. Chen, X. Sun, W. Fan, H.S. Kwok, X. Zhang, S. Chua, J. Appl. Phys. 98, 13505 (2005)

J. Sharma, G. Saint, N. Goyal, S. Tripathi, J. Optoelectron. Adv. Mater. 9, 3194 (2007)

C. Persson, C. Platzer-Björkman, J. Malmström, T. Törndahl, M. Edoff, Phys. Rev. Lett. 97, 146403 (2006)

C.E. Kim, P. Moon, S. Kim, J.-M. Myoung, H.W. Jang, J. Bang, I. Yun, Thin Solid Films 518, 6304 (2010)

D. Reynolds, D.C. Look, B. Jogai, J. Appl. Phys. 88, 5760 (2000)

A. Roth, J. Webb, D. Williams, Solid State Commun. 39, 1269 (1981)

B. Stjerna, E. Olsson, C.G. Granqvist, J. Appl. Phys. 76, 3797 (1994)

H.S. Hsu, J.C.A. Huang, Y.H. Huang, Y.F. Liao, M.Z. Lin, C.H. Lee, J.F. Lee, S.F. Chen, L.Y. Lai, C.P. Liu, Appl. Phys. Lett. 88, 242507 (2006)

N. Bouhssira, S. Abed, E. Tomasella, J. Cellier, A. Mosbah, M. Aida, M. Jacquet, Appl. Surf. Sci. 252, 5594 (2006)

N.S. Kumar, K.V. Bangeraand, G. Shivakumar, Appl. Nanosci. 4, 209 (2014)

H.H. Park, R. Heasley, R.G. Gordon, Appl. Phys. Lett. 102, 132110 (2013)

N. Kamoun, H. Bouzouita, B. Rezig, Thin Solid Films 515, 5949 (2007)

W. Daranfed, M.S. Aida, N. Attaf, J. Bougdira, H. Rinnert, J. Alloy. Compd. 542, 22 (2012)

M.A. Hossain, Z. Tianliang, L.K. Keat, L. Xianglin, R.R. Prabhakar, S.K. Batabyal, S.G. Mhaisalkar, L.H. Wong, J. Mater. Chem. A 3, 4147 (2015)

Acknowledgements

Authors acknowledge Solar Research and Development Center (SRDC) of Pandit Deendayal Petroleum University, Project No. 2 for funding of the research. The authors are grateful to Prof. U.S. Joshi at Gujarat University for providing AFM facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jani, M., Raval, D., Pati, R. et al. Structure, optical and electronic properties of solid solution Zn(O,S) thin films and the effect of annealing. Appl. Phys. A 123, 458 (2017). https://doi.org/10.1007/s00339-017-1061-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1061-8