Abstract

Double-cladding Yb3+-doped fiber with octagonal core is designed and fabricated using solution doping techniques. According to the simulated results, the octagonal-core fiber with core/cladding diameter of 30/250 μm has decreased the number of mode supported from 6 to 4, and the fiber with core/cladding diameter of 10/130 μm exhibits single-mode performance. Additionally, to confirm that the octagonal core does not influence the laser power and efficiency, CW and AO Q-switched pulsed fiber lasers using the 10/130 μm fiber are presented. The CW fiber laser has a single-mode output of 7.25 W with a slope efficiency of 80 %. For a pulsed fiber laser, an average power of 1.5 W, pulse width of 245 ns, is amplified to 18 W.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, fiber lasers have attracted researchers’ attention due to its compact size and the advantage of thermal management. When the large mode area double-cladding fiber (DCF) was applied, the development of high-power Yb3+-doped fiber laser (YDFL) has been accelerated, more and more powerful output and linear slope efficiency of YDFL have been obtained [1–3]. On the way of pursuing high-power fiber lasers, the beam quality is always a crucial limitation of the laser performance. Many fiber designs were attempted to obtain better beam quality, such as leakage channel fiber (LCF), tapered fiber and chirally-coupled-core fiber (3C fiber) [4–8]. However, much of these methods damage the laser power and efficiency, also the fabrication approach of those fiber designs is fairly complicated. Altering the shape of the fiber core can be a solution. While the study of the shaped-core fiber is just at the beginning. To date, some researchers have studied theoretically and experimentally on the elliptical-core and rectangular-core fibers [9, 10]. Recently, there are many analyses about hollow-core fiber both in theory and application [11]. However, seldom of these results report the laser performance of these corresponding fibers.

In this letter, we demonstrate, for the first time, an octagonal-shaped Yb3+-doped-core fiber. In order to confirm that the octagonal-core does not affect the laser power and efficiency, both continuous-wave (CW) and acousto-optic (AO) Q-switched fiber lasers will be studied to evaluate the performance of the fiber.

2 Theoretical simulation

The electric field distributions of an octagonal-shaped-core fiber, with the fiber dimensions of 10/130 μm, NA of 0.096, are studied using COMSOL. As indicated in Fig. 1a, only the fundamental modes are supported by the octagonal-shaped-core fiber, which indicates that a single-mode beam can be obtained when the fiber is utilized in fiber laser. For the circular-core fiber with the same size and NA, we can get the normalized frequency parameter V which is 2.7634 by

where a is the radius of the fiber core and λ is the wavelength of 1080 nm. This result indicates that the circular-core fiber supports higher-order mode LP11, which is figured out by MATLAB as in Fig. 1b.

For the dimension of 30/250 μm, NA of 0.06,the circular-core fiber exhibits many modes including LP01, LP11, LP21, LP12, LP31 and LP13; however, the octagonal-core fiber only allows LP01, LP11, LP12 and LP41 modes. This type of octagonal-shaped-core fiber we designed could reduce the number of the modes of the output beam and potentially could keep single-mode operation.

3 Experiments results and discussion

The fiber preform was fabricated using traditional MCVD and solution doping techniques. We specially treated the substrate tube by polishing the outside surface into octagon shape to get the octagonal-shaped core. The refractive index of the preform was analyzed using Photon Kinetics P104 (see Fig. 2). The inset of Fig. 2 shows the 10-/130-μm double-cladding fiber with a NA of 0.096; the core region of the fiber is shown brighter and star shaped and the deposited buffer layers shown darker. Other shaped fibers, such as elliptical-core fiber and rectangular-core fiber, can be fabricated based on the fabrication technique we used.

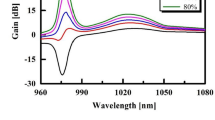

We set up a CW fiber laser pumped at 976 nm. The resonant cavity is formed by a fiber Bragg grating (FBG, R > 99 % at 1080 nm) and the perpendicularly cleaved end face of the Yb3+-doped fiber. For eliminating the residual pump in the cladding, a section of the fiber, before the output end face, was stripped off and buried in the pump stripper. The performance of the CW fiber laser is presented as a function of the pump power in Fig. 3. The y-axis shows the laser output power and the x-axis is the pump power. A 7.25-W single-mode laser beam was obtained with a slope efficiency of 80 % based on a 20-m-long active fiber. The corresponding optical-to-optical efficiency with respect to the absorbed pump power was 76.9 %.

We applied the octagonal-core fiber into an AO Q-switched pulsed laser. The pump of 976-nm diode laser was launched into the active fiber through a (1 + 1) × 1 combiner and a high-reflectivity (>99 % at 1064 nm) FBG. A low-reflectivity FBG was used as the output coupler which extracts 10 % of the light per pass. The active fiber utilized in the cavity is 8 m. A fiber-coupled AO modulator driven by an arbitrary waveform generator was inserted between the active fiber and the low-refractive-index FBG to provide active Q-switching. The repetition rate of the pulsed fiber laser can be tuned by changing the electrical pulse repetition of the arbitrary waveform generator. The pulse generated from the laser is illustrated in Fig. 4. The AO all-fiber Q-switched fiber laser produced 245-ns pulses at a 20-kHz repetition rate and 330 ns at 60.0-kHz repetition rate with an average output power of 1.5 W.

To scale the average power, an amplifier stage was added after the low-refractive-index FBG, forming a MOPA structure. A length of 6 m 30/250 μm Yb3 + -doped double-cladding fiber was used as the active fiber. Two 15-W, 915-nm LDs were utilized to pump the amplifier stage. The output end face was angle cleaved at 8 degree to eliminate the facet reflection. After the amplification, the output power reached up to 18 W, with a slope efficiency of 74 %, as shown in the inset of Fig. 5, and the line width was 2.61 nm. Along with the scaling of the pump, the duration of the pulse broadened. We recorded the pulse shape at the power of 5 and 10 W, respectively, as shown in Fig. 6. In the operation of 20-kHz repetition rate, the pulse width stretched to 306 ns and 415 ns at 5 W and 10 W, respectively. While in the operation of 60 kHz, the pulse width stretched to 372 ns and 512 ns at 5 and 10 W, respectively.

In comparison with the performance of the traditional circular-core fiber in CW and AO Q-switched pulsed lasers, the octagonal-shaped-core fiber does not affect the laser power or efficiency. This result together with the easy fabrication approach suggests that the proposed fiber is a pretty good solution to get better beam quality.

4 Conclusions

In conclusion, an octagonal Yb3+-doped-core fiber is designed and fabricated for the first time. According to the calculated electric field distribution, the octagonal core supports less modes comparing with the traditional circular-shaped core, indicating that this fiber can be applied into lasers to enhance the beam quality. We have investigated the disadvantage of the octagonal-shaped-core fiber by analyzing the laser efficiency during application of this fiber in the CW and AO Q-switched fiber laser. The CW operation achieved 80 % efficiency for a laser output of 9.43 W. For the AO Q-switched operation, 1.5-W pulses are generated at the repetition of 20 and 60 kHz. To boost the energy of the pulses, a MOPA structure pulse laser is constructed with an output power of 18 W. From the experimental data, the octagonal-core fiber has negligible damage to the laser power and efficiency. Additionally, the simple processing of the substrate tube makes it easy to implement the octagonal core. Therefore, it is a pretty good solution to obtain an enhanced beam quality. Further work will be aimed at confirming the advantages of the larger mode area octagonal-core fiber at a higher-power operation.

References

H.M. Pask, J.L. Archambault, D.C. Hanna, L. Reekie, P.S.J. Russell, J.E. Townsend, A.C. Tropper, Operation of cladding-pumped Yb3 + -doped silica fibre lasers in 1 μm region. Electron. Lett. 30, 863–865 (1994)

H. Zellmer, A. Tünnermann, H. Welling, V. Reichel, “Double-Clad Fiber Laser with 30 W Output Power”, Optical Amplifiers and Their Applications (OAA), Fiber and Active Wavelengths (FAW),Victoria, BC, 21 July 1997

Y. Jeong, J.K. Sahu, D.N. Payne, J. Nilsson, Ytterbium doped large core fiber laser with 1.36 kW continuous wave output power. Opt. Express 12, 6088–6092 (2004)

Q. Xiao, P. Yan, S. Yin, J. Hao, M. Gong, 100 W ytterbium-doped monolithic fiber laser with fused angle-polished side-pumping configuration. Laser Phys. Lett. 8, 125–129 (2011)

H. Po, J.D. Cao, B.M. Laliberte, R.A. Minns, R.F. Robinson et al., High power neodymium-doped single transverse mode fiber laser. Electron. Lett. 29, 1500–1501 (1993)

L. Dong, T.W. Wu, H.A. McKay, L. Fu, J. Li, H.G. Winful, All-glass large-core leakage channel fibers. IEEE J. Sel. Top. Quantum Electron. 15, 47–53 (2009)

L. Li, Q. Lou, J. Zhou, J. Dong, Y. Wei, S. Du, B. He, High power single transverse mode operation of a tapered large-mode-area fiber laser. Opt. Commun. 281, 655–657 (2008)

X. Ma, C. Zhu, I. Hu, A. Kaplan, A. Galvanauskas, Single-mode chirally-coupled-core fibers with larger than 50 μm diameter cores. Opt. Express 22, 9206–9219 (2014)

G. Das, J.W.Y. Lit, L-band multiwavelength fiber laser using an elliptical fiber. IEEE Photonics Technol. Lett. 14, 606–608 (2002)

Anurag Sharma, On approximate theories of single-mode rectangular waveguides. Opt. Quantum Electron. 21, 517–520 (1989)

G. Humbert, J.M. Le Floch, D. Mouneyrac, D. Férachou, M. Aubourg, M.E. Tobar, D. Cros, J.M. Blondy, Hollow-core resonator based on out-of-plane two-dimensional photonic band-gap crystal cladding at microwave frequencies. Appl. Phys. Lett. 96, 051108 (2010)

Acknowledgments

We thank the support of the “National High-Technology Research and Development Program of China” (2013AA031501) and “the Fundamental Research Funds for the Central Universities” (2014TS018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Liao, L., Zhao, N. et al. Experimental demonstration of optical fiber laser with octagonal-shaped core. Appl. Phys. A 119, 791–794 (2015). https://doi.org/10.1007/s00339-015-9032-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9032-4