Abstract

Ag-doped TiO2 with Ag content ranging from 1 to 7 mol% was synthesized by a modified sol–gel route, and its performance as the photoanode of dye-sensitized solar cells (DSSCs) was compared with undoped TiO2 photoanode. Titanium(IV)isopropoxide was used as precursor and hexamethylenetetramine as the capping agent. XRD results show the formation of TiO2 nanoparticles with an average crystallite size of 5 nm (1 % Ag-doped TiO2) and 9 nm (undoped TiO2), respectively. The TiO2 nanopowder was used to prepare its thin film photoelectrode using doctor’s blade method. Significant improvement in light-to-energy conversion efficiency was achieved when thin films of 1 % Ag-doped TiO2 were applied as photoanode in DSSC taking N719 as the sensitizer dye. As evidenced by EIS measurements, the electron lifetime of DSSC with Ag-doped TiO2 increased from 1.33 (for undoped TiO2) to 2.05 ms. The short-circuit current density (J sc), open-circuit voltage (V oc), fill factor (FF) and the overall energy conversion efficiency (η) were 1.07 mA cm−2, 0.72 V, 0.73 and 0.40 %, respectively, with the use of 1 % Ag-doped TiO2 photoanode, whereas with undoped TiO2 under similar conditions, J sc = 0.63 mA cm−2, V oc = 0.70 V, fill factor 0.45 and conversion efficiency 0.14 % could be obtained. Therefore, compared with the reference DSSC containing an undoped TiO2 photoanode, the power conversion efficiency of the cell based on Ag-doped TiO2 has been remarkably enhanced by ~70 %. The substantial improvement in the device performance is attributed to the reduced band-gap energy, retarded charge recombination and greater surface coverage of the sensitizing dye over Ag-doped TiO2, which ultimately resulted in improved IPCE, J SC and η values.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Dye-sensitized solar cells (DSSCs) have emerged as an alternative to conventional silicon-based solar cells due to their relatively high energy conversion efficiency and low cost [1–3]. Semiconductors such as TiO2 [4], ZnO [5], SnO2 [6], Nb2O5 [7] and SrTiO3 [8] have extensively been studied for use as photoanode materials to develop high-performance DSSCs. TiO2 has been proven to be the best semiconductor electrode material due to its chemical stability, nontoxicity, good electrical properties and low cost, and therefore, it is widely used in many applications such as photocatalysis, hydrogen production and solar cells [9–12]. Sol–gel method is a fascinating method to synthesize TiO2 due to its economical materials processing, high chemical purity, homogeneity and small particle size of the obtained TiO2 [13]. Among anatase, rutile and brookite crystalline phases of titanium dioxide, anatase TiO2 has the band-gap energy of 3.2 eV, for which the absorption thresholds correspond to 380 nm, suggesting for facile excitation under solar light irradiation. Nevertheless, properties of TiO2 are severely limited as spectroscopic studies reveal that almost 90 % of the photogenerated electron–hole (e −–h +) pairs recombine rapidly after excitation. Researches have focused on improving performance by modifying its surface by deposition of noble metals, thus extending absorption spectrum toward the visible region. Pt, Au, Ag, Cu have been largely doped in TiO2 to improve its properties. The dopant ions contribute to the change of electronic structure and light absorption efficiency of the TiO2. Specially, noble metals like Au and Ag have electron storage properties, thus facilitating charge separation in semiconductor–metal composites [14].

Many reports are there in which Ag-doped TiO2 has been employed as photoanode for DSSC application because it is comparatively cheap and the work function of silver is greater than Fermi level of TiO2 leading to effective tuning of the band gap. Chang et al. [15] have shown that Ag at TiO2 photoanode forms a porous structure, which possesses not only great surface area, but also good adsorption of dye could be achieved, and DSSC employing such a photoanode showed a photoelectric conversion efficiency of 6.06 % with controlled thickness of the film. Huang et al. [16] observed an improved interfacial electron transfer and light harvesting in dye-sensitized solar cells by using Ag nanowire/TiO2 nanoparticle composite films. The energy conversion efficiency of the DSSC with AgNWs reached 5.31 % compared to 4.68 % for DSSC without AgNWs. Dissanayak et al. [17] have shown that the efficiencies of plasmonic DSSCs with TiO2:AgNP were 6.51 %, representing an efficiency enhancement by 27 % for AgNPs, and ascribed it to localized surface plasmon resonance effect narrowing the energy band gap of TiO2 due to the presence of Ag nanoparticles. Yunyu et al. [18] have ascribed similar observations to enhanced conductivity of TiO2 thin-film photoanode, causing fast electron transport and correspondingly an increase in photocurrent. Jin et al. [19] reported that the electron lifetime of DSSCs with Ag-doped TiO2 nanofiber increased from 0.29 to 0.34 s and that electron recombination was reduced, and as a consequence, the conversion efficiency of TiO2 photoelectrode-based DSSCs was increased from 4.74 to 6.13 % after adding 5 wt% ATN into TiO2 films. Huang et al. [20] reported that the enhancement of light trapping (which leads to the increase in photocurrent), increase in open-circuit voltage and reduction of charge transport resistance led to the improvement of cell efficiency when thermally shrunk Ag nanoparticles were used as the etching masks for nanoporous TiO2 photoanodes.

The incorporation of Ag nanoparticles is beneficial for promoting the charge separation within the TiO2 film as well as improves the interfacial charge-transfer process. This results in an enhanced electrical conductivity [21]. In fact, electron transport in the DSSCs is dominated by diffusion and a faster electron transport results in a higher photocurrent. Li et al. [22] reported that the electron diffusion coefficient of the Ag-doped DSSC is about three times higher as compared to the undoped DSSC. Additionally, silver incorporated on TiO2 could be attributed to accelerate the formation of superoxide radical anion O2− and also decrease the probability of recombination of electrons and holes by scavenging the electrons in the conduction band by silver dopants. Doping the TiO2 with silver ions (Ag+ and Ag2+) may lead to the formation of space charge, and the e −/h + pairs are efficiently separated by the large electric filed before recombination [23]. Moreover, since the work function of silver is greater than Fermi level of TiO2, when they are in contact, a Schottky barrier is created, which facilitates the transfer of photogenerated electrons from TiO2 to Ag NPs and retards the recombination of electron–hole pairs [24]. The another merit of Ag/TiO2 composites, which the light absorption spectrum is extended toward the visible region, can be ascribed to the effect of Ag by acting as electron traps in TiO2 band gap [23].

In this work, we have synthesized undoped and Ag-doped TiO2 by a modified sol–gel method making use of hexamethylenetetramine (HMT) as capping agent and applied as the photoanode material in DSSC. The prime focus was to substantiate the idea that with the additive effect of capping agent and dopant, there is possibility of additional enhancement of sensitized photocurrent. The crystal structure of TiO2 and Ag-loaded TiO2 was examined by XRD. Morphologies and particle sizes of TiO2 and Ag-loaded TiO2 were investigated by SEM, HR-TEM and AFM. The chemical composition of TiO2 and Ag-loaded TiO2 nanoparticles was examined by EDXS. Photovoltaic performance was studied in DSSC configuration employing N719 dye.

2 Experimental

2.1 Materials

Titanium(IV)isopropoxide (Sigma-Aldrich), silver nitrate (Merck), isopropanol (Merck) and hexamethylenetetramine, HMT (Merck, purity >99 %) were used as received for preparing TiO2 powders. LiI (99.9 %, Aldrich), I2 (G. R. grade, 99.8 %, BDH) added as redox couple in cell electrolyte and propylene carbonate (>99 %, Merck) taken as the medium of cell electrolyte were used without any further purification. Platinum catalyst (T/SP paste) used for making counter electrode, the sealing agent (SX1170-60, 50 μm) and N719 dye used as photosensitizer were all obtained from Solaronix SA. Conducting glass plate (15 Ω/sq) was obtained from Pilkington, USA.

2.2 Preparation of TiO2 powder

Undoped TiO2 and Ag-doped TiO2 were synthesized by sol–gel method as detailed in Scheme 1. 0.2 M solution of titanium isopropoxide was prepared in isopropanol with constant stirring for 1 h. Then, 0.2 M hexamethylenetetramine was added into the above solution dropwise with constant stirring for another 1 h. For preparing the Ag-doped samples, AgNO3 solution was mixed in above solution dropwise, and the final mixture was then refluxed for 6 h at 80 °C to get clear solution. The brownish-white precipitate (in case silver-doped samples) and white precipitate in case of undoped TiO2 were obtained. The resulting precipitates were filtered and washed with distilled water followed by ethanol and dried at 100 °C. Finally, the TiO2 powders were annealed at 450 °C for 1 h.

2.3 Material characterization

The absorption and FTIR spectra of doped and undoped TiO2 powders were recorded with Shimadzu UV-1700 spectrophotometer and Varian 3100 FT-IR spectrometer, respectively. X-ray diffraction (XRD) study of the samples was carried out using D8 Advance X-ray diffractometer equipped with graphite monochromator and a Cu source (λ = 1 × 5418 Å, CuKα operating at 45 kV and 40 mA). AFM images were recorded by NT-MDT atomic force microscope (model Solver NEXT). Roughness was reckoned by NOVA Px 3.1.0 software. EIS studies were carried out using Autolab electrochemical workstation (model AUT 302 N). SEM and EDAX were obtained using SEM EVO Scanning Electron Microscope MA 15/18 and EDAX EDS 51N1000, respectively. HRTEM was carried out using HRTEM, TECNAI 20G2 (200kv) FEI company, Netherland.

2.4 Preparation of TiO2 electrode (photoanode) and counter electrode

TiO2 thin-film electrodes (photoanodes) were prepared by spreading the paste of as-synthesized TiO2 powders (prepared with ethanol) on the fluorine-doped tin oxide (FTO) glass substrates and applying the doctor’s blade method. Films were dried under ambient condition and annealed at 450 °C in air for 1 h in a tubular furnace. This resulted in TiO2 film of ~6 µm thickness. The dye (N719) was anchored onto the surface of the TiO2 thin film electrode by immersing it into ethanol solution of dye for 18 h. The platinum counter electrode was prepared on another FTO-coated glass substrate by depositing platinum catalyst using doctor’s blade method and annealing at 400 °C for half an hour in air.

2.5 Fabrication of DSSC

The photoelectrode (dye-coated TiO2 film) was put over platinum counter electrode in such a way that the conductive side of both the electrodes faced each other, and the cell was sealed from three sides using spacer/sealing tape (heating it at ~80 °C); one side was left open for the injection of electrolyte. The cell electrolyte (0.2 M lithium iodide and 0.02 M iodine in propylene carbonate) was injected through open side and was drawn into the space between the electrodes by capillary action. Thereafter, the open side of the cell assembly was sealed properly with araldite, and the contacts were made by copper wires using silver paste.

2.6 Photoelectrochemical measurements

A bi-potentiostat (Model no. AFRDE 4E, Pine Instrument Company, USA) and e-corder (Model 201, eDAQ, Australia) were used for current–potential measurements. For photoelectrochemical (PEC) measurements, a 150-W Xenon arc lamp with lamp housing (Model no. 66057) and power supply (Model no. 68752), all from Oriel Corporation, USA, were used as the light source. The semiconductor electrode was illuminated after passing the collimated light beam through a 6-inch-long water column (to filter IR part of the light) and condensing it with the help of fused silica lenses (Oriel Corporation, USA). The UV part of this IR-filtered light was cut off by using a long-pass filter (Model no. 51280, Oriel Corporation, USA), and the light obtained this way was used for irradiation. To obtain the action spectrum (J photo-λ) of the dye-sensitized TiO2 electrode, monochromatic light-induced photocurrent was measured with the help of a digital multimeter (Philips Model No. 2525) in combination with the potentiostat. The light was monochromatized, by using a grating monochromator (Oriel Model 77250 equipped with model 7798 grating). The width of the exit slit of the monochromator was kept at 0.5 mm. The intensities of light were measured with a digital photometer (Tektronix model J16 with model J 6502 sensor).

3 Results and discussion

3.1 Material characterizations

3.1.1 Optical properties of undoped and Ag-doped TiO2

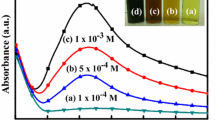

Figure 1 shows the absorption spectra of the undoped and 1 % Ag-doped TiO2 powders. From the figure, it is evident that the undoped TiO2 shows absorption in UV region only, whereas 1 % Ag-doped TiO2 shows appreciable absorption in the visible region of solar spectrum. This clearly indicates that the Ag doping has effectively extended the spectral sensitivity of TiO2 in the visible region. The band gap(s) of the undoped and 1 % Ag-doped TiO2 were obtained using the following relation:

where B is a constant, E g the band gap of the material, α is the absorption coefficient (cm−1) and hν is the photon energy. Based on this equation, the optical band gap (E g) of the TiO2 was obtained by extrapolating the linear portion of [(αhν)1/2 vs hν] plot to α → 0 as shown in Fig. 2. The results obtained have shown that the band gap became narrower and red-shifted for Ag-doped TiO2 (3.10 eV for the undoped TiO2 to 2.75 eV for 1 % Ag-doped TiO2). The narrower band gap is in fact due to a downward shift in the conduction band and upward shift in the valence band, which leads to a decrease in the band gap. It facilitates better conduction of electrons under illumination, and therefore, improved light-harvesting properties of Ag-doped TiO2 electrodes compared to undoped TiO2 are anticipated.

3.1.2 FTIR spectra

The FTIR spectra of undoped and 1 % Ag-doped TiO2 recorded in the range of 4000–400 cm−1 are shown in Fig. 3. It was observed that undoped and 1 % Ag-doped TiO2 samples exhibited quite similar FTIR spectra. An examination of the spectra reveals the peaks in the range of 400–900 cm−1, which are characteristics of the formation of O–Ti–O lattice and Ti–O stretching mode [25]. The peak around ~1630 cm−1 corresponds to bending vibration of H–O bond [26]. The broadband observed at 2900–3400 cm−1 may be assigned to the stretching vibration of –OH and weakly bound water molecules [27, 28].

3.1.3 X-ray diffraction

The doping of Ag in the TiO2 lattice was confirmed by X-ray powder diffraction (XRD). Figure 4 shows the XRD spectra for the undoped and 1 % Ag-doped TiO2 powders. Its comparison with the JCPDS Card File No. 21-1272 has proven that XRD patterns for all the samples have anatase structure. The diffraction peaks that appeared at 25.3°, 37.8°, 48.1°, 54.0°, 54.9° and 62.7° (2θ values) have been assigned to d (101), d (004), d (200), d (105), d (211) and d (204) planes (of the anatase type structure), respectively. In fact, under the specific preparation conditions, the films are comprised of anatase only and rutile phase was not detected. From the broadening of X-ray diffraction peaks and using the Scherrer equation (Eq. 2), the crystallite size L has been estimated

K is a constant taken as 0.89, λ is the wavelength of the X-ray radiation (1.5418 Å), β is the full width at half maximum height (FWHM) of the peak and θ is the diffracting angle. The average crystallite size of TiO2 powders determined from strongest peak at 25.3° (101 plane) was found to be 5 nm (1 % Ag-doped TiO2) and 9 nm (undoped TiO2), respectively. The X-ray diffraction patterns of the silver-doped TiO2 samples almost coincide with that of pure TiO2 and show no diffraction peaks due to the silver species, thus suggesting that the metal particles are well dispersed on the TiO2 surface. Doping with Ag does not perturb the crystal structure of anatase TiO2, indicating that the metal dopant is merely placed on the surface of the crystals without being covalently anchored into the crystal lattice. There are no diffraction pattern characteristics of the Ag metal in the XRD patterns.

3.1.4 Surface morphological properties

3.1.4.1 SEM and EDAX

Scanning electron microscopy (SEM) was used to investigate the morphology as shown in Figs. 5a and 6a for bare and 1 % Ag-doped TiO2, respectively. The SEM results showed the rough morphology and the presence of agglomerated nanoparticles. Bare TiO2 particles are irregular in shape and size of approximate 20 µm, whereas in the case of 1 % Ag-doped TiO2 particles are comprised of clusters of agglomerated nanoparticles with the average particle size of about 0.5 µm (<1 µm). SEM images of Ag–TiO2 nanoparticles confirm the presence of porous, sponge-like structure and complexity. Such structure indicates the high surface area, resulting in greater adsorption of dye, which has been proven to be useful for DSSC application. Such structure aids in the penetration of the electrolyte and expected to effectively enhance the efficiency [15]. The SEM revealed that the distribution of silver on the surface of TiO2 is not uniform, and silver-doped TiO2 contains irregular shaped particles, which are the aggregation of tiny crystals.

From the EDX spectra as shown in Figs. 5b and 6b, the chemical compositions of bare TiO2 and 1 % Ag-doped TiO2, respectively, were obtained and are given in Table 1(a, b), respectively. The characteristic peaks of Ag were observed to confirm the presence of Ag. The approximate weight percentage of Ag content was found to be approximately 1.27 %.

3.1.4.2 HRTEM

HRTEM was performed for determining the sizes and morphology of the nanoparticles. HRTEM characterization of the Ag-doped TiO2 nearly confirms the presence of Ag in TiO2. The average particle diameter of TiO2 and Ag-loaded TiO2 particles was in the range 8–12 nm and 2–6 nm as shown in Figs. 7 and 8, respectively. The particles are irregular in shape but agglomerated in both cases bare and 1 % Ag-doped TiO2.

3.1.4.3 AFM

The structural effects of Ag doping leading to morphological change were studied by AFM. In Figs. 9 and 10, the AFM images of the undoped TiO2 and 1 % Ag-doped TiO2 are given. The three-dimensional AFM images show the nature of height mode structures and surface morphology. The estimated average rough surface measurement of the undoped TiO2 and 1 % Ag-doped TiO2 surface was about 7.006 and 10.588 nm, respectively. The section analysis of undoped TiO2 and 1 % Ag-doped TiO2 surface was also done, and the morphological data obtained from AFM images of undoped and 1 % Ag-doped TiO2 are listed in Table 2. From the study of grain analysis, average size and surface area were found to be approximately 130 nm, 0.0202 µm2 and 48 nm, 0.00265 µm2 for undoped TiO2 and 1 % Ag-doped TiO2, respectively.

3.1.5 Electrochemical impedance studies

The structural effects of the Ag doping on the kinetic behavior of dye regeneration and triiodide reduction reaction taking place at TiO2 electrode and Pt counter electrode, respectively, were further investigated by electrochemical impedance spectroscopy measurements. Figure 11 depicts the impedance spectra of DSSC based on undoped TiO2 and 1 % Ag-doped TiO2 measured at OCV in the frequency range 10−1–105 Hz. Two semicircles, including a small semicircle at high frequency and a large one at low frequency, were observed in the Nyquist plots of EIS spectra. The charge-transfer resistance for TiO2/dye/electrolyte interface decreases with decreasing the semicircle diameter in the Nyquist plot. In the Bode phase plots, the frequency peak related to the 1 % Ag-doped TiO2/FTO electrode slightly shifted to a relatively low frequency. The electron lifetime (τ n ) has been estimated from equation, τ n = 1/2πf max, where f max is peak frequency. The τ n was found to be 1.33 and 2.05 ms for DSSC with undoped TiO2 and 1 % Ag-doped TiO2, respectively. This enhancement in electron lifetime can contribute to an increase in the electron collection efficiency, leading to the improved J sc value. The parameters obtained from the EIS studies are given in Table 3. It was observed that both R s and R ct decreased for Ag-doped TiO2. The decrease in charge-transfer resistance R ct of triiodide reduction according to the reaction given as ( 3 ) on the counter electrode gives rise to improved J sc. The lower value of ohmic serial resistance R s, which is responsible for the high ionic conductivity, may also cause the larger J sc [29–31].

Therefore, the photocurrent density improvement is related to the improved carrier transport properties of the photoanode and Ag incorporation in TiO2 increases the electrical conductivity, resulting in faster electron transport, which results in a higher photocurrent [22].

3.1.6 Photoelectrochemical studies

3.1.6.1 Current–potential curve (J–V curve)

The TiO2 powders (undoped TiO2 and 1 % Ag-doped TiO2) were used to make photoanodes and, after coating with N719 dye, were applied in fabricating DSSC. Figure 12i shows the photocurrent–potential (J–V) curves of such cells (dye-adsorbed TiO2 electrode/electrolyte/platinum counter electrode) determined under illumination with light of 140 mW/cm2 intensity. From the (J–V) curves, power conversion efficiency (η) and fill factors (FF) were evaluated using the following relations:

here J sc, V oc and I inc are short-circuit photocurrent, open-circuit potential and intensity of incident light, respectively. With Ag-doped TiO2, J SC, V OC, fill factor and overall efficiency were found to be 1.07 mA cm−2, 0.72 V, 0.73 and 0.4 %, respectively, under illumination of 140 mW cm−2 light intensity, whereas with undoped TiO2 under similar conditions, J sc = 0.63 mA cm−2, V oc = 0.70 V, fill factor 0.45 and conversion efficiency 0.14 % could be obtained. These output parameters are summarized in Table 3. Therefore, ~70 % increase in the photocurrent of the cell based on 1 % Ag-doped TiO2 electrode was obtained as compared to the undoped TiO2. The V oc value of DSSC with 1 % Ag-doped TiO2 electrode was also increased slightly. The electron lifetime of DSSC with Ag-doped TiO2 increased from 1.33 (for undoped TiO2) to 2.05 ms, and consequently, electron recombination was reduced. Therefore, the increased J sc value in DSSC with 1 % Ag-doped TiO2 electrode may be attributed to the enhancement of the dye adsorption and increased electron lifetime [32]. The increase in J sc is mainly due to enhanced optical absorption of the incident photons. The enhanced J sc with Ag doping implied that resistance was smaller than that of undoped TiO2. It might be a result of the fact that the silver nanoparticles in the photoanodes shorten the electron transport pathways, allow efficient electron transfer from the TiO2 layer to the substrate and enhance the efficiency [21].

The photocurrent–potential (J–V) curves were recorded for the Ag-modified photoanodes with different Ag contents and are shown in Fig. 8ii. The observed results clearly revealed that a further increase in the Ag content eventually led to a decrease in the conversion efficiency (Fig. 8ii; Table 4). This is probably due to the fact that with increase in Ag concentration the active sites were shielded by large amount of Ag, leading to low carrier generation and decrease in photo performance. Moreover, when the amount of Ag loaded on the surface of TiO2 is large, Ag becomes the recombination centre of photoelectron and hole, which leads to a decrease in the J sc and V oc, and consequently, the overall conversion efficiency of the DSSC gets deteriorated.

3.1.6.2 Power–potential curve

The product of current density and the voltage gives the power per unit area of the cell, and it takes a maximum value at a particular point on the J–V curve. The power curves were recorded for the Ag-modified photoanodes with different Ag contents and are shown in Fig. 13. The point at which the power becomes maximum is known as maximum power point (MPP), and in the present case, maximum power for 1 % Ag-doped TiO2 and undoped TiO2 was obtained as 0.6 and 0.2 mW/cm2, respectively, which are shown in Fig. 13.

3.1.6.3 Transient photocurrent–time profile

The transient current–time profiles are recorded to know the speed of the response of the photoanode to a light stimulus, and the sustainability of the photocurrent observed initially on illumination of the semiconductor electrode. For such an assessment, the time-dependent response of a dye-sensitized TiO2 electrode to light was determined in terms of the short-circuit current, and the results for the Ag-modified photoanodes with different Ag contents are shown in Fig. 14. Somewhat greater decay was observed in case of Ag-doped TiO2 compared to undoped TiO2.

3.1.6.4 Action spectra (IPCE vs λ)

To ascertain the sensitization of photocurrent by the dye under investigation, the action spectrum of dye-modified TiO2 electrode was determined and is shown in Fig. 15. The short-circuit photocurrent (J photo) induced by monochromatic light was determined in the 400–700 nm wavelength range. From the values of J sc and the intensity of the corresponding monochromatic light (I inc), the incident photon-to-current conversion efficiency (IPCE) was calculated at each excitation wavelength (λ) using following equation:

An enhanced IPCE was obtained in case of 1 % Ag-doped TiO2 compared to undoped TiO2. After doping with silver, the response of TiO2 nanoparticles to visible light was increased and showed red shift (toward longer wavelength). The red shift of the absorption curve results in a reduction of the band-gap energy and also the recombination rate and hence enhanced photoelectrochemical behavior.

3.1.6.5 Long-term stability

The stability of the DSSC was assessed by measuring intermittently during 6 h the J sc of two selected cells fabricated with photoanodes of undoped TiO2 and 1 % Ag-doped TiO2. From the results shown in Fig. 16, it was observed that during prolonged operation of the cell, the photocurrent was found to remain almost stable without any significant deterioration. Enhanced long-term stability was observed in DSSC containing Ag because of the strong adsorption properties. The optical band-gap energies decrease with the doping of silver ions, which allow the delay in recombination rate and enhance the photoelectrochemical behavior.

4 Conclusions

A simple approach to prepare Ag-doped TiO2 by sol–gel method under optimized Ag content to fabricate a photoanode for DSSC was demonstrated. The properties of the as-prepared TiO2 powders and their thin films used as photoelectrodes in N719-sensitized solar cells were studied using UV–visible absorption, FTIR, XRD, AFM and PEC characterizations. According to XRD analysis, the prepared TiO2 samples consisted mainly of anatase phase of titania. The optical band gap of the material was found to vary from 3.10 eV (undoped TiO2) to 2.75 eV (Ag-doped TiO2). Samples obtained with Ag dopant displayed differences in visible light absorption abilities due to red shifting of the band gap. The electron lifetime of DSSC with Ag-doped TiO2 increased from 1.33 (for undoped TiO2) to 2.05 ms. As a result of the longer τ n , the device fabricated using Ag-doped TiO2 showed improved J sc values compared to the undoped TiO2 photoanode-based DSSC. The characterizations suggested that greater surface coverage of the sensitizing dye with Ag-doped TiO2 is responsible for better photovoltaic performance, and hence, improved IPCE, J sc and η values were obtained.

References

D. Wei, Dye sensitized solar cells. Int. J. Mol. Sci. 11, 1103–1113 (2010)

B.C. O’Regan, J.R. Durrant, Kinetic and energetic paradigms for dye-sensitized solar cells: moving from the ideal to the real. Acc. Chem. Res. 42, 1799–1808 (2009)

A. Hagfeldt, G. Boschloo, L. Sun, L. Kloo, H. Pettersson, Dye-sensitized solar cells. Chem. Rev. 110, 6595–6663 (2010)

M.K. Nazeeruddin, F. De Angelis, S. Fantacci, A. Selloni, G. Viscardi, P. Liska, S. Ito, B. Takeru, M. Grätzel, Combined experimental and DFT-TDDFT computational study of photoelectrochemical cell ruthenium sensitizers. J. Am. Chem. Soc. 127, 16835–16847 (2005)

R.A. Jensen, H. Van Ryswyk, C.X. She, J.M. Szarko, L.X. Chen, J.T. Hupp, Dye-sensitized solar cells: sensitizer-dependent injection into ZnO nanotube electrodes. Langmuir 26, 1401–1404 (2010)

H.J. Snaith, C. Ducati, SnO2-based dye-sensitized hybrid solar cells exhibiting near unity absorbed photon-to-electron conversion efficiency. Nano Lett. 10, 1259–1265 (2010)

K. Hara, T. Horiguchi, T. Kinoshita, K. Sayama, H. Sugihara, H. Arakawa, Highly efficient photon-to-electron conversion with mercurochrome sensitized nanoporous oxide semiconductor solar cell. Sol. Energy Mater. Sol. Cells 64, 115–134 (2000)

S.M. Yang, H.Z. Kou, H.J. Wang, K. Cheng, J.C. Wang, Preparation and band energetics of transparent nanostructured SrTiO3 film electrodes. J. Phys. Chem. C 114, 815–819 (2010)

A. Fujishima, T.N. Rao, D.A. Tryk, Titanium dioxide photocatalysis. J. Photochem. Photobiol. C 1, 1–21 (2000)

K. Pirkanniemi, M. Sillanpää, Heterogeneous water phase catalysis as an environmental application: a review. Chemosphere 48, 1047–1060 (2002)

Y. Hu, H.L. Tsai, C.L. Huang, Effect of brookite phase on the anatase–rutile transition in titania nanoparticles. J. Eur. Ceram. Soc. 23, 691–696 (2003)

V. Samuel, R. Pasricha, V. Ravi, Synthesis of nanocrystalline rutile. Ceram. Int. 31, 555–557 (2005)

D. Crişan, N. Drăgan, M. Răileanu, M. Crişan, A. Ianculescu, D. Luca, A. Năstuţă, D. Mardare, Structural study of sol–gel Ag/TiO2 films from nanopowders. Appl. Surf. Sci. 257, 4227–4231 (2011)

B. Shanghavi, P.V. Kamat, Interparticle electron transfer in metal/semiconductor composites. Picosecond dynamics of CdS capped gold nanoclusters. J. Phys. Chem. B 101, 7675–7679 (1997)

H. Chang, C.-H. Chen, M.-J. Kao, H.-H. Hsiao, Effect of core-shell Ag@TiO2 volume ratio on characteristics of TiO2-based DSSCs. J. Nanomater. 2014 (2014). doi:10.1155/2014/264108

P.-C. Huang, T.-Y. Chen, Y.-L. Wang, C.-Y. Wu, T.-L. Lin, Improving interfacial electron transfer and light harvesting in dye-sensitized solar cells by using Ag nanowire/TiO2 nanoparticle composite films. RSC Adv. 5, 70172 (2015)

M.A.K.L. Dissanayak, J.M.K.W. Kumari, G.K.R. Senadeera, C.A. Thotawatthage, Efficiency enhancement in plasmonic dye-sensitized solar cells with TiO2 photoanodes incorporating gold and silver nanoparticles. J. Appl. Electrochem. 46, 47–58 (2016)

Y. Liu, G. She, X. Qi, L. Mu, X. Wang, W. Shi, Contributions of Ag nanowires to the photoelectric conversion efficiency enhancement of TiO2 dye-sensitized solar cells. J. Nanosci. Nanotechnol. 15(6), 7068–7073 (2015)

E.M. Jin, X.G. Zhao, J.-Y. Park, Gu H-B, Enhancement of the photoelectric performance of dye-sensitized solar cells using Ag-doped TiO2 nanofibers in a TiO2 film as electrode. Nanoscale Res. Lett. 7, 97 (2012)

H.-H. Huang, H. Chang, H.-W. Liu, C.-W. Hsu, C. Chiu, M.-Y. Teng, H.-J. Lai, I.-C. Cheng, J.-Z. Chen, Plasma-etched nanoporous TiO2 using Ag nanoparticle masks: application for photoanodes of dye-sensitized solar cells. Mater. Res. Express 1, 025505 (2014)

A. Ranjitha, N. Muthukumarasamy, M. Thambidurai, D. Velauthapillai, Enhanced photovoltaic performance of quantum dot sensitized solar cells with Ag-doped TiO2 nanocrystalline thin films. J. Mater. Sci. Mater. Electron. 25, 2724–2729 (2014)

J. Li, X. Chen, N. Ai, J. Hao, Q. Chen, S. Strauf, Y. Shi, Silver nanoparticle doped TiO2 nanofiber dye sensitized solar cells. Chem. Phys. Lett. 514, 141–145 (2011)

D.J.R. Gutiérreza, N.R. Mathewsb, S.S. Martínezc, Photocatalytic activity enhancement of TiO2 thin films with silver doping under visible light. J. Photochem. Photobiol. A 262, 57–63 (2013)

X. Houa, H. Maa, F. Liua, J. Denga, Y. Aia, X. Zhaoa, D. Maoa, D. Lia, B. Liaoba, Synthesis of Ag ion-implanted TiO2 thin films for antibacterial application and photocatalytic performance. J. Hazard. Mater. 299, 59–66 (2015)

G. Yang, Z. Jiang, H. Shi, T. Xiao, Z. Yan, Preparation of highly visible-light active N-doped TiO2 photocatalyst. J. Mater. Chem. 20, 5301–5309 (2010)

J. Geng, D. Yang, J. Zhu, D. Chen, Z. Jiang, Nitrogen-doped TiO2 nanotubes with enhanced photocatalytic activity synthesized by a facile wet chemistry method. Mater. Res. Bull. 44, 146–150 (2009)

H.K. Park, D.K. Kim, C. Hee, Effect of solvent on titania particle formation and morphology in thermal hydrolysis of TiCl4. J. Am. Ceram. Soc. 80, 743–749 (1997)

K. Yeung, S.T. Yau, A.J. Maira, J.M. Coronado, J. Soria, P.L. Yue, The influence of surface properties on the photocatalytic activity of nanostructured TiO2. J. Catal. 219, 107–116 (2003)

Q. Zheng, H. Kang, J. Yun, J. Lee, J.H. Park, S. Baik, Hierarchical construction of self-standing anodized titania nanotube arrays and nanoparticles for efficient and cost-effective front-illuminated dye-sensitized solar cells. ACS Nano 5, 5088–5093 (2011)

J. Bisquert, I.N. Mora-Sero, Simulation of steady-state characteristics of dye-sensitized solar cells and the interpretation of the diffusion length. J. Phys. Chem. Lett. 1, 450–456 (2009)

J. Bisquert, Chemical capacitance of nanostructured semiconductors: its origin and significance for nanocomposite solar cells. J. Phys. Chem. Chem. Phys. 5, 5360–5364 (2003)

A.R. Andersen, J. Halme, T. Lund, M.I. Asghar, P.T. Nguyen, K. Miettunen, E. Kemppainen, O. Albrektsen, Charge transport and photocurrent generation characteristics in dye solar cells containing thermally degraded N719 dye molecules. J. Phys. Chem. C 115, 15598–15606 (2007)

Acknowledgments

One of the authors (Arun Kumar Gupta) acknowledges the financial support received from the University Grant Commission, New Delhi, for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, A.K., Srivastava, P. & Bahadur, L. Improved performance of Ag-doped TiO2 synthesized by modified sol–gel method as photoanode of dye-sensitized solar cell. Appl. Phys. A 122, 724 (2016). https://doi.org/10.1007/s00339-016-0241-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0241-2