Abstract

The present work was aimed to develop a new kind of stone conservation materials (TEOS/PDMS/F127 hybrid coating) by a facile sol–gel method for the protection of decayed sandstones of Chongqing Dazu stone sculptures in China. The hydrophobic property, surface morphology, water vapor permeability, ultraviolet aging resistance and mechanical properties were measured to evaluate the effectiveness of TEOS/PDMS/F127 hybrid coating as a stone conservation material. The results showed that the addition of hydroxyl-terminated polydimethylsiloxane (PDMS-OH) contributed to improve the hydrophobic properties and incorporation of PEO–PPO–PEO (F127) surfactant resulted in the formation of superficial protrusions with micro- and nanoscopic structures and overall alteration of surface morphology and roughness, thus preventing the coating materials from cracking. After treatment with TEOS/PDMS/F127 hybrid coating materials, the ultraviolet aging resistance and mechanical properties of stone were also improved without the obvious effects on the breathability and color of the stone, indicating promising applications of TEOS/PDMS/F127 hybrid coating materials for conservation of historic stone sculptures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Chongqing Dazu stone sculpture enlisted in the list of the World Cultural Heritage by UNESO in 1999 is a valuable and important part of the cultural heritage. However, Dazu stone sculptures are presently subjected to various degrees of damages because of a combination of several different degradative factors, such as acid rain, intensive fluctuations of relative humidity and temperature (RH/T) and freeze/thaw effects [1] (Fig. 1). As a result, their conservation is receiving growing attention and becoming a focus of research. Therefore, it is very urgent and important to develop new kind of stone conservation materials for the protection of stone sculptures located outdoors and prevent the stone sculptures from being irreparably lost [2, 3].

Generally, stone conservation materials need to have certain properties such as good coagulation between grains comprising the stone sculptures to restore its strength and hydrophobicity to block water penetration [4–6]. Among numerous materials, consolidants based on tetraethoxysilane (TEOS) have been widely used in stone conservation [7–9]. They form Si–O network within the porous structure of the decaying stone through a facile sol–gel process, leading to significant enhancement of the cohesion and adhesion among the stone grains. They can also act as a barrier through the stone surface against water penetration, which is the main process responsible for deterioration phenomena [10, 11]. However, one serious drawback of TEOS-based consolidants is their tendency to form brittle gels susceptible to cracking due to the high capillary pressures created by the gel network during drying [12–14]. Such problem has been a great challenge and a major research focus in the fields of stone conservation applications.

In order to suppress the cracking during the drying process, several approaches have been adopted in recent years. One promising way is to prepare nanocomposites, which are obtained by introducing various inorganic nanoparticles (SiO2, TiO2, etc.) into siloxane polymers [15–17]. This process can prevent the gel from cracking by increasing gel pore size and reducing capillary pressure [18–20]. Although the addition of nanoparticles reduces the crack formation during the drying process, nanoparticles have been reported to notably change the appearance of the stone due to the high refraction index of the solid nanoparticles [21]. Another strategy has been recently developed in order to avoid cracking by adding a surfactant to the starting sol. The surfactant provides an efficient means of reducing capillary pressure and preventing cracking of the gel through decreasing of surface tension and coarsening of the gel network [22–25]. Despite this, there is a limited number of laboratory tests and reports about fabrication and practical application of stone consolidants with the addition of surfactants. Thus, continuing research to solve the cracking issue is still of great importance and in urgent demand.

The present work is aimed to develop TEOS/PDMS/F127 hybrid coating materials by a facile sol–gel method for the protection of decayed sandstones of Chongqing Dazu stone sculptures in China. We propose the use of hybrid materials based on TEOS and additives such as hydroxyl-terminated polydimethylsiloxane (PDMS-OH) and poly(ethylene oxide)–poly(phenylene oxide)–poly(ethylene oxide) (PEO–PPO–PEO, F127) surfactant to design a new stone consolidant formulation (TEOS/PDMS/F127 hybrid coating material). The hydrophobic property, surface morphology, water vapor permeability and mechanical properties of coating materials have been measured to evaluate their effectiveness as stone conservation materials. Ultraviolet aging tests have also been performed in order to estimate the long-term effectiveness of TEOS/PDMS/F127 hybrid coating materials.

2 Experimental

2.1 Materials and synthesis

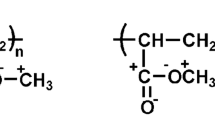

The tri-block copolymer EO106–PO70–EO106 (M w = 12,600, commercially known as F127 surfactant, with PEO and PPO representing polyethylene oxide and polypropylene oxide, respectively), a member of Pluronics copolymers, was purchased from Acros Corp. TEOS was obtained from Kelong Chemical Reagent Corporation. Hydroxyl-terminated PDMS (PDMS-OH) with a molecular mass 500–700 and a percentage of OH ranging from 6 to 8 wt% was supplied by Chenguang Research Institute of Chemical Industry. All reagents were used as received without any further purification.

TEOS/PDMS/F127 hybrid coating materials were prepared through acid-catalyzed TEOS hydrolysis with the additives of F127 surfactant and PDMS-OH. First, the silica sol was prepared by refluxing TEOS, ethanol, water and hydrochloric acid at 60 °C for 1 h with the addition of F127 surfactant. Next, PDMS-OH was incorporated into the mixture under vigorous stirring for another 1 h. The mole ratio of TEOS/H2O/ethanol/PDMS-OH/F127 was 1:4:4:0.03:0.001. Then, 5 wt% TEOS/PDMS/F127 hybrid coating materials were obtained after adding a certain amount of ethanol to the above solution.

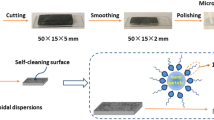

Sandstone samples from Chongqing Dazu stone sculptures were cut into 3 × 3 × 1 cm3 blocks, rinsed with deionized water for 1 h by ultrasonic agitation and dried in an oven at 110 °C for 4 h. Full immersion method was applied in the present work. Sandstone samples were soaked in consolidant solutions (TEOS/PDMS/F127 hybrid sol) for 24 h. Then, the stone samples were dried under laboratory conditions until the sol–gel process finished.

2.2 Characterization

The mineral composition of the sandstone samples was recorded on a TD-3500 X-ray diffractometer. The generator was operated at 40 kV and 25 mA. The chemical bonding of the coating materials were analyzed by Fourier transform infrared spectrophotometry (FTIR). The spectra were recorded in KBr pellets using a Varian Cary 670 FTIR spectrometer. The BET surface area, porous volume and pore size distribution of the coating materials were characterized by Tristar-3020 surface area analyzer, and the coating materials were evacuated for 12 h at 180 °C under vacuum before analysis.

The hydrophobic behavior of the hybrid coating materials was determined via static contact angle test. The static contact angle (θ) of the stone surfaces was measured using a JC2000C contact angle meter (Shanghai Zhongchen Digital Technic Apparatus Co., Ltd, China). The reported contact angle value was the average of five measurements.

Scanning electron microscopy (SEM) was used to visualize the morphology change of stone surface. The microscope employed was a Hitachi Fields S-4800 instrument. All specimens were sputter-coated with gold prior to examination.

The ultraviolet (UV) irradiation is the main facet of accelerating the real aging process of stone conservation materials. Therefore, the artificial ultraviolet aging test was conducted in a climatic chamber equipped with two 20 W ultraviolet lamps (wavelength = 253.7 nm). The annual sunlight illuminating time in Dazu is about 1314 h, two percent of which is ultraviolet light. It is calculated that the UV illumination for 30 days under our experimental conditions corresponds to 28 years of real aging. Every certain period of time, the treated stone samples were brought out to conduct water contact angle tests. The changes in stone color after treatment were determined using a solid reflection spectrophotometer. And the variations in stone color were evaluated using the parameter total color difference (ΔE*).

Water vapor permeability indicated the amount of water permeated through the stone surface in a certain time. The water vapor permeability test was processed as follows: fixing a sandstone sample as a cover on a cylindrical container filled partially with water, making sure that the vapor could only traverse through the bottom of stone cylinder. Then, the containers properly sealed with paraffin were placed in a desiccator with a relative humidity of RH 35 % and at constant temperature of 25 °C. The water vapor diffusivity coefficient was determined by the following equation:

where H is the water vapor diffusivity coefficient (g/mm2 s), Δm is the mass change (g), t is the time when Δm occurred (s), and S is the test area (mm2).

The compressive strength was measured to evaluate the mechanical properties of stone samples. The test was conducted through a rock mechanic test system according to the Test Method of Engineering Rock Mass (GB/T50266-99).

3 Results and discussion

X-ray diffraction (XRD) analysis was used to investigate the mineralogical characteristics of sandstones in Dazu stone sculptures. The XRD pattern of untreated sandstone samples is shown in Fig. 2. It is clear that quartz (SiO2) and calcium feldspar (CaAl2Si2O8·4H2O) are the main compositions of Dazu sandstone samples.

FTIR spectrum of TEOS/PDMS/F127 hybrid coating materials is shown in Fig. 3. There is a very strong absorption band at 1080 cm−1 assigned to the C–O stretching of F127 surfactant and overlap with the stretching vibration of Si–O–Si bonds, indicating that hybrid coating materials are mainly composed of Si–O–Si network [26]. The peak at 1264 cm−1 is attributed to the Si–(CH3)2 bond [27]. The broad band centered at about 3475 cm−1 is assigned to the O–H stretching absorptions [28]. These features convincingly show that PDMS-OH is covalently bonded to silanol through Si–O–Si bonds by dehydration between PDMS-OH and silanol [29], which effectively prevents the macrophase separation during the gel formation. The peaks centered at 2960 cm−1 are assigned to the absorption of methylene groups of F127 surfactant and the overlap with Si–CH3 absorption.

The N2 adsorption–desorption isotherms and corresponding pore size distribution curves of TEOS/PDMS/F127 hybrid coating materials are shown in Fig. 4. It is clear that the isotherms are typical Type IV with distinct hysteresis loops related to capillary condensation taking place in mesopores [30]. The BET surface area and total pore volume are 483 m2/g and 0.35 cm3/g, respectively. The average diameter of pore size is 13.8 nm, indicating narrow pore size distribution. These features indicate the role played by F127 surfactant, which coarsens the pore network and subsequently reduces the capillary pressure responsible for cracking during the gel drying process. The porous structure of the coating materials is beneficial for the breathability of the stone and thus do not decreases the water vapor permeability obviously.

One of the most important factors affecting stone degradation is water. Water can cause stone deterioration (disintegration, surface erosion, cracking, etc.) through freezing–thawing or wetting–drying cycles inside the pores [31, 32]. Therefore, stone conservation materials should have hydrophobic properties to prevent water penetration into the bulk of the stone. The hydrophobic properties of TEOS/PDMS/F127 hybrid coating materials are evaluated according to water contact angles. In Fig. 5, it is observed that the water droplet spreads out rapidly on the surface of untreated sandstone and soon completely wets the stone surface, which has a 0° static water contact angle. The mean contact angle value is 117° for TEOS/PDMS/F127 treated sandstone surface. Such excellent hydrophobicity of coating materials is due to the addition of PDMS-OH. The –Si(CH3)2– groups of PDMS cross-linked with the inorganic silica skeleton in the hybrid structure impart the water-repellent properties and hence the durability of the coatings in wet environments.

SEM measurement was taken to provide information concerning the changes in the stone surface morphology. In Fig. 6a, small disintegrated grains are deposited on the fractured surface of untreated sandstone. After treatment with TEOS/PDMS/F127 coating materials, a crack-free and continuous film is formed on the surface of sandstone (Fig. 6b). The coating is characterized by the formation of complex micro- and nanoscopic protrusions on the surface of treated sandstone (Fig. 4c). Given these findings, we have demonstrated that the addition of F127 surfactant to the siloxane composition resulted in the formation of superficial protrusions with a two-length-scale hierarchical structure and overall alteration of surface morphology and roughness of sandstone samples, which is responsible for the development of hydrophobic properties and crack-free homogeneity on the surface of sandstone [33].

Ultraviolet aging tests have been performed on sandstone samples to evaluate the long-term effectiveness of TEOS/PDMS/F127 hybrid coating materials. The effects of ultraviolet light on the hydrophobicity of TEOS/PDMS/F127 treated sandstone surface are shown in Fig. 7. Even if the value of contact angle decreases with the ultraviolet exposure time, the sandstone samples treated with TEOS/PDMS/F127 coating materials show a better durability to the ultraviolet light. Ultraviolet aging tests have not changed the surface morphology of sandstone samples, as shown in the SEM images of the sandstone samples after ultraviolet aging tests (Fig. 8).

The chemical changes of the hybrid coating upon UV exposure were characterized by FTIR measurement. As shown in Fig. 9, FTIR spectrum of TEOS/PDMS/F127 hybrid coating materials after UV illumination for 30 days presents that hydrocarbon absorptions are obviously decreased, indicating the hydrocarbon groups contained in the hybrid coating materials decompose (or be oxidized in air) and thus cause the decrease of hydrophobicity. For example, the breakdown of Si–CH3 bond occurs in PDMS chain and results in the formation of methane and hydrogen as volatile split-off compounds. The main chain of hybrid coating materials is comprised of strong Si–O bonds, which have higher bonding energy up to 460 kJ/mol and cannot be broken up by UV irradiation under our experimental conditions [34, 35].

We further evaluated the changes of stone color after the treatments. The total color difference value of the stone after TEOS/PDMS/F127 hybrid coating treatment is 1.86 ± 0.3, below the perceptibility threshold (<3). After ultraviolet aging tests, the total color difference value is 3.68 ± 0.5. The change in the stone color could be associated with long-time UV exposure. The weight change of stone samples after ultraviolet aging has also been studied. As shown in Fig. 10, there is no obvious weight loss for the stone samples, indicating the effectiveness of TEOS/PDMS/F127 hybrid coating materials, which prevent the weight loss of stone samples during the ultraviolet aging test.

The water vapor permeability was tested to evaluate the effect of coating materials on the breathability of stone. The water vapor diffusivity coefficient of untreated sandstone sample is 2.10 × 10−9 g/mm2 s. After treatment with TEOS/PDMS/F127 hybrid coating materials, the water vapor permeability is reduced by 12 %. It highlights that the breathability of stone after consolidation is only slightly reduced. The previous literature has reported that a material reducing the permeability by up to 50 % could still be considered to be a potential product for the conservation of stone cultural heritage [36].

The mechanical properties of stone samples untreated and treated with TEOS/PDMS/F127 hybrid coating materials are shown in Fig. 11. The compressive strength of treated stone sample is 20 % higher than that of untreated stone sample. The improved mechanical properties can be attributed to the strong interfacial interactions between TEOS oligomers and PDMS-OH, and they also form a good compatibility with F127 surfactant.

4 Conclusion

In summary, we have developed a new kind of TEOS/PDMS/F127 hybrid coating materials through a facile sol–gel method to conserve the decayed sandstones of Chongqing Dazu sculptures in China. It has been found that PDMS-OH is chemically bonded to TEOS oligomers through Si–O–Si bonds. The surface hydrophobicity of treated decayed sandstone increases with the addition of PDMS-OH. The addition of F127 surfactant to the siloxane composition results in the formation of micro- and nanoscopic protrusions with a two-length-scale hierarchical structure and overall alteration of surface morphology and roughness, which is responsible for the development of hydrophobic properties and crack-free homogeneity of sandstone surface. The TEOS/PDMS/F127 hybrid coating materials have also enhanced ultraviolet aging resistance and mechanical properties without obvious effects on the breathability and color of the stone, demonstrating these coating materials very promising for stone conservation applications.

References

D.J. Tong, Sci. Conserv. Archae. 15, 57–60 (2003)

L. Maurizio, M. Marco, W. Maduka, Z. Chiara, Appl. Phys. A 114, 673–683 (2014)

L. Maurizio, M. Marco, W. Maduka, Z. Chiara, Appl. Phys. A 116, 1525–1539 (2014)

S. Son, J. Won, J.J. Kim, Y.D. Jang, Y.S. Kang, S.D. Kim, ACS Appl. Mater. Interfaces 1, 393–401 (2009)

Q. Liu, Y.J. Liu, K.W. Zeng, F.L. Yang, H. Zhu, Q.J. Liu, J. Archaeol. Sci. 38, 1896–1900 (2011)

F.G. Xu, G.Y. Wang, D. Li, M. Wang, F. Xu, X.Q. Deng, Prog. Org. Coat. 81, 58–65 (2015)

A.A. El-Midany, M.K. Khallaf, S.E. El-Mofty, Surf. Interface Anal. 43, 1182–1188 (2011)

F.G. Xu, D. Li, J. Sol–Gel. Sci. Technol. 65, 212–219 (2013)

K. Ioannis, P. Alexandros, N.M. Panagiotis, E.A. Katerina, Mater. Lett. 131, 276–279 (2014)

J. Delgado, E. Charola, Sci. Technol. Cult. Herit. 5, 93–101 (1996)

R. Zarraga, J. Cervantes, C. Salazar-Hernandez, G. Wheeler, J. Cult. Herit. 11, 138–144 (2010)

J. Brus, P. Kotlik, Stud. Conserv. 41, 324–332 (1996)

M.J. Mosquera, J. Pozo, L. Esquivias, T. Rivas, B. Silva, J. Non-Cryst. Solids 311, 185–194 (2002)

M.J. Mosquera, J. Pozo, L. Esquivias, J. Sol–Gel. Sci. Technol. 26, 1227–1231 (2003)

C. Salazar-Hernández, M.J.P. Alquiza, P. Salgado, J. Cervantes, Appl. Organomet. Chem. 24, 481–488 (2010)

R. Liu, X.N. Han, X. Huang, W.D. Li, H.J. Luo, J. Sol–Gel. Sci. Technol. 68, 19–30 (2013)

D. Li, F.G. Xu, Z.H. Liu, J.Q. Zhu, Q.J. Zhang, L. Shao, Appl. Surf. Sci. 266, 368–374 (2013)

M.J. Mosquera, M. Bejarano, N. De la Rosa-Fox, L. Esquivias, Langmuir 19, 951–957 (2003)

E.K. Kim, J. Won, J.Y. Do, S.D. Kim, Y.S. Kang, J. Cult. Herit. 10, 214–221 (2009)

P.N. Manoudis, A. Tsakalof, I. Karapanagiotis, I. Zuburtikudis, C. Panayiotou, Surf. Coat. Technol. 203, 1322–1328 (2009)

L. De Ferri, P.P. Lottici, A. Lorenzi, A. Montenero, E. Salvioli-Mariani, J. Cult. Herit. 12, 356–363 (2011)

M.J. Mosquera, D.M. Santos, A. Montes, L. Valdez-Castro, Langmuir 24, 2772–2778 (2008)

M.J. Mosquera, D.M. De los Santos, T. Rivas, Langmuir 26, 6737–6745 (2010)

J.F. Illescas, M.J. Mosquera, ACS Appl. Mater. Interfaces 4, 4259–4269 (2012)

D.S. Facio, M.J. Mosquera, ACS Appl. Mater. Interfaces 5, 7517–7526 (2013)

A. Fidalgo, R. Ciriminna, L.M. Iharco, M. Pagliaro, Chem. Mater. 17, 6686–6694 (2005)

X. Zhang, H. Ye, B. Xiao, L. Yan, B. Jiang, J. Phys. Chem. C 114, 19979–19983 (2010)

J.F. Illescas, M.J. Mosquera, J. Phys. Chem. C 115, 14624–14634 (2011)

L. Tellez, J. Rubio, F. Rubio, E. Morales, J.L. Oteo, J. Mater. Sci. 38, 1773–1780 (2003)

R. Guillet-Nicolas, L. Marcoux, F. Kleitz, New J. Chem. 34, 355–366 (2010)

A. Jain, S. Bhadauria, V. Kumar, R.S. Chauhan, Build. Environ. 44, 1276–1284 (2009)

P. Martinec, M. Vavro, J. Scucka, M. Maslan, Eng. Geol. 115, 175–181 (2011)

L. Gao, J.T. McCarthy, Langmuir 22, 2966–2967 (2006)

X. Ding, S. Zhu, G. Gu, L. Wu, J. Mater. Chem. 21, 6161–6164 (2011)

S. Zhou, X. Ding, L. Wu, Prog. Org. Coat. 76, 563–570 (2013)

J.D. Rodrigues, A. Grossi, J. Cult. Herit. 8, 32–43 (2007)

Acknowledgments

The authors gratefully acknowledge the financial supports from Basic and Frontier Research Program of Chongqing Municipality (cstc2016jcyjA1785), the Major Research Training Program of Chongqing University of Arts and Sciences ([2014]48) and the First Excellent Young Teachers Program of Chongqing high school ([2011]65).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Liu, J. Fabrication of TEOS/PDMS/F127 hybrid coating materials for conservation of historic stone sculptures. Appl. Phys. A 122, 743 (2016). https://doi.org/10.1007/s00339-016-0275-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0275-5