Abstract

Ultrashort pulse lasers have been increasingly gaining importance for the selective structuring of dielectric thin films in industrial applications. In a variety of works the ablation of thin \(\hbox {SiO}_{2}\) and \({\hbox {SiN}}_{x}\) films from Si substrates has been investigated with near infrared laser wavelengths with photon energies of about 1.2 eV where both dielectrics are transparent (\(E_{{\mathrm{gap,SiO}_{2}}}\approx 8\,\hbox {eV}; E_{{\mathrm{gap,SiN}}_{x}}\approx 2.5\,\hbox {eV}\)). In these works it was found that few 100 nm thick \(\hbox {SiO}_{2}\) films are selectively ablated with a “lift-off” initiated by confined laser ablation whereas the \(\hbox {SiN}_{{x}}\) films are ablated by a combination of confined and direct laser ablation. In the work at hand, ultrafast pump-probe imaging was applied to compare the laser ablation dynamics of the two thin film systems directly with the uncoated Si substrate—on the same setup and under identical parameters. On the \(\hbox {SiO}_{2}\) sample, results show the pulse absorption in the Si substrate, leading to the confined ablation of the \(\hbox {SiO}_{2}\) layer by the expansion of the substrate. On the \(\hbox {SiN}_{{x}}\) sample, direct absorption in the layer is observed leading to its removal by evaporation. The pump-probe measurements combined with reflectivity corrected threshold fluence investigations suggest that melting of the Si substrate is sufficient to initiate the lift-off of an overlaying transparent film—evaporation of the substrate seems not to be necessary.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ultrashort pulse lasers have been widely applied for the selective structuring of dielectric thin films in industrial applications. The selective laser structuring process is aimed mostly at a film removal without damaging the underlying substrate or subsequent layers to realize, e.g., local contact openings in anti-reflection or passivation layers for selective emitters of high-efficiency crystalline silicon solar cells and laser structured grooves for the production of silicon microelectronic devices [1, 2]. The dielectric thin film has typically a thickness of about a few hundred nm. Ultrashort laser pulses with pulse durations of about 0.5–10 ps are able to remove the film in a single-pulse confined laser ablation process often referred to as “lift-off”, when a fluence of around \(1\,\hbox {J/cm}^{2}\) is applied [3, 4]. That precise single-pulse ablation process in combination with possible laser repetition rates of 1 MHz and higher enables the selective structuring of thin films with high process speeds, contact-free and high-precision processing and high-quality ablation with very little thermal damage in the underlying substrate [5, 6]. Up to now a significant amount of the literature has been focusing on the application of selective structuring on transparent thin films [7–12], but only a few isolated studies have been performed on the mechanisms of the selective structuring with ultrashort pulses. What is missing to date is a summarizing generalized overview of the subject, where the ablation of different thin films is compared to the ablation of uncoated substrate.

2 State of the art: selective laser structuring of dielectric thin films with ultrafast lasers

The laser structuring of uncoated silicon (Si) substrates [13], silicon dioxide (\(\hbox {SiO}_{2}\)) thin films on Si substrates [14–16] as well as silicon nitride (\(\hbox {SiN}_{x}\)) films on Si substrates [9, 11, 17] has been studied in several works. In general results of the thin film ablation are strongly depending on the applied laser fluence and the film thickness.

At fluences below \(0.5\,\hbox {J/cm}^{2}\) laser ablation with ultrashort laser pulses (pulse duration 0.5–10 ps) shows clean ablation spots in 100–500 nm films without thermal damage. As a reason for that, a confined ablation mechanism—a so called “indirectly- induced” ablation leading to a clean “lift-off”—was discussed [3, 4, 8, 18]; hereby, the ultrashort laser pulse is transmitted through the transparent \(\hbox {SiO}_{2}\) or \(\hbox {SiN}_{x}\) film and is absorbed at a few tens of nm thick interface layer in the absorbing substrate—generating a confined energy situation [4]. Sotrop et al. [19] simulated for a very similar thin film system (500 nm Mo thin film on glass substrate) that the pressure created by heating and melting of the interface exceeds to about 8 GPa and is about 105 times higher than the pressure generated by evaporation 75 kPa. Thus, evaporation should not be the driving force of the confined ablation. A similar ablation mechanism can be speculated here for thin transparent films on an absorbing substrate. The laser pulse energy is absorbed in the substrate, heat transfer is distributing the energy inside the substrate and partially to the transparent film. Heating and melting at the interface are creating an ultrafast thermal expansion within about 10 ps; steep pressure rise and a corresponding pressure wave are the consequence (at about 100 ps) leading to delamination, bulging, fractioning and removal of the overlying layer after about 10 ns [19–21]. As observed by Rapp et al. [22] the bulging velocity is controlled by the applied laser pulse fluence and the film thickness; higher fluences and thinner films lead to faster bulging.

At higher fluences the absorption is not only occurring at the interface. Multiphoton effects shift the absorption into the transparent film. In this regime delamination at the substrate-film interface can be superimposed with internal or surface ablation [23, 24].

At fluences \({\ge}0.6\,\hbox {J/cm}^{2}\) and about \(100\,\hbox {nm}\) thin \(\hbox {SiN}_{x}\) films an “island” of remaining \(\hbox {SiN}_{x}\) is remaining in the ablation center. This effect was explained by a direct absorption of the laser pulse in the spot center leading to direct laser ablation—a process well known for absorbing materials, e.g., steel [25]. The direct absorption in the spot center is related to the intensity maximum of the applied spatial Gaussian beam profile. At fluences above \(0.6\,\hbox {J/cm}^{2}\) a higher density of electrons in the conduction band of the Si substrate can be created by multiphoton absorption. The conduction band electrons can access further energy by impact ionization and inverse Auger scattering [26, 27]. Heinrich et al. [28] discussed that electrons with an energy exceeding the band gap energy of the \(\hbox {SiN}_{x}\) (\(E_{gap, SiN_{x}}\approx 2.5\,\hbox {eV}\)) are able to directly migrate from the conduction band of the Si to the conduction band of the \(\hbox {SiN}_{x}\). These electrons in the conduction band directly would absorb further photons of the laser pulse in the \(\hbox {SiN}_{x}\) causing direct ablation and preventing confined ablation. In the \(\hbox {SiO}_{2}\)/Si layer system this combination effect of direct and induced laser ablation could not be observed up to fluences of \(3\,\hbox {J/cm}^{2}\) by Rapp et al. [22]. A possible explanation could be that the higher band gap energy of the \(\hbox {SiO}_{2}\) film (\(E_{gap, SiO_{2}}\approx 8\,\hbox {eV}\)) avoids the excitation from electrons by multiphoton ionization to the conduction band up to these fluences [29].

At fluences \({>}5\,\hbox {J/cm}^{2}\) an additional ablation effect referred to as “quantized structuring” was reported on \({>}500\,\hbox {nm}\) thin \(\hbox {SiN}_{x}\) [23] and \(\hbox {SiO}_{2}\) films [30]. The thin film is ablated there partially in quantized steps. The depth of the steps is defined by an interference pattern created between the incident and the reflected (at film/substrate interface) laser pulse, with a periodicity of \(\lambda /2n_\mathrm{film}\).

For a study of the ablation mechanisms ultrafast time-resolved pump-probe investigations were performed on the \(\hbox {SiO}_{2}\hbox {/Si}\) [22, 31] and the \(\hbox {SiN}_{x}\hbox {/Si}\) [24, 32] layer systems. These measurements were taken up to the infinity state after a few tens of \({\upmu }\hbox {s}\) delay times. as on uncoated Si substrates up to several ns delay time were published already a few decades ago [33–36]. Transient reflectivity measurements of the thin film samples show phase transition from solid to liquid in the substrate, respectively, the \(\hbox {SiN}_{{x}}\) layer (for the island formation process) within the first 5–10 ps. This ultrafast melting process in Si is in the literature referred to as nonthermal melting, which denotes a dissociation of the solid state by creating about \(10\%\) of relatively free conduction band electrons [37, 38]. The bulging of the layers is observed after several hundred ps and the actual lift-off on a ns timescale. The direct ablation of the uncoated Si and the \(\hbox {SiN}_{x}\) during the island formation process occurs by a phase explosion—an effect of explosive boiling [39]—starting after several picoseconds.

3 Open questions and aim of this work

Previous studies on selective structuring of dielectric thin films with ultrafast lasers have been partly obtained by different work groups using different setups with different laser sources. However, for a direct comparison of the ablation processes, identical process and observation conditions (for example laser wavelength and pulse duration of pump and probe pulses) are required at laser fluences that are relevant for laser processing. Additionally previous works have shown that the underlying substrate plays an important role for the confined laser ablation of dielectric thin films [8, 28]. For a deeper understanding of the ablation mechanisms it thus is necessary to compare dielectric thin films and substrate—one by one—measured with an identical setup.

Therefore, in this work, the time-resolved behavior of three material systems—uncoated Si, \(\hbox {SiO}_{2}\) films on Si and \(\hbox {SiN}_{x}\) film on Si—was investigated by the same ultrafast pump-probe microscope. Measurements on uncoated Si substrates were repeated with the same setup that was already used for the measurements on the \(\hbox {SiO}_{2}\hbox {/Si}\) and the \(\hbox {SiN}_{x}\hbox {/Si}\) layer systems [22, 32]. The goal of these investigations was to reveal the different ablation mechanisms by a direct comparison and under identical processing and observation conditions and to generate an understanding at processing relevant laser fluences. The pump-probe measurements focus on the different absorption behavior of the dielectric films due to their different band gap energies (\(E_{\text{gap,SiO}_{2}} \approx 8\,\hbox {eV}; E_{\text{gap,SiN}_{x}}\approx 2.5\,\hbox {eV}\)) and the resulting different ablation types—indirectly induced confined laser ablation leading to a selective lift-off (\(\hbox {SiO}_{2}\) and \(\hbox {SiN}_{x} < 0.6\,\hbox {J/cm}^{2}\)), respectively, island formation by partial direct ablation (\(\hbox {SiN}_{x} \ge 0.6\,\hbox {J/cm}^{2}\)). Single ultrashort and spatially Gaussian shaped laser pulses at a center wavelength of 1053 nm (\(=\)1.2 eV) were applied (Fig. 1). The processing of uncoated Si (Fig. 1a) as well as the \(\hbox {SiO}_{2}\) lift-off (Fig. 1b) and the \(\hbox {SiN}_{x}\) lift-off and island formation processes (Fig. 1c) were observed.

Applied Gaussian shaped laser pulse (\(\tau = 660\,\hbox {fs}, \lambda = 1053\,\hbox {nm}, w_{0} = 20.1\,{\upmu }\hbox {m}\)) and the resulting ablated spot cross sections on Si, \(\hbox {SiO}_{2}\hbox {/Si}\) and \(\hbox {SiN}_{{\mathrm{x}}}\hbox {/Si}\) with the corresponding threshold fluences \(F_\mathrm{thr}\) shown on the left side. The \(\hbox {SiO}_{2}\) is ablated by a confined ablation (“lift-off”) process whereas a “\(\hbox {SiN}_{x}\) island” created by a partial direct ablation remains in the center of the ablation spot on the \(\hbox {SiN}_{x}\) sample

Moreover, fluence threshold investigations are presented to study the energetics of the \(\hbox {SiO}_{2}\) and \(\hbox {SiN}_{x}\) thin film lift-off and resolve the state of matter—liquid or vapor—at the energetic threshold for the lift-off reaction. The simulated findings by Sotrop et al. [19] that ultrafast melting is sufficient to initiate the film lift-off is checked experimentally that way.

4 Material and methods

4.1 Used samples

Experiments were performed on three different samples. Mono crystalline Czochralski-grown wafers with a \(\lbrace 100\rbrace\) crystal orientation are used as substrate. One sample was investigated without coating. A second sample was coated with \(100\,\hbox {nm}\) thermally grown \(\hbox {SiO}_{2}\). The third sample was coated with \(110\,\hbox {nm}\) thin amorphous \(\hbox {SiN}_{{\mathrm{x}}}\) (nitrogen-to-silicon ratio \(\approx 1.0\), hydrogen content \(20\%\)). The \(\hbox {SiN}_{x}\) layer was deposited by PECVD at a process temperature of \(450\,^{\circ }\hbox {C}\) using \(\hbox {SiH}_{4}\) and \(\hbox {NH}_{3}\) as process gases.

4.2 Method for threshold fluence \(F_\mathrm{thr}\) determination

The threshold fluences \(F_\mathrm{thr}\) for different laser induced processes—lift-off and island formation process (see Fig. 1)—as well as the focal beam radius \(w_0\) were determined by the common method described by Liu [40]. The following formula was applied.

D indicates the ablated spot diameter, \(w_0\) the beam focus radius, \(F_\mathrm{thr}\) the threshold fluence and \(F_0\) the applied pulse peak fluence. According to Eq. 1 the experimental measured squared ablation diameters should show a linear dependency with fluence in a semi logarithmic plot. The intersection point of the fit and the abscissa at \(D^2\) = 0 indicates the threshold fluence.

4.3 Pump-probe microscopy

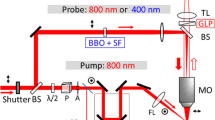

A short overview of the experimental pump-probe setup is shown in Fig. 2. Laser pulses at a center wavelength of \(\lambda =1053\,\hbox {nm}\) with a pulse duration of \(\tau _p=660\,\hbox {fs}\) emitted by a Nd/glass laser laser source were divided into pump and probe pulses by a polarizing beam splitter (ratio of 90–\(10\%\)). A mechanical shutter on the pump path separated a single pump pulse, used for initiating the ablation. Therefore, this pulse was focused on the sample (\(w_0 =20.1\pm 0.3\,{\upmu }\hbox {m}\) at \(e^{-2}\) intensity measured as described in Sect. 4.2). The probe pulse, used for illuminating an area of about \(300 \times 300\,{\upmu }\hbox {m}^2\), was frequency doubled (SHG) and optically delayed by a 4-fold optical delay on a \(300\,\hbox {mm}\) linear translation stage.

Pump-probe microscopy setup: laser pulses (\(\tau _{\mathrm{p}}= 660\,\hbox {fs}, \lambda = 1053\,\hbox {nm}\)) were divided into pump and probe pulses in BS 1. The pump pulse (red) was focused at the sample and initiates the reaction, the probe pulse (green) was frequency doubled (SHG) and temporally delayed for illumination (delay line for \(\Delta t < 4\,\hbox {ns}\)). For \(\Delta t > 4\,\hbox {ns}\), a \(600\,\hbox {ps}\) laser pulse was emitted by a second laser source. An image was captured by a CCD camera

The length of the translation stage limits maximal achievable delay times to \(\Delta t = 4\,\hbox {ns}\). For delay times above 4 ns a 600 ps FWHM actively q-switched and electronically delayed laser source was used for probing (\(\lambda = 532\,\hbox {nm}\)). Both probe paths were superimposed in a further beam splitter. The process area was imaged by a microscope and a CCD camera (calculated optical resolution = \(1.2\,{\upmu }\hbox {m}\)). Despite the \({\upmu }\hbox {s}\)-long exposure time of the CCD camera, the temporal resolution of the pump-probe measurement is defined by the pulse duration of the applied probe pulse of less than 1 ps [41].

The delay time zero is defined when the temporal overlap of pump and probe pulse is maximal. It was measured by an ultrafast reflectivity increase on a Si sample. The increase is caused by the excitation of electrons and is assumed to occur fast compared with the duration of the pump pulse [37]. The maximum overlap of pump and probe pulse is reached when the reflectivity increase reaches \(50\%\) of its maximum value. The uncertainty of the delay time zero determination was estimated to \(\pm 200\,\hbox {fs}\). The uncertainty from one sample to another is negligible (\({<}50\,\hbox {fs}\)).

To take a series of images covering the whole ablation process, the delay time was varied and the sample was irradiated by a new single pump-probe pulse combination at a new position for every image. A detailed description of the pump-probe microscopy setup was given in an earlier article [42], also explaining image acquisition and processing.

For a quantitative description of the ablation process, the relative reflectivity change was calculated by

where \(R_0\) describes the reflectivity of the sample prior to the pump pulse irradiation and \(R_t\) the reflectivity at a chosen delay time \(\Delta t\). For the calculation of R, the mean gray scale value of a squared area of 5x5 pixels (\(\widehat{=} 8\,{\upmu }\hbox {m}^2\)) was determined for the corresponding image.

4.4 Pump pulse reflectivity measurement

If threshold fluences for different processes on different material systems (for example lift-off or island formation) are compared, the absorbed (and not the incident) energy is important. To obtain comparable values regarding the absorbed pulse energy for every system, the applied fluences were corrected for reflectivity. The reflected parts of single focused pump pulses used for the structuring were measured by a photodiode (Fig. 2). The mean values of five reflected pulses from new positions for each pulse were calculated for all fluences. To determine the absorbed fluence, the mean reflected fluence was subtracted from the incident fluence. Calculations based on Fresnel reflection and thin film interference [43] were carried out to obtain reference values for very low fluences such as for unfocused and continuous wave illumination. Applied laser parameters for the measurements and the calculations were \(\tau = 660\,\hbox {fs}, \lambda = 1053\,\hbox {nm}\), incident angle \(35^{\circ }\), p-polarization.

5 Results

5.1 Threshold fluence \(F_\mathrm{thr}\) determination

The threshold fluences \(F_\mathrm{thr}\) were determined to define appropriate processing parameters according to chapter 4.2. The threshold fluences as well as the focal beam radius were calculated using equation 1. The final ablation states with the diameters for the threshold fluence determination are shown in Fig. 3. On the Si sample no clear ablation zone is observed in the applied fluence regime (Fig. 3a). The black traces in Fig. 3a can be related to a locally increased absorption due to defects in the crystalline lattice of the Si sample [13]. The actual ablation depth d was possibly too low to be resolved by a confocal microscope (\(d <10\,\hbox {nm}\)). For Si a threshold fluence determination was not feasible by analyzing the light or confocal microscopy images. Further considerations concerning the Si threshold fluence calculation will follow in the pump-probe Sect. 5.2.

Microscope images of laser processed spots on a uncoated Si (\(F_0 = 1.0\,\hbox {J/cm}^{2}\)), b 100 nm \(\hbox {SiO}_{2}\) on Si (\(F_0= 1.0\,\hbox {J/cm}^{2}\)), c 110 nm \(\hbox {SiN}_{x}\) on Si (\(F_{0}= 0.5\,\hbox {J/cm}^{2}\)) and d 110 nm \(\hbox {SiN}_{x}\) on Si (\(F_0= 0.6\,\hbox {J/cm}^{2}\)) with corresponding confocal cross sections. The \(\hbox {SiO}_{2}\) film is ablated by a lift-off in a confined ablation process as well as the \(\hbox {SiN}_{x}\) at \(0.5\,\hbox {J/cm}^{2}\) whereas a \(\hbox {SiN}_{x}\) island created by a partial direct ablation remains in the center of the ablation spot on the \(\hbox {SiN}_{x}\) sample at \(0.6\,\hbox {J/cm}^{2}\). Dotted lines mark the diameter for the threshold fluence determination (colors according to Fig. 4)

The threshold fluence for the \(\hbox {SiO}_{2}\) ablation was determined to be \(F_\mathrm{thr} = 0.33\,\hbox {J/cm}^{2}\) (Table 1) on the \(\hbox {SiO}_{2}\hbox {/Si}\) sample. The measured squared ablation diameters agree very well with the fitted graph up to fluences of \(2.0\,\hbox {J/cm}^{2}\) (Fig. 4 magenta squares). It has to be noted, that the ablation threshold fluence was defined here, as the fluence where the layer delaminates from the substrate. At fluences slightly above the ablation threshold the layer delaminates from the substrate, but stays attached to the surrounding thin film—the layer bulges without being removed completely [22]. The actual layer removal by lift-off was observed at fluences above \(0.60\,\hbox {J/cm}^{2}\). This fluence is defined as “punching” threshold fluence. At a fluence of, e.g., \(1.0\,\hbox {J/cm}^{2}\) a clean lift-off ablation was observed (Fig. 3b). Up to a maximum applied fluence of \(2.0\,\hbox {J/cm}^{2}\) only lift-off was observed.

\(F_\mathrm{thr}\) determination for the \(\hbox {SiO}_{2}\) lift-off process, respectively, the \(\hbox {SiN}_{x}\) lift-off and island formation process. Laser parameters: \(\tau =660\,\hbox {fs}, \lambda = 1053\,\hbox {nm}\). Fit function according to \(D^2=2\,w_{0}^{2}\,\hbox {ln}(F_0/F_\mathrm{thr})\); (fit parameters: \(w_0=20.1\,\pm 0.3\,{\upmu }\hbox {m}, F_\mathrm{thr}\) indicated under x-axis)

On the \(\hbox {SiN}_{x}\hbox {/Si}\) sample, two different threshold fluences were determined: a threshold for \(\hbox {SiN}_{x}\) lift-off at \(0.23\,\hbox {J/cm}^{2}\) and island formation at \(0.3\,\hbox {J/cm}^{2}\) (see Figs. 3, 4; Table 1). At fluences slightly above the lift-off threshold at \(0.23\,\hbox {J/cm}^{2}\) (blue data points in Figs. 3c, 4), significant parts of the film stay attached although delaminate. The punching fluence was measured to be \(0.47\,\hbox {J/cm}^{2}\) analog to the \(\hbox {SiO}_{2}\hbox {/Si}\) sample. Applied fluences slightly above the punching threshold, e.g., \(0.5\,\hbox {J/cm}^{2}\) as shown in Fig. 3c, lead to a clean ablation of the \(\hbox {SiN}_{x}\) thin film with only little film residuals at the rim. The second threshold fluence describes the island formation process. Here, a \(\hbox {SiN}_{x}\) island remains in the center of the spot (Fig. 3d). The confocal cross section profile in Fig. 3d shows a concave shape of the created island with a depth of 60 nm in the spot center. That could be due to the Gaussian cross section of the laser pulse and a surface ablation of a part of the \(\hbox {SiN}_{x}\) film. Additionally the rims of the \(\hbox {SiN}_{x}\) island could be bended upward as a remaining effect of a \(\hbox {SiN}_{{\mathrm{x}}}\) film delamination and lift-off process further outside at higher radii. It is remarkable that at an applied fluence of \(0.6\,\hbox {J/cm}^{2}\) noticeable ablation is achieved in the \(\hbox {SiN}_{x}\) film, whereas no detectable ablation is reached on the uncoated Si substrate at the significant higher fluence of \(1.0\,\hbox {J/cm}^{2}\) (absorbed fluences are 0.58 and \(0.70\,\hbox {J/cm}^{2}\), respectively). The \(\hbox {SiN}_{x}\) island is observed in the final ablation state at fluences higher than \(0.60\,\hbox {J/cm}^{2}\). The fit of the data points measured for the island formation process can be projected to an island formation threshold fluence of \(0.3\,\hbox {J/cm}^{2}\) (green triangles in Fig. 4).

The effect taking place at fluences between 0.3 and \(0.6\,\hbox {J/cm}^{2}\) was described already in [32]. At these fluences the island is created by direct multiphoton absorption in the beginning of the ablation process but it is removed by a lift-off in the proceeding process. Thus, the island is not detectable in the final ablation state. This process will be explained more detailed in Sect. 5.2.

The threshold fluence determination was performed at the same setup as the pump-probe measurements. The focal radius of the laser (slope of the fitted graphs) was determined for all measurement series to be \(20.1 \pm 0.3\,{\upmu }\hbox {m}\). This indicates the excellent comparability of the measurements series on uncoated Si and \(\hbox {SiO}_{2}\) as well as \(\hbox {SiN}_{x}\) coated Si.

As a consequence of the threshold measurements fluences well above or close to the threshold fluences of the relevant processes are chosen for the time-resolved investigations. The \(\hbox {SiO}_{2}\) lift-off is observed at the fluence of \(1.0\,\hbox {J/cm}^{2}\) well above the punching threshold fluence of \(0.60\,\hbox {J/cm}^{2}\). At this fluence the lift-off effect is clearly visible. The \(\hbox {SiN}_{x}\) lift-off ablation is observed at a fluence of \(0.5\,\hbox {J/cm}^{2}\) (punching threshold fluence \(0.47\,\hbox {J/cm}^{2}\)) and the island formation is observed at an incident fluence of \(0.60\,\hbox {J/cm}^{2}\) (at the threshold fluence for a remaining island). No threshold fluence is determined for the Si: here, the same fluence as for the \(\hbox {SiO}_{2}\hbox {/Si}\) investigations (\(1.0\,\hbox {J/cm}^{2}\)) is chosen.

5.2 Pump-probe measurements

In this section, four pump-probe measurement series—processing of uncoated Si, ablation of \(\hbox {SiO}_{2}\) on Si and ablation and island formation of \(\hbox {SiN}_{x}\) on Si—are presented (Fig. 5).

Pump-probe images of uncoated Si at \(F_0=1.0\,\hbox {J/cm}^{2}\) (first row), \(100\,\hbox {nm}\,\hbox {SiO}_{2}\) on Si at \(F_0= 1.0\,\hbox {J/cm}^{2}\) (second row) and \(110\,\hbox {nm}\,\hbox {SiN}_{x}\) on Si at \(F_0= 0.6\,\hbox {J/cm}^{2}\) (third row) and \(F_0= 0.6\,\hbox {J/cm}^{2}\) (fourth row). Laser parameters: \(\tau = 660\,\hbox {fs}, \lambda = 1053\,\hbox {nm}, w_0 = 20.1\,{\upmu }\hbox {m}\). Delay times are indicated over the images

In the first subsection, the transient ablation behavior of the Si sample is analyzed separately by describing qualitatively the measured series of images and by quantitatively evaluating the relative reflectivity change \(\Delta R/R\) (Fig. 6). The \(\Delta R/R\) calculations are performed in the spot center (\(F_0= 1.0\,\hbox {J/cm}^{2}\)) and in a decentral area (distance to the spot center \(r= 13.5\,{\upmu }\hbox {m}\)) corresponding to a fluence of \(0.41\,\hbox {J/cm}^{2}\). The reason for this choice will be explained in the following first subsection. The decentral area is defined in the following as “rim”.

Relative reflectivity changes \(\Delta R/R =R_t\hbox {-}R_0/R_0\) for three different samples; a uncoated Si (red) at \(F_0=1.0\,\hbox {J/cm}^{2}\), b \(\hbox {SiO}_{2}\) on Si (black) at \(F_0 = 1.0\,\hbox {J/cm}^{2}\) and c \(\hbox {SiN}_{{\mathrm{x}}}\) on Si (green) at \(F_0 = 0.6\,\hbox {J/cm}^{2}\). On each sample two different positions—center (intensive plots) and rim (weakened plots) shown on the images on the right side—are investigated

In the second subsection, the measurement series of the \(\hbox {SiO}_{2}\hbox {/Si}\) lift-off ablation is described in an analog way and in comparison with the Si measurement series. The pulse peak fluence is \(1.0\,\hbox {J/cm}^{2}\). The rim area here was chosen close to the lift-off threshold at \(r=14.4\,{\upmu }\hbox {m}\widehat{=}\,0.36\,\hbox {J/cm}^{2}\).

In the third subsection the \(\hbox {SiN}_{x}\hbox {/Si}\) lift-off and island formation is observed and compared to the two measurement series described before. The pulse peak fluence is \(0.5\,\hbox {J/cm}^{2}\) for the ablation process and \(0.6\,\hbox {J/cm}^{2}\) for the island formation. The rim area for the measurement series where the island is created was chosen again close to the lift-off threshold fluence where no island is created at \(r= 12.5\,{\upmu }\hbox {m}\widehat{=}\,0.23\,\hbox {J/cm}^{2}\).

Transient states during Si ablation At delay time zero, a weak bright spot can be observed in Fig. 5 first row. Half of the pump pulse has already reached the sample surface (Sect. 4.3). The energy is absorbed by valence electrons. They are excited to the conduction band. Electron-hole plasma is created with increased reflectivity. The relative reflectivity change can be described by a Drude expression for the refractive index of a plasma [33–35]. After 1 ps, the relative reflectivity change reaches a maximum value of \(\Delta R/R = 0.7\) in the center whereas the same maximum is reached in the rim only after about 2 ps (Fig. 6 red circles and crosses). An explanation for this time delay can be found in the lower applied fluence in the rim and a corresponding slower generation of the electron-hole plasma. The generation of the electron-hole plasma leads to the breakup of the periodic structure of the Si lattice—a molten phase is created. This ultrafast effect is described as nonthermal melting [37, 38].

From 10 ps on, a dark spot is created in the center of the irradiated spot whereas the rim remains bright. The apparently different behavior in this area gives reason to investigate this decentral area separately from the center and to denote it as rim. In the rim, the relative reflectivity change stays elevated at a level of \(\Delta R/R = 0.5\) to 0.7 up to delay times of several ns. The molten phase solidifies only at delay times higher than 3 ns (Fig. 5). In the center, the relative reflectivity decreases and reaches again its zero level of \(\Delta R/R = 0\) after about 6 ps and decreases further to \(\Delta R/R = 0.75\) at 30 ps. Here, the fluence is higher compared to the rim (1.0 vs \(0.41\,\hbox {J/cm}^{2}\)). The decreased reflectivity was explained in the literature by the creation of an inhomogeneous gas–liquid-phase scattering the reflected light due to a spallation process or a phase explosion. This is the onset of ablation [44, 45]. Additionally, ring systems are observed after several 100 ps between center and rim, which were explained in previous work by interference of light reflected from a proceeding spallation front and the underlying substrate [39, 44].

At 1 ns, the reflectivity in the center reaches again the value of the rim (Fig. 6 \(\Delta R/R = 0.5\)). It can be assumed that the gas–liquid phase is partly condensed and partly evaporated. In the following the diameter of the bright spot decreases in the center (Fig. 5). The molten phase cools down here as well until it is completely solidified between 20 and 100 ns.

A further phenomenon can be observed on the 10 and 20 ns images. A circular shape with increasing diameter (\(60\,{\upmu }\hbox {m}\) to \(100\,{\upmu }\hbox {m}\)) is emitted from the irradiated area. It can be related to a shock- or soundwave in air [46] created by the ultrafast expansion of the heated and molten Si.

The final process state is reached after a delay time of 100 ns without noticeable ablation. Apparently, the material removal by the phase explosion is not enough to create an ablation crater that can be resolved by the used confocal microscope, which has a depth resolution of about 10 nm.

Transient states during \(SiO_{2}/Si\) ablation At delay time zero a weak bright spot can be observed in Fig. 5, second row, identical to the observation on the uncoated Si sample in Fig. 5, first row. The laser pulse is absorbed again in the Si because the \(\hbox {SiO}_{2}\) is transparent at the applied laser wavelength (photon energy at \(1053\,\hbox {nm}\,E_{ph} = 1.2\,\hbox {eV}\), band gap energy for \(\hbox {SiO}_{2}\,E_{gap,SiO_{2}} \approx 8\,\hbox {eV}\)). Linear absorption in the \(\hbox {SiO}_{2}\) film is negligible; for nonlinear absorption the fluence seems to be too low. Electron-hole plasma is created at the Si interface causing nonthermal melting. The molten material has again a higher reflectivity compared to the solid Si. The relative reflectivity change is determined in Fig. 6 to \(\Delta R/R = 1.25\) in the center (black squares) as well as in the rim (crosses) at a delay time of 1 ps, respectively, 2 ps. Compared to the relative reflectivity increase in uncoated Si of 0.7 after 1 ps, the increase on the \(\hbox {SiO}_{2}\) coated Si sample is a factor 1.8 higher (\(\Delta R/R = 1.25\)). It has to be mentioned that relative reflectivity changes are observed. An explanation for the factor can be found in the higher base reflectivity of the uncoated Si compared to the \(\hbox {SiO}_{2}\) coated Si of nearly this factor (\(R_{\rm {Si}}= 26\%; R_{\rm{SiO_{2}}/Si} =15\%\), see Fig. 7). The difference in base reflection is \(26/15 = 1.7\). Further reasons for the different \(\Delta R/R\) can be addressed to the different absorbed laser fluence (see Sect. 5.3) and thin film interference phenomena on the coated sample.

After 10 ps, the spot center becomes darker (\(\Delta R/R = 0\) at 6 ps and \(\Delta R/R = 0.25\) at \(10\,\hbox {ps}\)) corresponding to the creation of a gas–liquid mixture and the start of a phase explosion that scatters the reflected light comparable to the uncoated sample. The difference to the ablation process on the uncoated Si sample is given by the fact that on the \(\hbox {SiO}_{2}\hbox {/Si}\) sample the phase explosion is confined at the layer interface—it forms a confined energy situation [3, 47]. The ultrafast generated pressure should again initiate a shock- or soundwave as it was observed on the Si sample. Here, the soundwave is coupling into the overlaying layer transferring energy to the \(\hbox {SiO}_{2}\) film. In the rim the fluence is too low to generate a scattering gas–liquid mixture, the reflectivity stays higher comparable to the results of the Si sample.

The images at a delay time of \(50\,\hbox {ps}\) and higher show a completely different appearance between uncoated and \(\hbox {SiO}_{2}\) coated Si. The center of the spot on the \(\hbox {SiO}_{2}\hbox {/Si}\) sample becomes brighter again (Figs. 5, 6 \(\Delta R/R = 1.0\)). From this delay time on the delamination of the \(\hbox {SiO}_{2}\) film can be assumed. The higher reflectivity can be related to the newly created interface between the delaminated film and the newly generated intermediate layer and a possible liquid Si surface, which exhibits a higher reflectivity than a solid Si surface [48]. The ultrafast thermal expansion of the Si and \(\hbox {SiO}_{2}\) at the substrate-layer interface creates a shockwave and transfers mechanical energy to the thin film; the layer delaminates and starts to bulge. Comparing these observations with the simulation of Sotrop et al. [19] that indicates the generation of a pressure wave without a contribution of a vapor phase, the Si gas–iquid mixture in the intermediate layer created by the phase explosion might cool adiabatically and condense to a liquid. The pressure wave might also be generated only by the ultrafast heating and melting and not evaporation. A strong sign for the absence of a high pressure vapor phase is the high reflectivity signal, which point to a highly transparent intermediate layer.

At 200 ps a dark ring can be observed in the spot center in Fig. 5. This ring is referred to as a Newton’s ring—an interference phenomena from light reflected from a flat surface given by the Si substrate and a spherical interface given by the bulging thin film. The first Newton’s ring corresponds to a bulging height of about \(d= 260\,\hbox {nm}\) calculated by a simple interference calculation and assuming that the intermediate layer is almost empty with a refractive index of \(n= 1\) [22]. From that delay time up to 1 ns the number of Newton’s rings and the corresponding bulging height increases up to \(2\,{\upmu }\hbox {m}\). In this time range the reflectivity signal in Fig. 6 exhibits an oscillatory behavior. An approximately constant bulging velocity of v \(\approx 1800\,\hbox {m/s}\) with an initial acceleration of about \(1.8\cdot 10^{12}\,\hbox {g}\) can be deducted from the interference data [22, 31]. Between 1 and 10 ns the number of Newton’s rings is too high to be spatially resolved by the used pump-probe microscopy setup.

At 10 ns the layer starts to disintegrate and particles with a diameter of \({<}5\,{\upmu }\hbox {m}\) are propagating toward the objective. They can be observed on the 30 and 100 ns pictures in Fig. 5. The final state shows a clean ablation spot without detectable thermal defects and with a diameter of \(30\,{\upmu }\hbox {m}\) corresponding to the diameter of the liquid phase at a delay time of 10 ps.

Transient states during \(SiN_{x}/Si\) ablation and island formation At delay time zero and after 1 ps, a weak bright spot is observed on the \(\hbox {SiN}_{x}\) samples irradiated with fluences of 0.5 and \(0.6\,\hbox {J/cm}^{2}\). The difference compared to the measurement series on uncoated Si and \(\hbox {SiO}_{2}\hbox {/Si}\) consists in the spatial brightness distribution of the spots. The images of the first two measurement series show homogeneous bright spots. In contrast, on the \(\hbox {SiN}_{x}\hbox {/Si}\) sample, the highest reflectivity is reached in the rim (Fig. 6 green stars \(\Delta R/R = 0.5\) at 1 ps for a fluence of \(0.6\,\hbox {J/cm}^{2}\)). In the center, the reflectivity increases only to about \(\Delta R/R = 0.2\). In this area, the island of not completely removed \(\hbox {SiN}_{x}\) is formed at a fluence of \(0.6\,\hbox {J/cm}^{2}\) and higher (Figs. 3d, 5 fourth row last image). The \(\hbox {SiN}_{{\mathrm{x}}}\) layer is removed here only partially by direct ablation. Thus, these two regions (rim \(\widehat{=}\) indirectly induced ablation; center \(\widehat{=}\) direct ablation) are investigated separately. At the fluence of \(0.5\,\hbox {J/cm}^{2}\) the appearance of the spot is identical compared to the spot at the fluence of \(0.6\,\hbox {J/cm}^{2}\) up to delay times of 50–200 ps. Thus it can be assumed that identical processes occur—the \(\hbox {SiN}_{x}\) island should also be created at the fluence of \(0.5\,\hbox {J/cm}^{2}\). However, the island is not visible in the final ablation state (Figs. 3c, 5 third row last image). Reasons for that will be addressed below.

The initial processes observed in the spot center in the first picoseconds leading to the island formation were explained in the literature as follows: in the first femtoseconds of the laser pulse impact the incident photons are absorbed in the Si substrate creating seed electrons that migrate into the \(\hbox {SiN}_{{\mathrm{x}}}\) layer overcoming its band gap energy (\(E_{\text{gap,SiN}_{x}} \approx 2.5\,\hbox {eV}\)) [28]. An alternative explanation is the assumption of a nonlinear multiphoton absorption in the \(\hbox {SiN}_{x}\) film. The generated conduction band electrons absorb further incident pump pulse photons causing direct photon absorption in the \(\hbox {SiN}_{x}\) layer. The absorption is shifted from the interface further up to the interior of the film. The direct absorption and the corresponding direct ablation at or close to the surface are then leading to the island formation.

On the \(\hbox {SiO}_{2}\hbox {/Si}\) sample this mechanism is not observed because of the higher band gap energy of the \(\hbox {SiO}_{2}\) (8 eV) suppressing the migration of electrons into the film or, alternatively, preventing a multiphoton absorption.

The reflectivity increase in the rim of the \(\hbox {SiN}_{{\mathrm{x}}}\hbox {/Si}\) can be related to nonthermal melting of the Si substrate identical to the measurement series on uncoated and \(\hbox {SiO}_{2}\) coated Si. In the center direct absorption followed by a direct surface ablation in the \(\hbox {SiN}_{x}\) layer takes place. Nonthermal melting of the Si substrate does not occur here or only in less distinctive manner because of absorption of the pump pulse photons and the corresponding energy in the \(\hbox {SiN}_{x}\) film [49].

Between 10 ps and 1 ns, the onset of ablation can be observed on the \(\hbox {SiN}_{x}\hbox {/Si}\) sample for both fluences. In the center, the reflectivity decreases to \(\Delta R/R = 0\) for the fluence of \(0.6\,\hbox {J/cm}^{2}\) after 6 ps and further to \(\Delta R/R = 0.5\) after 50 ps (Fig. 6). This decrease is very similar compared with the uncoated Si sample and can be related again to scattering losses in a gas-–iquid phase. The difference is that the gas–liquid phase occurs here in the \(\hbox {SiN}_{{\mathrm{x}}}\) due to the direct absorption in the \(\hbox {SiN}_{x}\) film and not in the Si. This leads to the partial direct surface ablation of the \(\hbox {SiN}_{x}\) layer visible in the final ablation state (Figs. 3d, 5 fourth row last image). It can be noted that in the center of all three samples the reflectivity increase due to nonthermal melting is compensated by a reflectivity decrease due to the scattering losses in the gas–liquid phase after 6 ps.

The ring systems observable on the 200 ps to 1 ns images can be again referred to as Newton’s rings when compared to the Si measurements. The spherical surface here could be formed by an expanding \(\hbox {SiN}_{x}\) spallation front [50]. The observation of Newton’s rings in \(\hbox {SiN}_{x}\) film is an additional strong argument for postulating a direct surface ablation here—as also observed in Si.

On the 10 ns to 500 ns images, the thin film removal can be observed. At the fluence of \(0.6\,\hbox {J/cm}^{2}\), small particles with a diameter of \({<}5\,{\upmu }\hbox {m}\) are emitted from the rim by a lift-off process (Fig. 5 fourth row). In the center, the final shape of the island becomes visible. At the fluence of \(0.5\,\hbox {J/cm}^{2}\), small particles are emitted again from the rim. An additional bigger particle (diameter \({>}10\,{\upmu }\hbox {m}\)) is detected on the 500 ns image and in contrary to the \(0.6\,\hbox {J/cm}^{2}\) sequence, the \(\hbox {SiN}_{x}\) island cannot be observed on the following images. In conclusion, the bigger particle is assumed to be the island during its removal [32]. This particle does not disintegrate into smaller parts maybe because the material is heated up due to the direct pulse absorption causing increased flexibility. Processes leading to the lift-off or to the island formation are competing here with each other. At 500 ns, the already created island is removed finally by a lift-off process.

Until the final ablation state, the reflectivity in the center of the \(\hbox {SiN}_{x}\hbox {/Si}\) sample processed at a fluence of \(0.6\,\hbox {J/cm}^{2}\) stays decreased at a level of \(\Delta R/R =0.3\) (Fig. 6). This can be explained by destructive interference of the probe pulse at the remaining island and the changed optical parameters of this island [24]. In contrast, on the \(\hbox {SiO}_{2}\hbox {/Si}\) sample and on the \(\hbox {SiN}_{x}\hbox {/Si}\) sample processed at a fluence of \(0.5\,\hbox {J/cm}^{2}\) the reflectivity increases again after about 200 ns because uncoated Si is exposed (Fig. 5).

The final ablation state is reached after several 100 ns. On the sample processed at a fluence of \(0.5\,\hbox {J/cm}^{2}\), the \(\hbox {SiN}_{x}\) film is removed completely by a confined (indirectly induced) laser ablation process. The same result is obtained in the rim of the sample processed at a fluence of \(0.6\,\hbox {J/cm}^{2}\). In the center of this sample, the island of remaining \(\hbox {SiN}_{x}\) is visible. It is created by a partial direct ablation of the \(\hbox {SiN}_{x}\) film.

5.3 Determination of process energetics

In this section the threshold fluence determination results from Sect. 5.1 are combined with the findings from the pump-probe measurements in Sect. 5.2. For a consideration of the energetics a reflectivity correction was applied to the threshold fluences for the melting and lift-off processes (Fig. 7; Table 2) on all samples (Si, \(\hbox {SiO}_{2}\hbox {/Si}\) and \(\hbox {SiN}_{x}\hbox {/Si}\)). To denote the difference to the fluence notation of previous sections, reflectivity corrected fluences are written with underline (e.g., \(\underline{F}_\mathrm{thr,SiO_{2}}\)).

To obtain comparable threshold fluence values for each sample the absorbed fluence has to be calculated. The reflected part does not contribute to the ablation process and has to be subtracted from the incident fluence. Thus, the reflected part of the pump pulse was measured in dependency of the fluence from 0.1 to \(3\,\hbox {J/cm}^{2}\). Results are shown in Fig. 7 (open symbols). Values at identical illumination parameters (wavelength, incident angle, polarization) are calculated with the literature values [51] for very low fluences to prove the consistency of the measured results. These values are plotted at \(F_0 \approx 0\,\hbox {J/cm}^{2}\) as filled symbols in Fig. 7.

Fluence dependent pump pulse reflectivity measured for uncoated Si, \(100\,\hbox {nm}\,\hbox {SiO}_{2}\) on Si and \(110\,\hbox {nm}\,\hbox {SiN}_{x}\) on Si. Calculated values based on the literature [51] for very low fluences \({<}1\,\hbox {mJ/cm}^{2}\) are plotted as reference at \(F_0 = 0.0\,\hbox {J/cm}^{2}\) (\(\tau = 660\,\hbox {fs}, \lambda = 1053\,\hbox {nm}\), incident angle \(35^{\circ }\), p-polarization)

Reflectivity for Si varies from \(25\%\) at \(0.1\,\hbox {J/cm}^{2}\) to \(40\%\) at \(3\,\hbox {J/cm}^{2}\) with a minimum of \(23\%\) at \(0.3\,\hbox {J/cm}^{2}\). Reflectivity for the coated samples varies between \(10\%\) and \(23\%\) for \(\hbox {SiO}_{2}\) and \(5\%\) and \(13\%\) for \(\hbox {SiN}_{x}\). The film of the coated samples acts as an index matching medium, exhibits anti-reflecting property and is generally reducing reflectivity compared with uncoated Si.

It can be seen that the reflectivity of each sample is fluence dependent. Reasons for this can be found in the fluence dependent change of the optical material parameters during the pulse impact. In the plasma approximation of the Drude model the reflectivity during the pulse impact is a function of the plasma frequency which is dependent on the density of excited electrons [34]. The electron density is coupled to the applied fluence. Thus, in this simplifying model the reflectivity during the pump pulse impact can increase or decrease depending on the absorbed fluence [52]. A second reason for a variable reflectivity could be given by nonlinear absorption effects at higher fluences. However, further investigations and calculations are necessary to completely understand the fluence dependent reflectivity behavior.

To obtain the reflectivity corrected values for the threshold fluences, the lift-off threshold fluences for the \(\hbox {SiO}_{2}\) and the \(\hbox {SiN}_{x}\) layer systems (Fig. 4) are reduced by the reflected part at the according fluence (Fig. 7). Results are summarized in Table 2. The values for the Si sample in Table 2 are obtained from the transient pump-probe measurements, where the spatial ranges for the melting, respectively, the phase explosion process are clearly visible (Sect. 5.2).

It can be seen, that the reflectivity corrected threshold fluences for the lift-off process on the two layer systems (\(\underline{F}_\mathrm{thr,SiO_{2}} = 0.29\,\hbox {J/cm}^{2}\); \(\underline{F}_\mathrm{thr,SiN_{x}} = 0.22\,\hbox {J/cm}^{2}\)) are higher than the melting threshold of uncoated Si (\(0.20\,\hbox {J/cm}^{2}\)), but lower than the threshold fluence for phase explosion (\(0.41\,\hbox {J/cm}^{2}\)). In conclusion, melting of the Si substrate seems to be sufficient to initiate the lift-off, evaporation should not obligatory be necessary. The energetics show that an ultrafast heating and melting may be enough to initiate the lift-off of the transparent films. This finding agrees very well with the simulations by Sotrop et al. [19]. In this work the ultrafast expansion by heating and melting creates a pressure wave provoking the mechanical motion of a thin Mo film which finally leads to a film lift-off.

This hypothesis is supported by the pump-probe investigations of the layer systems in the rim. There, a reflectivity corrected fluence slightly above the lift-off threshold fluence was applied as it becomes also evident in the final ablation state images (see Figs. 2, 3). At fluences of about \(\underline{F}_\mathrm{thr,SiO_{2}} = 0.32\,\hbox {J/cm}^{2}\) and \(\underline{F}_\mathrm{thr,SiN_{x}} = 0.22\,\hbox {J/cm}^{2}\) the layer is completely removed in the rim section. Both samples show here the constant increased reflectivity of molten Si up to 100 ps in the time-resolved data; a phase explosion indicated by a dark reflectivity decrease cannot not be observed in the rim section (Figs. 5, 6, dashed lines).

6 Industrial application of selective laser structuring in photovoltaics production

An efficient strategy for minimizing recombination losses of Si solar cells is to passivate the front and back surface area with dielectric layers and to minimize metal-semiconductor interface area by the creation of local contact openings with laser ablation [6, 15]. Actual three types of laser ablated contact openings for dielectric thin films are applied in current Si photovoltaics production lines. One is the selective front side contact opening, two others are backside contact openings for passivated emitter and rear cells (PERC) [53] and interdigitated back contact (IBC) [54] solar cells.

For front side contact opening a few 100 nm thick \(\hbox {SiN}_{x}\) transparent thin film on a textured Si surface has to be ablated on condition that a thermal damage of a 300–500 nm deep underlying p-n-junction is avoided [55]. It was shown earlier that a lift-off initiated by confined laser ablation with ultra-short pulse lasers in a wavelength range, where the \(\hbox {SiN}_{x}\) is transparent (near infrared (NIR) at about 1035 nm and visible (VIS) at about 532 nm) leads to an approximately 10 nm thick layer of amorphous Si at the interface of thin film and Si substrate [9, 24, 49]. Furthermore, according to the actual understanding, confined laser ablation is initiated by the ultrafast melting of a few 100 nm thick Si layer with subsequent heat expansion, pressure build up and generation of a pressure wave which is bulging and finally punching the \(\hbox {SiN}_{x}\) thin film [19, 22]. This process should leave a few 100 nm thick re-solidified and nonmonocrystalline layer of Si behind. It was also debated that lift-off \(\hbox {SiN}_{x}\) openings (with NIR and VIS ultrafast lasers) exhibit less electrical quality (e.g., higher dark current densities) as directly ablated openings with UV wavelengths, even when ns-UV-pulses were applied. The authors of [9] come to the conclusion, that “ps and fs laser ablation of dielectric layers from textured emitter surfaces were inapplicable for fabricating efficient solar cells”. In that study 400 fs pulses at 1030 nm, 9 ps pulses at 532 nm and 20 ns pulses at 355 nm were compared. The outcome displays that obviously confined laser ablation (even when ultrafast lasers are applied) is less suitable than direct laser ablation with ns-pulses.

From the above-mentioned observations it can be concluded that for a precise and selective laser ablation minimizing substrate damage the laser pulse energy must be deposited optically and limited thermally within the \(\hbox {SiN}_{x}\) film. Therefore, in current production lines the selective ablation of the \(\hbox {SiN}_{{\mathrm{x}}}\) film is performed by direct laser ablation with picosecond lasers in the UV in a single-pulse process to reach a minimum thermal damage. Typical used laser parameters are a wavelength of \(355\,\hbox {nm}\), 10 ps pulse duration, a repetition rate of 100 kHz to 1 MHz, corresponding to the creation of up to 1 million openings per second on the front side of the wafer (Rico Böhme, Innolas Solutions, Germany, personal communication, October 2016). The ultraviolet (UV) wavelength in combination with the ultrashort pulse duration of 10 ps is necessary to limit optical and thermal penetration depth to the dimension of the thin film.

For PERC back side contact opening the situation is different. The p-n junctions is located at the front side, which is a wafer thickness of a few \(100\,{\upmu }\hbox {m}\) and more away—in a safe distance. Additionally a thermal damage zone of 6 to \(12\,{\upmu }\hbox {m}\) of re-solidified Si at the back side is desirable to support the subsequent Al contacting. For an optimized galvanic contact the creation of an Al/Si eutectic is facilitated in a high temperature diffusion process (\({>}570\,^{\circ }\hbox {C}\)) by the re-solidified Si zone. Therefore, the laser process is supposed to create a deeper thermal damage zone (of about \(10\,{\upmu }\hbox {m}\)) compared with a front side opening and ns-laser pulses with durations of a few 10 ns can be applied for the PERC back side contact opening. For cost efficiency mostly the fundamental wavelength in the NIR is applied, but the process works also well with second and third harmonic wavelengths (Rico Böhme, Innolas Solutions, Germany, personal communication, October 2016).

For IBC cell contact opening at the back side a thermal \(\hbox {SiO}_{2}\) or a more cost-efficient oxynitride layer must be ablated in a single-pulse process leaving the p-n zone in a depth of 1–\(2\,{\upmu }\hbox {m}\) intact. The p-n-junction of an IBC cell is located in a depth of \({>}500\,\hbox {nm}\), which is somewhat deeper compared with the abovementioned front side openings. Therefore, the thermal damage zone in the absorbing substrate caused by a confined laser ablation process can be accepted. In this situation, a lift-off initiated by confined laser ablation with contribution of direct laser ablation fulfills the requirements. Thus a ps-laser at the second or third harmonic (typical parameters: 10 ps, 532 or 355 nm) is applied. The fundamental wavelength (e.g., 1064 nm) cannot be used because of its too high optical penetration depth of more than \(100\,{\upmu }\hbox {m}\) in silicon [56] (Rico Böhme, Innolas Solutions, Germany, personal communication, October 2016).

The three industrial applications show, that dielectric layers on Si substrates are selectively ablated with different strategies. If damage of the substrate must be avoided, such as for front side contact opening, a direct laser ablation process with an ultrafast laser is applied by using a wavelength where the dielectric film is absorbing. This limits the optical penetration depth to the dimension of the film. The pulse duration is selected to such an extent that also the thermal penetration depth is limited to the film dimension. Direct laser ablation however consumes more energy per ablated volume and requires an absorbing and relative costly UV laser wavelength. If a thermal damage zone of a few 100 nm in the substrate is acceptable, as with IBC cell back side contact opening, a cost effective confined laser ablation process can be used. Surprisingly confined laser ablation of dielectric thin film involves a certain amount of substrate damage, because according to actual theories the lift-off by confined laser ablation is initiated due to a few 100 nm thick ultrafast melting of the substrate interface layer [19]. If an even deeper thermal damage zone of about \(10\,{\upmu }\hbox {m}\) is desired, wavelength and pulse durations are chosen to match that depth, as it is the case for back side PERC contact opening and subsequent high temperature Al/Si eutectic generation.

These applications illustrate the importance of a profound understanding of the laser-material-interaction when processing thin film systems. Time-resolved pump-probe measurements allow the observation of the pulse absorption at the thin film-substrate-interface or inside the thin film depending on the investigated dielectric thin film material and the used laser parameters. In this way, time-resolved measurements can discriminate confined laser ablation from direct laser ablation and help to apply the right ablation mechanism to the requirement of the individual application.

7 Conclusion and summary

In this work, the laser ablation mechanisms of two thin film systems—\(\hbox {SiO}_{2}\) on Si and \(\hbox {SiN}_{x}\) on Si—were compared and set in relation to the processing of an uncoated Si substrate. For the ablation experiments a 660 fs laser system at a center wavelength of 1053 nm (\(=\)1.2 eV) was used. The different absorption behavior of the dielectrics due to their different band gap energies (\(E_{\text{gap,SiO}_{2}} \approx 8\,\hbox {eV}; E_{\text{gap,SiN}_{x}} \approx 2.5\,\hbox {eV}\)) and the resulting different ablation types were investigated. The \(\hbox {SiO}_{2}\) could be ablated with a lift-off initiated by confined ablation up to an irradiated pulse peak fluence of \(2.0\,\hbox {J/cm}^{2}\). In contrast, the \(\hbox {SiN}_{x}\) exhibited signs of a direct laser ablation or surface ablation already at fluences higher than \(0.29\,\hbox {J/cm}^{2}\). The temporal ablation processes were investigated by ultrafast pump-probe microscopy. In the first ten picoseconds the \(\hbox {SiO}_{2}\) and the \(\hbox {SiN}_{x}\) sample showed the same behavior as the uncoated Si sample. At higher delay times, a significant difference became obvious: in \(\hbox {SiO}_{2}\) films the pulse was absorbed in the Si substrate, leading to the confined ablation of the layer by the ultrafast expansion of the substrate combined with the generation of a pressure wave. On the \(\hbox {SiN}_{x}\) sample, a direct laser ablation in the center combined with a confined laser ablation in the rim section was observed. This leads to the conclusion that in the center the laser pulse is absorbed by nonlinear absorption in the film, whereas in the rim section, at lower fluences, the film stays transparent.

The direct comparison of all samples displays similarities in ablation behavior and mechanisms: the rim sections of \(\hbox {SiN}_{x}\) and \(\hbox {SiO}_{2}\) films both exhibit the lift-off character of a confined laser ablation, whereas the central section of \(\hbox {SiN}_{x}\) coated and uncoated Si show the typical appearance of a direct laser ablation. These similarities become only visible, when all three samples are compared one by one at identical observation parameters. With that comparison also the drastic difference of confined and direct laser ablation become obvious.

Moreover, by combining transient and energetic studies knowledge about the state of matter initiating the lift-off can be deducted, e.g., pump-probe measurements in a decentralized area at corresponding lower fluences combined with reflectivity corrected threshold fluence investigations suggest that the ultrafast heating and melting of the Si substrate should be sufficient to initiate the lift-off of the overlying \(\hbox {SiO}_{2}\) or \(\hbox {SiN}_{{\mathrm{x}}}\) film, evaporation seems not to be necessary.

These extensive investigations on the laser ablation of dielectric thin films with different band gap energies at fluences relevant for laser processing provide a general overview of different ablation types occurring during bulk material and thin film removal. They allow the generation of a profound knowledge of a variety of industrial relevant ablation processes, which was demonstrated on the example of three different laser processes for thin film ablation in nowadays photovoltaic production. A profound understanding of the laser-matter interaction is inevitable for improving efficiency and saving resources in nowadays production and society.

References

M. Kauf, R. Patel, J. Bovatsek, Laser Tech. J. 6(1), 33 (2009)

A.D. Compaan, I. Matulionis, S. Nakade, Opt. Lasers Eng. 34(1), 15 (2000)

R. Fabbro, J. Fournier, P. Ballard, D. Devaux, J. Virmont, J. Appl. Phys. 68(2), 775 (1990)

G. Heise, M. Englmaier, C. Hellwig, T. Kuznicki, S. Sarrach, H.P. Huber, Appl. Phys. A Mater. Sci. Process. 102(1), 173 (2011)

G. Heise, A. Börner, M. Dickmann, M. Englmaier, A. Heiss, M. Kemnitzer, J. Konrad, R. Moser, J. Palm, H. Vogt, H.P. Huber, Prog. Photovolt. Res. Appl. 23(10), 1291 (2014)

S. Zoppel, H. Huber, G.A. Reider, Appl. Phys. A Mater. Sci. Process. 89(1), 161 (2007)

G. Heise, D. Trappendreher, F. Ilchmann, R.S. Weiss, B. Wolf, H. Huber, J. Appl. Phys. 112(1), 13110 (2012)

G. Heise, M. Dickmann, M. Domke, A. Heiss, T. Kuznicki, J. Palm, I. Richter, H. Vogt, H. Huber, Appl. Phys. A Mater. Sci. Process. 104(1), 387 (2011)

S. Hermann, T. Dezhdar, N.P. Harder, R. Brendel, M. Seibt, S. Stroj, J. Appl. Phys. 108(11), 114514 (2010)

T. Rublack, G. Seifert, Opt. Mater. Express 1(4), 543 (2011)

V.V. Rana, Z. Zhang, Proc. SPIE 7193, 1 (2009)

G. Raciukaitis, M. Brikas, M. Gedvilas, T. Rakickas, Appl. Surf. Sci. 253(15), 6570 (2007)

J. Bonse, S. Baudach, J. Krüger, W. Kautek, M. Lenzner, Appl. Phys. A 74(1), 19 (2002)

T. Rublack, M. Schade, M. Muchow, H.S. Leipner, G. Seifert, J. Appl. Phys. 112(2), 023521 (2012)

S. Hermann, N.P. Harder, R. Brendel, D. Herzog, H. Haferkamp, Appl. Phys. A Mater. Sci. Process. 99(1), 151 (2010)

P. Engelhart, S. Hermann, T. Neubert, H. Plagwitz, R. Grischke, R. Meyer, U. Klug, A. Schoonderbeek, U. Stute, R. Brendel, Prog. Photovolt. Res. Appl. 15(6), 521 (2007)

J. Bonse, G. Mann, J. Krüger, M. Marcinkowski, M. Eberstein, Thin Solid Films 542, 420 (2013)

E.T. Karim, M. Shugaev, C. Wu, Z. Lin, R.F. Hainsey, L.V. Zhigilei, J. Appl. Phys. 115(18), 183501 (2014)

J. Sotrop, A. Kersch, M. Domke, G. Heise, H.P. Huber, Appl. Phys. A Mater. Sci. Process. 113(2), 397 (2013)

P. Peyre, R. Fabbro, Opt. Quantum Electron. 27(12), 1213 (1995)

M. Domke, S. Rapp, M. Schmidt, H.P. Huber, Appl. Phys. A Mater. Sci. Process. 109(2), 409 (2012)

S. Rapp, M. Domke, M. Schmidt, H.P. Huber, Phys. Proc. 41, 734 (2013)

K. Kumar, K.K.C. Lee, J. Li, J. Nogami, N.P. Kherani, P.R. Herman, Light Sci. Appl. 3(3), e157 (2014)

S. Rapp, G. Heinrich, M. Wollgarten, H.P. Huber, M. Schmidt, J. Appl. Phys. 117(10), 105304 (2015)

B.N. Chichkov, C. Momma, S. Nolte, F.V. Alvensleben, A. Tuennermann, Appl. Phys. A Mater. Sci. Process. 63(2), 109 (1997)

A. Rämer, O. Osmani, B. Rethfeld, J. Appl. Phys. 116(5), 053508 (2014)

H.M. van Driel, Phys. Rev. B 35(15), 8166 (1987)

G. Heinrich, A. Lawerenz, Sol. Energy Mater. Sol. Cells 120, 317 (2014)

B.C. Stuart, M.D. Feit, S. Herman, A.M. Rubenchik, B.W. Shore, M.D. Perry, Phys. Rev. 53(4), 1749 (1996)

K. Kumar, K.K. Lee, J. Li, J. Nogami, P.R. Herman, N.P. Kherani, in 2013 Conference on Lasers & Electro-Optics Europe & International Quantum Electronics Conference CLEO EUROPE/IQEC (2013), p. 1

J.P. McDonald, J.A. Nees, S.M. Yalisove, J. Appl. Phys. 102(6), 63109 (2007)

S. Rapp, G. Heinrich, M. Domke, H.P. Huber, Phys. Proc. 56, 998 (2014)

M.C. Downer, R.L. Fork, C.V. Shank, J. Opt. Soc. Am. A Opt. Image Sci. Vis. 2(4), 595 (1985)

C.V. Shank, R. Yen, C. Hirlimann, Phys. Rev. Lett. 50(6), 454 (1983)

K. Sokolowski-Tinten, J. Bialkowski, A. Cavalleri, D. Von Der Linde, A. Oparin, J. Meyer-Ter-Vehn, S.I. Anisimov, Phys. Rev. Lett. 81(1), 224 (1998)

A.J. Sabbah, D.M. Riffe, Phys. Rev. B 66(16), 1652171 (2002)

B. Rethfeld, K. Sokolowski-Tinten, D. Von Der Linde, S.I. Anisimov, Appl. Phys. A Mater. Sci. Process. 79(4–6), 767 (2004)

S.K. Sundaram, E. Mazur, Nat. Mater. 1(4), 217 (2002)

P. Lorazo, L. Lewis, M. Meunier, Phys. Rev. Lett. 91(22), 225502/1 (2003)

J.M. Liu, Opt. Lett. 7(5), 196 (1982)

D.H. Auston, C.V. Shank, P. LeFur, Phys. Rev. Lett. 35(15), 1022 (1975)

M. Domke, S. Rapp, M. Schmidt, H.P. Huber, Opt. Express 20(9), 10330 (2012)

R.M.A. Azzam, N.M. Bashra, Ellipsometry and Polarized Light (North-Holland Publishing Company, Amsterdam, 1977)

D. Von Der Linde, K. Sokolowski-Tinten, Appl. Surf. Sci. 154, 1 (2000)

J. Bonse, G. Bachelier, J. Siegel, J. Solis, H. Sturm, J. Appl. Phys. 103(5), 54910 (2008)

I. Mingareev, A. Horn, Appl. Phys. A Mater. Sci. Process. 92(4), 917 (2008)

E.T. Karim, M.V. Shugaev, C. Wu, Z. Lin, H. Matsumoto, M. Conneran, J. Kleinert, R.F. Hainsey, L.V. Zhigilei, Appl. Phys. A 122(4), 407 (2016)

K.M. Shvarev, B.A. Baum, P.V. Gel’d. Sov. Phys. Solid State 16(11), 2111 (1975)

G. Heinrich, M. Wollgarten, M. Bähr, A. Lawerenz, Appl. Surf. Sci. 278, 265 (2013)

P. Lorazo, L.J. Lewis, M. Meunier, Phys. Rev. B Condens. Matter Mater. Phys. 73(13) (2006)

E.D. Palik, Handbook of Optical Constants of Solids (Academic, Boston, 1985)

J.M. Liu, Appl. Phys. Lett. 39(9), 755 (1981)

A.W. Blakers, A. Wang, A.M. Milne, J. Zhao, M.A. Green, Appl. Phys. Lett. 55(13), 1363 (1989)

M.D. Lammert, R.J. Schwartz, IEEE Trans. Electron Devices 24(4), 337 (1977). doi:10.1109/T-ED.1977.18738

A. Knorz, M. Peters, A. Grohe, C. Harmel, R. Preu, Prog. Photovolt. Res. Appl. 17(2), 127 (2009)

M.A. Green, M.J. Keevers, Prog. Photovolt. Res. Appl. 3(3), 189 (1995). doi:10.1002/pip.4670030303

Acknowledgements

This work was partly funded by the Bundesministerium für Wirtschaft und Energie (BMWi) in MONOSCRIBE project (Grant No. 0325922A), by the Bayerische Forschungsstiftung in ORGANOLAS Project (Grant No. AZ-1119-14) and by the DFG in “Ellipsometrie” Project (Grant No. HU 1893/2-1). The authors acknowledge funding of the Erlangen Graduate School in Advanced Optical Technologies (SAOT) by the German Research Foundation (DFG) in the framework of the German excellence initiative. We thank Michael Kaiser and Christina Schindler from Munich University of Applied Sciences and Gerrit Heinrich from CiS Forschungsinstitut für Mikrosensorik GmbH for their support with sample preparation. Further, we thank Rico Böhme and Richard Grundmüller from Innolas Solutions GmbH, Krailling, Germany, for their valuable discussion regarding the actual industrial laser applications for selective structuring of transparent thin films in photovoltaics’ production lines.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rapp, S., Schmidt, M. & Huber, H.P. Selective femtosecond laser structuring of dielectric thin films with different band gaps: a time-resolved study of ablation mechanisms. Appl. Phys. A 122, 1035 (2016). https://doi.org/10.1007/s00339-016-0571-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0571-0